Visual Leakage Inspection in Chemical Process Plants Using Thermographic Videos and Motion Pattern Detection

Abstract

1. Leakage Inspection in Chemical Process Plant

2. Requirements for Efficient Leakage Detection

3. State of the Art

3.1. State of the Art in Leakage Monitoring

3.2. State of the Art in Motion Pattern Detection

4. Leakage Detection Using Kalman Filter

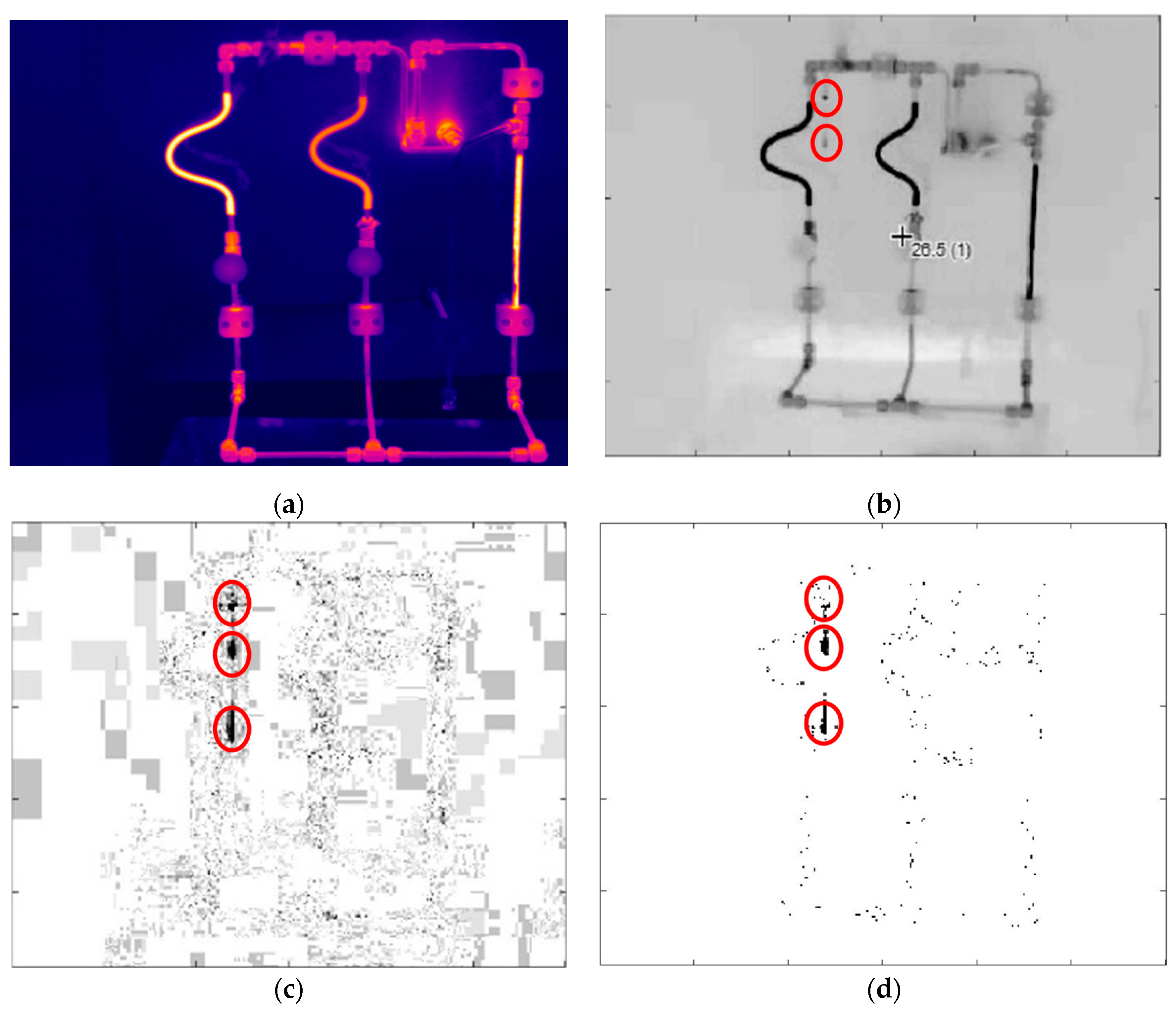

4.1. Data Acquisition and Pre-Processing

