Analysis of Electric Motor Magnetic Core Loss under Axial Mechanical Stress

Abstract

1. Introduction

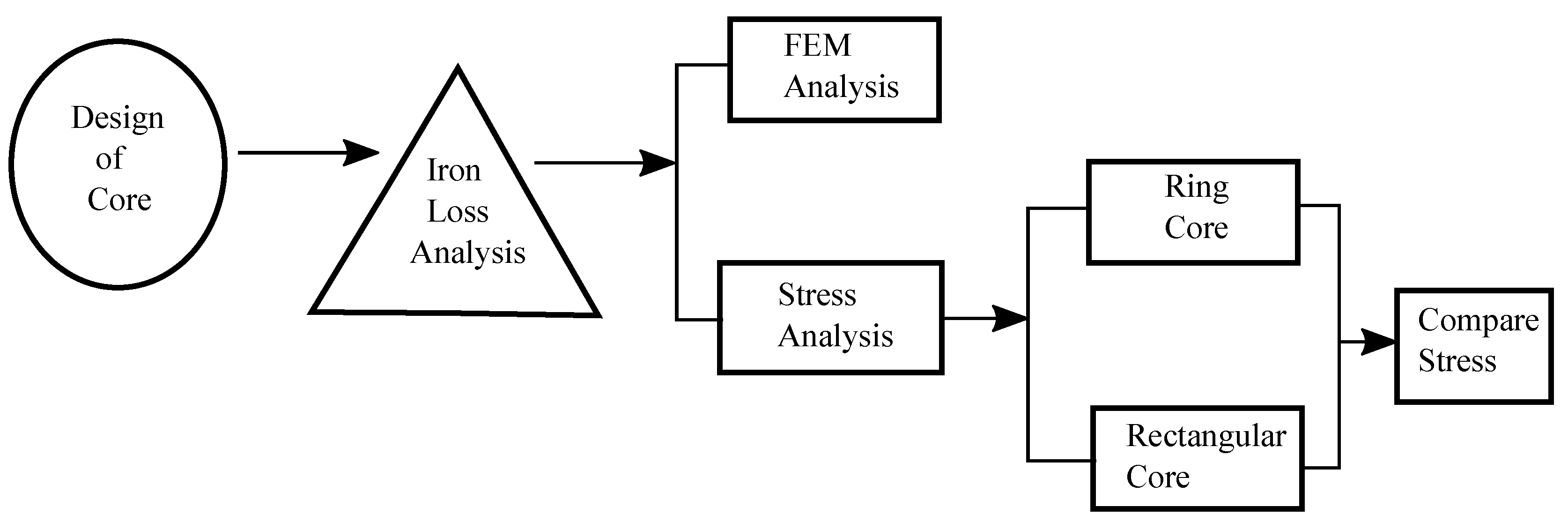

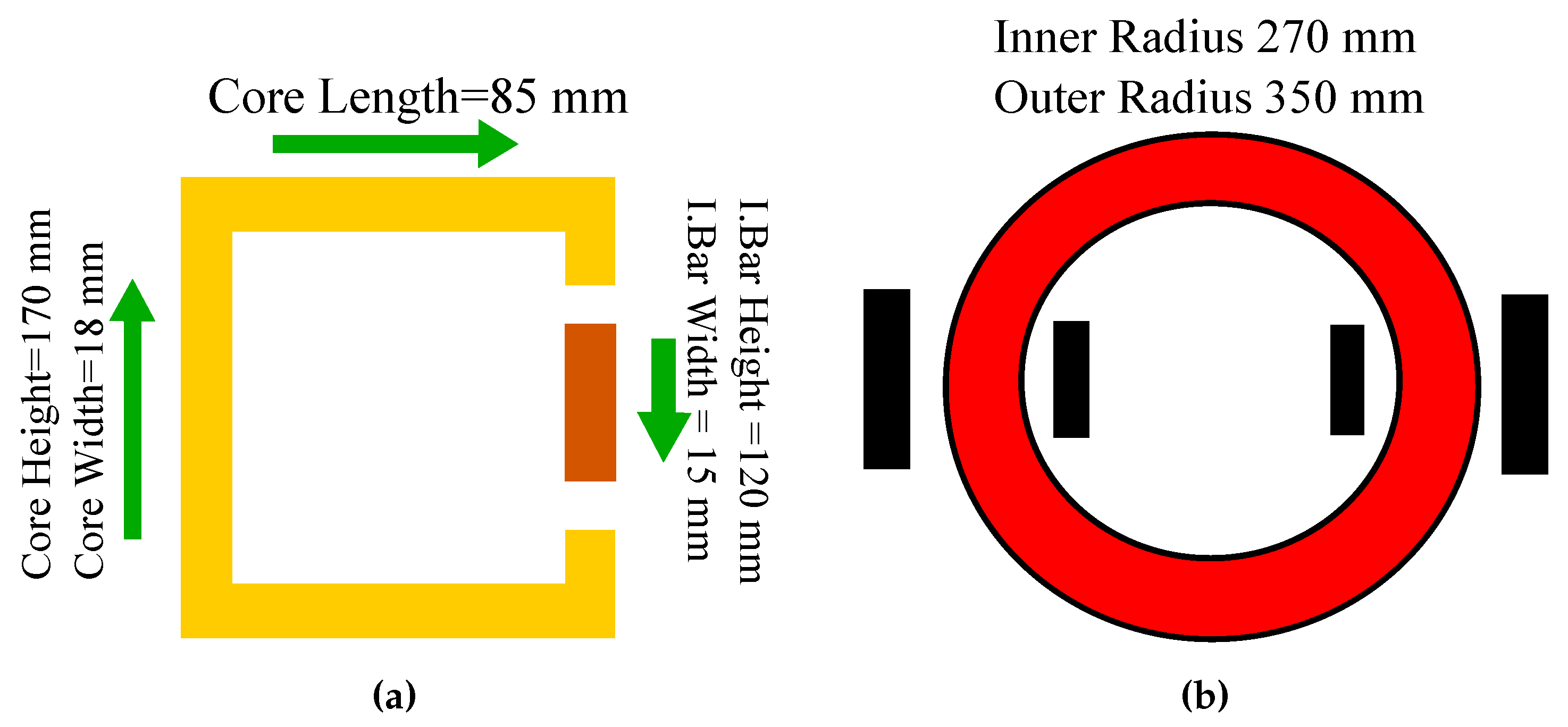

2. Methodology

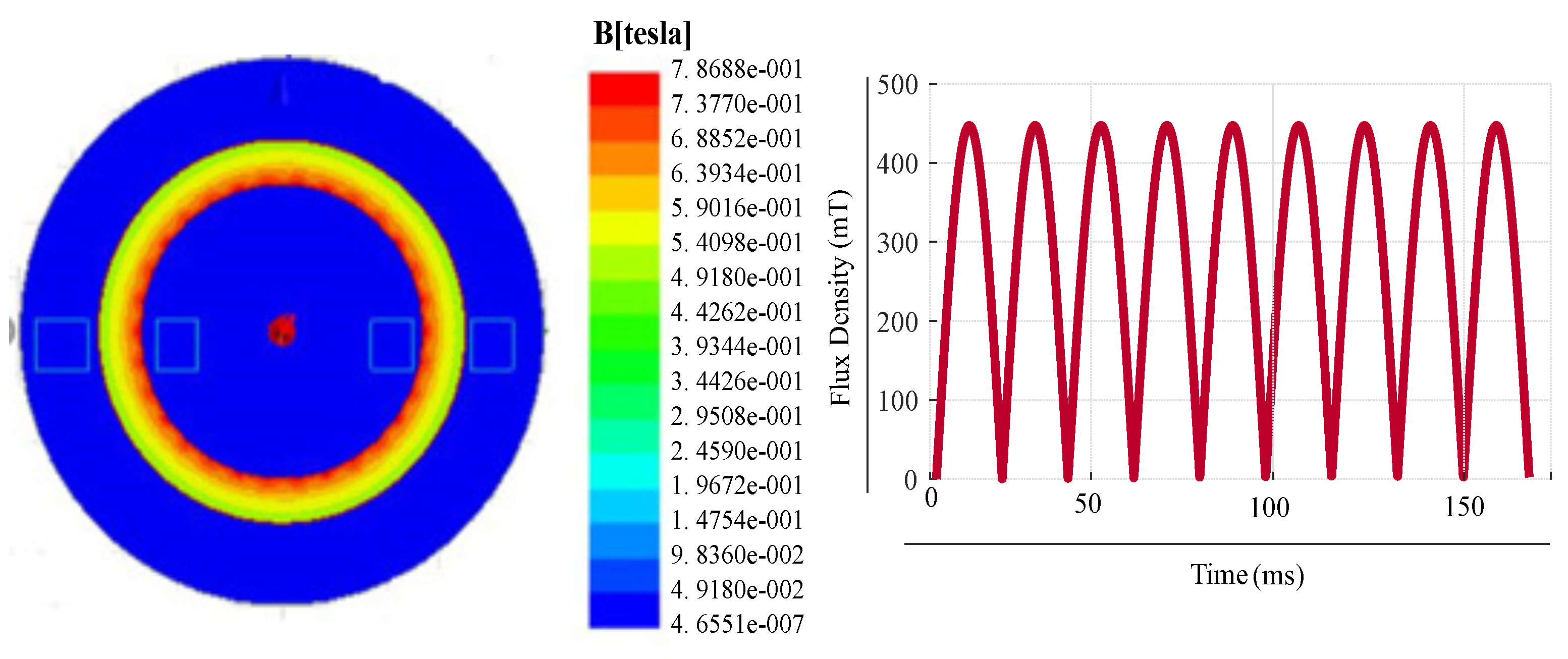

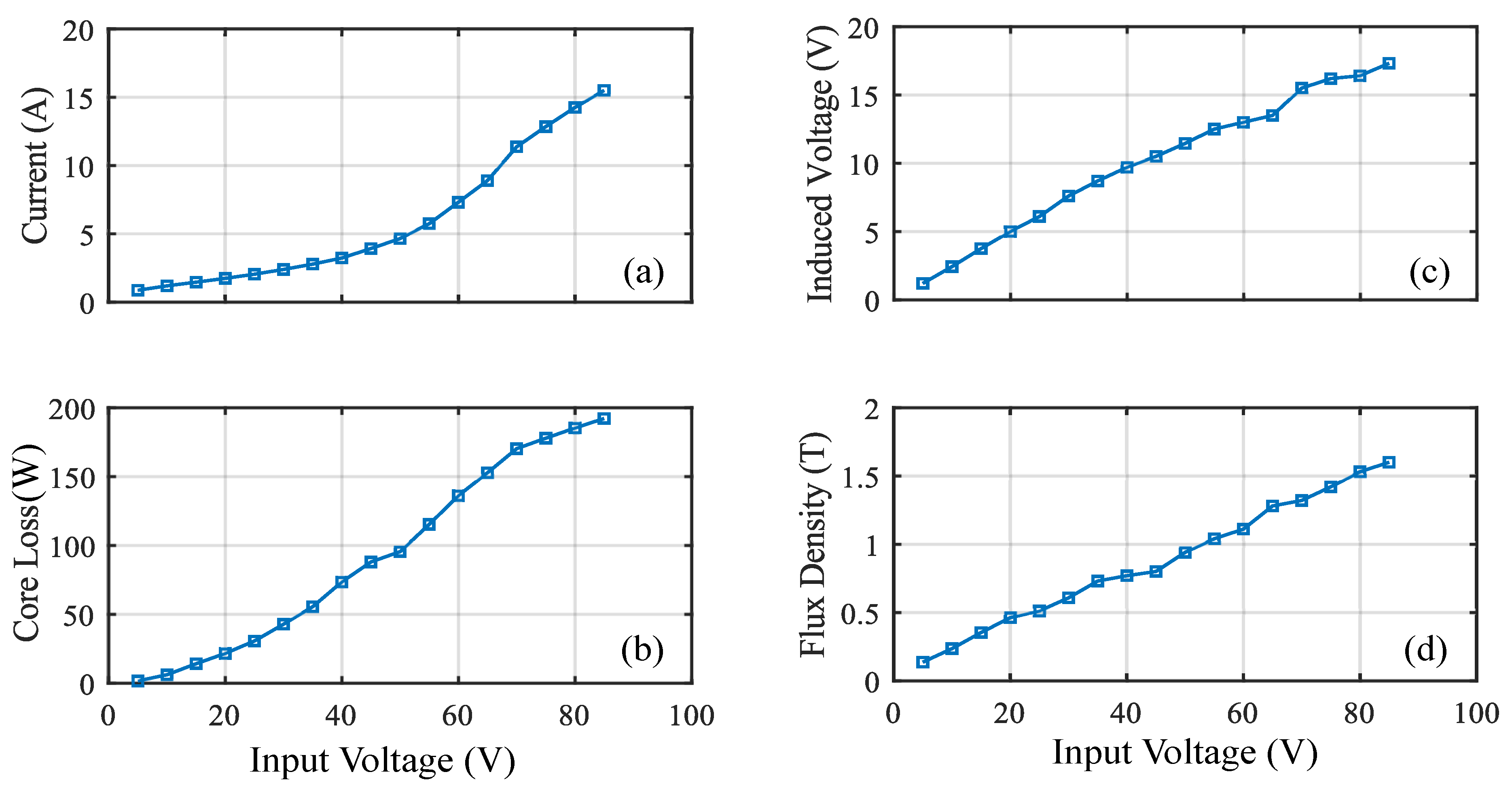

3. Simulation Results

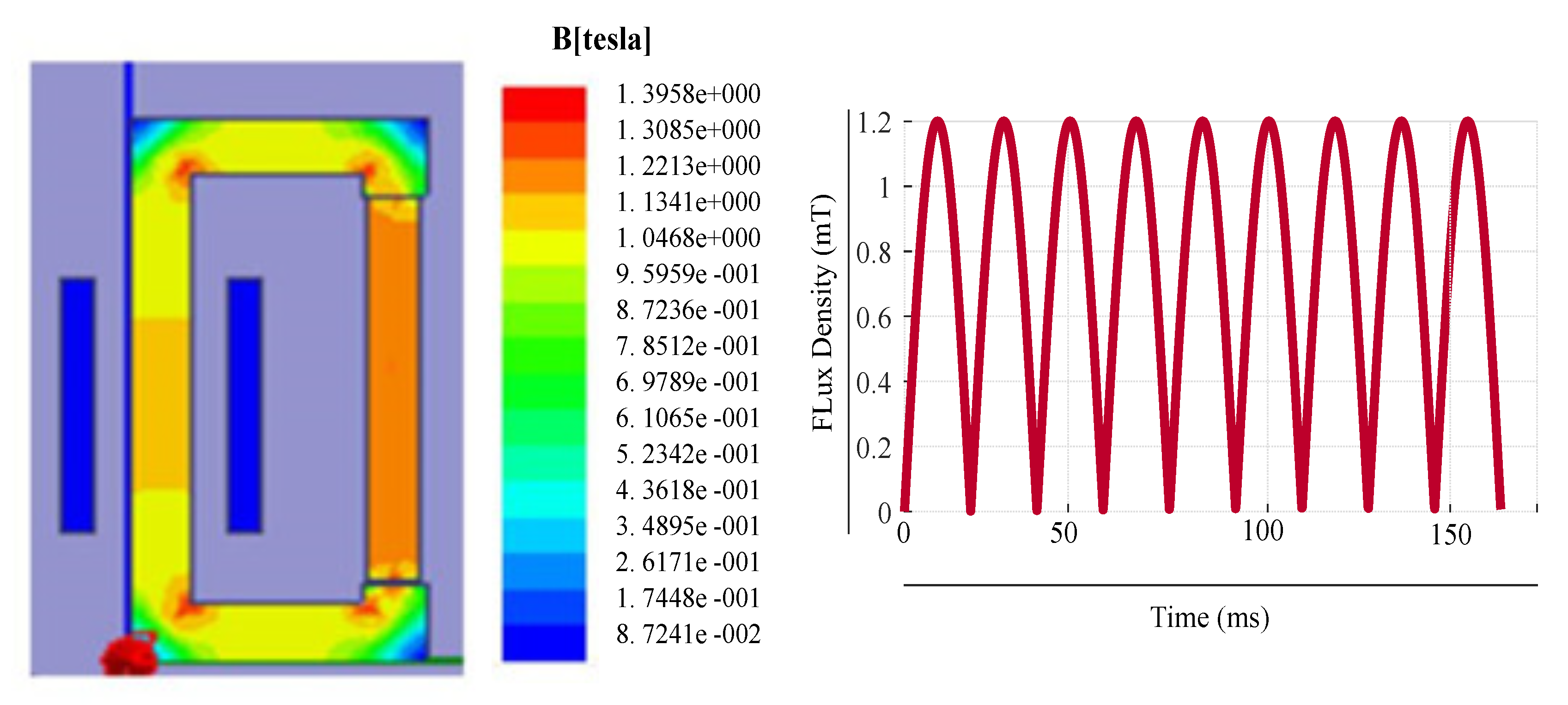

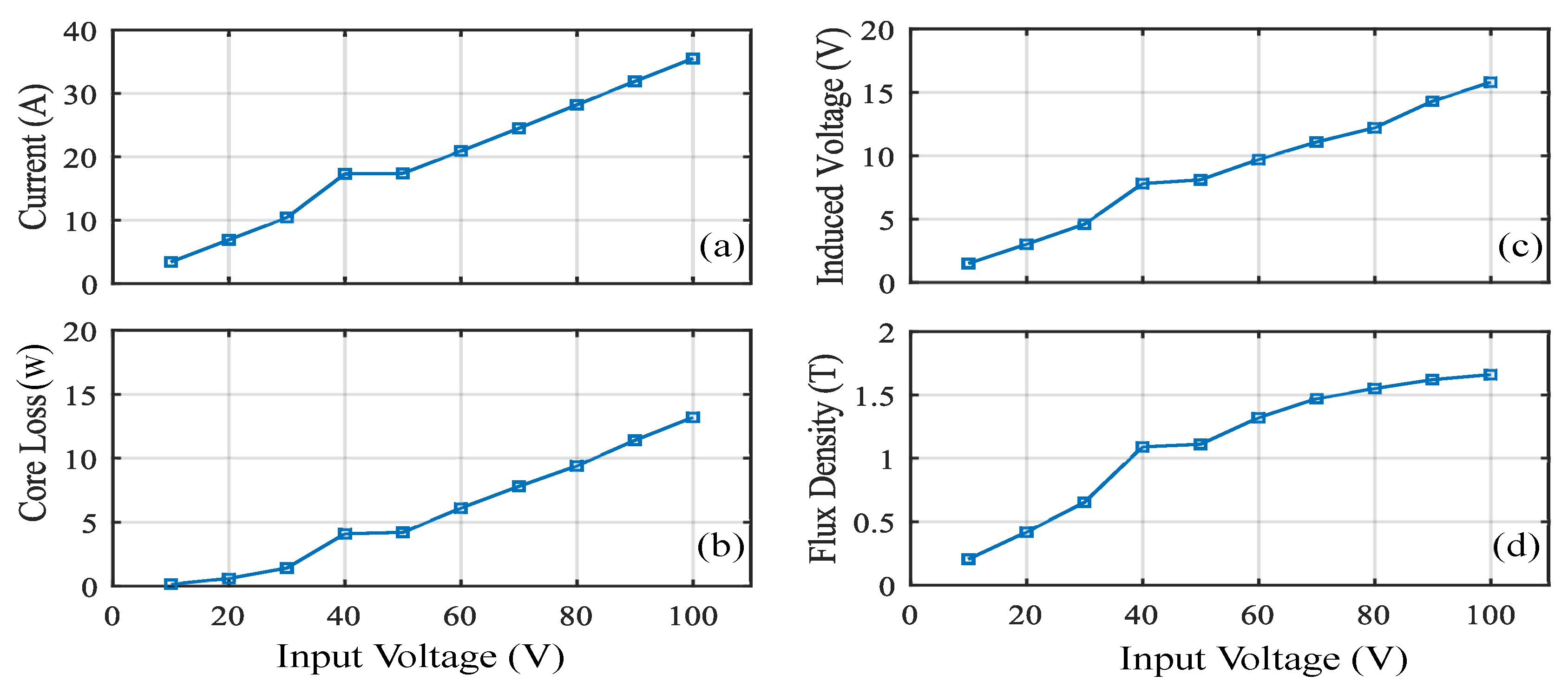

3.1. Result for Field Overlays of Rectangular Core

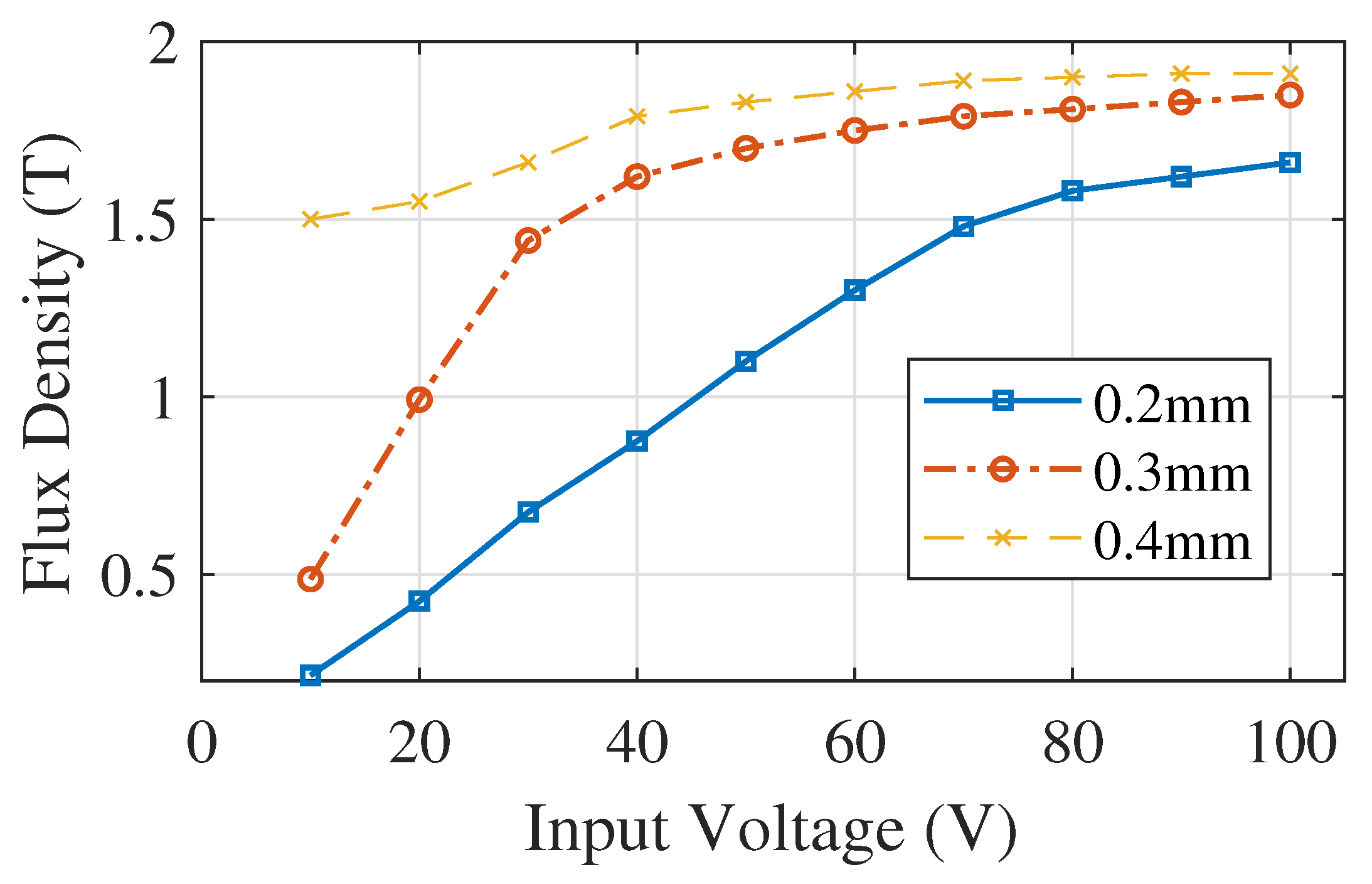

3.2. Comparison for Various Number of Turns

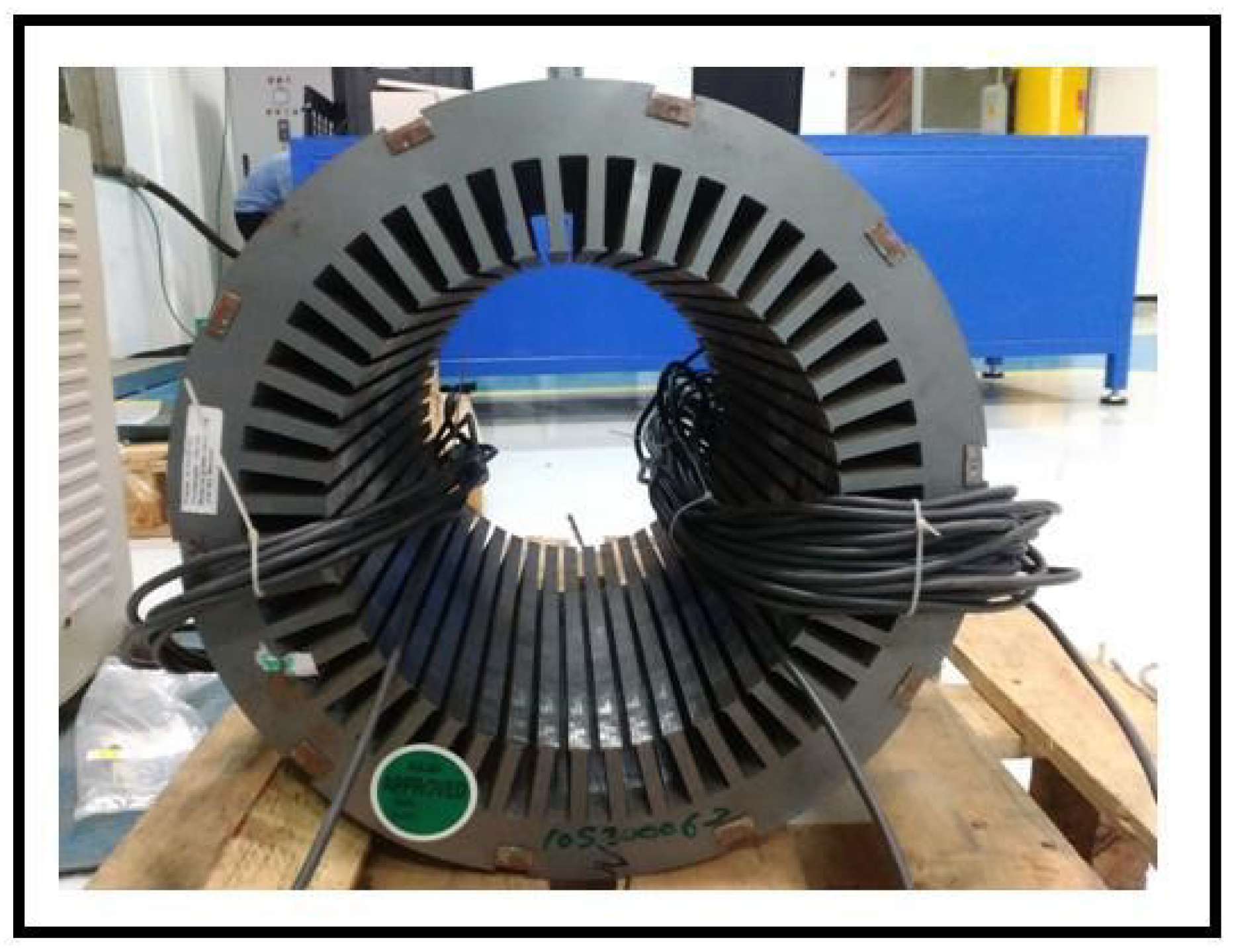

4. Experimental Results

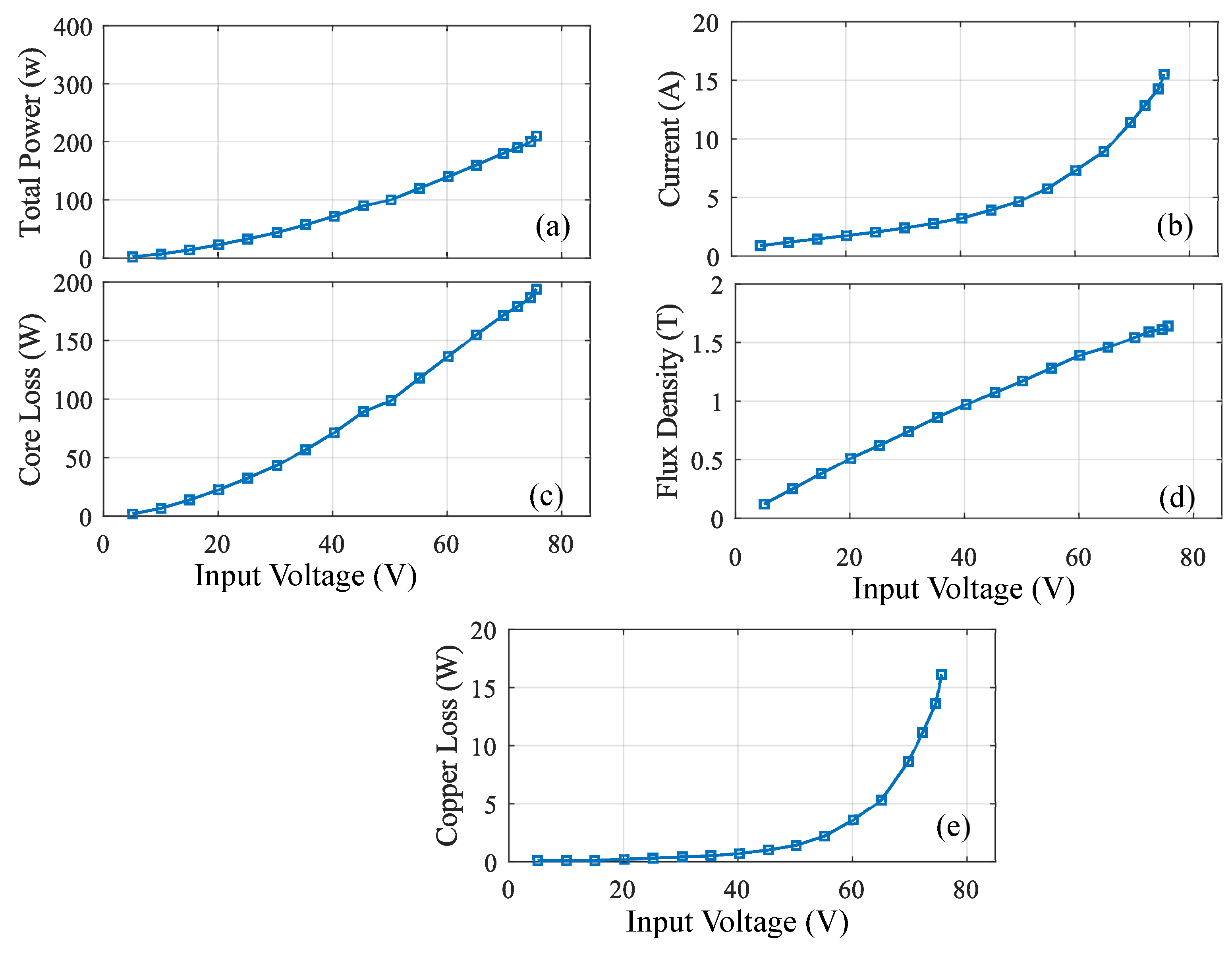

4.1. Ring Core Loop Test Under Loose Lamination (Without Mechanical Stress)

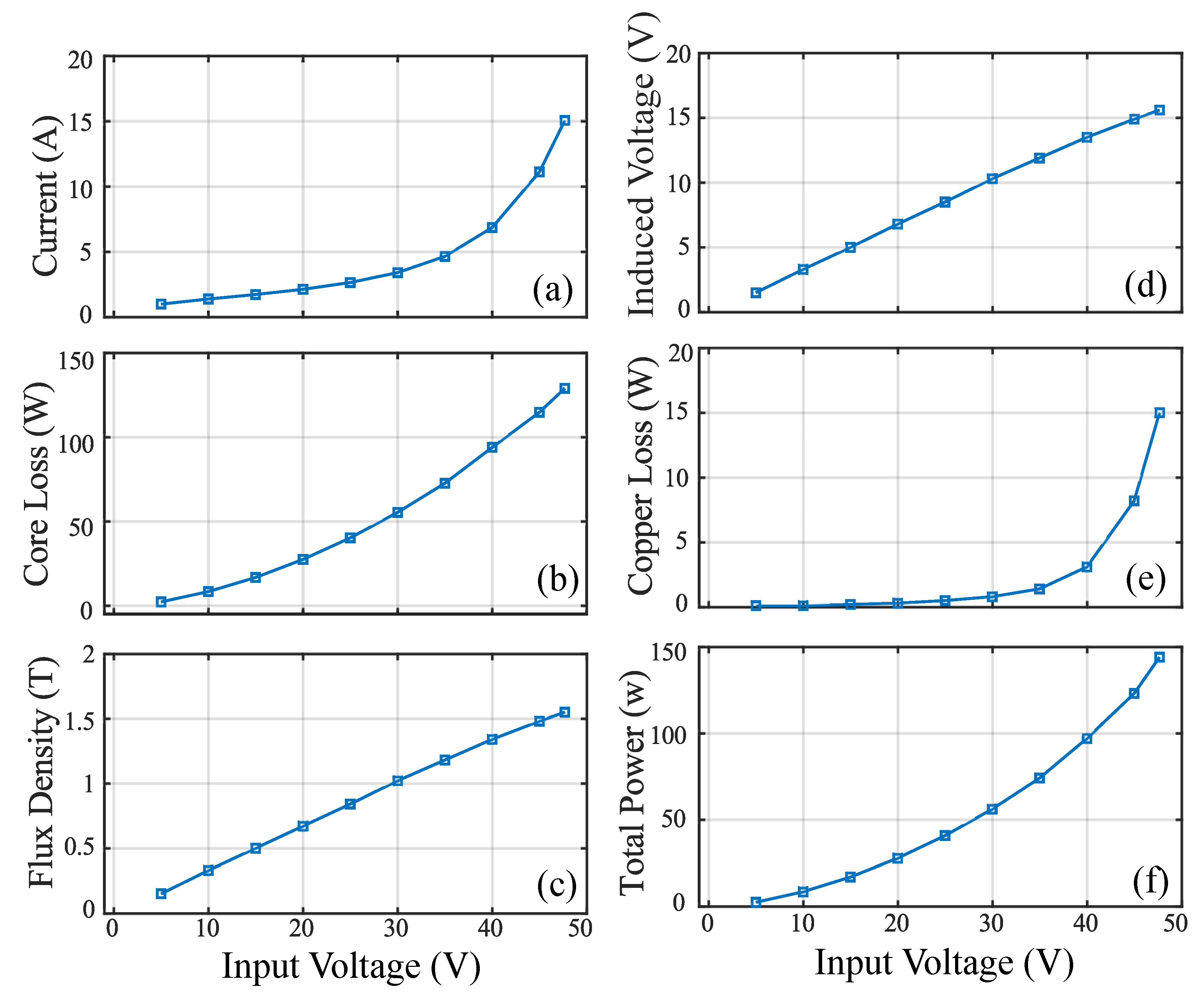

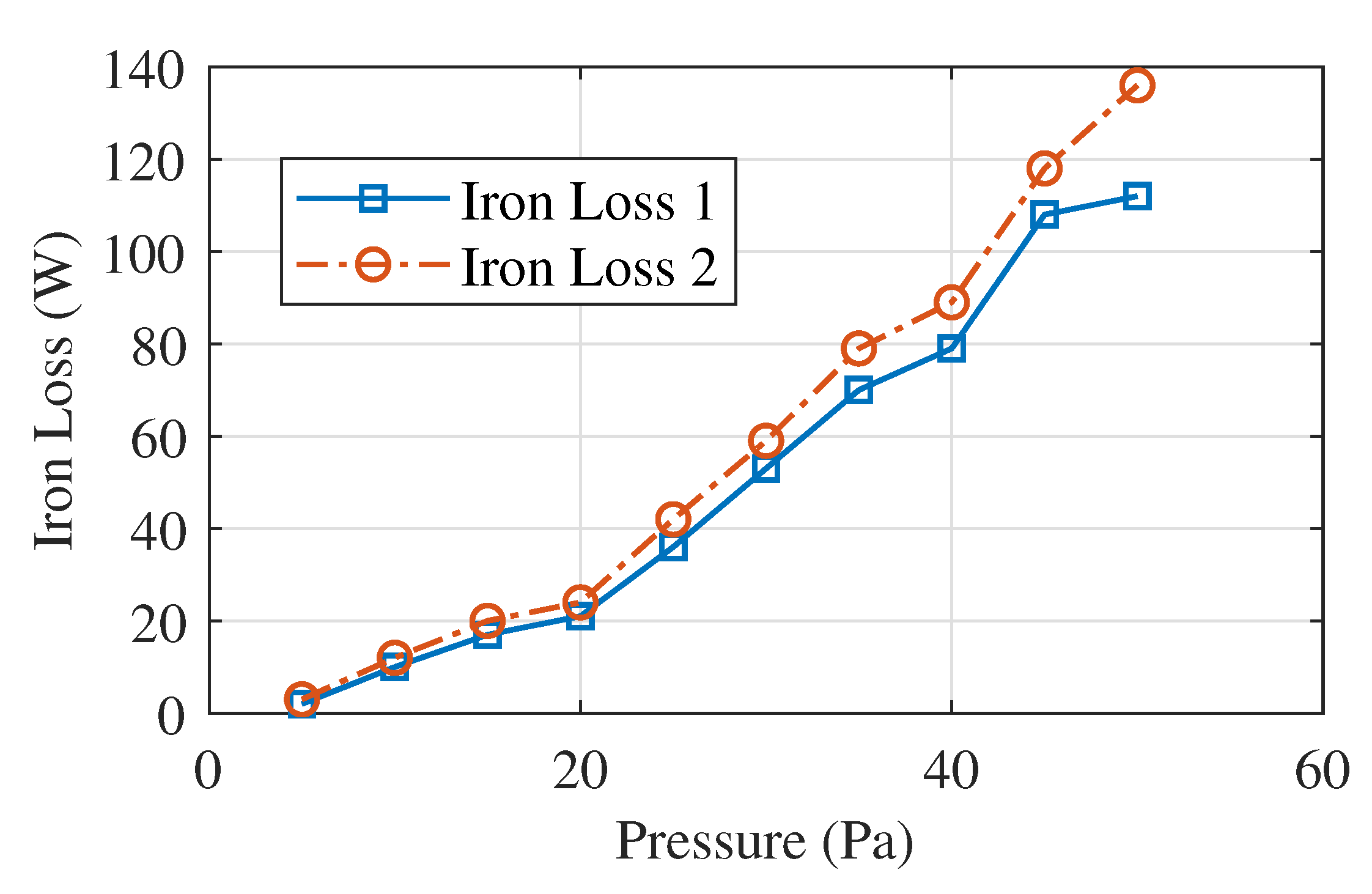

