A Systematic Approach to the Design and Characterization of a Smart Insole for Detecting Vertical Ground Reaction Force (vGRF) in Gait Analysis

Abstract

1. Introduction

2. Literature Review

3. Methodology

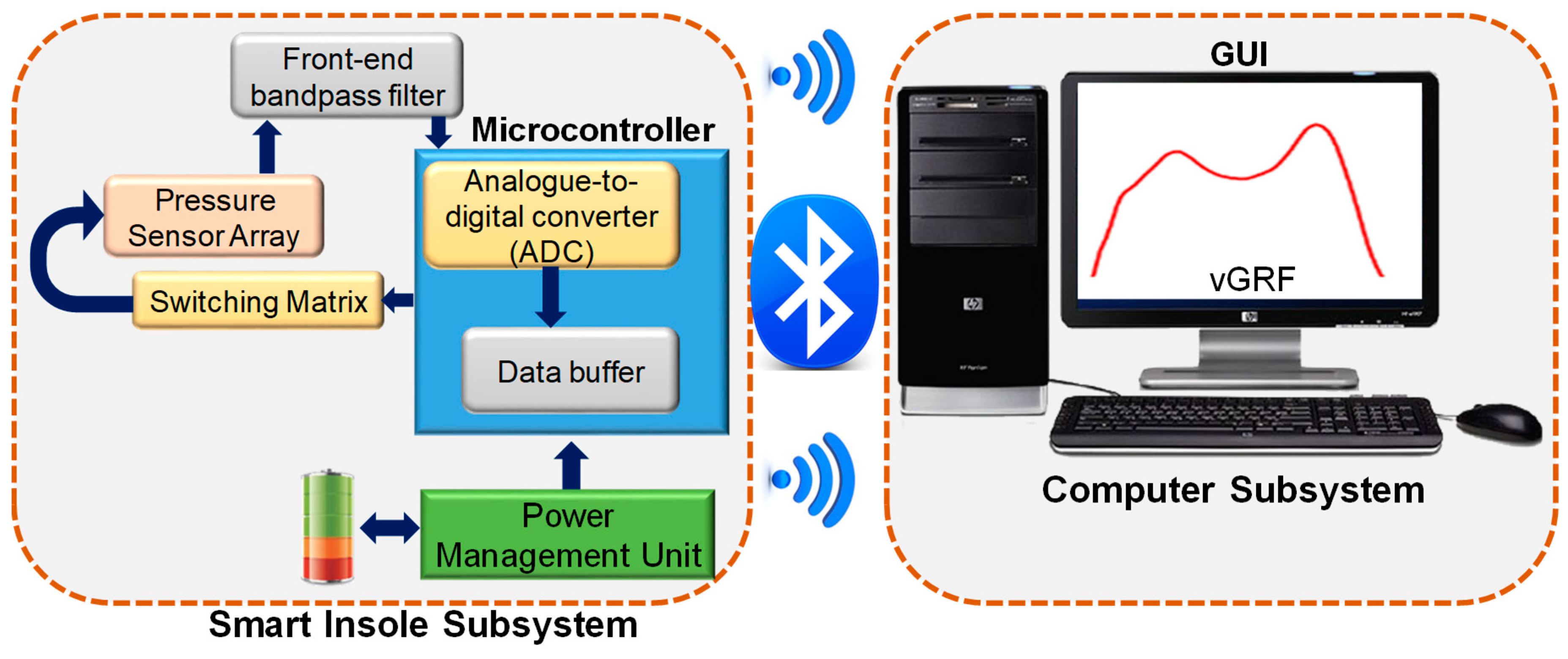

3.1. Smart Insole Sub-System

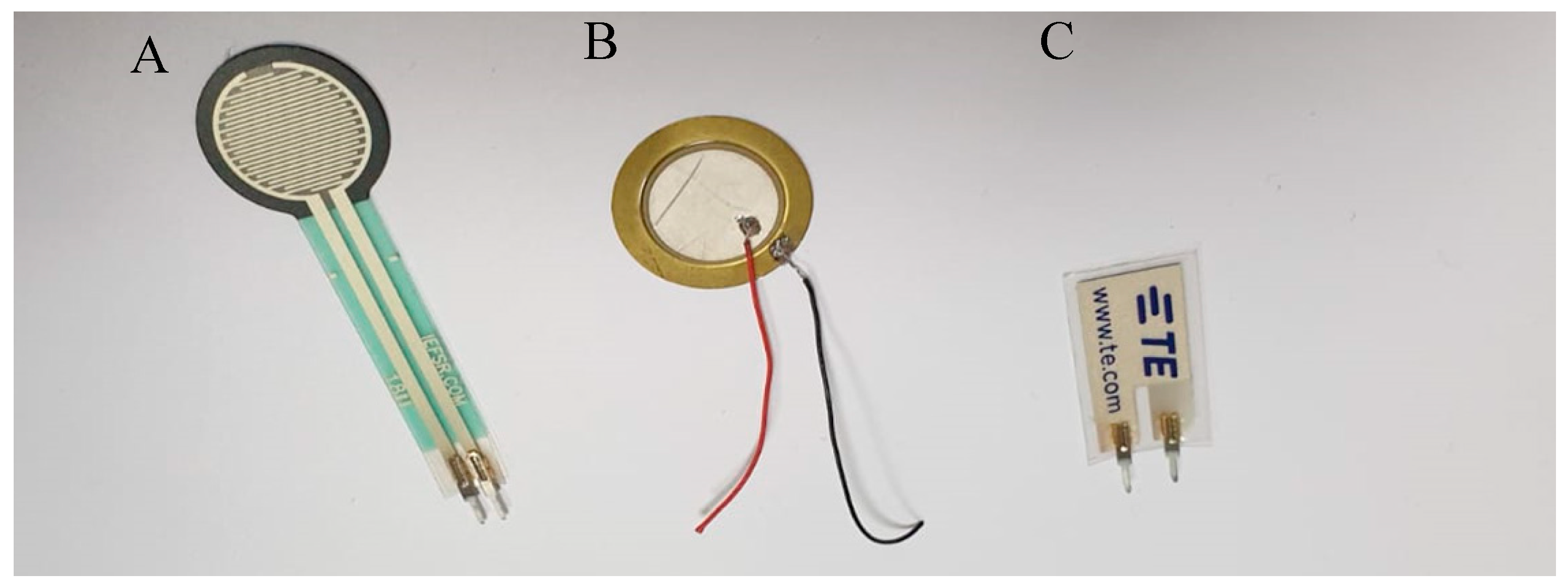

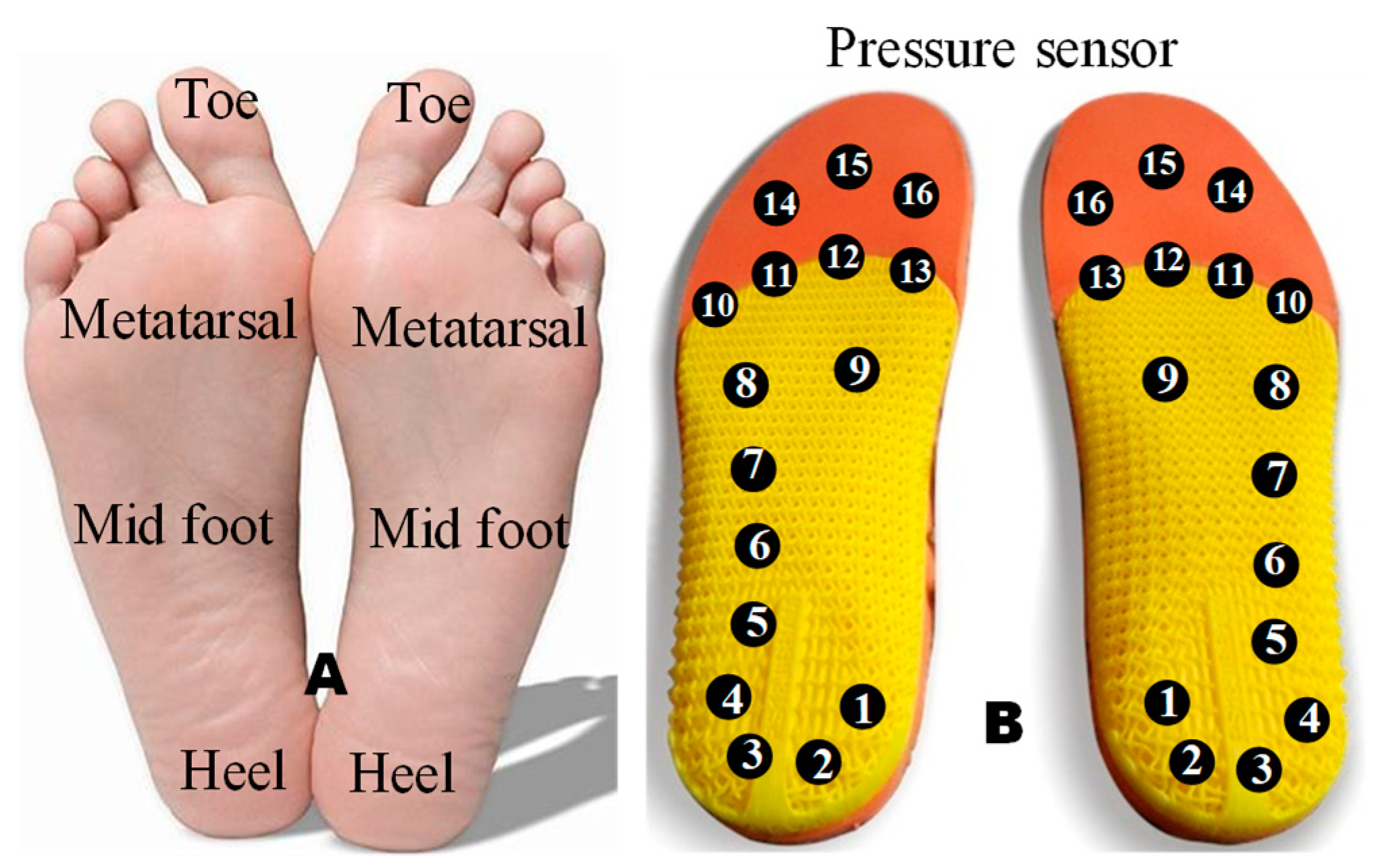

3.1.1. Pressure-Sensing Array

3.1.2. Data Acquisition System

3.1.3. Transmission Techniques

3.1.4. Power Management Unit (PMU)

3.1.5. Host Computer

3.2. Sensors’ Calibration

3.2.1. Force-Sensitive Resistor (FSR) Calibration

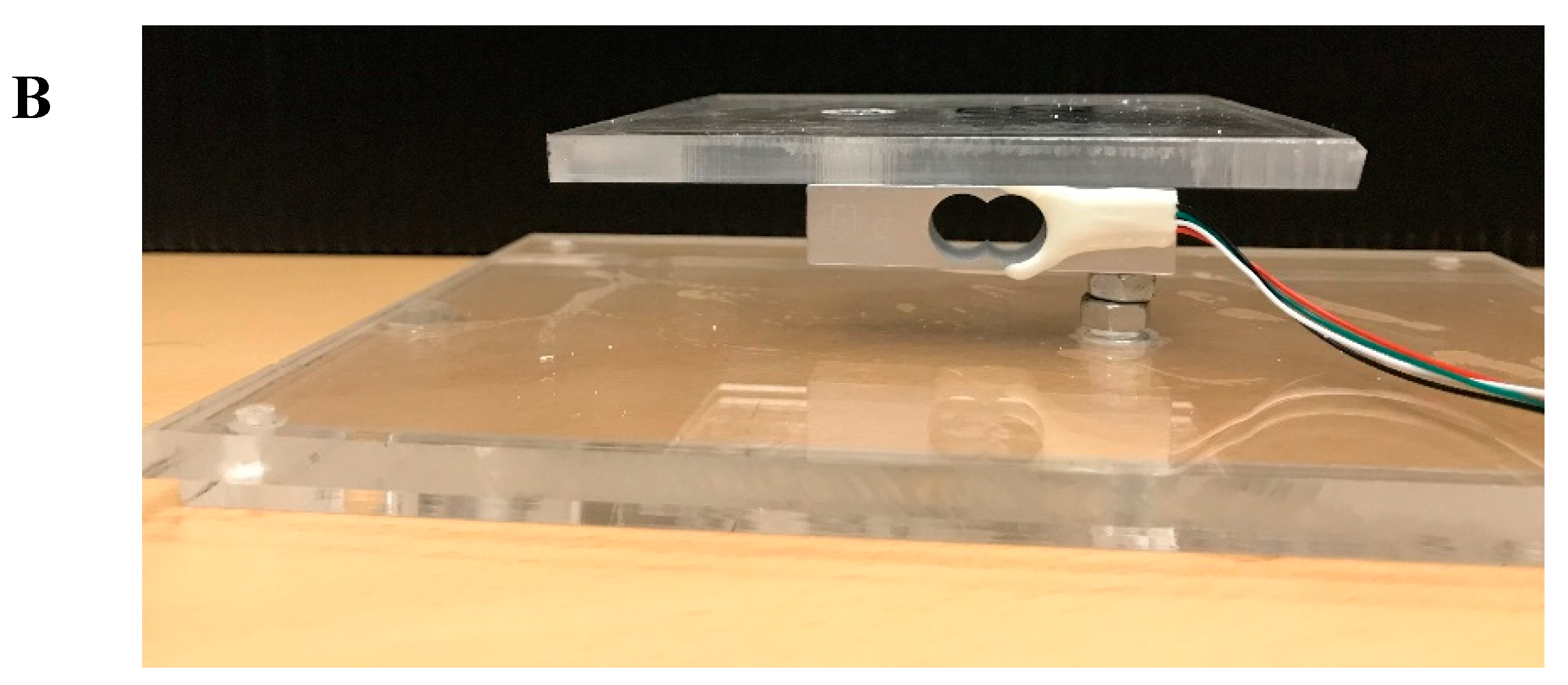

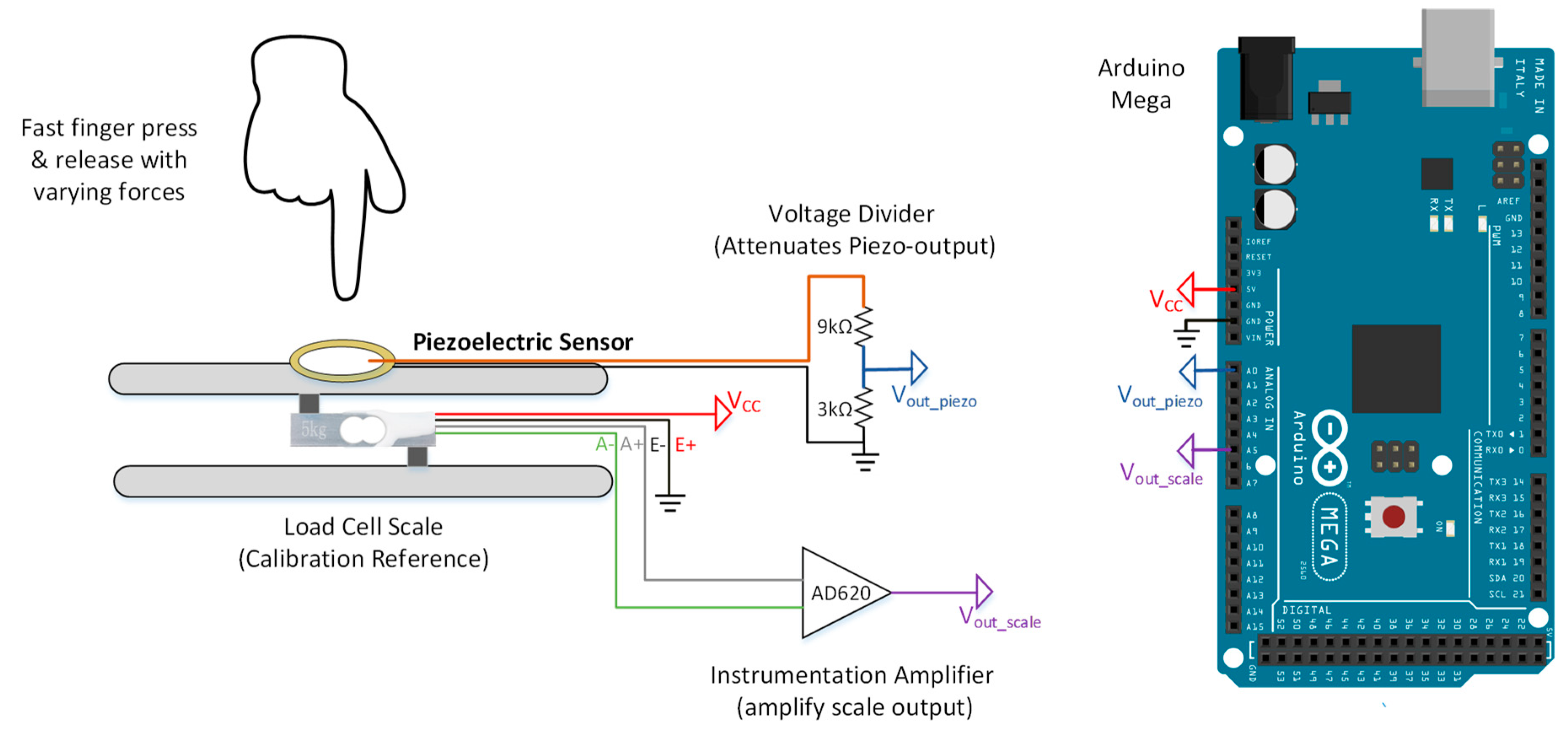

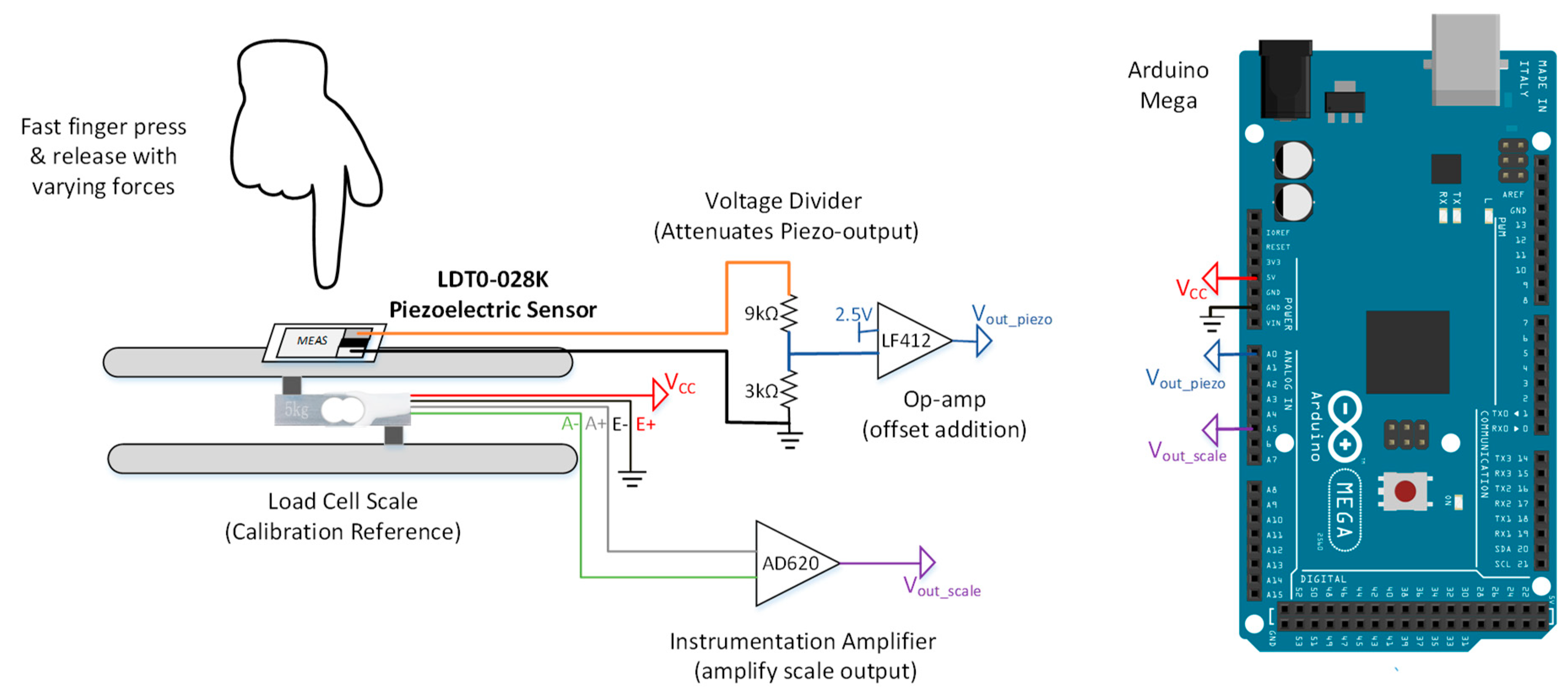

3.2.2. Piezo-Electric Sensor Calibration

3.2.3. Micro-Electromechanical Systems (MEMS) Sensor Calibration

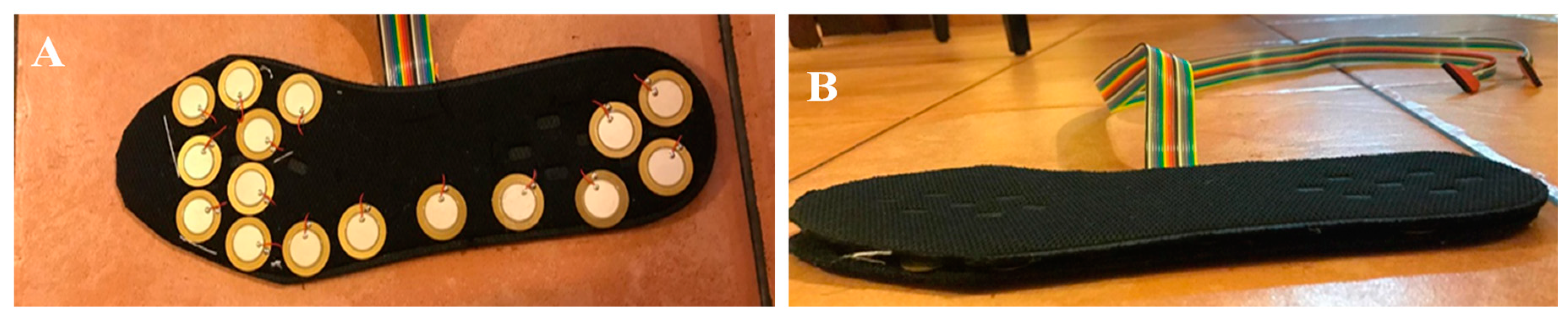

3.3. Insole Fabrication

