HFO-LADRC Lateral Motion Controller for Autonomous Road Sweeper

Abstract

1. Introduction

2. Related Work

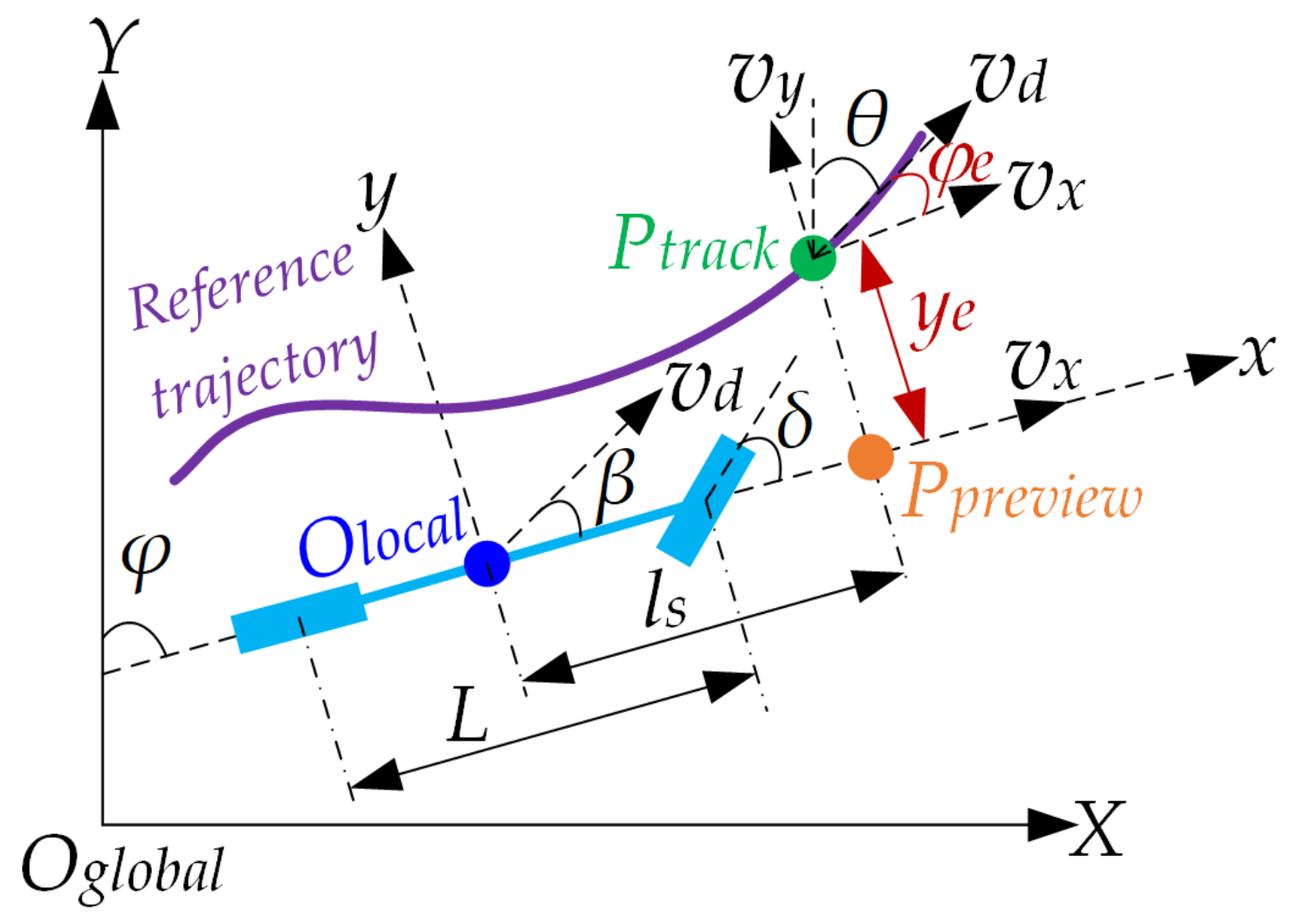

3. Lateral Error Model

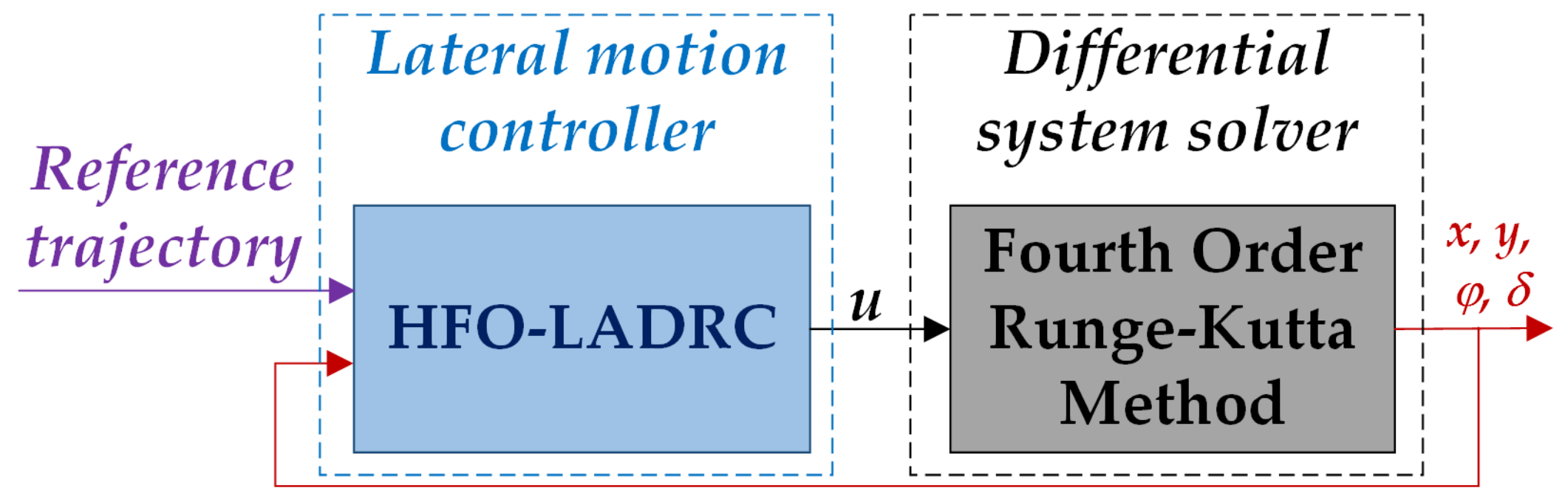

