Performance Evaluation of Knitted and Stitched Textile Strain Sensors

Abstract

1. Introduction

2. Textile Basics and Terminology

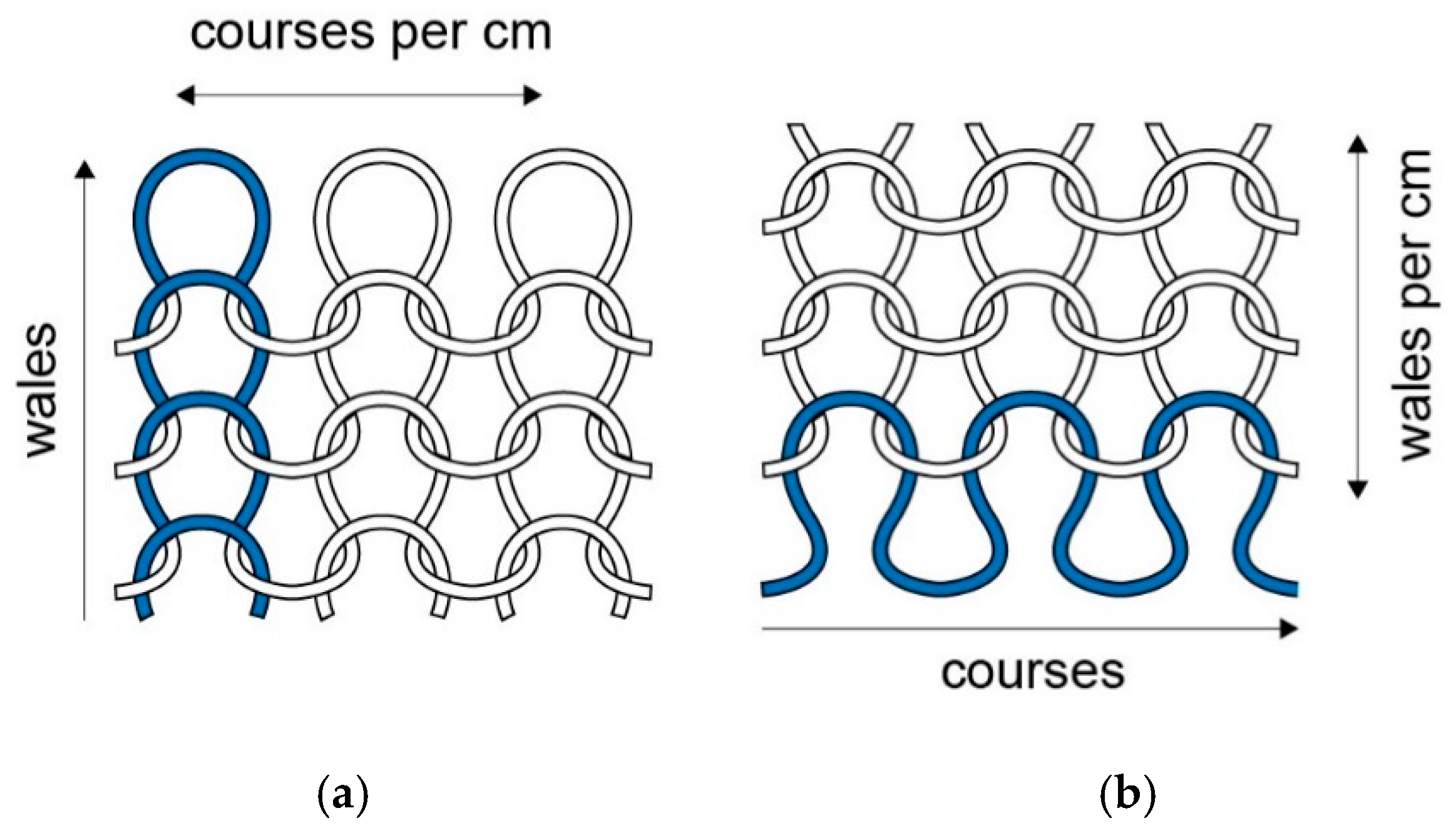

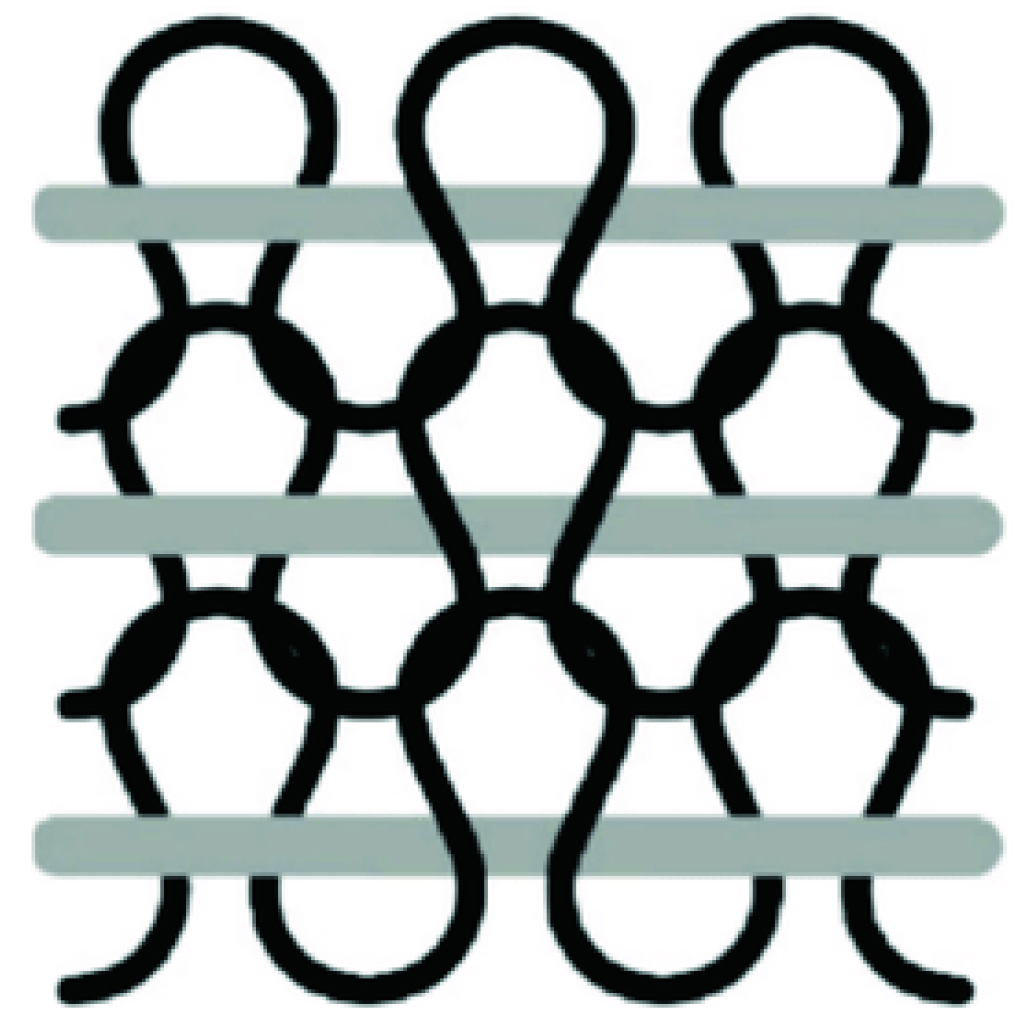

2.1. Knitting Basics

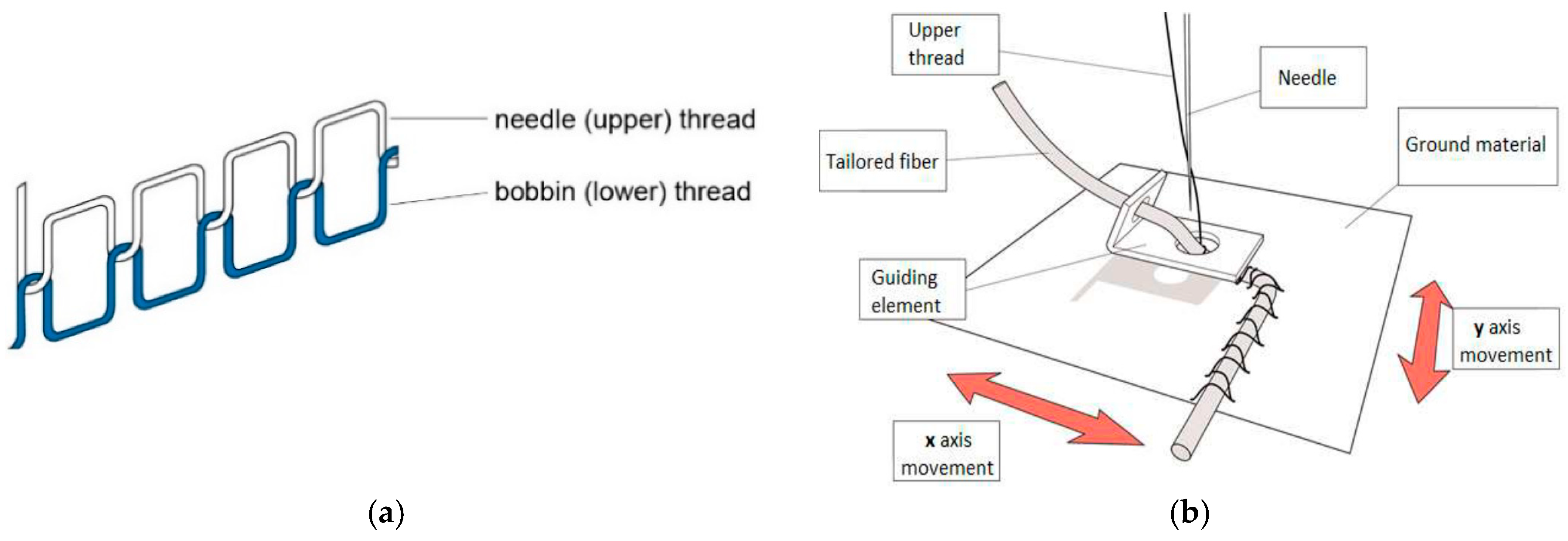

2.2. Stitching and Embroidery

3. Strain Sensors

3.1. Sensor Types

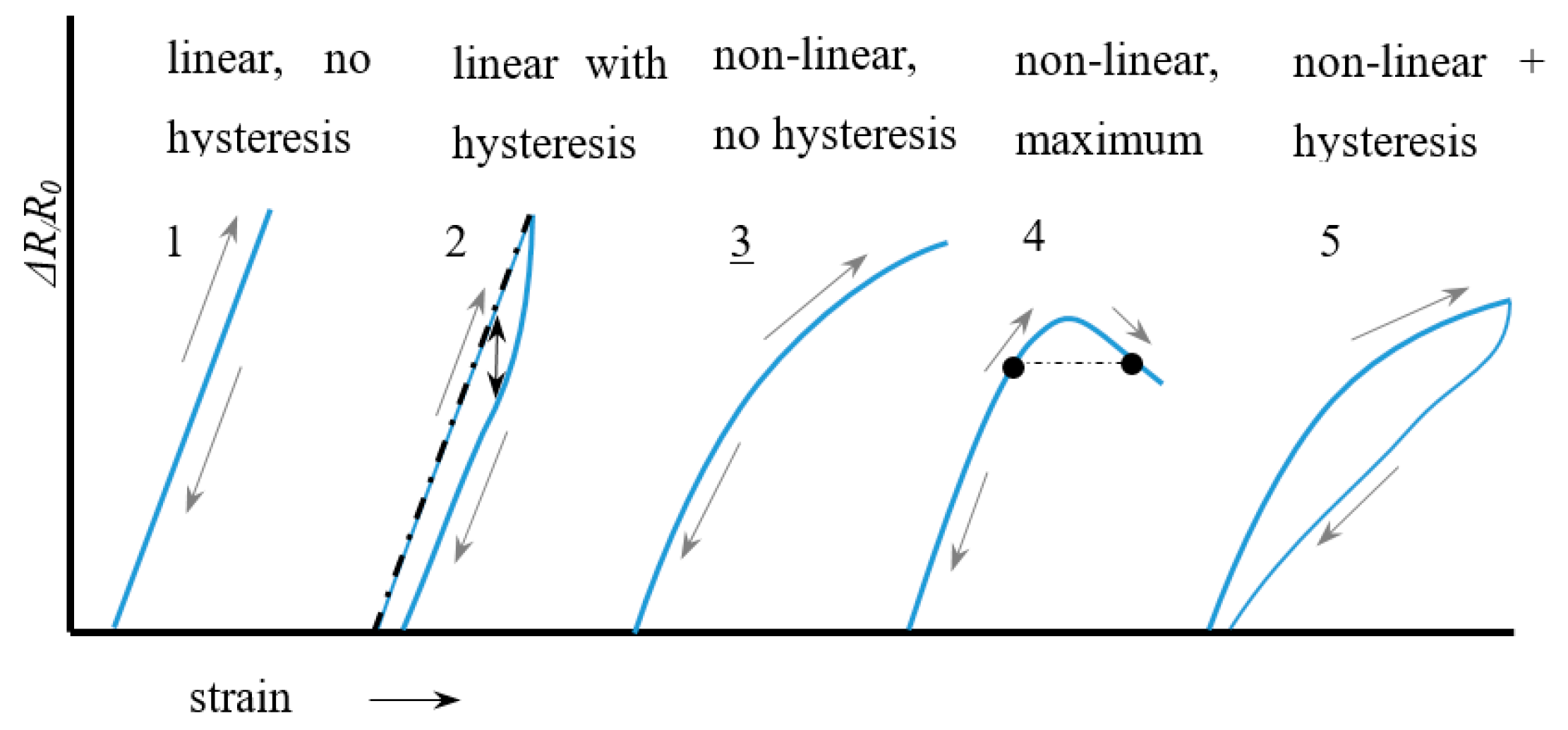

