1. Introduction

According to Faraday’s electromagnetic induction, the metal conductor in a changing magnetic field, or cutting the magnetic lines, an eddy current is generated in the target conductor. The sensor based on the eddy current effect is called the eddy current sensor. The eddy current sensor has been widely applied in the field of displacement measurement [

1], defect detection [

2,

3], thickness measurement [

4,

5], and many other fields, owning to its noncontact, simple structure and high sensitivity [

6,

7]. Sensitivity, resolution, long-term stability, and temperature drift are usually considered when evaluating a sensor’s performance metrics [

8]. The study of the eddy current sensor mostly focuses on the probe coil impedance [

9,

10], the optimal design for structural parameters [

11,

12,

13], etc. The aim of these studies is to promote the eddy current sensor’s performance, such as linearity [

14,

15] and the range of measurement [

16].

Most objects measured by the eddy current displacement sensor (ECDS) are planar conductors at present. Li Y et al. presented a tilt angle model to explore the influence of tilt angle on sensor’s measured values when the measurement surface was a plane and the experiments also testified that the measuring errors can be compensated well by the Gaussian function [

17]. Different surface shapes of measured conductors have different influence on the senor’s output. For three different detected surfaces—concave, plane and convexity—Zhang Y et al. built the relevant finite element models of three-dimensional eddy current field problem and the surface shape, curvature radius, and lift-off variation effects on coil’s reflected impedance had been analyzed [

18]. When the surface shape is a coaxial cylindrical surface, their center axes are intersecting vertically according to the installation requirement of the ECDS. In view of the advantages of friction-free, no wear, without lubricating, no pollution, low consuming, and long life, magnetic bearings suit high or super high speed, vacuum condition, and some special conditions [

19,

20]. However, the eccentric problem easily occurs under the condition of high-speed rotation, which further affects the output of the ECDS. Li H et al. detected the axial displacement of maglev rotor in its radial direction through the ECDS, which employed a step surface on the rotor. Due to the limiting effect of the protective bearings, Li H thought the axial and radial displacement of the rotor are generally in the range of −1–1 mm. For a typical magnetic suspension system, the rotor radius is much larger than the eccentricity, so the eccentricity usually does not affect the output voltage of the sensor [

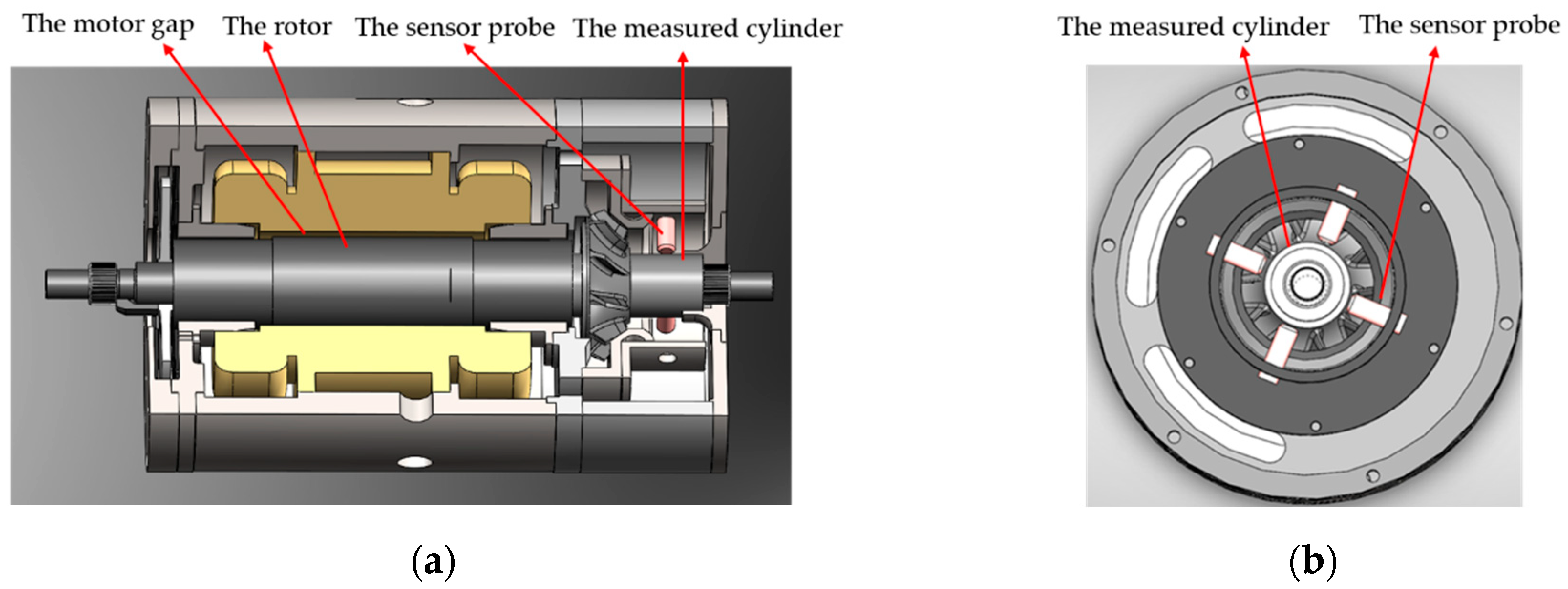

1]. In order to improve the eccentricity problem, the current solution is to use the differential structure. To a certain extent, the interferences of eccentricity and other common mode parameters are eliminated by the differential circuit when the control accuracy is not high. However, the accurate control of the magnetic suspended rotor position is very important for the work state of the motor. It is necessary to study the measurement technology of magnetic suspension motors with the existing eccentricity phenomena. The structure of a single-winding magnetic suspension motor with the rotor radial position detection unit is shown in

Figure 1.

Aiming at the accurate control of the rotor radial position in the magnetic suspension motor system, on the basis of the transformer model [

21] and the eccentric analytical model, this paper investigates the influence of eccentricity on the ECDS by the finite element method (FEM) and experiments. Then, aiming at different structures of the experimental platform, two compensation equations are put forward, respectively. Meanwhile, for the engineering application, the orthogonal direction measured value is used as the eccentricity, and the compensation order is proposed. The experiment results show that the presented compensation method is efficient.

