Abstract

In recent decades, nonlinear damping identification (NDI) in structural dynamics has attracted wide research interests and intensive studies. Different NDI strategies, from conventional to more advanced, have been developed for a variety of structural types. With apparent advantages over classical linear methods, these strategies are able to quantify the nonlinear damping characteristics, providing powerful tools for the analysis and design of complex engineering structures. Since the current trend in many applications tends to more advanced and sophisticated applications, it is of great necessity to work on developing these methods to keep pace with this progress. Moreover, NDI can provide an effective and promising tool for structural damage detection purposes, where the changes in the dynamic features of structures can be correlated with damage levels. This review paper provides an overview of NDI methods by explaining the fundamental challenges and potentials of these methods based on the available literature. Furthermore, this research offers a comprehensive survey of different applications and future research trends of NDI. For potential development and application work for nonlinear damping methods, the anticipated results and recommendations of the current paper can assist researchers and developers worldwide to find out the gaps and unsolved issues in the field of NDI.

1. Introduction

In recent decades, a huge number of engineering structures such as various civil structures (e.g., bridges, dams, buildings, etc.), rotating machines, aircraft, etc., have been designed and widely used in real life-services [1]. Such structures, with either simple or complex geometric or material properties, are subjected to different levels of vibrations from numerous sources, including earthquakes, wind loads, vehicle motions, imbalance of rotating machines, etc. [2]. Excessive levels of vibrations largely affect the performance, health condition, and serviceability of structures and even lead to structural instability and failures [3].

In general, structural damping is a preferable dynamic characteristic able to reduce the degree of system vibrations to an acceptable level [4]. Damping and its variation occur due to the continuous dissipation of energy [5], both internally and externally, linked with factors such as material degradation, geometrical changes, boundary conditions, etc. [6]. With complex mechanisms, structural damping is commonly classified into three types. First, the fluid damping, which originates from hydrodynamic or aerodynamic forces surrounding the structures [7]. Second, the material damping, which appears due to complex atomic-molecular interactions inside materials [8]. Third, the structural damping, resulting from Coulomb friction between parts within a structural system [9]. For damping characterization, several simplified models have been suggested; for instance, viscous damping, hysteretic damping, and Coulomb frictional damping models [10]. In real applications, equivalent viscous damping is commonly used to model the overall behavior of damped systems [11].

Most structural systems show a certain extent of nonlinearity associated with different sources [12,13]. However, neglecting the nonlinearity is acceptable in many cases for the sake of simplification of analysis [14,15]. In other cases, nonlinear behavior plays a dominant role. Nonlinearity neglection should be prevented in such cases, as it may lead to erroneous predictions of system behaviors [16]. Among the causes of system nonlinearity, nonlinear damping [17,18] is often regarded as the most influential; this complexity of which makes it challenging to perform system identification [19]. Moreover, to better accommodate the development of advanced material with strong nonlinear behavior, research on the impact of nonlinear damping is of increasing importance [20,21,22].

Some damping identification approaches, theoretical and experimental, have been developed [23]. Experimental techniques for damping estimation show advantages in accuracy and reliability. Damping identification approaches provide straightforward explanations for damping properties as compared with theoretical approaches [24]. The enhancement technique of engineering structures is carried out by measuring inputs and outputs during the experiment of real structures. This enhancement technique is made to avoid unwanted behavior of the system subject to damping effects [25].

Several hypotheses can be used for linear and nonlinear damping of low-damping systems [26,27,28]. High-damping systems usually involve structural damage [29]; however, nonlinear effects on vibrating systems cannot be neglected because of their significant impact on dynamic behaviors [30,31]. Linear damping approaches can provide precise structural numerical predictions [32,33]. Nevertheless, in numerous modern applications, the effectiveness of these methods cannot be guaranteed, especially when the structures are complex, e.g., composed of composite materials or operating in a hostile environment [34,35]. Therefore, linear methods should be limited to identifying damping in specific simple structures that operate under normal conditions [36]. These drawbacks have, in the last decade, contributed to the rapid development of nonlinear damping methods [37,38].

Damping identification is a challenging task [39] performed by developing a variety of analytical [40,41,42] and experimental methods of linear and nonlinear systems [43,44,45]. Moreover, NDI is a practical aspect being conducted to prevent structural failure and tragic events caused by structural damages [46,47]. In addition to enhancing the safety and maintenance of key structures, it also contributes to the control of systems and predicting structural systems responses under nonlinear damping properly [48,49].

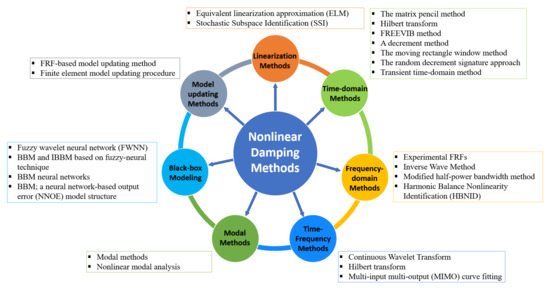

NDI for dynamic systems can be classified into seven categories: Linearization methods, time-domain methods, frequency-domain methods, time-frequency methods, modal methods, black-box modeling, and model updating methods [1]. Classification can also be made from other perspectives, for example, parametric and non-parametric [50,51]. An example of linearization methods is the equivalent linearization approximation (ELA), which is a common method used in applications such as a spring-suspended sectional model system. ELA is utilized for bridges and aeroelastic systems and dampers and shock absorbers used in control systems [52].

The time-domain methods are well-known methods such as the log decrement method used in lightly damped systems and aeroelastic systems [53,54]. In addition, the Hilbert transform (HT) is used to analyze vibration systems [55], heat exchangers, and damage detection of reinforced concrete (RC) structures and composite materials [56,57]. The frequency-domain methods are known by their mathematical simplicity and ability to provide insightful interpretation [58]. For example, harmonic balance nonlinearity identification (HBNID) was employed in systems such as civil engineering, actuators, bioengineering devices, sensors, and robotics [59]. Furthermore, the frequency response functions (FRFs) have been widely utilized to study nonlinear damping in adhesive joints [60,61].

Time-frequency methods, e.g., those based on continuous wavelet transform (CWT), are powerful tools used in applications such as vibration absorbers that are broadly used in naval architecture, rotor-bearing systems, and constructions [62]. In addition, HT was employed in applications such as unbalance of rotating machines, ship movement control, and damage detection of RC beams based on free vibration measurements for nonlinear damping determination [63]. Modal methods are considered particularly useful in the field of structural dynamics and damage identification. The resonant decay method (RDM) was applied to investigate the nonlinear damping in civil, aircraft, and various types of dampers [23]. The wavelet transform (WT) was used in instantaneous damping coefficient identification for damage detection in concrete, automotive, aerospace, and simple built-up structures comprising two bolted beams [64]. Black-box modeling (BBM) is an accurate and efficient method in describing the dynamic behaviors of structures. For example, a fuzzy wavelet neural network (FWNN) was used for nonlinear identification in systems such as vehicle magnetorheological (MR) fluid dampers, aeroelastic systems, modern industries, control systems, and military and defense equipment [65].

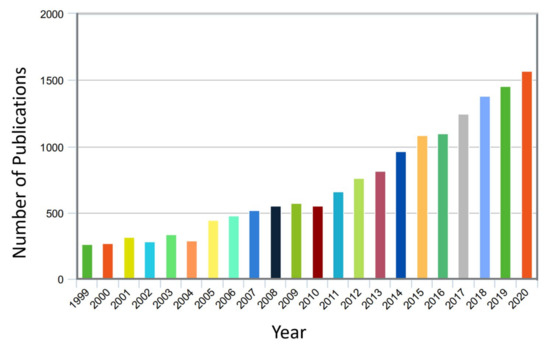

Model updating methods include, for instance, the identification of structural damping using the FRF-based model updating method and damping identification for accurate prediction of the measured FRFs using finite element updated models of the mechanical system [66,67]. Recently, several studies were conducted on dynamic systems. These studies showed the high feasibility of the NDI methods compared to the linear methods because they give more reliable results despite their difficulty [1]. The nonlinear research focuses primarily on the development of efficient and functional methods for reacting to nonlinear structural damping as a fundamental scientific and technological problem. A survey of available research in the engineering community has provided many studies of nonlinear damping, as shown in Figure 1. It is expected that interest from researchers in this field will continue.

Figure 1.

The number of publications for nonlinear damping studies (According to the Scopus engine system in the duration from January 1999 to November 2020).

To summarize, NDI methods are essential and emerging methods leverage on their importance in structural dynamics in general. Such methods are able to provide crucial aspects and useful tools to track structural changes and dynamic alterations. Moreover, this can deliver potential future research in the field of structural dynamics as well as damage identification.

This review paper discusses the progress of NDI methods based on available literature in terms of surveying possible methods and applications. Section 2 offers a critical review of the recent nonlinear damping methods based on previous studies to identify the role and placement of NDI methods. Nonlinear damping methods are also discussed using their theoretical principles and schematic diagram. The second section is followed by an overview of possible applications of nonlinear damping methods in many different fields. At the end of this work, a summary and concluding remarks are presented.