3.3.1. FSR Insole Characterization

3.3.2. Piezo-Electric Insole Characterization

3.4. Performance Evaluation of the Prototype System

4. Analysis

4.1. Sensors’ Calibration

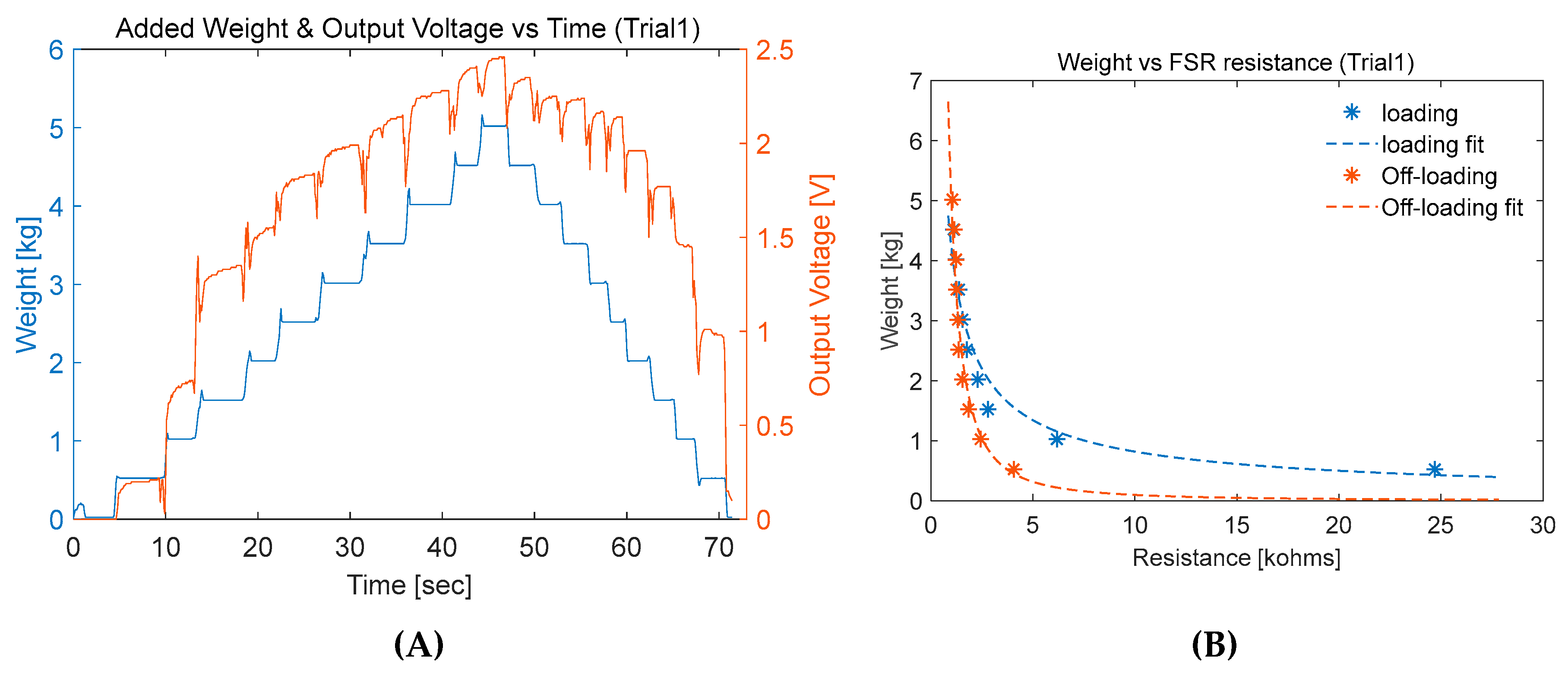

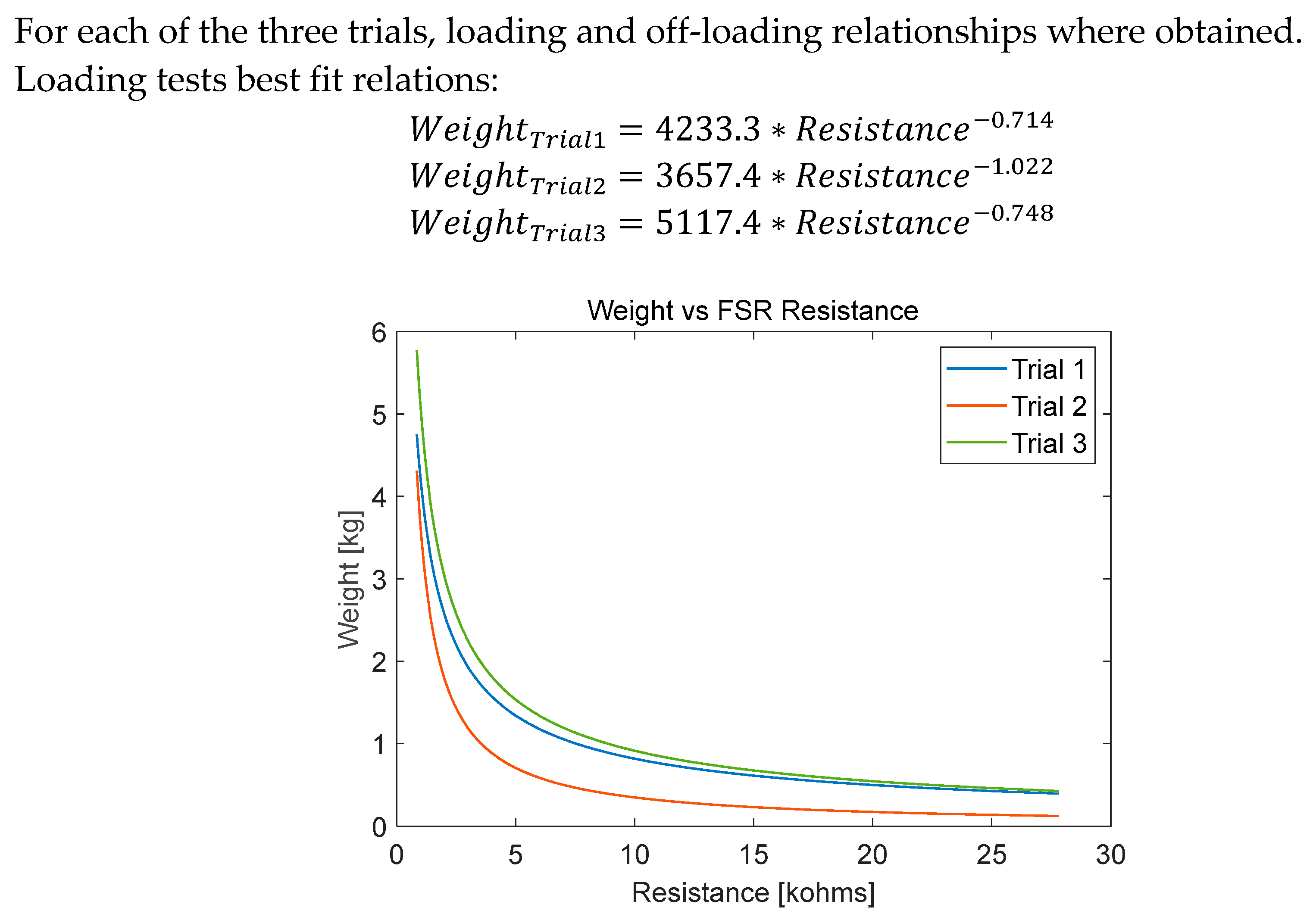

4.1.1. FSR Sensor Calibration

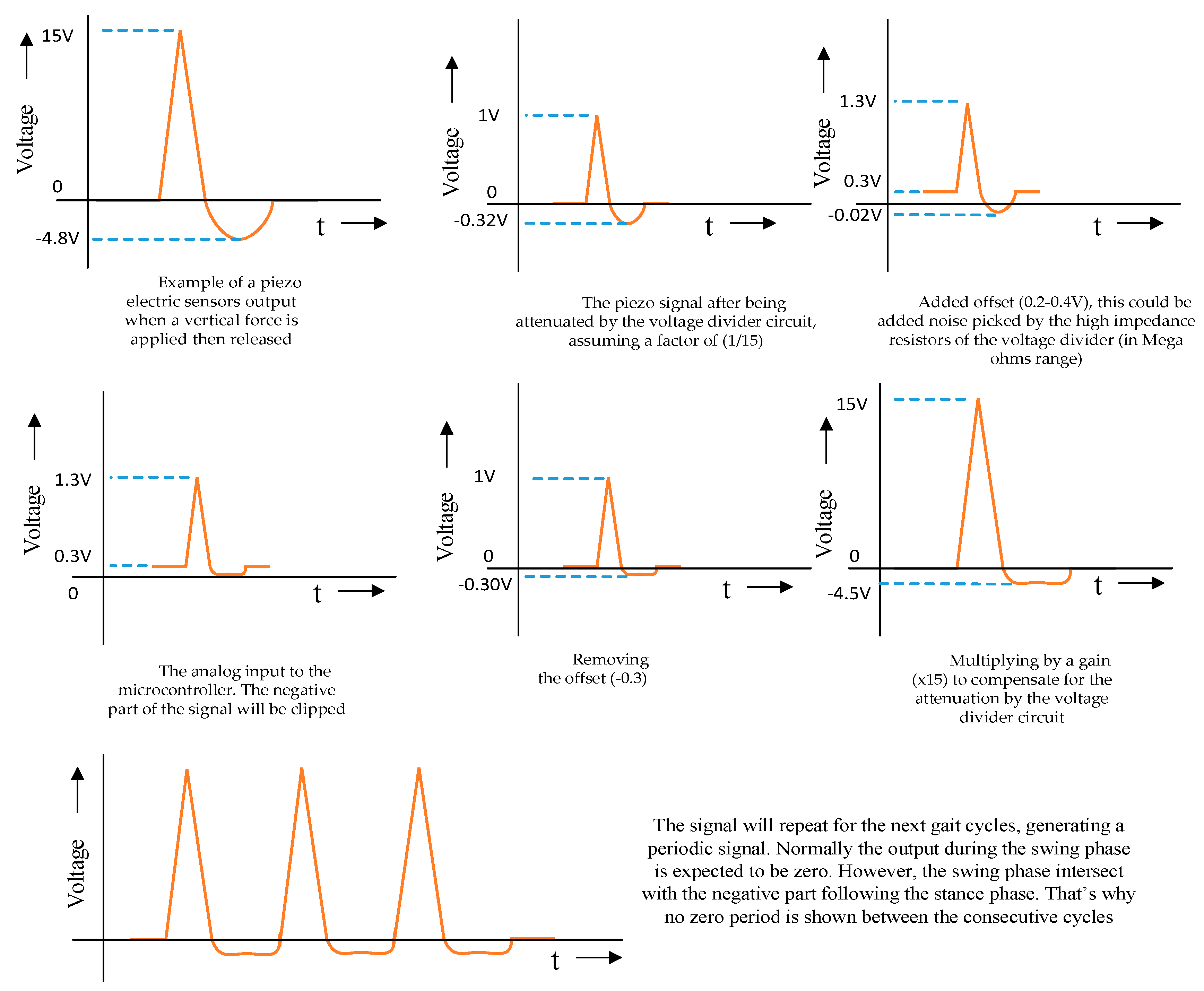

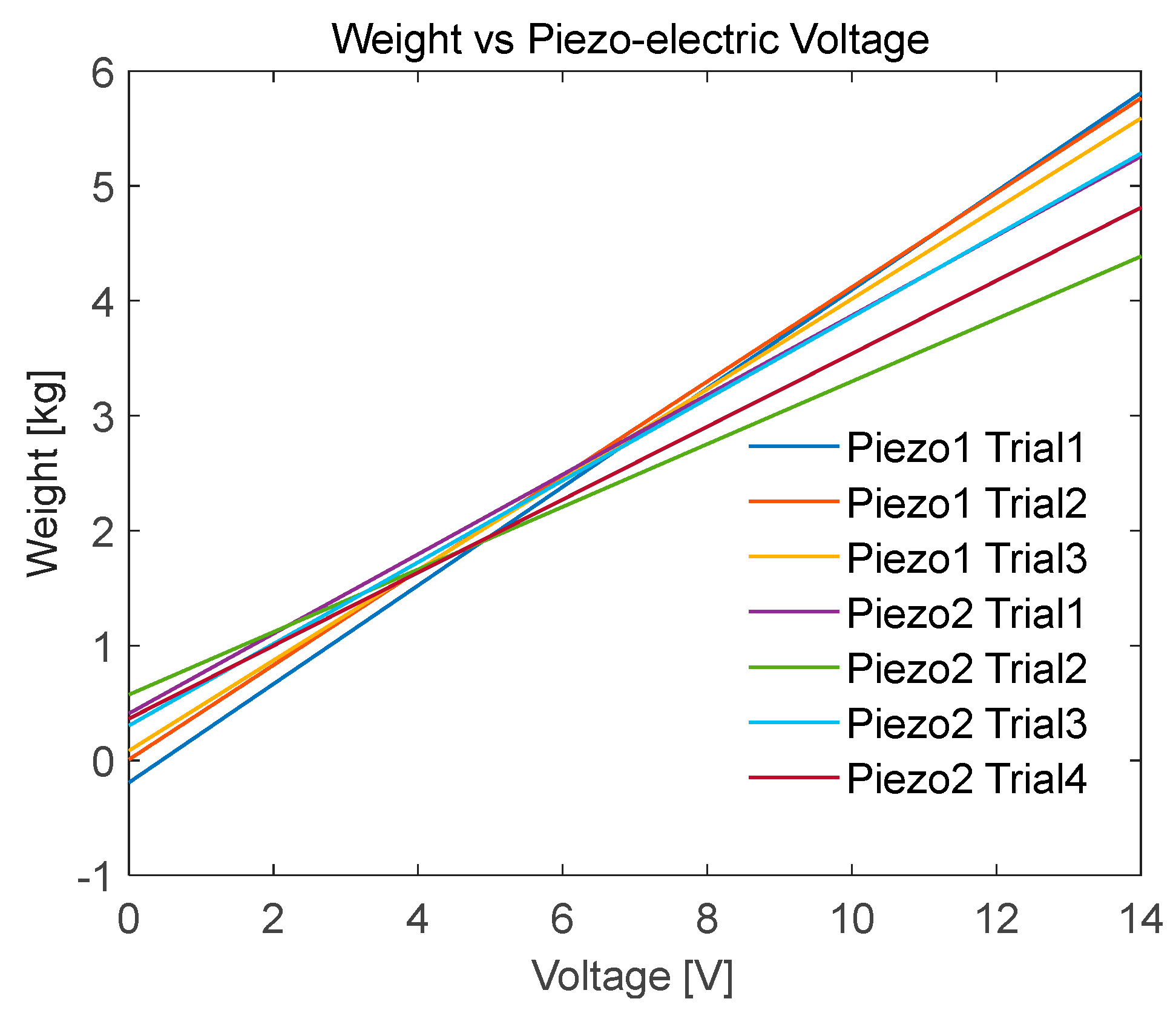

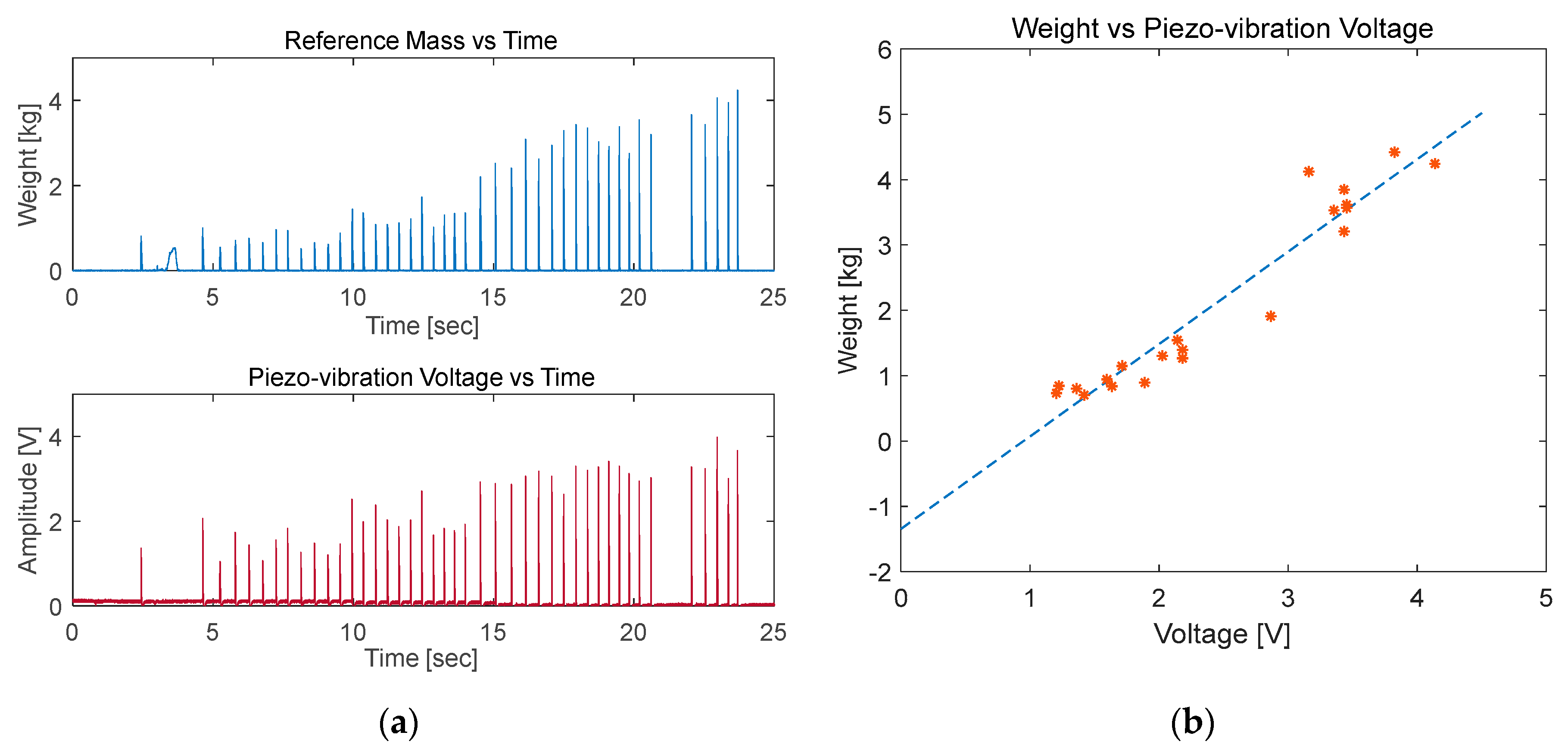

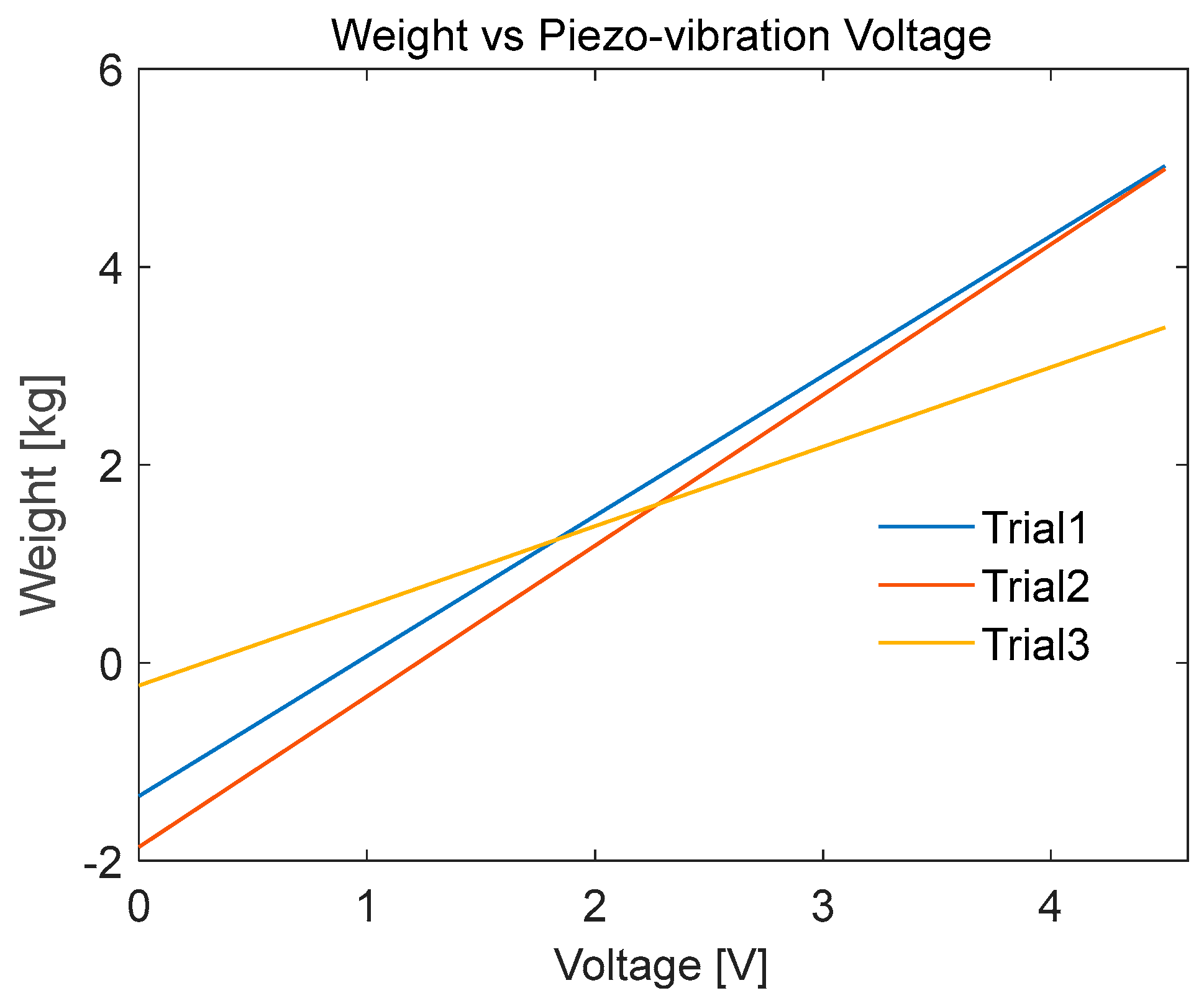

4.1.2. Piezo-Electric Sensor Calibration

4.1.3. MEMS Sensor Calibration

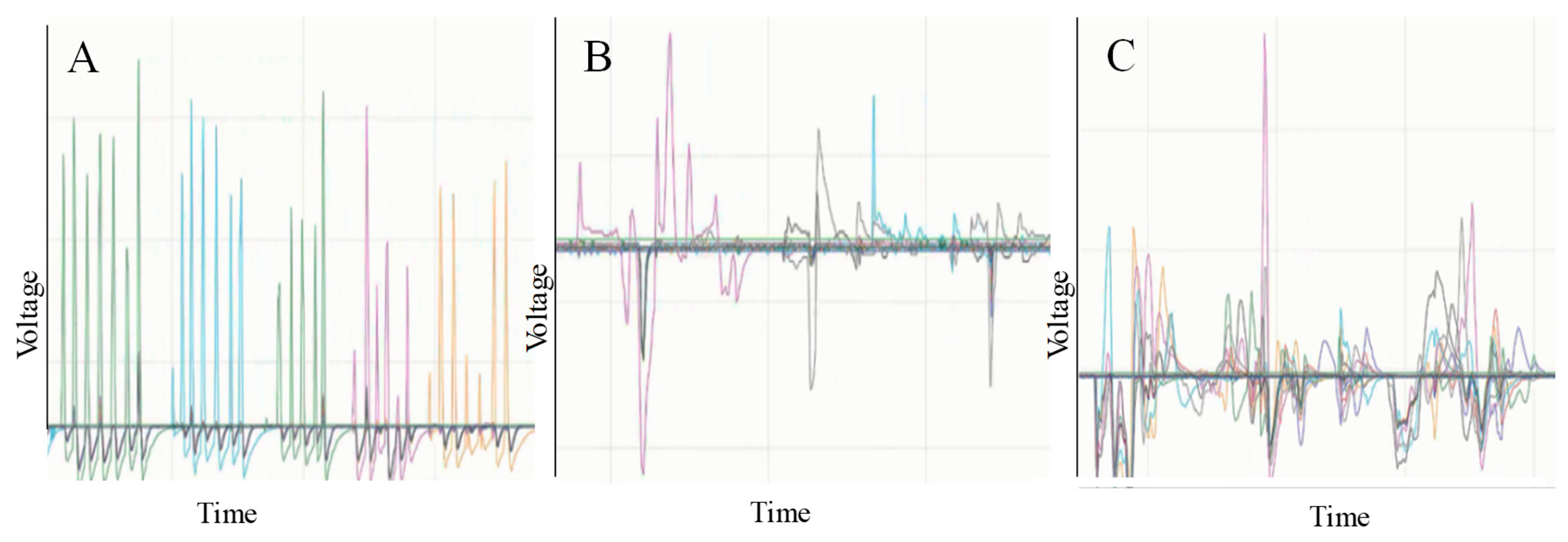

4.2. Piezo-Electric Sensor Response

5. Results and Discussion

5.1. Sensors’ Calibration

5.1.1. FSR Sensor Calibration

5.1.2. Piezo-Electric Sensor Calibration

5.1.3. MEMS Sensor Calibration

5.2. Insole Charecterization

5.2.1. FSR-Based Insole Characterization

5.2.2. Piezoelectric Sensor Based-Insole Characterization

