Combined Long-Period Fiber Grating and Microcavity In-Line Mach–Zehnder Interferometer for Refractive Index Measurements with Limited Cross-Sensitivity †

Abstract

1. Introduction

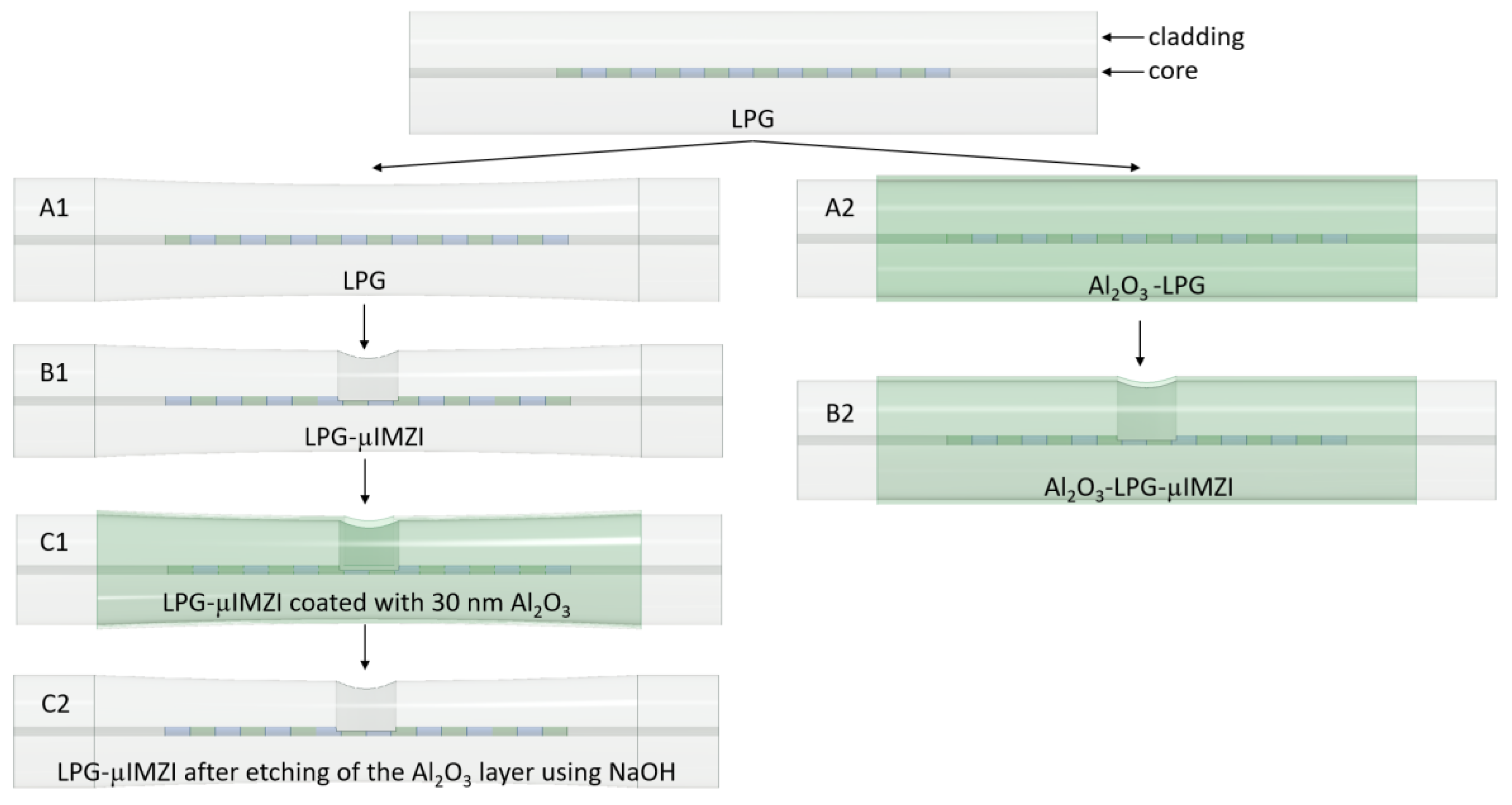

2. Materials and Methods

2.1. Fabrication of LPG

2.2. Fabrication of μIMZI

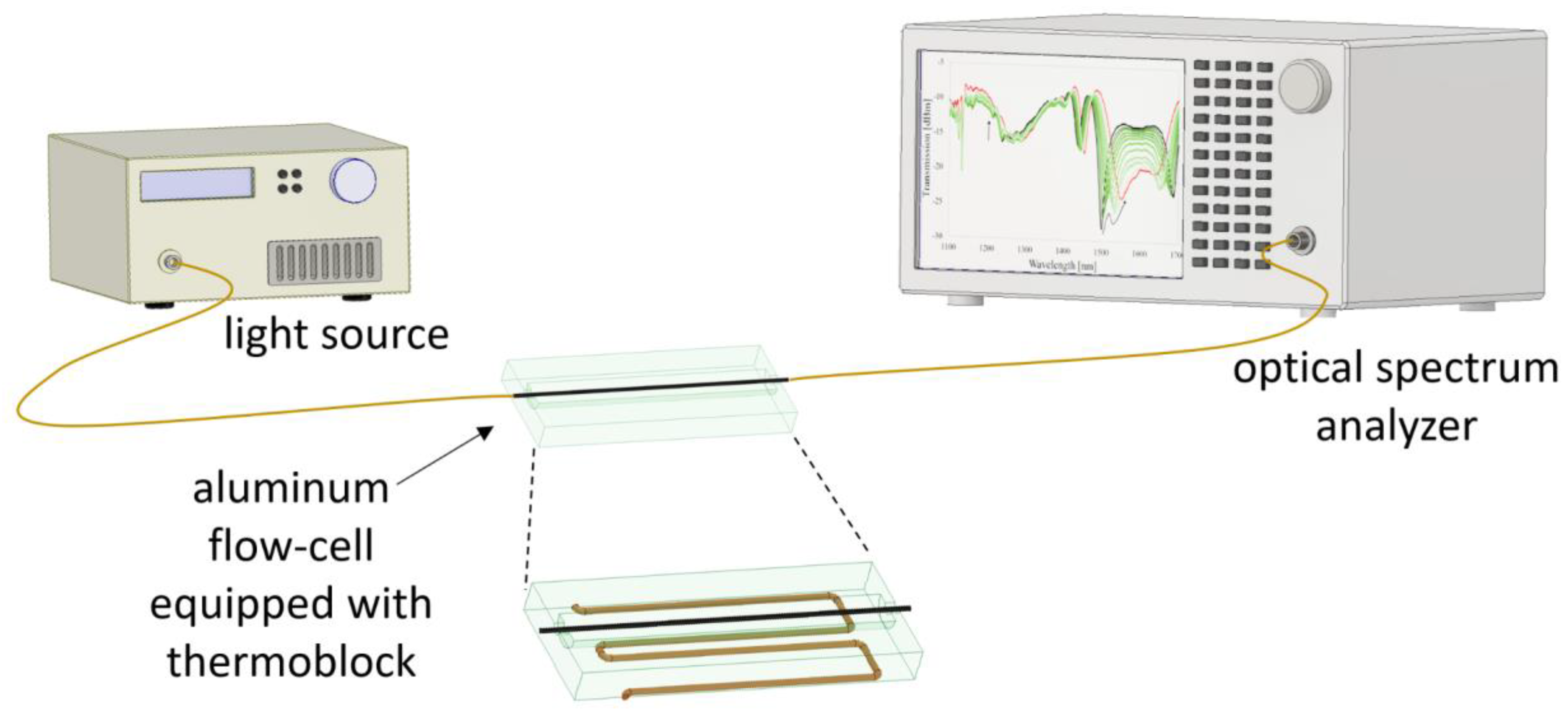

2.3. LPG and LPG-μIMZI Analysis

2.4. Monitoring of RI Changes at the Surface with LPG-µMZI.

3. Results and Discussion

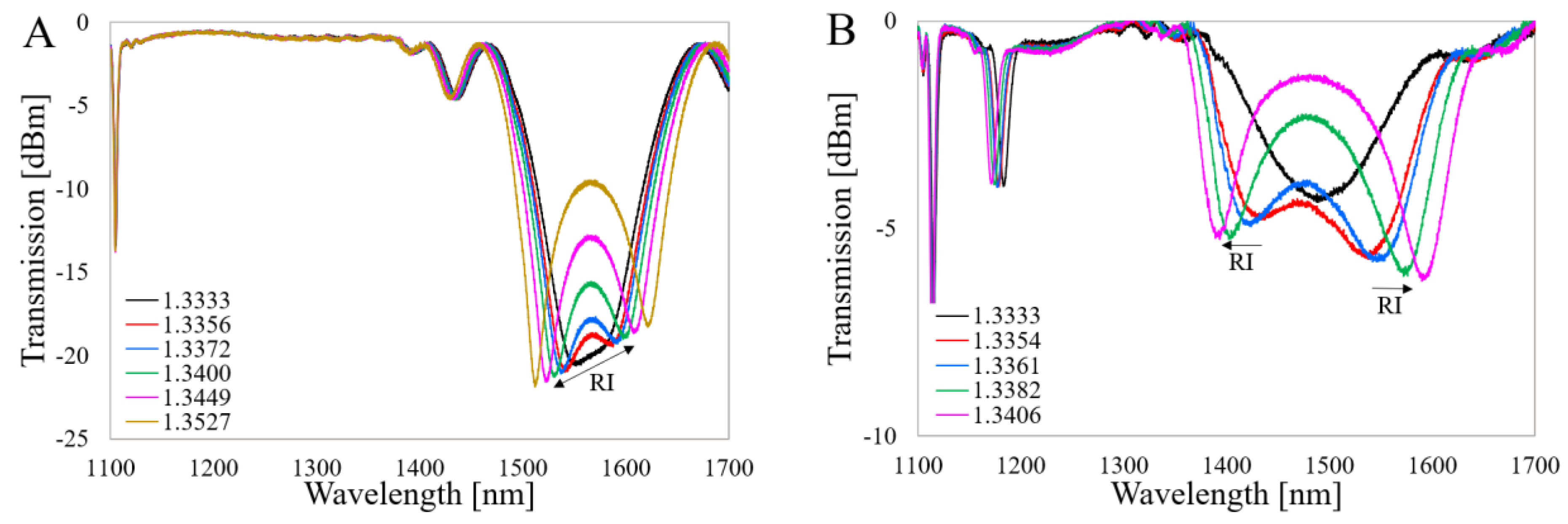

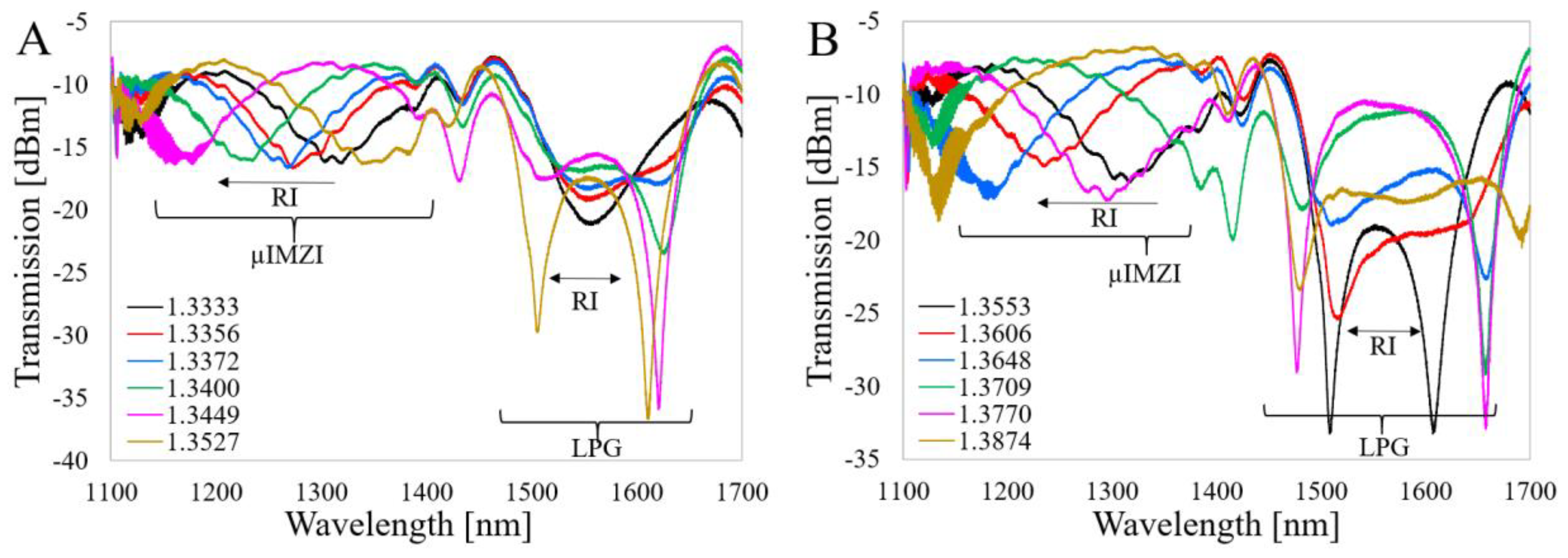

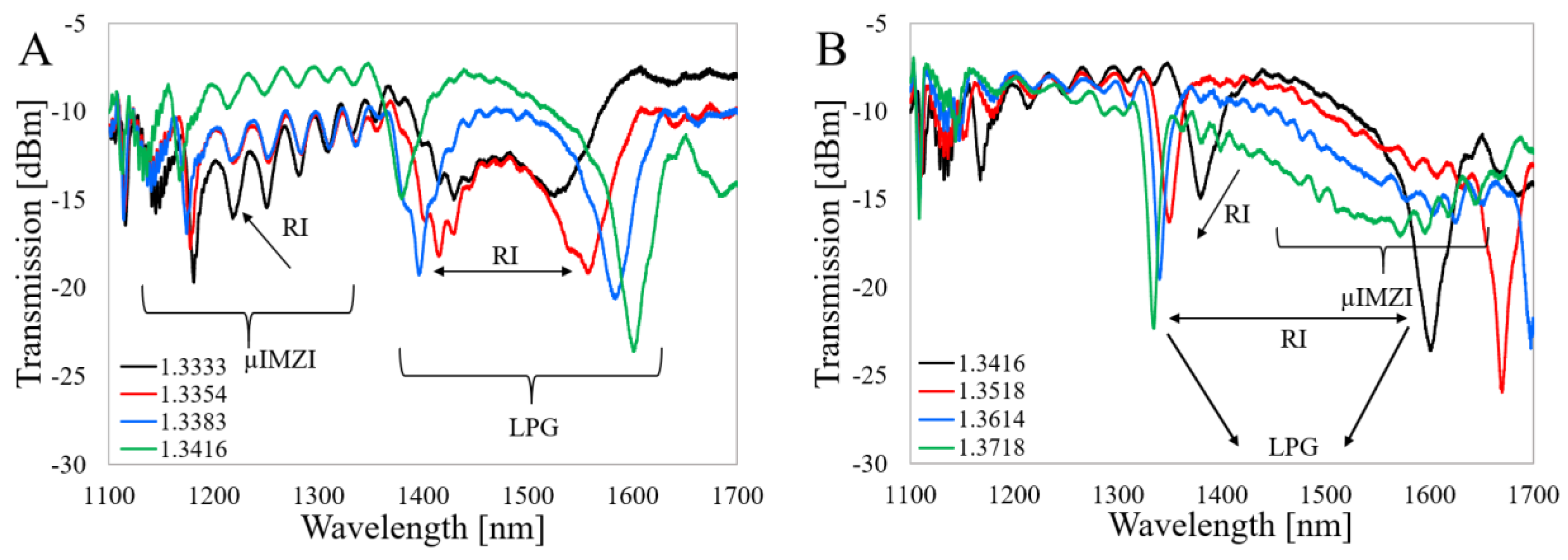

3.1. RI Sensing with LPG or µMZI Structure

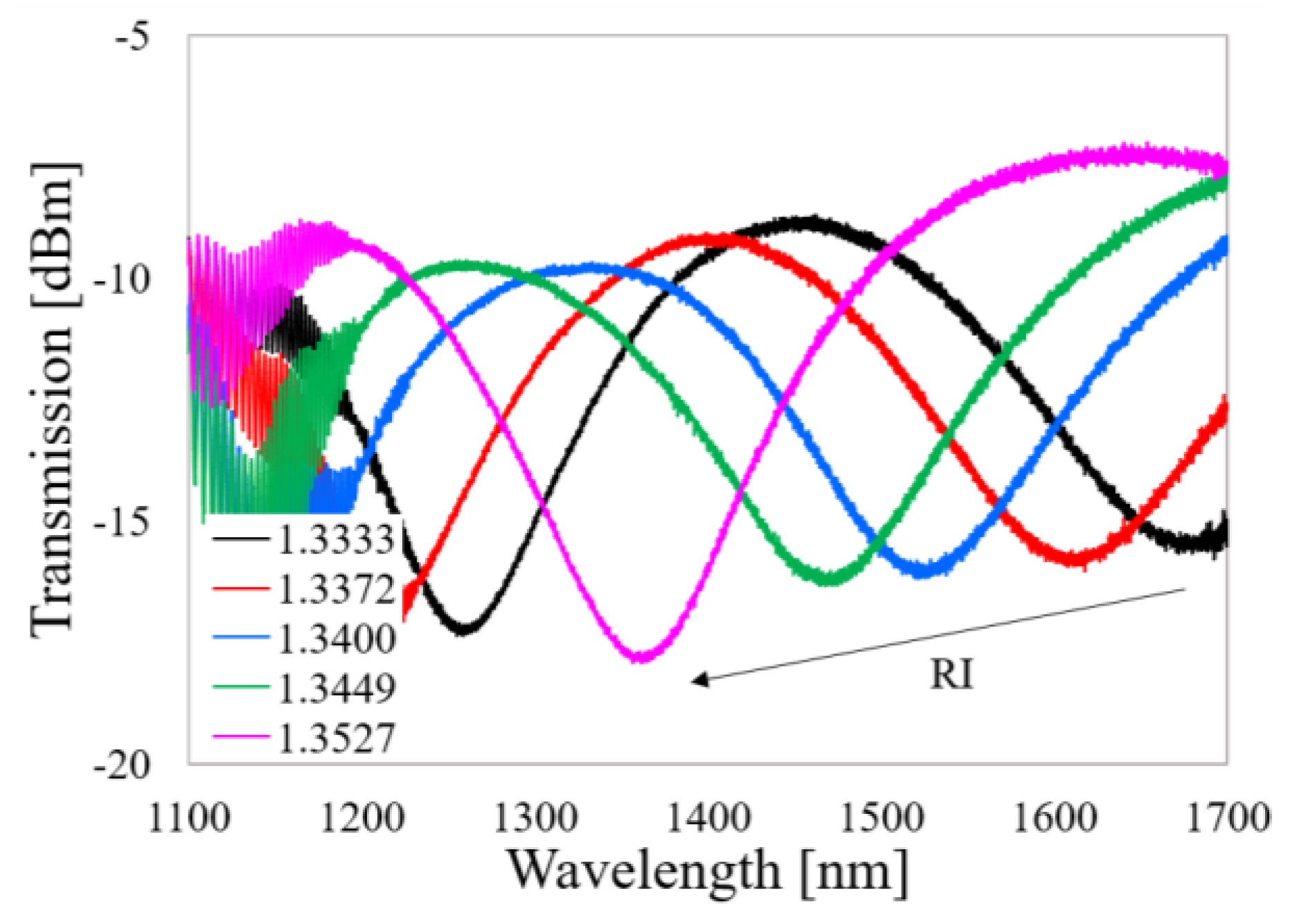

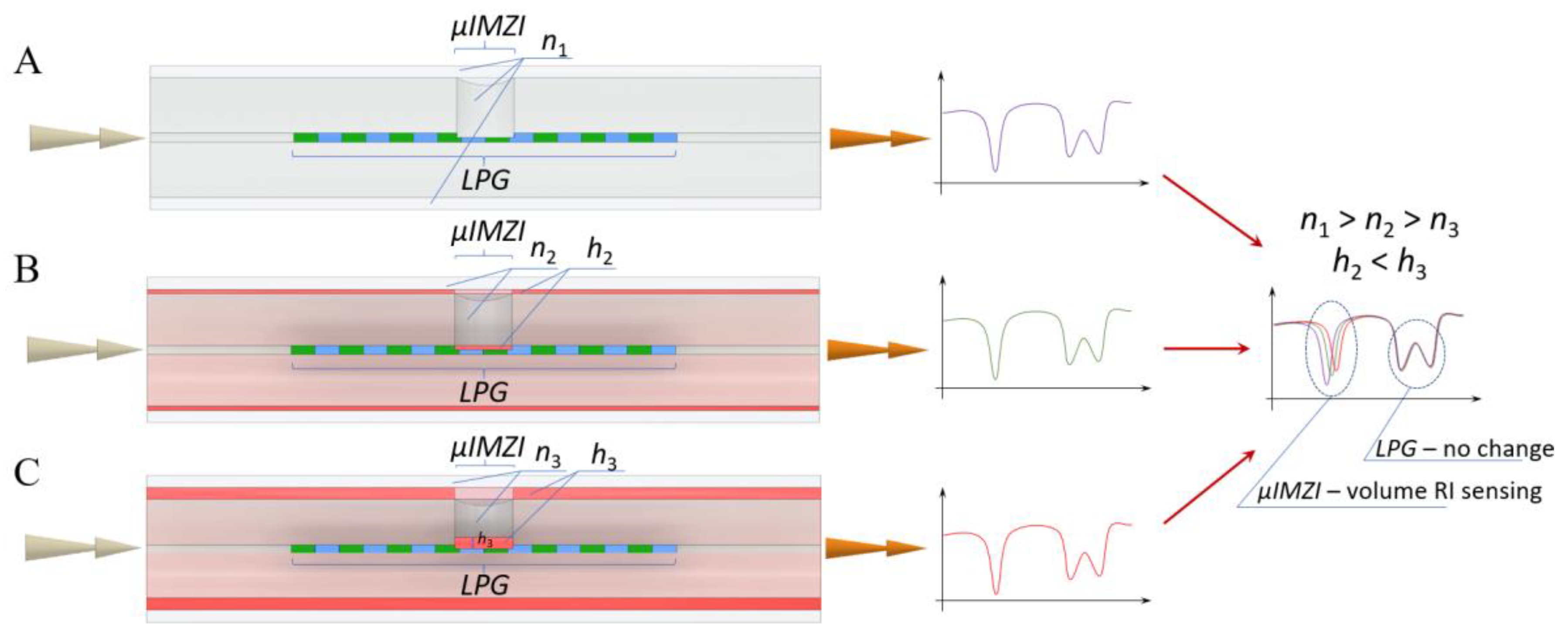