2. Nonlinear Damping Identification Methods

The early study on the identification of nonlinearity of structural models can be traced back to 1970s [1]. The objective of this section is to survey the NDI methods that evolved over the last few years as a result of the development of novel industrial materials and structures [68]. Various nonlinear factors have led to different systems’ behaviors, which means that each system has unique behavior and therefore requires a different approach [69]. Relevant studies were first focused on single-degree of freedom (SDOF) systems [70]. Then, with the advancement of computational techniques, studies were extended to more complex, multi-degree of freedom (MDOF) systems [71,72,73]. Specific structural types under investigation include bridges, tall buildings, aircraft, etc. [74]. Apart from previous review articles that are mainly about nonlinear system identification [1,2,23], the focus of this study resides on the development of various NDI methods. The methods can be classified into seven categories, as shown in Figure 2.

Figure 2.

Nonlinear damping identification methods.

2.1. Linearization Methods

The linearization method is a process whose objective is to approximate a nonlinear system that is described by a nonlinear differential equation with a linear one for ease of processing. Equivalent linearization (EL) is a widely used approximation method for dynamic system analysis [75]. Krylov and Bogoliuboff introduced the first linearization process of deterministic systems. The stochastic systems approach was then extended by Caughey. Then, some expanded versions of the equivalent linearization method have been established. The Equivalent Linearization method is considered the most accessible tool extensively used for analyzing nonlinear stochastic problems, but its accuracy depends on the averaging process [76]. Other classical methods include the Fokker-Planck equation, moment closure, stochastic averaging, perturbation, etc. However, they are limited to relatively straightforward and specific nonlinear systems, and some of them are computationally expensive, mainly when applied in MDOF systems [77].

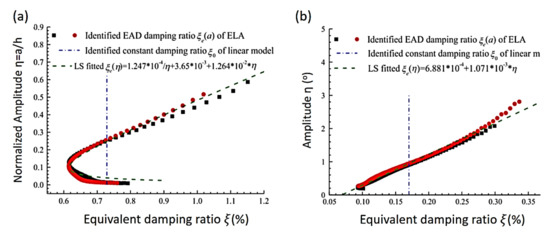

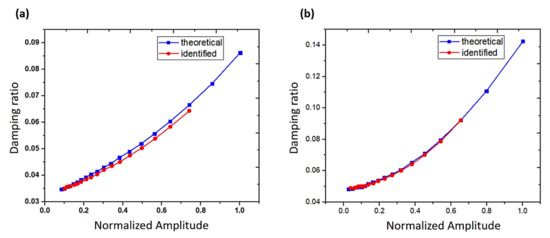

Wang and Low [78] proposed a reliable EL method to predict the response of nonlinear systems with viscous damping subject to impact. Moreover, the influences of nonlinearity and viscous damping on the safety of packaged products were discussed. Additionally, coefficients such as the damping ratio in the cushion system were investigated. According to their analysis, both the nonlinear properties and viscous damping afforded are proven to be positive factors able to minimize the rigid impact to some extent. Bajrić and Høgsberg [79] presented an approach for output-only system identification. This method is effective for analyzing the random responses with SDOF oscillators under hysteretic damping. The Bouc-Wen model was used to take advantage of the restoring force to derive the model of an equivalent linear relaxation. The identification was carried out in the state space, where the derived linear relaxation damping model replaced the hysteretic system model. The equivalent linear model proposed that the response motion is harmonic with a slow variation of phase and amplitude, and thus the method was restricted to tackle narrow band response. To study a spring-suspended sectional model system of bridges, Gao et al. [80] developed an EL approach to improving the precision of measuring self-excited force in the sectional model test. The effect of added damping and stiffness on the free decay response at zero wind speed state was explored. Based on their findings, the nonlinear characteristics associated with the influence of the added damping influences are much more significant than that associated with the influence of the added stiffness. In another work, Gao and Zhu [81] proposed an approach where the spring-suspended sectional models (SSSM) were used to evaluate the equivalent amplitude-dependent damping ratio and frequency. The equations of the ELA are derived by applying a multiple-scale method to represent the mechanical nonlinearities in the first-order approximate sense. The proposed ELA and nonlinear system identification methods are then found to be accurate enough to model the mechanical nonlinearities of the proposed system. Figure 3 shows a comparison of identified equivalent amplitude-dependent damping and natural frequency of the SSSM under bending and torsional modes. The nonlinear behavior of damping ratios originates from complicated energy-dissipative mechanisms, such as material damping, Coulomb friction, viscous damping, and nonlinear damping caused by additional SSSM system dampers. In an ELA, weak nonlinear response of a SDOF system is considered as a perturbation on the responses of undamped oscillators, so a nonlinear motion equation that governs the free decay response of the system is presented as follows:

where is the displacement; is the velocity; is the acceleration of the sectional model; is the circular frequency; is the generalized nonlinear force; and is a small factor showing that the previous term is a small quantity; is the linear restoring force. Equation (1) can be solved based on the Krylov–Bogoliubov averaging approach. An ELA method was then applied to model the physical nonlinearity of a weak nonlinear system by using a damping coefficient D(A) and a restoring force coefficient S(A),

and by inserting the equivalent viscous damping ratio and frequency, Equation (2) can be represented as:

where is the equivalent amplitude-dependent damping ratio; is the equivalent circular frequency.

Figure 3.

Comparison of identified equivalent amplitude-dependent damping and natural frequency of the spring-suspended sectional models. (a) Bending mode; (b) torsional mode [81].

Both nonlinear damping and frequency depend on amplitude and are accurate in modeling the physical nonlinearity of a weakly nonlinear spring-suspension system.

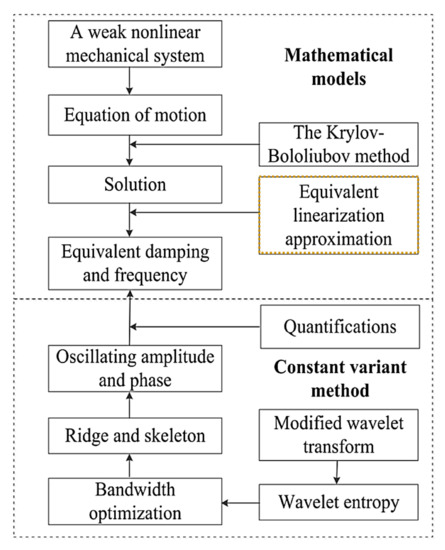

Recently, Chen and Tse [82] proposed an enhanced method to determine the physical nonlinearity of weakly nonlinear spring suspension systems. The method was effectively implemented in hybrid aeroelastic pressure balance (HAPB) systems. In the HAPB system, the frequency and damping associated with a linear model are constant and cause major differences in predictions of response due to ignorance of the system’s slowly changing characteristics. The solution of a proposed system is obtained by deriving the averaging method of Krylov–Bogoliubov and the ELA method, as shown in Figure 4.

Figure 4.

A diagram for nonlinearity identification of weakly nonlinear systems [82].

2.2. Time-Domain Methods

In time-domain methods, analyzed data are in the form of time-series during the identification process [83]. The benefit is the simplicity in data analysis without much cost of time and effort since the time history of data can always be acquired directly [84].

Typical work is introduced by Jacobson et al. [85], where they evaluated the damping identification methods using time-domain simulation based on an aeroelastic system for the applications of flutter constraints to gradient-based optimization. Several time-domain methods were applied with CFD-based methodology. The matrix pencil method was demonstrated to be the most effective approach in estimating damping over a set of input signals. In another study of heat exchanger tube arrays, Eret and Meskell [86] investigated the validity of two identification methods applied in a SDOF fluid elastic system by using experimental data. The free vibration analysis (FREEVIB) method was used to identify nonlinearity and was then compared with the nonlinear decrement method. According to the results, the nonlinear decrement method produced more accurate results. Nevertheless, its deficiency was that the functional form of the system needs to be predetermined. Meskell [87] presented a technique for simultaneously evaluating different types of nonlinear damping and viscous damping. This technique relies on successive peak decrements in the transient system. The study was restricted to SDOF systems. This technique was optimized based on the consideration that the system was weakly nonlinear, lightly damped subject to linear, and cube damping. The accuracy of this method was demonstrated using simulated responses. It was concluded that the method was promising for a lightly damped system using experimental data, particularly in fluid elastic systems. Frizzarin et al. [88] developed an approach for damage detection in a concrete structure. The approach relies on the analysis of nonlinear damping extracted from structural vibration responses. The feasibility of the approach was demonstrated using a large-scale concrete bridge model suffering from seismic damage caused during shaking table tests. Nonlinear damping was successfully identified by random decrement signature approach based on its ambient vibration responses. The results showed that the magnitude of nonlinear damping increased along with an increasing degree of seismic damage. Strong correlation between increasing nonlinear damping and degrading structural stiffness was also found.