4.2. Core Ring Loop Test Under Tight Lamination (Under Mechanical Stress)

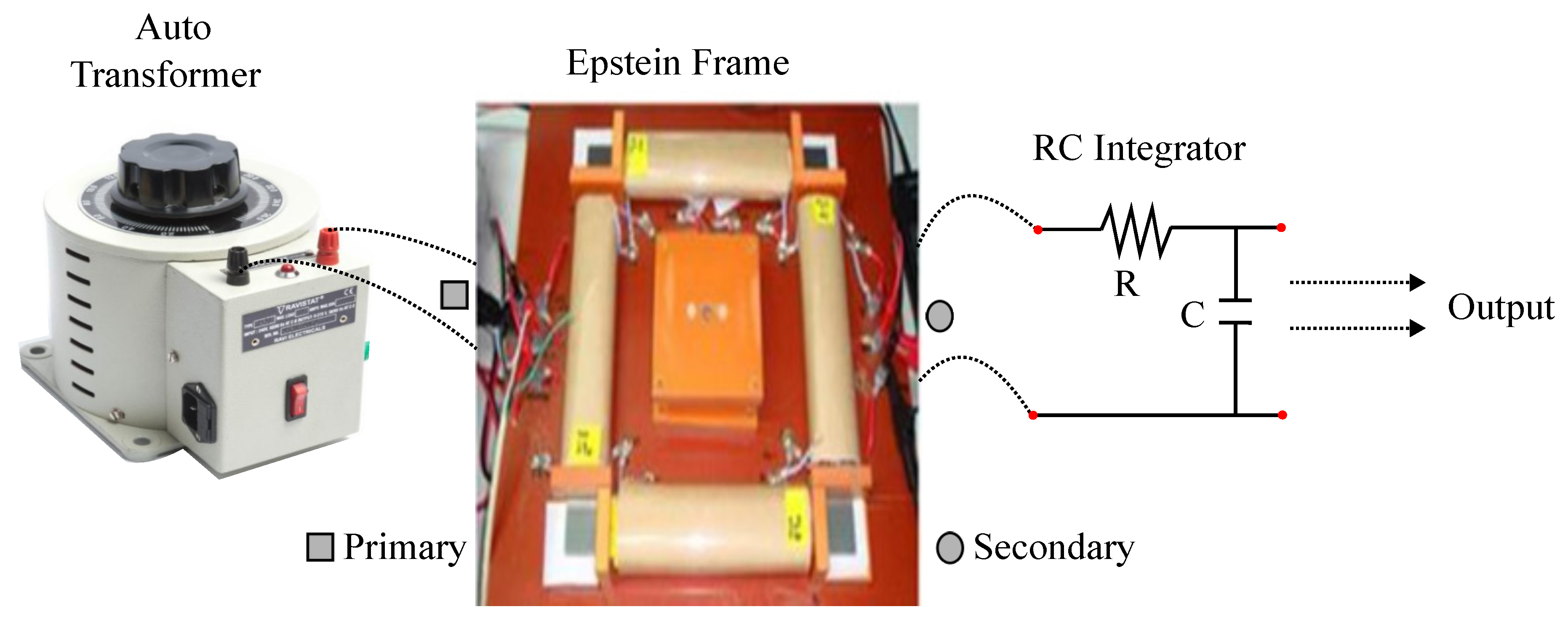

4.3. Epstein Frame Test

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, D.; Liu, T.; Zhao, H.; Wu, T. An Analytical Iron Loss Calculation Model of Inverter-Fed Induction Motors Considering Supply and Slot Harmonics. IEEE Trans. Ind. Electron. 2019, 66, 9194–9204. [Google Scholar] [CrossRef]

- Ge, L.; Burkhart, B.; De Doncker, R.W. Fast Iron Loss and Thermal Prediction Method for Power Density and Efficiency Improvement in Switched Reluctance Machines. IEEE Trans. Ind. Electron. 2020, 67, 4463–4473. [Google Scholar] [CrossRef]

- Stiller, M.; Hahn, I. Different Iron Loss Models for Electrical Steel Sheets considering Harmonic Flux Signals. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 302–307. [Google Scholar]