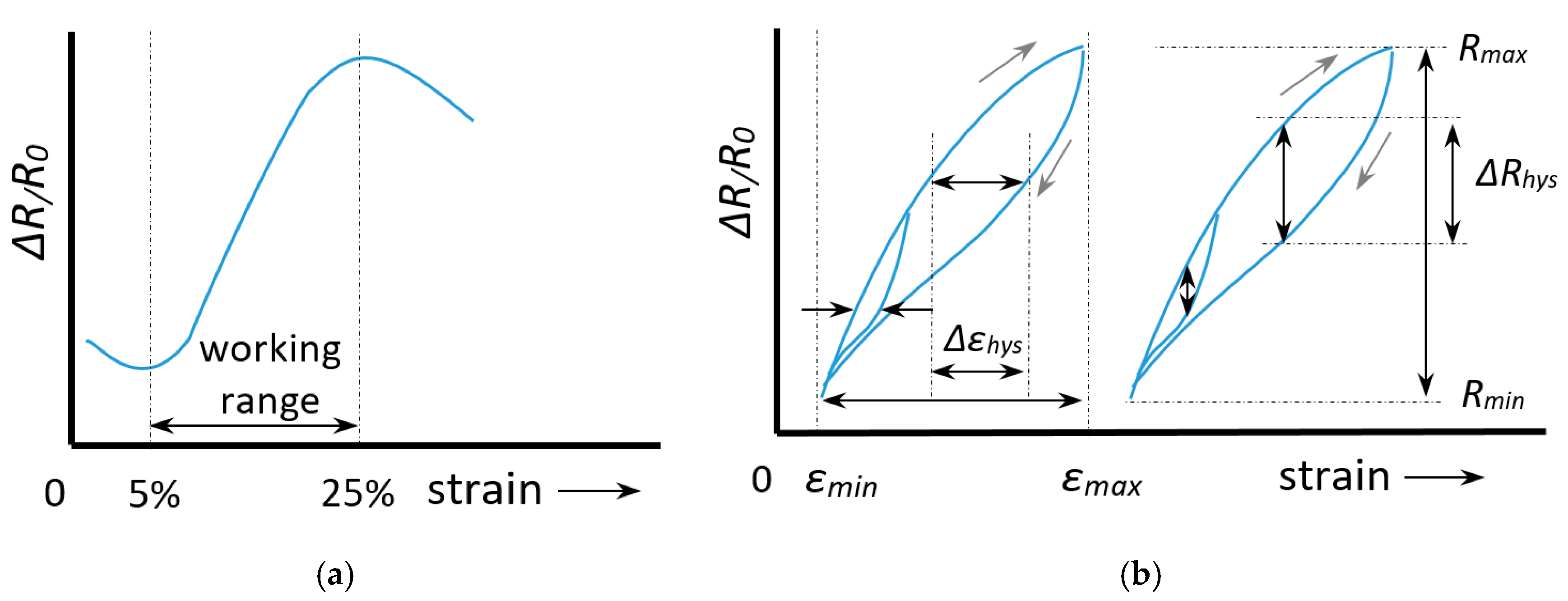

3.2. Sensor Response Characterization

3.3. Sensor Resistance

4. Knitted and Stitched Strain Sensors

- -

- Wide working range (up to 45% for measuring stretch on the human body)

- -

- High enough gauge factor (sensitivity)

- -

- Low hysteresis

- -

- No signal drift

- -

- Good repeatability (i.e., after multiple cycles and after washing)