4.2. Typical Kalman Filter

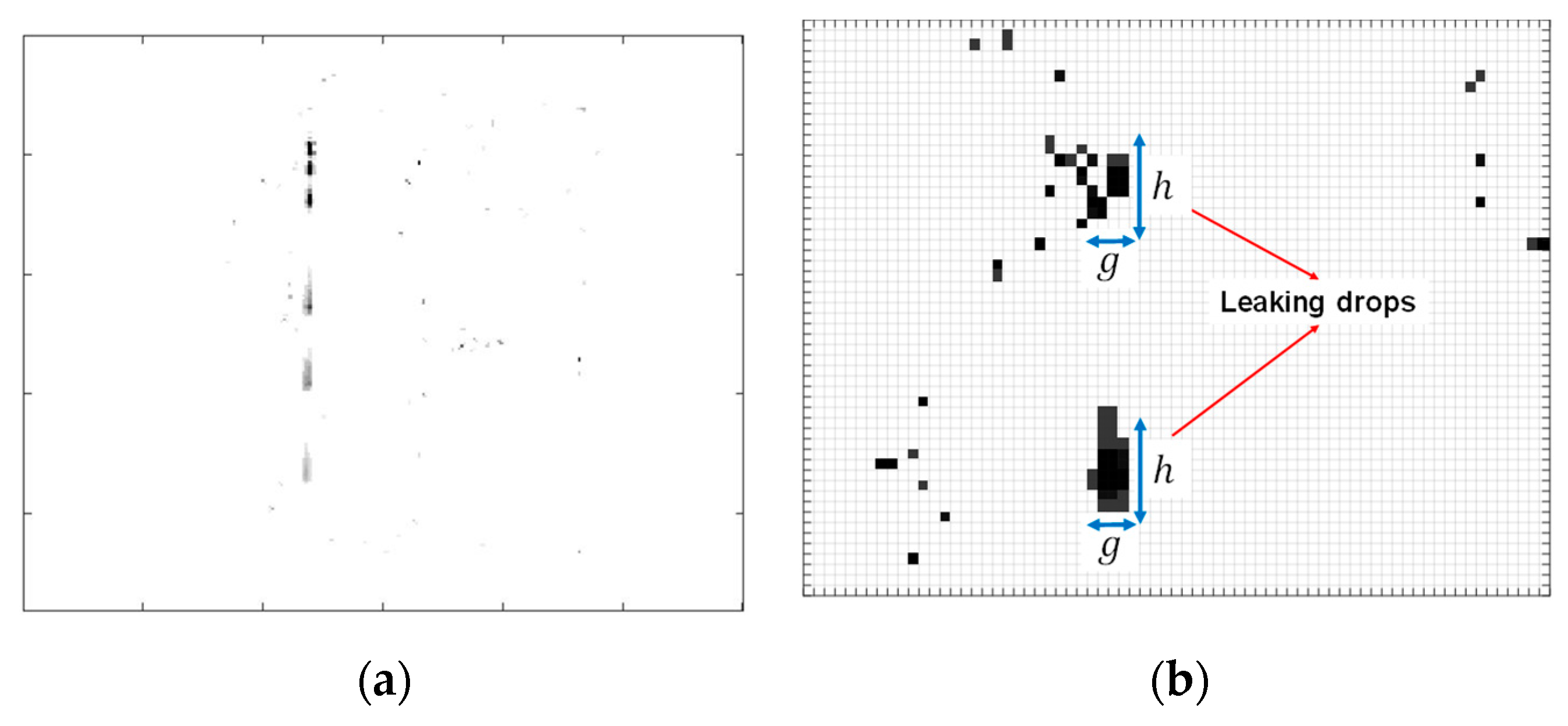

4.3. Calculation of Measurement Points in Training Set: Segmentation, Object Definition, and Feature Extraction

4.4. Estimation of Velocity and Acceleration for Each Leakage Pattern in Training Set

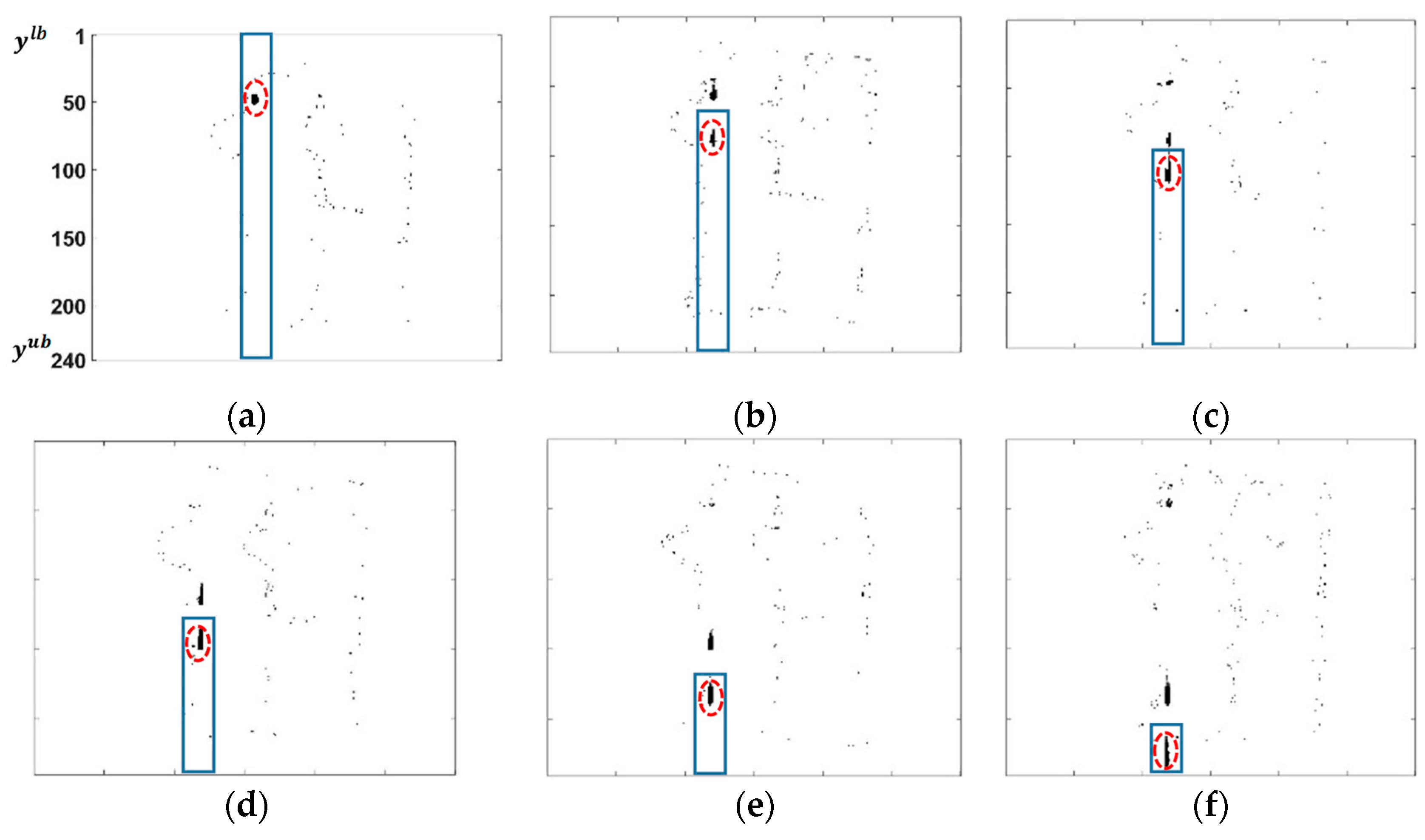

4.5. Leakage Detection in Test Video: Possible Positions and Predicted Positions

4.6. Leakage Detection in Test Video: Particle Filter as a Baseline Method