3. Simulation Analyses

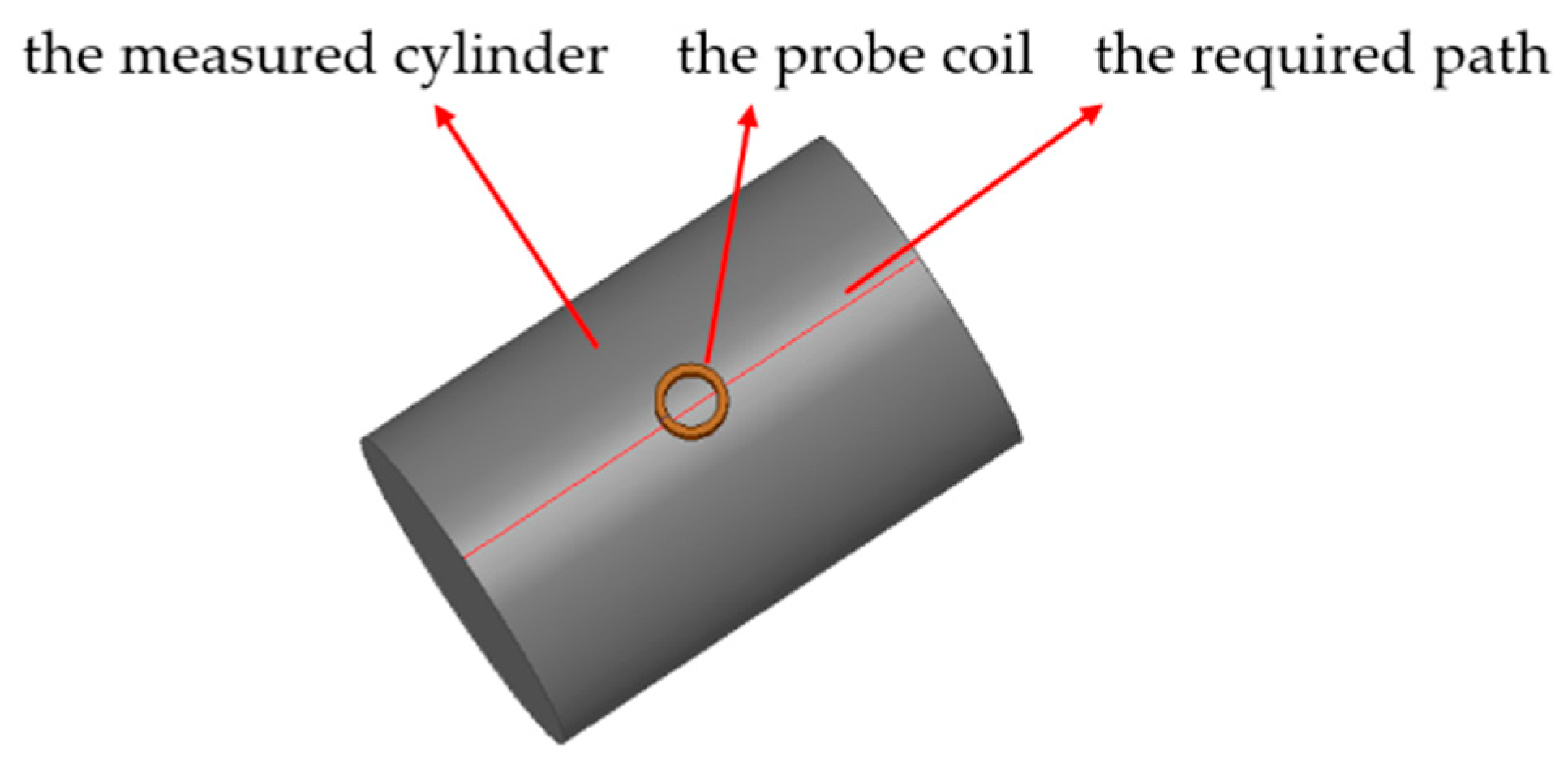

The influences of the cylinder radius and the eccentricity on detection was investigated by the FEM, ANSYS Maxwell. The solution type Eddy Current was selected. The material of the coil and the cylinder were defined as copper and aluminum. The inner radius, outer radius, and thickness of the probe coil are 3, 4, and 3 mm, respectively. The length of the cylinder is 60 mm. The excitation frequency is 10 kHz, and the solution region is 300%. Considering the effect of skin on the eddy current distribution, the mesh operation for the measured cylinder was defined as skin depth subdivision. In the solution of the eddy current field, the information of the eddy density distribution, magnetic inductive intensity distribution, coil inductance, and other information in the postprocessing results were mainly extracted. Before the solution, the required path was set in advance as shown in

Figure 5.

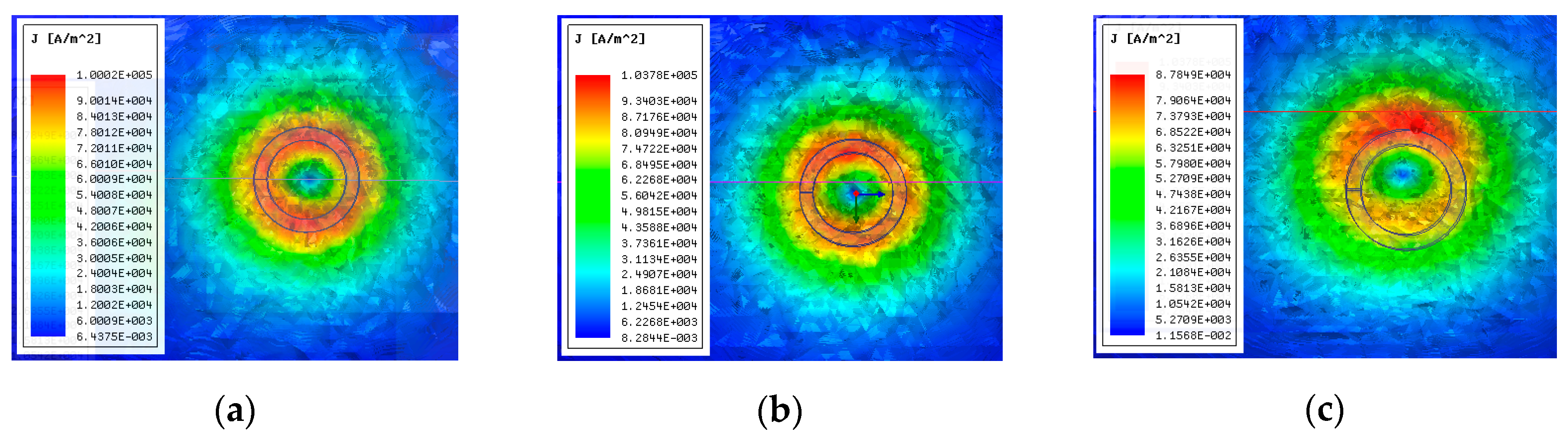

To validate the effect of

E on the induced eddy current, the eddy current distributions under different

E were carried out by the FEM, as shown in

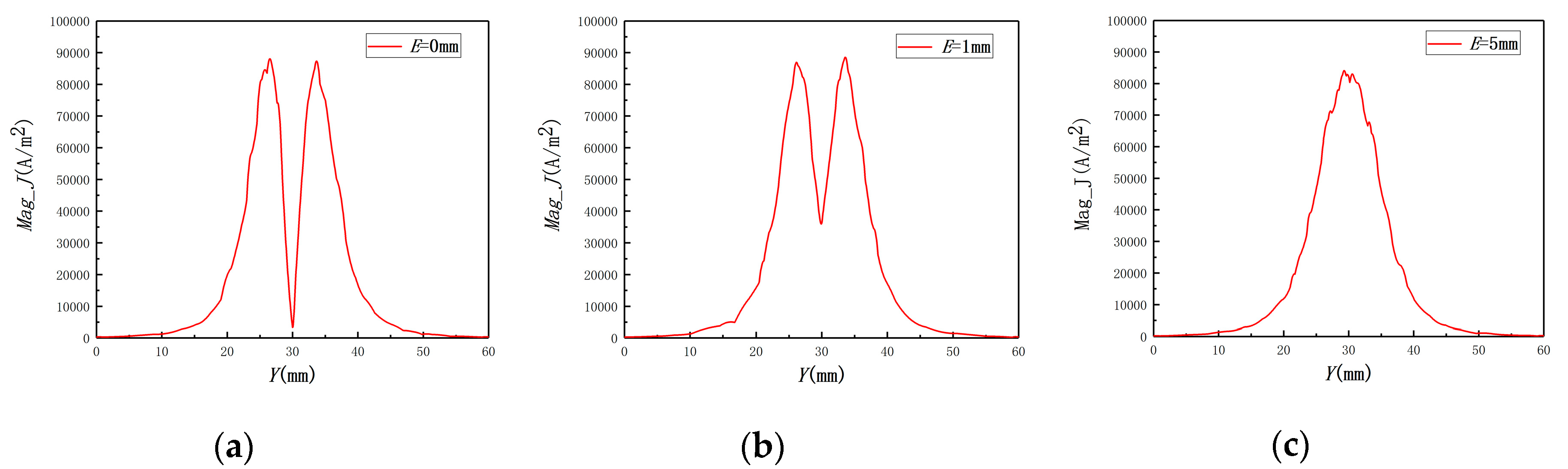

Figure 6. The distribution curves of the eddy current density on the required path are shown in

Figure 7.

As shown in

Figure 6 and

Figure 7, the eddy current distribution and amplitude are different when the eccentricity changes. Based on Faraday electromagnetic induction law, the secondary magnetic field caused by the eddy current will affect the variety of the primary magnetic field, while

E and

C affect the secondary magnetic field. This will finally affect

and the electric signal output.

