Machine Learning-Enriched Lamb Wave Approaches for Automated Damage Detection

Abstract

1. Introduction

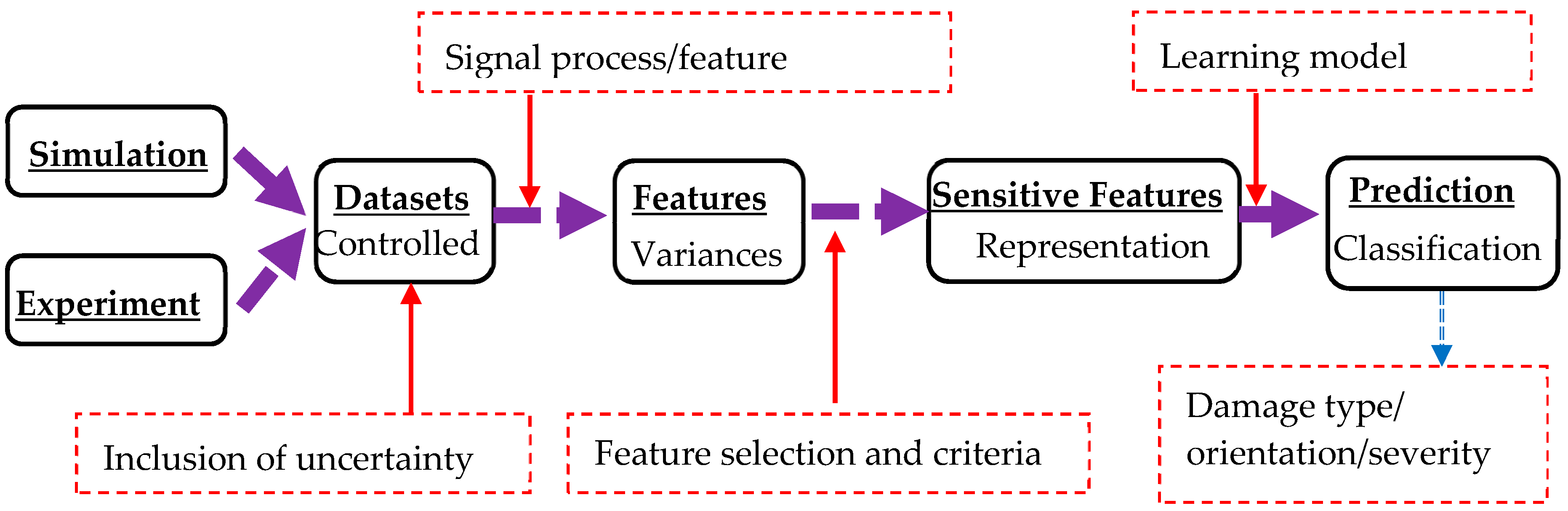

2. Machine Learning Enriched Lamb Wave Approaches

3. Datasets Generated from Lamb Wave Approaches

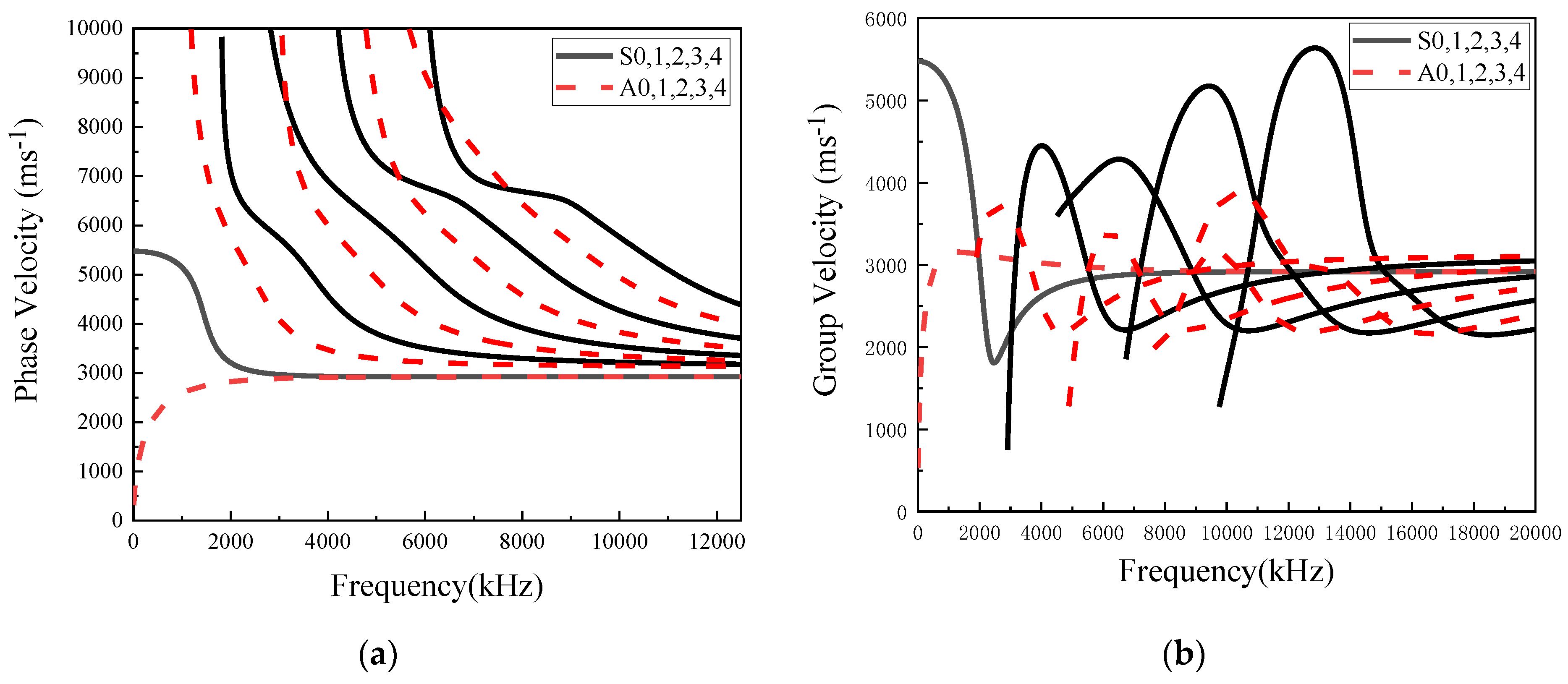

3.1. Concept of Lamb Wave Excitation

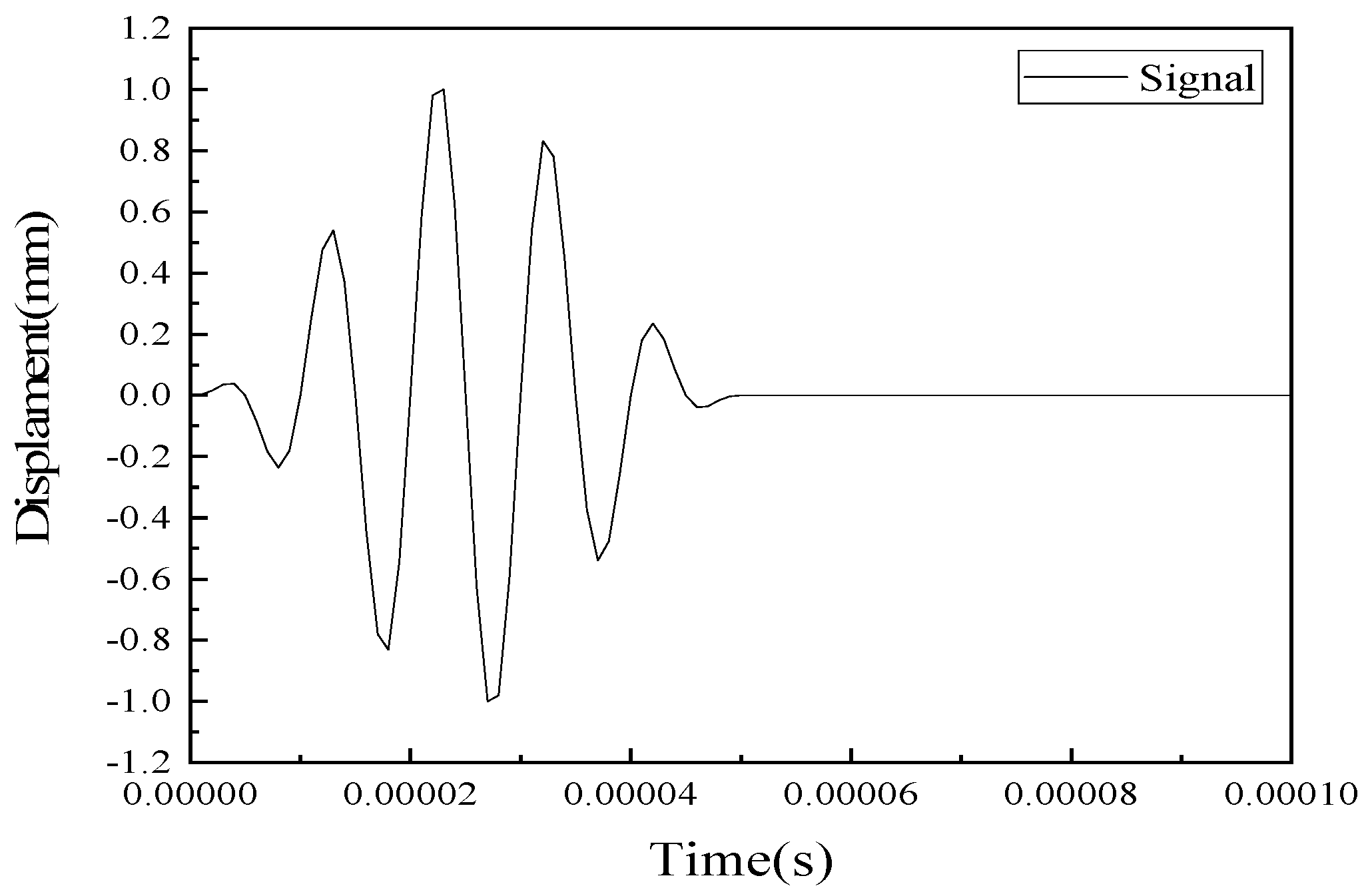

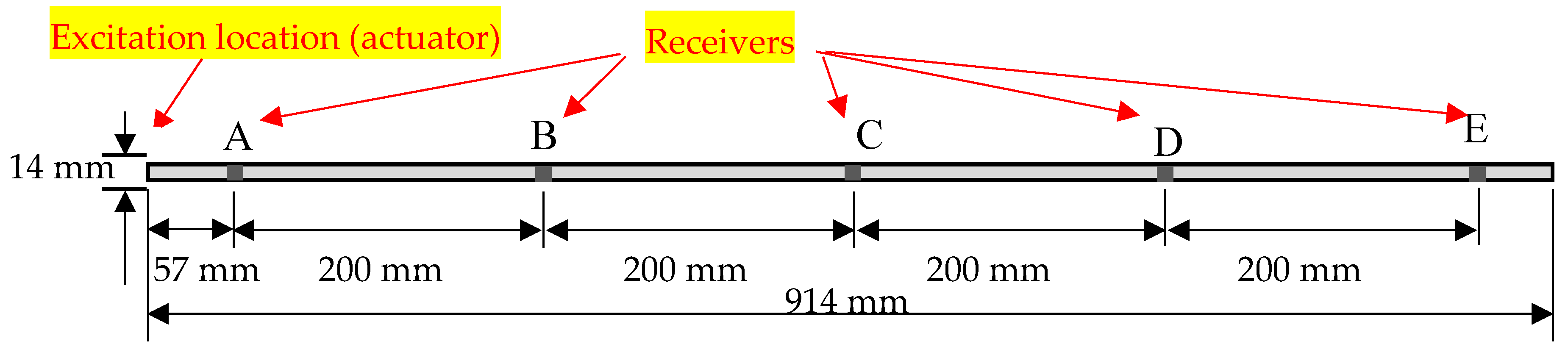

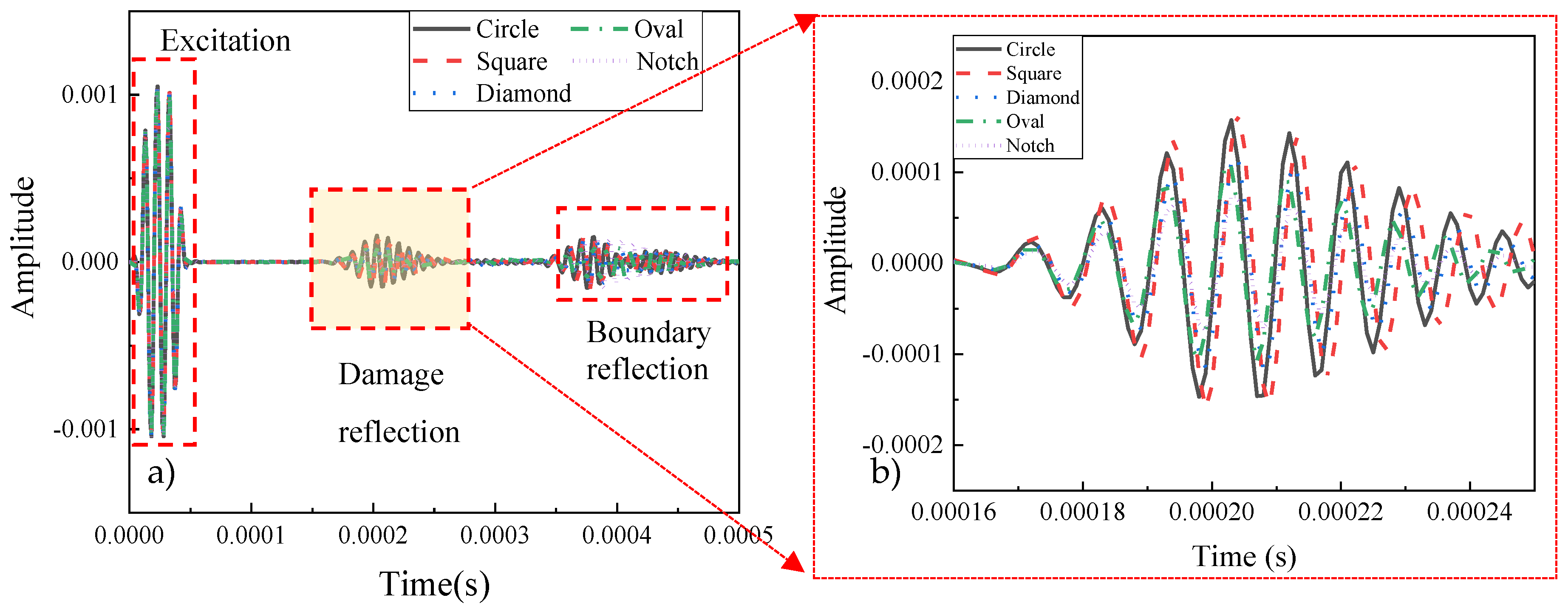

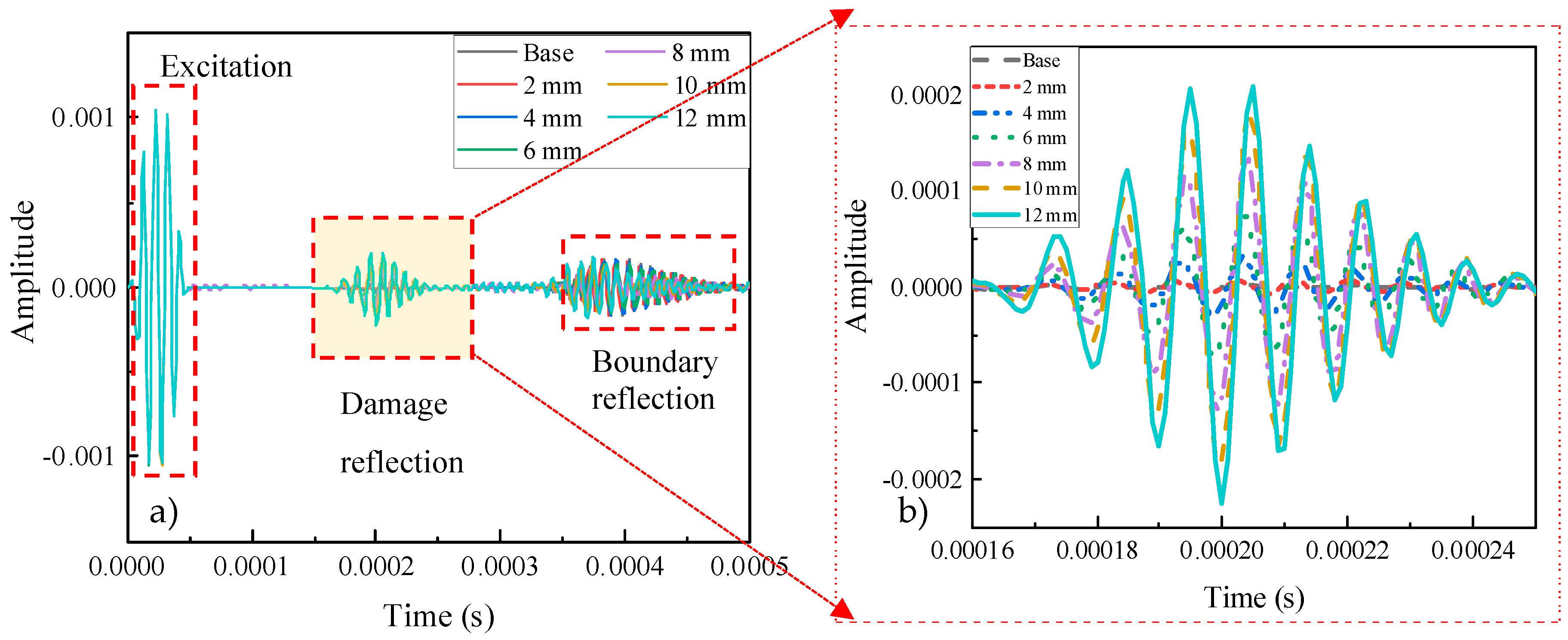

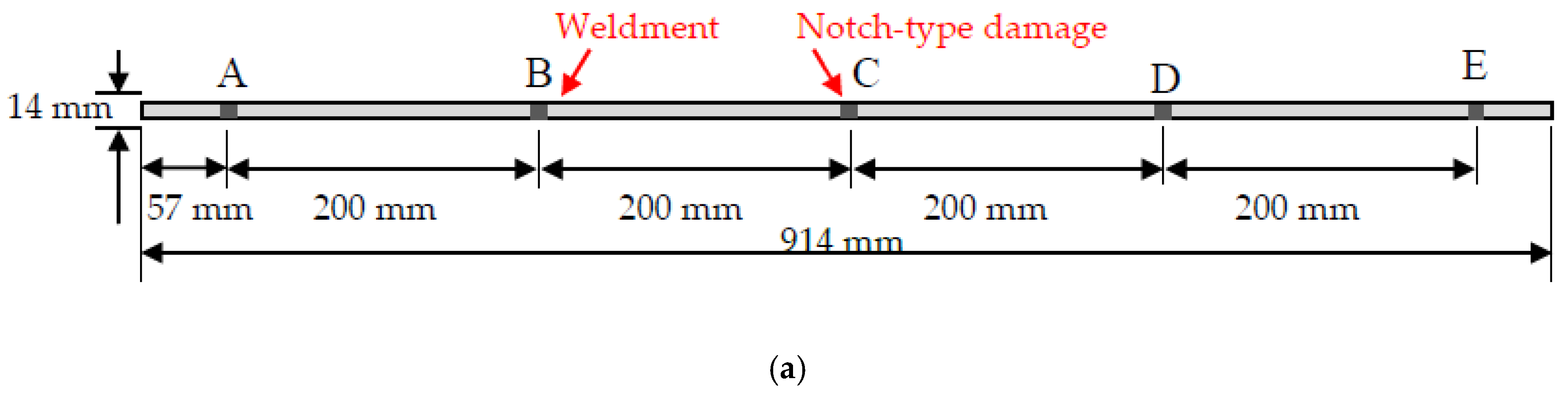

3.2. Simulation of Lamb Wave Excitation Along Structural Components

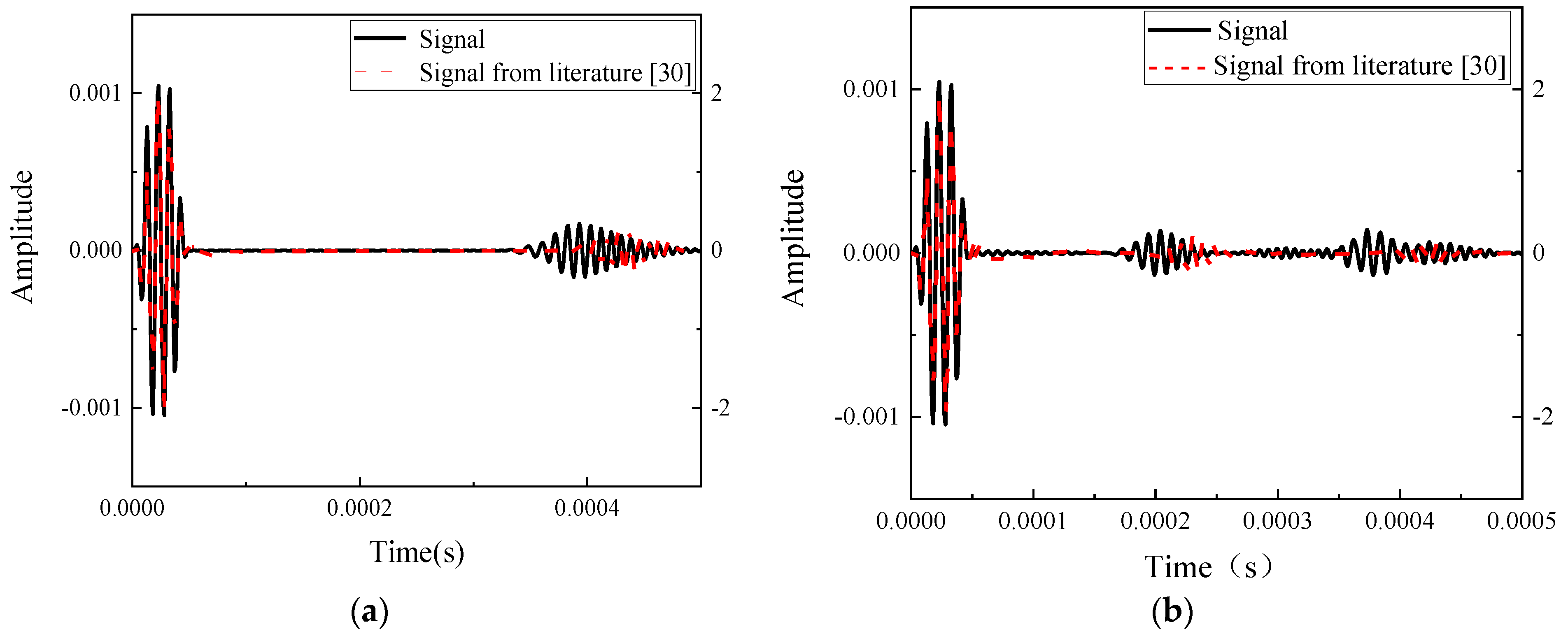

3.3. Calibration of Simulation

3.4. Design of Scenarios and Data Augmentation

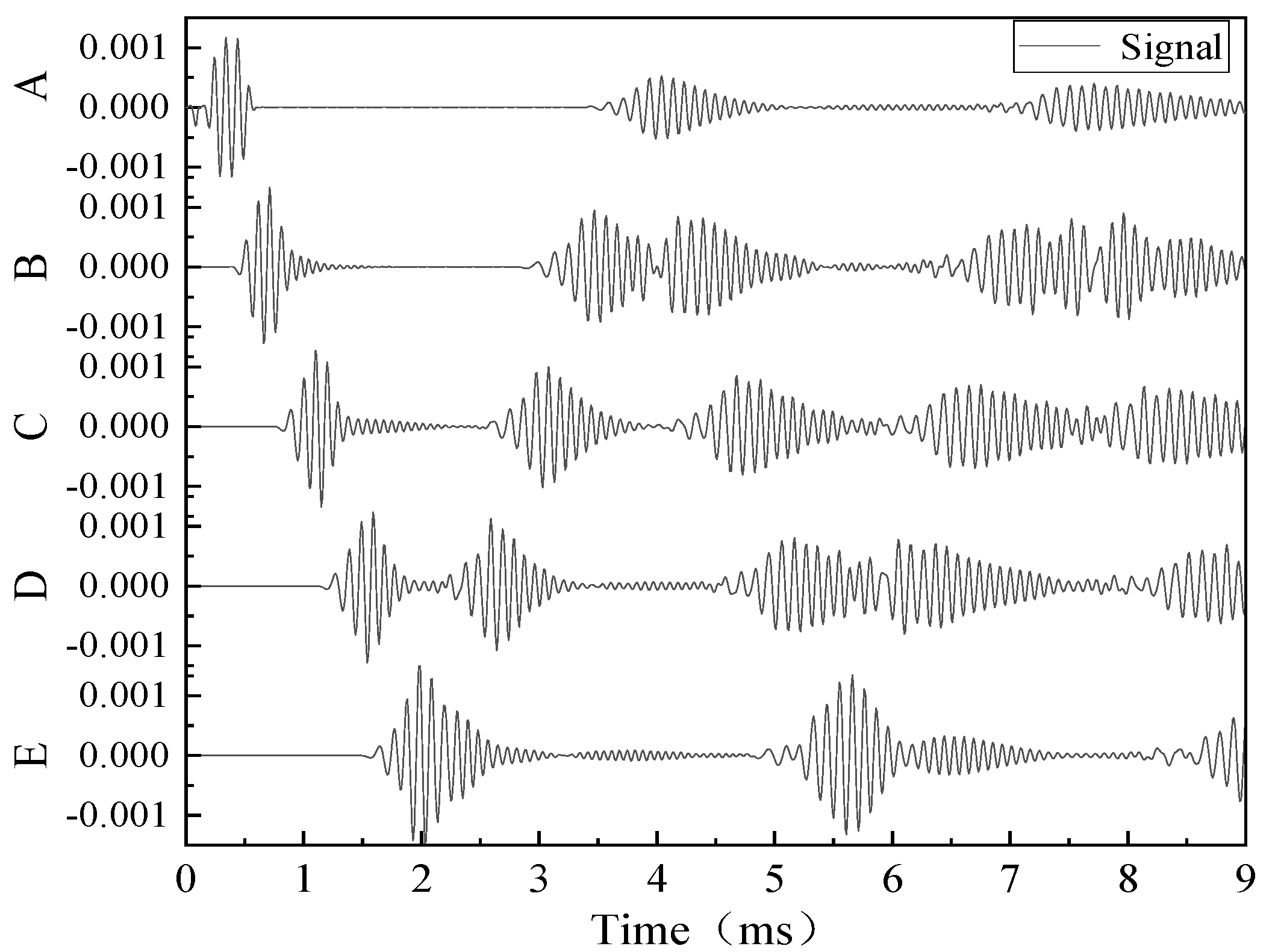

3.4.1. Design of Scenarios

3.4.2. Data Augmentation and Noise Interferences

4. Feature Representation and Classification using Machine Learning

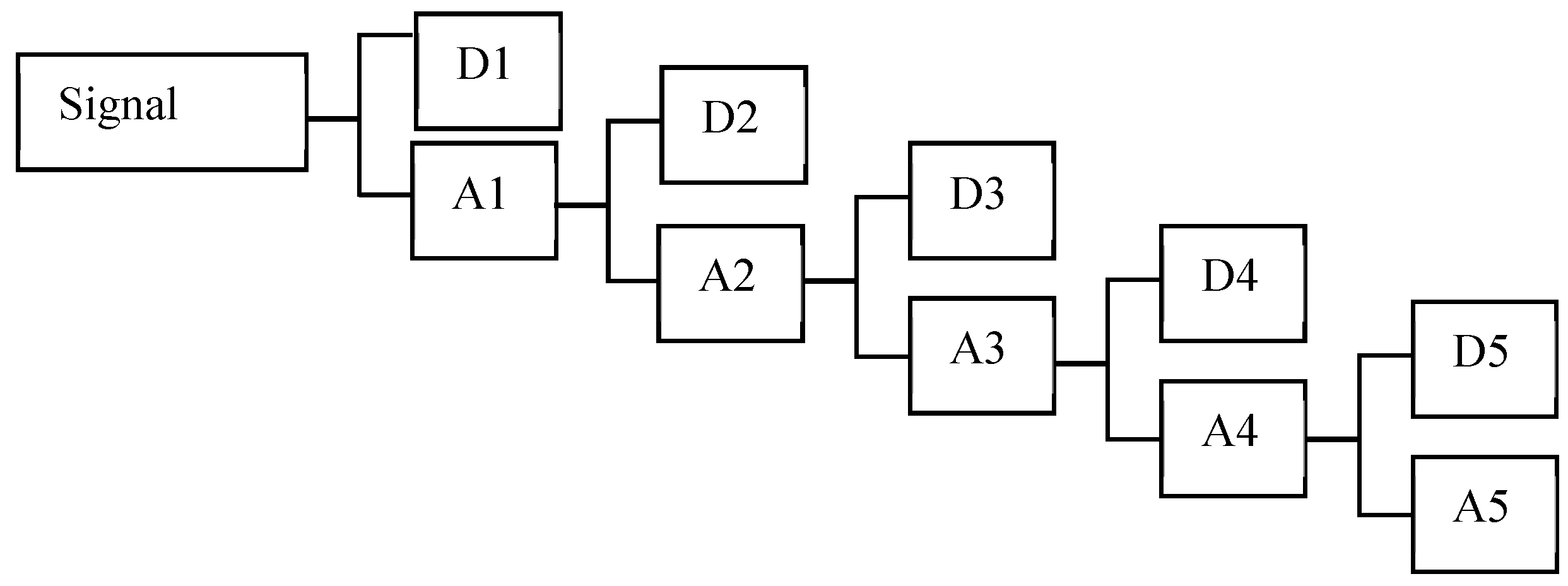