4. HFO-LADRC Controller Design

4.1. Heading-Error-Based Model

4.2. Controller Design

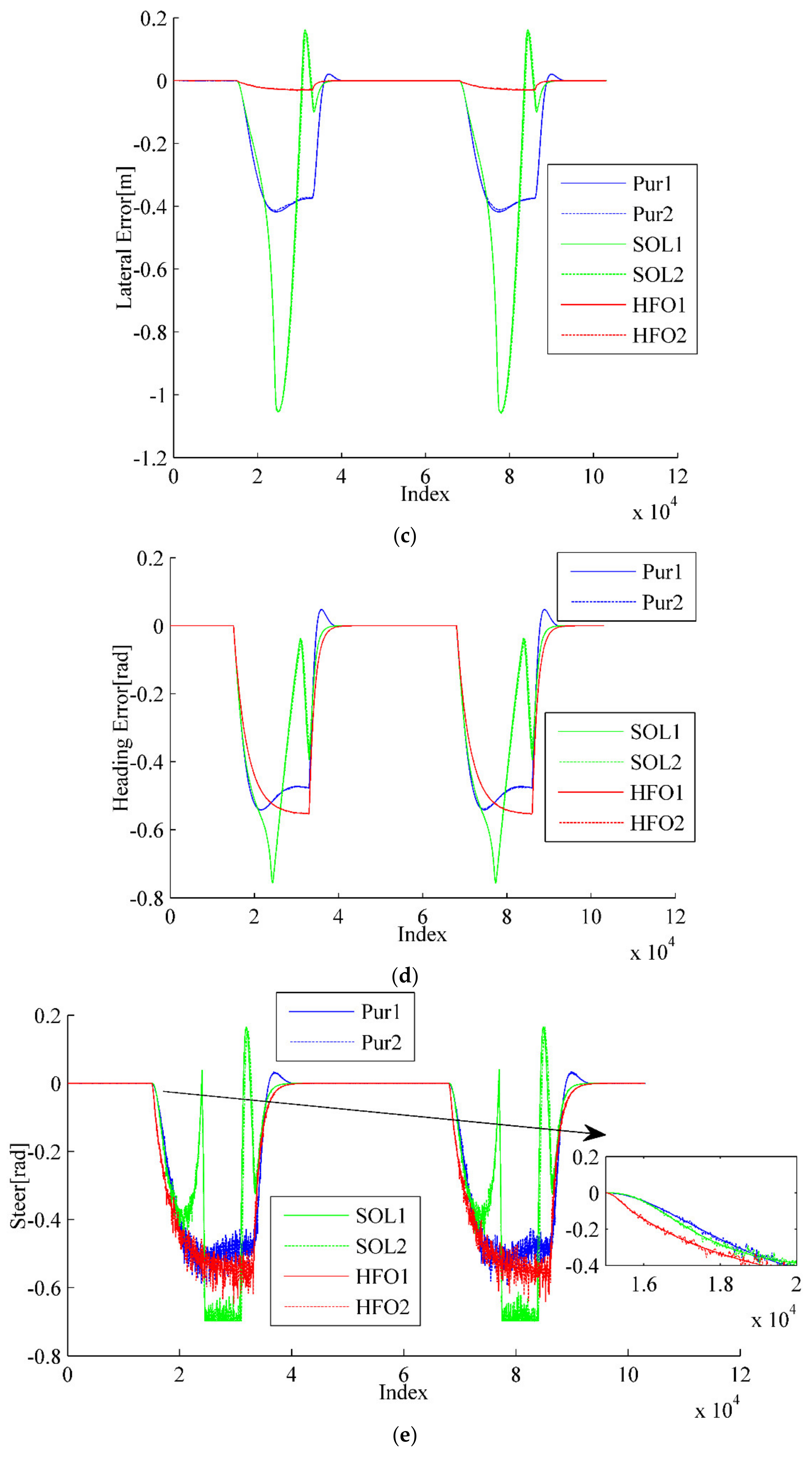

5. Experimental Results and Discussion

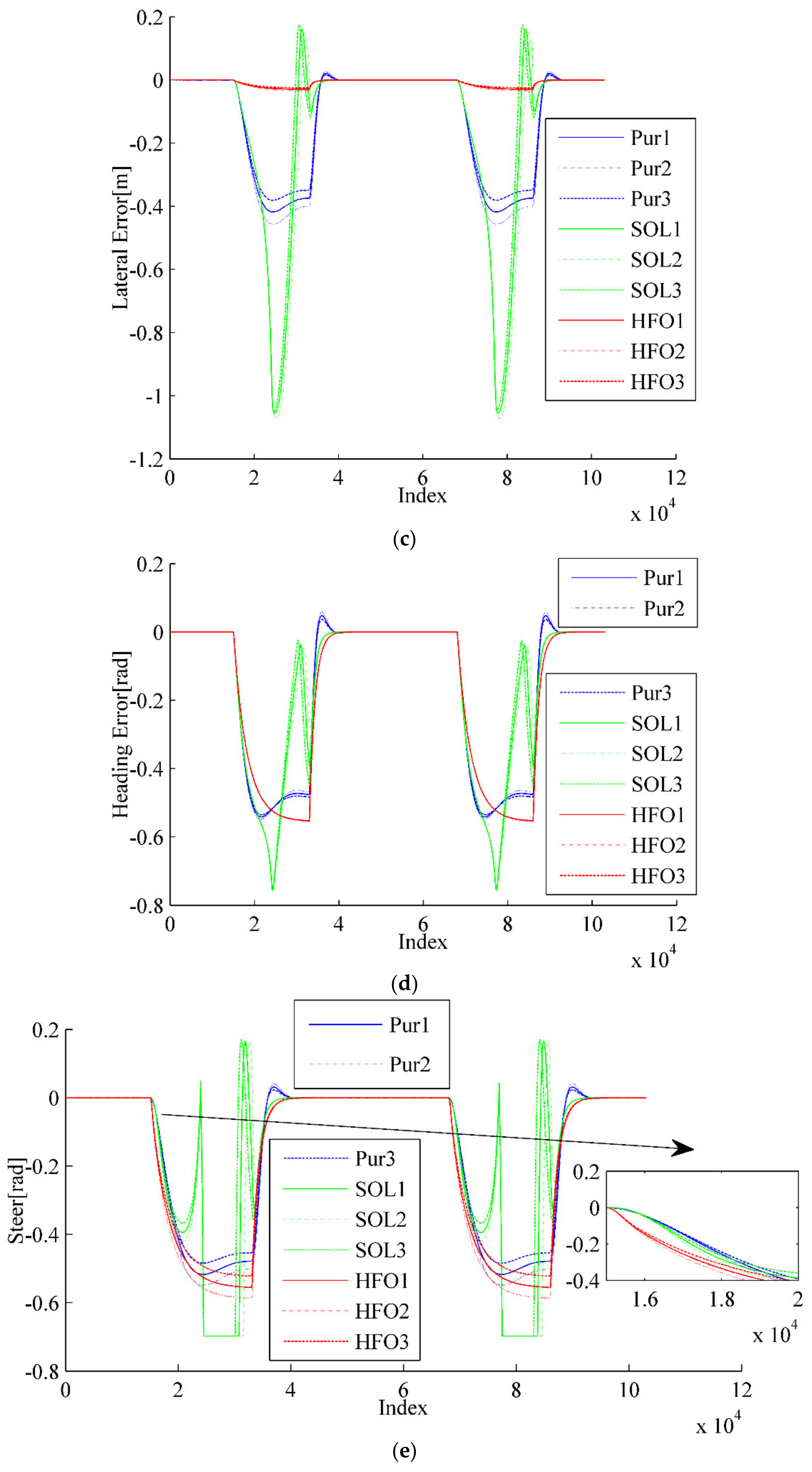

