Measuring Biomechanical Risk in Lifting Load Tasks Through Wearable System and Machine-Learning Approach

Abstract

1. Introduction

2. Materials and Methods

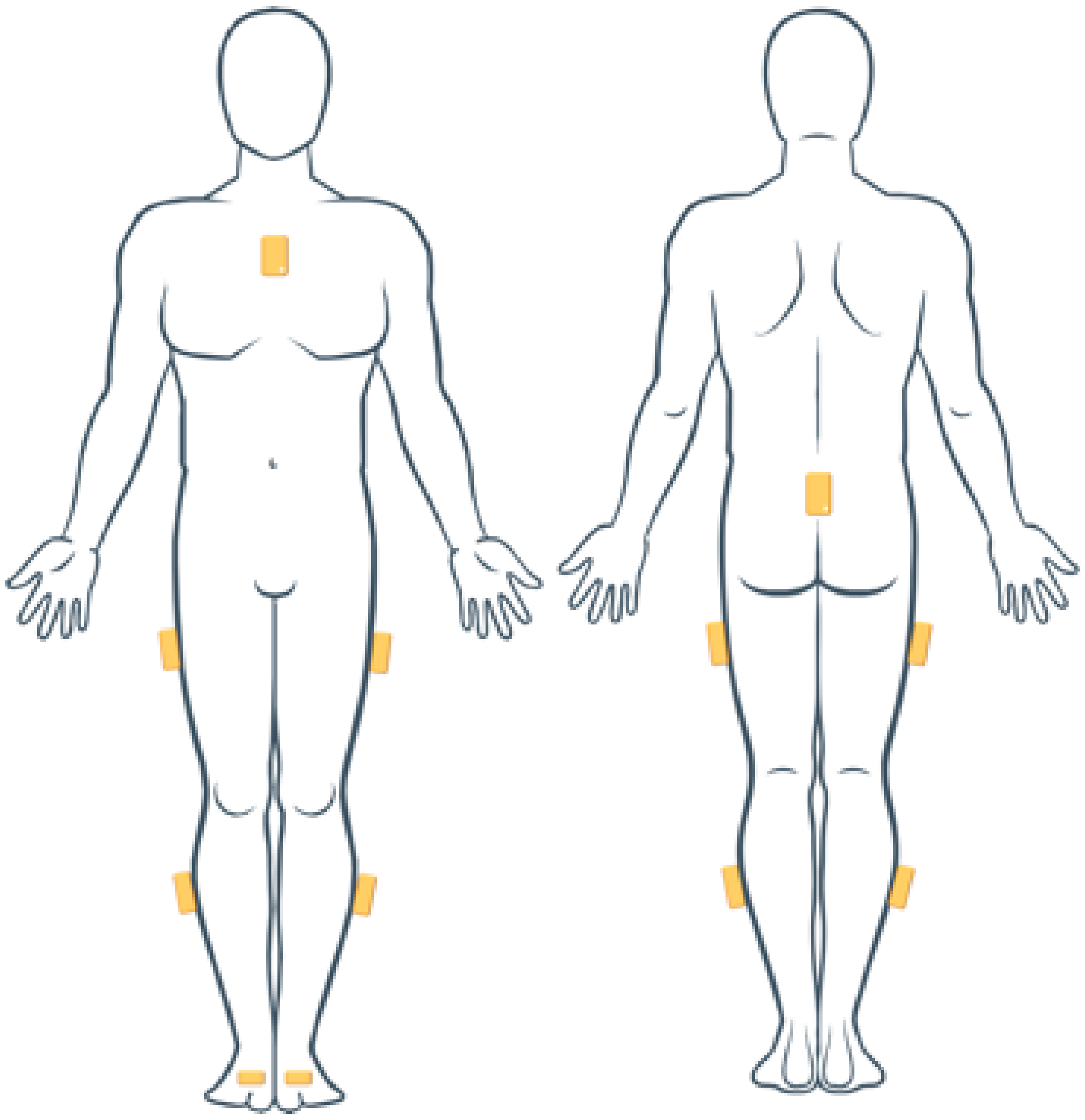

2.1. Experimental Setup

2.2. Experimental Procedure

2.3. Data Processing

2.4. Statistical Analysis

2.5. Machine Learning Classifier

- Accuracy (Acc)