4.1. Feature Extraction Methods

4.2. Feature Selection and Criteria

4.3. Support Vector Machine for Classification

4.4. Assessment of Effectiveness of Learning Models using ROC Curves

5. Results and Discussion

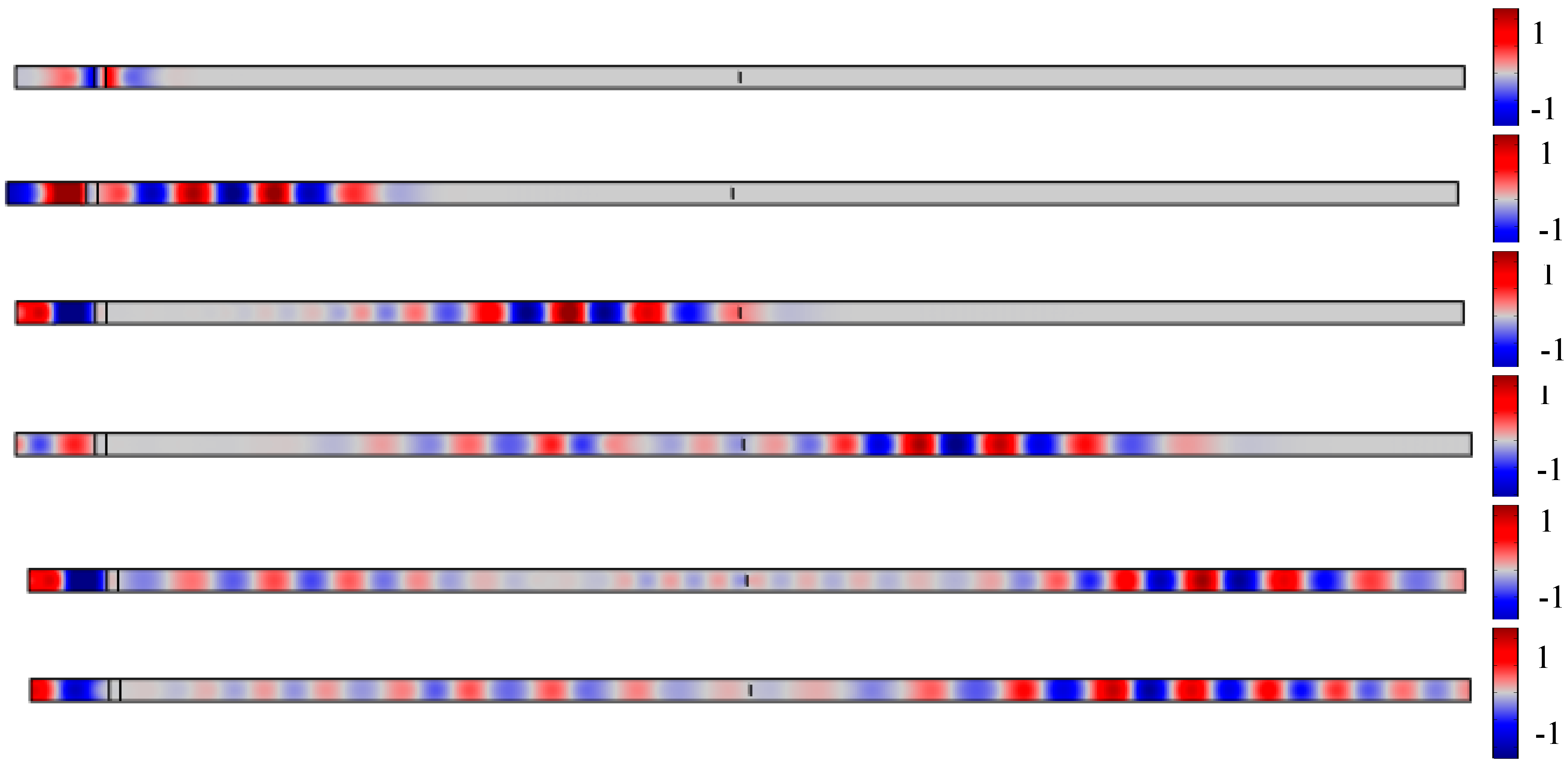

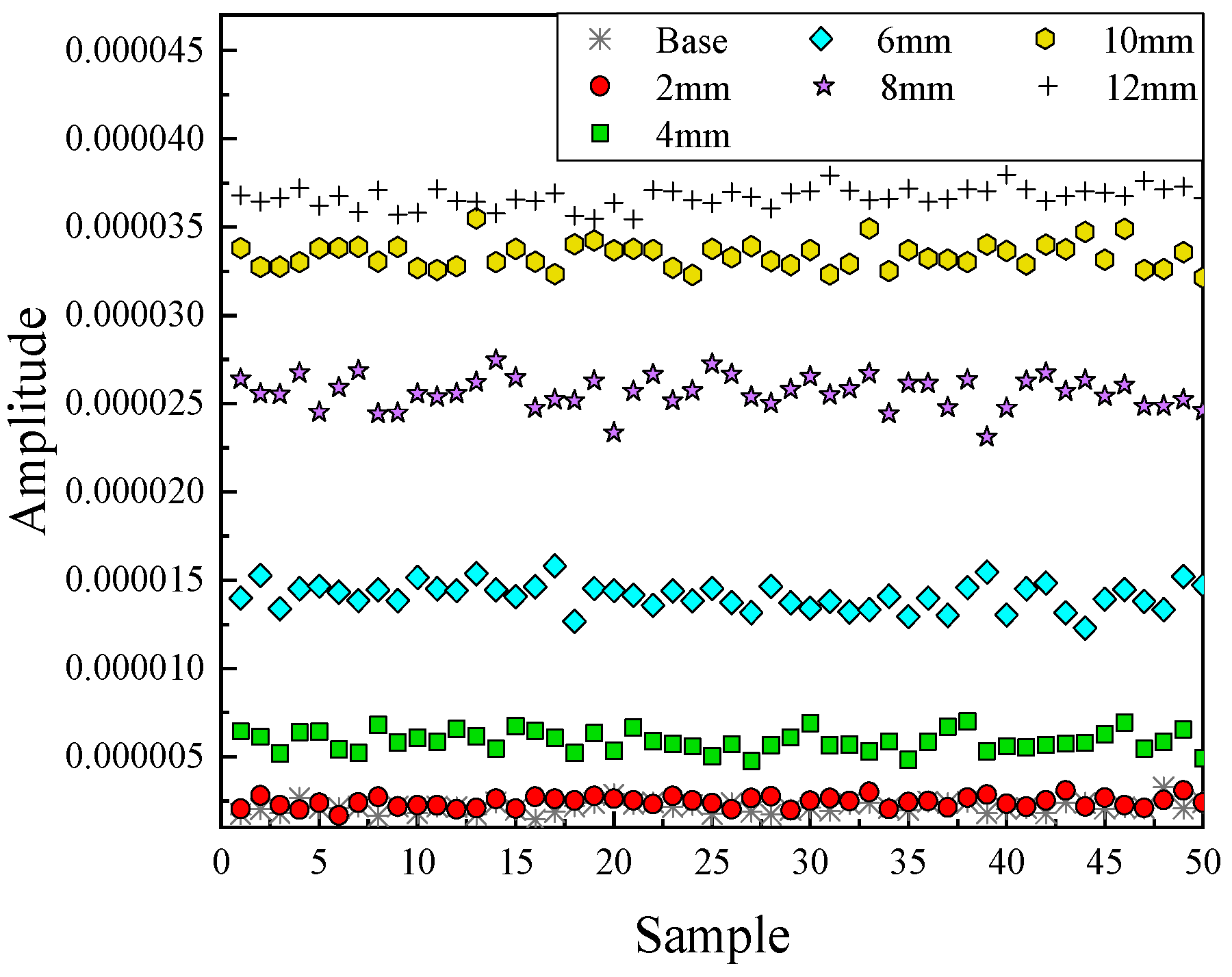

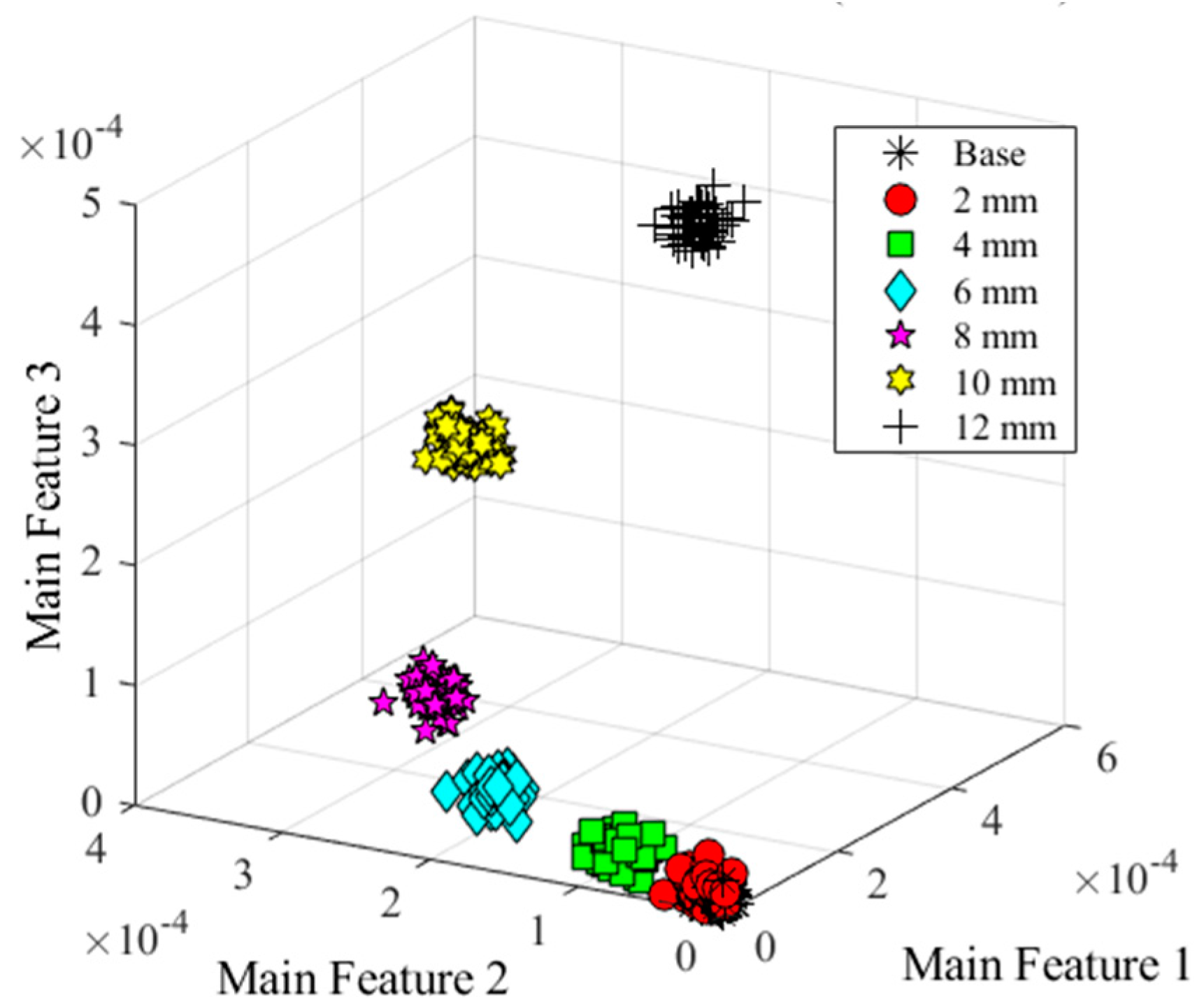

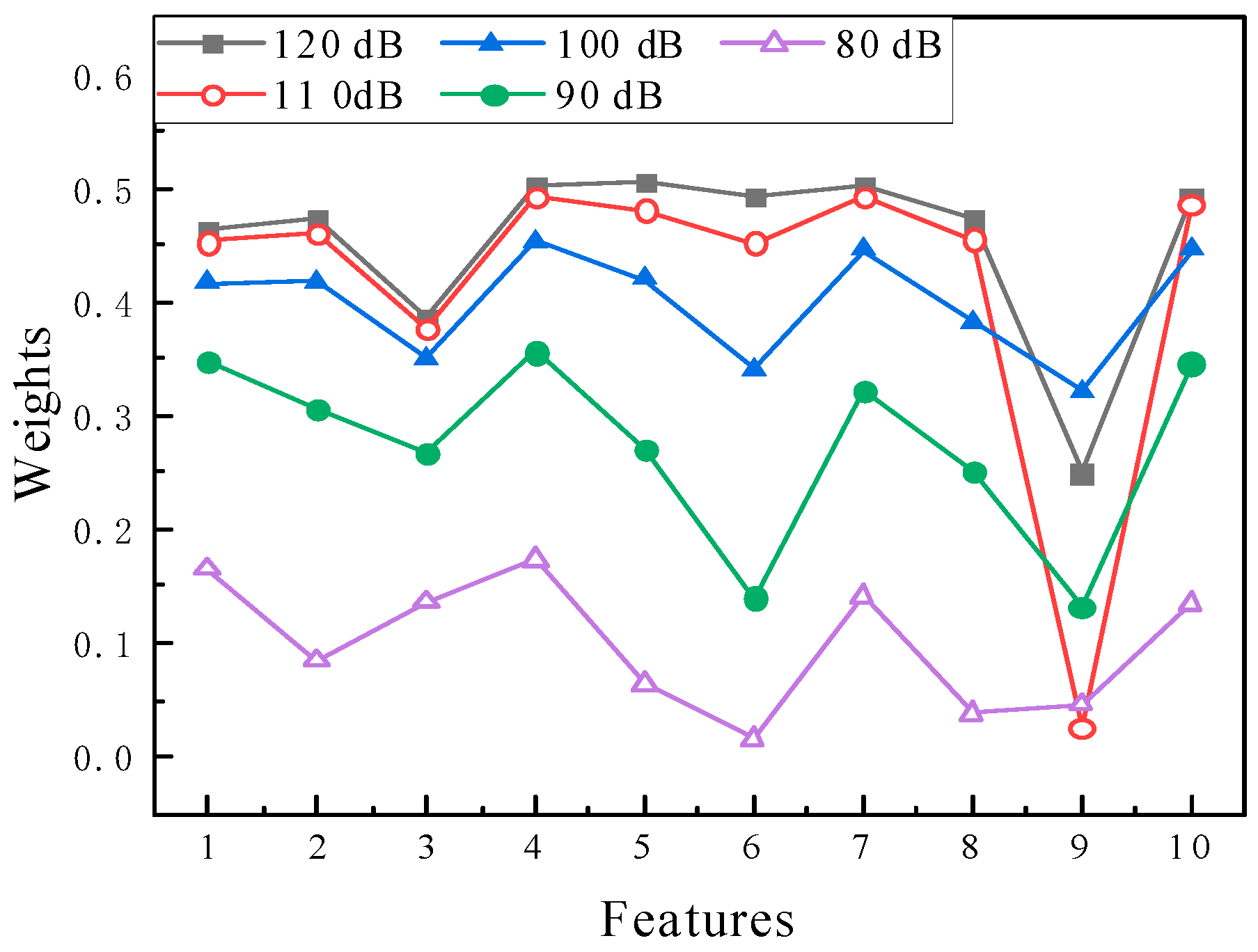

5.1. Damage-Sensitive Features

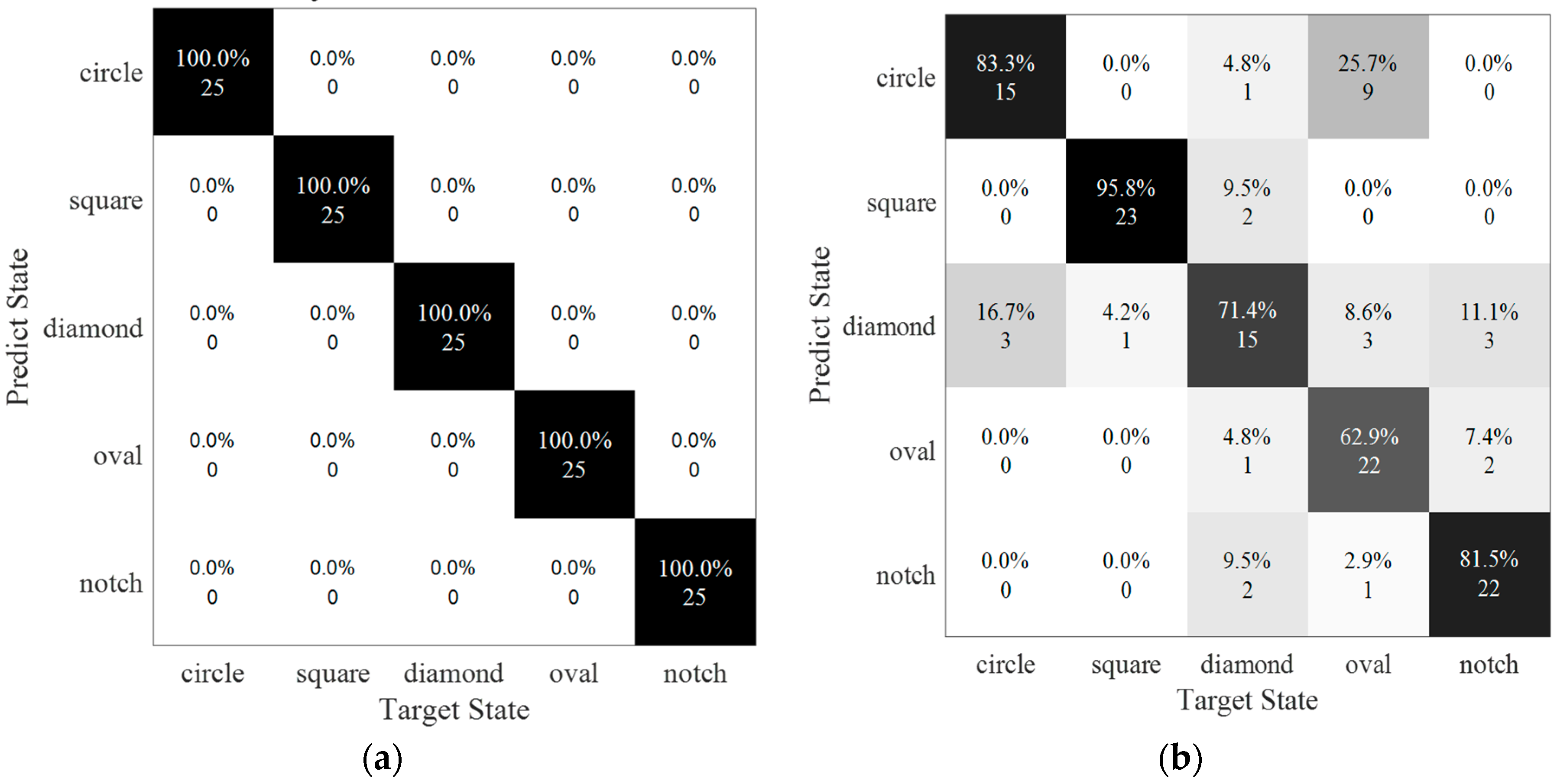

5.2. Effectiveness and Sensitivity of the Feature Extraction Methods to Data Classification

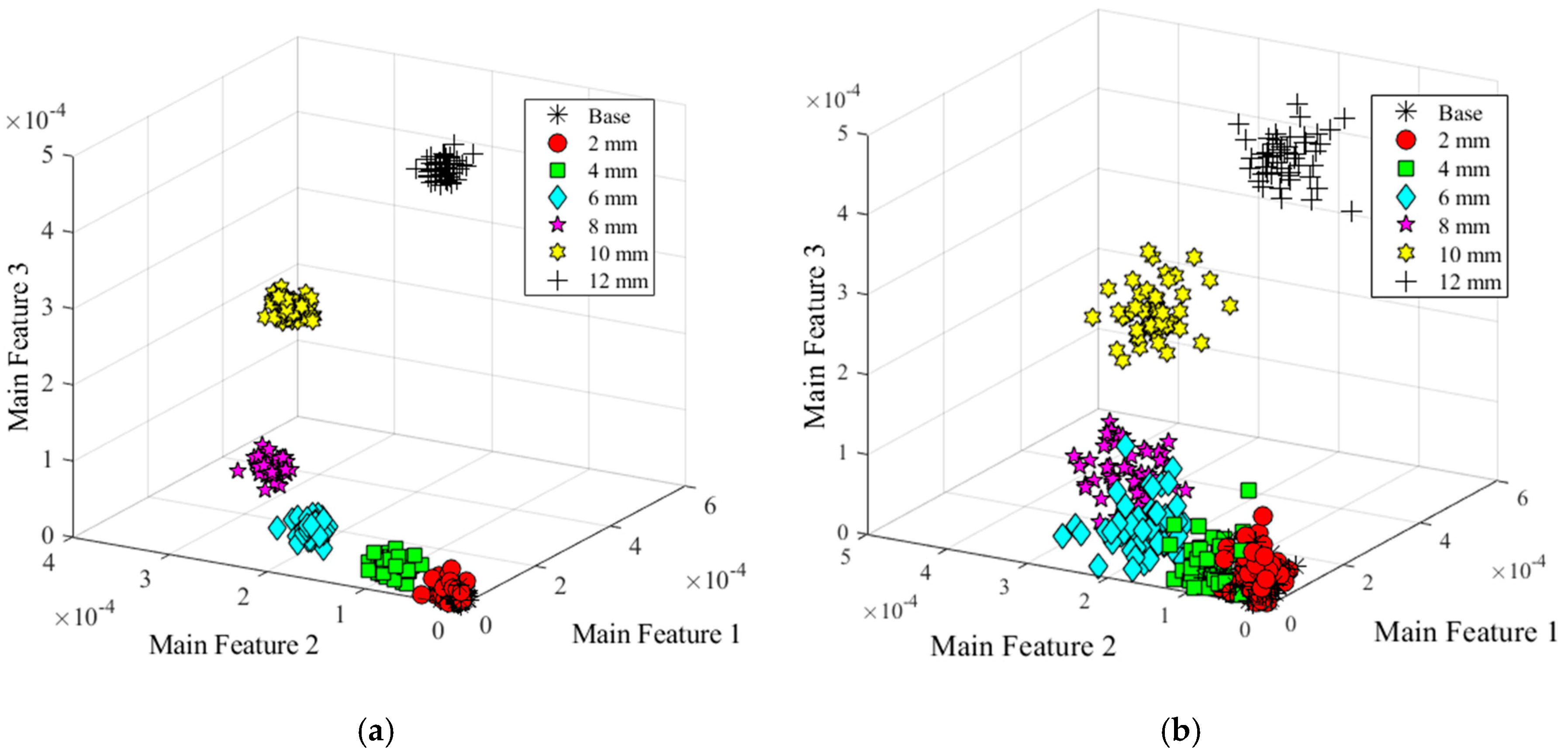

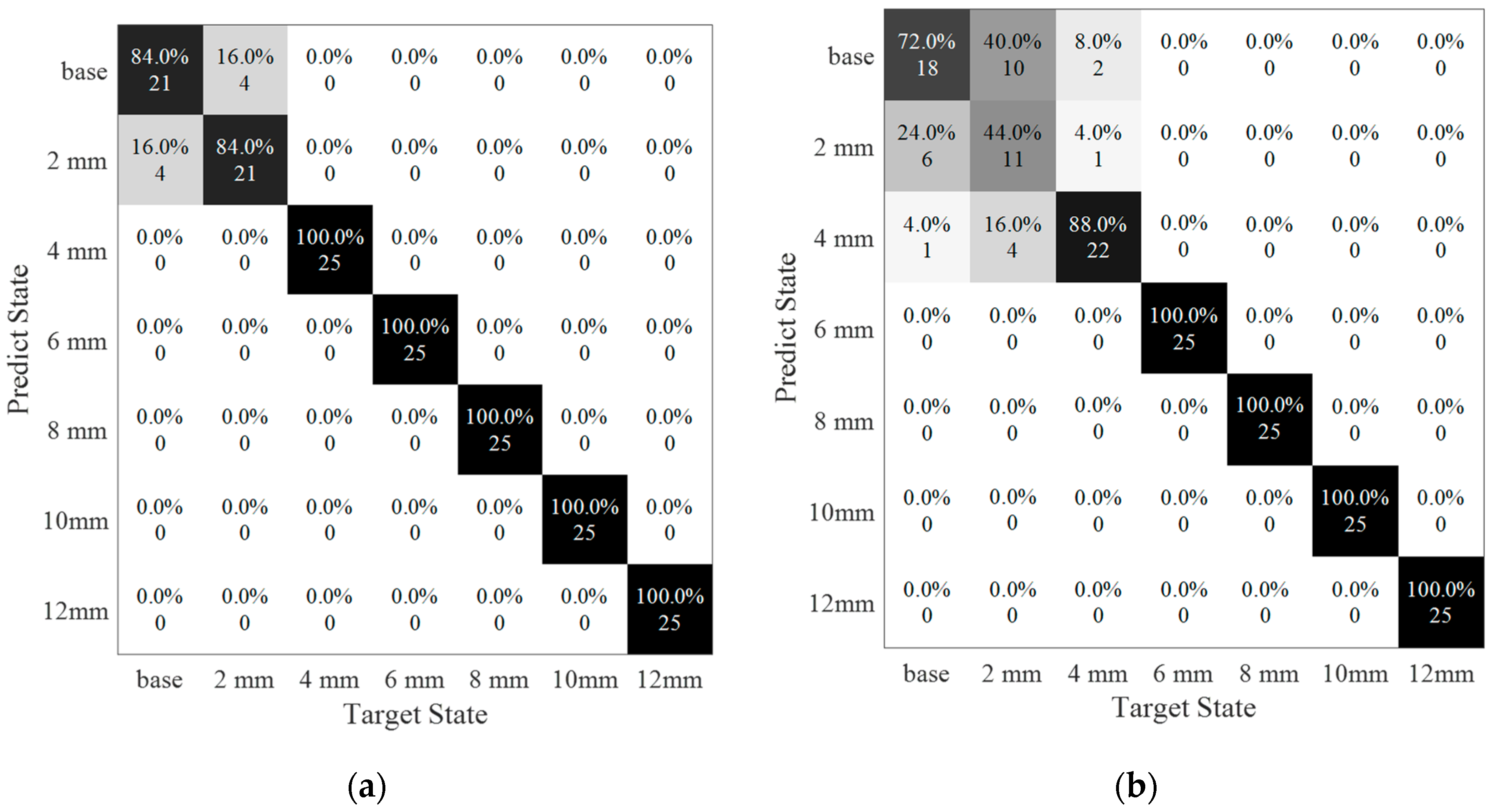

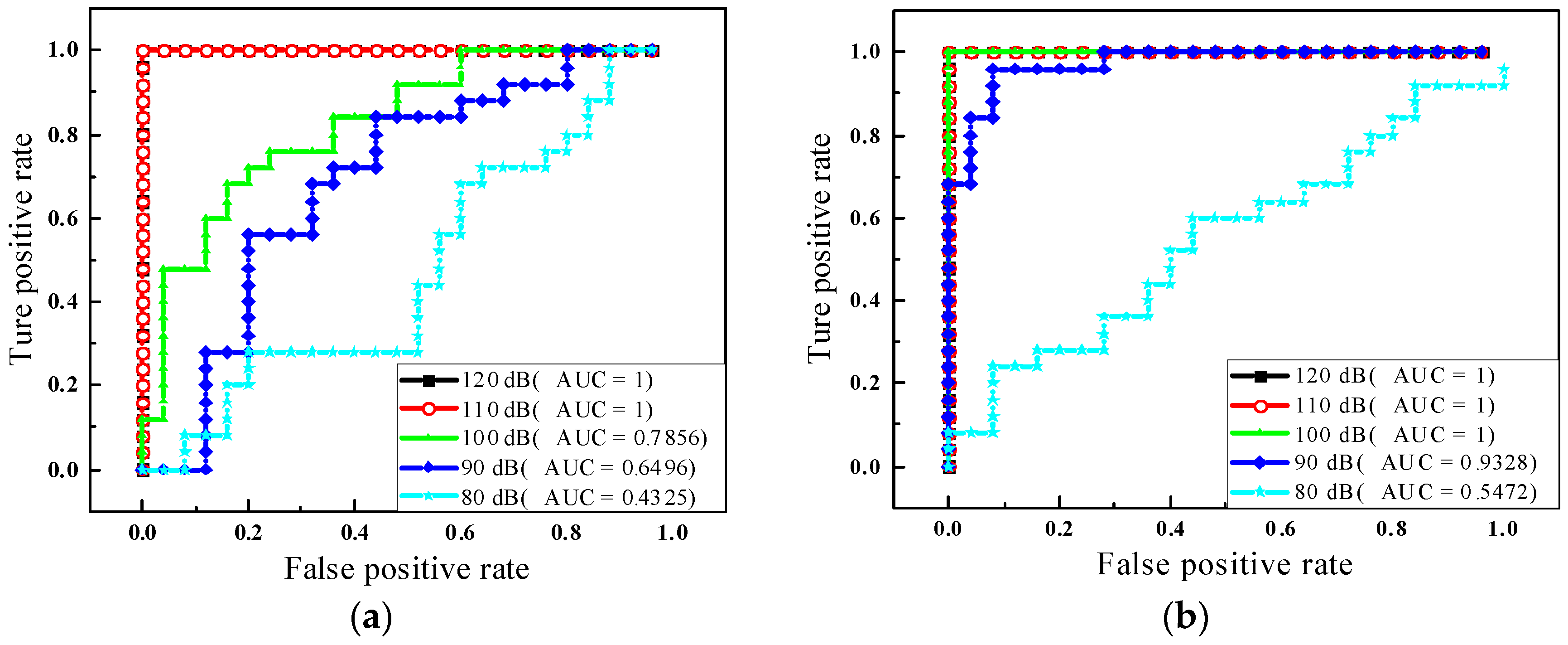

5.3. Effectiveness of the Damage Type and Size to the Robustness of the Feature Captured

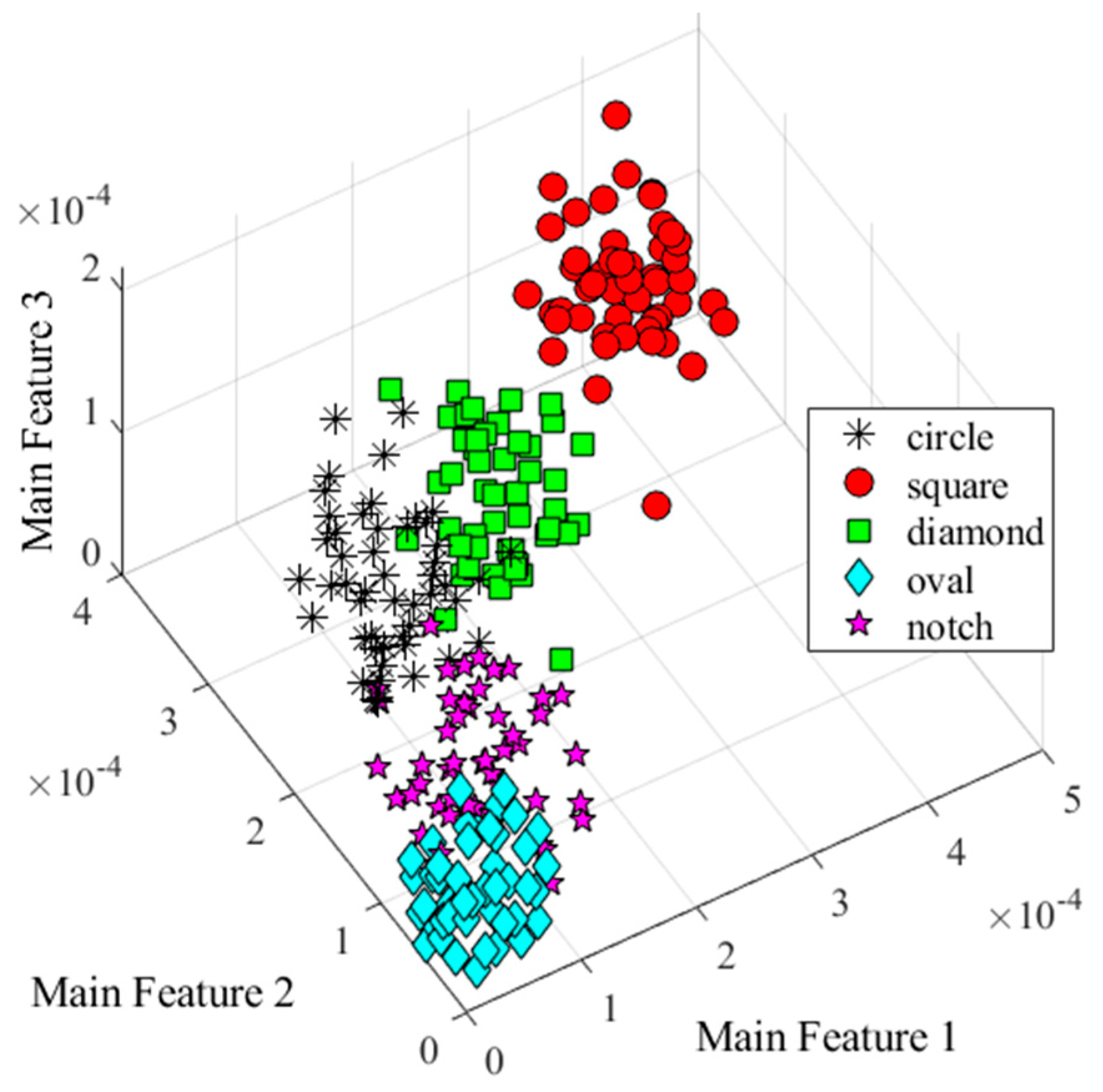

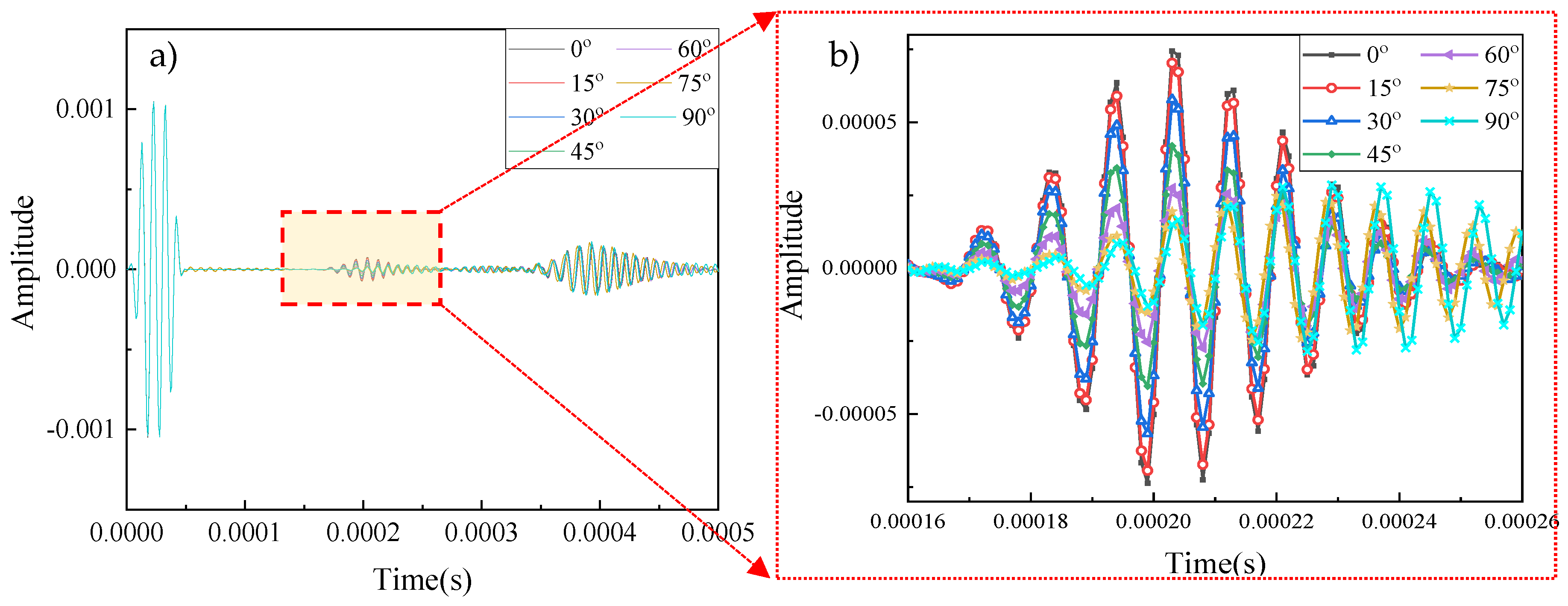

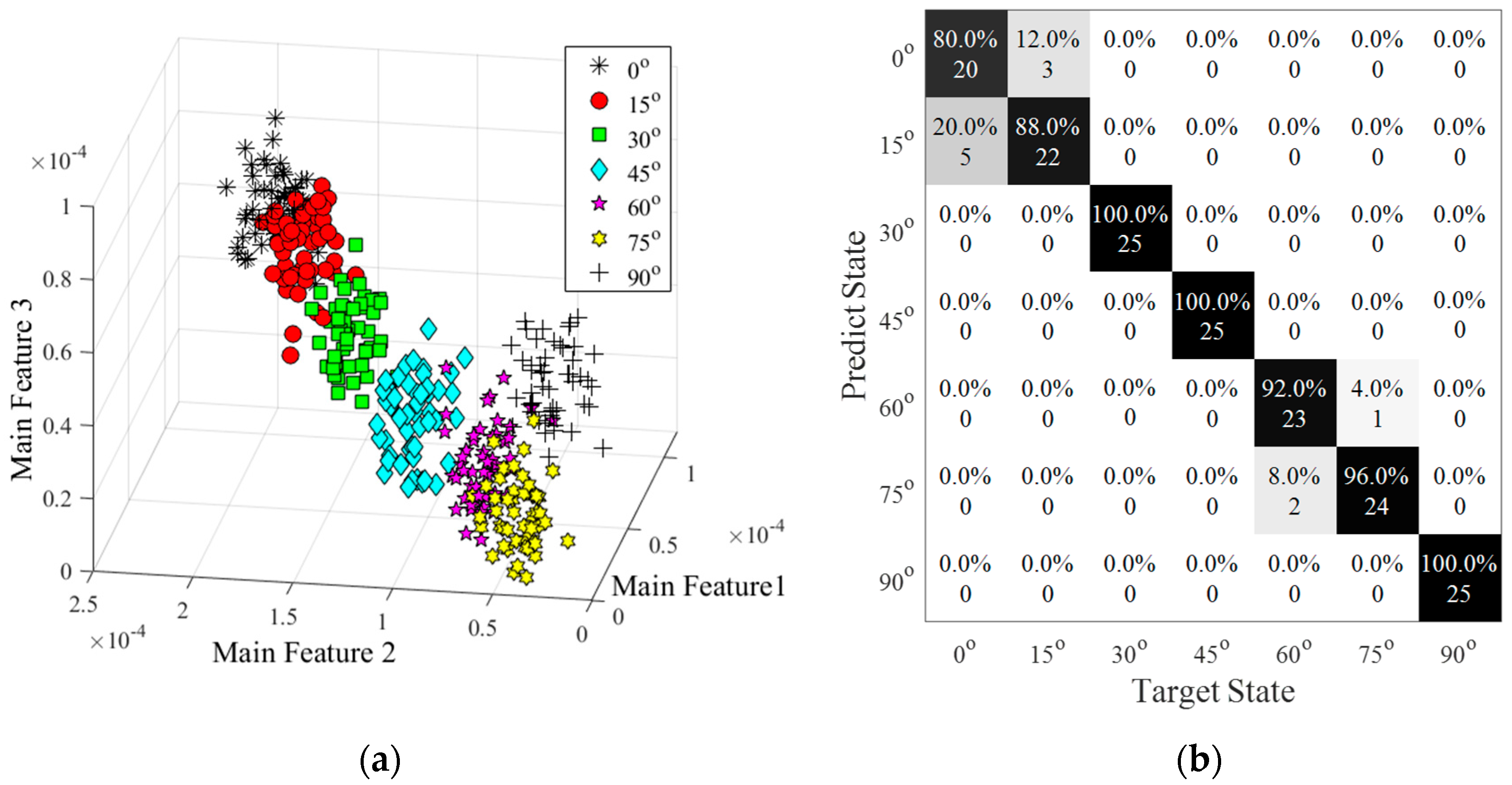

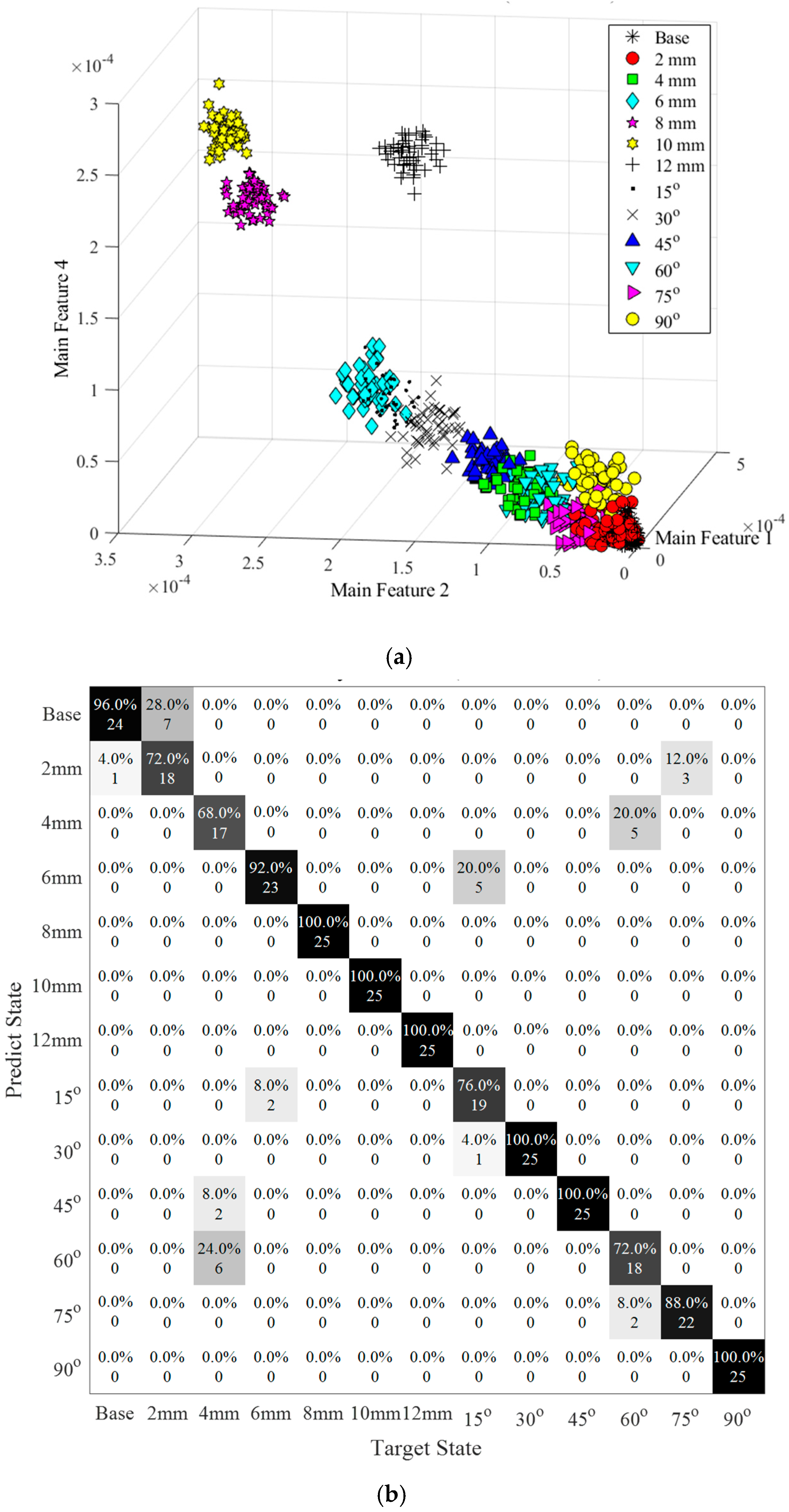