4.1. Knitted Sensors

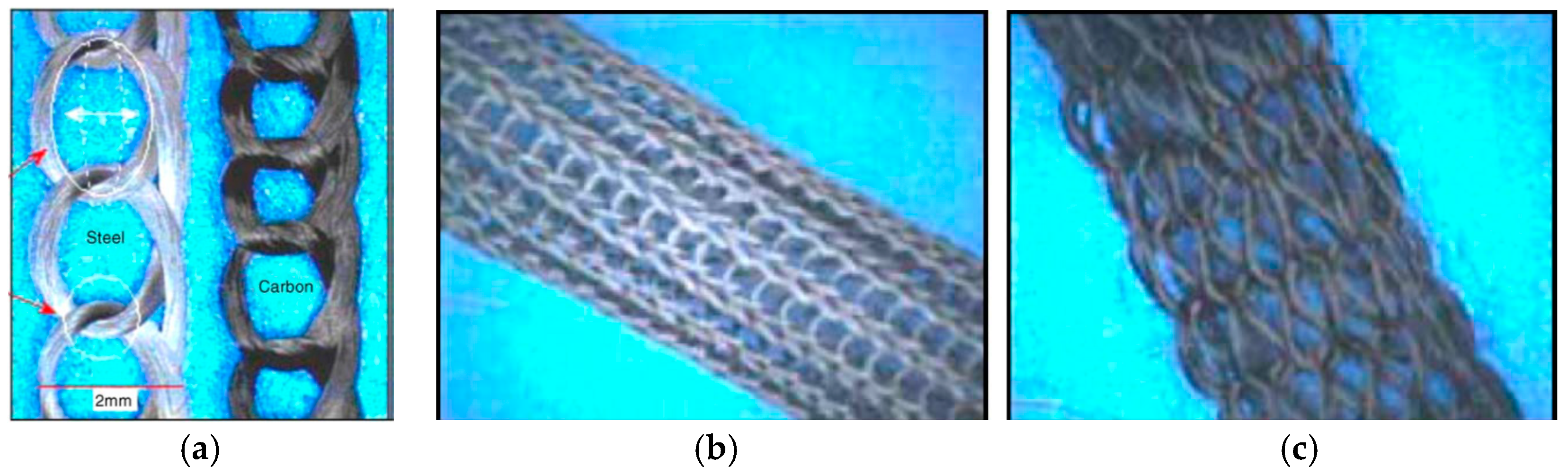

4.1.1. Strain Sensitive Knitted Structures (1999–2009)

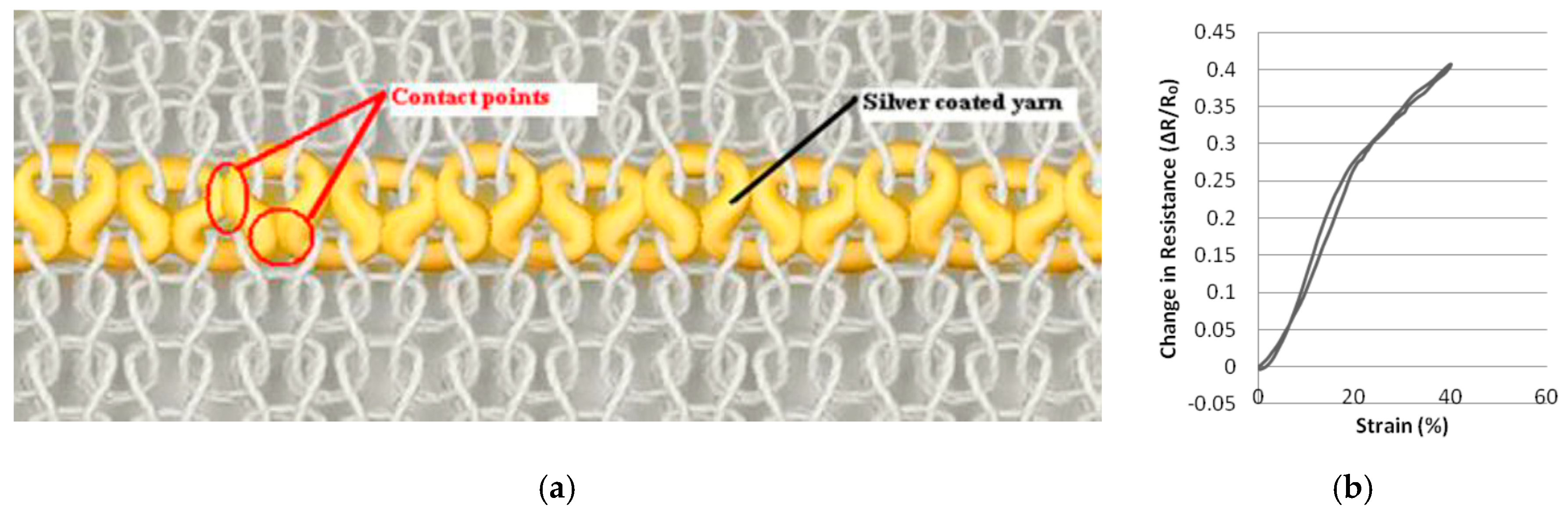

4.1.2. Strain Sensitive Knitted Structures (2010–2020)

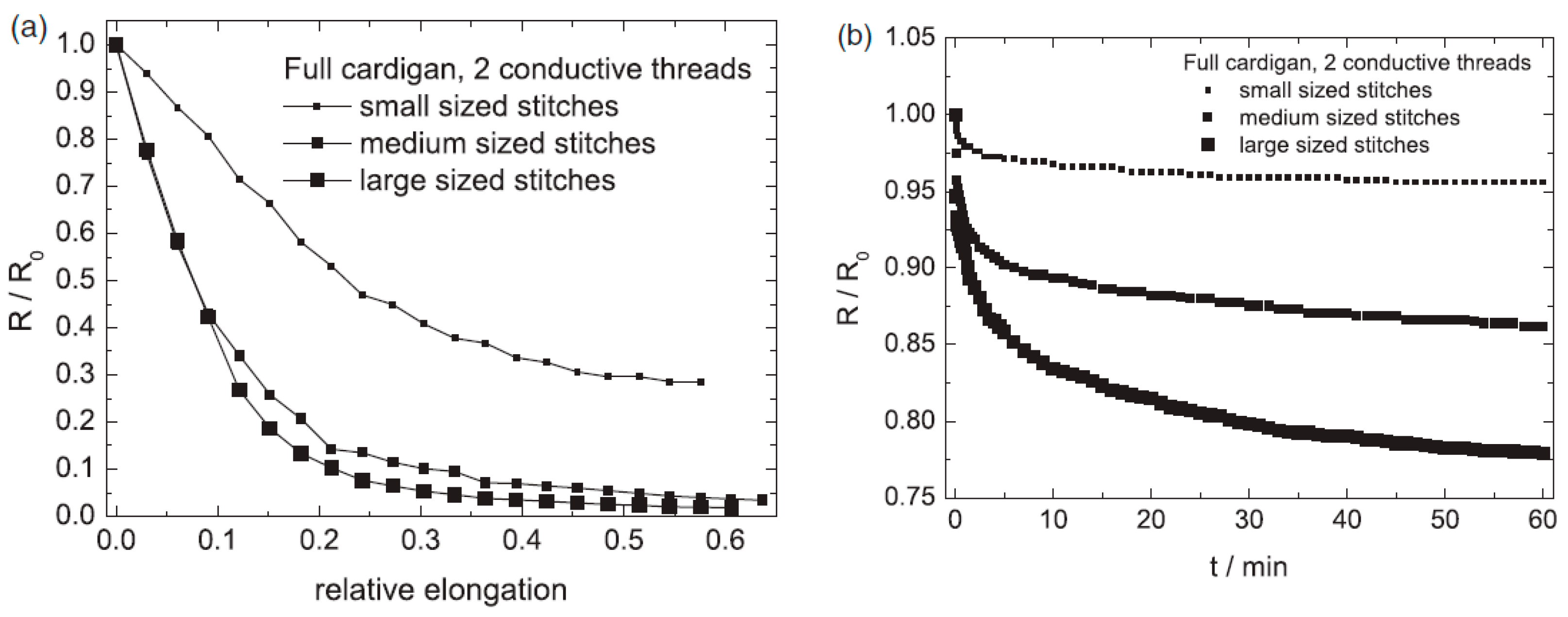

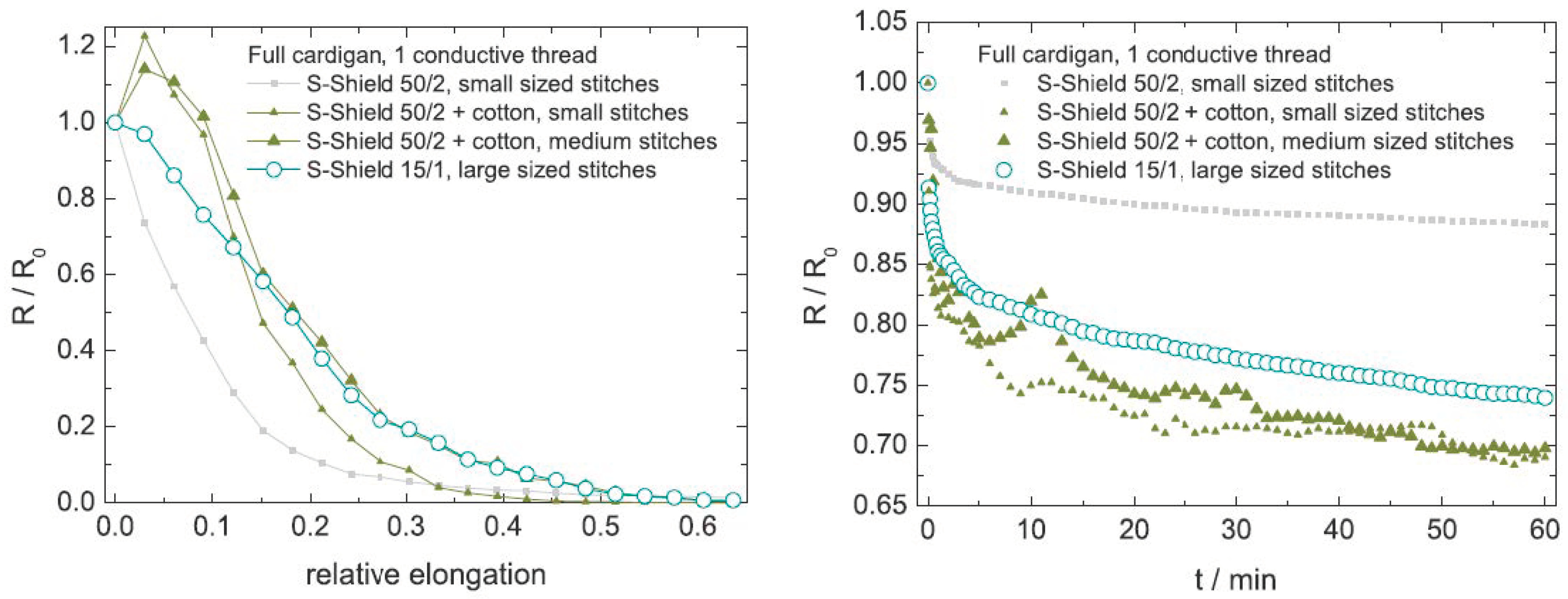

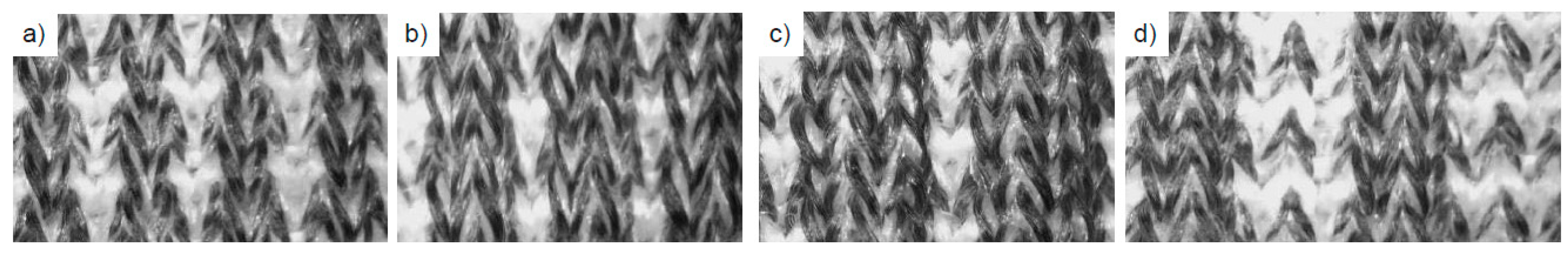

- -

- Stitch type: double face, single face, Milano rib and full cardigan;

- -

- Stitch cam settings NP = 9.5 (small), 10.5 (medium) and 11.5 (large);

- -

- Conductive yarn type: four types of S-Shield PES and cotton blended stainless steel yarns (single thread, two thread; 50/2 with 20% steel fibers or 15/1 Nm with 50% steel);

- -

- Fabric orientation: 0, 30, 45, 60, and 90°.

