Insulation Failure Quantification Based on the Energy of Digital Images Using Low-Cost Imaging Sensors

Abstract

1. Introduction

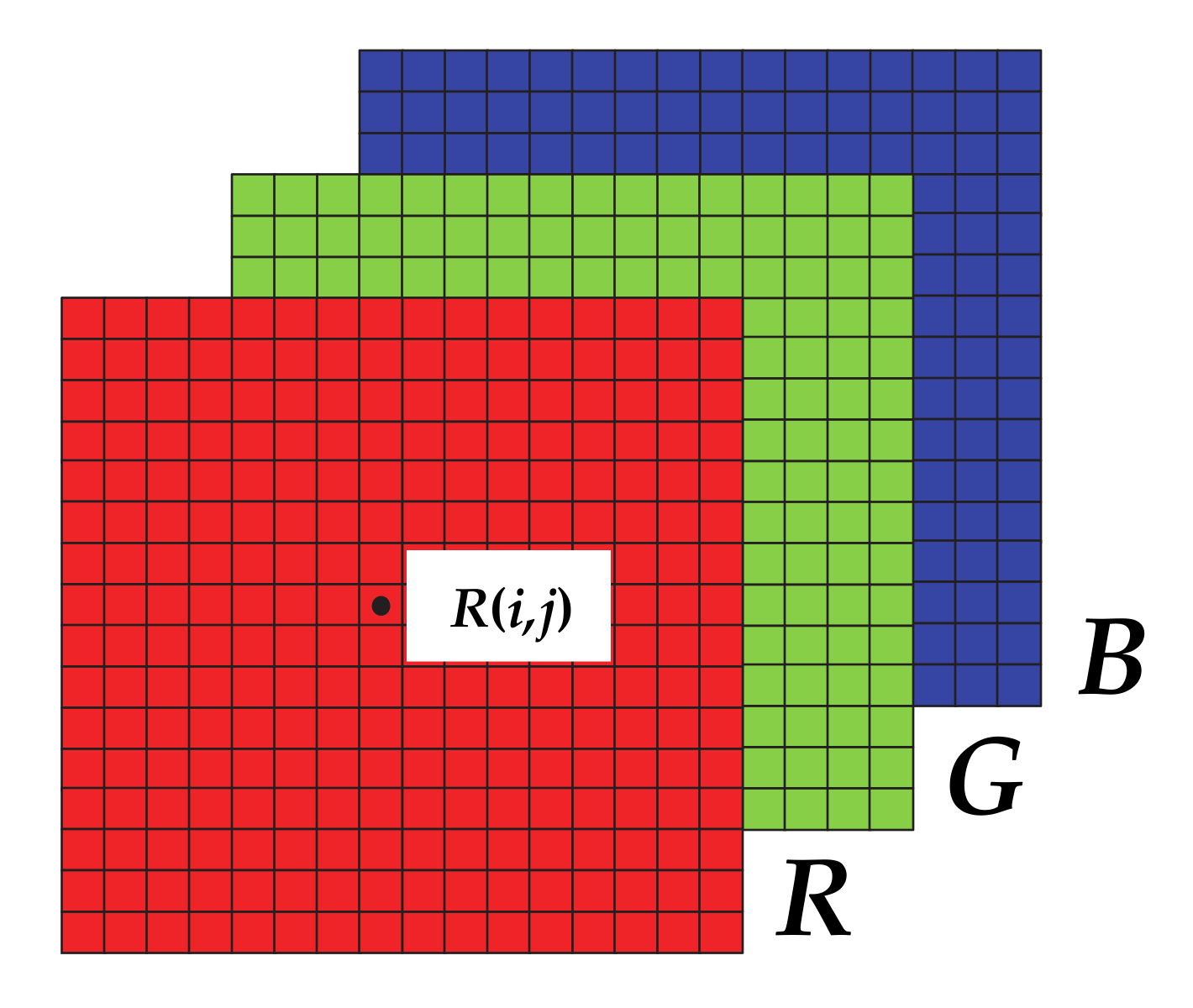

2. Applied Digital Image Processing Techniques

- R = image_RGB (:,:,1);

- G = image_RGB (:,:,2);

- B = image_RGB (:,:,3);

- m = size(Image_RGB,1);

- n = size(Image_RGB,2);

- image_GRAY = 0.299 * R + 0.587 * G + 0.114 * B;

- energy = sum(sum(image_GRAY));

- energy_normalized = 100*energy/(n*m*255);