A method of nonlinear damping analysis using ambient vibration data was developed for baseline-free damage detection in RC structures. Viscous and friction damping models were combined to obtain the envelope of free vibration response of the structure, as shown in Equation (4):

where is the initial amplitude; is the natural frequency; and are the damping ratios for viscous and friction damping, respectively.

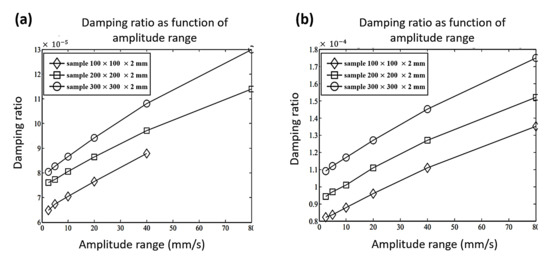

Another time-domain method was proposed by Wu et al. [89] to enable simultaneous identification of nonlinear damping and Coulomb friction in mechanical systems. A moving rectangular window method was introduced based on nonlinear damping properties. Different models of nonlinear damping in a SDOF system were studied, with a constant amount of Coulomb friction. The simulation results showed that the proposed identification technique was efficient and applicable. Furthermore, the identification precision of nonlinear damping was higher than that of the force of Coulomb friction. Figure 5 presents the nonlinear relationship between the damping ratios and amplitudes in terms of exponential and quadratic functions, respectively. The accuracy of determining the quadratic damping is the highest compared to that of determining other types of nonlinear viscous damping. In the quantification of unwanted effects on the overall measured damping of steel alloys, Vanwalleghem et al. [90] identified external damping sources in damped material by applying transient time-domain methods and introducing an effective damping test setup configuration. The results showed that the value of damping was dependent on both the specimen size and level of excitation. In addition, damping will increase with enlarged response amplitudes regardless of the sample sizes, as illustrated in Figure 6. Moreover, the damping capacity differed from one steel alloy to another. Therefore, one type cannot be generalized to others. In another related work, Baştürk et al. [91] studied the nonlinear dynamic response of hybrid laminated composite plates under the influence of blast load with damping involved. The effects of factors such as damping ratio, aspect ratio, and various values of peak pressures were studied. The thermal effect of the blast wave was avoided throughout the analysis. The results showed that the amplitude of the damping ratio played a significant role in the deflection of the plate and the frequencies. The vibration amplitude decreased in a short time due to the damping effect. Recently, Feldman and Braun [92] presented promising experimental methods for the identification of nonlinear damping and stiffness in a vibration system. The methods were based on measuring inputs and outputs in the time-domain and the implementation of the Hilbert transform of the measured signals under free and forced vibration states. Based on their findings, the approach of nonlinear characteristics representation was accurate and efficient.

Figure 5.

Curves of damping ratio versus amplitude. (a) Exponent relationship; (b) quadratic relationship [89].

Figure 6.

Damping ratio as a function of (a) specimen response amplitude (first mode shape); (b) specimen response amplitude (second mode shape) for three specimen sizes [90].

2.3. Frequency-Domain Methods

The frequency domain-method is featured by handling data in the form of spectra or FRFs throughout the identification process [93]. Some frequency-domain methods have been reviewed in technical literature in the past years [94,95]. These methods show advantages such as ease of computation and the ability to give some explanations of nonlinear systems [96]. Unlike time-series signals, the data processed in the frequency domain could take various forms, such as Fourier spectra, power spectra, or any other form [97,98]. Since data analysis in the frequency domain only focuses on a specific frequency range, the computational burden can be reduced, and a large number of nonlinear parameters can be calculated precisely and effectively [23].

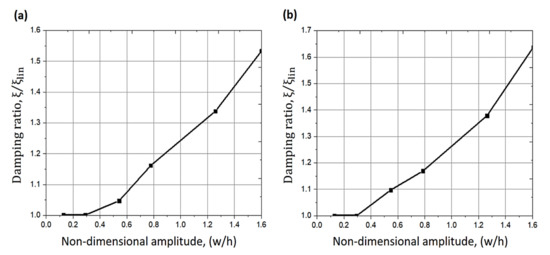

Sun et al. [99] presented a modified method for damping identification for a nonlinear stiffness structure based on the well-known half-power bandwidth method. The formula was verified by using numerical simulation. The procedure has been validated by applying a hard coating specimen with soft nonlinearity, and the damping parameters of the structure were acquired under various exciting levels. Thothadri et al. [100] extended a nonlinear system identification method named harmonic balance nonlinearity identification (HBNID) to the MDOF fluid-structure systems. Two theoretical models were examined using this extended method. The results showed that HBNID worked well in determining unknown parameters if the model structure was identified. In another related study, Balasubramanian et al. [101] conducted experimental and numerical investigations to determine the increase in damping with the amplitude of the vibration of a rubber plate using three different dissipation models. The nonlinear responses were measured utilizing a laser Doppler vibrometer. According to the results, the increase of damping was around 60% when the vibration amplitude is 1.6 times the plate thickness. The dissipation determined from various models was examined as it confirms the predominant nonlinear nature of damping as a function of the amplitude of vibration, as shown in Figure 7. To reduce the vibration in vehicles for the comfort of occupants, Ho et al. [102] investigated, experimentally and numerically, the vibration isolation using the nonlinear damping performed by a MR damper. The frequency-domain technique was adopted, as the efficiency of the isolation system could be assessed over a wide range of frequencies. Experimental and numerical results showed that a good effect of vibration isolation around resonance regions and high frequencies was achieved, and hence significantly improved conventional dampers’ performance.

Figure 7.

Changes of damping ratio with respect to the amplitude of vibration (a) using model 1, (b) using model 2 [101].

The equation of motion representing the nonlinear viscous damping of a SDOF vibration isolation system can be expressed as:

where ; M is the mass; is the spring stiffness; is the nonlinear damping force given by

where is the constant of the nonlinear damping; , is the damping exponent; is a sinusoidal input displacement specified by with frequency and amplitude .

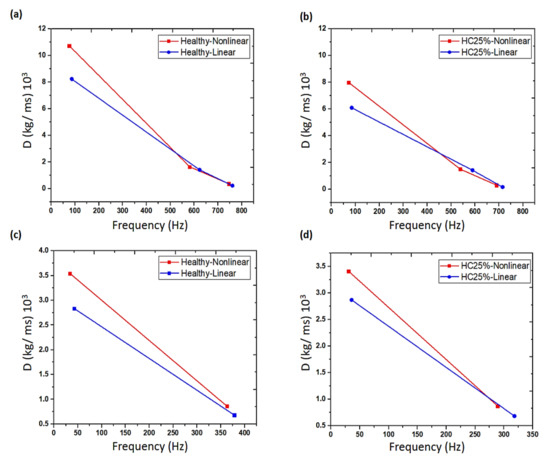

Pazand and Nobari [103] investigated the effects of damage on the effective damping of viscoelastic adhesives using the inverse-eigen sensitivity identification method for adhesive behavior in the linear and nonlinear regions. Results showed that the adhesive damping decreased when frequency decreased. Additionally, debonding damage had an adverse influence on adhesive damping, and the reduction (softening) became more important as the rate of damage increased. Figure 8 shows that the effective adhesive damping decreases with increasing frequency in both linear and nonlinear regions. In addition, the reduction pattern is different for various modes such as bending and shearing modes. Cherif et al. [104] presented a damping loss factor assessment approach for two-dimensional structures based on the measurement of the displacement field by using a laser vibrometer. This approach was then compared with the other three approaches: i.e., half-power bandwidth method, decay rate method, and steady-state power input method. From the results, the proposed inverse wave approach was accurate and reliable for the evaluation of the wavenumber and damping loss factor. Figure 9 shows that at mid frequencies, the three methods agree well, but at low frequencies about (100–300) Hz, the power input method shows some discrepancy compared to other methods. The explanation is that these frequencies have a low number of modes. At high frequencies, the damping loss factor evaluated by both the decay rate and the inverse wave methods was in good agreement. Roncen et al. [105] experimentally and numerically analyzed the nonlinear rubber isolator, which was subjected to two random excitations, i.e., the harmonic and broadband excitations. The relation between the stiffness and the damping versus the amplitude of the relative displacement of the rubber isolator was investigated. Nonlinear vibration prediction of the beam exposed to random excitation was conducted by adopting the harmonic balance method and shooting method. According to the comparison between the experimental and numerical investigations, it was observed that there were functional correlations between harmonic and broadband random excitations. This demonstrates the validity and efficacy of the rubber isolator modeling as well as the proposed nonlinear methodology. Recently, Colin et al. [106] investigated many nonlinear quadratic damping features of cantilever beams under harmonic base excitations. The frequency-domain identification techniques were used to identify the linear and nonlinear modal damping coefficients.

Figure 8.

Identified effective damping coefficients for linear and nonlinear areas, for the intact and damaged bonds (a,b) with bending modes, (c,d) with shear modes [103].