- Xia, C.; Wang, H.; Wu, Y.; Wang, H. Joining of the Laminated Electrical Steels in Motor Manufacturing: A Review. Materials 2020, 13, 4583. [Google Scholar] [CrossRef]

- Cimino, A.; Jenau, F.; Staubach, C. Causes of cyclic mechanical aging and its detection in stator winding insulation systems. IEEE Electr. Insul. Mag. 2019, 35, 32–40. [Google Scholar] [CrossRef]

- Wen, H.; Cheng, M. Unified Analysis of Induction Machine and Synchronous Machine Based on the General Airgap Field Modulation Theory. IEEE Trans. Ind. Electron. 2019, 66, 9205–9216. [Google Scholar] [CrossRef]

- Banchhor, D.K.; Dhabale, A. Modified Distributed Winding for Harmonic Reduction in Space MMF Distribution. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018; pp. 1–6. [Google Scholar]

- Chen, Q.; Liang, D.; Jia, S.; Ze, Q.; Liu, Y. Analysis of Winding MMF and Loss for Axial Flux PMSM With FSCW Layout and YASA Topology. IEEE Trans. Ind. Appl. 2020, 56, 2622–2635. [Google Scholar] [CrossRef]

- Jia, S.; Zhang, P.; Liang, D.; Dai, M.; Liu, J. Design and Comparison of Three Different Types of IE4 Efficiency Machines. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–4. [Google Scholar]

- Aydin, U.; Martin, F.; Rasilo, P.; Belahcen, A.; Haavisto, A.; Singh, D.; Daniel, L.; Arkkio, A. Rotational Single Sheet Tester for Multiaxial Magneto-Mechanical Effects in Steel Sheets. IEEE Trans. Magn. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Li, S. Laser welding of laminated electrical steels. J. Mater. Process. Technol. 2016, 230, 99–108. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y. Modeling of Eddy-Current Losses of Welded Laminated Electrical Steels. IEEE Trans. Ind. Electron. 2017, 64, 2992–3000. [Google Scholar] [CrossRef]

- Diao, K.; Sun, X.; Lei, G.; Bramerdorfer, G.; Guo, Y.; Zhu, J. System-level Robust Design Optimization of a Switched Reluctance Motor Drive System Considering Multiple Driving Cycles. IEEE Trans. Energy Convers. 2020, 1, 1. [Google Scholar] [CrossRef]

- Sun, X.; Shi, Z.; Lei, G.; Guo, Y.; Zhu, J. Multi-Objective Design Optimization of an IPMSM Based on Multilevel Strategy. IEEE Trans. Ind. Electron. 2020, 68, 139–148. [Google Scholar] [CrossRef]

- Sun, X.; Shen, Y.; Wang, S.; Lei, G.; Yang, Z.; Han, S. Core Losses Analysis of a Novel 16/10 Segmented Rotor Switched Reluctance BSG Motor for HEVs Using Nonlinear Lumped Parameter Equivalent Circuit Model. IEEE/ASME Trans. Mechatron. 2018, 23, 747–757. [Google Scholar] [CrossRef]

- Parent, G.; Penin, R.; Lecointe, J.P.; Brudny, J.F.; Belgrand, T. Determination of Specific Losses in the Limbs of an Epstein Frame Using a Three Epstein Frame Methodology Applied to Grain Oriented Electrical Steels. Sensors 2016, 16, 826. [Google Scholar] [CrossRef] [PubMed]

- Soda, N.; Enokizono, M. Stator Core Shape Design for Low Core Loss and High Power Density of a Small Surface-Mounted Permanent Motor. Sensors 2020, 20, 1418. [Google Scholar] [CrossRef] [PubMed]

- Sai Ram, B.; Baghel, A.P.S.; Kulkarni, S.V.; Daniel, L.; Nlebedim, I.C. A Frequency-Dependent Scalar Magneto-Elastic Hysteresis Model Derived Using Multi-Scale and Jiles Atherton Approaches. IEEE Trans. Magn. 2020, 56, 1–5. [Google Scholar] [CrossRef]

- Rasilo, P.; Aydin, U.; Holopainen, T.P.; Arkkio, A. Analysis of iron losses on the cutting edges of induction motor core laminations. In Proceedings of the 2016 XXII International Conference on Electrical Machines, Lausanne, Switzerland, 4–7 September 2016; pp. 1312–1317. [Google Scholar]

- Aydin, U.; Rasilo, P.; Martin, F.; Belahcen, A.; Daniel, L.; Haavisto, A.; Arkkio, A. Effect of multi-axial stress on iron losses of electrical steel sheets. J. Magn. Magn. Mater. 2019, 469, 19–27. [Google Scholar] [CrossRef]

- Yamazaki, K.; Sato, Y.; Domenjoud, M.; Daniel, L. Iron Loss Analysis of Permanent-Magnet Machines by Considering Hysteresis Loops Affected by Multi-Axial Stress. IEEE Trans. Magn. 2020, 56, 1–4. [Google Scholar] [CrossRef]