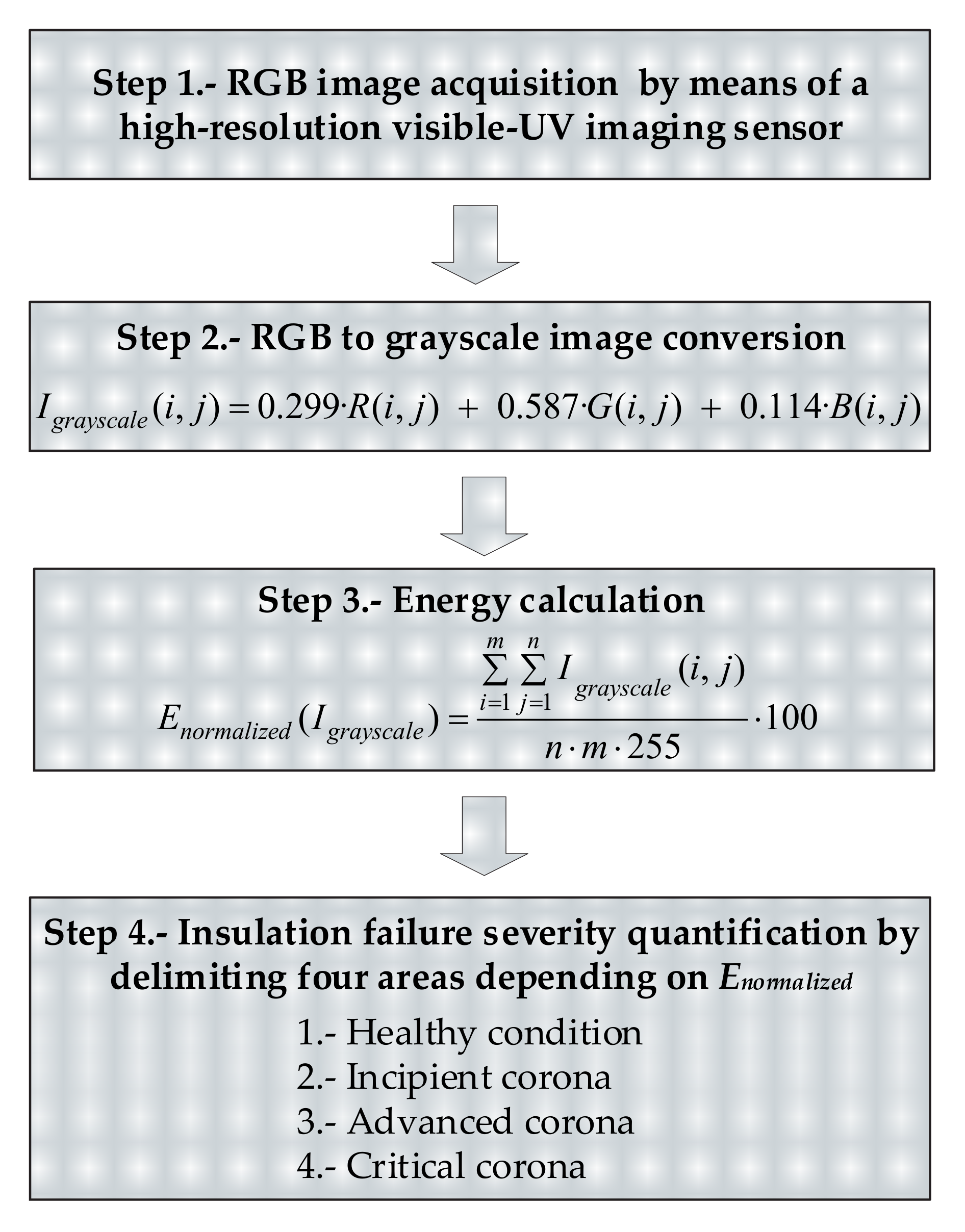

- Step 1.

- Image acquisition using a high-resolution image sensor. The long-exposure photographs were taken for 32 s long using ISO 400 sensitivity, with manual focus, automatic white balance and RGB mode.

- Step 2.

- All RGB images are converted to grayscale by applying the transformation in (2).

- Step 3.

- The normalized energy of each image is calculated by applying (3).

- Step 4.

