Highly Sensitive, Calibration-Free WM-DAS Method for Recovering Absorbance—Part II: Experimental Analysis

Abstract

1. Introduction

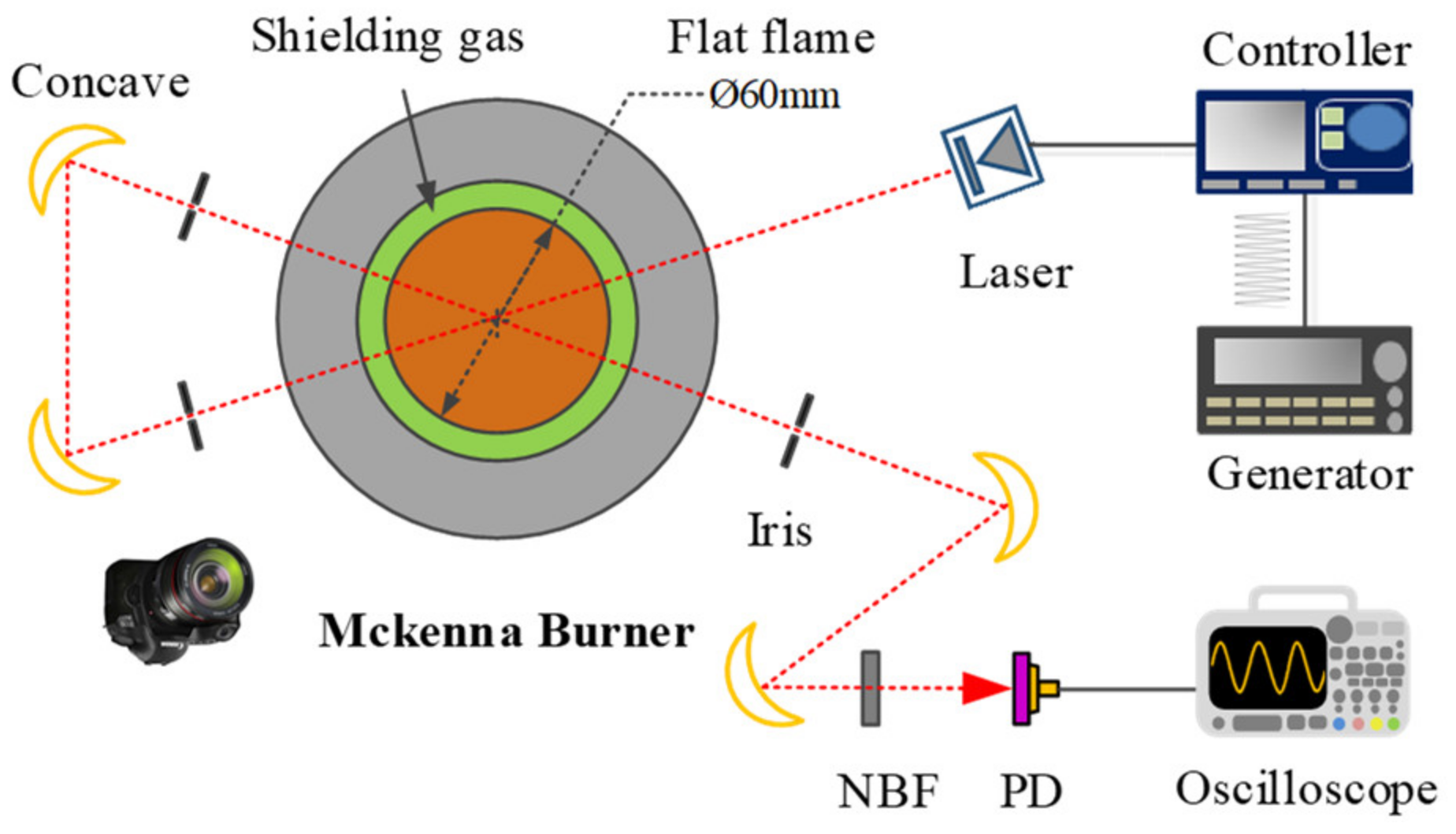

2. Experimental System

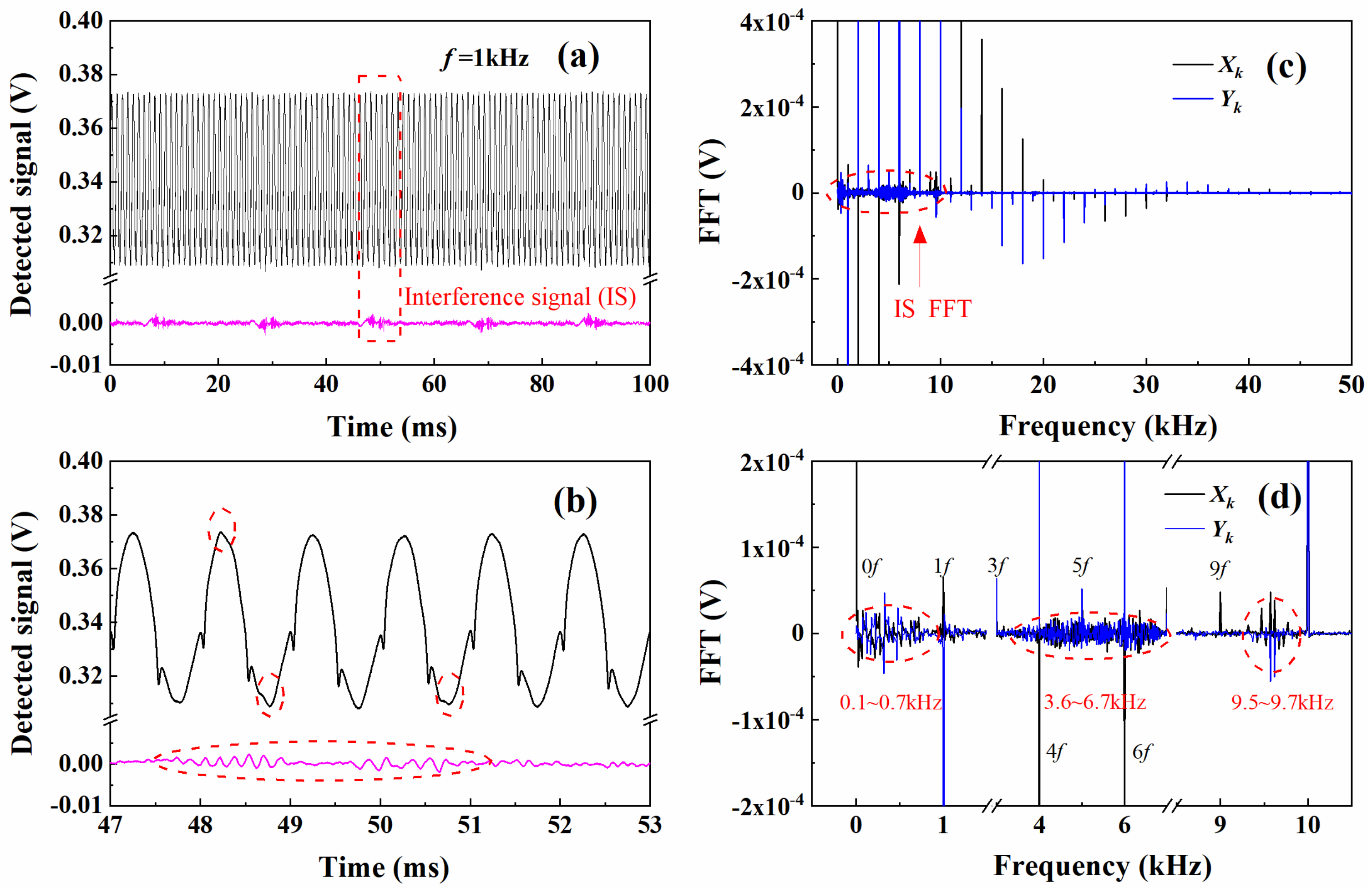

3. Characteristic of WM-DAS

3.1. Noise Rejection Ability

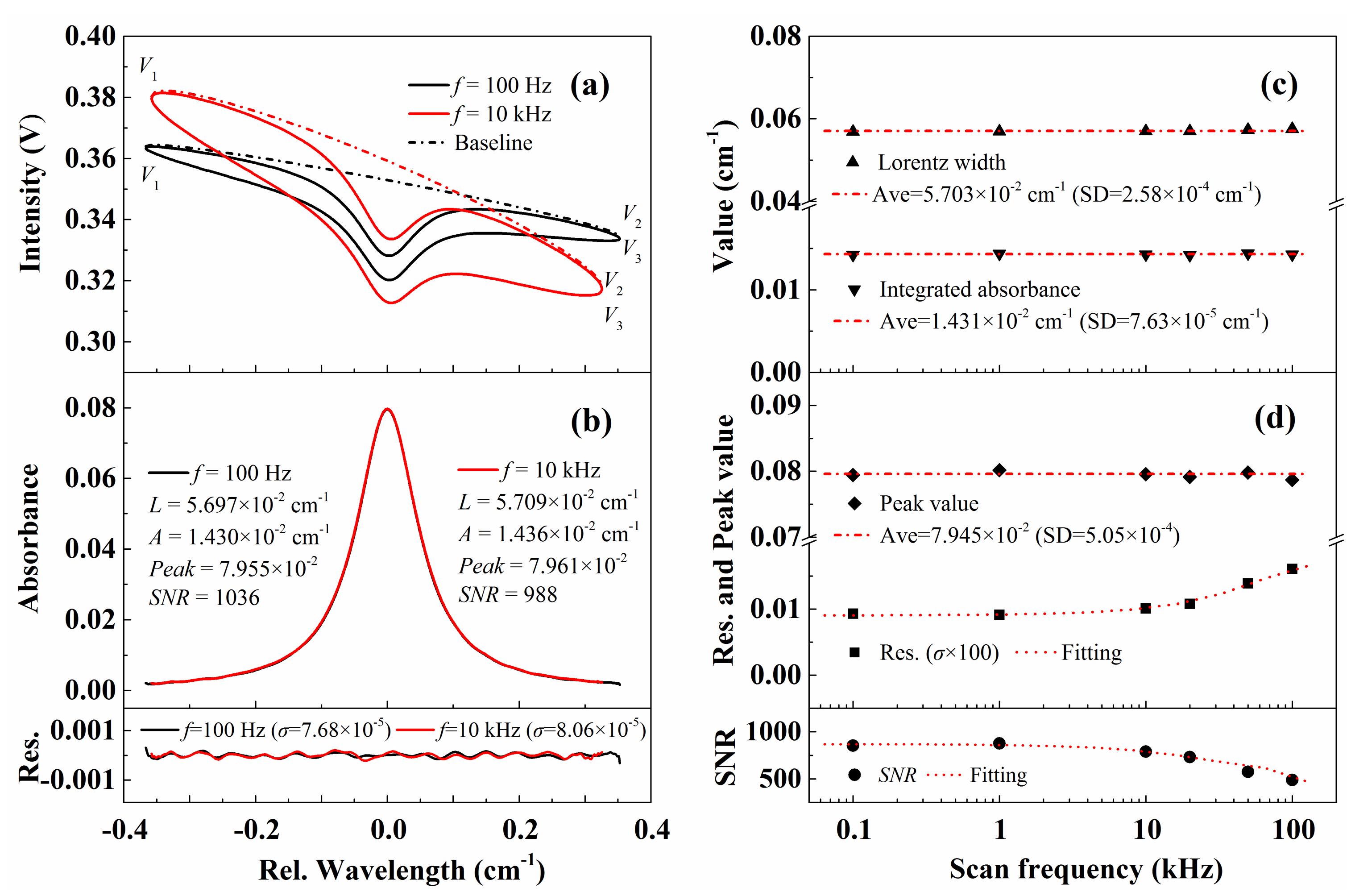

3.2. Temporal Resolution

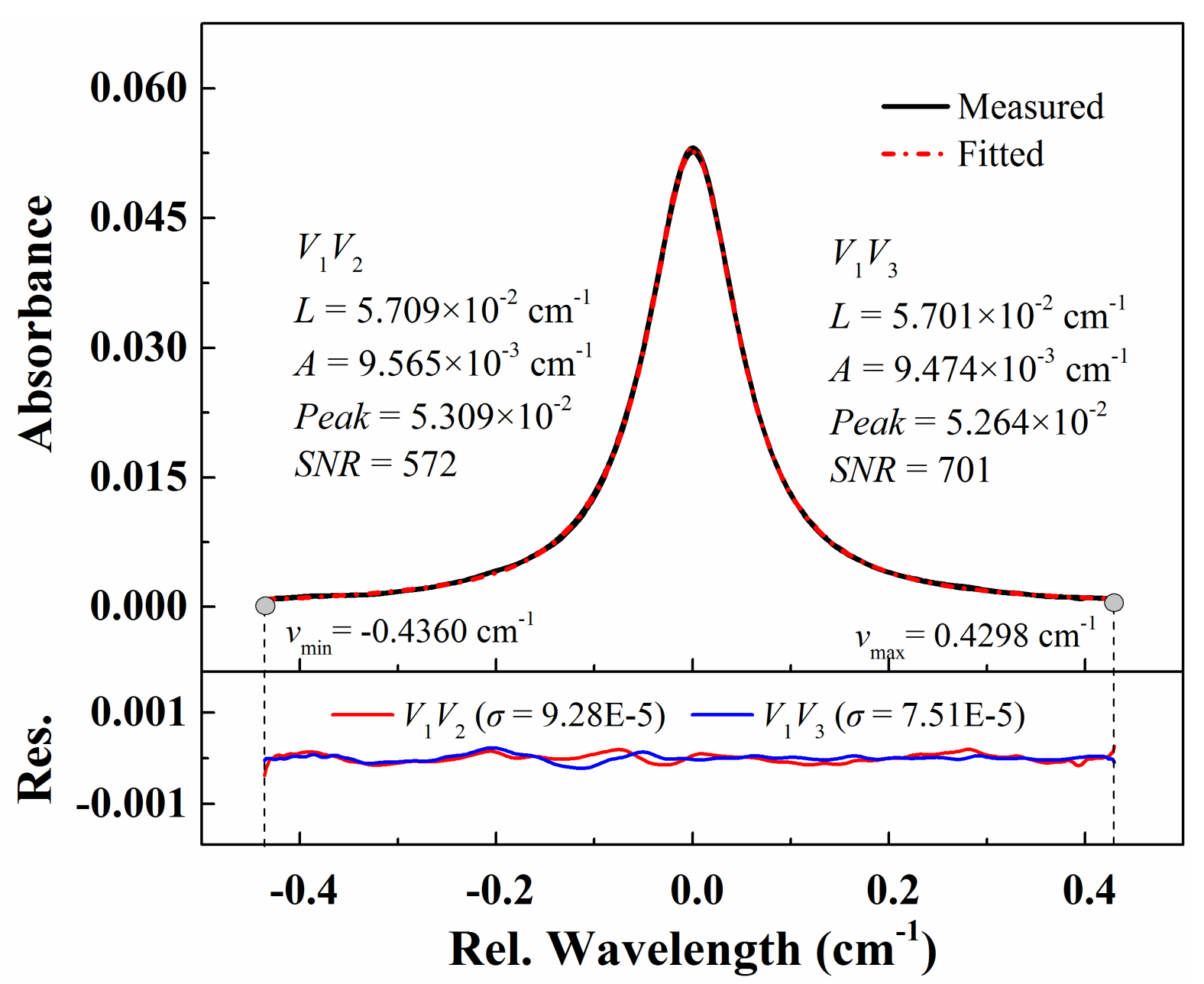