- Specificity (True Negative Rate—TNR)

- Sensitivity/Recall (True Positive Rate—TPR)

- Precision (Positive Predictive Value—PPV)

3. Results

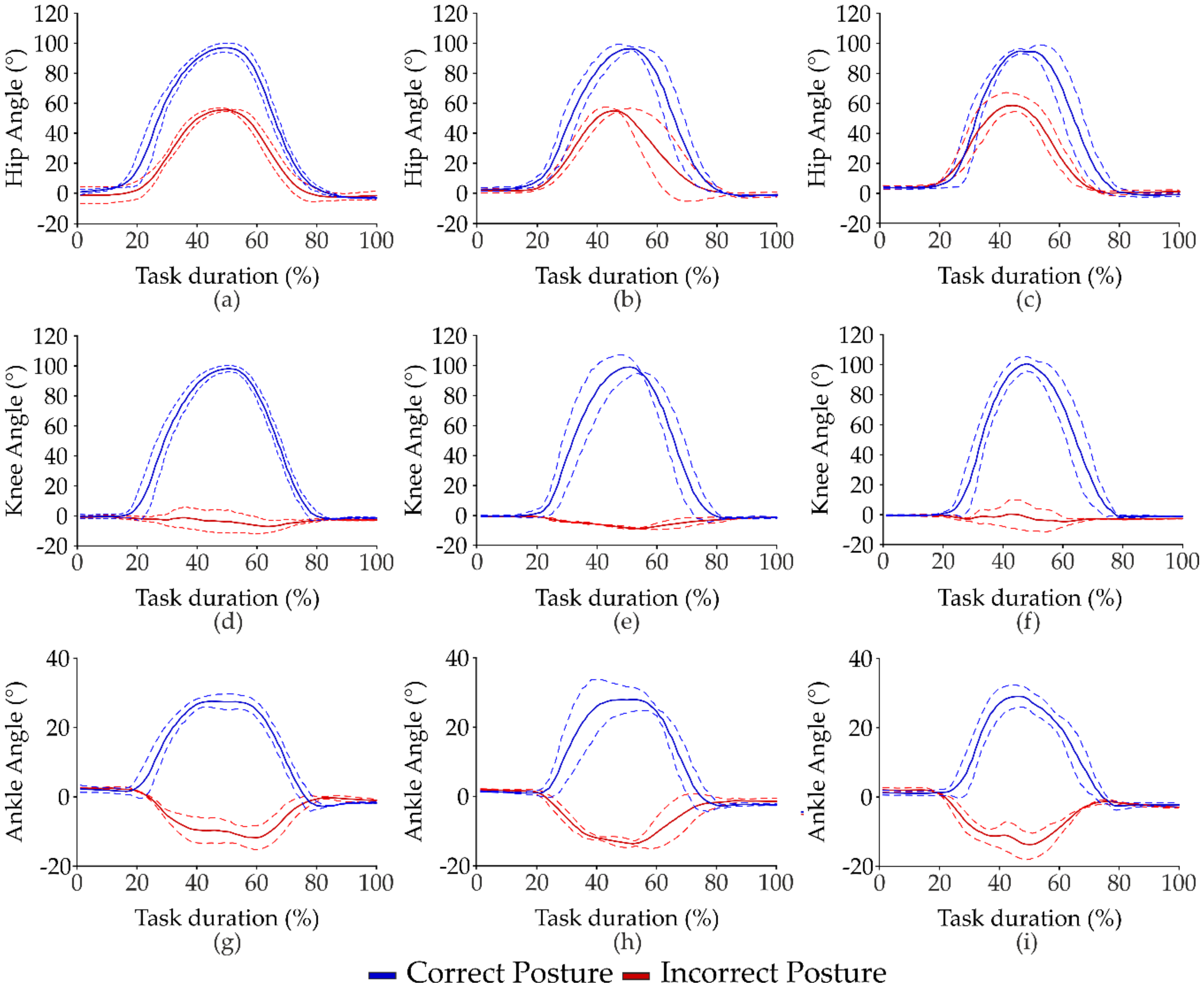

3.1. Results of the Statistical Analysis

3.2. Results of Machine Learning Classifier

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Antwi-Afari, M.F.; Li, H.; Edwards, D.J.; Pärn, E.A.; Seo, J.; Wong, A.Y.L. Biomechanical analysis of risk factors for work-related musculoskeletal disorders during repetitive lifting task in construction workers. Autom. Constr. 2017, 83, 41–47. [Google Scholar] [CrossRef]

- Valero, E.; Sivanathan, A.; Bosché, F.; Abdel-Wahab, M. Analysis of construction trade worker body motions using a wearable and wireless motion sensor network. Autom. Constr. 2017, 83, 48–55. [Google Scholar] [CrossRef]

- Ray, S.J.; Teizer, J. Real-time construction worker posture analysis for ergonomics training. Adv. Eng. Informatics 2012, 26, 439–455. [Google Scholar] [CrossRef]

- Yan, X.; Li, H.; Li, A.R.; Zhang, H. Wearable IMU-based real-time motion warning system for construction workers’ musculoskeletal disorders prevention. Autom. Constr. 2017, 74, 2–11. [Google Scholar] [CrossRef]

- Reid, C.R.; McCauley Bush, P.; Karwowski, W.; Durrani, S.K. Occupational postural activity and lower extremity discomfort: A review. Int. J. Ind. Ergon. 2010, 40, 247–256. [Google Scholar] [CrossRef]

- Pope, M.H.; Goh, K.L.; Magnusson, M.L. Spine Ergonomics. Annu. Rev. Biomed. Eng. 2002, 4, 49–68. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Qiu, J.; Ahn, C. Construction worker’s awkward posture recognition through supervised motion tensor decomposition. Autom. Constr. 2017, 77, 67–81. [Google Scholar] [CrossRef]

- Yan, X.; Li, H.; Wang, C.; Seo, J.O.; Zhang, H.; Wang, H. Development of ergonomic posture recognition technique based on 2D ordinary camera for construction hazard prevention through view-invariant features in 2D skeleton motion. Adv. Eng. Inform. 2017, 34, 152–163. [Google Scholar] [CrossRef]