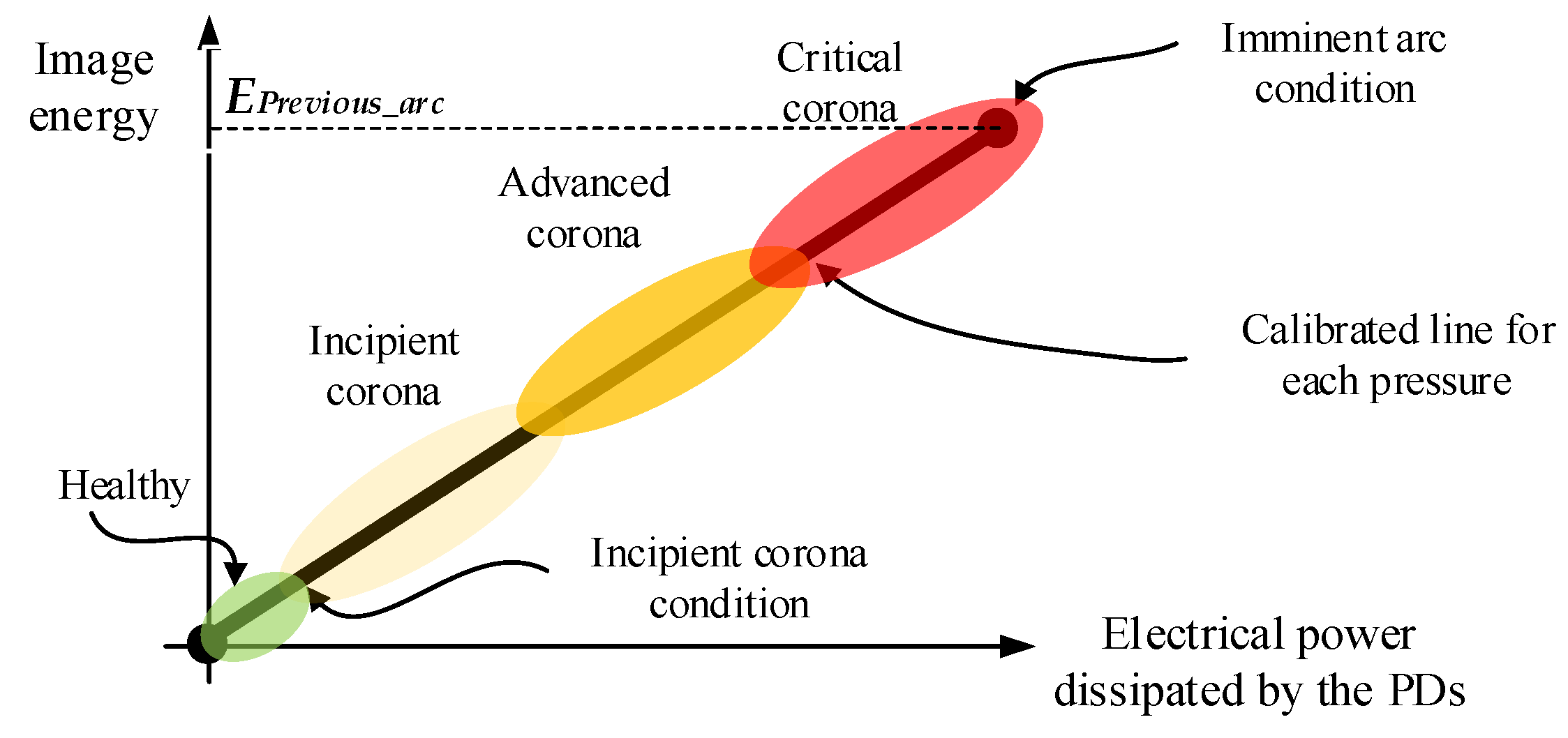

- As it will be proved in Section 3, the energy of an image is proportional to the power dissipated by the partial discharges, thus allowing the severity level of insulation faults to be quantified on four levels, i.e., healthy condition, incipient corona, advanced corona, and critical corona.