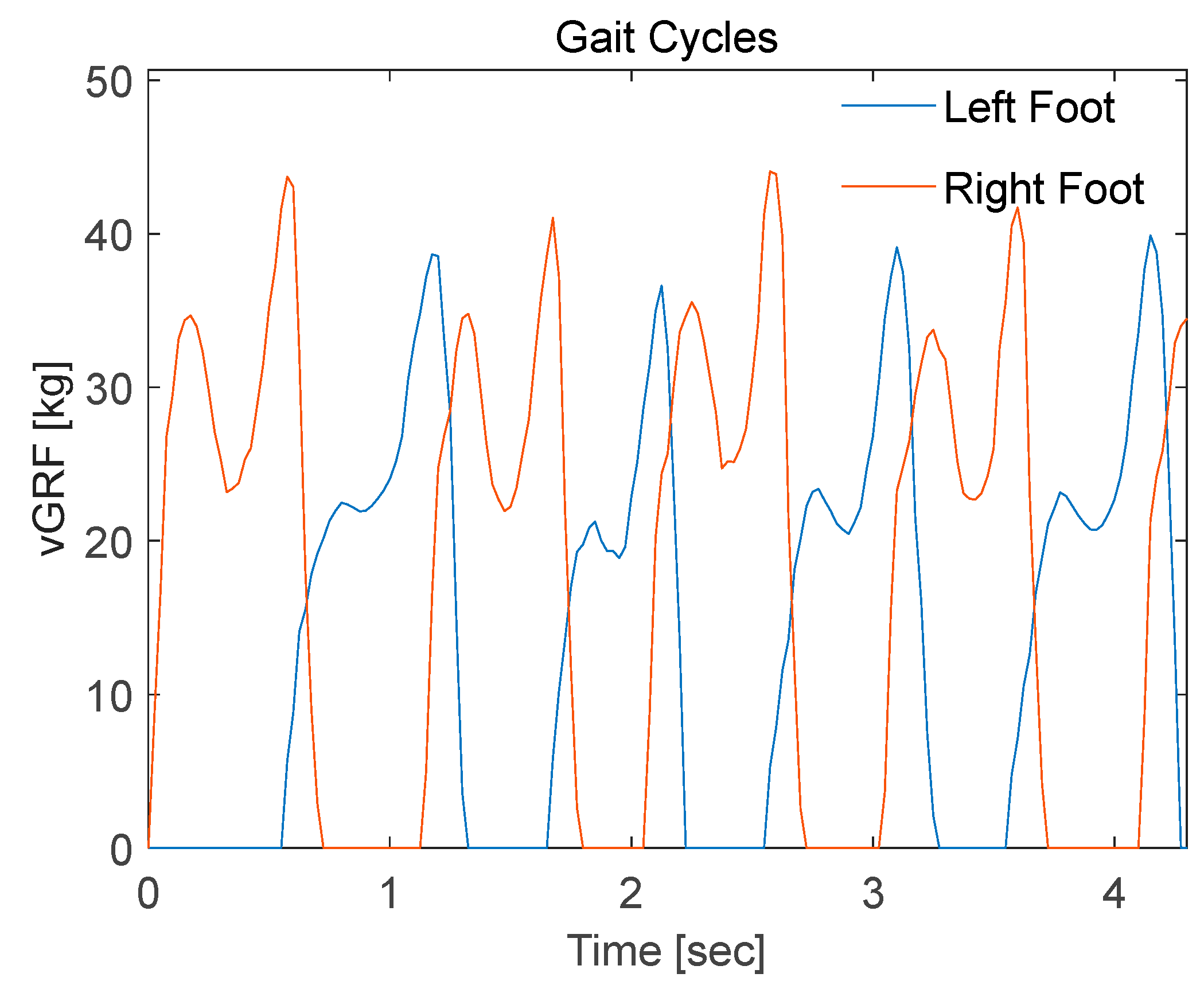

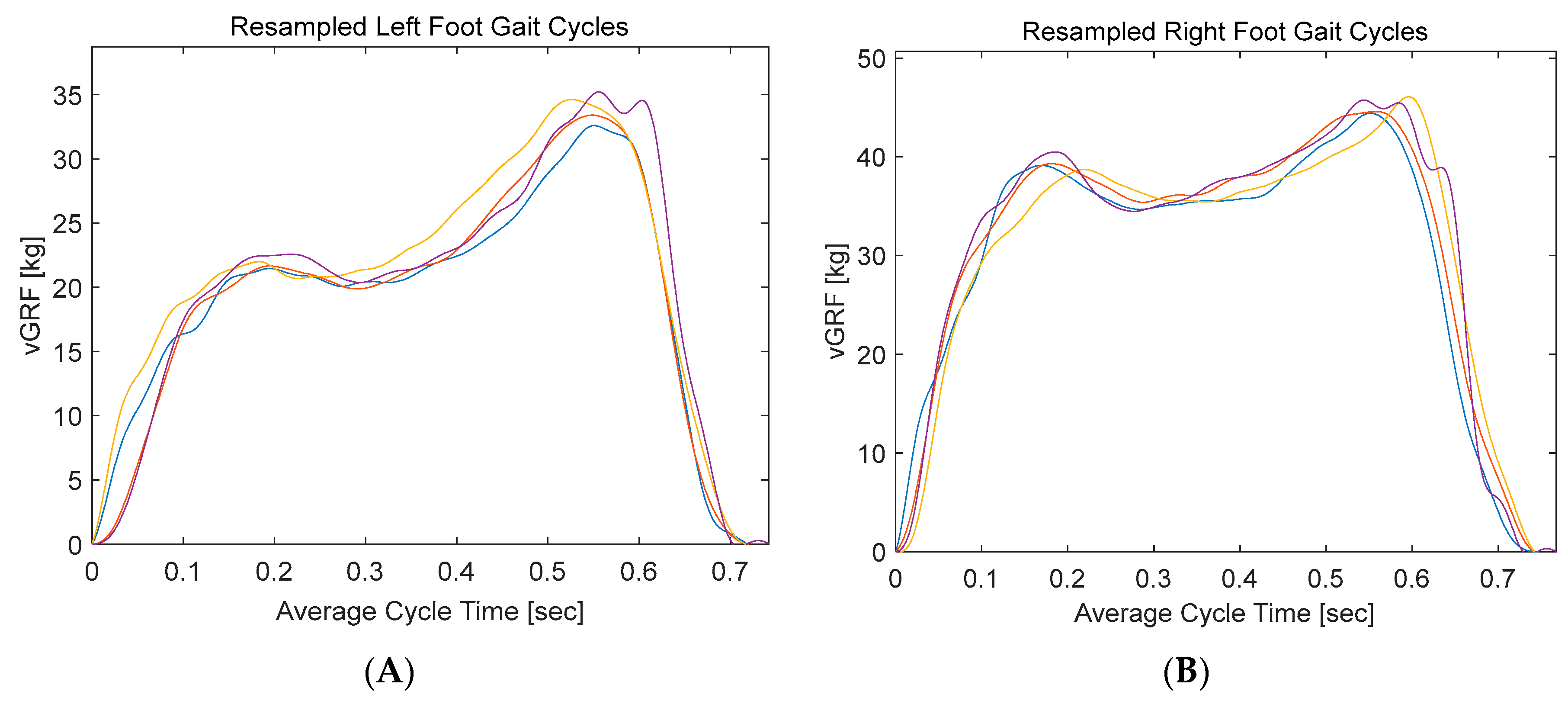

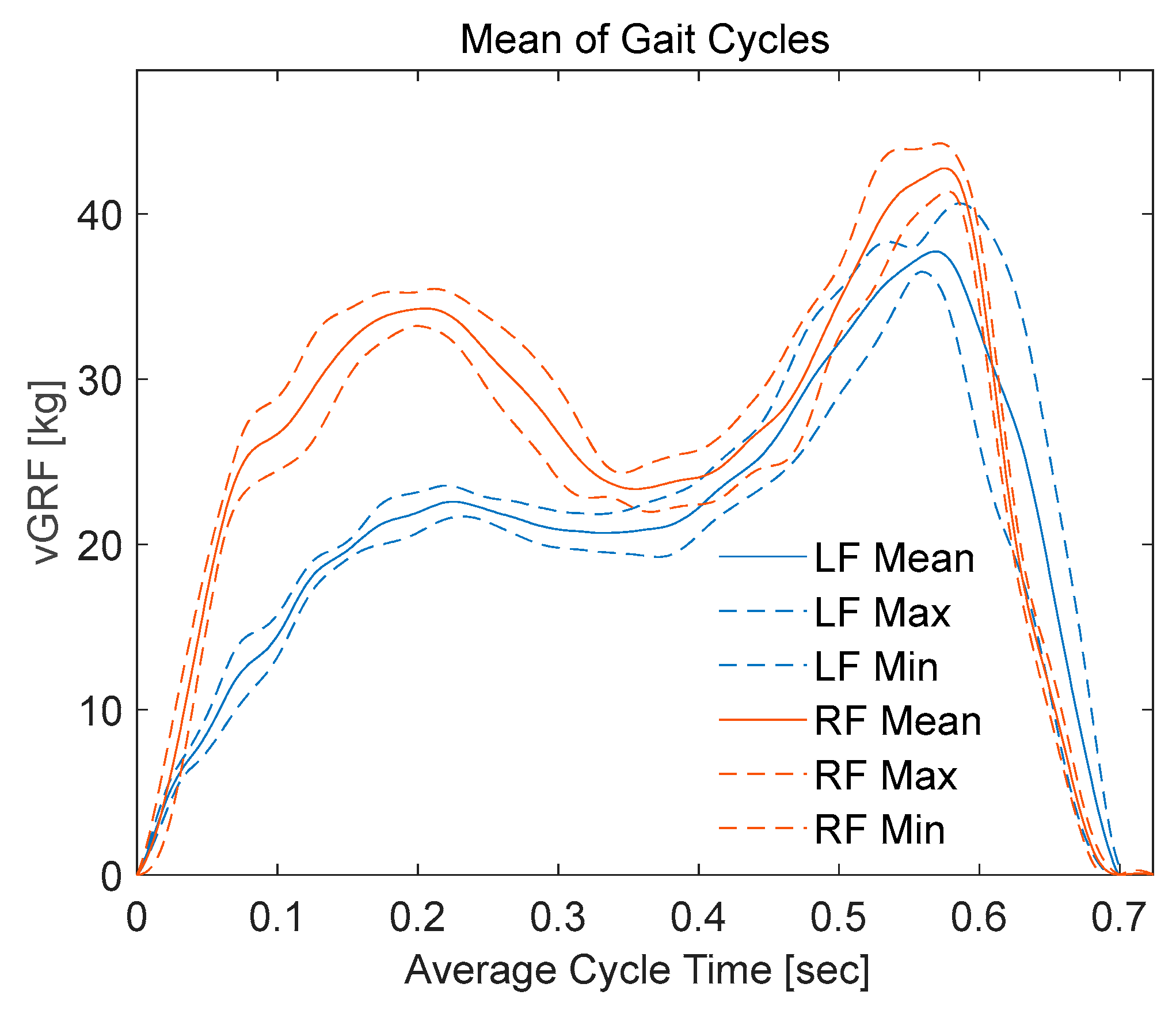

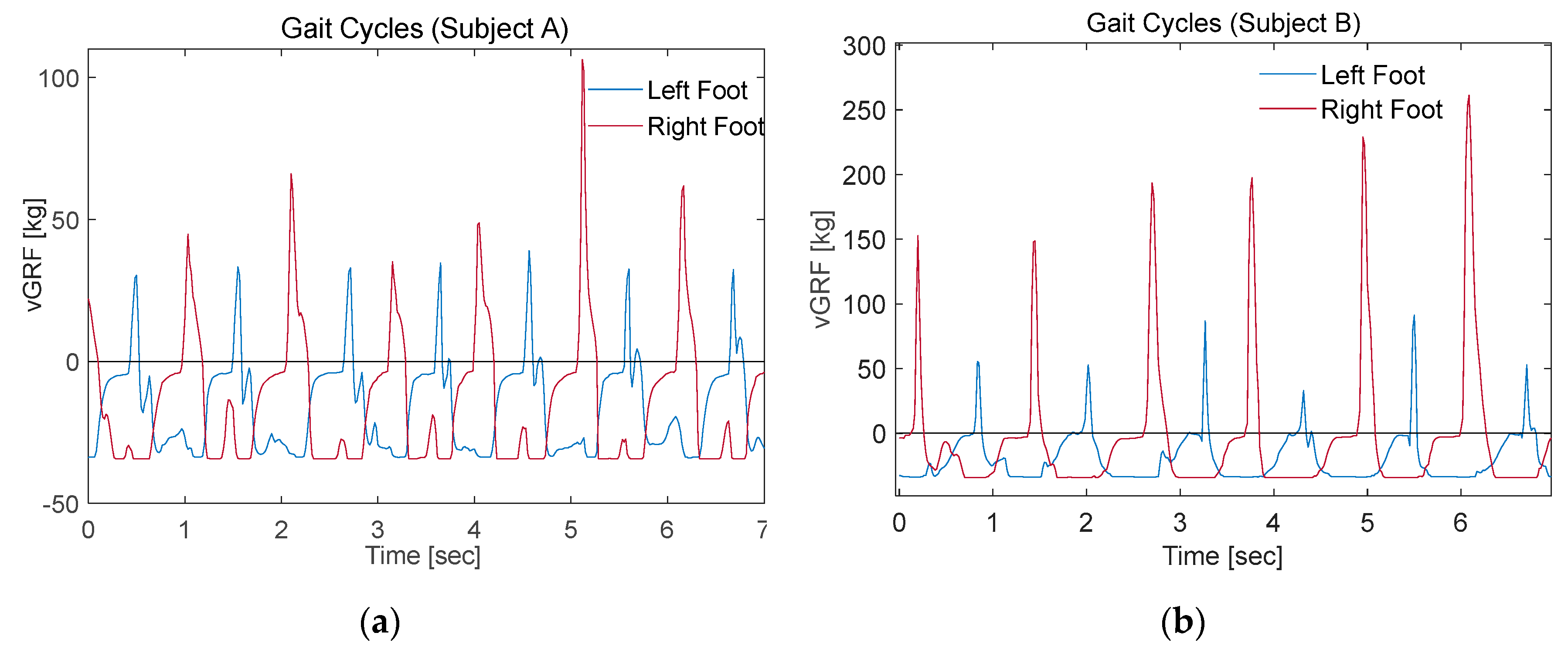

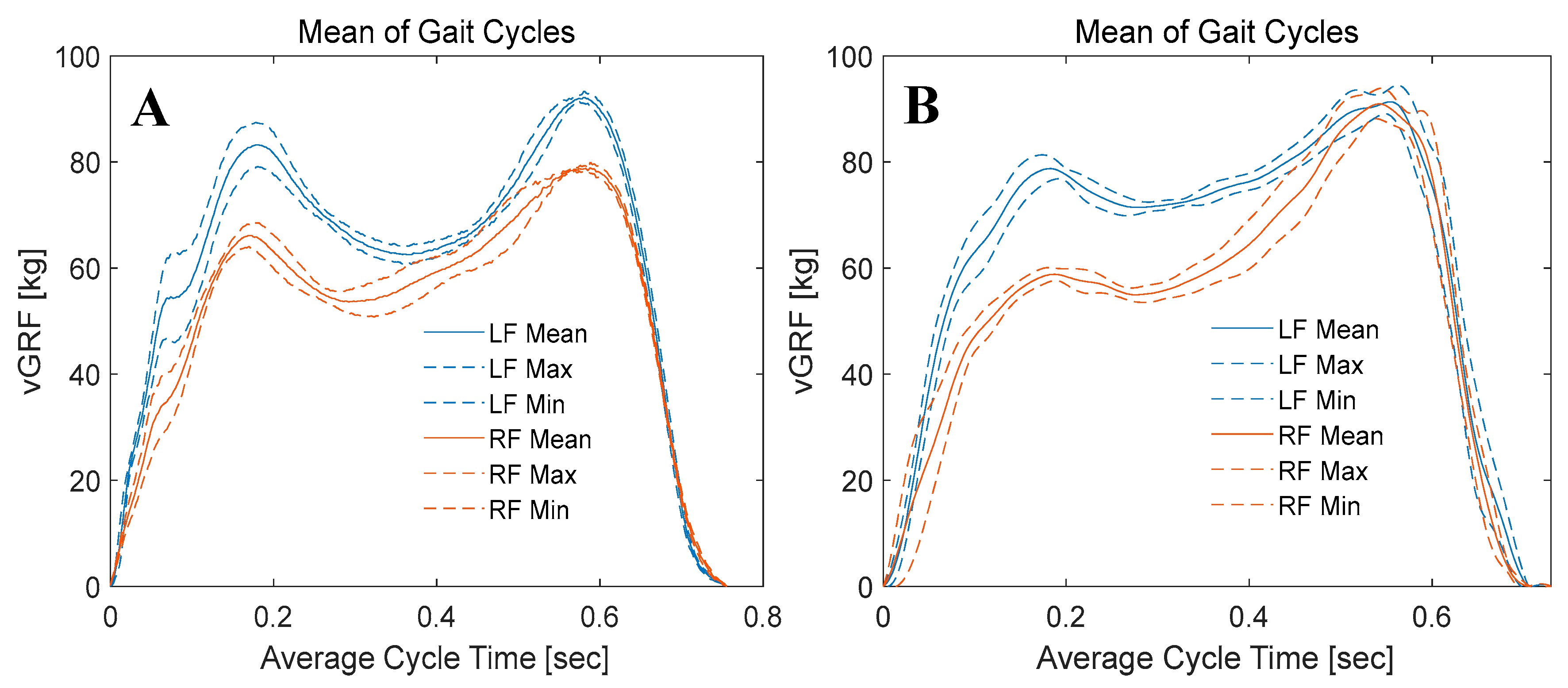

5.3. Performance Evaluation of the FSR-Based System

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kowalski, E.; Catelli, D.S.; Lamontagne, M. Side does not matter in healthy young and older individuals–Examining the importance of how we match limbs during gait studies. Gait Posture 2019, 67, 133–136. [Google Scholar]

- Tao, W.; Liu, T.; Zheng, R.; Feng, H. Gait analysis using wearable sensors. Sensors 2012, 12, 2255–2283. [Google Scholar] [CrossRef] [PubMed]

- Howell, A.M.; Kobayashi, T.; Hayes, H.A.; Foreman, K.B.; Bamberg, S.J.M. Kinetic gait analysis using a low-cost insole. IEEE Trans. Biomed. Eng. 2013, 60, 3284–3290. [Google Scholar] [CrossRef] [PubMed]