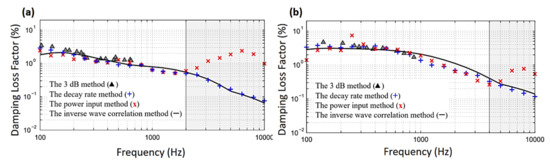

Figure 9.

Effect of frequency on experimental damping loss factor of (a) a thin composite panel, (b) a thick composite panel [104].

2.4. Time-Frequency Methods

Recently, applications of time-frequency domain methods have become more frequent and widespread than time-domain and frequency-domain methods [107]. These methods detect damping through common temporal and frequency characteristics of the responses of the vibrating structures resulting from the analysis using time-frequency methods [108,109]. Several methods have recently been presented to perform time-frequency analysis [110,111,112]. One of the most robust approaches is the continuous wavelet transform, which has been progressively utilized for NDI in different applications. A common property of nonlinear vibrations is that, according to the form of nonlinearity, both instantaneous natural frequency and damping coefficient may become time functions [113].

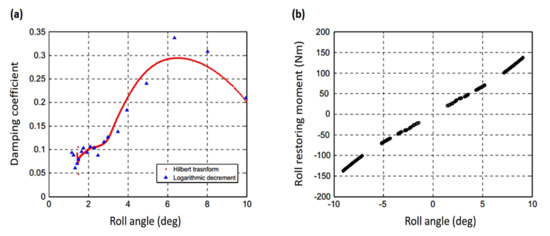

In the field of ships and floating bodies, Kim and Park [114] predicted the nonlinear damping and restoring coefficient of a floating production system via the Hilbert transform of free decay signal obtained by a free-roll decay experiment. A comparison was made between the present method and the traditional logarithmic decrement method in the performance of damping coefficient identification. The damping and restoring moment’s nonlinear coefficients were successfully obtained. Figure 10 shows some fluctuations at a small roll angle; however, damping can only be approximated using a quadratic model within a roll angle range of around 6 rad; beyond this range, the damping coefficient decreases. This is owing to the vortex memory effect nearby the bilge keel. The presented technique shows greater accuracy than the logarithmic decrement, especially when the nonlinear terms are combined in the restoring term.

Figure 10.

The floating production storage and offloading identified dynamic parameters with respect to the roll angle. (a) Damping coefficient; (b) restoring moment [114].

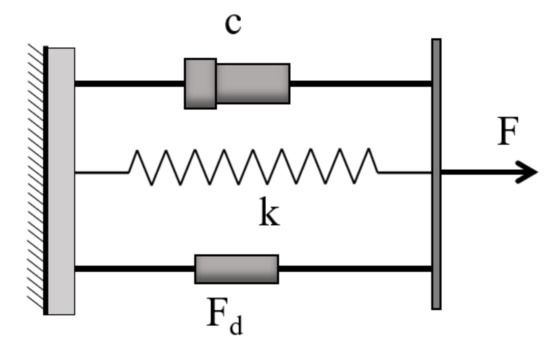

Franchetti and Modena [115] developed a damage detection technique for precast Prestressed reinforced concrete (PRC) structural members based on free vibration experiments and NDI. Three precast specimens of the PRC beam were tested. The dynamic responses were analyzed by using various methods, including the multi-input multi-output (MIMO) curve fitting and the HT method. The actual energy dissipation mechanism of the PRC beams was represented by a proposed nonlinear quadratic damping factor associated with actual damage levels. The results revealed that the quadratic damping factor could be used efficiently to detect damage due to its high sensitivity. However, the effectiveness of this approach might be constrained by the difficulty of obtaining a free structural vibration response. The pure viscous damping and polynomial damping are combined in the proposed model, as displayed in Figure 11. The most popular form of the force of polynomial damping is quadratic:

where is a constant, and the value of the absolute velocity is added to ensure that the force is at all times velocity opposed.

Figure 11.

The combined damping model [115].

The equation of motion of the combined viscous and quadratic system can then be represented as follows:

where m is the mass, c is the viscous damping coefficient, and k is the stiffness,

where a is the amplitude of oscillation, a0 is the initial amplitude, c1 and c2 are constants, and t is the time. The exact solution of pure viscous damping () is formulated as follows:

Tang et al. [116] experimentally investigated the assessment of the nonlinear vibration absorber parameters from free vibration tests. HT was utilized to estimate both instantaneous amplitude and damped natural frequency. Then the stiffness and damping were determined for a nonlinear vibration absorber. By comparing the present method and Restoring Force Surface (RFS) method, it was shown that there was a difference of only about 13%. Chandra and Sekhar [117] presented a nonlinear damping estimation approach in a rotor-bearing system using the CWT based method. Two different nonlinear damping models were examined. The free vibration signal envelope was obtained by employing the wavelet-based approach. The validity and applicability of the proposed method were reported using the acquired signals from the experimental results. Joseph and Minh-Nghi [118] used wavelet transform in the identification and quantification of damping in a nonlinear oscillator based on free decay response. Two methods based on wavelet transform have been used; firstly, the cross-section of the wavelet transform, secondly, the ridge and skeleton of the wavelet transform. The proposed method herein was used to study a nonlinear SDOF oscillator exclusively. Numerical results showed that the method is accurate in the estimation of natural frequency and damping coefficient, even with noisy data.

Curadelli et al. [119] introduced a new scheme for structural damage detection using the instantaneous damping coefficient identification via wavelet transform. Based on their findings, the damping of various structures is significantly affected by the existence of damage. Evidence for damage effects on the dynamic characteristics of the RC frame has been provided. Therefore, the structural damping parameters can be used as damage indicators due to their high sensitivity to damage existence. It has also been shown that the wavelet transform can be used to determine the damping through a structural response to free vibration.

In another related work, Heller et al. [120] experimentally analyzed the influence of mechanical joints and their functional parameters on the dynamic behavior of built-up structures. The equivalent modal parameters based on the application of wavelet transformation used to the free-decay response were adopted to describe the expected nonlinear dynamic behavior. Experimental results demonstrated that the frictional joints are the major sources of energy dissipation during the relative motion of substructures in the built-up structure. Furthermore, the negative damping capacity can be significantly increased by widening the interface area.

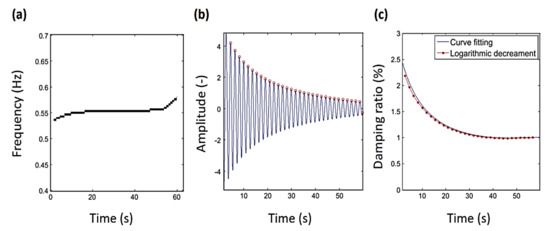

Recently, Dziedziech et al. [121] examined the dynamics of a tuned liquid column damper (TLCD), where the time-varying characteristics of nonlinear damping and other properties were identified. CWT was used for mode separation, and then the recognition of the instantaneous damping ratio of the first mode of vibration was conducted. The findings showed that the damping ratio was nonlinear, time-varying, and based on the level of vibration. The introduced model can be employed to represent the dissipative behavior of the first mode of vibration of the tuned liquid column damper. The time-varying damping was successfully recognized utilizing the combined envelope analysis, curve fitting, and logarithmic decrement, as shown in Figure 12.

Figure 12.

The first mode identification results of vibration of the analyzed tuned liquid column damper (TLCD): (a) Natural frequency, (b) vibration response, (c) damping ratio [121].

2.5. Modal Methods

Modal characteristics are considered highly important in the process of designing linear engineering structures [122]. Typical structural modal parameters are natural frequencies, mode shapes, and damping [123]. It is a beneficial tool used in the study of the dynamic behavior of various structures around their resonance state. This linear approach is considered to be mature and widely used [124]. On the contrary, methods for identifying nonlinear modal are in one of the promising directions of recent research in the field of structural dynamics [125,126]. Some related approaches have been introduced in the surveys in 2006 and 2016 [1,23]. Noteworthy progress has been made over the past two decades, so nonlinear modal identification is a very active field of study [23].

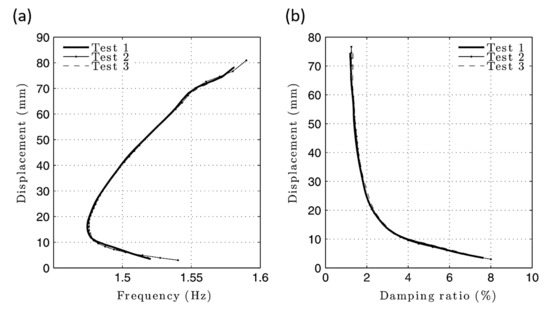

In order to improve engineering designs, reliability, and performance of structures, Mezghani et al. [127] investigated the dynamic characteristics of an isolator consisting of stiffness and damping elements. The investigations were performed under various excitations to promote the minimization of the vibration transmissions using modal methods. The proposed nonlinear identification method allows designers to predict nonlinear dynamic behavior via experimental data. Results revealed that the present technique is valid and applicable in determining the nonlinear parameters of a metal mesh isolator. The nonlinear damping may also be suppressed as the base excitation amplitude increases. Naylor et al. [128] introduced the resonant decay method to estimate the MDOF nonproportional damped systems. Though there were some imperfections, the method performed well and produced an acceptable modal damping matrix. The results indicate that there were small errors in the estimation process. Londoño et al. [129] introduced a method to extract the backbone curves of the lightly damped nonlinear systems utilizing a modified resonance decay method. The experimental and numerical results show that the proposed procedure can offer an accurate estimation of damping ratios. Moreover, results indicate that the small damping ratio lower than 5% does not influence the estimated instantaneous frequency of the nonlinear system, as shown in Figure 13.