5. Evaluation of the Proposed Method in Leakage Detection and Localization

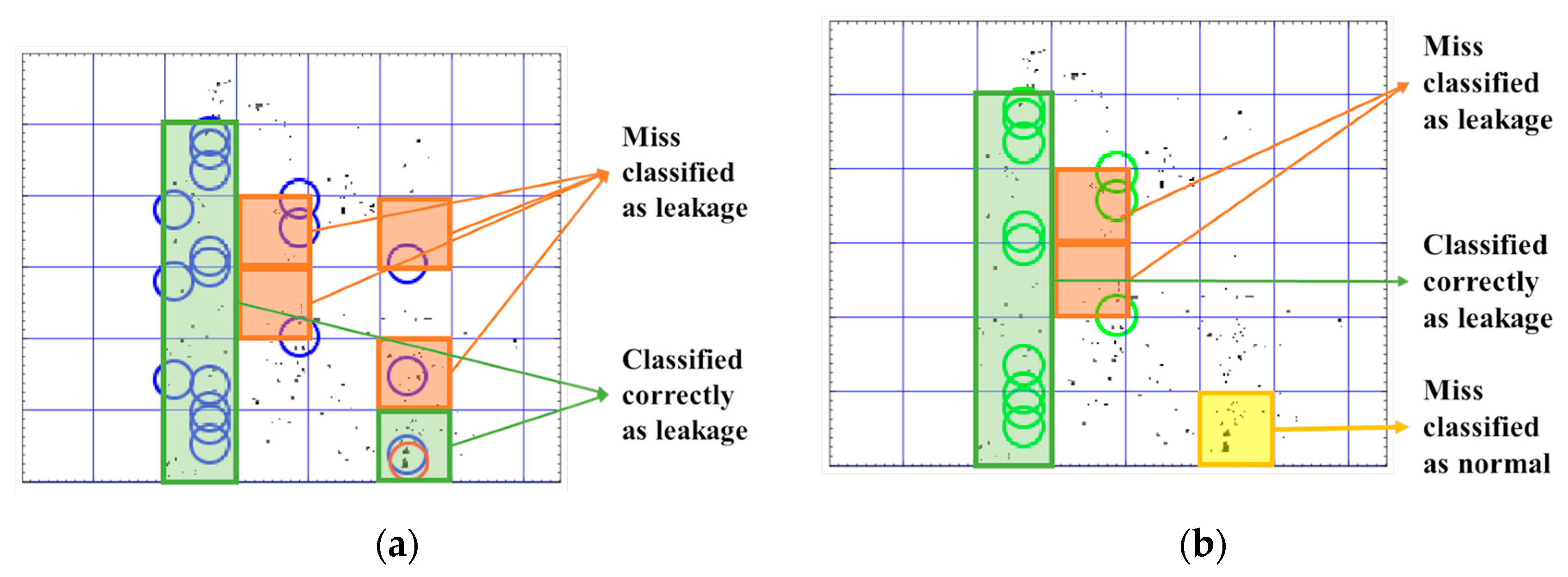

Evaluation of the Accuracy of the Proposed Method for Leakage Detection in Test Videos

6. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Scott, S.L.; Barrufet, M.A. Worldwide Assessment of Industry Leak Detection Capabilities for Single and Multiphase Pipelines; Offshore Technology Research Center: College Station, TX, USA, 2003. [Google Scholar]

- Si, H.; Ji, H.; Zeng, X. Quantitative risk assessment model of hazardous chemicals leakage and application. Saf. Sci. 2012, 50, 1452–1461. [Google Scholar] [CrossRef]

- Barz, T.; Bonow, G.; Hegenberg, J.; Habib, A.; Cramar, L.; Welle, J.; Schulz, D.; Kroll, A.; Schmidt, L. Unmanned Inspection of Large Industrial Environments. In Proceedings of the 7th Security Research Conference, Future Security 2012, Bonn, Germany, 4–6 September 2012; Volume 318, pp. 216–219. [Google Scholar]