- Nath, N.D.; Akhavian, R.; Behzadan, A.H. Ergonomic analysis of construction worker’s body postures using wearable mobile sensors. Appl. Ergon. 2017, 62, 107–117. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Ahn, C.R.; Han, S. Detecting the Hazards of Lifting and Carrying in Construction through a Coupled 3D Sensing and IMUs Sensing System. Comput. Civ. Build. Eng. 2014, 1110–1117. [Google Scholar] [CrossRef]

- Jebelli, H.; Ahn, C.R.; Stentz, T.L. Fall risk analysis of construction workers using inertial measurement units: Validating the usefulness of the postural stability metrics in construction. Saf. Sci. 2016, 84, 161–170. [Google Scholar] [CrossRef]

- Spielholz, P.; Davis, G.; Griffith, J. Physical risk factors and controls for musculoskeletal disorders in construction trades. J. Constr. Eng. Manag. 2006, 132, 1059–1068. [Google Scholar] [CrossRef]

- Wang, D.; Dai, F.; Ning, X. Risk assessment of work-related musculoskeletal disorders in construction: State-of-the-art review. J. Constr. Eng. Manag. 2015, 141, 1–15. [Google Scholar] [CrossRef]

- Umer, W.; Li, H.; Szeto, G.P.Y.; Wong, A.Y.L. Identification of Biomechanical Risk Factors for the Development of Lower-Back Disorders during Manual Rebar Tying. J. Constr. Eng. Manag. 2017, 143, 1–10. [Google Scholar] [CrossRef]

- Cho, Y.K.; Kim, K.; Ma, S.; Ueda, J. A robotic wearable exoskeleton for construction worker’s safety and health. In Proceedings of the ASCE Construction Research Congress 2018, New Orleans, LA, USA, 2–4 April 2018; pp. 19–28. [Google Scholar]

- CDC—NIOSH Publications and Products. Ergonomic Guidelines for Manual Material Handling (2007-131). Available online: https://www.cdc.gov/niosh/docs/2007-131/default.html (accessed on 7 March 2020).