3.3. Performance with Narrow Scan

4. Applications of WM-DAS

4.1. High-Accuracy Measurement of Spectroscopic Parameters (Experimental Scheme Shown in Figure 1)

4.2. High-Speed Measurement on Combustion (Experimental Scheme Shown in Figure 2)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Goldenstein, C.S.; Jeffries, J.B.; Hanson, R.K. Diode laser measurements of linestrength and temperature-dependent lineshape parameters of H2O-, CO2-, and N2-perturbed H2O transitions near 2474 and 2482 nm. J. Quant. Spectrosc. Radiat. Transf. 2013, 130, 100–111. [Google Scholar] [CrossRef]

- Pogány, A.; Klein, A.; Ebert, V. Measurement of water vapor line strengths in the 1.4–2.7 µm range by tunable diode laser absorption spectroscopy. J. Quant. Spectrosc. Radiat. Transf. 2015, 165, 108–122. [Google Scholar] [CrossRef]

- Es-sebbar, E.; Farooq, A. Intensities, broadening and narrowing parameters in the v3 band of methane. J. Quant. Spectrosc. Radiat. Transf. 2014, 149, 241–252. [Google Scholar] [CrossRef]

- Li, J.S.; Liu, N.W.; Ding, J.Y.; Zhou, S.; He, T.B.; Zhang, L. Piezoelectric effect-based detector for spectroscopic application. Opt. Lasers Eng. 2019, 115, 141–148. [Google Scholar] [CrossRef]