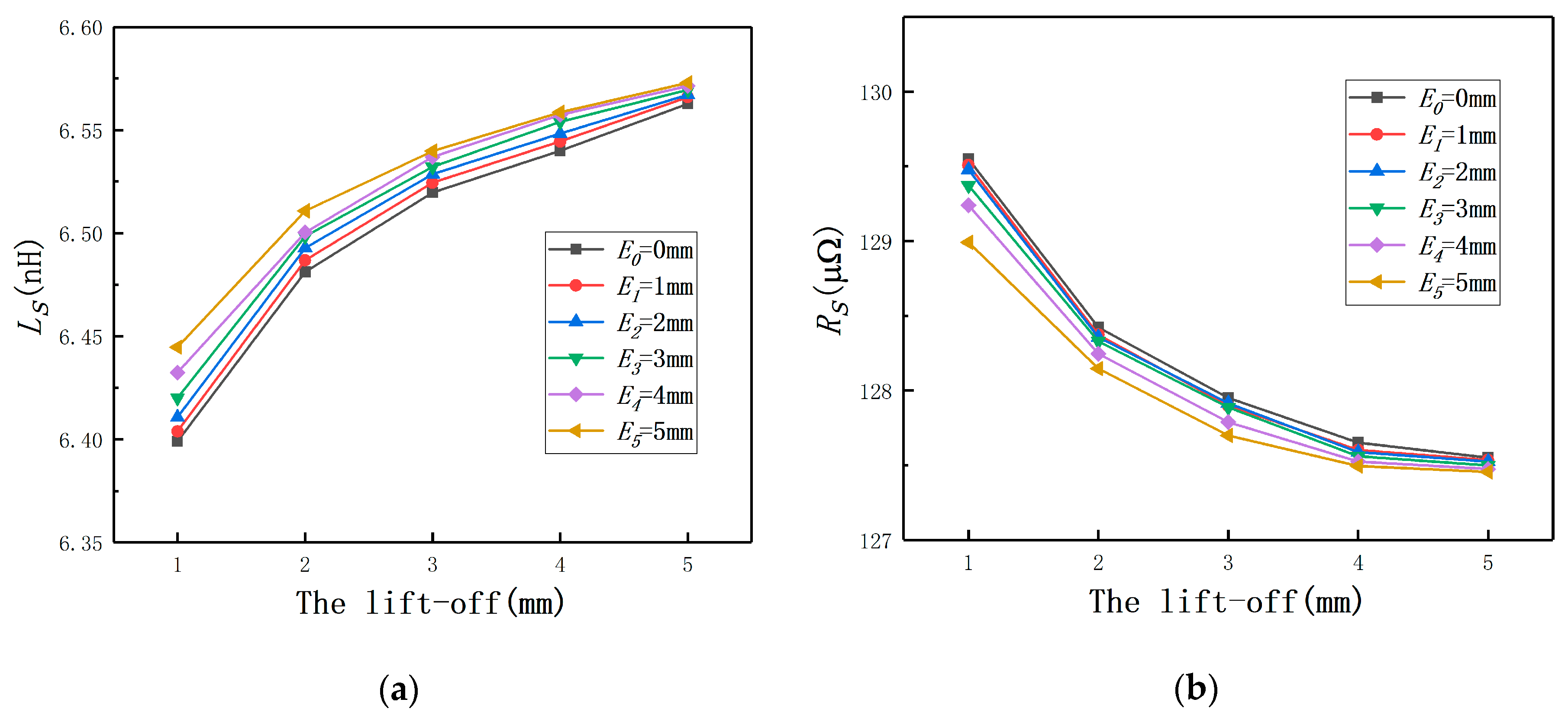

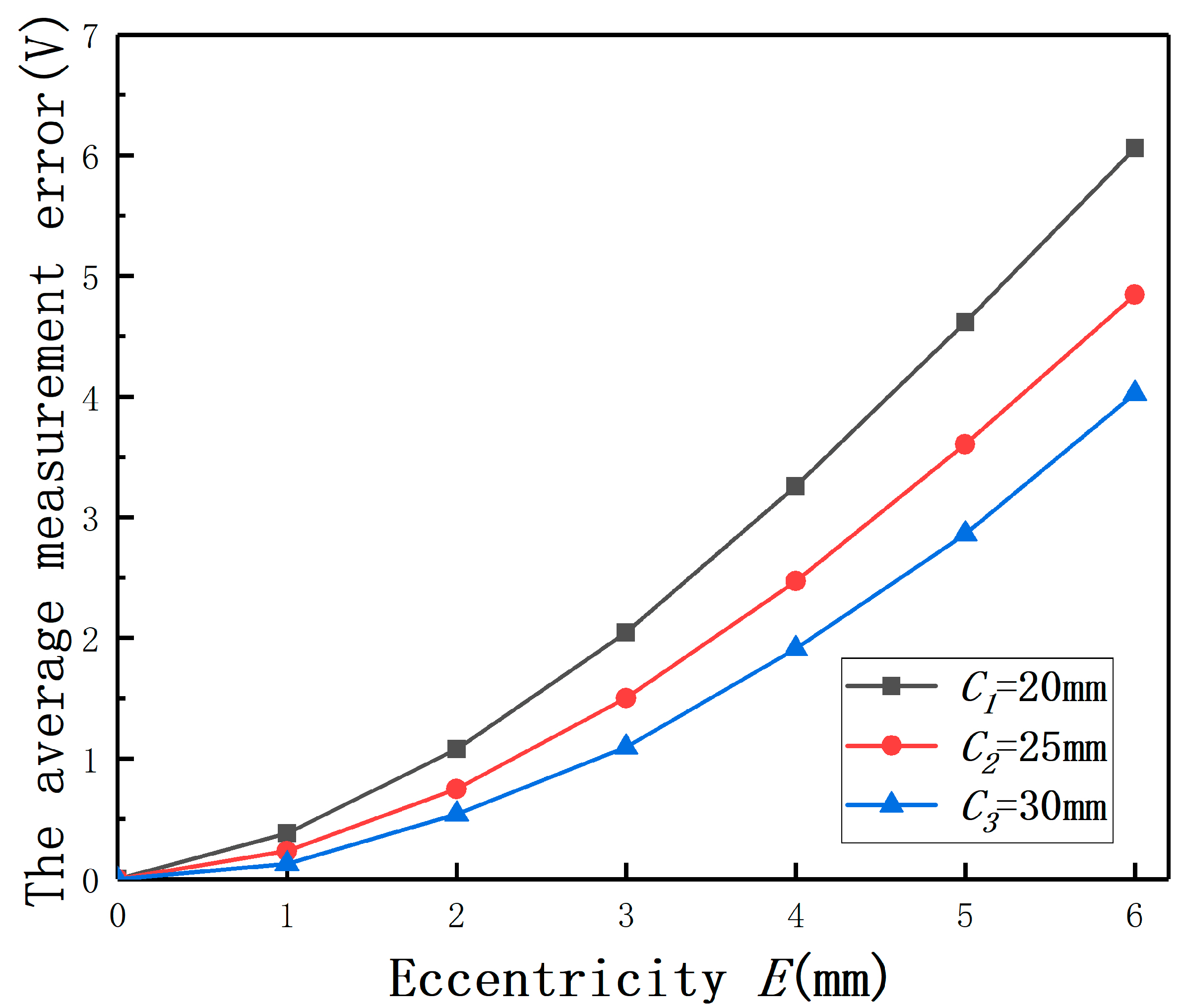

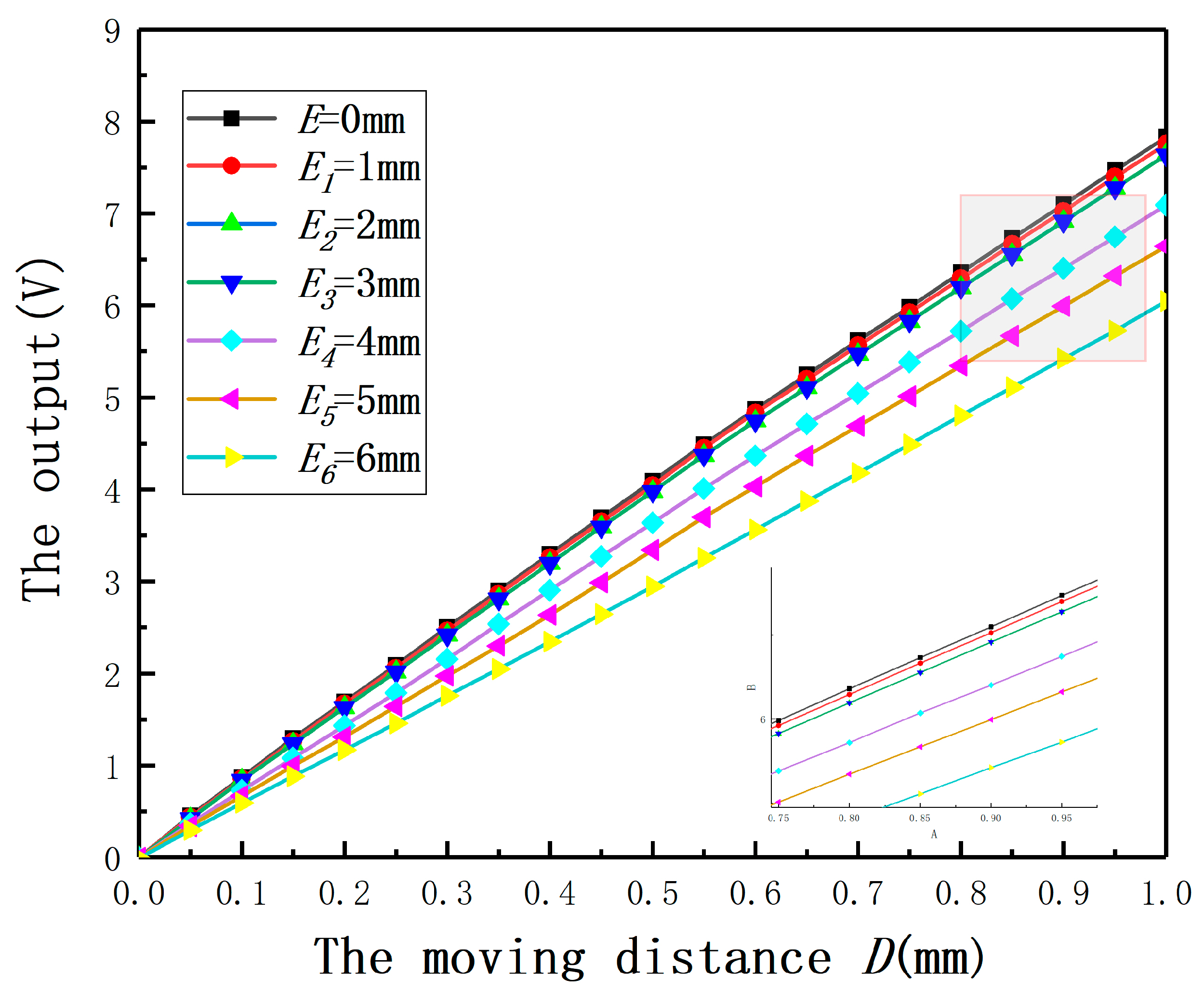

3.1. Change Laws of Coil Equivalent Impedance under Different Eccentricities and Lift-Off

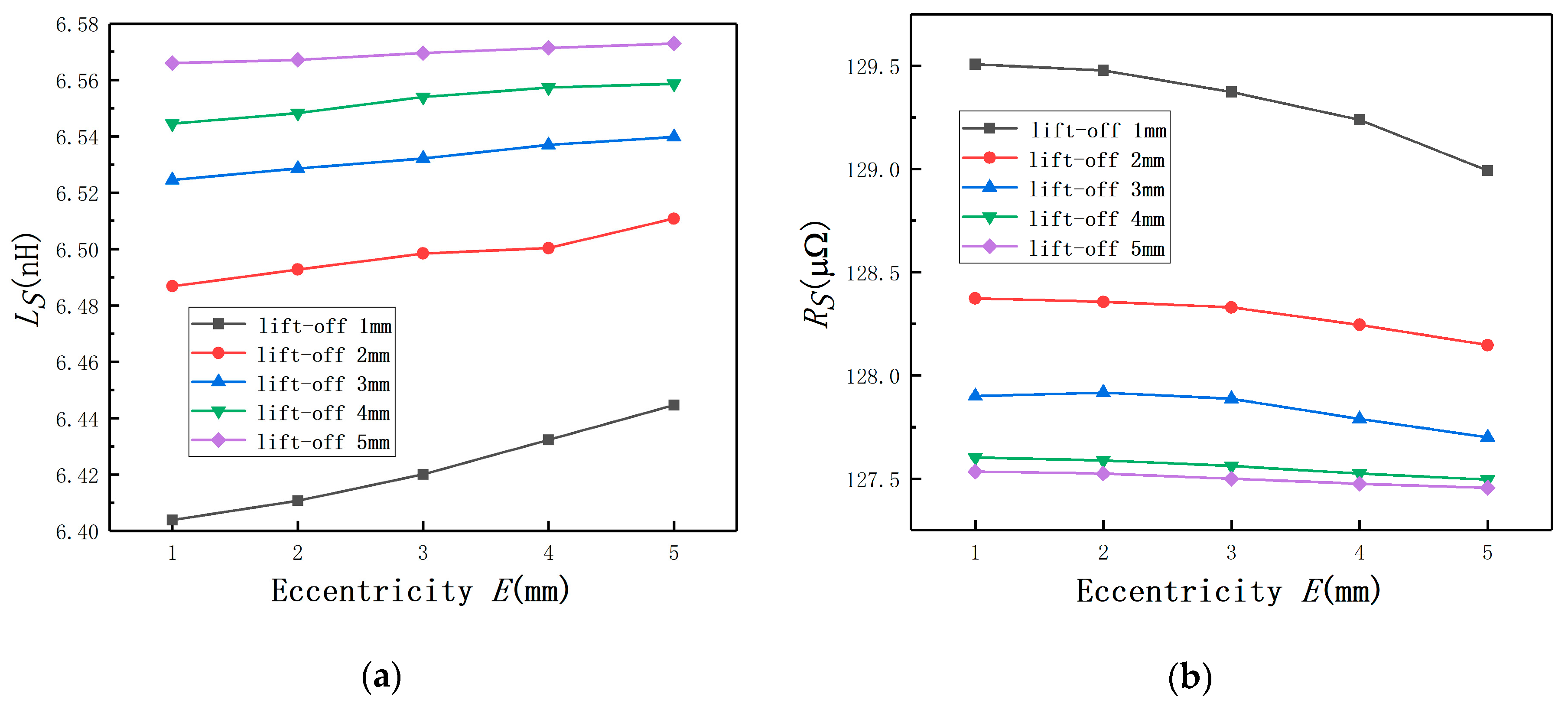

In order to investigate the effect of E on the detection, it also could be transformed into the study of the change law of the coil equivalent impedance under different E and lift-off. E was set as 0, 1, 2, 3, 4, 5 mm, respectively, and the radius of the measured cylinder was 30 mm. The lift-off refers to the distance moved along the axis of the probe coil. The lift-off was set as 1, 2, 3, 4, and 5 mm, respectively.

By using Maxwell, it could be found that

increases with the lift-off until to the probe coil self-inductance, as shown in

Figure 8a. The variation of

is contrary to

and also remains unchanged at the end as shown in

Figure 8b. The results of

E = 0 mm proved the validity of the transformer model. In addition, the curves of different

E prove that no effects are found on the applicability and effectiveness of the transformer model.

When the lift-off remains constant, the change laws of

are shown in

Figure 9a. It can be seen that, with the increase of

E,

increases. It means that the effect of

E on the eddy current sensor is the same with that of the lift-off. As the coil equivalent impedance contains two components, the variation laws of

are also shown in

Figure 9b. It also can be concluded that

L and the lift-off have the same influence tendency for the eddy current displacement measurement. It means

E will lead to a bigger measured value.