3.2. RI Sensing with LPG-µMZI Structures

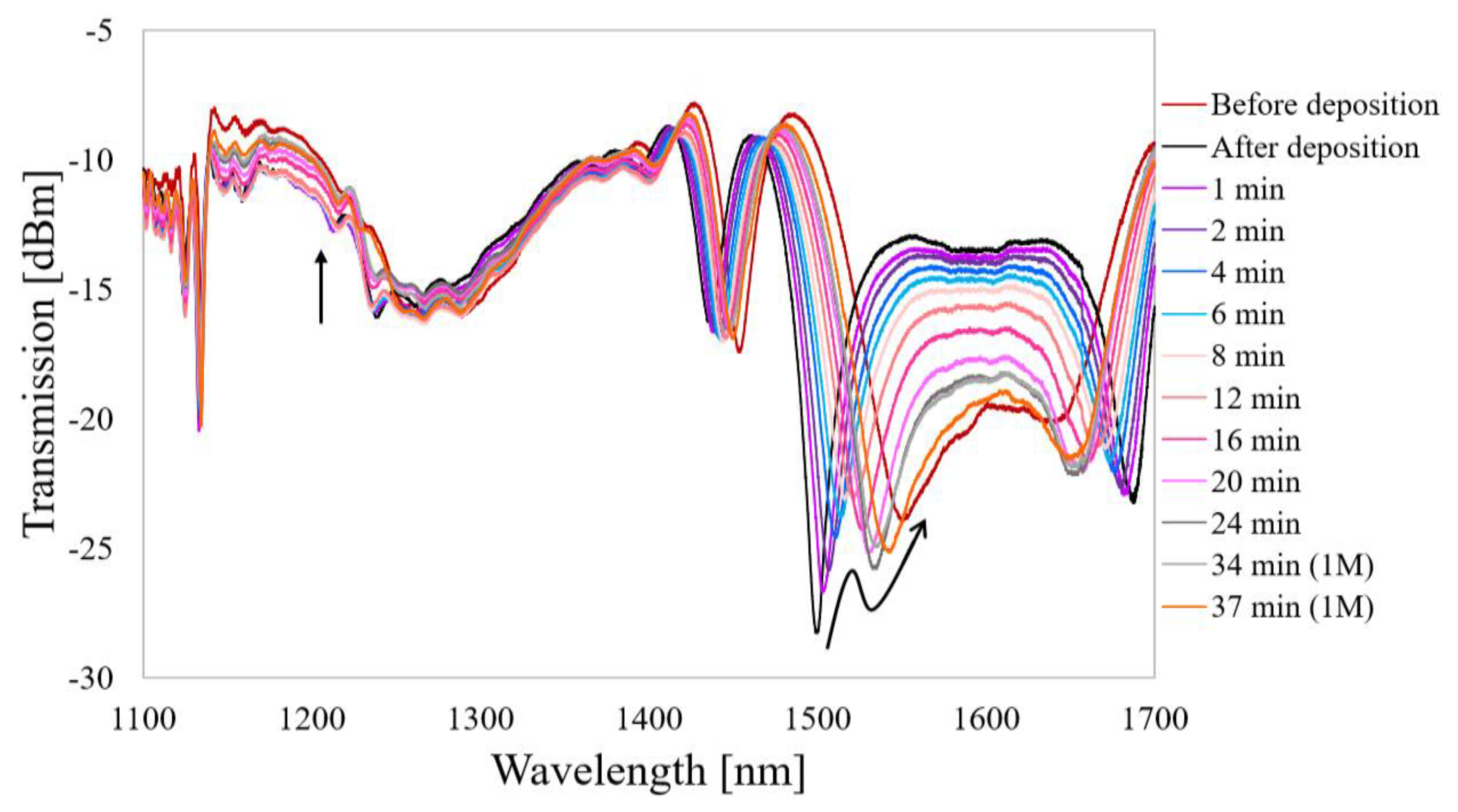

3.3. Monitoring of RI at the Surface with the LPG-µMZI

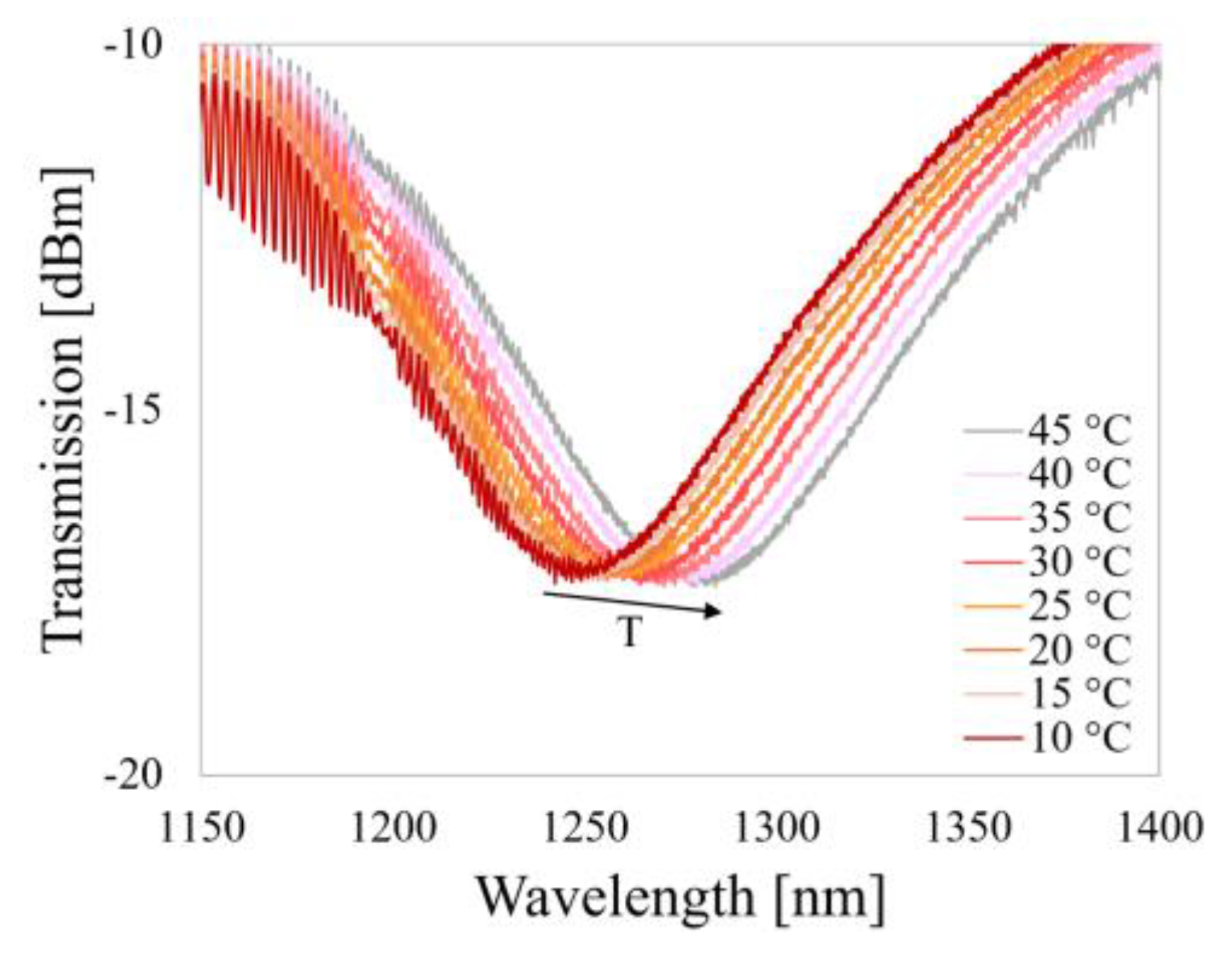

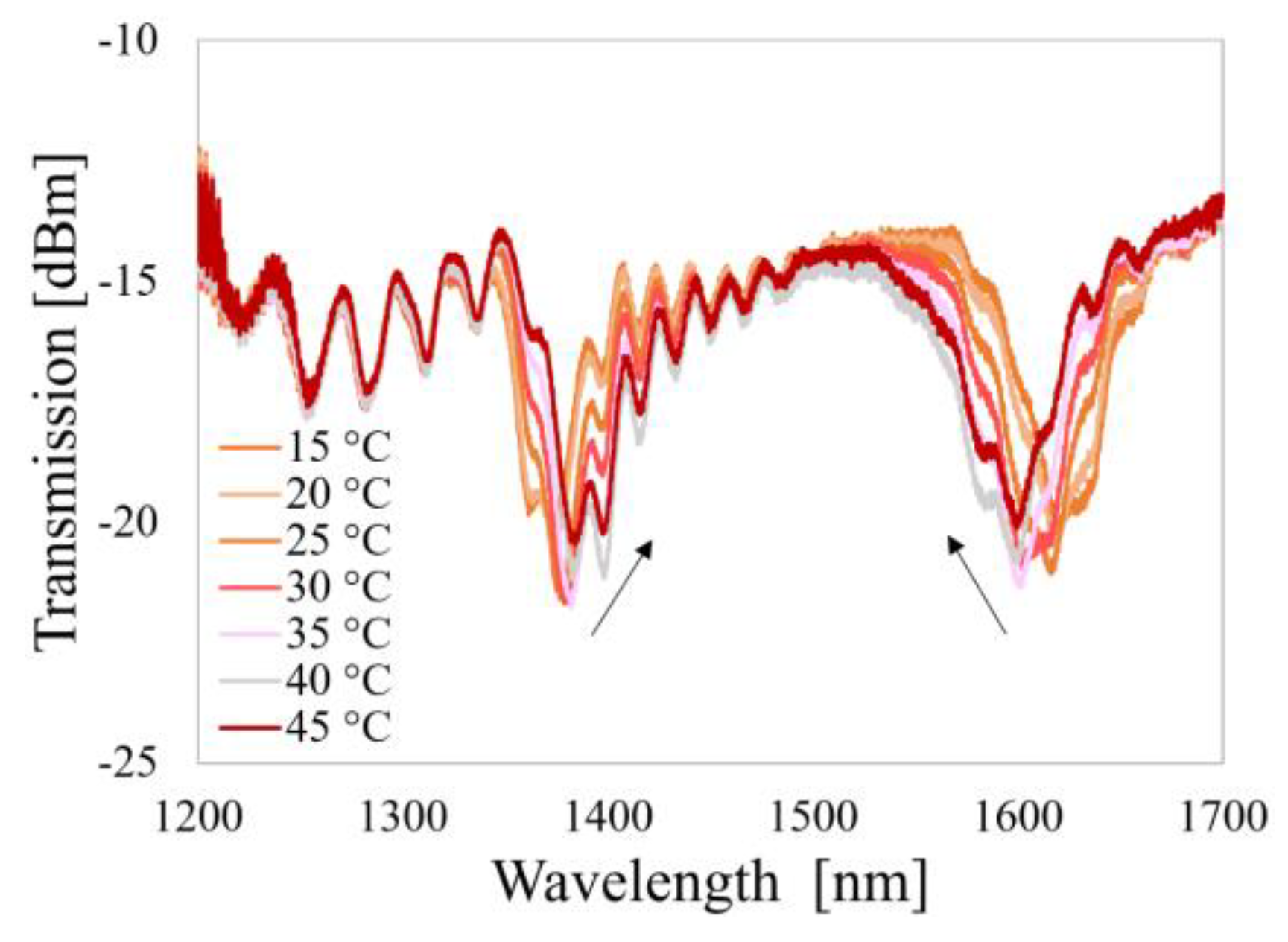

3.4. Temperature Sensitivity of LPG-µIMZI

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.D.; Wolfbeis, O.S. Fiber-optic chemical sensors and biosensors (2015–2019). Anal. Chem. 2020, 92, 397–430. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.W.; Shen, F.; Chen, X.; Wang, A. Simultaneous measurement of refractive index and temperature based on a reflection-mode long-period grating and an intrinsic Fabry–Perot interferometer sensor. Opt. Lett. 2005, 30, 3000. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.X.; Huang, X.G.; Li, J.Y.; Zhong, Z.B. Simultaneous measurement of refractive index and temperature by integrating an external Fabry-Perot cavity with a fiber Bragg grating. Rev. Sci. Instrum. 2012, 83, 053113. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Zhang, A.P.; Shao, L.; Ding, J.; He, S.; Member, S. Simultaneous measurement of refractive index and temperature by using dual long-period gratings with an etching process. Sensors (Peterborough, NH) 2007, 7, 1360–1361. [Google Scholar] [CrossRef]

- Yao, Q.; Meng, H.; Wang, W.; Xue, H.; Xiong, R.; Huang, B.; Tan, C.; Huang, X. Simultaneous measurement of refractive index and temperature based on a core-offset Mach-Zehnder interferometer combined with a fiber Bragg grating. Sens. Actuators A Phys. 2014, 209, 73–77. [Google Scholar] [CrossRef]

- Liao, C.R.; Wang, Y.; Wang, D.N.; Yang, M.W. Fiber in-line Mach-Zehnder interferometer embedded in FBG for simultaneous refractive index and temperature measurement. IEEE Photonics Technol. Lett. 2010, 22, 1686–1688. [Google Scholar] [CrossRef]

- Pevec, S.; Donlagić, D. Multiparameter fiber-optic sensors: A review. Opt. Eng. 2019, 58, 1. [Google Scholar] [CrossRef]

- James, S.W.; Tatam, R.P. Optical fibre long-period grating sensors: Characteristics and application. Meas. Sci. Technol. 2003, 14. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, H.; Lv, R.; Zhao, J. Review of optical fiber Mach–Zehnder interferometers with micro-cavity fabricated by femtosecond laser and sensing applications. Opt. Lasers Eng. 2019, 117, 7–20. [Google Scholar] [CrossRef]

- Vengsarkar, A.M.; Lemaire, P.J.; Judkins, J.B.; Bhatia, V.; Erdogan, T.; Sipe, J.E. Long-period fiber gratings as band-rejection filters. J. Light. Technol. 1996, 14, 58–64. [Google Scholar] [CrossRef]

- Shu, X.; Zhang, L.; Bennion, I. Sensitivity characteristics of long-period fiber gratings. J. Light. Technol. 2002, 20, 255–266. [Google Scholar] [CrossRef]

- Śmietana, M.; Koba, M.; Mikulic, P.; Bock, W.J. Combined plasma-based fiber etching and diamond-like carbon nanooverlay deposition for enhancing sensitivity of long-period gratings. J. Light. Technol. 2016, 34, 4615–4619. [Google Scholar] [CrossRef]

- Śmietana, M.; Myśliwiec, M.; Mikulic, P.; Witkowski, B.S.; Bock, W.J. Capability for fine tuning of the refractive index sensing properties of long-period gratings by atomic layer deposited Al2O3 overlays. Sensors 2013, 13, 16372–16383. [Google Scholar] [CrossRef]

- Śmietana, M.; Koba, M.; Mikulic, P.; Bock, W.J. Towards refractive index sensitivity of long-period gratings at level of tens of µm per refractive index unit: Fiber cladding etching and nano-coating deposition. Opt. Express 2016, 24, 11897. [Google Scholar] [CrossRef]

- Grochowski, J.; Myśliwiec, M.; Mikulic, P.; Bock, W.J.; Smietana, M. Temperature cross-sensitivity for highly refractive index sensitive nanocoated long-period gratings. Acta Phys. Pol. A 2013, 124, 421–424. [Google Scholar] [CrossRef]

- Janczuk-Richter, M.; Dominik, M.; Koba, M.; Mikulic, P.; Bock, W.J.; MacKowski, S.; Jonsson-Niedziolka, M.; Niedziolka-Jonsson, J.; Smietana, M. Water-induced fused silica glass surface alterations monitored using long-period fiber gratings. J. Light. Technol. 2019, 37, 4542–4548. [Google Scholar] [CrossRef]

- Janik, M.; Myśliwiec, A.K.; Koba, M.; Celebańska, A.; Bock, W.J.; Śmietana, M. Sensitivity pattern of femtosecond laser mach-zehnder interferometers, as applied to small-scale refractive index sensing. IEEE Sens. J. 2017, 17, 3316–3322. [Google Scholar] [CrossRef]