- Marras, W.S.; Parakkat, J.; Chany, A.M.; Yang, G.; Burr, D.; Lavender, S.A. Spine loading as a function of lift frequency, exposure duration, and work experience. Clin. Biomech. 2006, 21, 345–352. [Google Scholar] [CrossRef]

- Ning, X.; Zhou, J.; Dai, B.; Jaridi, M. The assessment of material handling strategies in dealing with sudden loading: The effects of load handling position on trunk biomechanics. Appl. Ergon. 2014, 45, 1399–1405. [Google Scholar] [CrossRef]

- Kingma, I.; Baten, C.T.M.; Dolan, P.; Toussaint, H.M.; Van Dieën, J.H.; De Looze, M.P.; Adams, M.A. Lumbar loading during lifting: A comparative study of three measurement techniques. J. Electromyogr. Kinesiol. 2001, 11, 337–345. [Google Scholar] [CrossRef]

- Leskinen, T.P.J.; Stålhammar, H.R.; Kuorinka, I.A.A.; Troup, J.D.G. A dynamic analysis of spinal compression with different lifting techniques. Ergonomics 1983, 26, 595–604. [Google Scholar] [CrossRef]

- Hoozemans, M.J.M.; Kingma, I.; de Vries, W.; van Dieën, J. Effect of lifting height and load mass on low back loading. Ergonomics 2008, 51, 1053–1063. [Google Scholar] [CrossRef]

- Harari, Y.; Riemer, R.; Bechar, A. Differences in spinal moments, kinematics and pace during single-task and combined manual material handling jobs. Appl. Ergon. 2019, 81, 102871. [Google Scholar] [CrossRef]

- Application Manual for the Revised NIOSH Lifting Equation. Available online: https://www.cdc.gov/niosh/docs/94-110/pdfs/94-110.pdf?id=10.26616/NIOSHPUB94110 (accessed on 7 March 2020).

- NIOSH. Observation-based posture assessment: Review of current practice and recommendations for improvement. Anim. Genet. 2014, 39, 1–30. [Google Scholar]

- Straker, L. Evidence to support using squat, semi-squat and stoop techniques to lift low-lying objects. Int. J. Ind. Ergon. 2003, 31, 149–160. [Google Scholar] [CrossRef]

- Van Dieen, J.H.; Van Hoozemans, M.J.M.; Van Toussaint, H.M. A Review of Biomechanical Studies on Stoop and Squat Lifting. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2000, 44, 643–646. [Google Scholar] [CrossRef]

- Bazrgari, B.; Shirazi-Adl, A.; Arjmand, N. Analysis of squat and stoop dynamic liftings: Muscle forces and internal spinal loads. Eur. Spine J. 2007, 16, 687–699. [Google Scholar] [CrossRef] [PubMed]

- McAtamney, L.; Nigel Corlett, E. RULA: A survey method for the investigation of work-related upper limb disorders. Appl. Ergon. 1993, 24, 91–99. [Google Scholar] [CrossRef]

- Hignett, S.; McAtamney, L. Rapid Entire Body Assessment (REBA). Appl. Ergon. 2000, 31, 201–205. [Google Scholar] [CrossRef]

- Kee, D.; Karwowski, W. A Comparison of Three Observational Techniques for Assessing Postural Loads in Industry. Int. J. Occup. Saf. Ergon. 2007, 13, 3–14. [Google Scholar] [CrossRef]

- David, G.C. Ergonomic methods for assessing exposure to risk factors for work-related musculoskeletal disorders. Occup. Med. (Chic. Ill). 2005, 55, 190–199. [Google Scholar] [CrossRef]