- Base yarn: Elastane/polyester 22/78 yarn

- Function non-conductive yarn: 25 Tex cotton

- Functional conductive: Shieldex dTex110 and dTex110*2

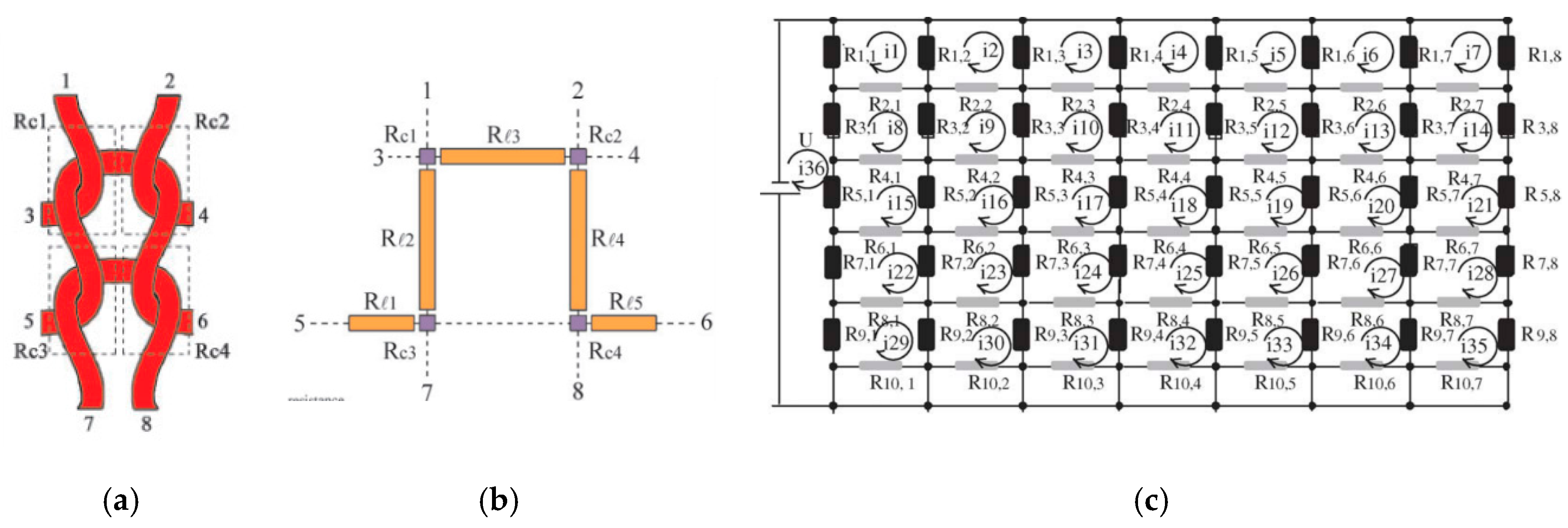

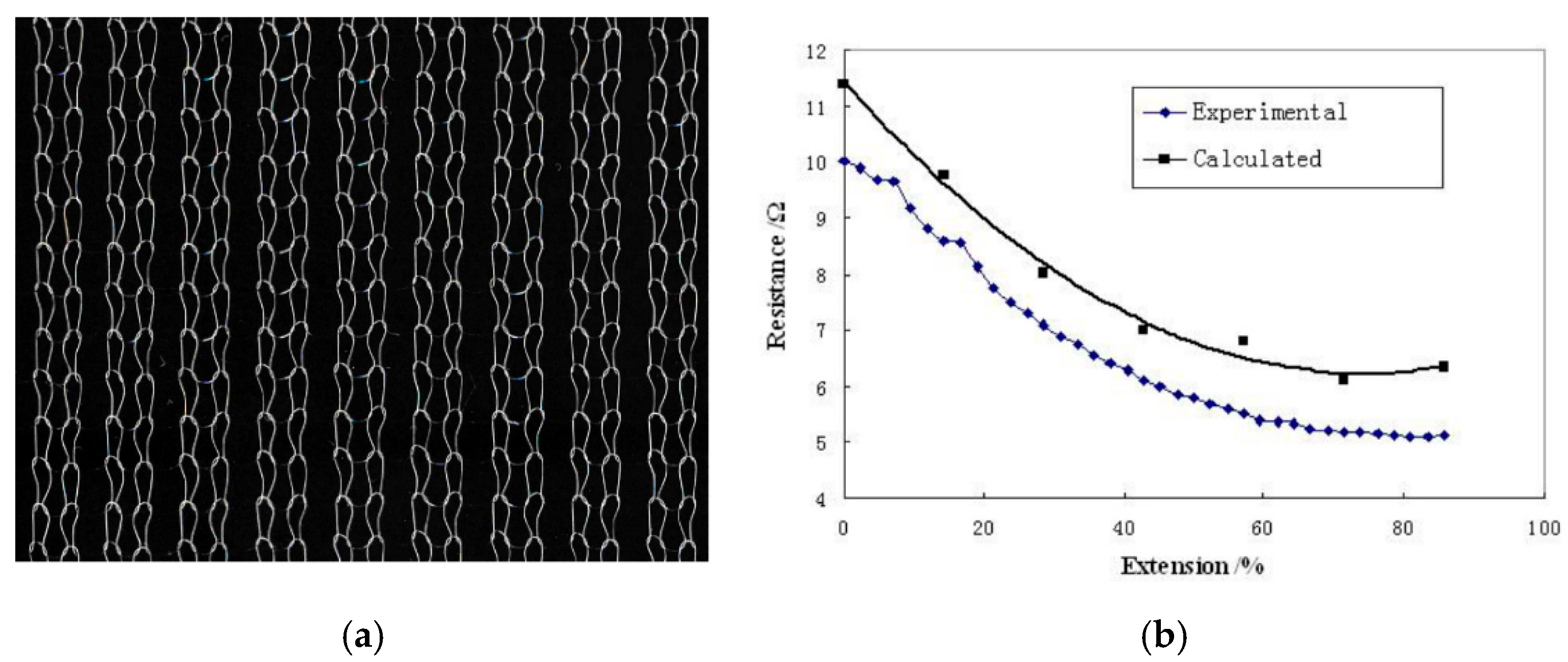

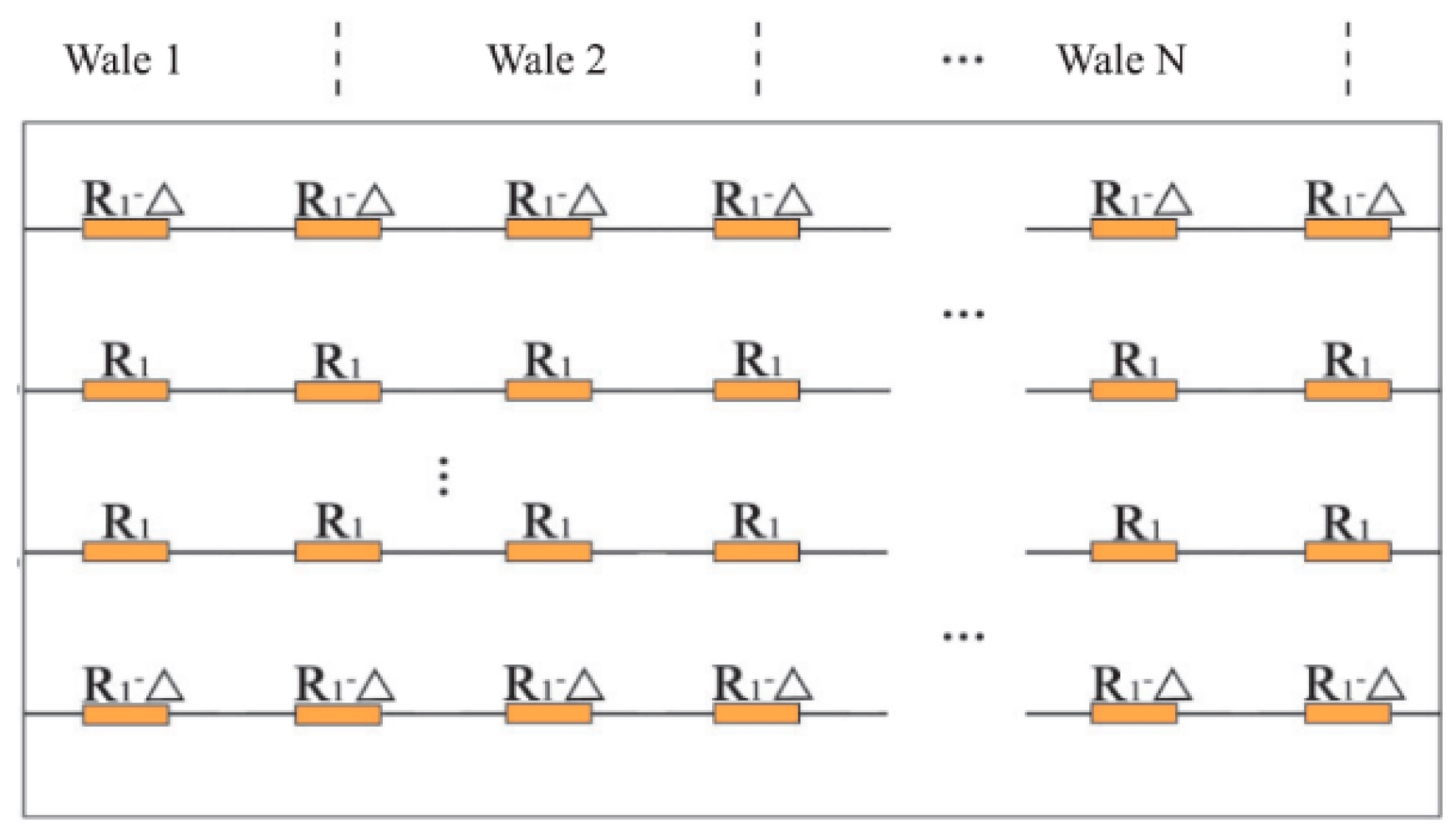

4.1.3. Modelling of Knitted Sensor Electromechanical Behaviour

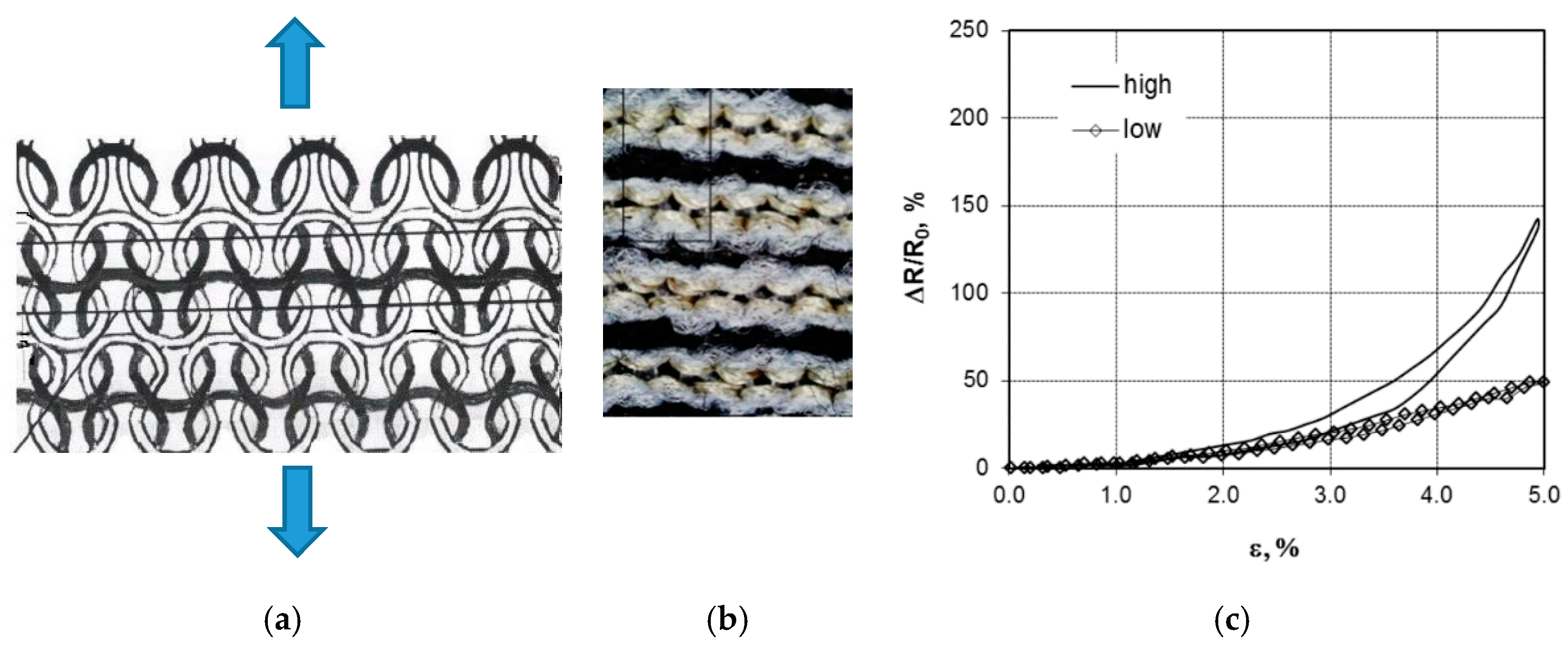

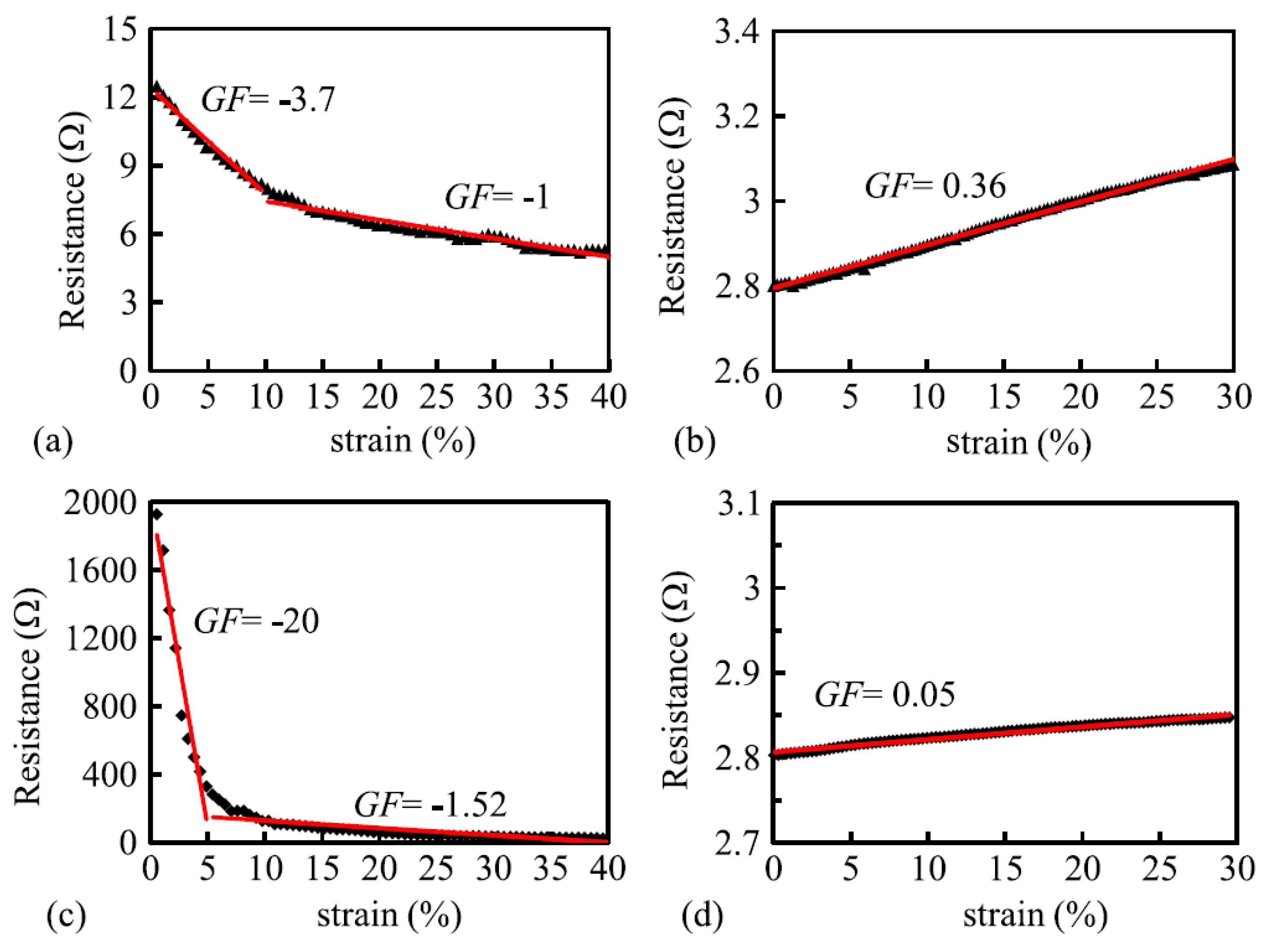

- Stage 1: Reduction of contact points: the opening of the structure (gradually) disconnects contacting loops which were connected in the initial state due to elastic contraction of the base structure. This is typical for the first 10–20% stretching and causes a resistance increase;

- Stage 2: Yarn slippage and shifting of contact points due to a rearrangement of the knitted structure. This results in a larger yarn length (and resistance) between a fixed number of contact points and can be a dominating effect for high resistance yarns. Between 10 and 40% strain;

- Stage 3: Increased contact pressure between hooked conductor loops. This effect starts to play a role for strains above, say, 20% and causes the resistance to decrease. In bare metal conductive yarns this may start earlier and is the dominating effect;

- Stage 4: The stretching of the conductor yarn segments itself. This occurs when all slack is out of the system and loop segments have straightened. Depending on the structure this may start above 50 to 80%. For metal coated and carbon filled yarns this results in an increase in resistance whereas for yarns consisting of metal filaments blended with non-conductors the resistance decreases due to the squeezing effect.