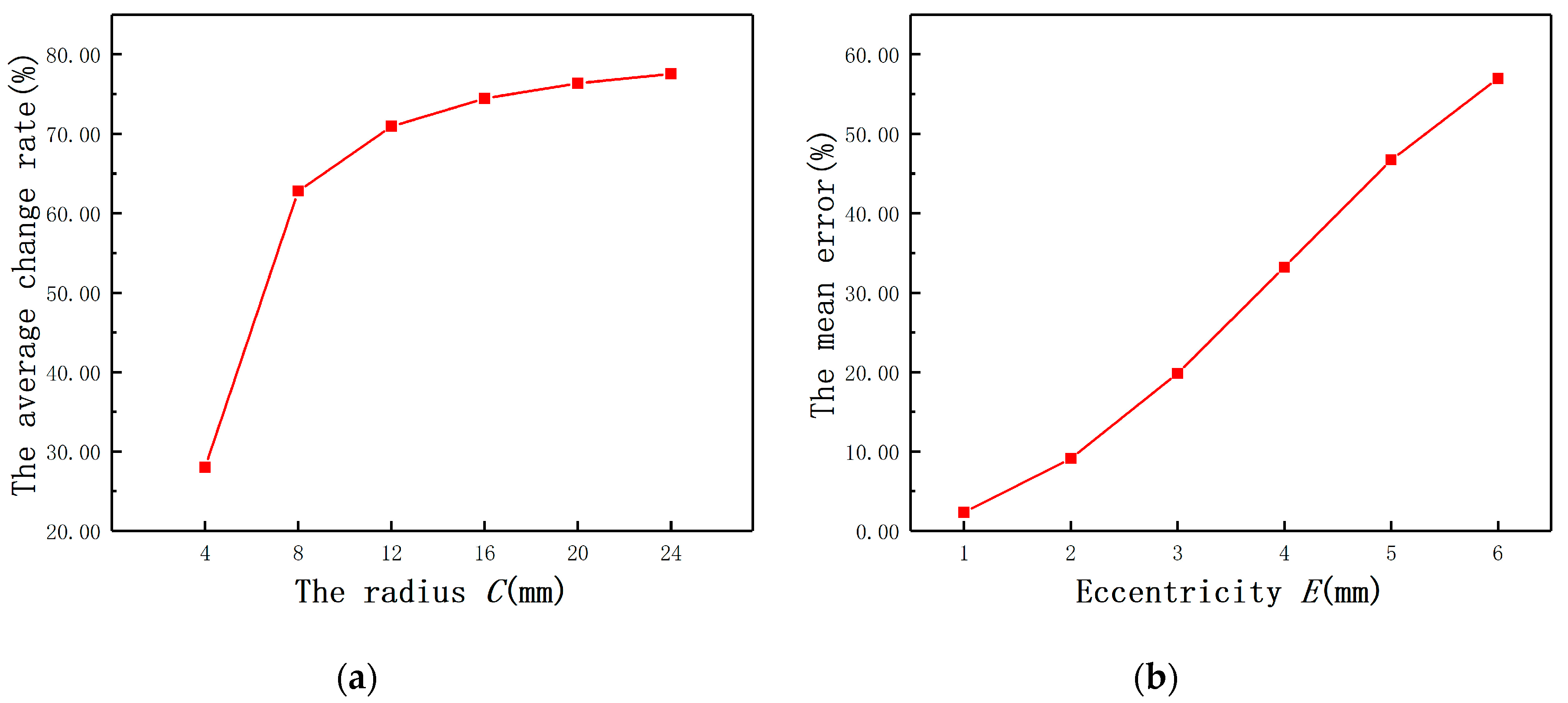

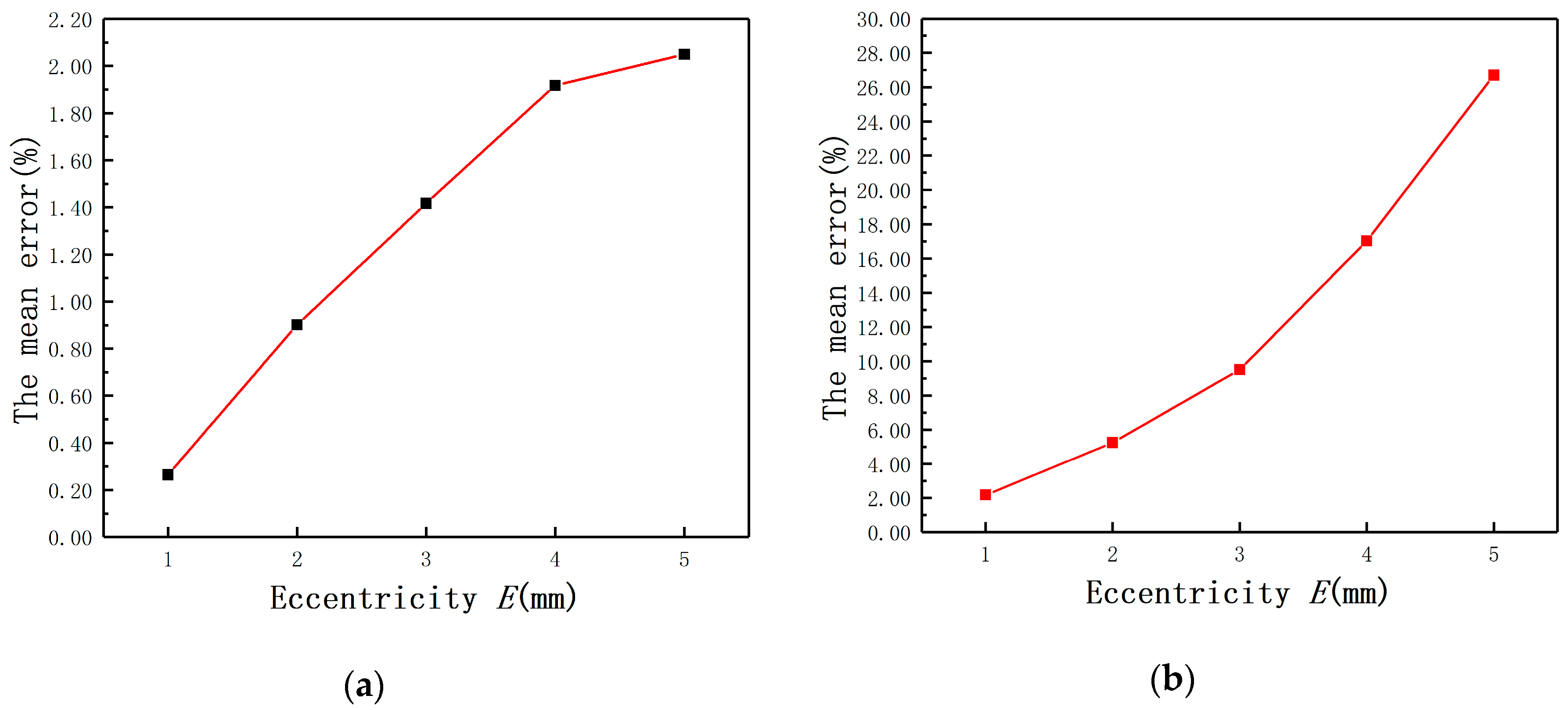

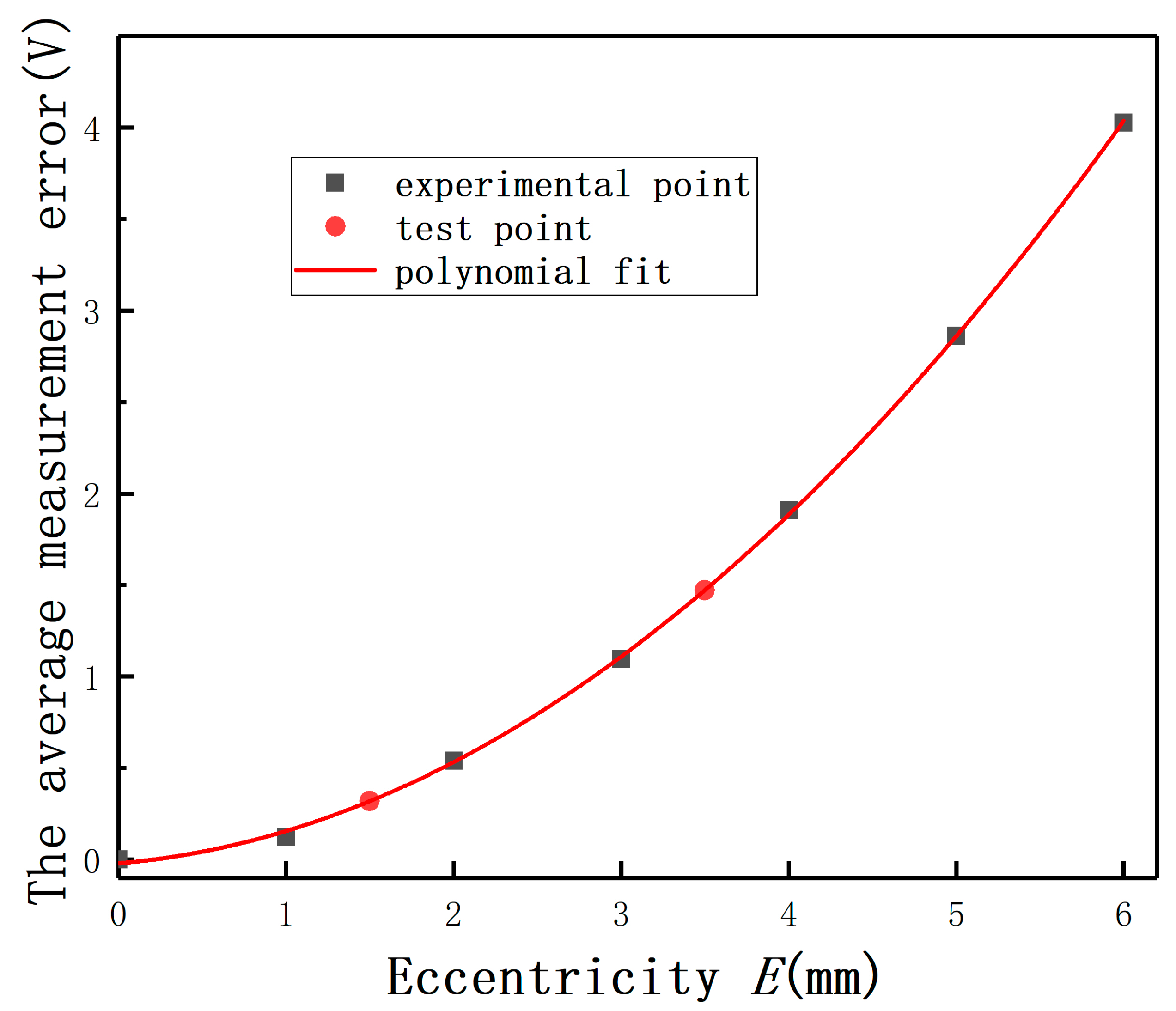

In order to undertake the quantitative analysis, the effect of

E on the displacement measurement was compared by the mean error. The mean error of