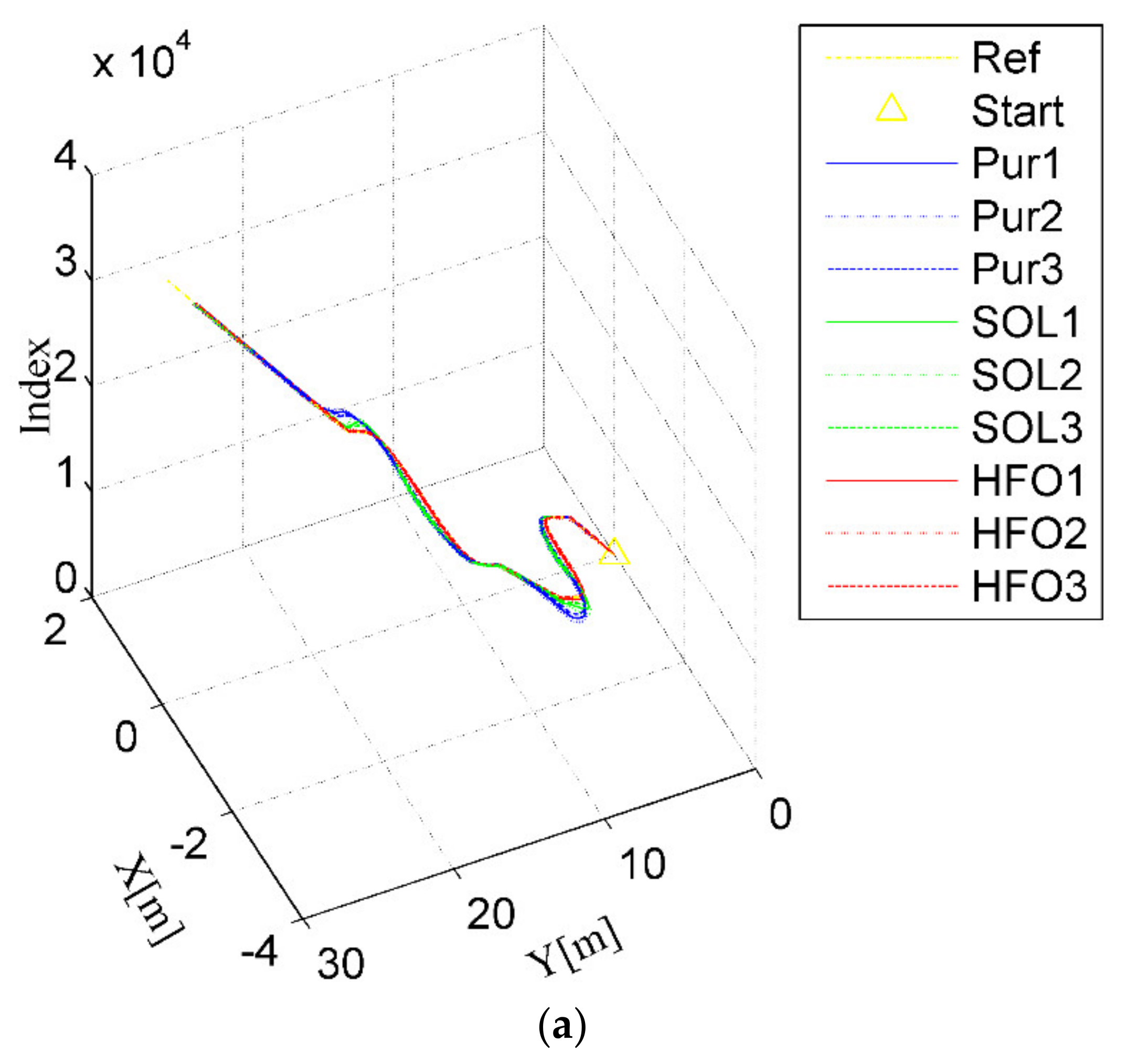

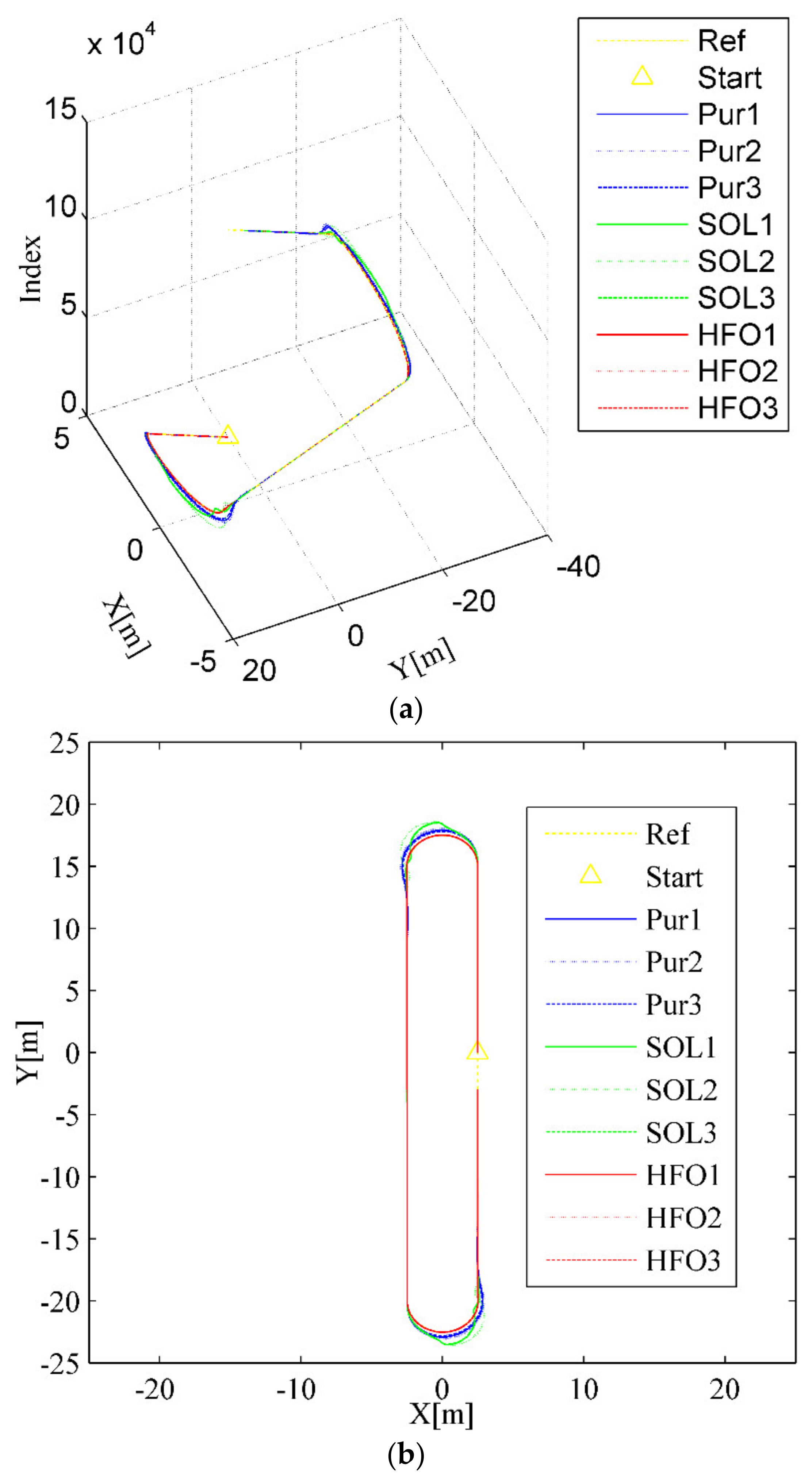

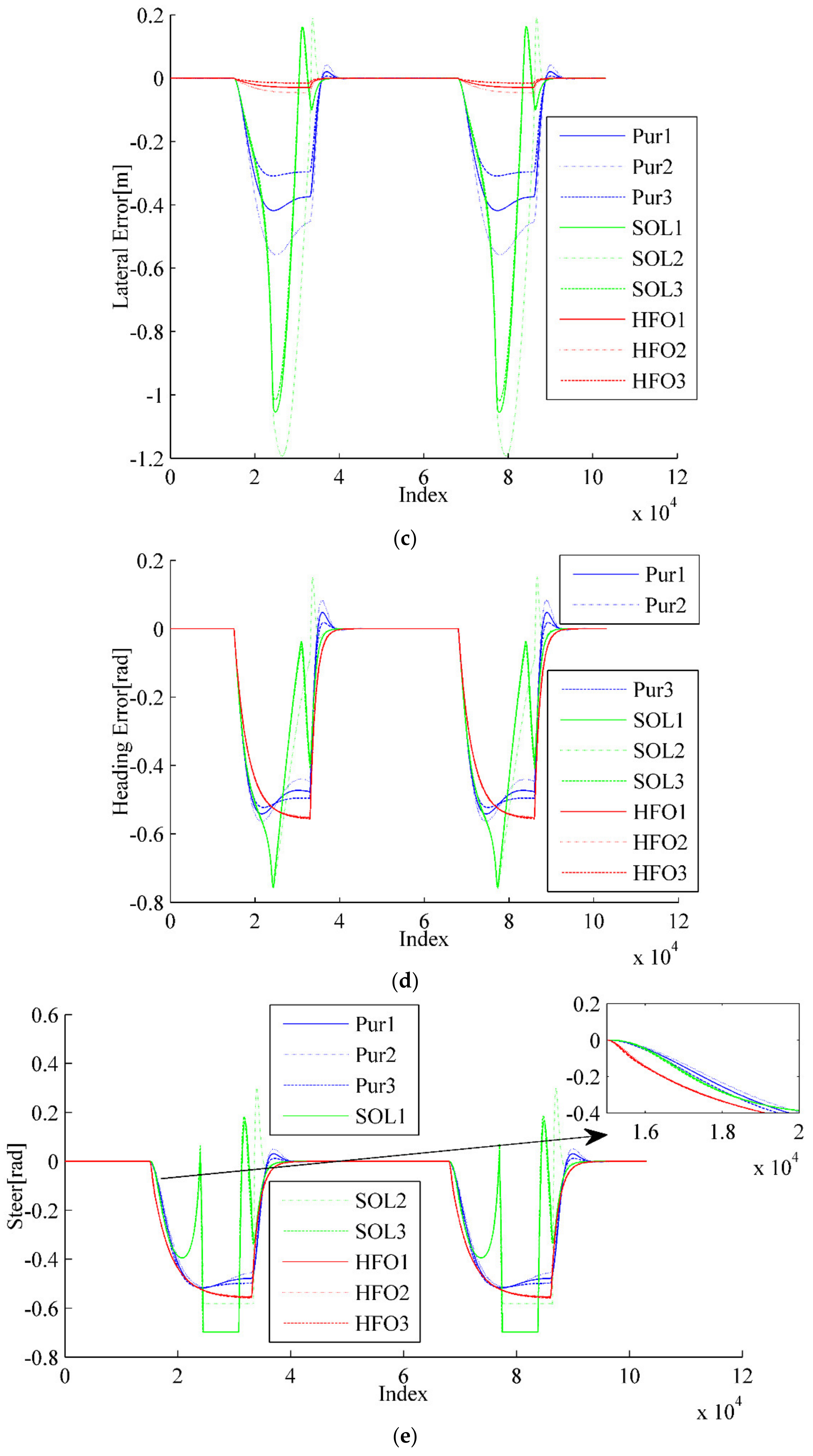

5.1. Wheelbase Uncertainty

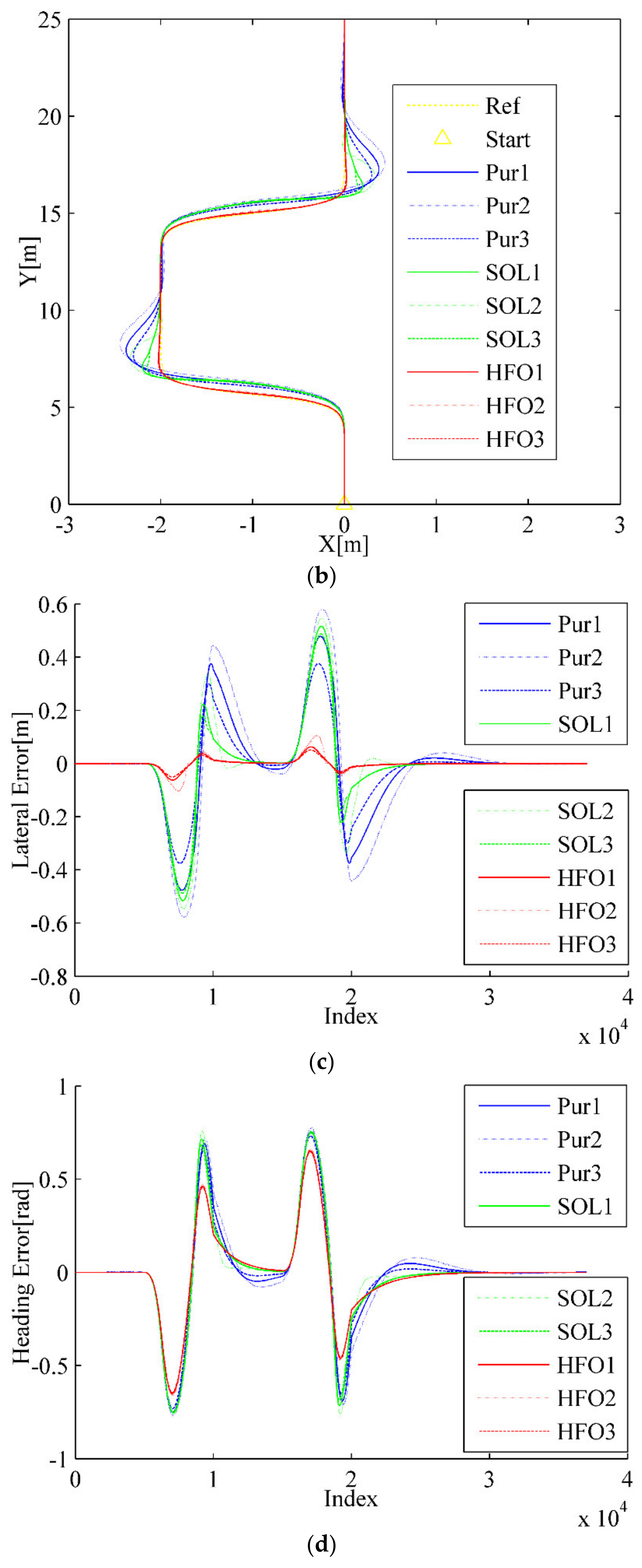

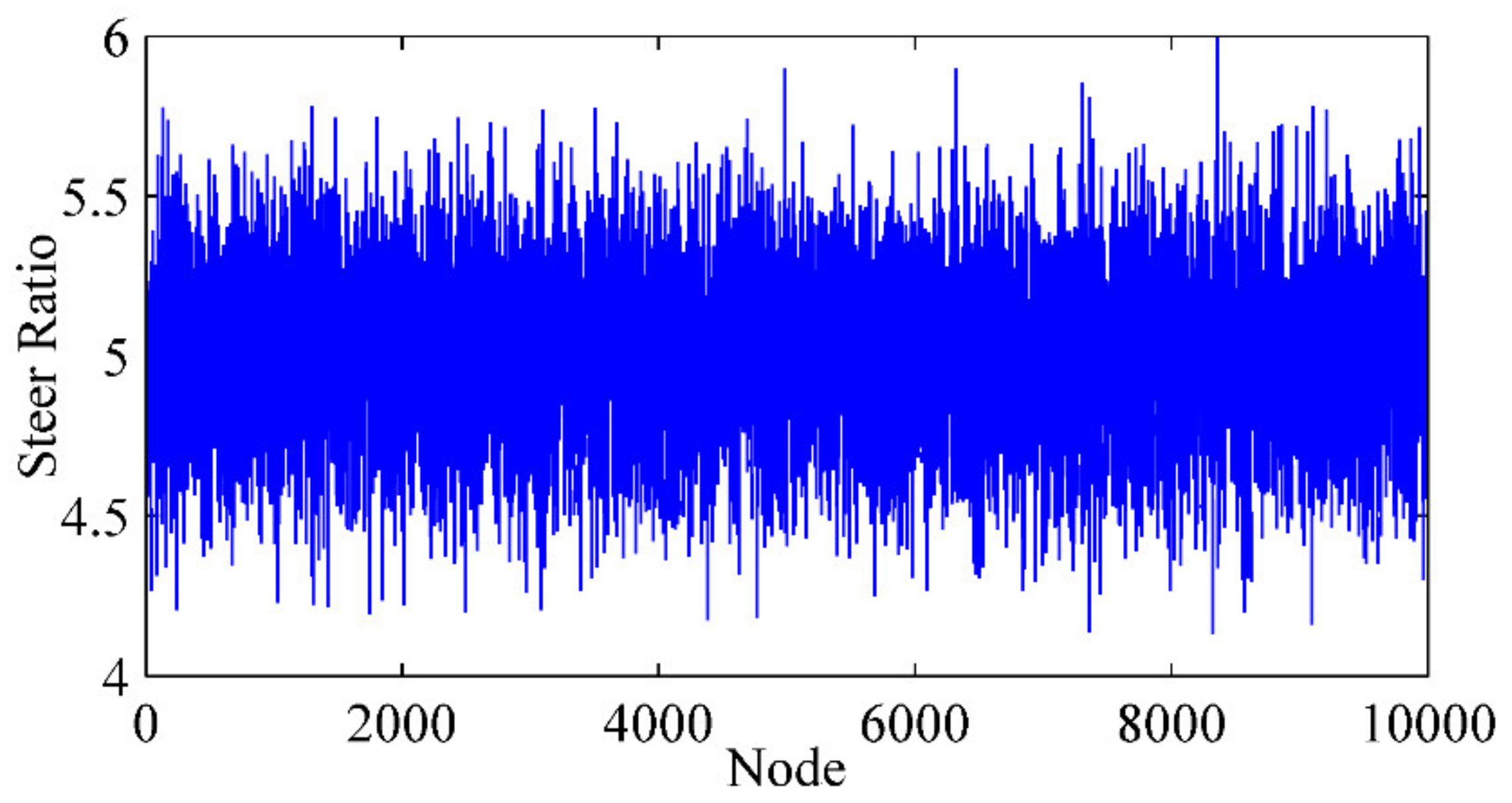