Figure 13.

The estimated skeleton curves from the experiment: (a) Frequency (Hz); (b) damping ratio (%) [129].

By analyzing the envelope of decaying response, the dissipation properties of the system can be evaluated. For a classic, well-known SDOF system with a common equation

where is the acceleration; is the velocity, is the displacement, is the damping ratio, is the natural frequency.

In terms of system parameters and initial conditions, the envelope of the free vibration response can be represented as

It should be noted that the operation of damping is accounted for by the exponential term. This expression can be generalized to enable the change of instantaneous frequency and damping, which would occur in a nonlinear system by modifying Equation (12) to be

The effective damping then could be determined by

where denotes the instantaneous angular frequency. Therefore, the effective damping ratio can be assessed from the envelope tangent slope of the decaying response represented in a semi-logarithmic scale with respect to time.

Krack et al. [130] developed a novel reduced order model (ROM) method for numerical calculation of nonlinear modes of mechanical systems. The study included some types of nonlinearity, such as dissipative and strong and non-smooth nonlinearities. The nonlinear modal characteristics were utilized to evaluate the forced and self-excited vibration. The obtained results were in very good agreement with results obtained by conventional approaches. In another related work, Krack [131] proposed an identification method of the nonlinear modes of nonconservative systems. Two methods for nonlinear modal analysis were presented: The harmonic balance method and the shooting method. The results show that the proposed method provides accurate predictions for a broad range of working conditions. However, it is limited to the isolated nonlinear modes and low modal damping ratios as it is also restricted to periodic motions. Peter et al. [132] numerically and experimentally proposed a new technique for the nonlinear modal analysis of non-smooth mechanical systems. The numerical technique was found based on two combined methods. They are the harmonic balance method and the shooting method generating a time-frequency representation. In comparison, the experimental technique relies on a nonlinear phase resonance method. It was found that the numerical results were in good agreement with results obtained by experiments. Scheel et al. [133] developed a new technique based on an experimental procedure for nonlinear modal testing for modern turbine blades. The technique allows the experimental extraction of modal damping ratios in addition to both natural frequencies and deflection shapes as a function of the vibration level. It is simple and more time-effective as its validity and accuracy have been proved through comparison to other methods. It also has high resistance against measurement noise and does not require much prior knowledge of the tested systems or special equipment. In another related work, Scheel et al. [134] designed a new test rig named rubbing beam resonator for experimental nonlinear modal analysis. The proposed method performs the analysis based on the concept of the extended periodic motion in order to obtain the modal characteristics. The results show that the modal damping ratio increases by about 15%, while the frequency decreases by 36% for the first mode of vibration. Recently, Karaağaçlı and Özgüven [135] proposed a nonlinear experimental modal analysis procedure called response-controlled stepped-sine testing (RCT) to extract the nonlinear modal parameters. Many nonlinearities at different places were investigated numerically and experimentally. The numerical and experimental results showed that the proposed identification procedure was efficient and applicable to many applications.

2.6. Black-Box Modeling

Nonlinear black-box is a typical model used to characterize nonlinear dynamic behaviors of systems only based on data. Nonlinear black-box modeling is a mapping from past observed data to a regressor space pursued by a nonlinear function expansion type, mapping to the space of the outputs of the system [136]. Nonlinear mapping can be performed by several methods, e.g., wavelet networks, artificial neural networks, and neuro-fuzzy models [137].

Witters and Swevers [138] discussed the black box identification of an electro-hydraulic semi-active damper for a vehicle suspension. For the representation of the complex nonlinear damper dynamics, a neural network-based output error structure has been chosen. It has been shown that a model described using single optimal testing can adequately describe the nonlinear dynamic behavior of the damper throughout its entire working period. Truong and Ahn [139] introduced a nonlinear black-box model and an inverse black-box model to study the magneto-rheological fluid damper. A fuzzy mapping system is used for the identification of the damper properties. A neural network method was used to improve the accuracy of the model by decreasing the modeling error function. A series of investigations were performed to verify the effectiveness of the models on two systems using the same damper. Khalid et al. [140] investigated a small-scale MR damper model with the valve mode mechanism using a dynamic recurrent neural network modeling method to generate its hysteretic nonlinear response. The modified model of Bouc-Wen was used to generate the training data to construct the numerical model. The results show that the proposed model is effectively capable of accurately predicting the MR damper response over a wide range of operating conditions. Recently, Dou et al. [141] investigated a nonlinear identification method based on a fuzzy wavelet neural network for a nonlinear aeroelastic system. Nonlinear damping was considered in the aeroelastic system identification, and a new FWNN structure was introduced. Numerical simulation shows that the fuzzy wavelet neural network attained a high level of accuracy and effectiveness.

2.7. Model Updating Methods

Finite element (FE) model updating is an operation intended to calibrate the FE model of a structure for matching the experimental and numerical results [142,143]. This process aimed to obtain an accurate model that is able to reproduce the measured data [144,145,146]. Despite the rapid development of computer-aided methods, numerical models still need to be compared with empirical data to update them in order to improve their accuracy and reliability [147].

Arora et al. [148] proposed a new scheme for damped FE model updating to improve the FRF compatibility based on the implementation of the damping identification method. Two steps are carried out, the first is the updating of mass and stiffness matrices using the response function method, and the second is the identification of the damping matrix following the first step. The results show that the updated model is able to predict the measured FRFs.

First, the eigenvalue problem related to a viscously damped system written as

where M, C, and K are the mass, damping, and stiffness matrices, respectively; and are the complex eigenvectors.

Furthermore, the damping matrix can be assessed using the following relation

where is the diagonal matrix of complex eigenvalues, and the overall bar refers to complex conjugations. The complex eigenvectors are standardized as

The updated mass and stiffness obtained in the preceding part are exploited to normalize complex eigenvectors.

Recently, Arora [149] introduced a new technique for the identification of structural damping. It is a direct and explicit identification method. The updated matrices of mass and stiffness were used for the identification of the structural damping matrix. Some instances were provided, illustrating the performance of the proposed technique. According to the results, the current technique was accurately proficient in predicting the experimental FRFs of the system with all damping levels. Table 1 summarizes the NDI methods in several application areas, with some strengths and weaknesses of these methods based on previous studies. It also provides a useful means for researchers to compare the different studies and facilitate understanding of the NDI methods.

Table 1.

Literature survey of nonlinear damping identification methods.

3. Trending Applications

In recent years, many engineering applications have used nonlinear damping to study the nonlinearity phenomenon. This phenomenon has been exploited in the development of various areas of life, such as automotive, bridges, buildings, aerodynamics, marine, defense, and bio-engineering, as shown in Figure 14. This progress would not have been possible without the development of technologies that helped to build and test these applications in terms of safety and reliability [150]. Many improvements have been made to applications such as the use of composites materials and alloys that have good properties that combine safety and performance [151]. Most engineering applications are subjected to unwanted vibrations that should be controlled. Exposure to time-variant loads, such as vehicles, wind, earthquakes, and sea waves, in addition to an imbalance in rotating machines, lead to damage and failure of applications.

Figure 14.

Nonlinear damping applications.

As mentioned earlier, there is continuous development in various practical life applications. One of the most important facts that many new materials and applications exhibit nonlinear behavior. Such structures require nonlinear study. This study can accurately predict the behavior of dynamic systems.

Nonlinear damping is one of the most critical and complex aspects of nonlinearity. Researchers are spending more efforts to develop many solutions, theories, mathematical models, and conduct experiments. These efforts were made to accurately predict the dynamic behavior, control the level of vibrations, and avoid problems resulting from excessive vibrations.

3.1. Automotive Applications

Several real-world applications of nonlinear dynamic behavior have been reported in the literature. Automotive dampers are one example of complex systems in which their responses are unstable. For example, vehicles are facing changing conditions, which can be specifically expressed on the basis of the frequency. Moreover, automotive dampers are robustly reliant on temperature due to viscosity effects, and hence the variation of the damper response. In automotives, brake squeal, which results from the friction difference between the pads and the rotor, is annoying and considered as an example of an unwanted effect of nonlinearity. The rapid development in the design of automotive technology led to more stability in the performance, comfort, and safety of passengers [152].