- Allen, M.G. Diode laser absorption sensors for gas-dynamic and combustion flows. Meas. Sci. Technol. 1998, 9, 545–562. [Google Scholar] [CrossRef] [PubMed]

- Goldenstein, C.S.; Spearrin, R.M.; Jeffries, J.B.; Hanson, R.K. Infrared laser-absorption sensing for combustion gases. Prog. Energy Combust. Sci. 2017, 60, 132–176. [Google Scholar] [CrossRef]

- Xu, K.K.; Chen, Y.X.; Okhal, T.A.; Snyman, L.W. Micro optical sensors based on avalanching silicon light-emitting devices monolithically integrated on chips. Opt. Mater Express 2019, 9, 3985–3997. [Google Scholar] [CrossRef]

- Seals, L.; Gole, J.L.; Tse, L.A.; Hesketh, P.J. Rapid, reversible, sensitive porous silicon gas sensor. J. Appl. Phys. 2002, 91, 2519–2523. [Google Scholar] [CrossRef]

- Hanson, R.K. Applications of quantitative laser sensors to kinetics, propulsion and practical energy systems. Proc. Combust. Inst. 2011, 33, 1–40. [Google Scholar] [CrossRef]

- Reuter, S.; Sousa, J.S.; Stancu, G.D.; van Helden, J.P.H. Hubertus Van Helden. Review on VUV to MIR absorption spectroscopy of atmospheric pressure plasma jets. Plasma Sources Sci. Technol. 2015, 24, 054001. [Google Scholar] [CrossRef]

- Douat, C.; Kacem, I.; Sadeghi, N.; Bauville, G.; Fleury, M.; Puech, V. Space-time resolved density of helium metastable atoms in a nanosecond pulsed plasma jet: Influence of high voltage and pulse frequency. J. Phys. D 2016, 49, 285204. [Google Scholar] [CrossRef]

- Röpcke, J.; Lombardi, G.; Rousseau, A.; Davies, P.B. Application of mid-infrared tunable diode laser absorption spectroscopy to plasma diagnostics: A review. Plasma Sources Sci. Technol. 2006, 15, S148–S168. [Google Scholar] [CrossRef]

- Goldenstein, C.S.; Strand, C.L.; Schultz, I.A.; Sun, K.; Jeffries, J.B.; Hanson, R.K. Fitting of calibration-free scanned-wavelength-modulation spectroscopy spectra for determination of gas properties and absorption lineshapes. Appl. Opt. 2014, 53, 356–367. [Google Scholar] [CrossRef]

- Rieker, G.B.; Jeffries, J.B.; Hanson, R.K. Calibration-free wavelength-modulation spectroscopy for measurements of gas temperature and concentration in harsh environments. Appl. Opt. 2009, 48, 5546–5560. [Google Scholar] [CrossRef]

- Sun, K.; Chao, X.; Sur, R.; Goldenstein, C.S.; Jeffries, J.B.; Hanson, R.K. Analysis of calibration-free wavelength-scanned wavelength modulation spectroscopy for practical gas sensing using tunable diode lasers. Meas. Sci. Technol. 2013, 24, 125203. [Google Scholar] [CrossRef]

- McManus, J.B.; Zahniser, M.S.; Nelson, J.D.D.; Shorter, J.H.; Herndon, S.C.; Wood, E.C.; Wehr, R. Application of quantum cascade lasers to high-precision atmospheric trace gas measurements. Opt. Eng. 2010, 49, 111124. [Google Scholar] [CrossRef]

- Nelson, D.D.; McManus, J.B.; Herndon, S.C.; Shorter, J.H.; Zahniser, M.S.; Blaser, S.; Hvozdara, L.; Muller, A.; Giovannini, M.; Faist, J. Characterization of a near-room-temperature, continuous-wave quantum cascade laser for long-term, unattended monitoring of nitric oxide in the atmosphere. Opt. Lett. 2006, 31, 2012–2014. [Google Scholar] [CrossRef]

- Xu, K.; Huang, L.; Zhang, Z.; Zhao, J.; Zhang, Z.; Snyman, L.W.; Swart, J.W. Light emission from a poly-silicon device with carrier injection engineering. Mater. Sci. Eng. B 2018, 231, 28–31. [Google Scholar] [CrossRef]