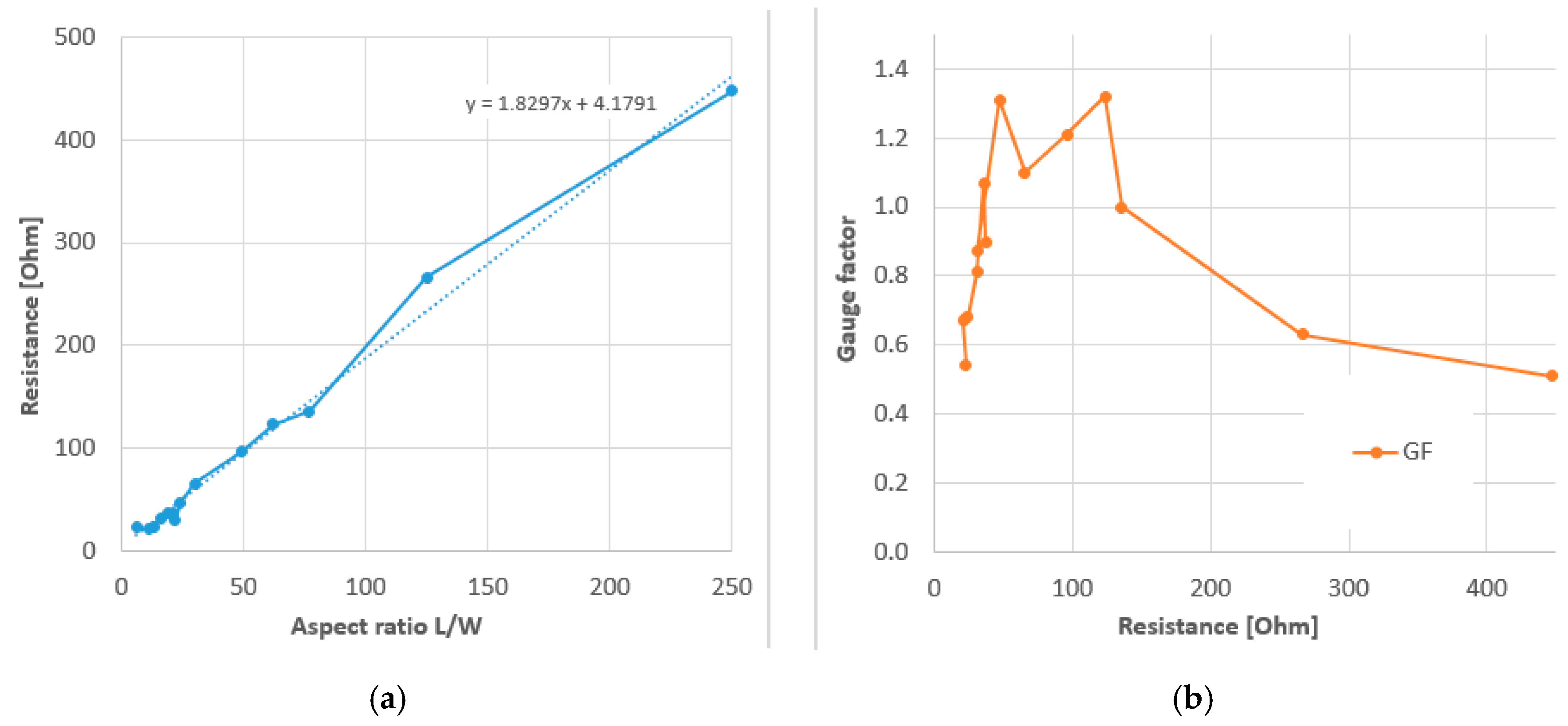

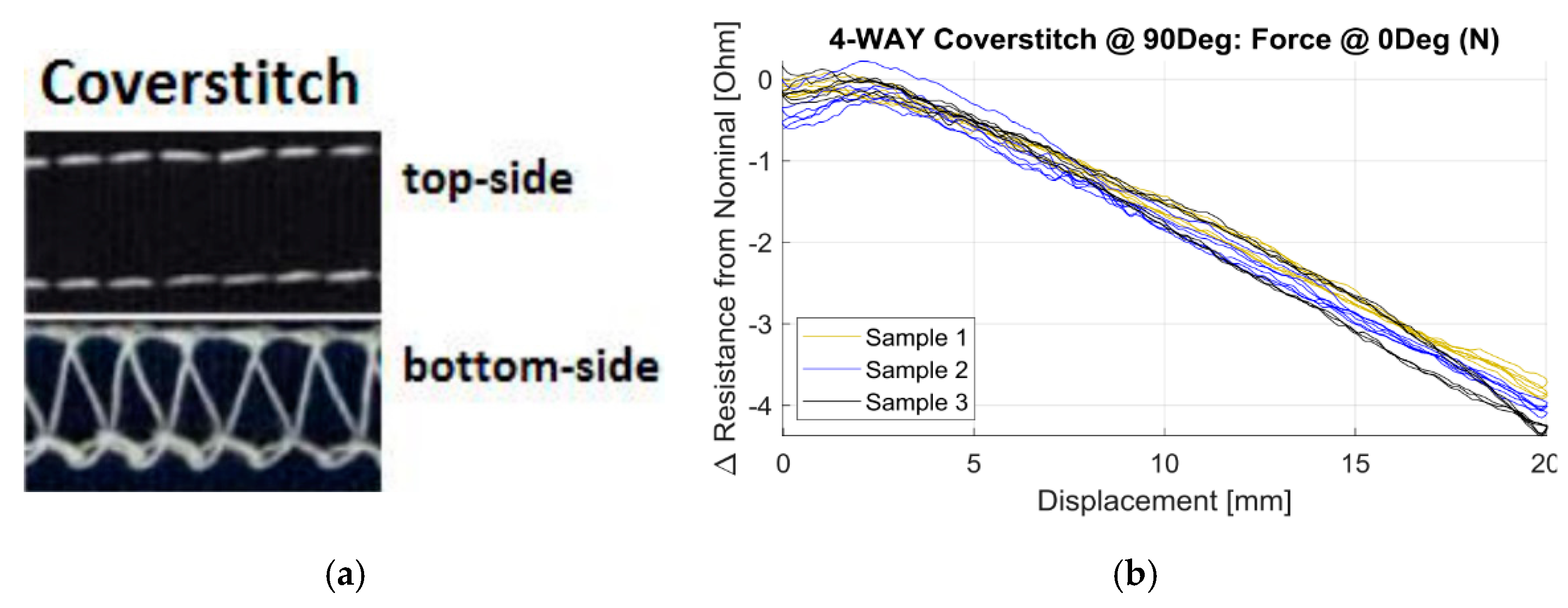

4.2. Stitched Sensors

5. Discussion

5.1. Knitted Sensors

5.1.1. Initial Resistance

5.1.2. Conductive Yarns

5.1.3. Performance Indicators

5.2. Stitched Sensors

6. Conclusions

6.1. Sensor Selection (“Do’s and Don’ts”)

- Knitted strain gauges are best produced with silver plated nylon yarn as the conductor thread. Blended yarn combinations like stainless steel/polyester should be avoided since this results in less reproducible sensor performance

- The loop-wise embedding configuration of the conductive yarn as used by Atalay [38] results in the best overall sensor performance

- Knitted gauges of non-rectangular shapes suffer from sensor noise and poor reproducibility due to the need to truncate conductive yarns outside the sensor area [67]

- In order to reduce hysteresis and relaxation effects in stitched strain sensors it is important to use a highly elastic substrate fabric with minimum mechanical hysteresis.

- The bottom coverstich sensor of Dupler [37] has hardly any hysteresis, and is thus the preferred configuration. As alternative the zig-zag stitch also performs well

- The sensitivity of stitched sensors can probably be improved by increasing the stitch density

6.2. Topics for Future Research

Funding

Conflicts of Interest

References

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112. [Google Scholar] [CrossRef]

- Castano, L.M.; Flatau, A.B. Smart fabric sensors and e-textile technologies: A review. Smart Mater. Struct. 2014, 23. [Google Scholar] [CrossRef]

- Gibbs, P.T.; Asada, H. Wearable Conductive Fiber Sensors for Multi-Axis Human Joint Angle Measurements. J. Neuroeng. Rehabil. 2005, 2, 7. [Google Scholar] [CrossRef] [PubMed]

- McLaren, R.; Joseph, F.; Baguley, C.; Taylor, D. A review of e-textiles in neurological rehabilitation: How close are we? J. Neuroeng. Rehabil. 2016, 13, 59. [Google Scholar] [CrossRef]

- Post, E.R.; Orth, M.; Russo, P.R.; Gershenfeld, N. E-broidery: Design and fabrication of textile-based computing. IBM Syst. J. 2000, 39, 840–860. [Google Scholar] [CrossRef]

- Poupyrev, I.; Gong, N.-W.; Fukuhara, S.; Karagozler, M.E.; Schwesig, C.; Robinson, K.E. Project Jacquard. In Proceedings of the 2016 CHI Conference on Human Factors in Computing Systems, San Jose, CA, USA, 7–12 May 2016; pp. 4216–4227. [Google Scholar]

- Roh, J.-S. Conductive Yarn Embroidered Circuits for System on Textiles. Wearable Technol. 2018. [Google Scholar] [CrossRef]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. Neuroeng. Rehabil. 2012, 9, 21. [Google Scholar] [CrossRef]

- Rodgers, M.M.; Pai, V.M.; Conroy, R.S. Recent Advances in Wearable Sensors for Health Monitoring. IEEE Sens. J. 2015, 15, 3119–3126. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Wearable Flexible Sensors: A Review. IEEE Sens. J. 2017, 17, 3949–3960. [Google Scholar] [CrossRef]

- Bosowski, P.; Hoerr, M.; Me Fika, V.; Gries, T.; Jockenhoevel, S. Design and Manufacture of Textile-Based Sensors. In Electronic Textiles; Woodhead Publishing: Cambridge, UK, 2015. [Google Scholar]

- Wilson, S.; Laing, R. Fabrics and Garments as Sensors: A Research Update. Sensors 2019, 19, 3570. [Google Scholar] [CrossRef]

- Seyedin, S.; Zhang, P.; Naebe, M.; Qin, S.; Chen, J.; Wang, X.; Razal, J.M. Textile strain sensors: A review of the fabrication technologies, performance evaluation and applications. Mater. Horiz. 2019, 6, 219–249. [Google Scholar] [CrossRef]

- Lee, J.; Llerena Zambrano, B.; Woo, J.; Yoon, K.; Lee, T. Recent Advances in 1D Stretchable Electrodes and Devices for Textile and Wearable Electronics: Materials, Fabrications, and Applications. Adv. Mater. 2020, 32, 1902532. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lu, C.; Zhang, K. Textile-Based Strain Sensor for Human Motion Detection. Energy Environ. Mater. 2020, 3, 80–100. [Google Scholar] [CrossRef]

- Zhang, R.; Deng, H.; Valenca, R.; Jin, J.H.; Fu, Q.; Bilotti, E.; Peijs, T. Carbon nanotube polymer coatings for textile yarns with good strain sensing capability. Sens. Actuator A Phys. 2012, 179, 83–91. [Google Scholar] [CrossRef]

- Xue, P.; Wang, J.; Tao, X. Flexible textile strain sensors from polypyrrole-coated XLA™ elastic fibers. High Perform. Polym. 2014, 26, 364–370. [Google Scholar] [CrossRef]

- Ding, Y.; Invernale, M.A.; Sotzing, G.A. Conductivity Trends of PEDOT-PSS Impregnated Fabric and the Effect of Conductivity on Electrochromic Textile. ACS Appl. Mater. Interfaces 2010, 2, 1588–1593. [Google Scholar] [CrossRef] [PubMed]

- Foroughi, J.; Spinks, G.M.; Aziz, S.; Mirabedini, A.; Jeiranikhameneh, A.; Wallace, G.G.; Kozlov, M.E.; Baughman, R.H. Knitted Carbon-Nanotube-Sheath/Spandex-Core Elastomeric Yarns for Artificial Muscles and Strain Sensing. ACS Nano 2016, 10, 9129–9135. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, Z.; Ding, J.; Lepró, X.; Fang, S.; Jiang, N.; Yuan, N.; Wang, R.; Yin, Q.; Lv, W.; et al. Downsized Sheath–Core Conducting Fibers for Weavable Superelastic Wires, Biosensors, Supercapacitors, and Strain Sensors. Adv. Mater. 2016, 28, 4998–5007. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, Y.; Su, M.; Li, W.; Li, Y.; Li, H.; Qian, X.; Zhang, X.; Li, F.; Song, Y. Electronic Textile by Dyeing Method for Multiresolution Physical Kineses Monitoring. Adv. Electron. Mater. 2017, 3, 1700253. [Google Scholar] [CrossRef]

- Behabtu, N.; Young, C.C.; Tsentalovich, D.E.; Kleinerman, O.; Wang, X.; Ma, A.W.K.; Bengio, E.A.; ter Waarbeek, R.F.; de Jong, J.J.; Hoogerwerf, R.E.; et al. Strong, Light, Multifunctional Fibers of Carbon Nanotubes with Ultrahigh Conductivity. Science 2013, 339, 182. [Google Scholar] [CrossRef]

- Seyedin, S.; Moradi, S.; Singh, C.; Razal, J.M. Continuous production of stretchable conductive multifilaments in kilometer scale enables facile knitting of wearable strain sensing textiles. Appl. Mater. Today 2018, 11, 255–263. [Google Scholar] [CrossRef]

- Wang, J.; Xue, P.; Tao, X.; Yu, T. Strain Sensing Behavior and Its Mechanisms of Electrically Conductive PPy-Coated Fabric. Adv. Eng. Mater. 2014, 16, 565–570. [Google Scholar] [CrossRef]

- Oh, K.W.; Park, H.J.; Kim, S.H. Stretchable conductive fabric for electrotherapy. J. Appl. Polym. Sci. 2003, 88, 1225–1229. [Google Scholar] [CrossRef]

- Tadesse, M.G.; Loghin, C.; Chen, Y.; Wang, L.; Catalin, D.; Nierstrasz, V. Effect of liquid immersion of PEDOT: PSS-coated polyester fabric on surface resistance and wettability. Smart Mater. Struct. 2017, 26, 065016. [Google Scholar] [CrossRef]