- Buchholz, B.; Paquet, V.; Punnett, L.; Lee, D.; Moir, S. PATH: A work sampling-based approach to ergonomic job analysis for construction and other non-repetitive work. Appl. Ergon. 1996, 27, 177–187. [Google Scholar] [CrossRef]

- Hwang, S.; Kim, Y.; Kim, Y. Lower extremity joint kinetics and lumbar curvature during squat and stoop lifting. BMC Musculoskelet. Disord. 2009, 10, 1–10. [Google Scholar] [CrossRef]

- Schelldorfer, S.; Ernst, M.J.; Rast, F.M.; Bauer, C.M.; Meichtry, A.; Kool, J. Low back pain and postural control, effects of task difficulty on centre of pressure and spinal kinematics. Gait Posture 2015, 41, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Kollmitzer, J.; Oddsson, L.; Ebenbichler, G.R.; Giphart, J.E.; DeLuca, C.J. Postural control during lifting. J. Biomech. 2002, 35, 585–594. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Lockhart, T.E. Fall Risk Assessments Based on Postural and Dynamic Stability Using Inertial Measurement Unit. Saf. Health Work 2012, 3, 192–198. [Google Scholar] [CrossRef] [PubMed]

- Faber, G.S.; Chang, C.C.; Kingma, I.; Dennerlein, J.T.; van Dieën, J.H. Estimating 3D L5/S1 moments and ground reaction forces during trunk bending using a full-body ambulatory inertial motion capture system. J. Biomech. 2016, 49, 904–912. [Google Scholar] [CrossRef] [PubMed]

- Gholipour, A.; Arjmand, N. Artificial neural networks to predict 3D spinal posture in reaching and lifting activities; Applications in biomechanical models. J. Biomech. 2016, 49, 2946–2952. [Google Scholar] [CrossRef] [PubMed]

- Yan, X.; Li, H.; Zhang, H.; Rose, T.M. Personalized method for self-management of trunk postural ergonomic hazards in construction rebar ironwork. Adv. Eng. Inform. 2018, 37, 31–41. [Google Scholar] [CrossRef]

- Mileti, I.; Taborri, J.; Rossi, S.; Del Prete, Z.; Paoloni, M.; Suppa, A.; Palermo, E. Measuring age-related differences in kinematic postural strategies under yaw perturbation. In Proceedings of the MeMeA 2018—2018 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Rome, Italy, 11–13 June 2018; pp. 1–6. [Google Scholar]

- Erra, C.; Mileti, I.; Germanotta, M.; Petracca, M.; Imbimbo, I.; De Biase, A.; Rossi, S.; Ricciardi, D.; Pacilli, A.; Di Sipio, E.; et al. Immediate effects of rhythmic auditory stimulation on gait kinematics in Parkinson’s disease ON/OFF medication. Clin. Neurophysiol. 2019, 130, 1789–1797. [Google Scholar] [CrossRef]

- Taborri, J.; Palermo, E.; Rossi, S. Automatic detection of faults in race walking: A comparative analysis of machine-learning algorithms fed with inertial sensor data. Sensors (Switzerland) 2019, 19, 1461. [Google Scholar] [CrossRef]

- Conforti, I.; Mileti, I.; Del Prete, Z.; Palermo, E. Assessing ergonomics and biomechanical risk in manual handling of loads through a wearable system. In Proceedings of the 2019 IEEE International Workshop on Metrology for Industry 4.0 and IoT, MetroInd 4.0 and IoT 2019, Naples, Italy, 4–6 June 2019; pp. 388–393. [Google Scholar]

- Begg, R.; Kamruzzaman, J. A machine learning approach for automated recognition of movement patterns using basic, kinetic and kinematic gait data. J. Biomech. 2005, 38, 401–408. [Google Scholar] [CrossRef]

- Attal, F.; Mohammed, S.; Dedabrishvili, M.; Chamroukhi, F.; Oukhellou, L.; Amirat, Y. Physical human activity recognition using wearable sensors. Sensors (Switzerland) 2015, 15, 31314–31338. [Google Scholar] [CrossRef]