5.4. Effectiveness of Damage Orientation to the Robustness of the Feature Captured

6. Further Discussion of Structural Uncertainty Related to Engineering Applications

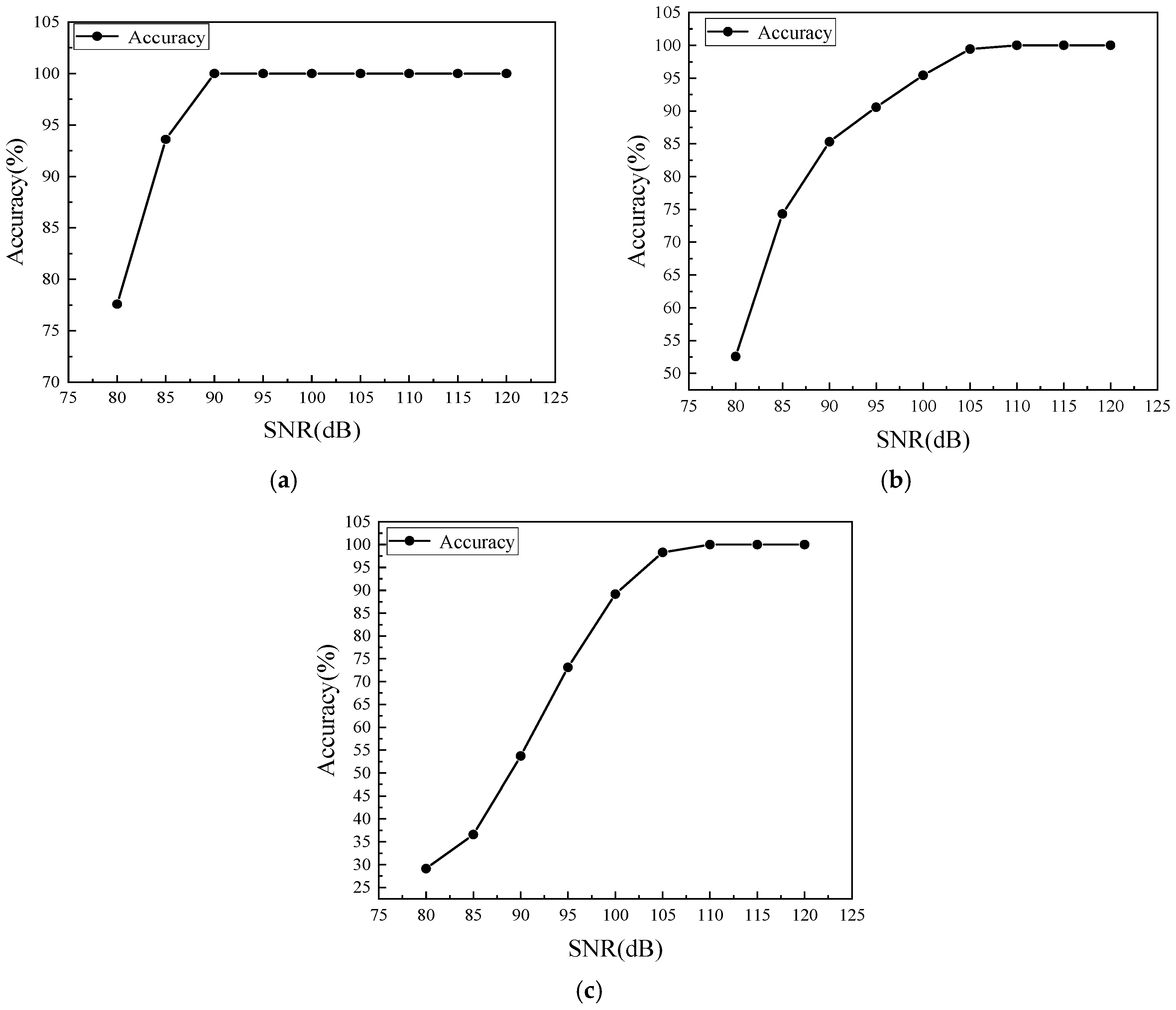

6.1. Impacts of Structural Uncertainty due to Noise Interferences to the Robustness of Data Classification

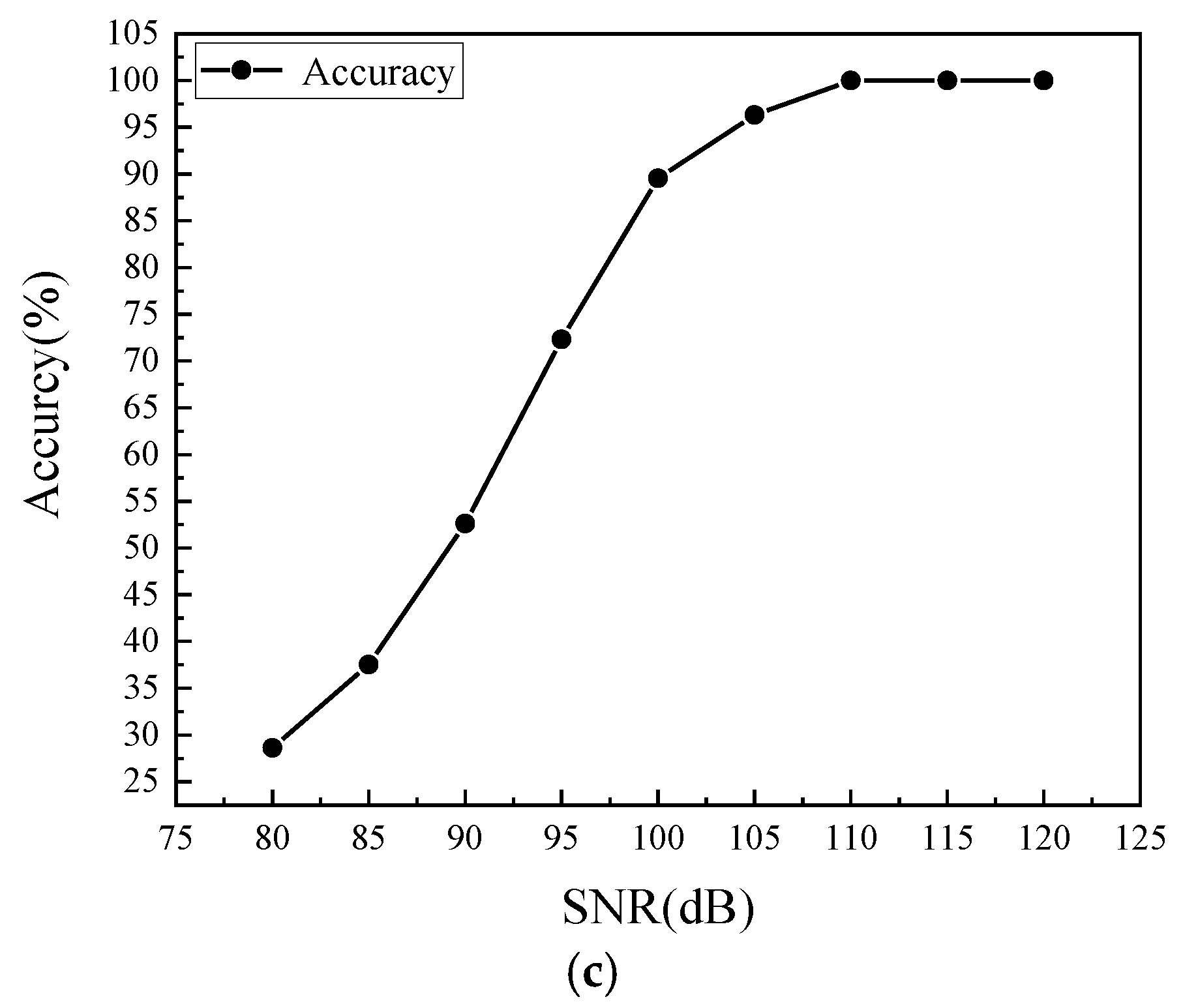

6.2. Impacts of Structural Uncertainty due to Mixed Data Types to the Robustness of Data Classification

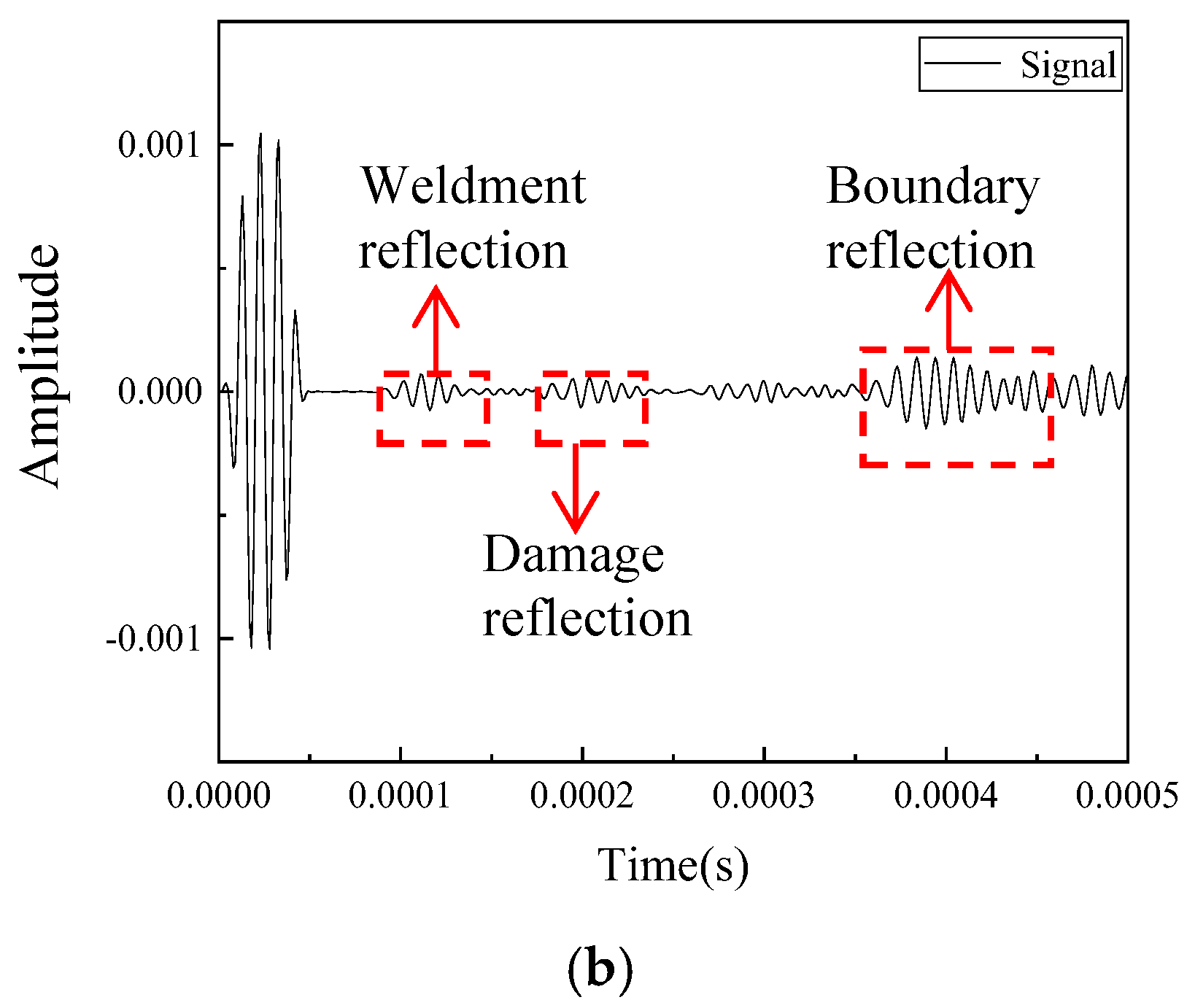

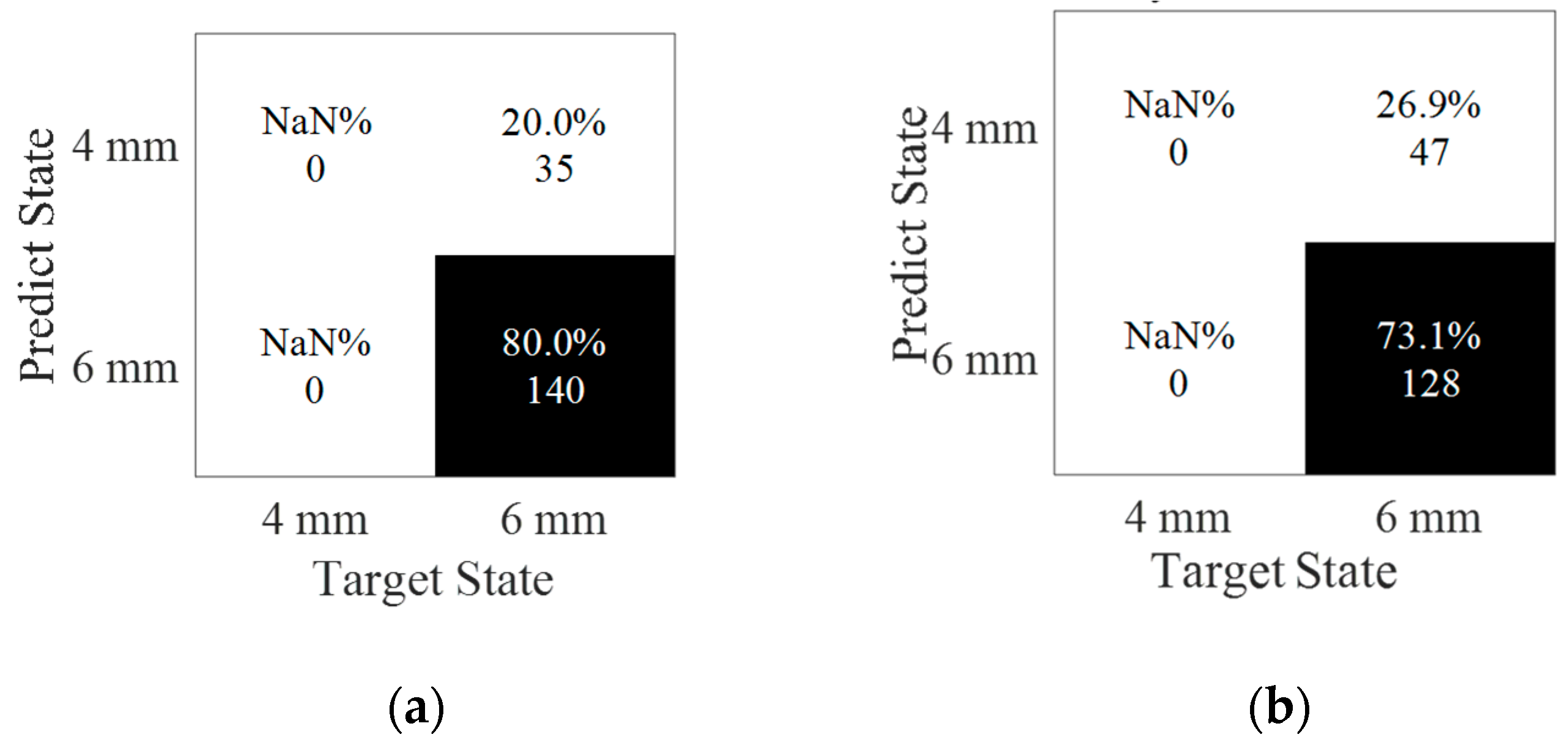

6.3. Impacts of Structural Uncertainty due to Material Discontinuity from Weldment to the Robustness of Data Classification

7. Conclusions

- (a)

- The learning framework provided a workflow from dataset generation, to sensitive feature extraction and to prediction model for lamb-wave-based damage detection. Note that although SVM learning algorithms were designed for learning model training, the deep learning could be deployed in future work.