- Bamberg, S.J.M.; Benbasat, A.Y.; Scarborough, D.M.; Krebs, D.E.; Paradiso, J.A. Gait analysis using a shoe-integrated wireless sensor system. IEEE Trans. Inf. Technol. Biomed. 2008, 12, 413–423. [Google Scholar] [CrossRef] [PubMed]

- De Rossi, S.; Lenzi, T.; Vitiello, N.; Donati, M.; Persichetti, A.; Giovacchini, F.; Vecchi, F.; Carrozza, M.C. Development of an in-shoe pressure-sensitive device for gait analysis. In Proceedings of the 2011 Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Boston, MA, USA, 30 August–3 September 2011; IEEE: Piscataway, NJ, USA, 2011. [Google Scholar]

- Smart Tracking and Wearables: Techniques in Gait Analysis and Movement in Pathological Aging. Available online: https://www.intechopen.com/books/smart-healthcare/smart-tracking-and-wearables-techniques-in-gait-analysis-and-movement-in-pathological-aging (accessed on 9 February 2020).

- Gurchiek, R.D.; Choquette, R.H.; Beynnon, B.D.; Slauterbeck, J.R.; Tourville, T.W.; Toth, M.J.; McGinnis, R.S. Remote gait analysis using wearable sensors detects asymmetric gait patterns in patients recovering from ACL reconstruction. In Proceedings of the 2019 IEEE 16th International Conference on Wearable and Implantable Body Sensor Networks (BSN), Chicago, IL, USA, 19–22 May 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Brognara, L.; Palumbo, P.; Grimm, B.; Palmerini, L. Assessing gait in parkinson’s disease using wearable motion sensors: A systematic review. Diseases 2019, 7, 18. [Google Scholar] [CrossRef] [PubMed]

- Mills, P.M.; Morrison, S.; Lloyd, D.G.; Barrett, R.S. Repeatability of 3D gait kinematics obtained from an electromagnetic tracking system during treadmill locomotion. J. Biomech. 2007, 40, 1504–1511. [Google Scholar] [CrossRef]