- Luštrek, M.; Kaluža, B. Fall detection and activity recognition with machine learning. Informatica 2009, 33, 205–212. [Google Scholar]

- Zhang, J.; Lockhart, T.E.; Soangra, R. Classifying lower extremity muscle fatigue during walking using machine learning and inertial sensors. Ann. Biomed. Eng. 2014, 42, 600–612. [Google Scholar] [CrossRef] [PubMed]

- Mileti, I.; Germanotta, M.; Di Sipio, E.; Imbimbo, I.; Pacilli, A.; Erra, C.; Petracca, M.; Rossi, S.; Del Prete, Z.; Bentivoglio, A.R.; et al. Measuring gait quality in Parkinson’s disease through real-time gait phase recognition. Sensors (Switzerland) 2018, 18, 919. [Google Scholar] [CrossRef] [PubMed]

- Suárez Sánchez, A.; Riesgo Fernández, P.; Sánchez Lasheras, F.; De Cos Juez, F.J.; García Nieto, P.J. Prediction of work-related accidents according to working conditions using support vector machines. Appl. Math. Comput. 2011, 218, 3539–3552. [Google Scholar] [CrossRef]

- Sun, Y.; Huang, R.; Zheng, J.; Dong, D.; Chen, X.; Bai, L.; Ge, W. Design and speed-adaptive control of a powered geared five-bar prosthetic knee using bp neural network gait recognition. Sensors (Switzerland) 2019, 19, 4662. [Google Scholar] [CrossRef]

- Antwi-Afari, M.F.; Li, H.; Seo, J.O.; Wong, A.Y.L. Automated Recognition of Construction Workers’ Activities for Productivity Measurement Using Wearable Insole Pressure System. In Proceedings of the 2019 CIB World Building Congress, Hong Kong, 17–21 June 2019; pp. 3084–3093. [Google Scholar]

- Alwasel, A.; Sabet, A.; Nahangi, M.; Haas, C.T.; Abdel-Rahman, E. Identifying poses of safe and productive masons using machine learning. Autom. Constr. 2017, 84, 345–355. [Google Scholar] [CrossRef]

- Ryu, J.; Seo, J.; Liu, M.; Lee, S.; Haas, C.T. Action Recognition Using a Wristband-Type Activity Tracker: Case Study of Masonry Work. In Proceedings of the Construction Research Congress 2016, San Juan, Puerto Rico, 31 May–2 June 2016; pp. 790–799. [Google Scholar]

- Escamilla, R.F. Squat Exercise. Med. Sci. Sports Exerc. 2001, 33, 127–141. [Google Scholar] [CrossRef]

- Kritz, M.; Cronin, J.; Hume, P.; Zealand, N.; Zealand, N.; Science, H. The Bodyweight Squat: A Movement Screen for the Squat Pattern. Natl. Strength Cond. Assoc. 2009, 31, 76–85. [Google Scholar] [CrossRef]

- Palermo, E.; Rossi, S.; Marini, F.; Patanè, F.; Cappa, P. Experimental evaluation of accuracy and repeatability of a novel body-to-sensor calibration procedure for inertial sensor-based gait analysis. Measurement 2014, 52, 145–155. [Google Scholar] [CrossRef]

- Pacilli, A.; Mileti, I.; Germanotta, M.; Di Sipio, E.; Imbimbo, I.; Aprile, I.; Padua, L.; Rossi, S.; Palermo, E.; Cappa, P. A wearable setup for auditory cued gait analysis in patients with Parkinson’s Disease. In Proceedings of the 2016 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Benevento, Italy, 15–18 May 2016; pp. 1–6. [Google Scholar]

| CLL Task | ILL Task | p-Value | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 kg | 2 kg | 5 kg | 1 kg | 2 kg | 5 kg | Posture | Weight | ||

| plPTtrk | AP (mm) | 222 ± 68 | 215 ± 74 | 215 ± 71 | 298 ± 59 | 288 ± 62 | 284 ± 76 | <0.01 * | 0.21 |