5.2. Steer Ratio Uncertainty

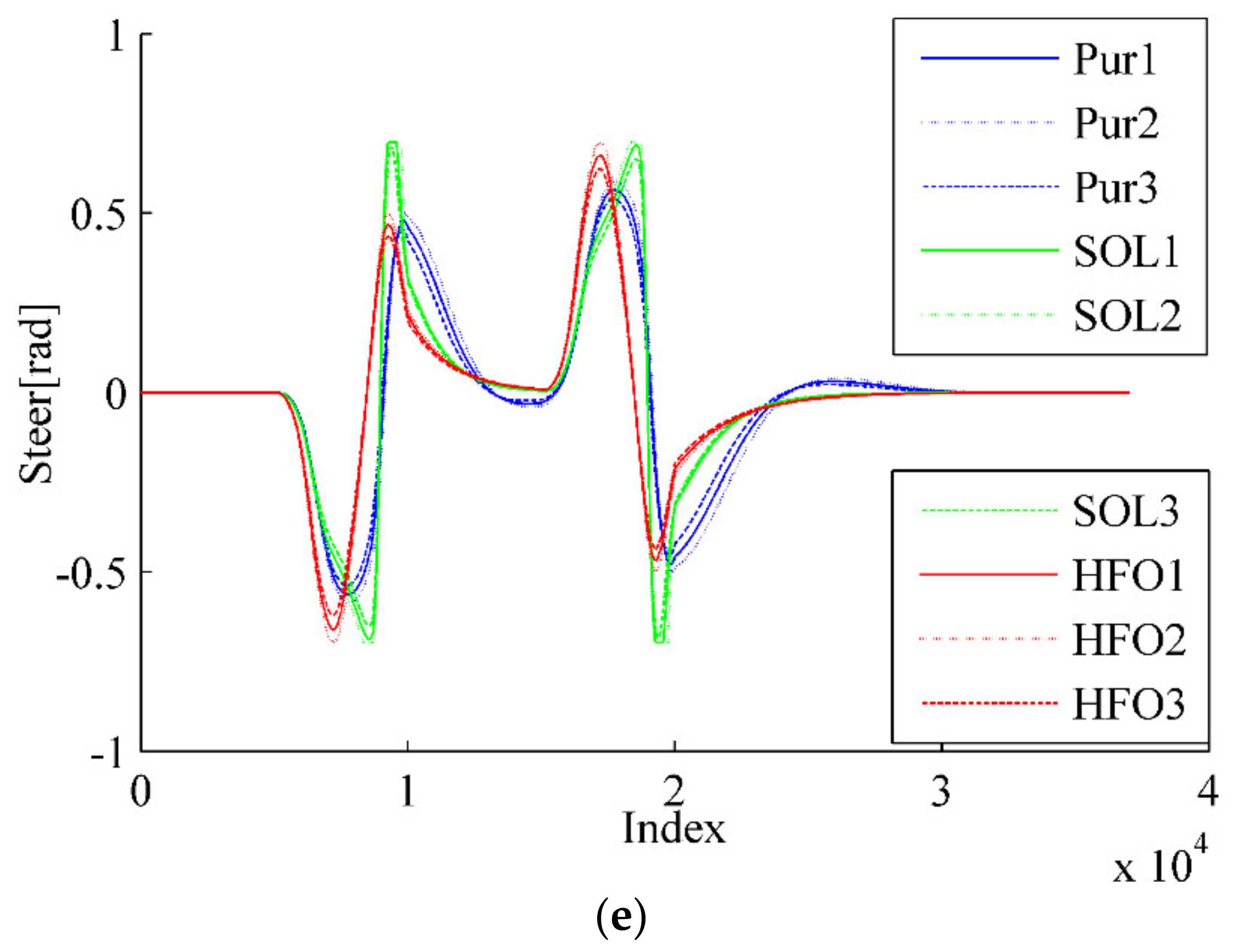

5.3. Gaussian White Noise Disterbance

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gao, K.; Yan, D.; Yang, F.; Xie, J.; Liu, L.; Du, R.; Xiong, N. Conditional artificial potential field-based autonomous vehicle safety control with interference of lane changing in mixed traffic scenario. Sensors 2019, 19, 4199. [Google Scholar] [CrossRef] [PubMed]