- Huang, E.; Sharp, M.T.; Osborn, E.; MacLellan, A.; Mlynash, M.; Kemp, S.; Buckwalter, M.S.; Lansberg, M.G. Abstract TP173: Feasibility and Utility of Home-Based Gait Analysis Using Body-Worn Sensors. Stroke 2019, 50, ATP173. [Google Scholar] [CrossRef]

- Liu, T.; Inoue, Y.; Shibata, K. A wearable ground reaction force sensor system and its application to the measurement of extrinsic gait variability. Sensors 2010, 10, 10240–10255. [Google Scholar] [CrossRef] [PubMed]

- Razak, A.; Hadi, A.; Zayegh, A.; Begg, R.K.; Wahab, Y. Foot plantar pressure measurement system: A review. Sensors 2012, 12, 9884–9912. [Google Scholar] [CrossRef] [PubMed]

- Alam, U.; Riley, D.R.; Jugdey, R.S.; Azmi, S.; Rajbhandari, S.; D’Août, K.; Malik, R.A. Diabetic neuropathy and gait: A review. Diabetes Ther. 2017, 8, 1253–1264. [Google Scholar] [CrossRef] [PubMed]

- Farahpour, N.; Jafarnezhad, A.; Damavandi, M.; Bakhtiari, A.; Allard, P. Gait ground reaction force characteristics of low back pain patients with pronated foot and able-bodied individuals with and without foot pronation. J. Biomech. 2016, 49, 1705–1710. [Google Scholar] [CrossRef] [PubMed]

- Sacco, I.C.; Picon, A.P.; Macedo, D.O.; Butugan, M.K.; Watari, R.; Sartor, C.D. Alterations in the lower limb joint moments precede the peripheral neuropathy diagnosis in diabetes patients. Diabetes Technol. Ther. 2015, 17, 405–412. [Google Scholar]

- Dabbah, M.A.; Graham, J.; Petropoulos, I.N.; Tavakoli, M.; Malik, R.A. Automatic analysis of diabetic peripheral neuropathy using multi-scale quantitative morphology of nerve fibres in corneal confocal microscopy imaging. Med. Image Anal. 2011, 15, 738–747. [Google Scholar] [CrossRef] [PubMed]

- International Diabetes Federation: IDF Diabetes Atlas. Available online: https://www.idf.org/e-library/epidemiology-research/diabetes-atlas/19-atlas-6th-edition.html (accessed on 9 February 2020).