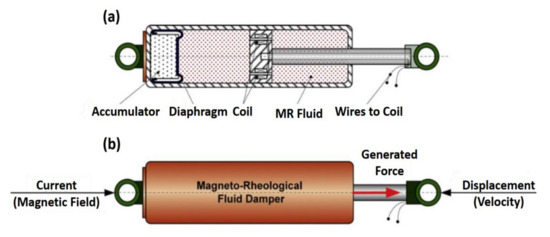

Worden et al. [153] considered three nonlinear system identification methods of the suspension system of automotive dampers. The methods are the restoring force surfaces, the nonlinear identification by the feedback of outputs approach, and the nonlinear optimization using a neural network analogy. This study was performed to provide complete insights into the behavior of the systems. In related work, Metered et al. [154] applied an experimental identification procedure based on the black-box modeling, the feed-forward, and recurrent neural networks. The study was carried out to investigate the dynamic behavior of Magnetorheological fluid dampers and the use of the identified parameters in the control of such damper. In another related work, Truong and Ahn [139] presented a nonlinear black-box model and an inverse black-box model to identify the MR fluid damper and applied them to form a new force-sensorless control approach for any damping system. Figure 15 shows a typical MR fluid damper, the hardware structure, and the working principle, which is widely used in many applications such as automotive, aviation, and control. In another research, Salton et al. [155] developed a nonlinear discrete-time control approach for the fast-tracking of quadrotor-like automobiles. A disturbance observer was performed to assist the system in terms of rejecting disturbances and minimizing the effects of unmodeled dynamics. The nonlinear damping was presented to the system using a composite nonlinear feedback control law. Recently, Bonisoli et al. [156] experimentally investigated the influences of the shock absorber of a vehicle chassis on the identification of modal properties and damping matrices via the Layer Method.

Figure 15.

The magnetorheological (MR) fluid damper: (a) Hardware structure, (b) working principle [139].

3.2. Rotors Applications

It is well known that nonlinearity effects are significant to the stability of rotor dynamics. Foundations and supporting structures have substantial effects on the performance of the rotating machine [157]. Accordingly, an equivalent system of a rotor foundation must be determined to reproduce the vibration behavior of the overall system to represent the actual behavior. Squeeze film dampers are often used in current turbomachinery, particularly aero-engine, to control the vibration magnitude of the rotor. Some necessary information, such as fluid forces, are required to predict the characteristics of such dampers [158].

The high-speed turbomachines used in power generation should be power-saving, economical, and have high performance. Using gas-lubricated bearings may contribute to many advantages like lower power loss, reduced vibration, and higher operating speed. This can be achieved by selecting a suitable damping system [159,160].

The study of rotating structures comprises many different challenges, unlike stationary structures. Nonlinear impacts are apparent once the amplitude levels of vibration are high. The main difficulties associated with defining a linear system of rotor-bearing systems have been discussed in many previous studies, unlike nonlinear systems that still need a broader study.

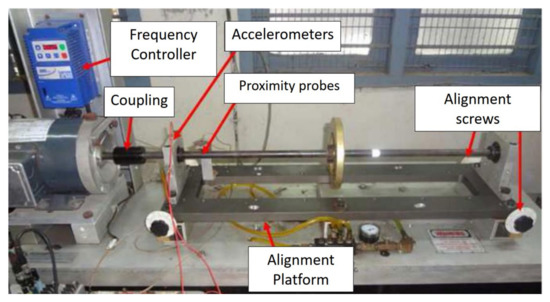

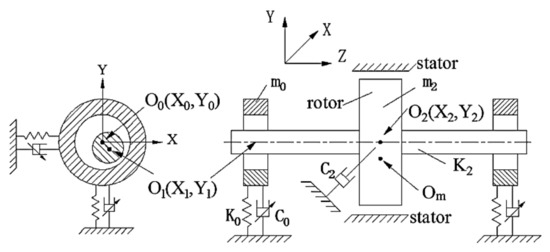

Several techniques are available in the literature to determine the effects of nonlinear damping. In recent decades, various theoretical and laboratory experiments to evaluate the effects of nonlinear damping and the behavior of rotor-bearing structures have been carried out. Tasker and Chopra [161] determined the equivalent linear viscous damping properties for a nonlinear damping system from sampled, noise, multi-mode transient response data. The study was carried out through updated versions of the moving-block analysis and sparse time-domain technique. Numerical simulation was used for typical rotor environment representation. They studied two kinds of nonlinear damping, the Coulomb damping and quadratic damping. In a study of turbomachinery, especially aero-engines, Zhang and Roberts [162] developed a novel frequency-domain approach to estimate unknown parameters in nonlinear dynamic systems. The study was conducted through the direct application of the window functions for different terms in the motion equations. The results of simulation tests were carried out on a nonlinear model of the squeeze-film damper showed that the introduced method could provide satisfactory estimations for different unknown parameters. Figure 16 shows an experimental setup for nonlinear damping identification in rotors. In another study, Smith and Wereley [163] analyzed three methods for damping identification for linear and nonlinear helicopter rotor systems from transient experiment data. The methods are the analyses based on a periodic Fourier series decomposition, the FFT-based moving block analyses, and the HT-based method. They evaluated the influences of data block length, error at the assumed frequency, and noise on the precision of the particularized damping parameters. In another study [164], they evaluated three nonlinear damping identification methods for magnetorheological (MR) dampers of helicopter rotor systems using extracted transient data with known levels of Coulomb and quadratic damping. In related work, Yan et al. [165] performed a computational study to investigate the influence of nonlinear damping suspension on the non-periodic motions of a flexible rotor in journal bearings. The effect of nonlinear damping was dependent on the speed of the rotor. The numerical method of a fourth-order Runge-Kutta (R-K) was used in the solution of the dimensionless equations of motions. The proposed method can be used for vibration isolation between the bearing and environment. Figure 17 shows a nonlinear damping suspension in a flexible rotor in journal bearings. Yu et al. [166] introduced a detection method for the identification of the equivalent system of structures with non-proportional hysteretic damping assumptions. The vibration measurement of the structure subjected to harmonic excitation was employed. Yamada et al. [167] numerically and experimentally studied the effect of surface texture on journal bearings’ dynamic properties. The study aimed to investigate the damping and stiffness coefficients of the oil film of the bearings in the rotating system. Recently, Delgado and Ertas [168] introduced the compliantly damped hybrid gas bearings (CHGB) to study the dynamic characteristics performance of a damped gas-lubricated bearing system of turbomachinery applications. The results show that stiffness increases with increasing excitation frequency and rotor speed, whereas damping decreases.

Figure 16.

Experimental setup for nonlinear damping identification in rotors [117].

Figure 17.

Nonlinear damping suspension in a flexible rotor in journal bearings [165].

3.3. Bridges Applications

Bridges are exposed to many external excitations. Some of these excitations are earthquakes, winds, vehicle loads, chemical, and environmental conditions. These excitations lead to the deterioration of the bridges’ conditions, and consequently, catastrophic collapses due to unrecognized damage during periodic visual inspections [169]. The visual inspection is not enough for damage recognition; therefore, it is necessary to use modern technologies. One of these techniques is the use of damping as a damage indicator due to its high sensitivity to the presence of structural damage. By comparing both intact and damaged cases, we can recognize damages in bridges, where there is a relationship between the damping magnitude and damage levels [170].

During the last decades, several types of research have been carried out to understand the relationship between nonlinear damping and the level of damage to bridges. Frizzarin et al. [88] developed a time-domain damage detection technique for a concrete structure. It utilized nonlinear damping as a damage indicator for RC structural parts. The approach had successfully identified nonlinear bridge damping with seismic damage due to the acoustic vibration reaction through the application of a random decrement signature technique. The nonlinear damping-based approach successfully identified different levels of seismic damage on the bridge model.

In another investigation, Zarafshan et al. [171] determined damping in an operational highway bridge by applying two methods, specifically, the decay of motion direct measurement and the natural excitation method. The research described was intended to demonstrate the efficacy of simplified approaches for the determination of the damping properties of typical highway bridges. In a related study of damage detection of bridges, Dammika et al. [172] proposed an energy-based damping identification method for a steel truss bridge. They analytically and experimentally estimated the damping parameters of the bridge, and therefore the modal damping ratios were analytically estimated.

Recently, Dammika et al. [173] introduced an analytical method based-energy for the evaluation of the modal damping ratios for the bridges and followed by an experimental test on a steel arch bridge. The proposed method has proved its ability for the determination of the damping sources in steel bridges and the contributions to every modal damping ratio and complements the experimental structural health monitoring of bridges. Figure 18 shows a bridge under the influence of moving different vehicles where there is a problem of interaction between the moving vehicles and the structure of the bridge. This movement induces unwanted vibrations that affect the bridge structure over the long-term.

Figure 18.

Two views of a steel arch bridge [173].