under different

E was defined as the average of

and the mean error of

under different

E was defined as the average of

. As shown in

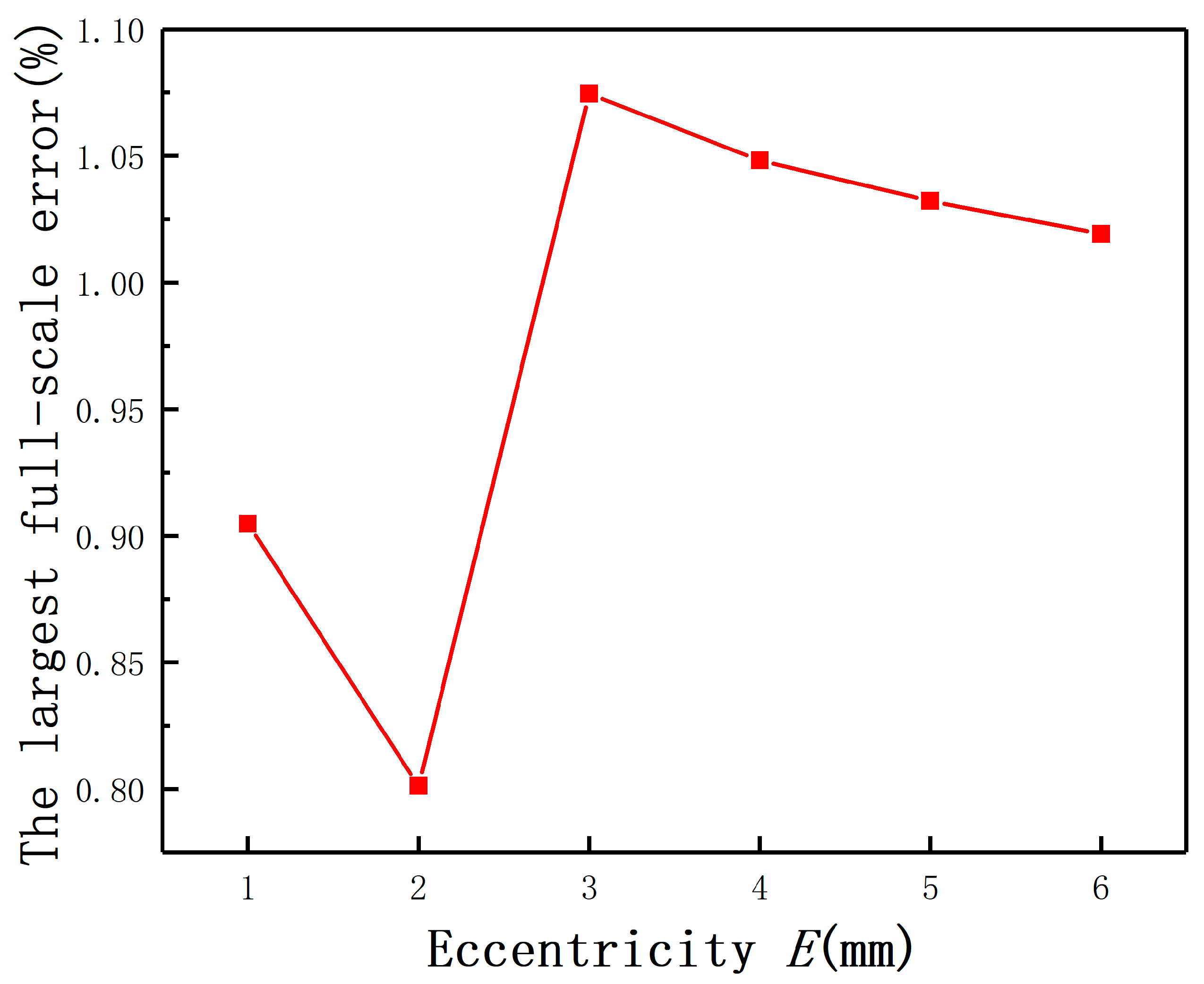

Figure 10, the mean error of

(

E = 4 mm) is one order of magnitude bigger than the mean error of

(

E = 1 mm), so is

. It means that the measurement error must be compensated when the

E-

C ratio is over 0.1. The conclusion is consistent with the result of the mathematical model analysis.