- Mulvihill, C.R.; Alturaifi, S.A.; Petersen, E.L. High-temperature He- and O2- broadening of the R(12) line in the 1←0 band of carbon monoxide. J. Quant. Spectrosc. Radiat. Transf. 2018, 217, 432–439. [Google Scholar] [CrossRef]

- Du, Y.J.; Peng, Z.M.; Ding, Y.J. High-accuracy sinewave-scanned direct absorption spectroscopy. Opt. Express 2018, 26, 29550–29560. [Google Scholar] [CrossRef]

- Long, D.A.; Bielska, K.; Lisak, D.; Havey, D.K.; Okumura, M.; Miller, C.E.; Hodges, J.T. The air-broadened, near-infrared CO2 line shape in the spectrally isolated regime: Evidence of simultaneous Dicke narrowing and speed dependence. J. Chem. Phys. 2011, 135, 064308. [Google Scholar] [CrossRef] [PubMed]

- Zaharov, V.V.; Farahi, R.H.; Snyder, P.J.; Davision, B.H.; Passian, A. Karhunen-Loeve treatment to remove noise and facilitate data analysis in sensing, spectroscopy and other applications. Analyst 2014, 139, 5927–5935. [Google Scholar] [CrossRef] [PubMed]

- Li, J.D.; Du, Y.J.; Peng, Z.M.; Ding, Y.J. Measurements of spectroscopic parameters of CO2 transitions for Voigt, Rautian, Galatry and speed-dependent Voigt profiles near 1.43 µm using the WM-DAS method. J. Quant. Spectrosc. Radiat. Transf. 2019, 224, 197–205. [Google Scholar] [CrossRef]

- McGettrick, A.J.; Duffin, K.; Johnstone, W.; Stewart, G.; Moodie, D.G. Tunable diode laser spectroscopy with wavelength modulation: A phasor decomposition method for calibration-free measurements of gas concentration and pressure. J. Lightwave Technol. 2008, 26, 432–440. [Google Scholar] [CrossRef]

- Li, H.; Farooq, A.; Jeffries, J.B.; Hanson, R.K. Diode laser measurements of temperature-dependent collisional-narrowing and broadening parameters of Ar-perturbed H2O transitions at 1391.7 and 1397.8 nm. J. Quant. Spectrosc. Radiat. Transf. 2008, 109, 132–143. [Google Scholar] [CrossRef]

- Buerkle, S.; Dreizler, A.; Ebert, V.; Wagner, S. Experimental comparison of a 2D laminar diffusion flame under oxy-fuel and air atmosphere. Fuel 2018, 212, 302–308. [Google Scholar] [CrossRef]

- Li, S.; Farooq, A.; Hanson, R.K. H2O temperature sensor for low-pressure flames using tunable diode laser absorption near 2.9 µm. Meas. Sci. Technol. 2011, 22, 125301. [Google Scholar] [CrossRef]

- Zheng, S.; Liang, W.K.; Chu, H.Q.; Zhou, H.C. Effect of radiation reabsorption of C1-C6 hydrocarbon flames at normal and elevated pressures. Fuel 2020, 266, 117061. [Google Scholar] [CrossRef]

- Liu, C.; Xu, L.; Cao, Z. Measurement of nonuniform temperature and concentration distributions by combining line-of-sight tunable diode laser absorption spectroscopy with regularization methods. Appl. Opt. 2013, 52, 4827–4842. [Google Scholar] [CrossRef]

- Ma, L.; Lau, L.; Ren, W. Non-uniform temperature and species concentration measurements in a laminar flame using multi-band infrared absorption spectroscopy. Appl. Phys. B-Lasers O. 2017, 123, 83. [Google Scholar] [CrossRef]

- Tranter, R.S.; Brezinsky, K.; Fulle, D. Design of a high-pressure single pulse shock tube for chemical kinetic investigations. Rev. Sci. Instrum. 2001, 72, 3046–3054. [Google Scholar] [CrossRef]

- Hanson, R.K.; Davidson, D.F. Recent advances in laser absorption and shock tube methods for studies of combustion chemistry. Prog. Energy Combust. Sci. 2014, 44, 103–114. [Google Scholar] [CrossRef]

- Peng, Z.; Du, Y.; Ding, Y. Highly sensitive, Calibration-free WM-DAS method for recovering absolute absorbance—Part I: Theoretical analysis. Sensors 2020, 20, 681. [Google Scholar] [CrossRef]