- Li, R.; Huang, H.; Xin, K.; Tao, T. A review of methods for burst/leakage detection and location in water distribution systems. Water Supply 2014, 15, 429–441. [Google Scholar] [CrossRef]

- Vollmer, M.; Möllmann, K.-P. Infrared Thermal Imaging: Fundamentals, Research and Applications; Wiley: Weinheim, Germany, 2017; Available online: http://onlinelibrary.wiley.com/book/10.1002/9783527693306 (accessed on 29 September 2017).

- Moulijn, J.A.; Makkee, M.; van Diepen, A. Chemical Process Technology; John Wiley & Sons Inc: Chichester, UK, 2013. [Google Scholar]

- Kurada, S.; Bradley, C. A review of machine vision sensors for tool condition monitoring. Comput. Ind. 1997, 34, 55–72. [Google Scholar] [CrossRef]

- Golnabi, H.; Asadpour, A. Design and application of industrial machine vision systems. Robot. Comput. Manuf. 2007, 23, 630–637. [Google Scholar] [CrossRef]

- Ostapkowicz, P. Leak detection in liquid transmission pipelines using simplified pressure analysis techniques employing a minimum of standard and non-standard measuring devices. Eng. Struct. 2016, 113, 194–205. [Google Scholar] [CrossRef]

- He, G.; Liang, Y.; Li, Y.; Wu, M.; Sun, L.; Xie, C.; Li, F. A method for simulating the entire leaking process and calculating the liquid leakage volume of a damaged pressurized pipeline. J. Hazard. Mater. 2017, 332, 19–32. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Xu, M. An integrated detection and location model for leakages in liquid pipelines. J. Pet. Sci. Eng. 2019, 175, 852–867. [Google Scholar] [CrossRef]

- Datta, S.; Sarkar, S. A review on different pipeline fault detection methods. J. Loss Prev. Process. Ind. 2016, 41, 97–106. [Google Scholar] [CrossRef]

- Rubinstein, A. Fluid Leakage Detection System. U.S. Patent 9939345B2, 10 April 2018. [Google Scholar]

- Abhulimen, K.E.; Susu, A.A. Liquid pipeline leak detection system: Model development and numerical simulation. Chem. Eng. J. 2004, 97, 47–67. [Google Scholar] [CrossRef]

- Yin, S.; Li, X.; Gao, H.; Kaynak, O. Data-Based Techniques Focused on Modern Industry: An Overview. IEEE Trans. Ind. Electron. 2015, 62, 657–667. [Google Scholar] [CrossRef]

- Ozevin, D. Geometry-based spatial acoustic source location for spaced structures. Struct. Health Monit. 2010, 10, 503–510. [Google Scholar] [CrossRef]

- Ozevin, D.; Harding, J. Novel leak localization in pressurized pipeline networks using acoustic emission and geometric connectivity. Int. J. Press. Vessel. Pip. 2012, 92, 63–69. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, Y.; Zhang, W.; Xu, N.; Guo, Z.; Wu, G. Improved PSO-based Method for Leak Detection and Localization in Liquid Pipelines. IEEE Trans. Ind. Inform. 2018, 14, 1. [Google Scholar] [CrossRef]

- Sun, L.; Chang, N. Integrated-signal-based leak location method for liquid pipelines. J. Loss Prev. Process. Ind. 2014, 32, 311–318. [Google Scholar] [CrossRef]

- Qu, Z.; Feng, H.; Zeng, Z.; Zhuge, J.; Jin, S. A SVM-based pipeline leakage detection and pre-warning system. Measurement 2010, 43, 513–519. [Google Scholar] [CrossRef]

- Da Silva, H.V.; Morooka, C.K.; Guilherme, I.R.; Da Fonseca, T.C.; Mendes, J.R. Leak detection in petroleum pipelines using a fuzzy system. J. Pet. Sci. Eng. 2005, 49, 223–238. [Google Scholar] [CrossRef]