3.4. Buildings Applications

It is well-known that the dynamic characteristics of many structures, such as high-rise buildings, vary depending on the amplitude of the vibration [174]. Determining damping in structural systems is a very complicated problem due to damping related to many physical phenomena [175,176]. Damping plays an essential role in making tall buildings more flexible and withstanding external influences such as earthquakes and strong winds [177]. Figure 19 shows a tuned liquid column damper (TLCD) used in the damping test of buildings. Such a damper can be used for improving the dynamic of a substructure where it can absorb the energy transferred from the vibrating structure [178]. This type of dampers can be used widely in civil engineering structures and constructions to reduce the effects of earthquakes and wind loadings. Many problems are encountered due to extensive oscillations of tall buildings, such as the discomfort of the building occupants and may lead to severe damage to structures and possibly collapse [179]. Structural nonlinearities occur due to certain causes such as structural damage and joint loosening that disallow the linear analysis of structural dynamics, which means the necessity of inserting the concept of nonlinearity [180].

Figure 19.

Tuned liquid column damper (TLCD) used in the test of buildings [121].

During the last decades, numerous studies have been made to determine the relationship between nonlinear damping and the level of damage to buildings’ structures. Ling and Haldar [181] proposed a new time-domain identification technique for the evaluation of nondestructive damage of structures. It correctly recognized the stiffness of the structure for both viscous linear and nonlinear damping cases. Furthermore, the proposed method was capable of identifying structures, even with noise-contaminated response data. Noteworthy is a study by Kareem and Gurley [182] that used the random decrement method to estimate the damping in structures focusing on the treatment of uncertainty in its prediction and evaluation. They examined some types of damping sources to structures and the uncertainty treatment in the estimation of damping for real-world applications. In another related work, Huang and Gu [183] proposed an envelope random decrement technique (RDT) for the estimation of nonlinear damping of tall buildings. Three numerical simulations were performed to compare and analyze the performance of the proposed technique in evaluating the amplitude dependence of damping ratio with both conventional RDT and RDT peak. The superiority of the proposed method was proved over the other two methods in assessing the amplitude-based nonlinear damping ratio, as it was also applied to a practical application. In another related study, Béliveau [184] developed a damping identification method in structural dynamics based on modal information within a Bayesian framework. For the calculation of the natural frequencies and damping constants, the modified scheme of Newton-Raphson was used. The actual data of the nine-story steel structure were utilized in the application of the approach.

Recently, Mimura and Mita [185] proposed an automatic evaluation method for obtaining frequencies and damping ratios under the assumption that the information on mass distribution and pattern shapes was available. They tested 40-story steel structural models built with RC. The proposed method was applied to 29-story high-rise steel buildings damaged by an earthquake.

3.5. Marine Applications

Marine ships are one of the most important devices of transportation in the current days [186]. There are many marine applications, such as passenger and cargo ships, barges, and warships [187]. These ships are subject to continuous periodic motion as a result of wave flow [188,189]. The motion affects the comfort of passengers and crews, structural safety, and ship controlling and directing [190,191]. The main reason for such behavior is owing to the very high nonlinear characteristics of the sophisticated damping mechanism of the ship, such as the effect of fluid viscosity. Consequently, during the ship design process, nonlinearity must be taken into account. An accurate ship movement forecast allows designers to achieve the requisite dynamic stability.

There has been considerable effort to study this phenomenon; however, understanding nonlinear damping is extremely difficult due to the strong nonlinearity. Golding et al. [192] presented an estimation method for the online identification of nonlinear viscous damping forces for a surface vessel. The approach is based on parameter estimation in conjunction with qualitative data around longitudinally distributed drag parameters extracted from measured data. The proposed method was applied to realistic conditions and provided accurate estimations of the viscous nonlinear drag forces. In other related work, Jang et al. [193] studied the identification of nonlinear roll damping moments of ships containing the same structures. A regularization approach was used to suppress instability. The issue of determining damping was mathematically included in the first type of the integrated Volterra equation between the roll responses and unknown nonlinear roll damping. Figure 20 shows a model of a testing vessel. Jang et al. [194] performed a free-roll experiment for a particular ship to determine the functional form of the nonlinear roll damping. The first kind of the integrated equation of a Volterra-type was mathematically created to identify the nonlinear damping function. The solution instability was suppressed using Tikhonov’s regularization method. Jang [195] identified the nonlinear damping and restoring properties of nonlinear vibration systems in a nonparametric form in which the nonlinear damping is described as a function of velocity only. He introduced the concept of the zero-crossings, which was employed to present a technique for a nonlinear simultaneous identification. In a related study, Han and Kinoshita [196] studied a novel nonparametric and output-only identification method of nonlinear damping. They formulated a stochastic inverse problem for nonlinear damping based on the concept of the stochastic state space. Numerical and experimental investigations were conducted to establish the validity and effectiveness of the proposed method. Recently, Sathyaseelan et al. [197] presented an identification method for nonlinear damping coefficients to a ship roll motion model using the Legendre wavelet spectral method. They made a comparison between the findings obtained using the Legendre wavelet spectral method and the fourth-order R-K algorithm. The proposed approach could be applied to multiple degrees of freedom problems.

Figure 20.

Model of a testing vessel [194].

4. Summary and Recommended Research Directions

Nonlinear damping methods are more accurate and provide a better understanding of the dynamic behavior of real structures and are increasingly used compared to linear methods. In general, nonlinear damping methods are rapidly evolving and increasingly technologically, due to their superior features, with a wide range of uses across all the engineering, vehicles, rotating machines, bridges, buildings, and ships. This critical review discusses the common nonlinear damping methods such as linearization methods, time-domain methods, frequency-domain methods, time-frequency methods, modal methods, black-box modeling, and model updating methods with fundamental difficulties and strengths as well as applications of these methods. This review paper also provides a credible platform for academicians and researchers in this area to understand the basic principles and nuances of these methods. Although there has been much improvement in the development of these methods in recent years to determine nonlinear damping, other aspects still have to be studied to understand this phenomenon. The recommended research directions are summarized to move forward on this topic.

- (1)

- The issue of NDI should be considered in the early design stages as this has an impact on improving the safety and efficiency of engineering structures.

- (2)

- Damping has a higher sensitivity and reliability than natural frequencies and mode shapes to structural damage detection and can be used as a useful indicator for determining damage, which should be further clarified.

- (3)

- Concerning the damping ratio, the instantaneous damping coefficient is a particular property of nonlinear damping, and it is suitable to give an appropriate image that helps in assessing the structural damage caused due to the nonlinearity. Therefore, more attention must be paid to such methods in order to identify the coefficient of the instantaneous damping.

- (4)

- One of the main reasons why using nonlinear damping is more challenging to employ in the process of determining structural damage is the uncertainty in damping evaluation. Therefore, robust and reliable techniques should be developed that can give accurate and reliable results.

- (5)

- Wavelet-based time-frequency techniques for nonlinear damping identification have shown the feature of robustness to noise and usefulness in identifying nonlinear damping. A crucial step towards advancing such techniques lies in overcoming the outstanding matter of choosing optimal wavelets for the analysis.

- (6)

- Damping in composite materials is complicated, as it includes various energy dissipation mechanisms. Besides, composite materials are anisotropic and non-uniform shapes; it needs further study.

- (7)

- In some cases, it is convenient using more than one method to describe the nonlinear damping behavior of structural dynamics accurately. One approach may not give a complete explanation because of many influencing factors on systems. So, it is recommended to use two or more methods as complementary.

- (8)

- The damping nonlinearity identification process is very complicated due to the presence of a mixture of different damping mechanisms at the same time. Therefore, in many cases, the theoretical study for the NDI in structures should be followed by experimental work to validate the results.

Author Contributions

Conceptualization, T.A.-h. and M.C.; methodology, M.C., B.S. and N.F.A.; formal analysis, T.A.-h., M.C. and H.X.; investigation, T.A.-h., M.C. and B.S.; resources, M.C.; writing—original draft preparation, T.A.-h.; writing—review and editing, M.C., B.S., N.F.A. and H.X.; visualization, T.A.-h., N.F.A. and H.X.; supervision, M.C.; project administration, M.C.; funding acquisition, M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

This work is supported by Nantong Science and Technology Plan Project (No. MS22019016), the China Postdoctoral Science Foundation (2020T130170), and the Transportation Science Research Project of Jiangsu Province (No. 2019Z02).