- Mailhé, B.J. Characterization and Modelling of the Magnetic Behavior of Electrical Steel under Mechanical Stress. Ph.D. Thesis, Universidade Federal de Santa Catarina, Florianópolis, Brazil, 2018. [Google Scholar]

- Martin, F.; Aydin, U.; Ruzibaev, A.; Ge, Y.; Daniel, L.; Bernard, L.; Rasilo, P.; Benabou, A.; Belahcen, A. Analysis of the Magneto-Mechanical Anisotropy of Steel Sheets in Electrical Applications. IEEE Trans. Magn. 2020, 56, 1–4. [Google Scholar] [CrossRef]

- Yamazaki, K.; Mukaiyama, H.; Daniel, L. Effects of Multi-Axial Mechanical Stress on Loss Characteristics of Electrical Steel Sheets and Interior Permanent Magnet Machines. IEEE Trans. Magnet. 2018, 54, 1–4. [Google Scholar] [CrossRef]

- Rens, J.; Vandenbossche, L.; Dorez, O. Iron Loss Modelling of Electrical Traction Motors for Improved Prediction of Higher Harmonic Losses. World Electr. Veh. J. 2020, 11, 24. [Google Scholar] [CrossRef]

- Ebrahimi, H.; Gao, Y.; Dozono, H.; Muramatsu, K. Coupled Magneto-Mechanical Analysis in Isotropic Materials Under Multiaxial Stress. IEEE Trans. Magn. 2014, 50, 285–288. [Google Scholar] [CrossRef]

- Singh, D.; Martin, F.; Rasilo, P.; Belachen, A. Magnetomechanical Model for Hysteresis in Electrical Steel Sheet. IEEE Trans. Magn. 2016, 52, 1–9. [Google Scholar] [CrossRef]

- Bernard, L.; Mailhe, B.J.; Avila, S.L.; Daniel, L.; Batistela, N.J.; Sadowski, N. Magnetic Hysteresis Under Compressive Stress: A Multiscale-Jiles Atherton Approach. IEEE Trans. Magn. 2020, 56, 1–4. [Google Scholar] [CrossRef]

- Aydin, U.; Rasilo, P.; Singh, D.; Lehikoinen, A.; Belahcen, A.; Arkkio, A. Coupled Magneto-Mechanical Analysis of Iron Sheets Under Biaxial Stress. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Rasilo, P.; Aydin, U.; Martin, F.; Belahcen, A.; Kouhia, R.; Daniel, L. Equivalent Strain and Stress Models for the Effect of Mechanical Loading on the Permeability of Ferromagnetic Materials. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Barmpatza, A.C.; Kappatou, J.C. Finite Element Method Investigation and Loss Estimation of a Permanent Magnet Synchronous Generator Feeding a Non-Linear Load. Energies 2018, 11, 3404. [Google Scholar] [CrossRef]

- Baghel, A.; Sai Ram, B.; Daniel, L.; Kulkarni, S.; Krebs, G.; Blumenfeld, J.; Santandrea, L. An alternative approach to model mechanical stress effects on magnetic hysteresis in electrical steels using complex permeability. Int. J. Comput. Mater. Sci. Surf. Eng. 2019, 166, 96–104. [Google Scholar] [CrossRef]

- Millinger, J.; Wallmark, O.; Soulard, J. High-Frequency Characterization of Losses in Fully Assembled Stators of Slotless PM Motors. IEEE Trans. Ind. Appl. 2018, 54, 2265–2275. [Google Scholar] [CrossRef]

- Daem, A.; Sergeant, P.; Dupré, L.; Chaudhuri, S.; Bliznuk, V.; Kestens, L. Magnetic Properties of Silicon Steel after Plastic Deformation. Materials 2020, 13, 4361. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Height of core | 170 mm |

| Length of core | 85 mm |

| Core width (Axial length) | 18 mm |

| Width 1 of core | 24.5 mm |

| Width 2 of core | 6.5 mm |

| Inner length of core | 134 mm |

| Inner height of core | 49 mm |

| Bar height | 120 mm |

| Bar width | 15 mm |

| Diameter of wire | 0.2 mm |

| Stacking length of core | 30 mm |

| Density of material | 7700 kg/m3 |

| Stacking factor | 0.9 |

| Input voltage | 100 V |

| Frequency | 50 Hz |

| Number of turns | 50 Turns |

| Parameters | Values |

|---|---|

| Outer radius | 350 mm |

| Inner radius | 270 mm |

| Inner diameter | 175 mm |

| Outer diameter | 135 mm |

| Height | 350 mm |

| Number of primary turns | 24 Turns |

| Number of secondary turns | 8 Turns |

| Input voltage | 50 V |

| Stacking length of the core | 30 mm |

| Stacking factor | 0.9 |

| Frequency | 50 Hz |

| Diameter of wire | 1.3 mm |

| Density of material | 7700 kg/m3 |

| Resistivity of copper | |

| Permeability of free space | |

| Magnetic field intensity | 200 A/m |

| Parameters | Primary | Secondary |

|---|---|---|

| No.of turns | 24 | 8 |

| Resistance | 0.06 | 0.025 |

| Inductance | 3.8 mH | 0.397 mH |

| Parameters | Values |

|---|---|

| Primary voltage | 60 V |

| Current | 7.31 A |

| Secondary induced voltage | 13 V |

| Core loss | 136.1 W |

| MF | 1.1 T |

| Parameters | Values |

|---|---|

| Primary input voltage | 90 V |

| Current | 31.9 A |

| Induced voltage | 11.4 V |

| Core loss | 14.3 W |

| MF | 1.6 T |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, L.A.; Raj, B.M.; Vijayakumar, V.; Indragandhi, V.; Subramaniyaswamy, V.; Karimi, H.R.; Veluvolu, K.C. Analysis of Electric Motor Magnetic Core Loss under Axial Mechanical Stress. Sensors 2020, 20, 6818. https://doi.org/10.3390/s20236818

Kumar LA, Raj BM, Vijayakumar V, Indragandhi V, Subramaniyaswamy V, Karimi HR, Veluvolu KC. Analysis of Electric Motor Magnetic Core Loss under Axial Mechanical Stress. Sensors. 2020; 20(23):6818. https://doi.org/10.3390/s20236818

Chicago/Turabian StyleKumar, L. Ashok, Bagianathan Madhan Raj, Varadarajan Vijayakumar, Vairavasundaram Indragandhi, Vairavasundaram Subramaniyaswamy, Hamid. R. Karimi, and Kalyana C. Veluvolu. 2020. "Analysis of Electric Motor Magnetic Core Loss under Axial Mechanical Stress" Sensors 20, no. 23: 6818. https://doi.org/10.3390/s20236818

APA StyleKumar, L. A., Raj, B. M., Vijayakumar, V., Indragandhi, V., Subramaniyaswamy, V., Karimi, H. R., & Veluvolu, K. C. (2020). Analysis of Electric Motor Magnetic Core Loss under Axial Mechanical Stress. Sensors, 20(23), 6818. https://doi.org/10.3390/s20236818