| ML (mm) | 41 ± 19 | 41 ± 21 | 46 ± 20 | 48 ± 24 | 51 ± 25 | 58 ± 30 | <0.01 * | <0.01 * | |

| V (mm) | 80 ± 50 | 76 ± 55 | 75 ± 49 | 151 ± 54 | 137 ± 54 | 140 ± 62 | <0.01 * | 0.27 | |

| RoM | Sacr (°) | 36.7 ± 12.4 | 35.7 ± 14.2 | 35.4 ± 13.1 | 52.5 ± 10.0 | 49.9 ± 11.1 | 49.6 ± 13.4 | <0.01 * | 0.17 |

| Hip (°) | 99.4 ± 10.7 | 102.1 ± 11.3 | 104.5 ± 13.2 | 75.3 ± 15.2 | 77.6 ± 15.6 | 80.0 ± 16.5 | <0.01 * | <0.01 * | |

| Knee (°) | 102.1 ± 16.8 | 104.4 ± 17.8 | 106.1 ± 17.4 | 29.6 ± 20.8 | 28.1 ± 19.7 | 30.5 ± 18.6 | <0.01 * | 0.08 | |

| Ankle (°) | 27.6 ± 7.9 | 27.8 ± 7.5 | 28.1 ± 7.4 | 12.8 ± 4.9 | 12.8 ± 5.2 | 12.8 ± 4.6 | <0.01 * | 0.80 | |

| CRL Task | IRL Task | p-Value | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 kg | 2 kg | 5 kg | 1 kg | 2 kg | 5 kg | Posture | Weight | ||

| plPTtrk | AP (mm) | 234 ± 73 | 231 ± 75 | 226 ± 75 | 304 ± 57 | 295 ± 61 | 287 ± 75 | <0.01 * | 0.14 |

| ML (mm) | 48 ± 21 | 47 ± 23 | 49 ± 20 | 52 ± 25 | 57 ± 26 | 61 ± 29 | <0.01 * | 0.11 | |

| V (mm) | 89 ± 60 | 86 ± 61 | 85 ± 53 | 162 ± 58 | 143 ± 57 | 146 ± 63 | <0.01 * | 0.26 | |

| RoM | Sacr (°) | 39.3 ± 14.2 | 38.5 ± 14.8 | 37.5 ± 14.1 | 55.0 ± 9.9 | 51.6 ± 11.3 | 50.6 ± 12.9 | <0.01 * | 0.09 |

| Hip (°) | 100.4 ± 11.5 | 103.4 ± 11.0 | 105.7 ± 11.5 | 75.0 ± 16.4 | 77.1 ± 16.6 | 78.0 ± 16.2 | <0.01 * | <0.01 * | |

| Knee (°) | 104.1 ± 17.1 | 106.8 ± 18.4 | 108.9 ± 17.9 | 28.2 ± 19.3 | 27.9 ± 19.5 | 27.4 ± 17.5 | <0.01 * | 0.27 | |

| Ankle (°) | 26.8 ± 7.7 | 26.8 ± 7.7 | 26.2 ± 7.2 | 12.4 ± 4.1 | 11.9 ± 5.1 | 12.0 ± 4.2 | <0.01 * | 0.44 | |

| LL Task | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 kg | 2 kg | 5 kg | |||||||||||

| SVM kernels | Acc | TNR | TPR | PPV | Acc | TNR | TPR | PPV | Acc | TNR | TPR | PPV | |

| T-Ll | Linear | 98.7 | 98.7 | 98.7 | 98.7 | 94.9 | 94.9 | 94.9 | 94.9 | 98.1 | 98.7 | 97.4 | 98.7 |

| Quadratic | 95.5 | 96.2 | 94.9 | 96.1 | 99.4 | 98.7 | 100 | 98.7 | 97.4 | 96.2 | 98.7 | 96.3 | |

| Cubic | 96.8 | 97.4 | 96.2 | 97.4 | 98.7 | 98.7 | 98.7 | 98.7 | 96.8 | 96.2 | 97.4 | 96.2 | |