- Hu, T.Y.; Wang, D.N. Optical fiber in-line Mach–Zehnder interferometer based on dual internal mirrors formed by a hollow sphere pair. Opt. Lett. 2013, 38, 3036–3039. [Google Scholar] [CrossRef]

- Śmietana, M.; Janik, M.; Koba, M.; Bock, W.J. Transition between bulk and surface refractive index sensitivity of micro-cavity in-line Mach-Zehnder interferometer induced by thin film deposition. Opt. Express 2017, 25, 26118–26123. [Google Scholar] [CrossRef]

- Brzozowska, E.; Śmietana, M.; Koba, M.; Górska, S.; Pawlik, K.; Gamian, A.; Bock, W.J. Recognition of bacterial lipopolysaccharide using bacteriophage-adhesin-coated long-period gratings. Biosens. Bioelectron. 2015, 67, 93–99. [Google Scholar] [CrossRef]

- Piestrzyńska, M.; Dominik, M.; Kosiel, K.; Janczuk-Richter, M.; Szot-Karpińska, K.; Brzozowska, E.; Shao, L.; Niedziółka-Jonsson, J.; Bock, W.J.; Śmietana, M. Ultrasensitive tantalum oxide nano-coated long-period gratings for detection of various biological targets. Biosens. Bioelectron. 2019, 133, 8–15. [Google Scholar] [CrossRef] [PubMed]

- Smietana, M.; Bock, W.J.; Mikulic, P.; Ng, A.; Chinnappan, R.; Zourob, M. Detection of bacteria using bacteriophages as recognition elements immobilized on long-period fiber gratings. Opt. Express 2011, 19, 7971–7978. [Google Scholar] [CrossRef] [PubMed]

- Śmietana, M.; Koba, M.; Mikulic, P.; Bock, W.J. Measurements of reactive ion etching process effect using long-period fiber gratings. Opt. Express 2014, 22, 5986–5994. [Google Scholar] [CrossRef]

- Śmietana, M.; Dominik, M.; Mikulic, P.; Bock, W.J. Temperature and refractive index sensing with Al2O3-nanocoated long-period gratings working at dispersion turning point. Opt. Laser Technol. 2018, 107, 268–273. [Google Scholar] [CrossRef]

- Janik, M.; Member, S.; Eftimov, T.; Koba, M.; Smietana, M.; Bock, W.J.; Member, L. Tailoring properties of microcavity in-line mach-zehnder interferometer by the microcavity enlargement using femtosecond laser. J. Light. Technol. 2019, 37, 4501–4506. [Google Scholar] [CrossRef]

- Śmietana, M.; Mikulic, P.; Bock, W.J. Nano-coated long-period gratings for detection of sub-nanometric changes in thin-film thickness. Sens. Actuators A Phys. 2018, 270, 79–83. [Google Scholar] [CrossRef]

- Janik, M.; Koba, M.; Celebańska, A.; Bock, W.J.; Śmietana, M. Live E. coli bacteria label-free sensing using a microcavity in-line Mach-Zehnder interferometer. Sci. Rep. 2018, 8. [Google Scholar] [CrossRef]

- Janik, M.; Koba, M.; Celebańska, A.; Bock, W.J.; Śmietana, M. Sensing properties of micro-cavity in-line Mach-Zehnder interferometer enhanced by reactive ion etching. Opt. Laser Technol. 2018, 103, 260–266. [Google Scholar] [CrossRef]

- Ran, Z.L.; Rao, Y.J.; Liu, W.J.; Liao, X.; Chiang, K.S. Laser-micromachined Fabry-Perot optical fiber tip sensor for high-resolution temperature-independent measurement of refractive index. Opt. Express 2008, 16, 2252. [Google Scholar] [CrossRef]

- Smietana, M.; Bock, W.J.; Mikulic, P. Temperature sensitivity of silicon nitride nanocoated long-period gratings working in various surrounding media. Meas. Sci. Technol. 2011, 22. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Ma, C.; Zhou, Y. Micro-structured optical fiber sensor for simultaneous measurement of temperature and refractive index. Opt. Fiber Technol. 2018, 41, 168–172. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janik, M.; Koba, M.; Król, K.; Mikulic, P.; Bock, W.J.; Śmietana, M. Combined Long-Period Fiber Grating and Microcavity In-Line Mach–Zehnder Interferometer for Refractive Index Measurements with Limited Cross-Sensitivity. Sensors 2020, 20, 2431. https://doi.org/10.3390/s20082431

Janik M, Koba M, Król K, Mikulic P, Bock WJ, Śmietana M. Combined Long-Period Fiber Grating and Microcavity In-Line Mach–Zehnder Interferometer for Refractive Index Measurements with Limited Cross-Sensitivity. Sensors. 2020; 20(8):2431. https://doi.org/10.3390/s20082431

Chicago/Turabian StyleJanik, Monika, Marcin Koba, Krystian Król, Predrag Mikulic, Wojtek J. Bock, and Mateusz Śmietana. 2020. "Combined Long-Period Fiber Grating and Microcavity In-Line Mach–Zehnder Interferometer for Refractive Index Measurements with Limited Cross-Sensitivity" Sensors 20, no. 8: 2431. https://doi.org/10.3390/s20082431

APA StyleJanik, M., Koba, M., Król, K., Mikulic, P., Bock, W. J., & Śmietana, M. (2020). Combined Long-Period Fiber Grating and Microcavity In-Line Mach–Zehnder Interferometer for Refractive Index Measurements with Limited Cross-Sensitivity. Sensors, 20(8), 2431. https://doi.org/10.3390/s20082431