- Tao, B.; Hu, Z.; Fan, W.; Wang, S.; Ye, J.; Zhang, Z. Novel method for quantitative and real-time measurements on engine combustion at varying pressure based on the wavelength modulation spectroscopy. Opt. Express 2017, 25, A762–A776. [Google Scholar] [CrossRef]

- Farooq, A.; Jeffries, J.B.; Hanson, R.K. In situ combustion measurements of H2O and temperature near 2.5 µm using tunable diode laser absorption. Meas. Sci. Technol. 2008, 19, 075604. [Google Scholar] [CrossRef]

- Li, H.; Rieker, G.B.; Liu, X.; Jeffries, J.B.; Hanson, R.K. Extension of wavelength-modulation spectroscopy to large modulation depth for diode laser absorption measurements in high-pressure gases. Appl. Opt. 2006, 45, 1052–1061. [Google Scholar] [CrossRef]

- Zhao, G.; Tan, W.; Jia, M.; Hou, J.; Ma, W.; Dong, L.; Zhang, L.; Feng, X.; Wu, X.; Yin, W.; et al. Intensity-stabilized fast-scanned direct absorption spectroscopy instrumentation based on a distributed feedback laser with detection sensitivity down to 4 × 10−6. Sensors 2016, 16, 1544. [Google Scholar] [CrossRef]

- Benoy, T.; MLengden Stewart, G.; Johnstone, W. Recovery of absorption line shapes with correction for the wavelength modulation characteristics of DFB lasers. IEEE Photonics J. 2016, 8, 1–17. [Google Scholar] [CrossRef]

- Du, Y.; Peng, Z.M.; Ding, Y.J. A high-accurate and universal method to characterize the relative wavelength response (RWR) in wavelength modulation spectroscopy (WMS). Opt. Express 2020, 28, 3482–3494. [Google Scholar] [CrossRef]

- Nwaboh, J.A.; Werhahn, O.; Ebert, V. Line strength and collisional broadening coefficients of H2O at 2.7 µm for natural gas quality assurance applications. Mol. Phys. 2014, 112, 2451–2461. [Google Scholar] [CrossRef]

- Devi, V.M.; Benner, D.C.; Smith, M.A.H.; Mantz, A.W.; Sung, K.; Brown, L.R.; Predoi-Cross, A. Spectral line parameters including temperature dependences of self- and air-broadening in the 2←0 band of CO at 2.3 µm. J. Quant. Spectrosc. Radiat. Transf. 2012, 113, 1013–1033. [Google Scholar] [CrossRef]

- Goldenstein, C.S.; Hanson, R.K. Diode-laser measurements of linestrength and temperature-dependent lineshape parameters for H2O transitions near 1.4 µm using Voigt, Rautian, Galatry, and speed-dependent Voigt profiles. J. Quant. Spectrosc. Radiat. Transf. 2015, 152, 127–139. [Google Scholar] [CrossRef]

| v0 (cm−1) | S (cm−2/atm) | γair (cm−1/atm) | γself (cm−1/atm) | E″ (cm−1) | |

|---|---|---|---|---|---|

| Line1 | 4300.6999 | 2.616 × 10−21 | 0.0564 | 0.062 | 253.6672 |

| Line2 | 4300.6030 | 1.935 × 10−30 | 0.0420 | 0.041 | 5100.2381 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, Z.; Du, Y.; Ding, Y. Highly Sensitive, Calibration-Free WM-DAS Method for Recovering Absorbance—Part II: Experimental Analysis. Sensors 2020, 20, 616. https://doi.org/10.3390/s20030616

Peng Z, Du Y, Ding Y. Highly Sensitive, Calibration-Free WM-DAS Method for Recovering Absorbance—Part II: Experimental Analysis. Sensors. 2020; 20(3):616. https://doi.org/10.3390/s20030616

Chicago/Turabian StylePeng, Zhimin, Yanjun Du, and Yanjun Ding. 2020. "Highly Sensitive, Calibration-Free WM-DAS Method for Recovering Absorbance—Part II: Experimental Analysis" Sensors 20, no. 3: 616. https://doi.org/10.3390/s20030616

APA StylePeng, Z., Du, Y., & Ding, Y. (2020). Highly Sensitive, Calibration-Free WM-DAS Method for Recovering Absorbance—Part II: Experimental Analysis. Sensors, 20(3), 616. https://doi.org/10.3390/s20030616