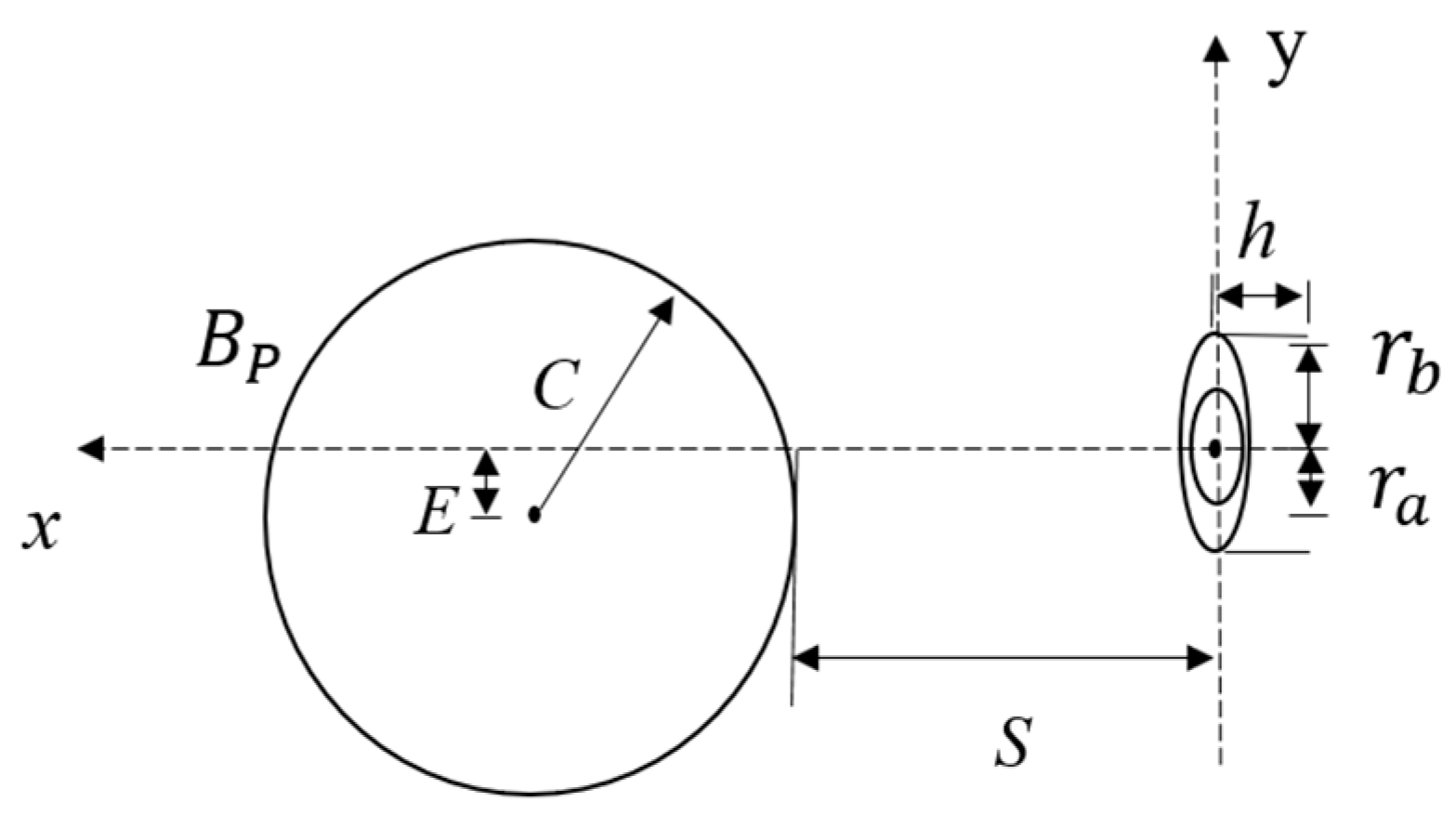

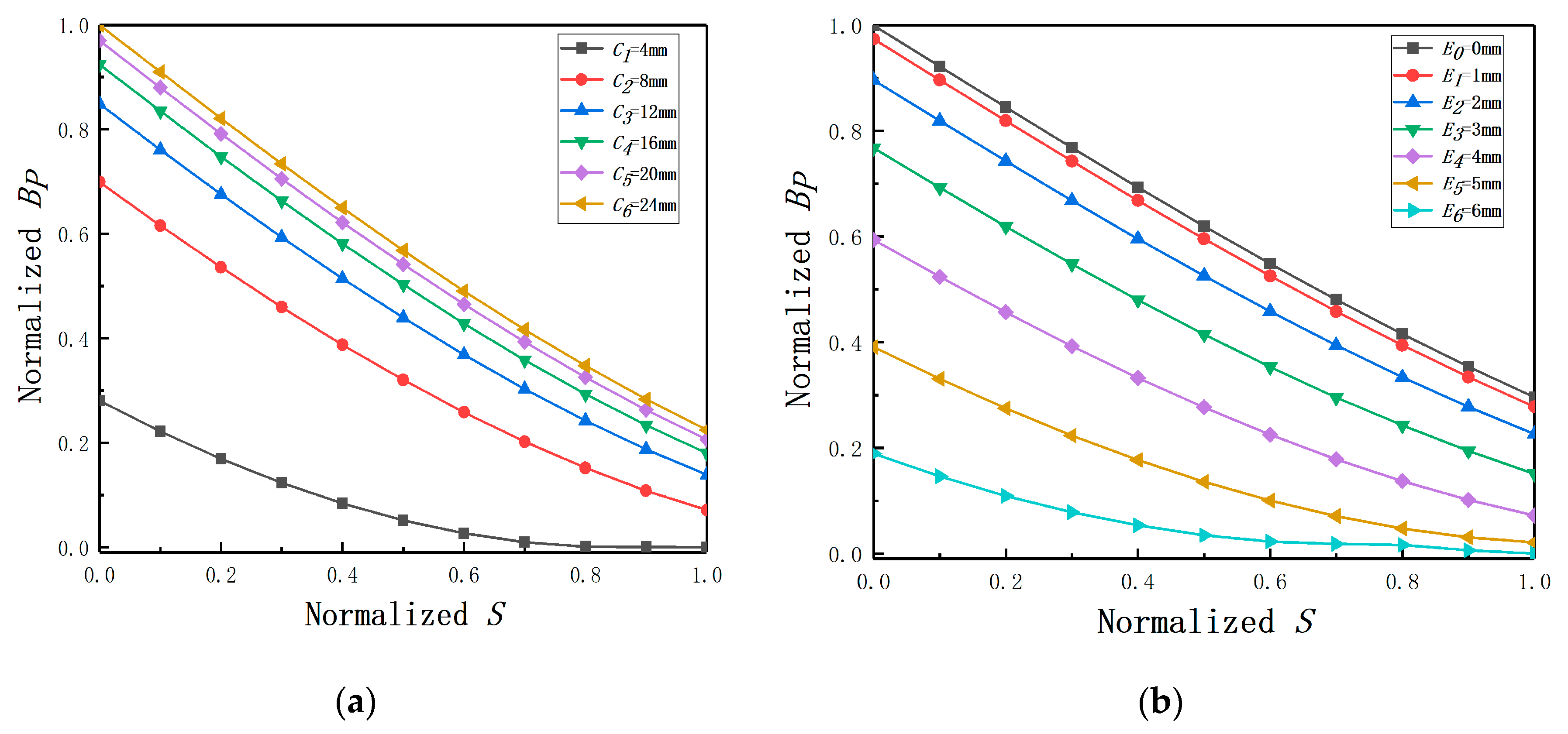

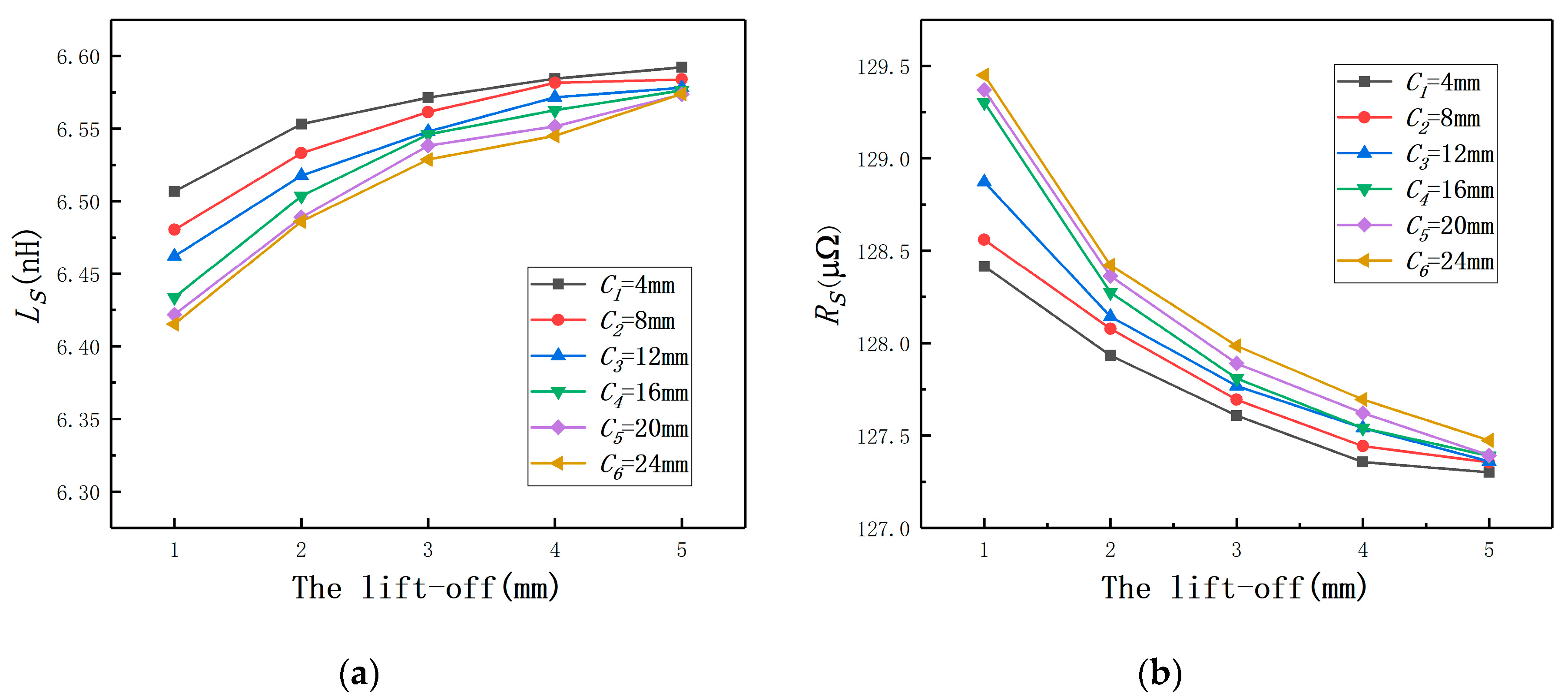

To verify the reliability of the type selection of the ECDS in the analysis of mathematical model,

C was set as 4, 8, 12, 16, 20, and 24 mm, respectively, and the probe radius was 4 mm. By using Maxwell, it could be found that

increases with

C until to the probe coil self-inductance, as shown in

Figure 11a. The variation of

is contrary to

and

also remains unchanged at the end as shown in the

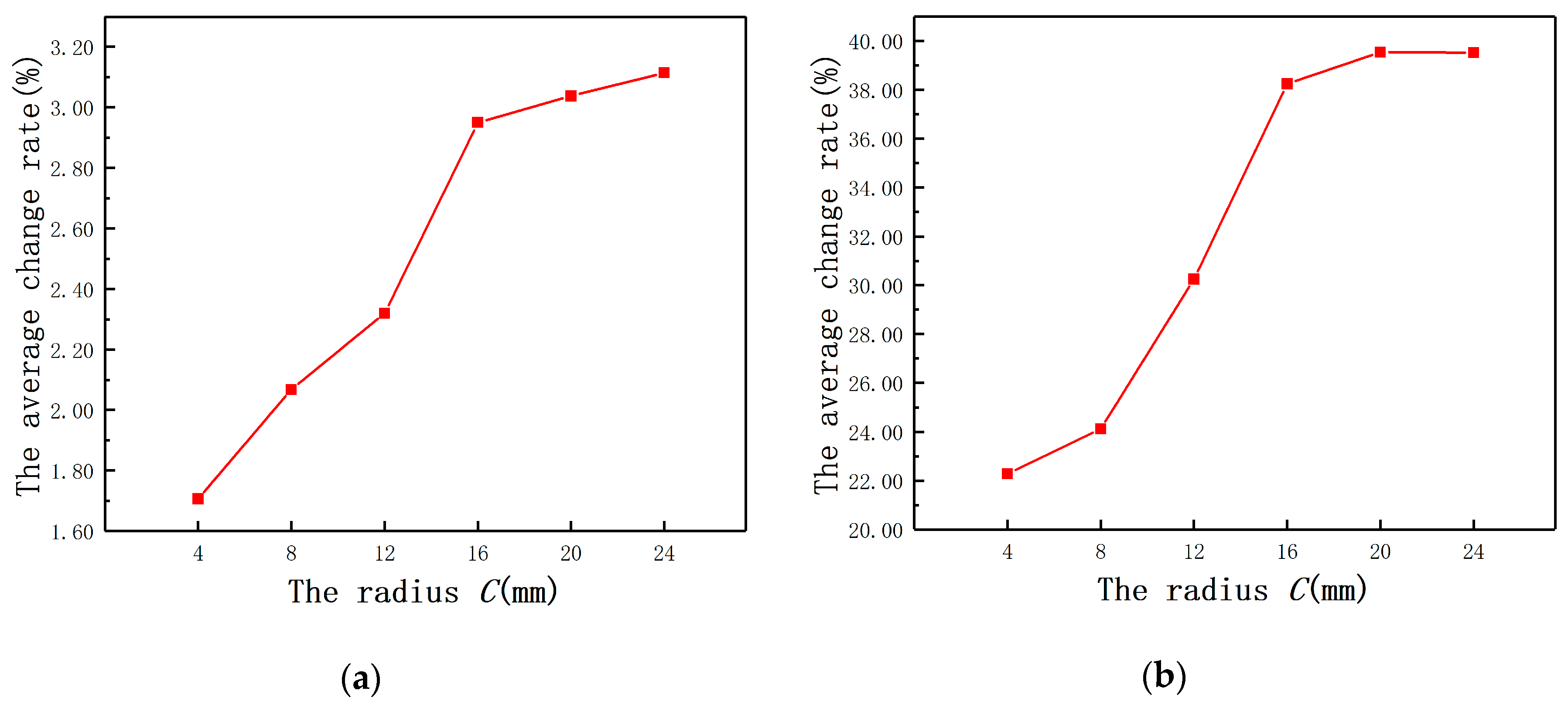

Figure 11b. As shown in

Figure 12, when the

C-

ratio is over 3, the average change rate of

remains approximately constant, so does

. The result is consistent with the conclusion in the previous quantitative analysis.