- Wachla, D.; Przystałka, P.; Moczulski, W. A Method of Leakage Location in Water Distribution Networks using Artificial Neuro-Fuzzy System. IFAC-PapersOnLine 2015, 48, 1216–1223. [Google Scholar] [CrossRef]

- Nellis, M. Application of thermal infrared imagery to canal leakage detection. Remote Sens. Environ. 1982, 12, 229–234. [Google Scholar] [CrossRef]

- Adefila, K.; Yan, Y.; Wang, T.; Kehinde, A. Leakage detection of gaseous CO2 through thermal imaging. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, Pisa, Italy, 11–14 May 2015; pp. 261–265. [Google Scholar]

- Kroll, A.; Baetz, W.; Peretzki, D. On autonomous detection of pressured air and gas leaks using passive IR-thermography for mobile robot application. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 921–926. [Google Scholar]

- Dai, D.; Wang, X.; Zhang, Y.; Zhao, L.; Li, J. Leakage Region Detection of Gas Insulated Equipment by Applying Infrared Image Processing Technique. In Proceedings of the 2017 9th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Changsha, China, 14–15 January 2017; pp. 94–98. [Google Scholar]

- Atef, A.; Zayed, T.; Hawari, A.H.; Khader, M.; Moselhi, O. Multi-tier method using infrared photography and GPR to detect and locate water leaks. Autom. Constr. 2016, 61, 162–170. [Google Scholar] [CrossRef]

- Kuzmanić, I.; Soda, J.; Antonić, R.; Vujović, I.; Beros, S. Monitoring of oil leakage from a ship propulsion system using IR camera and wavelet analysis for prevention of health and ecology risks and engine faults. Mater. Werkst. 2009, 40, 178–186. [Google Scholar] [CrossRef]

- Fahimipirehgalin, M.; Trunzer, E.; Odenweller, M.; Vogel-Heuser, B. Automatic Visual Leakage Inspection by Using Thermographic Video and Image Analysis. In Proceedings of the 2019 IEEE 15th International Conference on Automation Science and Engineering (CASE), Vancouver, BC, Canada, 22–26 August 2019; pp. 1282–1288. [Google Scholar]

- Ojha, S.; Sakhare, S. Image processing techniques for object tracking in video surveillance- A survey. In Proceedings of the 2015 International Conference on Pervasive Computing (ICPC), Pune, India, 8–10 January 2015; pp. 1–6. [Google Scholar]

- Grimson, W.; Stauffer, C.; Romano, R.; Lee, L. Using adaptive tracking to classify and monitor activities in a site. In Proceedings of the 1998 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (Cat. No.98CB36231), Santa Barbara, CA, USA, 25–25 June 1998; pp. 22–29. [Google Scholar]

- Hu, W.; Xiao, X.; Fu, Z.; Xie, D.; Tan, T.; Maybank, S.J. A system for learning statistical motion patterns. IEEE Trans. Pattern Anal. Mach. Intell. 2006, 28, 1450–1464. [Google Scholar] [CrossRef] [PubMed]

- Basharat, A.; Gritai, A.; Shah, M. Learning object motion patterns for anomaly detection and improved object detection. In Proceedings of the 2008 IEEE Conference on Computer Vision and Pattern Recognition, Anchorage, AK, USA, 23–28 June 2008; pp. 1–8. [Google Scholar]

- Arulampalam, M.S.; Maskell, S.; Gordon, N.; Clapp, T. A tutorial on particle filters for online nonlinear/non-Gaussian Bayesian tracking. IEEE Trans. Signal Process. 2002, 50, 174–188. [Google Scholar] [CrossRef]

- Gustafsson, F. Particle filter theory and practice with positioning applications. IEEE Aerosp. Electron. Syst. Mag. 2010, 25, 53–82. [Google Scholar] [CrossRef]

- Bewley, A.; Ge, Z.; Ott, L.; Ramos, F.; Upcroft, B. Simple online and realtime tracking. In Proceedings of the 2016 IEEE International Conference on Image Processing (ICIP), Phoenix, AZ, USA, 25–28 September 2016; pp. 3464–3468. [Google Scholar]