- Moreno, F.A.; Monroy, J.; Ruiz-Sarmiento, J.R.; Galindo, C.; Gonzalez-Jimenez, J. Automatic Waypoint Generation to Improve Robot Navigation Through Narrow Spaces. Sensors 2020, 20, 240. [Google Scholar] [CrossRef] [PubMed]

- Heger, J.; Voss, T. Optimal Scheduling for Automated Guided Vehicles (AGV) in Blocking Job-Shops. In Advances in Production Management Systems; The Path to Intelligent, Collaborative and Sustainable Manufacturing: IFIP WG 5.7 International Conference, APMS 2017; Lödding, H., Riedel, R., Thoben, K.D., Von Cieminski, G., Kiritsis, D., Eds.; Springer: Hamburg, Germany, 2017; Volume 514, pp. 151–158. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, J.; Li, Q.; Jiang, Z.; Ding, Q.; Du, L.; Wang, W. A new contouring error estimation for the high form accuracy of a multi-axis CNC machine tool. Int. J. Adv. Manuf. Technol. 2019, 101, 1403–1421. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, L.; Tian, X. A robot welding approach for the sphere-pipe joints with swing and multi-layer planning. Int. J. Adv. Manuf. Technol. 2019, 105, 265–278. [Google Scholar] [CrossRef]

- Mizuno, N.; Ohno, K.; Hamada, R.; Kojima, H.; Fujita, J.; Amano, H.; Westfechtel, T.; Suzuki, T.; Tadokoro, S. Enhanced path smoothing based on conjugate gradient descent for firefighting robots in petrochemical complexes. Adv. Robot. 2019, 33, 687–698. [Google Scholar] [CrossRef]

- Strengers, Y. Robots and roomba riders: Non-human performers in theories of social practice. In Social Practices and Dynamic Non-Humans; Springer: Cham, Switzerland, 2018; pp. 215–234. [Google Scholar] [CrossRef]

- Guo, M.; Shi, P.; Yu, H. Development a feeding assistive robot for eating assist. In Proceedings of the 2017 2nd Asia-Pacific Conference on Intelligent Robot Systems (ACIRS), Wuhan, China, 16–18 June 2017; pp. 299–304. [Google Scholar] [CrossRef]

- De Marvao, A.; Dawes, T.J.; Howard, J.P.; O’Regan, D.P. Artificial intelligence and the cardiologist: What you need to know for 2020. Heart 2020, 106, 399–400. [Google Scholar] [CrossRef]

- Maggipinto, M.; Terzi, M.; Masiero, C.; Beghi, A.; Susto, G.A. A computer vision-inspired deep learning architecture for virtual metrology modeling with 2-dimensional data. IEEE Trans. Semicond. Manuf. 2018, 31, 376–384. [Google Scholar] [CrossRef]

- Javanmardi, E.; Gu, Y.; Javanmardi, M.; Kamijo, S. Autonomous vehicle self-localization based on abstract map and multi-channel LiDAR in urban area. IATSS Res. 2019, 43, 1–13. [Google Scholar] [CrossRef]

- Gruber, A.; Gadringer, M.; Schreiber, H.; Amschl, D.; Bösch, W.; Metzner, S.; Pflügl, H. Highly scalable radar target simulator for autonomous driving test beds. In Proceedings of the 2017 European Radar Conference (EURAD), Nuremberg, Germany, 11–13 October 2017; pp. 147–150. [Google Scholar] [CrossRef]

- Lim, W.; Lee, S.; Sunwoo, M.; Jo, K. Hierarchical trajectory planning of an autonomous car based on the integration of a sampling and an optimization method. IEEE Trans. Intell. Transp. Syst. 2018, 19, 613–626. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, D.; Lv, L.; Zhang, Q. Multi-task learning for dangerous object detection in autonomous driving. Inf. Sci. 2018, 432, 559–571. [Google Scholar] [CrossRef]

- Rosenband, D.L. Inside Waymo’s self-driving car: My favorite transistors. In Proceedings of the 2017 Symposium on VLSI Circuits, Kyoto, Japan, 5–8 June 2017; pp. C20–C22. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar] [CrossRef]

- Cao, Y.; Xiao, C.; Yang, D.; Fang, J.; Yang, R.; Liu, M.; Li, B. Adversarial objects against lidar-based autonomous driving systems. arXiv 2019, arXiv:1907.05418. [Google Scholar]

- Paden, B.; Čáp, M.; Yong, S.Z.; Yershov, D.; Frazzoli, E. A survey of motion planning and control techniques for self-driving urban vehicles. IEEE Trans. Intell. Veh. 2016, 1, 33–55. [Google Scholar] [CrossRef]

- Guo, J.; Li, K.; Luo, Y. Review on the research of motion control for intelligent vehicles. Automob. Appl. Technol. 2016, 72, 151–159. (In Chinese) [Google Scholar] [CrossRef]

- Fang, Z.; Duan, J.; Zheng, B. Longitudinal motion control of intelligent vehicle based on two hierarchies optimal method. In Proceedings of the 2015 Chinese Automation Congress (CAC), Wuhan, China, 27–29 November 2015; pp. 1092–1097. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, H.; Zhang, G.; Wang, J. Robust Weighted Gain-Scheduling Hoo Vehicle Lateral Motion Control with Considerations of Steering System Backlash-Type Hysteresis. IEEE Trans. Control Syst. Technol. 2014, 22, 1740–1753. [Google Scholar] [CrossRef]

- Cheng, H. Longitudinal Motion Control for Intelligent Vehicles. In Autonomous Intelligent Vehicles; Springer: London, UK, 2011; pp. 139–150. [Google Scholar] [CrossRef]

- Yang, J.; Feng, J.F.; Qi, D.; Li, Y.L. Longitudinal motion control of underwater vehicle based on fast smooth second order sliding mode. Optik 2016, 127, 9118–9130. [Google Scholar] [CrossRef]

- Kachroo, P.; Tomizuka, M.; Agogino, A.M. A comprehensive strategy for longitudinal vehicle control with fuzzy supervisory expert system. In Proceedings of the 1995 IEEE International Conference on Systems, Man and Cybernetics, Intelligent Systems for the 21st Century, Vancouver, Canada, 22–25 October 1995; Volume 1, pp. 765–770. [Google Scholar] [CrossRef]

- Dai, Y.; Luo, Y.; Li, K. Longitudinal and lateral coordinated motion control of four-wheel-independent drive electric vehicles. In Proceedings of the 2013 world electric vehicle symposium and exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; pp. 1–9. [Google Scholar] [CrossRef]

- Cariou, C.; Lenain, R.; Thuilot, B.; Martinet, P. Motion planner and lateral-longitudinal controllers for autonomous maneuvers of a farm vehicle in headland. In Proceedings of the 2009 IEEE/RSJ International Conference on Intelligent Robots and Systems, Saint Louis, MO, USA, 10–15 October 2009; pp. 5782–5787. [Google Scholar] [CrossRef]