3. Experimental Setup

4. Experimental Results and Discussion

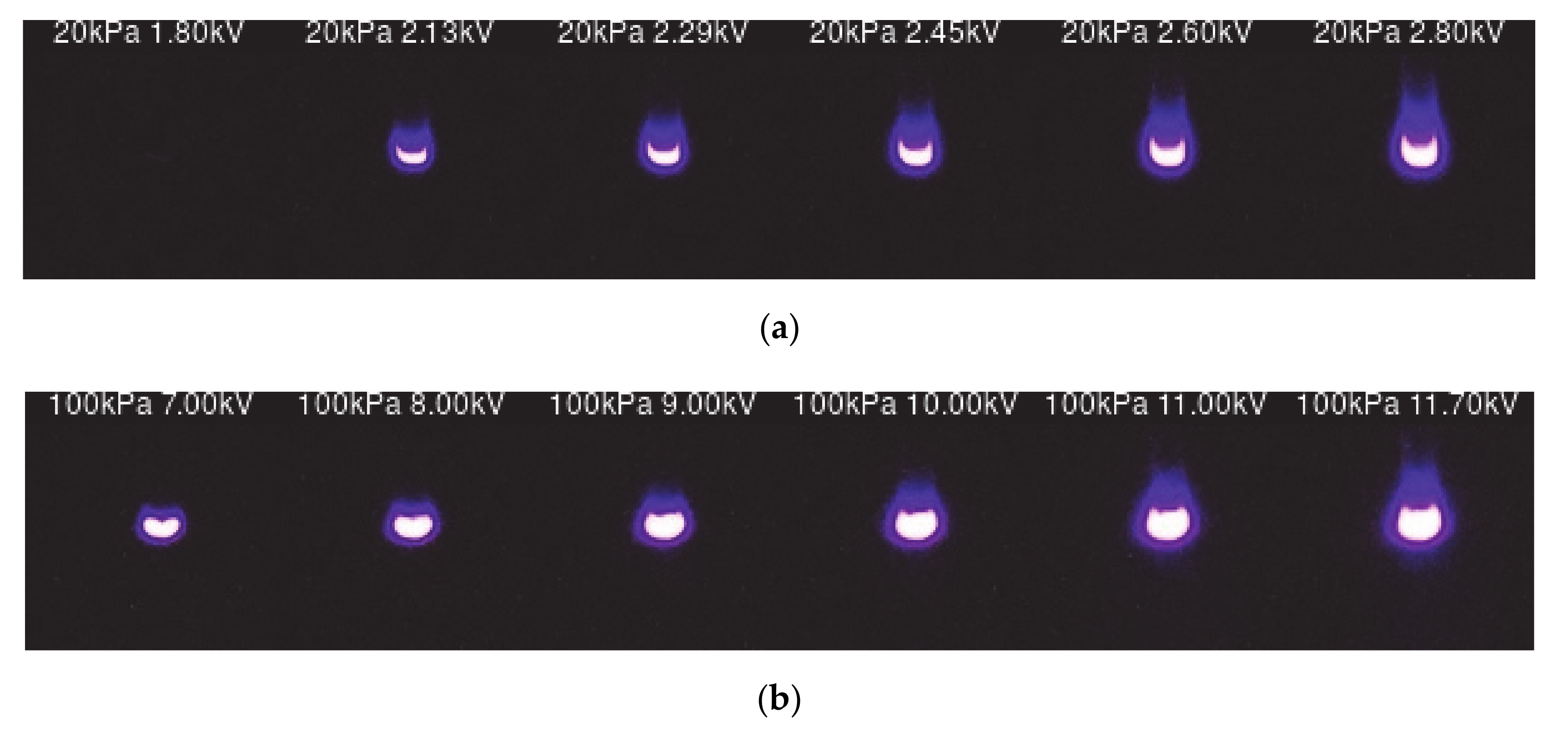

4.1. Long-Exposure Photographs

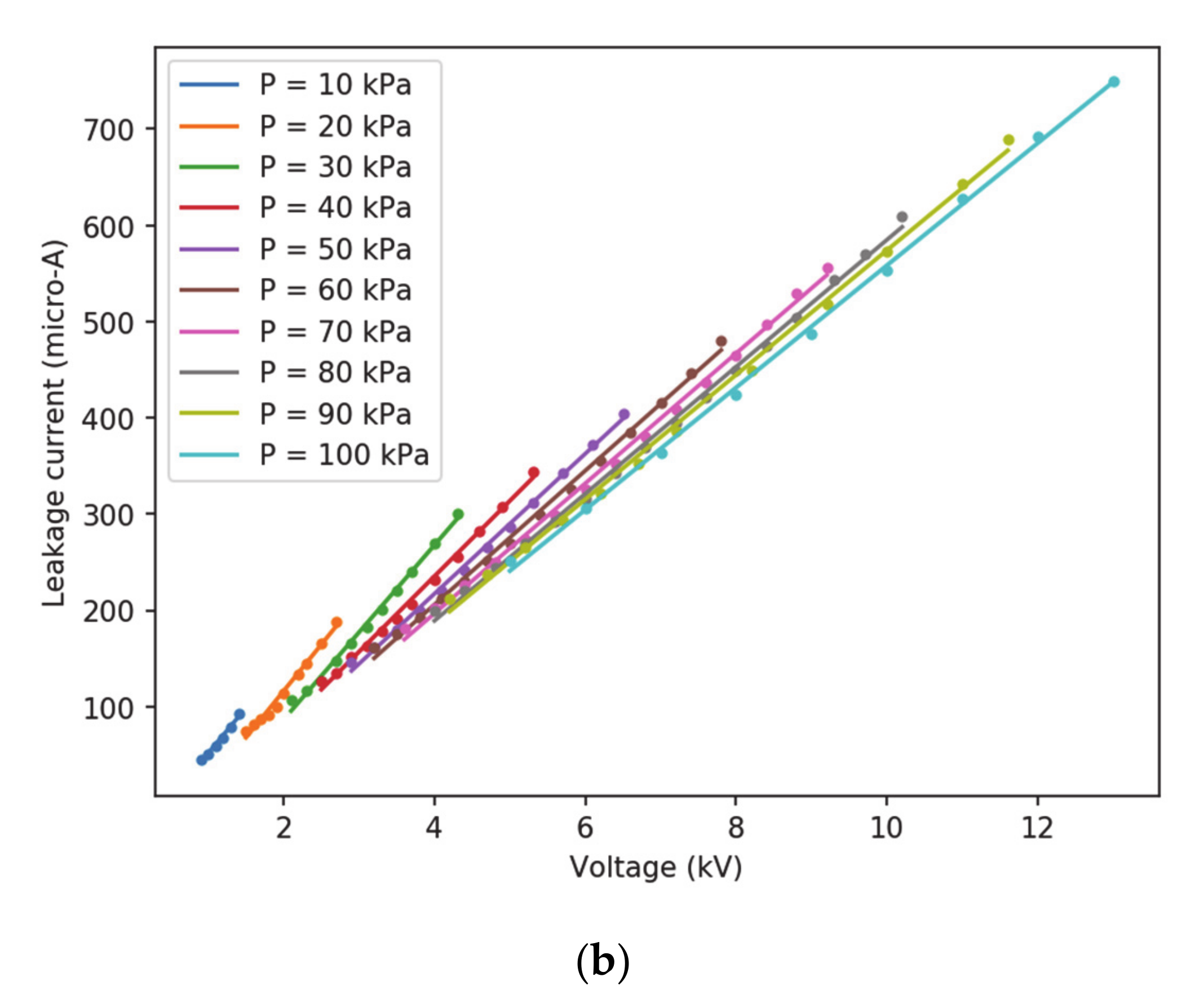

4.2. Electrical Measurements: Leakage Current versus Applied Voltage

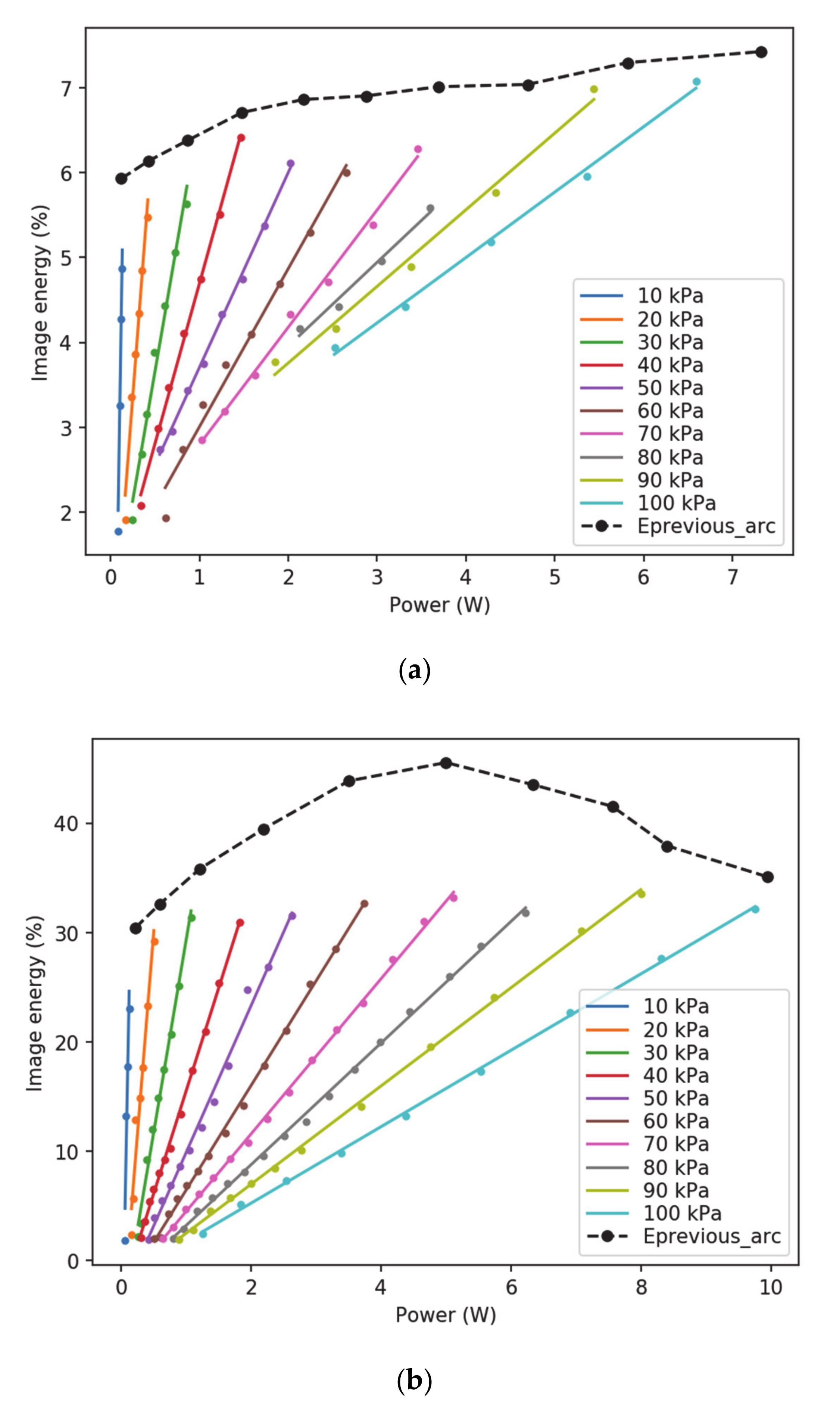

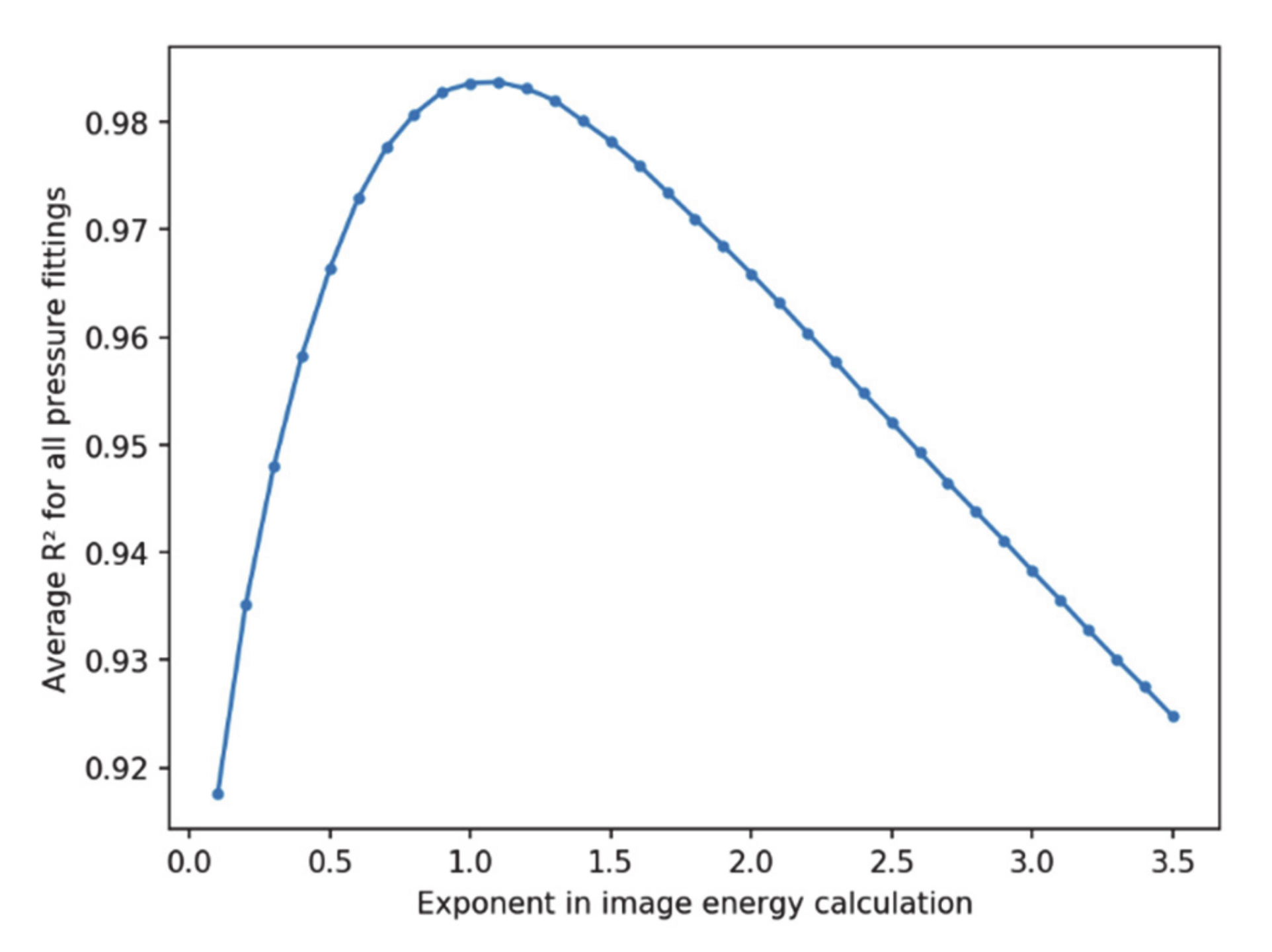

4.3. Relationship between the Energy of the Images and the Electrical Power Dissipated by the PDs

4.4. Criterion to Determine the Early Appearance of Insulation Faults

- Healthy condition, between 0% and 10% of EPrevious_arc;

- Incipient corona, between 10% and 40% of EPrevious_arc;

- Advanced corona, between 40% and 70% of EPrevious_arc;

- Critical corona, between 70% and 100% of EPrevious_arc.

- Healthy condition: image energy values between 0 and 4.5%;

- Incipient corona: image energy values between 4.5% and 18.1%;

- Advanced corona: image energy values between 18.1% and 31.6%;

- Critical corona: image energy values between 31.6% and 45.2%.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Federal Aviation Administration. Aircraft Electrical Wiring Interconnect System (EWIS) Best Practices; Federal Aviation Administration: Washington, DC, USA, 2020.