- Liu, S. The research of multi-object tracking algorithm using Kalman filtering method. Int. J. Innov. Comput. Appl. 2019, 10, 107. [Google Scholar] [CrossRef]

- Li, X.; Wang, K.; Wang, W.; Li, Y. A multiple object tracking method using Kalman filter. In Proceedings of the 2010 IEEE International Conference on Information and Automation, Harbin, China, 20–23 June 2010; pp. 1862–1866. [Google Scholar]

- Shantaiya, S.; Kesari, V.; Mehta, K. Multiple object tracking using Kalman filter and optical flow. Eur. J. Adv. Eng. Technol. 2015, 2, 34–39. [Google Scholar]

- Chavan, R.; Gengaje, S.R. Multiple Object Detection using GMM Technique and Tracking using Kalman Filter. Int. J. Comput. Appl. 2017, 172, 20–25. [Google Scholar] [CrossRef]

- Hamuda, E.; Mc Ginley, B.; Glavin, M.; Jones, E. Improved image processing-based crop detection using Kalman filtering and the Hungarian algorithm. Comput. Electron. Agric. 2018, 148, 37–44. [Google Scholar] [CrossRef]

- Emami, P.; Pardalos, P.M.; Elefteriadou, L.; Ranka, S. Machine Learning Methods for Solving Assignment Problems in Multi-Target Tracking. Available online: https://arxiv.org/pdf/1802.06897 (accessed on 19 February 2018).

- Kalman, R.E. A New Approach to Linear Filtering and Prediction Problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef]

- Salhi, A.; Ghozzi, F.; Fakhfakh, A. Estimation for Motion in Tracking and Detection Objects with Kalman Filter. In Dynamic Data Assimilation—Beating the Uncertainties; IntechOpen: London, UK, 2020. [Google Scholar]

- Duan, Y.; Zhang, X.; Li, Z. A New Quaternion-Based Kalman Filter for Human Body Motion Tracking Using the Second Estimator of the Optimal Quaternion Algorithm and the Joint Angle Constraint Method with Inertial and Magnetic Sensors. Sensors 2020, 20, 6018. [Google Scholar] [CrossRef]

- Khalkhali, M.B.; Vahedian, A.; Yazdi, H.S. Vehicle tracking with Kalman filter using online situation assessment. Robot. Auton. Syst. 2020, 131, 103596. [Google Scholar] [CrossRef]

| R1 | R2 | R3 | R4 | R5 | R6 | |

|---|---|---|---|---|---|---|

| Summary of the requirements | High accuracy | Robust to the noise | Detection of small drops | Multiple leakages | Leakage localization | Independent of physical properties |

| Position of the Leakage in Vertical Direction | ||||||

|---|---|---|---|---|---|---|

| Tracking Window 1 | 47 | 85 | 115 | 148 | 185 | 225 |

| Tracking Window 2 | 46 | 88 | 114 | 150 | 182 | 221 |

| Tracking Window 3 | 46 | 82 | 118 | 147 | 189 | 224 |

| Tracking Window 4 | 47 | 91 | 120 | 196 | - | - |

| Parameters | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| value | 0.5 | 10 | 5 × 3 | 0.7 | 9 | 50 | 10 | 20,000 | 2 |

| Actual Class | |||||||

|---|---|---|---|---|---|---|---|

| Normal Videos | Normal | Anomalous | Acc. | F1 | |||

| Video 1 | Predicted class | Normal | 48 (100%) | 0 (0%) | 100 | 1 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Video 2 | Predicted class | Normal | 48 (100%) | 0 (0%) | 100 | 1 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Video 3 | Predicted class | Normal | 48 (100%) | 0 (0%) | 100 | 1 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Video 4 | Predicted class | Normal | 48 (100%) | 0 (0%) | 100 | 1 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Anomalous Videos | Video 5 | Predicted class | Normal | 40 (83%) | 0 (0.0%) | 100 | 1 |