- (b)

- Different features generated from different domains could provide various levels of sensitivity to damage. With the aid of feature selection, time-frequency features and wavelet coefficients, the highest damage-sensitivity was exhibited, as compared to the features in either the time domain or frequency domain. These features that contained the information in both time- and frequency-domains were also much more robust to noise.

- (c)

- The results in the case study demonstrated that the SVM method could effectively classify the damage type and damage size to certain noise levels, near 110 dB. With an increase of noise to 80 dB, the accuracy of the classification dramatically dropped to 57%.

- (d)

- The damage orientation could be classified using features of wavelet coefficients. The accuracy of the result was slightly lower than that of the damage size, mainly because the signals generated by the finite element method were from a one-dimensional propagation of the wave, and thus lacked the entire spatial information about the two-dimensional orientation. For further studies, two-dimensional wave propagation could be used for more accurate spatial information about the damage.

- (e)

- Noise interference, mixed data types, the level and material discontinuity from weldment were used to address the structural uncertainty and their impacts to the effectiveness of the proposed methods. The findings revealed that the proposed methods were still effective for data classification. Further research will be carried out, as noise is still a big challenge when its level reached up to a similar order as to where the signals were, while material discontinuity from weldment also posed a complex situation for classification.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Giurgiutiu, V. Structural Health Monitoring: With Piezoelectric Wafer Active Sensors; Elsevier: New York, NY, USA, 2007. [Google Scholar]