- Dworkin, R.H.; Malone, D.C.; Panarites, C.J.; Armstrong, E.P.; Pham, S.V. Impact of postherpetic neuralgia and painful diabetic peripheral neuropathy on health care costs. J. Pain 2010, 11, 360–368. [Google Scholar] [CrossRef]

- Dyck, P.J.; Overland, C.J.; Low, P.A.; Litchy, W.J.; Davies, J.L.; Dyck, P.J.B.; O’brien, P.C. Signs and symptoms versus nerve conduction studies to diagnose diabetic sensorimotor polyneuropathy: Cl vs. NPhys trial. Muscle Nerve 2010, 42, 157–164. [Google Scholar]

- Taksande, B.; Ansari, S.; Jaikishan, A.; Karwasara, V. The diagnostic sensitivity, specificity and reproducibility of the clinical physical examination signs in patients of diabetes mellitus for making diagnosis of peripheral neuropathy. J. Endocrinol. Metab. 2011, 1, 21–26. [Google Scholar] [CrossRef][Green Version]

- Watari, R.; Sartor, C.D.; Picon, A.P.; Butugan, M.K.; Amorim, C.F.; Ortega, N.R.; Sacco, I.C. Effect of diabetic neuropathy severity classified by a fuzzy model in muscle dynamics during gait. J. Neuroeng. Rehabil. 2014, 11, 11. [Google Scholar] [CrossRef]

- England, J.; Gronseth, G.; Franklin, G.; Carter, G.; Kinsella, L.; Cohen, J.; Asbury, A.; Szigeti, K.; Lupski, J.; Latov, N. Practice Parameter: Evaluation of distal symmetric polyneuropathy: Role of laboratory and genetic testing (an evidence-based review) Report of the American Academy of Neurology, American Association of Neuromuscular and Electrodiagnostic Medicine, and American Academy of Physical Medicine and Rehabilitation. Neurology 2009, 72, 185–192. [Google Scholar]

- Zhang, Q.; Wang, Y.L.; Xia, Y.; Wu, X.; Kirk, T.V.; Chen, X.D. A low-cost and highly integrated sensing insole for plantar pressure measurement. Sens. Bio-Sens. Res. 2019, 26, 100298. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, B.; Wang, J.; Mohamed, A.; Jia, H. Ultrasensitive and wearable strain sensors based on natural rubber/graphene foam. J. Alloys Compd. 2019, 785, 1001–1008. [Google Scholar] [CrossRef]

- Sengupta, D.; Pei, Y.; Kottapalli, A.G.P. Ultralightweight and 3D Squeezable Graphene-Polydimethylsiloxane Composite Foams as Piezoresistive Sensors. ACS Appl. Mater. Interfaces 2019, 11, 35201–35211. [Google Scholar] [CrossRef] [PubMed]

- Shu, L.; Hua, T.; Wang, Y.; Li, Q.; Feng, D.D.; Tao, X. In-shoe plantar pressure measurement and analysis system based on fabric pressure sensing array. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 767–775. [Google Scholar] [PubMed]

- Giovanelli, D.; Farella, E. Force sensing resistor and evaluation of technology for wearable body pressure sensing. J. Sens. 2016, 2016. [Google Scholar] [CrossRef]

- Feasibility of Force Detection in 3D Printed Flexible Material Using Embedded Sensors. Available online: https://www.spiedigitallibrary.org/conference-proceedings-of-spie/10970/109702F/Feasibility-of-force-detection-in-3D-printed-flexible-material-using/10.1117/12.2514051.short?SSO=1 (accessed on 9 February 2020).

- Heng, W.; Pang, G.; Xu, F.; Huang, X.; Pang, Z.; Yang, G. Flexible Insole Sensors with Stably Connected Electrodes for Gait Phase Detection. Sensors 2019, 19, 5197. [Google Scholar] [CrossRef]

- Lee, W.; Hong, S.-H.; Oh, H.-W. Characterization of Elastic Polymer-Based Smart Insole and a Simple Foot Plantar Pressure Visualization Method Using 16 Electrodes. Sensors 2019, 19, 44. [Google Scholar] [CrossRef]

- Theodosiou, A.; Kalli, K. Recent trends and advances of fibre Bragg grating sensors in CYTOP polymer optical fibres. Opt. Fiber Technol. 2020, 54, 102079. [Google Scholar] [CrossRef]

- Abdelhady, M.; van den Bogert, A.; Simon, D. A High-Fidelity Wearable System for Measuring Lower-Limb Kinetics and Kinematics. IEEE Sens. J. 2019. [Google Scholar] [CrossRef]

- Kim, J.; Bae, M.N.; Lee, K.B.; Hong, S.G. Gait event detection algorithm based on smart insoles. ETRI J. 2019. [Google Scholar] [CrossRef]

- Vilas-Boas, M.d.C.; Rocha, A.P.; Choupina, H.M.P.; Cardoso, M.; Fernandes, J.M.; Coelho, T.; Cunha, J.P.S. TTR-FAP Progression Evaluation Based on Gait Analysis Using a Single RGB-D Camera. In Proceedings of the 2019 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Berlin, Germany, 23–27 July 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Cui, X.; Zhao, Z.; Ma, C.; Chen, F.; Liao, H. A Gait Character Analyzing System for Osteoarthritis Pre-diagnosis Using RGB-D Camera and Supervised Classifier. In Proceedings of the World Congress on Medical Physics and Biomedical Engineering, Prague, Czech Republic, 3–8 June 2018; Springer: Berlin, Germany, 2018. [Google Scholar]

- Barnea, A.; Oprisan, C.; Olaru, D. Force Sensitive Resistors Calibration for the Usage in Gripping Devices. Diagn. Predict. Mech. Eng. Szstems DIPRE 2012, 3, 18–27. [Google Scholar]

- Parmar, S.; Khodasevych, I.; Troynikov, O. Evaluation of flexible force sensors for pressure monitoring in treatment of chronic venous disorders. Sensors 2017, 17, 1923. [Google Scholar] [CrossRef]

- Insole Energy Harvesting from Human Movement Using Piezoelectric Generators. Available online: https://trepo.tuni.fi/handle/123456789/25768 (accessed on 9 February 2020).

- Development of a Smart Insole System for Real-Time Detection of Temporal Gait Parameters and Related Deviations in Unilateral Lower-Limb Amputees. Available online: https://scholarlyrepository.miami.edu/cgi/viewcontent.cgi?article=1393&context=oa_theses (accessed on 9 February 2020).

- Sacco, I.; Amadio, A. A study of biomechanical parameters in gait analysis and sensitive cronaxie of diabetic neuropathic patients. Clin. Biomech. 2000, 15, 196–202. [Google Scholar] [CrossRef]

- Menz, H.B.; Lord, S.R.; St George, R.; Fitzpatrick, R.C. Walking stability and sensorimotor function in older people with diabetic peripheral neuropathy1. Arch. Phys. Med. Rehabil. 2004, 85, 245–252. [Google Scholar] [CrossRef] [PubMed]

- Dementyev, A.; Hodges, S.; Taylor, S.; Smith, J. Power consumption analysis of Bluetooth Low Energy, ZigBee and ANT sensor nodes in a cyclic sleep scenario. In Proceedings of the 2013 IEEE International Wireless Symposium (IWS), Beijing, China, 14–18 April 2013; IEEE: Piscataway, NJ, USA, 2013. [Google Scholar]

- Sacco, I.; Amadio, A. Influence of the diabetic neuropathy on the behavior of electromyographic and sensorial responses in treadmill gait. Clin. Biomech. 2003, 18, 426–434. [Google Scholar] [CrossRef]

- Kwon, O.-Y.; Minor, S.D.; Maluf, K.S.; Mueller, M.J. Comparison of muscle activity during walking in subjects with and without diabetic neuropathy. Gait Posture 2003, 18, 105–113. [Google Scholar]

- Akashi, P.M.; Sacco, I.C.; Watari, R.; Hennig, E. The effect of diabetic neuropathy and previous foot ulceration in EMG and ground reaction forces during gait. Clin. Biomech. 2008, 23, 584–592. [Google Scholar] [CrossRef] [PubMed]

- Sacco, I.C.; Akashi, P.M.; Hennig, E.M. A comparison of lower limb EMG and ground reaction forces between barefoot and shod gait in participants with diabetic neuropathic and healthy controls. BMC Musculoskelet. Disord. 2010, 11, 24. [Google Scholar] [CrossRef]

- Gomes, A.A.; Onodera, A.N.; Otuzi, M.E.; Pripas, D.; Mezzarane, R.A.; Sacco, N.; Isabel, C. Electromyography and kinematic changes of gait cycle at different cadences in diabetic neuropathic individuals. Muscle Nerve 2011, 44, 258–268. [Google Scholar]

- Sawacha, Z.; Spolaor, F.; Guarneri, G.; Contessa, P.; Carraro, E.; Venturin, A.; Avogaro, A.; Cobelli, C. Abnormal muscle activation during gait in diabetes patients with and without neuropathy. Gait Posture 2012, 35, 101–105. [Google Scholar]

- Zhu, H.; Wertsch, J.J.; Harris, G.F.; Loftsgaarden, J.D.; Price, M.B. Foot pressure distribution during walking and shuffling. Arch. Phys. Med. Rehabil. 1991, 72, 390–397. [Google Scholar]

| Latency | Speed | Power Consumption | Range | |

|---|---|---|---|---|

| ZigBee | 15 ms | 250 Kbps | 9.3 mA | 291 m |

| Bluetooth Low Energy | 6 ms | 1–11 Mbps | 4.5 mA | 10 m |

| Wi-Fi | ≥25 ms | 1.3 Gbps over 5 GHz and 450 Mbps over 2.4 GHz | 35 mA | 50 m |

| Number of Subjects | Age (Year) | Weight (kg) | Height (cm) | Body Mass Index (kg/m2) | Gender |

|---|---|---|---|---|---|

| 7 | 30.1 ± 13.1 | 77.3 ± 21.2 | 159.8 ± 4.9 | 30.3 ± 7.9 | Female |

| 5 | 52.3 ± 4.8 | 83.5 ± 3.34 | 172.7 ± 11.7 | 28.3 ± 2.9 | Male |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahir, A.M.; Chowdhury, M.E.H.; Khandakar, A.; Al-Hamouz, S.; Abdalla, M.; Awadallah, S.; Reaz, M.B.I.; Al-Emadi, N. A Systematic Approach to the Design and Characterization of a Smart Insole for Detecting Vertical Ground Reaction Force (vGRF) in Gait Analysis. Sensors 2020, 20, 957. https://doi.org/10.3390/s20040957

Tahir AM, Chowdhury MEH, Khandakar A, Al-Hamouz S, Abdalla M, Awadallah S, Reaz MBI, Al-Emadi N. A Systematic Approach to the Design and Characterization of a Smart Insole for Detecting Vertical Ground Reaction Force (vGRF) in Gait Analysis. Sensors. 2020; 20(4):957. https://doi.org/10.3390/s20040957

Chicago/Turabian StyleTahir, Anas M., Muhammad E. H. Chowdhury, Amith Khandakar, Sara Al-Hamouz, Merna Abdalla, Sara Awadallah, Mamun Bin Ibne Reaz, and Nasser Al-Emadi. 2020. "A Systematic Approach to the Design and Characterization of a Smart Insole for Detecting Vertical Ground Reaction Force (vGRF) in Gait Analysis" Sensors 20, no. 4: 957. https://doi.org/10.3390/s20040957

APA StyleTahir, A. M., Chowdhury, M. E. H., Khandakar, A., Al-Hamouz, S., Abdalla, M., Awadallah, S., Reaz, M. B. I., & Al-Emadi, N. (2020). A Systematic Approach to the Design and Characterization of a Smart Insole for Detecting Vertical Ground Reaction Force (vGRF) in Gait Analysis. Sensors, 20(4), 957. https://doi.org/10.3390/s20040957