| Anomalous | 0 (0.0%) | 8 (17%) | |||||

| Video 6 | Predicted class | Normal | 32 (67%) | 0 (0.0%) | 100 | 1 | |

| Anomalous | 0 (0.0%) | 16 (33%) | |||||

| Video 7 | Predicted class | Normal | 40 (83%) | 1 (2%) | 93 | 0.96 | |

| Anomalous | 2 (4%) | 5 (11%) | |||||

| Video 8 | Predicted class | Normal | 35 (72%) | 0 (6%) | 93 | 0.95 | |

| Anomalous | 3 (6%) | 10 (20%) | |||||

| Video 9 | Predicted class | Normal | 32 (67%) | 0 (6%) | 91 | 0.94 | |

| Anomalous | 4 (8%) | 12 (25%) | |||||

| Video 10 | Predicted class | Normal | 36 (75%) | 2 (4%) | 91 | 0.94 | |

| Anomalous | 2 (4%) | 8 (17%) | |||||

| Actual Class | |||||||

|---|---|---|---|---|---|---|---|

| Normal Videos | Normal | Anomalous | Acc. | F1 | |||

| Video 1 | Predicted class | Normal | 48 (100%) | 0 (0%) | 100 | 1 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Video 2 | Predicted class | Normal | 48 (100%) | 0 (0%) | 100 | 1 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Video 3 | Predicted class | Normal | 48 (100%) | 0 (0%) | 93 | 0.96 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Video 4 | Predicted class | Normal | 48 (100%) | 0 (0%) | 93 | 0.96 | |

| Anomalous | 0 (0%) | 0 (0%) | |||||

| Anomalous Videos | Video 5 | Predicted class | Normal | 40 (93%) | 0 (0.0%) | 100 | 1 |

| Anomalous | 0 (0.0%) | 8 (17%) | |||||

| Video 6 | Predicted class | Normal | 30 (62%) | 2 (4%) | 95 | 0.96 | |

| Anomalous | 0 (0.0%) | 16 (34%) | |||||

| Video 7 | Predicted class | Normal | 38 (80%) | 4 (8%) | 91 | 0.95 | |

| Anomalous | 0 (0.0%) | 6 (12%) | |||||

| Video 8 | Predicted class | Normal | 35 (73%) | 0 (0.0%) | 93 | 0.95 | |

| Anomalous | 3 (6%) | 10 (21%) | |||||

| Video 9 | Predicted class | Normal | 32 (67%) | 4 (8%) | 91 | 0.94 | |

| Anomalous | 0 (0.0%) | 12 (25%) | |||||

| Video 10 | Predicted class | Normal | 33 (69%) | 1 (2%) | 87 | 0.91 | |

| Anomalous | 5 (10%) | 9 (19%) | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fahimipirehgalin, M.; Vogel-Heuser, B.; Trunzer, E.; Odenweller, M. Visual Leakage Inspection in Chemical Process Plants Using Thermographic Videos and Motion Pattern Detection. Sensors 2020, 20, 6659. https://doi.org/10.3390/s20226659

Fahimipirehgalin M, Vogel-Heuser B, Trunzer E, Odenweller M. Visual Leakage Inspection in Chemical Process Plants Using Thermographic Videos and Motion Pattern Detection. Sensors. 2020; 20(22):6659. https://doi.org/10.3390/s20226659

Chicago/Turabian StyleFahimipirehgalin, Mina, Birgit Vogel-Heuser, Emanuel Trunzer, and Matthias Odenweller. 2020. "Visual Leakage Inspection in Chemical Process Plants Using Thermographic Videos and Motion Pattern Detection" Sensors 20, no. 22: 6659. https://doi.org/10.3390/s20226659

APA StyleFahimipirehgalin, M., Vogel-Heuser, B., Trunzer, E., & Odenweller, M. (2020). Visual Leakage Inspection in Chemical Process Plants Using Thermographic Videos and Motion Pattern Detection. Sensors, 20(22), 6659. https://doi.org/10.3390/s20226659