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this paper:

| BBM | Black-box modeling |

| CFD | Computational fluid dynamics |

| CHGB | Compliantly damped hybrid gas bearings |

| CWT | Continuous wavelet transform |

| EL | Equivalent linearization |

| ELA | Equivalent linearization approximation |

| FE | Finite element |

| FREEVIB | Free vibration analysis |

| FRFs | Frequency response functions |

| FWNN | Fuzzy wavelet neural network |

| HAPB | Hybrid aeroelastic pressure balance |

| HBNID | Harmonic balance nonlinearity identification |

| HT | Hilbert transforms |

| MDOF | Multi-degree of freedom |

| MIMO | Multi-input multi-output |

| MR | Magnetorheological |

| NDI | Nonlinear damping identification |

| PRC | Prestressed reinforced concrete |

| RC | Reinforced concrete |

| RCT | Response-controlled stepped-sine testing |

| RDM | Resonant decay method |

| RDT | Random decrement technique |

| RFS | Restoring force surface |

| R-K | Runge-Kutta |

| ROM | Reduced-order model |

| SDOF | Single-degree of freedom |

| SSSM | Spring-suspended sectional models |

| TLCD | Tuned liquid column damper |

| WT | Wavelet transform |

References

- Kerschen, G.; Worden, K.; Vakakis, A.F.; Golinval, J.C. Past, present and future of nonlinear system identification in structural dynamics. Mech. Syst. Signal Process. 2006, 20, 505–592. [Google Scholar] [CrossRef]

- Cao, M.S.; Sha, G.G.; Gao, Y.F.; Ostachowicz, W. Structural damage identification using damping: A compendium of uses and features. Smart Mater. Struct. 2017, 26, 043001. [Google Scholar] [CrossRef]

- Blackwell, C.; Palazotto, A.; George, T.J.; Cross, C.J. The evaluation of the damping characteristics of a hard coating on titanium. Shock Vib. 2007, 14, 37–51. [Google Scholar] [CrossRef]

- Eichler, A.; Moser, J.; Chaste, J.; Zdrojek, M.; Wilson-Rae, I.; Bachtold, A. Nonlinear damping in mechanical resonators made from carbon nanotubes and graphene. Nat. Nanotechnol. 2011, 6, 339–342. [Google Scholar] [CrossRef]

- Liang, J.W.; Feeny, B.F. Identifying Coulomb and viscous friction in forced dual-damped oscillators. J. Vib. Acoust. Trans. ASME 2004, 126, 118–125. [Google Scholar] [CrossRef]

- Mevada, H.; Patel, D. Experimental Determination of Structural Damping of Different Materials. Proc. Eng. 2016, 144, 110–115. [Google Scholar] [CrossRef]

- Zhang, X.; Du, X.; Brownjohn, J. Frequency modulated empirical mode decomposition method for the identification of instantaneous modal parameters of aeroelastic systems. J. Wind Eng. Ind. Aerodyn. 2012, 101, 43–52. [Google Scholar] [CrossRef]

- Kulkarni, P.; Bhattacharjee, A.; Nanda, B.K. Study of damping in composite beams. Mater. Today Proc. 2018, 5, 7061–7067. [Google Scholar] [CrossRef]

- Chatterjee, A.; Chintha, H.P. Identification and parameter estimation of cubic nonlinear damping using harmonic probing and volterra series. Int. J. Non. Linear. Mech. 2020, 125, 103518. [Google Scholar] [CrossRef]

- Dou, C.; Fan, J.; Li, C.; Cao, J.; Gao, M. On discontinuous dynamics of a class of friction-influenced oscillators with nonlinear damping under bilateral rigid constraints. Mech. Mach. Theory 2020, 147, 103750. [Google Scholar] [CrossRef]

- Heitz, T.; Giry, C.; Richard, B.; Ragueneau, F. Identification of an equivalent viscous damping function depending on engineering demand parameters. Eng. Struct. 2019, 188, 637–649. [Google Scholar] [CrossRef]

- Ghiringhelli, G.L.; Terraneo, M. Analytically driven experimental characterisation of damping in viscoelastic materials. Aerosp. Sci. Technol. 2015, 40, 75–85. [Google Scholar] [CrossRef]

- Amabili, M. Nonlinear damping in nonlinear vibrations of rectangular plates: Derivation from viscoelasticity and experimental validation. J. Mech. Phys. Solids 2018, 118, 275–292. [Google Scholar] [CrossRef]

- Anastasio, D.; Marchesiello, S.; Kerschen, G.; Noël, J.P. Experimental identification of distributed nonlinearities in the modal domain. J. Sound Vib. 2019, 458, 426–444. [Google Scholar] [CrossRef]

- Moradi, H.; Vossoughi, G.; Movahhedy, M.R. Experimental dynamic modelling of peripheral milling with process damping, structural and cutting force nonlinearities. J. Sound Vib. 2013, 332, 4709–4731. [Google Scholar] [CrossRef]

- Olejnik, P.; Awrejcewicz, J. Coupled oscillators in identification of nonlinear damping of a real parametric pendulum. Mech. Syst. Signal Process. 2018, 98, 91–107. [Google Scholar] [CrossRef]

- Ciang, C.C.; Lee, J.R.; Bang, H.J. Structural health monitoring for a wind turbine system: A review of damage detection methods. Meas. Sci. Technol. 2008, 19, 12. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Penna, A.; Magenes, G. Seismic damage diagnosis of a masonry building using short-term damping measurements. J. Sound Vib. 2017, 394, 366–391. [Google Scholar] [CrossRef]

- Ji, H.; Qiu, J.; Zhu, K.; Badel, A. Two-mode vibration control of a beam using nonlinear synchronized switching damping based on the maximization of converted energy. J. Sound Vib. 2010, 329, 2751–2767. [Google Scholar] [CrossRef]

- Shariyat, M.; Jahangiri, M. Nonlinear impact and damping investigations of viscoporoelastic functionally graded plates with in-plane diffusion and partial supports. Compos. Struct. 2020, 245, 112345. [Google Scholar] [CrossRef]

- Peters, R.D. Nonlinear Damping of the ‘Linear’ Pendulum. arXiv 2003, arXiv:physics/0306081. [Google Scholar]

- Zaitsev, S.; Shtempluck, O.; Buks, E. Nonlinear damping in a micromechanical oscillator. Nonlinear Dyn. 2012, 67, 859–883. [Google Scholar] [CrossRef]

- Noël, J.P.; Kerschen, G. 10 years of advances in nonlinear system identification in structural dynamics: A review. In Proceedings of the ISMA 2016-International Conference on Noise and Vibration Engineering, Leuven, Belgium, 19–21 September 2016. [Google Scholar]

- Karaağaçlı, T.; Özgüven, H.N. A frequency domain nonparametric identification method for nonlinear structures: Describing surface method. Mech. Syst. Signal Process. 2020, 144, 106872. [Google Scholar] [CrossRef]

- Boltežar, M.; Slavič, J. Enhancements to the continuous wavelet transform for damping identifications on short signals. Mech. Syst. Signal Process. 2004, 18, 1065–1076. [Google Scholar] [CrossRef]

- Heaney, P.S.; Bilgen, O. System identification of lumped parameter models for weakly nonlinear systems. J. Sound Vib. 2019, 450, 78–95. [Google Scholar] [CrossRef]

- Li, A.; Ma, L.; Keene, D.; Klingel, J.; Payne, M.; Wang, X. Forced oscillations with linear and nonlinear damping. Am. J. Phys. 2016, 84, 32–37. [Google Scholar] [CrossRef]

- Lamarque, C.H.; Savadkoohi, A.T.; Charlemagne, S. Experimental results on the vibratory energy exchanges between a linear system and a chain of nonlinear oscillators. J. Sound Vib. 2018, 437, 97–109. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Tinard, V.; Fond, C. The modelling of nonlinear rheological behaviour and Mullins effect in High Damping Rubber. Int. J. Solids Struct. 2015, 75–76, 235–246. [Google Scholar] [CrossRef]

- Haghdoust, P.; Conte, A.L.; Cinquemani, S.; Lecis, N. A numerical method to model non-linear damping behaviour of martensitic shape memory alloys. Materials 2018, 11, 2178. [Google Scholar] [CrossRef]

- Yuan, D.N. Dynamic modeling and analysis of an elastic mechanism with a nonlinear damping model. JVC/J. Vib. Control 2013, 19, 508–516. [Google Scholar] [CrossRef]

- Phani, A.S.; Woodhouse, J. Viscous damping identification in linear vibration. J. Sound Vib. 2007, 303, 475–500. [Google Scholar] [CrossRef]

- Prandina, M.; Mottershead, J.E.; Bonisoli, E. An assessment of damping identification methods. J. Sound Vib. 2009, 323, 662–676. [Google Scholar] [CrossRef]

- Botelho, E.C.; Campos, A.N.; de Barros, E.; Pardini, L.C.; Rezende, M.C. Damping behavior of continuous fiber/metal composite materials by the free vibration method. Compos. Part B Eng. 2005, 37, 255–263. [Google Scholar] [CrossRef]

- Berthelot, J.M.; Assarar, M.; Sefrani, Y.; el Mahi, A. Damping analysis of composite materials and structures. Compos. Struct. 2008, 85, 189–204. [Google Scholar] [CrossRef]

- Guo, Z.; Sheng, M.; Ma, J.; Zhang, W. Damping identification in frequency domain using integral method. J. Sound Vib. 2015, 338, 237–249. [Google Scholar] [CrossRef]

- Jeong, B.; Cho, H.; Yu, M.F.; Vakakis, A.F.; McFarland, D.M.; Bergman, L.A. Modeling and measurement of geometrically nonlinear damping in a microcantilever-nanotube system. ACS Nano 2013, 7, 8547–8553. [Google Scholar] [CrossRef]

- Ruderman, M.S. Nonlinear damped standing slow waves in hot coronal magnetic loops. Astron. Astrophys. 2013, 553, A23. [Google Scholar] [CrossRef]