- Dias, T.; Beatty, P.; Cooke, W.; Wijesiriwardana, R.; Mukhopadhyay, S.; Hurley, W. Knitted Transducer Devices. Europe Patent EP1624800, 15 January 2009. [Google Scholar]

- Spencer, J.D. Knitting Techonology; Woodhead Publishing Limited: Cambridge, UK, 2001. [Google Scholar]

- Au, K.F. Advances in Knitting Technology; Woodhead Publishing Limited: Cambridge, UK, 2011. [Google Scholar]

- Ou, J.F.; Oran, D.; Haddad, D.D.; Paradiso, J.; Ishii, H. SensorKnit: Architecting Textile Sensors with Machine Knitting. 3D Print. Addit. Manuf. 2019, 6, 1–11. [Google Scholar] [CrossRef]

- Guignier, C.; Camillieri, B.; Schmid, M.; Rossi, R.; Bueno, M.A. E-Knitted Textile with Polymer Optical Fibers for Friction and Pressure Monitoring in Socks. Sensors 2019, 19, 3011. [Google Scholar] [CrossRef] [PubMed]

- Nayak, R.P. Rajiv Garment Manufacturing Technology; Woodhead Publishing Limited: Cambridge, UK, 2015. [Google Scholar] [CrossRef]

- Mecnika, V.; Hoerr, M.; Krievins, I.; Jockenhoevel, S.; Gries, T. Technical Embroidery for Smart Textiles: Review. Mater. Sci. Text. Cloth. Technol. 2015, 9. [Google Scholar] [CrossRef]

- Wijesiriwardana, R.; Dias, T.; Mukhopadhyay, S. Resistive fibre-meshed transducers. In Proceedings of the Seventh IEEE International Symposium on Wearable Computers, White Plains, NY, USA, 21–23 October 2003; pp. 200–209. [Google Scholar]

- Dhawan, A.; Ghosh, T.K.; Seyam, A.M.; Muth, J.F. Woven Fabric-Based Electrical Circuits: Part II: Yarn and Fabric Structures to Reduce Crosstalk Noise in Woven Fabric-Based Circuits. Text. Res. J. 2004, 74, 955–960. [Google Scholar] [CrossRef]

- Dupler, E.; Dunne, L.E. Effects of the textile-sensor interface on stitched strain sensor performance. In Proceedings of the 23rd International Symposium on Wearable Computers—ISWC ′19, London, UK, 9–13 September 2019; pp. 45–53. [Google Scholar]

- Atalay, O.; Kennon, W.R.; Husain, M.D. Textile-based weft knitted strain sensors: Effect of fabric parameters on sensor properties. Sensors 2013, 13, 11114–11127. [Google Scholar] [CrossRef]

- Grassi, A.; Cecchi, F.; Maselli, M.; Roling, M.; Laschi, C.; Cianchetti, M. Warp-Knitted Textile as a Strain Sensor: Characterization Procedure and Application in a Comfortable Wearable Goniometer. IEEE Sens. J. 2017, 17, 5927–5936. [Google Scholar] [CrossRef]

- Oliveri, A.; Maselli, M.; Lodi, M.; Storace, M.; Cianchetti, M. Model-Based Compensation of Rate-Dependent Hysteresis in a Piezoresistive Strain Sensor. IEEE Trans. Ind. Electron. 2019, 66, 8205–8213. [Google Scholar] [CrossRef]

- Liu, R.; Shao, Q.; Wang, S.; Ru, C.; Balkcom, D.; Zhou, X. Reconstructing Human Joint Motion with Computational Fabrics. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2019, 3, 1–26. [Google Scholar] [CrossRef]

- Tangsirinaruenart, O.; Stylios, G. A Novel Textile Stitch-Based Strain Sensor for Wearable End Users. Materials 2019, 12, 1469. [Google Scholar] [CrossRef] [PubMed]

- Farringdon, J. Wearable sensor badge & jacket for context awareness. In Proceedings of the Third International Symposium on Wearable Computers, San Francisco, CA, USA, 18–19 October 1999. [Google Scholar]

- Vogl, A.; Parzer, P.; Babic, T.; Leong, J.; Olwal, A.; Haller, M. StretchEBand. In Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems, Denver, CO, USA, 6–11 May 2017; pp. 2617–2627. [Google Scholar]

- Bickerton, M. Effects of fibre interactions on conductivity, within a knitted fabric stretch sensor. In Proceedings of the 2003 IEE Eurowearable, Birmingham, UK, 4–5 September 2003; pp. 67–72. [Google Scholar]

- Wijesiriwardana, R. Inductive fiber-meshed strain and displacement transducers for respiratory measuring systems and motion capturing systems. IEEE Sens. J. 2006, 6, 571–579. [Google Scholar] [CrossRef]

- Lorussi, F.; Carbonaro, N.; De Rossi, D.; Tognetti, A. Strain- and Angular-Sensing Fabrics for Human Motion Analysis in Daily Life. In Smart Textiles: Fundamentals, Design, and Interaction; Schneegass, S., Amft, O., Eds.; Springer: Cham, Switzerland, 2017; pp. 49–70. [Google Scholar] [CrossRef]

- Scilingo, E.P. Strain-sensing fabric for wearable kinaesthetic-like systems. Sens. J. 2003, 3, 460–467. [Google Scholar] [CrossRef]

- Tognetti, A.; Lorussi, F.; Bartalesi, R.; Quaglini, S.; Tesconi, M.; Zupone, G.; De Rossi, D. Wearable kinesthetic system for capturing and classifying upper limb gesture in post-stroke rehabilitation. J. Neuroeng. Rehabil. 2005, 2, 8. [Google Scholar] [CrossRef]

- Pacelli, M.; Caldani, L.; Paradiso, R.; IEEE. Performances evaluation of piezoresistive fabric sensors as function of yarn structure. In Proceedings of the 35th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Osaka, Japan, 3–7 July 2013; pp. 6502–6505. [Google Scholar]

- Paradiso, R.; Caldani, L.; Pacelli, M. Chapter 3.1—Knitted Electronic Textiles. In Wearable Sensors; Academic Press: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Paradiso, R.; Loriga, G.; Taccini, N. A wearable health care system based on knitted integrated sensors. IEEE Trans. Inf. Technol. Biomed. 2005, 9, 337–344. [Google Scholar] [CrossRef]

- Zhang, H.; Tao, X.; Yu, T.; Wang, S. Conductive knitted fabric as large-strain gauge under high temperature. Sens. Actuators A Phys. 2006, 126, 129–140. [Google Scholar] [CrossRef]

- Zhang, H.; Tao, X.; Wang, S.; Yu, T. Electro-Mechanical Properties of Knitted Fabric Made From Conductive Multi-Filament Yarn Under Unidirectional Extension. Text. Res. J. 2005, 75, 598–606. [Google Scholar] [CrossRef]

- Yang, K.; Song, G.-L.; Zhang, L.; Li, L.-W. Modelling the Electrical Property of 1x1 Rib Knitted Fabrics Made from Conductive Yarns. In Proceedings of the 2009 Second International Conference on Information and Computing Science, England, UK, 21–22 May 2009; pp. 382–385. [Google Scholar]

- Li, L.; Au, W.M.; Li, Y.; Wan, K.M.; Chung, W.Y.; Wong, K.S. A Novel Design Method for an Intelligent Clothing Based on Garment Design and Knitting Technology. Text. Res. J. 2009, 79, 1670–1679. [Google Scholar] [CrossRef]

- Li, L.; Liu, S.; Ding, F.; Hua, T.; Au, W.M.; Wong, K.-S. Electromechanical analysis of length-related resistance and contact resistance of conductive knitted fabrics. Text. Res. J. 2012, 82, 2062–2070. [Google Scholar] [CrossRef]

- Zięba, J.; Frydrysiak, M.; Błaszczyk, J. Textronic clothing with resistance textile sensor to monitoring frequency of human breathing. In Proceedings of the 2012 IEEE International Symposium on Medical Measurements and Applications, Budapest, Hungary, 18–19 May 2012; pp. 1–6. [Google Scholar]

- Atalay, O.; Kennon, W.R. Knitted strain sensors: Impact of design parameters on sensing properties. Sensors 2014, 14, 4712–4730. [Google Scholar] [CrossRef]

- Atalay, O.; Kennon, W.R.; Demirok, E. Weft-Knitted Strain Sensor for Monitoring Respiratory Rate and Its Electro-Mechanical Modeling. IEEE Sens. J. 2015, 15, 110–122. [Google Scholar] [CrossRef]

- Atalay, O.; Tuncay, A.; Husain, M.D.; Kennon, W.R. Comparative study of the weft-knitted strain sensors. J. Ind. Text. 2017, 46, 1212–1240. [Google Scholar] [CrossRef]

- Ehrmann, A.; Heimlich, F.; Brücken, A.; Weber, M.O.; Haug, R. Suitability of knitted fabrics as elongation sensors subject to structure, stitch dimension and elongation direction. Text. Res. J. 2014, 84, 2006–2012. [Google Scholar] [CrossRef]

- Wang, J.; Long, H.; Soltanian, S.; Servati, P.; Ko, F. Electro-mechanical properties of knitted wearable sensors: Part 2—Parametric study and experimental verification. Text. Res. J. 2013, 84, 200–213. [Google Scholar] [CrossRef]

- Oks, A.; Katashev, A.; Litvak, J. Knitted Resistive Fabric: Properties and Applications. Mater. Sci. Text. Cloth. Technol. 2015, 9. [Google Scholar] [CrossRef]

- Xie, J.; Long, H.R.; Miao, M.H. High sensitivity knitted fabric strain sensors. Smart Mater. Struct. 2016, 25, 105008. [Google Scholar] [CrossRef]

- Raji, R.K.; Miao, X.; Zhang, S.; Li, Y.; Wan, A. Influence of Rib Structure and Elastic Yarn Type Variations on Textile Piezoresistive Strain Sensor Characteristics. Fibres Text. East. Eur. 2018, 26, 24–31. [Google Scholar] [CrossRef]

- Raji, R.K.; Miao, X.; Zhang, S.; Li, Y.; Wan, A.; Boakye, A. Knitted piezoresistive strain sensor performance, impact of conductive area and profile design. J. Ind. Text. 2019. [Google Scholar] [CrossRef]

- Li, L.; Au, W.; Wan, K.; Wan, S.; Chung, W.; Wong, K. A Resistive Network Model for Conductive Knitting Stitches. Text. Res. J. 2010, 80, 935–947. [Google Scholar] [CrossRef]