- Shafiq, M.; Robles, G.; Kauhaniemi, K.; Stewart, B.; Lehtonen, M. Propagation Characteristics of Partial discharge Signals in Medium Voltage Branched Cable Joints using HFCT Sensor. In CIRED 2019 Conference; CIRED: Madrid, Spain, 2019; pp. 1–5. [Google Scholar]

- IEEE Std 100–2000. The Authoritative Dictionary of IEEE Standards Terms, 7th ed.; IEEE Std 100–2000: Piscataway, NJ, USA, 2000; pp. 1–1362. [Google Scholar]

- Riba, J.-R.; Morosini, A.; Capelli, F. Comparative Study of AC and Positive and Negative DC Visual Corona for Sphere-Plane Gaps in Atmospheric Air. Energies 2018, 11, 2671. [Google Scholar] [CrossRef]

- Abomailek, C.; Riba, J.-R.; Casals-Torrens, P. Feasibility Analysis of Reduced-Scale Visual Corona Tests in High Voltage Laboratories. IET Gener. Transm. Distrib. 2019, 13, 2543–2549. [Google Scholar] [CrossRef]

- Du, B.X.; Liu, Y.; Liu, H.J. Effects of low pressure on tracking failure of printed circuit boards. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1379–1384. [Google Scholar] [CrossRef]

- Mermigkas, A.C.; Clark, D.; Manu Haddad, A. Investigation of High Altitude/Tropospheric Correction Factors for Electric Aircraft Applications. In Lecture Notes in Electrical Engineering; Springer: Cham, Switzerland, 2020; Volume 598, pp. 308–315. [Google Scholar]