- Feng, D.; Feng, M.Q.; Monitoring, H. Vision-based multipoint displacement measurement for structural health monitoring. Struct. Control. Health Monit. 2016, 23, 876–890. [Google Scholar] [CrossRef]

- Pan, H.; Zhang, Z.; Wang, X.; Lin, Z. Image-Based Damage Conditional Assessment of Large-Scale Infrastructure Systems using Remote Sensing and Deep Learning Approaches. In Proceedings of the 2019 TechConnect World Innovation Conference, Boston, MA, USA, 17–19 June 2019. [Google Scholar]

- Doebling, S.W.; Farrar, C.R.; Prime, M.B. A summary review of vibration-based damage identification methods. Shock Vib. Dig. 1998, 30, 91–105. [Google Scholar] [CrossRef]

- Kong, X.; Cai, C.-S.; Hu, J. The state-of-the-art on framework of vibration-based structural damage identification for decision making. Appl. Sci. 2017, 7, 497. [Google Scholar] [CrossRef]

- Kong, X.; Cai, C.; Kong, B. Damage detection based on transmissibility of a vehicle and bridge coupled system. J. Eng. Mech. 2014, 141, 04014102. [Google Scholar]

- Mitra, M.; Gopalakrishnan, S. Guided wave based structural health monitoring: A review. Smart Mater. Struct. 2016, 25, 053001. [Google Scholar] [CrossRef]

- Ahmed, M.N. A Study of Guided Ultrasonic Wave Propagation Characteristics in Thin Aluminum Plate for Damage Detection; University of Toledo: Toledo, HO, USA, 2014. [Google Scholar]

- Saravanos, D.A.; Heyliger, P.R. Coupled layerwise analysis of composite beams with embedded piezoelectric sensors and actuators. J. Intell. Mater. Syst. Struct. 1995, 6, 350–363. [Google Scholar] [CrossRef]

- Seale, M.D.; Smith, B.T.; Prosser, W.H. Lamb wave assessment of fatigue and thermal damage in composites. J. Acoust. Soc. Am. 1998, 103, 2416–2424. [Google Scholar] [CrossRef]