- Xie, J.; Long, H. Equivalent resistance calculation of knitting sensor under strip biaxial elongation. Sens. Actuators A Phys. 2014, 220, 118–125. [Google Scholar] [CrossRef][Green Version]

- Gioberto, G.; Dunne, L. Theory and Characterization of a Top-Thread Coverstitched Stretch Sensor. In Proceedings of the 2012 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Seoul, Korea, 14–17 October 2012; pp. 3275–3280. [Google Scholar]

- Gioberto, G.D.; Dunne, L.E. Overlock-stitched stretch sensors. J. Text. Appar. Technol. Manag. 2013, 8, 1–14. [Google Scholar]

- Gioberto, G.; Compton, C.; Dunne, L. Machine-stitched E-textile stretch sensors. Sens. Transducers 2016, 202, 25–37. [Google Scholar]

- Ruppert-Stroescu, M.; Balasubramanian, M. Effects of stitch classes on the electrical properties of conductive threads. Text. Res. J. 2017, 88, 2454–2463. [Google Scholar] [CrossRef]

- Greenspan, B.; Hall, M.L.; Cao, H.T.; Lobo, M.A. Development and testing of a stitched stretch sensor with the potential to measure human movement. J. Text. Inst. 2018, 109, 1493–1500. [Google Scholar] [CrossRef]

- Tognetti, A.; Lorussi, F.; Mura, G.D.; Carbonaro, N.; Pacelli, M.; Paradiso, R.; De Rossi, D. New generation of wearable goniometers for motion capture systems. J. Neuroeng. Rehabil. 2014, 11. [Google Scholar] [CrossRef]

- Raji Rafiu, K.; Miao, X.; Zhang, S.; Li, Y.; Wan, A.; Frimpong, C. A comparative study of knitted strain sensors fabricated with conductive composite and coated yarns. Int. J. Cloth. Sci. Technol. 2019, 31, 181–194. [Google Scholar] [CrossRef]

| Reference | Knit Type | Conductive Yarn 1 | Non-Conductive Yarn | R0 (Ω) | GF (Range) 2 | Working Range (%) 3 | Hysteresis Hε 4 | Remarks | Application |

|---|---|---|---|---|---|---|---|---|---|

| Farringdon 1999 [43] | - | - | - | 50.000 | 17 | 40% | Sensor strips | Activity sensing | |

| Bickerton 2003 [45] | plain | Carbon fibre | Lycra | 90.000 | 14 | 40% | Body kinematics | ||

| Wije 2003 [35] | - | Carbon rubber | elastic | 400.000 | 2.4 | 10% | Body kinematics | ||

| Atalay 2013 [38] | interlock | 235 dtex Sil-Ny, 200 Ω/m | 800 dtex elastic | 166 | 3.75 | 10–40% | 0.10 | 1-course loopwise embedded | Body kinematics |

| Atalay 2014 [59] | interlock | Sil-Ny, 200 Ω/m | 800 dtex elastic | - | 1.86 | 6 to >40% | 0.07 | 1-course loopwise embedded | |

| Atalay 2017 [61] | plain | Sil-Ny, 200 Ω/m | 800 dtex elastic | 10.4 | 1.05 | 80% | noisy | ||

| plain | Sil-Ny, 200 Ω/m | 167 dtex polyester | 5.3 | −0.38 | 20% | noisy | |||

| interlock | Sil-Ny, 200 Ω/m | 800 dtex elastic | 2.3 | 0.97 | 40% | noisy | |||

| interlock | Sil-Ny, 200 Ω/m | 167 dtex polyester | 4.6 | −0.70 | 55% | noisy | |||

| Atalay 2015 [60] | interlock | Sil-Ny, 200 Ω/m | 800 dtex elastic | 261 | 3.44 (8%) | >40% | 0.08 | 1-course loopwise embedded | Respiration monitoring |

| Zhang 2005 [54] | plain | Bare SS | - | 12 | −8.6 (10%) | 22% | |||

| Zhang 2006 [53] | Single warp | carbon | - | 15.000 | −13 (2%) | 8% | 0.08 | ||

| Yang 2009 [55] | 1 × 1 rib | Bare SS | - | 11.5 | −1.1 (40%) | 50% | |||

| Ehrmann 2014 [62] | full cardigan | PES/SS, 525 k Ω/m | cotton | - | −6.2 (10%) | 20% | Resistance drops to zero | ||

| Double face | PES/SS, 525 k Ω/m | - | −2.2 (20%) | 55% | Large relaxation | Respiration monitoring | |||

| Pacelli 2013 [50] | intarsia | Cf-Ny (Belltron) | Lycra | 44.300 | 0.75 (16%) | >16% | 0.14 | Rehabilitation, Body kinematics | |

| Oks 2014 [64] | plain | Sil-Ny | Elastane, PES, cotton | 12 | >10 (5%) | 5–10% | 0.10 | Alternating conductive rows | Sensing glove, sock |

| Tognetti 2014 [75] | intarsia | Cf-Ny (Belltron) | Lycra | 90.000 | 6.7 | >10% | 0.14 | Single layer strip | Rehabilitation, Body kinematics |

| Ou 2019 [31] | interlock | Sil-Ny | Spandex, PES | 60 | 2.3 | L0 estimated | Human Computer Interaction | ||

| Xie 2016 [65] | plain | Cotton/SS, 500 Ω/m | cotton | 12 | −3.7 (10%) | 40% | Custom blended yarn | Body kinematics | |

| plain | Sil-Ny, 500 Ω/m | 2.8 | 0.36 (>30%) | >30% | |||||

| Raji 2018 [66] | 1 × 1 rib | Sil-Ny, 7700 Ω/m | Nylon covered spandex | 32.8 | 1.25 | >10% | Respiration, smart bra | ||

| 1 × 2 rib | 25.3 | 1.5 | |||||||

| 1 × 3 rib | 25.9 | 1.6 | |||||||

| 2 × 2 rib | 31.7 | 1.4 | |||||||

| 1 × 1 rib | Bare spandex | 14.9 | 2.45 | ||||||

| 1 × 2 rib | 12.3 | 2.85 | |||||||

| 1 × 3 rib | 11.1 | 2.3 | |||||||

| 2 × 2 rib | 15.1 | 2.2 | |||||||

| Raji 2019 | [76] 1 × 1 rib | Sil-Ny, 7700 Ω/m | Nylon covered spandex | 47.1 | 1.31 | >10% | 12 other sizes tested | Respiration, smart bra |

| Author | Stitch Type | Conductive Yarn 1 | Substrate Fabric | R0 (Ω) | GF (Range) 2 | Working Range (%) 3 | Hysteresis Hε 4 | Remarks | Application |

|---|---|---|---|---|---|---|---|---|---|

| Gioberto 2012 [70] | 602, top coverstitch | Sil-Ny, Lamé, 81 Ω/m | - | 120 | 0.54 (12%) | 10% | - | Non-linear, low hysteresis | |

| Gioberto 2013 [71] | 514, Overlock | Sil-Ny, 50 Ω/m | 100% PES jersey | 43 | 0.94 (10%) | 19 | - | HR = 0.19 | |

| 60 cotton/40 PES | 55 | 0.48 (10%) | 21 | - | HR = 0.35 | ||||

| 90 PES/10 spandex | 58 | 2.22 (10%) | 17 | - | HR = 3.04 | ||||

| 94 cotton/6 spandex | 43 | 1.41 (10%) | 22 | 0.17 | HR = 1.15 | ||||

| 82 Ny/18 spandex | 43 | 1.43 (10%) | 29 | - | HR = 0.82 | ||||

| Gioberto 2016 [72] | 602, bottom coverstitch | 2-ply Sil-Ny Shieldex | Jersey knit elastomeric blend | 2370 | −1.22 (50%) | >50% | - | Noisy signal | |

| 4-ply Sil-Ny Shieldex | Jersey knit elastomeric blend | 61 | −0.89 (50%) | >50% | - | Good signal | Spinal posture sensing | ||

| Dupler 2019 [37] | 406, Bottom coverstitch | Sil-Ny Shieldex | 4-way PES/Spandex | 10.9 | −1.15 (30%) | >30% | 0.02 | HR = 0.23 | |

| 401, Chain stitch | 7.7 | −1.76 (30%) | >30% | - | HR = 0.34 | ||||

| 406, Bottom coverstitch | 2-way PES | 10.9 | −1.13 (30%) | >30% | - | HR = 0.08 | |||

| 401, Chain stitch | 7.7 | −2.20 (30%) | >30% | - | HR = 0.34 | ||||

| Greenspan 2018 [74] | 304, Zigzag | Sil-Ny/PET, 30 kΩ/m | 90% PES/10% elastane | 7000 | 1.0 (5–28%) | >30% | 0.10 | Body kinematics | |

| Tangsiri 2019 [42] | 304, Zigzag | 2-ply Sil-Ny 117/17 | 75% Ny/25% Spandex | 125 | 1.61 (50%) | 50% | 0.07 | HR = 0.09 | |

| 406, chain stitch | 2-ply Sil-Ny 117/17 | 71.5 | 3.71 (25%) | 25% | 0.20 | HR = 2.51 | |||

| 4-ply Sil-Ny 234/34 | 55.6 | 2.71 (8%) | 8% | 0.55 | HR = 0.71 | ||||

| 506, overlock | 2-ply Sil-Ny 117/17 | 649 | 0.099 (16%) | 16% | 0.36 | HR = 0.05 | |||

| 4-ply Sil-Ny 234/34 | 46.7 | 5.16 (12%) | 12% | 0.51 | HR = 0.54 | ||||

| 605, coverstitch | 2-ply Sil-Ny 117/17 | 240 | 0.21 (18%) | 18% | 0.04 | HR = 0.59 | |||

| 4-ply Sil-Ny 234/34 | 39.3 | 1.65 (18%) | 18% | 0.14 | HR = 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jansen, K.M.B. Performance Evaluation of Knitted and Stitched Textile Strain Sensors. Sensors 2020, 20, 7236. https://doi.org/10.3390/s20247236

Jansen KMB. Performance Evaluation of Knitted and Stitched Textile Strain Sensors. Sensors. 2020; 20(24):7236. https://doi.org/10.3390/s20247236

Chicago/Turabian StyleJansen, Kaspar M.B. 2020. "Performance Evaluation of Knitted and Stitched Textile Strain Sensors" Sensors 20, no. 24: 7236. https://doi.org/10.3390/s20247236

APA StyleJansen, K. M. B. (2020). Performance Evaluation of Knitted and Stitched Textile Strain Sensors. Sensors, 20(24), 7236. https://doi.org/10.3390/s20247236