- Robledo-Martinez, A.; Sobral, H.; Ruiz-Meza, A. Effect of pressure in fast-front lightning discharges in air. IEEE Trans. Plasma Sci. 2008, 36, 948–949. [Google Scholar] [CrossRef]

- Rui, R.; Cotton, I. Impact of low pressure aerospace environment on machine winding insulation. In Proceedings of the 2010 IEEE International Symposium on Electrical Insulation, San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar]

- Riba, J.-R.; Gómez-Pau, Á.; Moreno-Eguilaz, M.; Bogarra, S. Arc Tracking Control in Insulation Systems for Aeronautic Applications: Challenges, Opportunities, and Research Needs. Sensors 2020, 20, 1654. [Google Scholar] [CrossRef]

- Degardin, V.; Kone, L.; Valensi, F.; Laly, P.; Lienard, M.; Degauque, P. Characterization of the High-Frequency Conducted Electromagnetic Noise Generated by an Arc Tracking between DC wires. IEEE Trans. Electromagn. Compat. 2016, 58, 1228–1235. [Google Scholar] [CrossRef]

- El Bayda, H.; Valensi, F.; Masquere, M.; Gleizes, A. Energy losses from an arc tracking in aeronautic cables in DC circuits. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 19–27. [Google Scholar] [CrossRef]