| Gaussian | 98.1 | 98.7 | 97.4 | 98.7 | 99.4 | 100 | 98.7 | 100 | 97.4 | 96.2 | 98.7 | 96.3 | |

| UpB | Linear | 73.7 | 70.5 | 76.9 | 72.3 | 72.4 | 67.9 | 76.9 | 70.6 | 71.2 | 73.1 | 69.2 | 72.0 |

| Quadratic | 76.9 | 76.9 | 76.9 | 76.9 | 71.8 | 70.5 | 73.1 | 71.3 | 67.3 | 67.9 | 66.7 | 67.5 | |

| Cubic | 62.2 | 56.4 | 67.9 | 60.9 | 62.8 | 55.1 | 70.5 | 61.1 | 70.5 | 69.2 | 71.8 | 70.0 | |

| Gaussian | 69.2 | 66.7 | 71.8 | 68.3 | 73.1 | 70.5 | 75.6 | 72.0 | 69.2 | 69.2 | 69.2 | 69.2 | |

| RL Task | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 kg | 2 kg | 5 kg | |||||||||||

| SVM kernels | Acc | TNR | TPR | PPV | Acc | TNR | TPR | PPV | Acc | TNR | TPR | PPV | |

| T-Ll | Linear | 99.4 | 98.7 | 100 | 98.7 | 99.4 | 98.7 | 100 | 98.7 | 98.7 | 100 | 97.4 | 100 |

| Quadratic | 98.1 | 98.7 | 97.4 | 98.7 | 99.4 | 98.7 | 100 | 98.7 | 94.9 | 93.6 | 96.2 | 93.8 | |

| Cubic | 97.4 | 98.7 | 96.2 | 98.7 | 99.4 | 98.7 | 100 | 98.7 | 95.5 | 93.6 | 97.4 | 93.8 | |

| Gaussian | 98.1 | 97.4 | 98.7 | 97.5 | 98.7 | 97.4 | 100 | 97.5 | 98.1 | 98.7 | 97.4 | 98.7 | |

| UpB | Linear | 72.4 | 67.9 | 76.9 | 70.6 | 67.9 | 69.2 | 66.7 | 68.4 | 70.5 | 82.1 | 59.0 | 76.7 |

| Quadratic | 71.2 | 62.8 | 79.5 | 68.1 | 74.4 | 70.5 | 78.2 | 72.6 | 76.3 | 73.1 | 79.5 | 74.7 | |

| Cubic | 78.8 | 83.3 | 74.4 | 81.7 | 67.9 | 69.2 | 66.7 | 68.4 | 68.6 | 59.0 | 78.2 | 65.6 | |

| Gaussian | 83.3 | 78.2 | 88.5 | 80.2 | 76.9 | 80.8 | 73.1 | 79.2 | 71.2 | 65.4 | 76.9 | 69.0 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conforti, I.; Mileti, I.; Del Prete, Z.; Palermo, E. Measuring Biomechanical Risk in Lifting Load Tasks Through Wearable System and Machine-Learning Approach. Sensors 2020, 20, 1557. https://doi.org/10.3390/s20061557

Conforti I, Mileti I, Del Prete Z, Palermo E. Measuring Biomechanical Risk in Lifting Load Tasks Through Wearable System and Machine-Learning Approach. Sensors. 2020; 20(6):1557. https://doi.org/10.3390/s20061557

Chicago/Turabian StyleConforti, Ilaria, Ilaria Mileti, Zaccaria Del Prete, and Eduardo Palermo. 2020. "Measuring Biomechanical Risk in Lifting Load Tasks Through Wearable System and Machine-Learning Approach" Sensors 20, no. 6: 1557. https://doi.org/10.3390/s20061557

APA StyleConforti, I., Mileti, I., Del Prete, Z., & Palermo, E. (2020). Measuring Biomechanical Risk in Lifting Load Tasks Through Wearable System and Machine-Learning Approach. Sensors, 20(6), 1557. https://doi.org/10.3390/s20061557