- Lin, F.; Zhang, Y.; Zhao, Y.; Yin, G.; Zhang, H.; Wang, K. Trajectory tracking of autonomous vehicle with the fusion of DYC and longitudinal–Lateral control. Chin. J. Mech. Eng. 2019, 32, 1–16. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Kadir, K.; Joyo, M.K. LQR based controller design for altitude and longitudinal movement of quad-rotor. J. Appl. Sci. 2016, 16, 588–593. [Google Scholar] [CrossRef]

- Le, T.P.; Dat, L.V.; Stiharu, I. Application of neural networks to design the controller for autonomous vehicles by learning driver’s behavior. In Proceedings of the 2013 International Conference on Control, Automation and Information Sciences (ICCAIS), Nha Trang, Vietnam, 25–28 November 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Alcala, E.; Puig, V.; Quevedo, J.; Escobet, T.; Comasolivas, R. Autonomous vehicle control using a kinematic Lyapunov-based technique with LQR-LMI tuning. Control Eng. Pract. 2018, 73, 1–12. [Google Scholar] [CrossRef]

- Lakhwani, D.A.; Adhyaru, D.M. Performance comparison of PD, PI and LQR controller of autonomous under water vehicle. In Proceedings of the 2013 Nirma University International Conference on Engineering (NUiCONE), Ahmedabad, India, 28–30 November 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Hu, C.; Wang, R.; Yan, F.; Chen, N. Output constraint control on path following of four-wheel independently actuated autonomous ground vehicles. IEEE Trans. Veh. Technol. 2015, 65, 4033–4043. [Google Scholar] [CrossRef]

- Li, Y.; Song, S. A survey of control algorithms for quadrotor unmanned helicopter. In Proceedings of the 2012 IEEE Fifth International Conference on Advanced Computational Intelligence (ICACI), Nanjing, China, 18–20 October 2012; pp. 365–369. [Google Scholar] [CrossRef]

- Khodayari, M.H.; Balochian, S. Modeling and control of autonomous underwater vehicle (AUV) in heading and depth attitude via self-adaptive fuzzy PID controller. J. Mar. Sci. Technol. 2015, 20, 559–578. [Google Scholar] [CrossRef]

- Ren, T.J.; Chen, T.C.; Chen, C.J. Motion control for a two-wheeled vehicle using a self-tuning PID controller. Control Eng. Pract. 2018, 16, 365–375. [Google Scholar] [CrossRef]

- Li, Y.; Wang, D.Z.; Zhang, X.H.; Bian, P.B. Research on PID Linear Motion Control Strategy of Self-balanced Two-wheeled Vehicle. Adv. Mater. Res. 2013, 694–697, 1679–1683. [Google Scholar] [CrossRef]

- Sarhadi, P.; Noei, A.R.; Khosravi, A. Model reference adaptive pid control with anti-windup compensator for an autonomous underwater vehicle. Robot. Auton. Syst. 2016, 83, 87–93. [Google Scholar] [CrossRef]

- Rathore, A.; Kumar, M. Robust steering control of autonomous underwater vehicle: Based on pid tuning evolutionary optimization technique. Int. J. Comput. Appl. 2015, 117, 1–6. [Google Scholar] [CrossRef]

- Han, X.; Zhang, X.; Du, Y.; Cheng, G. Design of Autonomous Vehicle Controller Based on BP-PID. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Hubei, China, 14–16 December 2018; Volume 234, pp. 1–10. [Google Scholar] [CrossRef]

- Samuel, M.; Hussein, M.; Binti, M. A review of some pure-pursuit based path tracking techniques for control of autonomous vehicle. Int. J. Comput. Appl. 2016, 135, 35–38. [Google Scholar] [CrossRef]

- Snider, J.M. Automatic Steering Methods for Autonomous Automobile Path Tracking; Tech. Rep. CMU-RITR-09-08; Robotics Institute: Pittsburgh, PA, USA, 2009. [Google Scholar]

- Rankin, A.L.; Crane, C.D.; Armstrong, D.G. Evaluating a pid, pure pursuit, and weighted steering controller for an autonomous land vehicle. Proc. SPIE Int. Soc. Opt. Eng. 1998, 3210, 1–12. [Google Scholar] [CrossRef]

- Maslak, W.; Butkiewicz, B.S. Autonomous Vehicle with Fuzzy Control. In Proceedings of the Signal Processing Symposium, Serock, Poland, 5–7 June 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Ryoo, Y.J.; Lim, Y.C. Neuro-fuzzy control system for vision-based autonomous vehicle. In Proceedings of the IEEE International Fuzzy Systems Conference, Seoul, South Korea, 22–25 August 1999; pp. 131–137. [Google Scholar] [CrossRef]

- Wu, H.; Chang, W.; He, H.G.; Xi, P. Fuzzy control method for lateral control of autonomous land vehicle. In Mobile Robots X; International Society for Optics and Photonics: Philadephia, PA, USA, 1995; Volume 2591, pp. 125–131. [Google Scholar] [CrossRef]

- Nakhoob, S.; Chatraei, A.; Shojaei, K. Fuzzy Adaptive Control for Trajectory Tracking of Autonomous Underwater Vehicle. J. Intell. Proced. Electr. Technol. 2014, 4, 71–77. [Google Scholar]

- Naranjo, J.E.; Gonzalez, C.; Garcia, R.; De Pedro, T. Lane-change fuzzy control in autonomous vehicles for the overtaking maneuver. IEEE Trans. Intell. Transp. Syst. 2008, 9, 438–450. [Google Scholar] [CrossRef]

- Yamada, K.; Jinyama, H.; Yamashita, M. Automatic Acquisition Method of Fuzzy Control Knowledge for Orbit Tracking of Autonomous Vehicle in Agricultural Works Using Genetic Algorithms. In Soft Computing as Transdisciplinary Science and Technology; Springer: Berlin/Heidelberg, Germany, 2005; pp. 93–102. [Google Scholar] [CrossRef]

- Amer, N.H.; Hudha, K.; Zamzuri, H.; Aparow, V.R.; Murrad, M. Adaptive modified stanley controller with fuzzy supervisory system for trajectory tracking of an autonomous armoured vehicle. Robot. Auton. Syst. 2018, 105, 94–111. [Google Scholar] [CrossRef]

- Besselmann, T.; Morari, M. Autonomous vehicle steering using explicit LPV-MPC. In Proceedings of the 2009 European Control Conference (ECC), Budapest, Hungary, 23–26 August 2009; pp. 2628–2633. [Google Scholar] [CrossRef]

- Wang, H.; Huang, Y.; Khajepour, A.; Zhang, Y.; Rasekhipour, Y.; Cao, D. Crash mitigation in motion planning for autonomous vehicles. IEEE Trans. Intell. Transp. Syst. 2019, 20, 3313–3323. [Google Scholar] [CrossRef]

- Raffo, G.V.; Gomes, G.K.; Normey-Rico, J.E.; Kelber, C.R.; Becker, L.B. A predictive controller for autonomous vehicle path tracking. IEEE Trans. Intell. Transp. Syst. 2009, 10, 92–102. [Google Scholar] [CrossRef]

- Wang, H.; Liu, B.; Ping, X.; An, Q. Path Tracking Control for Autonomous Vehicles Based on an Improved MPC. IEEE Access 2019, 7, 161064–161073. [Google Scholar] [CrossRef]