- Riba, J.-R.; Larzelere, W.; Rickmann, J. Voltage Correction Factors for Air-Insulated Transmission Lines Operating in High-Altitude Regions to Limit Corona Activity: A Review. Energies 2018, 11, 1908. [Google Scholar] [CrossRef]

- Riba, J.-R.; Gómez-Pau, Á.; Moreno-Eguilaz, M. Experimental Study of Visual Corona under Aeronautic Pressure Conditions Using Low-Cost Imaging Sensors. Sensors 2020, 20, 411. [Google Scholar] [CrossRef] [PubMed]

- Belijar, G.; Chanaud, G.; Hermette, L.; Risacher, A. Study of Electric arc Ignition, Behavior and Extinction in Aeronautical Environment, in Presence of FOD. HAL 2017, hal-01656176. [Google Scholar]

- Cella, B. On-Line Partial Discharges Detection in Conversion Systems used in Aeronautics; Université de Toulouse: Toulouse, France, 2015. [Google Scholar]

- Zhang, L. Electrical Tracking over Solid Insulating Materials for Aerospace Applications; University of Manchester: Manchester, UK, 2011. [Google Scholar]

- Clean Sky. Clean Sky Annex: 11th Call for Proposals (CFP11)-List and Full Description of Topics Call Text; Clean Sky: Brussels, Belgium, 2019. [Google Scholar]

- Clean Sky. Clean Sky Annex V: 9th Call for Proposals (CFP09)—List and Full Description of Topics; Clean Sky: Brussels, Belgium, 2018; pp. 1–354. [Google Scholar]

- Yuan, Z.; Ye, Q.; Wang, Y.; Guo, Z. State Recognition of Surface Discharges by Visible Images and Machine Learning. IEEE Trans. Instrum. Meas. 2020. [Google Scholar] [CrossRef]

- Nagi, Ł.; Kozioł, M.; Wotzka, D. Analysis of the spectrum of electromagnetic radiation generated by electrical discharges. IET Sci. Meas. Technol. 2019, 13, 812–817. [Google Scholar] [CrossRef]

- Nagi, Ł.; Kozioł, M.; Zygarlicki, J. Optical Radiation from an Electric Arc at Different Frequencies. Energies 2020, 13, 1676. [Google Scholar] [CrossRef]

- Wang, S.; Lv, F.; Liu, Y. Estimation of discharge magnitude of composite insulator surface corona discharge based on ultraviolet imaging method. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1697–1704. [Google Scholar] [CrossRef]

- Yuanyuan, W.; Shengchang, J.; Jinyu, L.; Lipeng, Z.; Yanjie, C.; Wei, W. Ultraviolet images of 50-Hz AC discharges in SF6 atmosphere. IEEE Trans. Plasma Sci. 2014, 42, 2840–2841. [Google Scholar] [CrossRef]

- Prasad, D.S.; Reddy, B.S. Study on Corona Activity Using an Image Processing Approach. IEEE Trans. Ind. Appl. 2017, 53, 4008–4014. [Google Scholar] [CrossRef]

- Shirmohammadi, S.; Ferrero, A. Camera as the instrument: The rising trend of vision based measurement. IEEE Instrum. Meas. Mag. 2014, 17, 41–47. [Google Scholar] [CrossRef]

- Gu, J.C.; Lai, D.S.; Wang, J.M.; Huang, J.J.; Yang, M.T. Design of a DC series arc fault detector for photovoltaic system protection. IEEE Trans. Ind. Appl. 2019, 55, 2464–2471. [Google Scholar] [CrossRef]

- SAE. SAE AS6019: ARC Fault Circuit Breaker (AFCB), Aircraft, Trip-Free 28 VDC—SAE International; SAE: Warrendale, PA, USA, 2012; pp. 1–60. [Google Scholar]

- Saleh, S.A.; Valdes, M.E.; Mardegan, C.S.; Alsayid, B. The State-of-the-Art Methods for Digital Detection and Identification of Arcing Current Faults. IEEE Trans. Ind. Appl. 2019, 55, 4536–4550. [Google Scholar] [CrossRef]

- Lisnyak, M. Theoretical, Numerical and Experimental Study of DC and AC Electric Arcs. Ph.D. Thesis, GREMI Universite d’Orleans, Orléans, France, 2018. [Google Scholar]

- Lectromec. 2016 Statistical Analysis of EWIS Failures of the US Commercial Aircraft Fleet and How to Improve; Lectromec: Chantilly, VA, USA, 2017. [Google Scholar]

- Grassetti, R.; Ottoboni, R.; Rossi, M.; Toscani, S. A low-cost arc fault detector for aerospace applications. IEEE Instrum. Meas. Mag. 2013, 16, 37–42. [Google Scholar] [CrossRef]

- Wang, Z.; McConnell, S.; Balog, R.S.; Johnson, J. Arc fault signal detection—Fourier transformation vs. wavelet decomposition techniques using synthesized data. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 3239–3244. [Google Scholar]

- Sastry, S.S.; Mallika, K.; Rao, B.G.S.; Tiong, H.S.; Lakshminarayana, S. Identification of phase transition temperatures by statistical image analysis. Liq. Cryst. 2012, 39, 695–700. [Google Scholar] [CrossRef]

- González, R.C.; Woods, R.E. Digital Image Processing, 3rd ed.; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2008; ISBN 978-0-13-168728-8. [Google Scholar]