- Hu, N.; Shimomukai, T.; Fukunaga, H.; Su, Z. Damage identification of metallic structures using A0 mode of Lamb waves. Struct. Health Monit. 2008, 7, 271–285. [Google Scholar]

- Xu, B.; Giurgiutiu, V. Single mode tuning effects on Lamb wave time reversal with piezoelectric wafer active sensors for structural health monitoring. J. Nondestruct. Eval. 2007, 26, 123–134. [Google Scholar] [CrossRef]

- Kong, X.; Cai, C.; Kong, B. Numerically extracting bridge modal properties from dynamic responses of moving vehicles. J. Eng. Mech. 2016, 142, 04016025. [Google Scholar] [CrossRef]

- Kong, X.; Cai, C.; Deng, L.; Zhang, W. Using dynamic responses of moving vehicles to extract bridge modal properties of a field bridge. J. Bridge Eng. 2017, 22, 04017018. [Google Scholar] [CrossRef]

- Nair, A.; Cai, C.; Kong, X. Acoustic emission pattern recognition in CFRP retrofitted RC beams for failure mode identification. Compos. Part B Eng. 2019, 161, 691–701. [Google Scholar] [CrossRef]

- Pan, H.; Gui, G.; Lin, Z.; Yan, C. Deep BBN learning for health assessment toward decision-making on structures under uncertainties. KSCE J. Civ. Eng. 2018, 22, 928–940. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Pan, H.; Lin, Z. Corrosion-Induced Damage Identification in Metallic Structures using Machine Learning Approaches. In Proceedings of the 2019 Defense TechConnect Innovation Summit, National Harbor, MD, USA, 7–10 October 2019. [Google Scholar]

- Zhang, Z.; Pan, H.; Lin, Z. Data-Driven Identification for Early-Age Corrosion-Induced Damage in Metallic Structures. In Proceedings of the Bridge Engineering Institute Conference 2019 (BEI-2019), Honolulu, HI, USA, 22–25 July 2019. [Google Scholar]

- Pan, H.; Ge, Y.; Lin, Z. AI-Enabled Disaster Assessment and Resilience for Interdependent Critical Civil Infrastructures. In Proceedings of the 2019 Defense TechConnect Innovation Summit, National Harbor, MD, USA, 7–10 October 2019. [Google Scholar]

- Wang, W.; Bao, Y.; Zhou, W.; Li, H. Sparse representation for Lamb-wave-based damage detection using a dictionary algorithm. Ultrasonics 2018, 87, 48–58. [Google Scholar] [CrossRef]

- Yang, J.; He, J.; Guan, X.; Wang, D.; Chen, H.; Zhang, W.; Liu, Y. A probabilistic crack size quantification method using in-situ Lamb wave test and Bayesian updating. Mech. Syst. Signal Process. 2016, 78, 118–133. [Google Scholar] [CrossRef]

- Legendre, S.; Massicotte, D.; Goyette, J.; Bose, T.K. Neural classification of Lamb wave ultrasonic weld testing signals using wavelet coefficients. IEEE Trans. Instrum. Meas. 2001, 50, 672–678. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L. Lamb wave-based quantitative identification of delamination in CF/EP composite structures using artificial neural algorithm. Compos. Struct. 2004, 66, 627–637. [Google Scholar] [CrossRef]

- Das, S.; Chattopadhyay, A.; Srivastava, A.N. Classifying induced damage in composite plates using one-class support vector machines. AIAA J. 2010, 48, 705–718. [Google Scholar] [CrossRef]

- Sun, F.; Wang, N.; He, J.; Guan, X.; Yang, J.J. Lamb wave damage quantification using GA-based LS-SVM. Materials 2017, 10, 648. [Google Scholar] [CrossRef]

- HosseinAbadi, H.Z.; Amirfattahi, R.; Nazari, B.; Mirdamadi, H.R.; Atashipour, S.A. GUW-based structural damage detection using WPT statistical features and multiclass SVM. Appl. Acoust. 2014, 86, 59–70. [Google Scholar] [CrossRef]

- Su, Z.; Ye, L. Identification of Damage Using Lamb Waves: From Fundamentals to Applications; Springer Science & Business Media: New York, NY, USA, 2009. [Google Scholar]

- Achenbach, J. Wave Propagation in Elastic Solids; Elsevier: New York, NY, USA, 2012. [Google Scholar]

- Yang, M.; Qiao, P. Modeling and experimental detection of damage in various materials using the pulse-echo method and piezoelectric sensors/actuators. Smart Mater. Struct. 2005, 14, 1083. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Bao, J.; Zhao, W. Piezoelectric wafer active sensor embedded ultrasonics in beams and plates. Experimental mechanics Exp. Mech. 2003, 43, 428–449. [Google Scholar] [CrossRef]

- Lin, Z.; Pan, H.; Wang, X.; Li, M. Data-driven structural diagnosis and conditional assessment: From shallow to deep learning. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2018; International Society for Optics and Photonics: Denver, CO, USA, 2018. [Google Scholar]

- Pan, H.; Lin, Z.; Gui, G. Enabling damage identification of structures using time series–based feature extraction algorithms. J. Aerosp. Eng. 2019, 32, 04019014. [Google Scholar] [CrossRef]

- Gui, G.; Pan, H.; Lin, Z.; Li, Y.; Yuan, Z. Data-driven support vector machine with optimization techniques for structural health monitoring and damage detection. KSCE J. Civ. Eng. 2017, 21, 523–534. [Google Scholar] [CrossRef]

- Kira, K.; Rendell, L.A. The Feature Selection Problem: Traditional Methods and a New Algorithm; Aaai: Cambridge, MA, USA, 1992. [Google Scholar]

- Kononenko, I.; Šimec, E.; Robnik-Šikonja, M. Overcoming the myopia of inductive learning algorithms with RELIEFF. Appl. Intell. 1997, 7, 39–55. [Google Scholar] [CrossRef]

- Stief, A.; Ottewill, J.R.; Baranowski, J. Relief F-based feature ranking and feature selection for monitoring induction motors. In 2018 23rd International Conference on Methods & Models in Automation & Robotics (MMAR); IEEE: Miedzyzdroje, Poland, 2018. [Google Scholar]

- Vapnik, V. The Nature of Statistical Learning Theory; Springer Science & Business Media: New York, NY, US, 2013. [Google Scholar]

- Dibike, Y.B.; Velickov, S.; Solomatine, D.; Abbott, M.B. Model induction with support vector machines: Introduction and applications. J. Comput. Civ. Eng. 2001, 15, 208–216. [Google Scholar] [CrossRef]

- Burges, C.J.C. A tutorial on support vector machines for pattern recognition. Data Min. Knowl. Discov. 1998, 2, 121–167. [Google Scholar] [CrossRef]

- Boswell, D.J.; Diego, E. Introduction to Support Vector Machines. Available online: http://www.work.caltech.edu/~boswell/IntroToSVM.pdf (accessed on 21 March 2020).

- Burbidge, R.; Buxton, B.J. An Introduction to Support Vector Machines for Data Mining. Available online: http://www.cs.ucl.ac.uk/staff/r.burbidge/pubs/yor12-svm-intro.html (accessed on 21 March 2020).

- Santos, A.; Figueiredo, E.; Silva, M.; Sales, C.; Costa, J.C.M.A. Machine learning algorithms for damage detection: Kernel-based approaches. J. Sound Vib. 2016, 363, 584–599. [Google Scholar] [CrossRef]

- Han, S.; Qubo, C.; Meng, H. Parameter selection in SVM with RBF kernel function. World Automation Congress 2012; IEEE: Puerto Vallarta, Mexico, 2012. [Google Scholar]

- Hsu, C.-W.; Chang, C.-C.; Lin, C.-J. A Practical Guide to Support Vector Classification. Available online: https://www.researchgate.net/profile/Chenghai_Yang/publication/272039161_Evaluating_unsupervised_and_supervised_image_classification_methods_for_mapping_cotton_root_rot/links/55f2c57408ae0960a3897985/Evaluating-unsupervised-and-supervised-image-classification-methods-for-mapping-cotton-root-rot.pdf (accessed on 21 March 2020).

- Pan, H.; Azimi, M.; Yan, F.; Lin, Z. Time-frequency-based data-driven structural diagnosis and damage detection for cable-stayed bridges. J. Bridge Eng. 2018, 23, 04018033. [Google Scholar] [CrossRef]

- Wang, Z. Deep learning-based intrusion detection with adversaries. IEEE Access 2018, 6, 38367–38384. [Google Scholar] [CrossRef]

- Shah, M.; Wang, D.; Rubadue, C.; Suster, D.; Beck, A. Deep learning assessment of tumor proliferation in breast cancer histological images. In 2017 IEEE International Conference on Bioinformatics and Biomedicine (BIBM); IEEE: Kansas City, MO, USA, 2017. [Google Scholar]

- Urbanowicz, R.J.; Meeker, M.; La Cava, W.; Olson, R.S.; Moore, J.H. Relief-based feature selection: Introduction and review. J. Biomed. Inform. 2018, 85, 189–203. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Upadhye, S.; Worster, A. Understanding receiver operating characteristic (ROC) curves. Can. J. Emerg. Med. 2006, 8, 19–20. [Google Scholar] [CrossRef] [PubMed]

| Case | Label | Damage Type | Damage Size | Damage Orientation | Noise Interference |

|---|---|---|---|---|---|

| Reference | State #1 | / | / | / | Noise levels of from 80 dB to 120 dB |

| Variance due to damage type | State #2 | Notch-shaped damage | 6-mm long | 90 degree | |

| State #3 | Circular-shaped damage | 6-mm diameter | / | ||

| State #4 | Square-shaped damage | 6-mm long | / | ||

| State #5 | Diamond-shaped damage | 6-mm long | / | ||

| State #6 | Oval-shaped damage | 6-mm long | / | ||

| Variance due to damage size | State #7 | Notch-shaped damage | 2-mm long | 90 degree | |

| State #8 | Notch-shaped damage | 4-mm long | 90 degree | ||

| State #2 | Notch-shaped damage | 6-mm long | 90 degree | ||

| State #9 | Notch-shaped damage | 8-mm long | 90 degree | ||

| State #10 | Notch-shaped damage | 10-mm long | 90 degree | ||

| State #11 | Notch-shaped damage | 12-mm long | 90 degree | ||

| Variance due to damage orientation | State #12 | Notch-shaped damage | 6-mm long | 0 degree | |

| State #13 | Notch-shaped damage | 6-mm long | 15 degree | ||

| State #14 | Notch-shaped damage | 6-mm long | 30 degree | ||

| State #15 | Notch-shaped damage | 6-mm long | 45 degree | ||

| State #16 | Notch-shaped damage | 6-mm long | 60 degree | ||

| State #17 | Notch-shaped damage | 6-mm long | 75 degree | ||

| State #2 | Notch-shaped damage | 6-mm long | 90 degree |

| Noise Level | Feature Rank | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th | |

| 120 dB | W_5 | W_4 | Frq | W_6 | RMS | W_2 | Amp | W_1 | W_3 | Cor |

| 110 dB | W_4 | Frq | RMS | W_5 | W_2 | Amp | W_1 | W_6 | W_3 | Cor |

| 100 dB | W_4 | RMS | Frq | W_5 | W_2 | W_1 | Amp | W_3 | W_6 | Cor |

| 90 dB | W_4 | W_1 | RMS | Frq | W_2 | W_5 | W_3 | Amp | W_6 | Cor |

| 80 dB | W_4 | W_1 | Frq | W_3 | RMS | W_2 | W_5 | Cor | Amp | W_6 |

| Method | Classification by Physics-Based | Classification by SVM | |||||

|---|---|---|---|---|---|---|---|

| Features | Amp | Frq | RMS | No feature selection | Feature selection | ||

| Physics based Features | All Features | Selected features (wavelet coefficients) | |||||

| Noise level | 120 dB | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% | 100.00% |

| 110 dB | 97.71% | 100.00% | 98.86% | 98.86% | 98.86% | 100.00% | |

| 100 dB | 81.14% | 86.29% | 84.00% | 92.00% | 84.00% | 95.43% | |

| 90 dB | 44.00% | 64.00% | 72.00% | 80.00% | 72.00% | 86.29% | |

| 80 dB | 19.43% | 34.86% | 39.43% | 53.71% | 39.43% | 56.00% | |

| Noise Level | 120 dB | 110 dB | 100 dB | 90 dB | 80 dB |

|---|---|---|---|---|---|

| Without weldment | 100.00% | 100.00% | 100.00% | 100.00% | 56.4% |

| With weldment | 100.00% | 100.00% | 80.00% | 73.10% | 65.71% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Pan, H.; Wang, X.; Lin, Z. Machine Learning-Enriched Lamb Wave Approaches for Automated Damage Detection. Sensors 2020, 20, 1790. https://doi.org/10.3390/s20061790

Zhang Z, Pan H, Wang X, Lin Z. Machine Learning-Enriched Lamb Wave Approaches for Automated Damage Detection. Sensors. 2020; 20(6):1790. https://doi.org/10.3390/s20061790

Chicago/Turabian StyleZhang, Zi, Hong Pan, Xingyu Wang, and Zhibin Lin. 2020. "Machine Learning-Enriched Lamb Wave Approaches for Automated Damage Detection" Sensors 20, no. 6: 1790. https://doi.org/10.3390/s20061790

APA StyleZhang, Z., Pan, H., Wang, X., & Lin, Z. (2020). Machine Learning-Enriched Lamb Wave Approaches for Automated Damage Detection. Sensors, 20(6), 1790. https://doi.org/10.3390/s20061790