- Sun, C.; Zhang, X.; Zhou, Q.; Tian, Y. A model predictive controller with switched tracking error for autonomous vehicle path tracking. IEEE Access 2019, 7, 53103–53114. [Google Scholar] [CrossRef]

- Wang, Y.; Boyd, S. Fast model predictive control using online optimization. IEEE Trans. Control Syst. Technol. 2009, 18, 267–278. [Google Scholar] [CrossRef]

- Wang, S. ADRC and feedforward hybrid control system of PMSM. Math. Probl. Eng. 2013, 2013, 1–12. [Google Scholar] [CrossRef]

- Ruan, J.; Li, Y. ADRC Based Ship Course Controller Design and Simulations. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Qingdao, China, 1–3 September 2008; pp. 2731–2735. [Google Scholar] [CrossRef]

- Han, J.Q. Auto Disturbance Rejection Controller and It’s Applications. Control Decis. 1998, 13, 19–23. (In Chinese) [Google Scholar] [CrossRef]

- Han, J. Active Disturbance Rejection Control Technique—The Technique for Estimating and Compensating the Uncertainties; National Defense Industry Press: Beijing, China, 2008; pp. 197–270. (In Chinese) [Google Scholar]

- Han, J. From pid to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Tao, L.; Chen, Q.; Nan, Y.; Dong, F.; Jin, Y. Speed Tracking and Synchronization of a Multimotor System Based on Fuzzy ADRC and Enhanced Adjacent Coupling Scheme. Complexity 2018, 2018, 1–16. [Google Scholar] [CrossRef]

- Yang, R.; Sun, M.; Chen, Z. Graphical design for stability of linear active disturbance rejection control to first order time delay plants. Int. J. Syst. Control Inf. Process. 2012, 1, 118–130. [Google Scholar] [CrossRef]

- Yang, R.; Sun, M.; Chen, Z. Active disturbance rejection control on first-order plant. J. Syst. Eng. Electron. 2011, 22, 95–102. [Google Scholar] [CrossRef]

- Jin, H.; Liu, L.; Lan, W.; Zeng, J. On stability and robustness of linear active disturbance rejection control: A small gain theorem approach. In Proceedings of the 2017 36th Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017; pp. 3242–3247. [Google Scholar] [CrossRef]

- Ronghui, L.I. Active disturbance rejction based tracking control of underactuated surface ships. Ph.D. Thesis, Dalian Maritime University, Dalian, China, 2013. (In Chinese). [Google Scholar]

- Wang, J. Research on Path Planning and Path Tracking for Automobile in Two Steering Conditions. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2015. (In Chinese). [Google Scholar]

- Dormand, J.R.; Prince, P.J. A family of embedded runge-kutta formulae. J. Comput. Appl. Math. 1980, 6, 19–26. [Google Scholar] [CrossRef]

- Jameson, A.J.; Schmidt, W.; Turkel, E. Solutions of the euler equations by finite volume methods using runge-kutta time-stepping schemes. AIAA J. 1981, 1259, 1–14. [Google Scholar] [CrossRef]

- ISO 3888-2: 2002. Passenger Cars–Test Track for a Severe Lane Change Manoeuvre–Part 2: Obstacle Avoidance; International Organization for Standardization: Geneva, Switzerland, 2002.

- Zhao, Y.Q.; Wang, J.; Zang, L.G.; Li, B.; Wu, Y. Path tracking for different wheelbase vehicles. J. Shanghai Jiaotong Univ. 2015, 49, 481–486. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Y.Q.; Ji, X.W.; Liu, Y.H.; Zang, L.G. Path tracking for parallel parking based on linear extended state observer. Huanan Ligong Daxue Xuebao/J. South China Univ. Technol. (Nat. Sci.) 2014, 42, 71–77. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.; Zhao, Y.; Ji, X.; Liu, Y.; Zang, L. Path tracking for vehicle parallel parking based on ADRC controller. J. Beijing Inst. Technol. 2015, 24, 213–221. [Google Scholar] [CrossRef]

| Parameter | Setting | Parameter | Setting | Parameter | Setting |

|---|---|---|---|---|---|

| Designed wheelbase L | 1.34 m | Working speed vd | 5.0 km/h | Preview distance ls | 1.34 m |

| Designed Steer ratio i | 5.0 | Maximum steer angle | 0.698 rad | LESO period TLESO | 0.01 s |

| c0 | 0.09 π/ls | c1 | 10/ls | c2 | 0.1/ls |

| b0 | −0.1 vd/ls/L | LSEF gain wc | 0.4 | LESO gain wo | 4 |

| Label | Method | Real L | Label | Method | Real L | Label | Method | Real L |

|---|---|---|---|---|---|---|---|---|

| Pur1 | Pure Pursuit | 1.34 m | SOL1 | SO-LADRC | 1.34 m | HFO1 | HFO-LADRC | 1.34 m |

| Pur2 | Pure Pursuit | 1.44 m | SOL2 | SO-LADRC | 1.44 m | HFO2 | HFO-LADRC | 1.44 m |

| Pur3 | Pure Pursuit | 1.24 m | SOL3 | SO-LADRC | 1.24 m | HFO3 | HFO-LADRC | 1.24 m |

| Label | Method | Real i | Label | Method | Real i | Label | Method | Real i |

|---|---|---|---|---|---|---|---|---|

| Pur1 | Pure Pursuit | 5.0 | SOL1 | SO-LADRC | 5.0 | HFO1 | HFO-LADRC | 5.0 |

| Pur2 | Pure Pursuit | 6.0 | SOL2 | SO-LADRC | 6.0 | HFO2 | HFO-LADRC | 6.0 |

| Pur3 | Pure Pursuit | 4.0 | SOL3 | SO-LADRC | 4.0 | HFO3 | HFO-LADRC | 4.0 |

| Label | Method | Real i | Label | Method | Real i | Label | Method | Real i |

|---|---|---|---|---|---|---|---|---|

| Pur1 | Pure Pursuit | 5.0 | SOL1 | SO-LADRC | 5.0 | HFO1 | HFO-LADRC | 5.0 |

| Pur2 | Pure Pursuit | GWN | SOL2 | SO-LADRC | GWN | HFO2 | HFO-LADRC | GWN |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, D.; Yu, Z.; Xiong, L.; Fu, Z.; Li, Z.; Zhang, P.; Leng, B.; Shan, F. HFO-LADRC Lateral Motion Controller for Autonomous Road Sweeper. Sensors 2020, 20, 2274. https://doi.org/10.3390/s20082274

Zeng D, Yu Z, Xiong L, Fu Z, Li Z, Zhang P, Leng B, Shan F. HFO-LADRC Lateral Motion Controller for Autonomous Road Sweeper. Sensors. 2020; 20(8):2274. https://doi.org/10.3390/s20082274

Chicago/Turabian StyleZeng, Dequan, Zhuoping Yu, Lu Xiong, Zhiqiang Fu, Zhuoren Li, Peizhi Zhang, Bo Leng, and Fengwu Shan. 2020. "HFO-LADRC Lateral Motion Controller for Autonomous Road Sweeper" Sensors 20, no. 8: 2274. https://doi.org/10.3390/s20082274

APA StyleZeng, D., Yu, Z., Xiong, L., Fu, Z., Li, Z., Zhang, P., Leng, B., & Shan, F. (2020). HFO-LADRC Lateral Motion Controller for Autonomous Road Sweeper. Sensors, 20(8), 2274. https://doi.org/10.3390/s20082274