- Prasad, D.S.; Reddy, B.S. Digital image processing techniques for estimating power released from the corona discharges. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 75–82. [Google Scholar] [CrossRef]

- Stein, J.Y. Digital Signal Processing. A Computer Science Perspective; John Wiley & Sons Inc.: New York, NY, USA, 2000; ISBN 0-471-29546-9. [Google Scholar]

- Abeysekara, A.H.A.D.; Kumara, J.R.S.S.; Fernando, M.A.R.M.; Eakanayake, M.P.B.; Godaliyadda, G.M.R.I.; Wijayakulasooriya, J.V. Remote leakage current detector for identification of insulators discharges. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2449–2458. [Google Scholar] [CrossRef]

- Riba, J.-R.; Abomailek, C.; Casals-Torrens, P.; Capelli, F. Simplification and cost reduction of visual corona tests. IET Gener. Transm. Distrib. 2018, 12, 834–841. [Google Scholar] [CrossRef]

- Cotton, I.; Nelms, A. Higher voltage aircraft power systems. IEEE Aerosp. Electron. Syst. Mag. 2008, 23, 25–32. [Google Scholar] [CrossRef]

- Turner, J.; Igoe, D.; Parisi, A.V.; McGonigle, A.J.; Amar, A.; Wainwright, L. A review on the ability of smartphones to detect ultraviolet (UV) radiation and their potential to be used in UV research and for public education purposes. Sci. Total Environ. 2020, 706, 135873. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Chang, K.; Min, J.; Moon, K.; Kim, J.; Chang, D. Reliability and availability study on critical safety systems of an offshore drilling platform. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering—OMAE, Vancouver, BC, Canada, 20–25 June 2004; Volume 2, pp. 55–61. [Google Scholar]

| Parameters | 10 kPa | 20 kPa | 30 kPa | 40 kPa | 50 kPa | 60 kPa | 70 kPa | 80 kPa | 90 kPa | 100 kPa | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Positive DC | Io (μA) | −7.8 | −12.7 | −14.9 | −20.2 | −27.4 | −31.0 | −36.4 | −39.2 | −49.2 | −66.6 |

| k1 (μA/kV) | 57.5 | 57.9 | 57.3 | 57.6 | 58.3 | 58.3 | 58.7 | 58.2 | 59.1 | 60.5 | |

| R2 | 0.995 | 0.999 | 0.999 | 0.999 | 0.998 | 0.999 | 0.999 | 0.999 | 0.999 | 1.000 | |

| Negative DC | Io (μA) | −42.1 | −77.3 | −95.0 | −78.4 | −74.0 | −72.5 | −73.6 | −74.8 | −73.2 | −76.7 |

| k1 (μA/kV) | 93.7 | 96.7 | 90.7 | 78.4 | 72.8 | 69.6 | 67.6 | 66.0 | 64.7 | 63.5 | |

| R2 | 0.983 | 0.987 | 0.994 | 0.996 | 0.997 | 0.997 | 0.998 | 0.998 | 0.998 | 0.999 |

| Parameters | 10 kPa | 20 kPa | 30 kPa | 40 kPa | 50 kPa | 60 kPa | 70 kPa | 80 kPa | 90 kPa | 100 kPa | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Positive DC | Eo (−) | −3.591 | −0.066 | 0.681 | 0.919 | 1.406 | 0.944 | 1.414 | 1.979 | 1.951 | 1.770 |

| k2 (−/W) | 65.41 | 13.68 | 5.930 | 3.773 | 2.298 | 2.024 | 1.382 | 0.988 | 0.903 | 0.810 | |

| R2 | 0.960 | 0.974 | 0.989 | 0.997 | 0.997 | 0.981 | 0.995 | 0.984 | 0.991 | 0.995 | |

| Negative DC | Eo (−) | −15.44 | −7.399 | −5.027 | −3.421 | −3.664 | −3.196 | −2.671 | −2.410 | −2.053 | −1.786 |

| k2 (−/W) | 311.0 | 74.00 | 33.08 | 18.83 | 13.46 | 9.581 | 7.106 | 5.571 | 4.499 | 3.501 | |

| R2 | 0.904 | 0.962 | 0.986 | 0.998 | 0.992 | 0.998 | 0.999 | 0.999 | 0.999 | 0.999 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riba, J.-R.; Gómez-Pau, Á.; Moreno-Eguilaz, M. Insulation Failure Quantification Based on the Energy of Digital Images Using Low-Cost Imaging Sensors. Sensors 2020, 20, 7219. https://doi.org/10.3390/s20247219

Riba J-R, Gómez-Pau Á, Moreno-Eguilaz M. Insulation Failure Quantification Based on the Energy of Digital Images Using Low-Cost Imaging Sensors. Sensors. 2020; 20(24):7219. https://doi.org/10.3390/s20247219

Chicago/Turabian StyleRiba, Jordi-Roger, Álvaro Gómez-Pau, and Manuel Moreno-Eguilaz. 2020. "Insulation Failure Quantification Based on the Energy of Digital Images Using Low-Cost Imaging Sensors" Sensors 20, no. 24: 7219. https://doi.org/10.3390/s20247219

APA StyleRiba, J.-R., Gómez-Pau, Á., & Moreno-Eguilaz, M. (2020). Insulation Failure Quantification Based on the Energy of Digital Images Using Low-Cost Imaging Sensors. Sensors, 20(24), 7219. https://doi.org/10.3390/s20247219