3.2. Change Laws of Impedance Plane under Different Excitation Frequencies

As the previous section suggests,

E will cause a bigger measured value. The impedance plane method is an effective way for presenting results in the eddy current testing [

22] and can be considered as another perspective to discuss the effect of

E on the eddy current displacement measurement. The normalized

R and

X are defined using Equation (7):

( = ) is the coil equivalent reactance and is the coil equivalent resistance. The coil self-reactance is expressed by (). and are the coil self-resistance and self-inductance. and represent the angular frequency and the excitation frequency, respectively. Finally, the impedance plane is formed by drawing normalized R vs. normalized X.

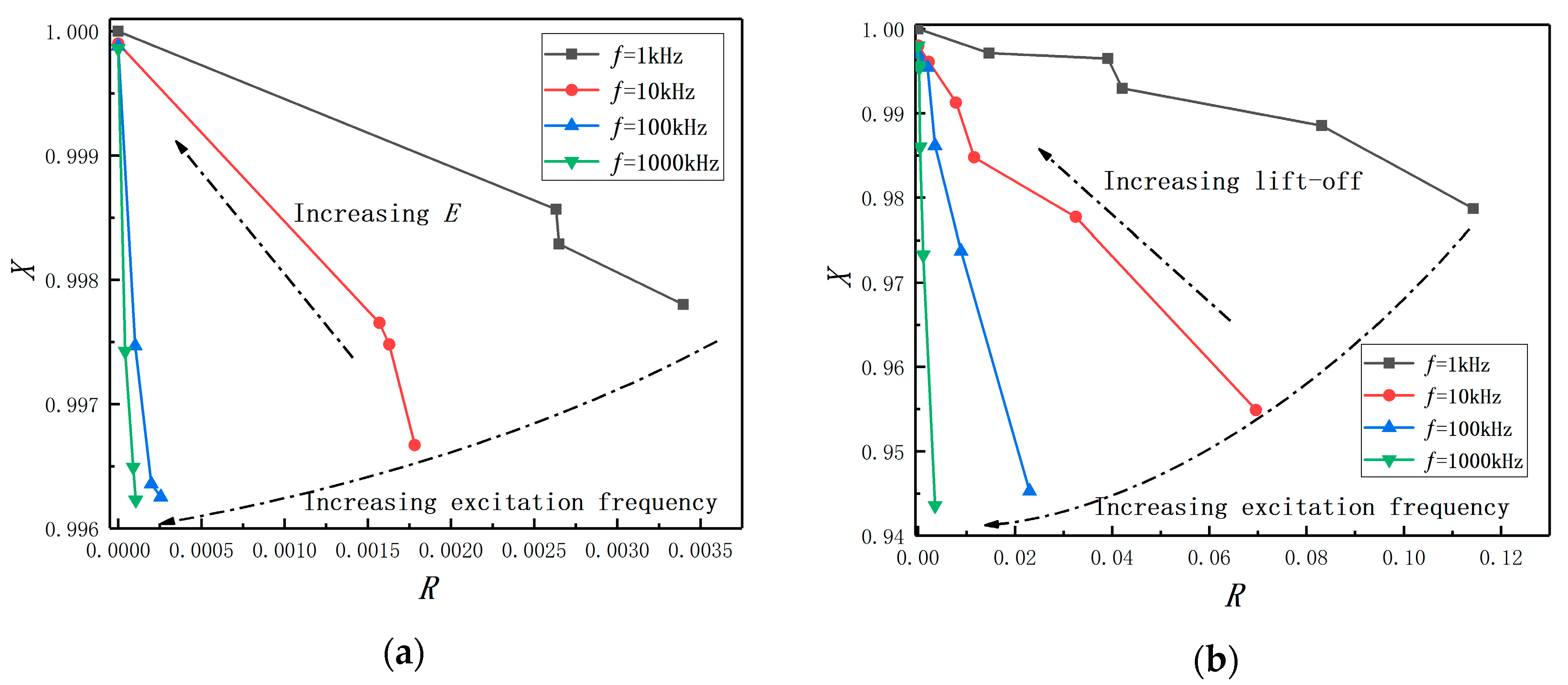

In

Figure 13a,

E is set as 0, 1, 3, and 5 mm, respectively, under fixed lift-off (2 mm). The lift-off is set as 0,1, 2, 3, 4, and 5 mm, respectively, under fixed

E (

E = 0 mm), as shown in

Figure 13b. Combining with Equation (7), the coil normalized impedance will be located on the point (0, 1) as a reference point. From the normalized impedance plan graphs, the coil normalized impedance gets closer to the reference point with the increase of

E under different

. Analogously, the normalized impedance gets closer to the reference point with the increase of the lift-off under different

, as shown in

Figure 13b. Thus, the change law of the coil impedance with

E is similar to the change law of the coil impedance with lift-off. Therefore, it can be concluded that the effect of

E on the probe coil equivalent impedance is similar to the effect of the lift-off, which means that

E will cause a bigger electrical signal in the eddy current displacement measurement. The conclusion is consistent with the conclusion of the previous simulation analysis.

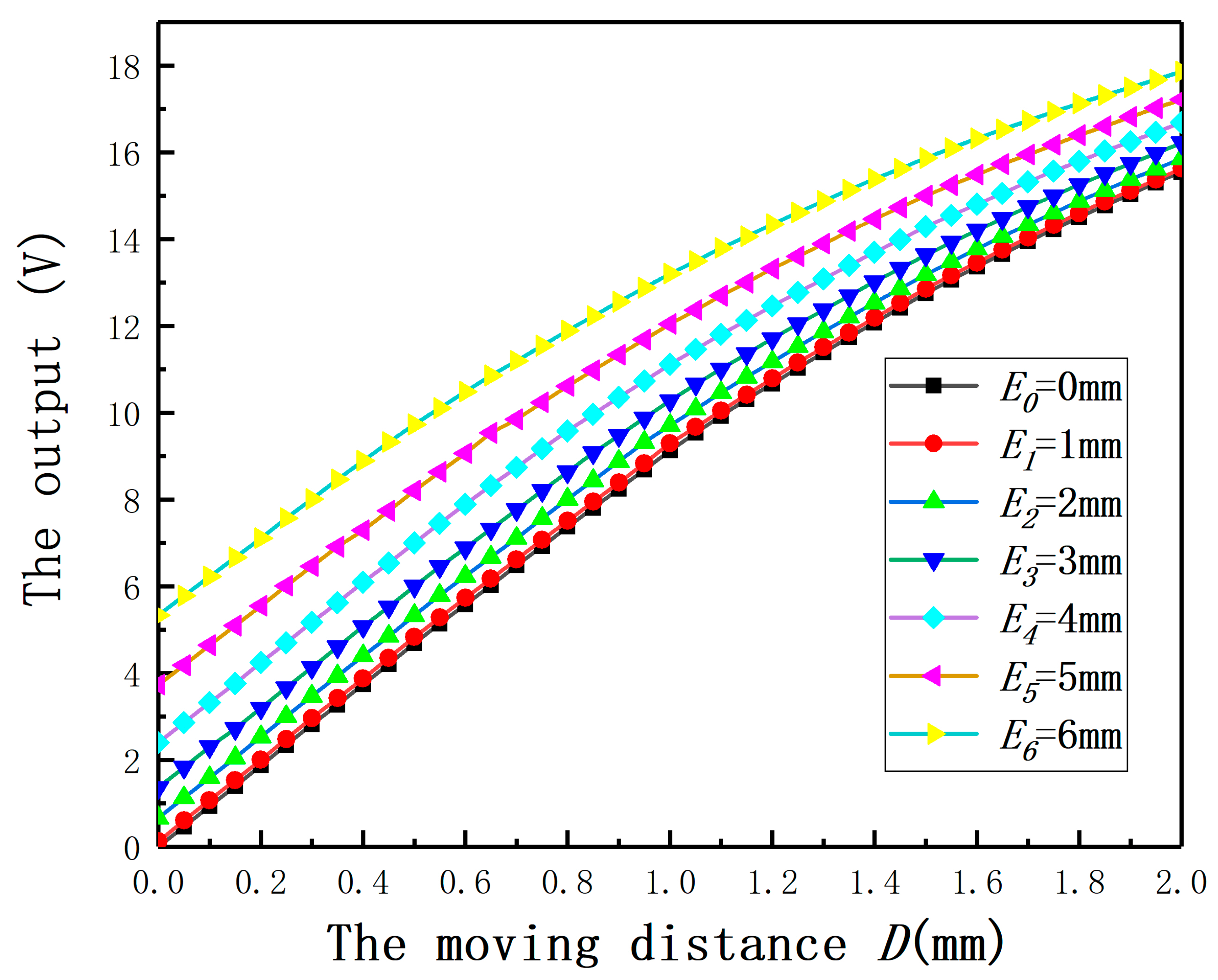

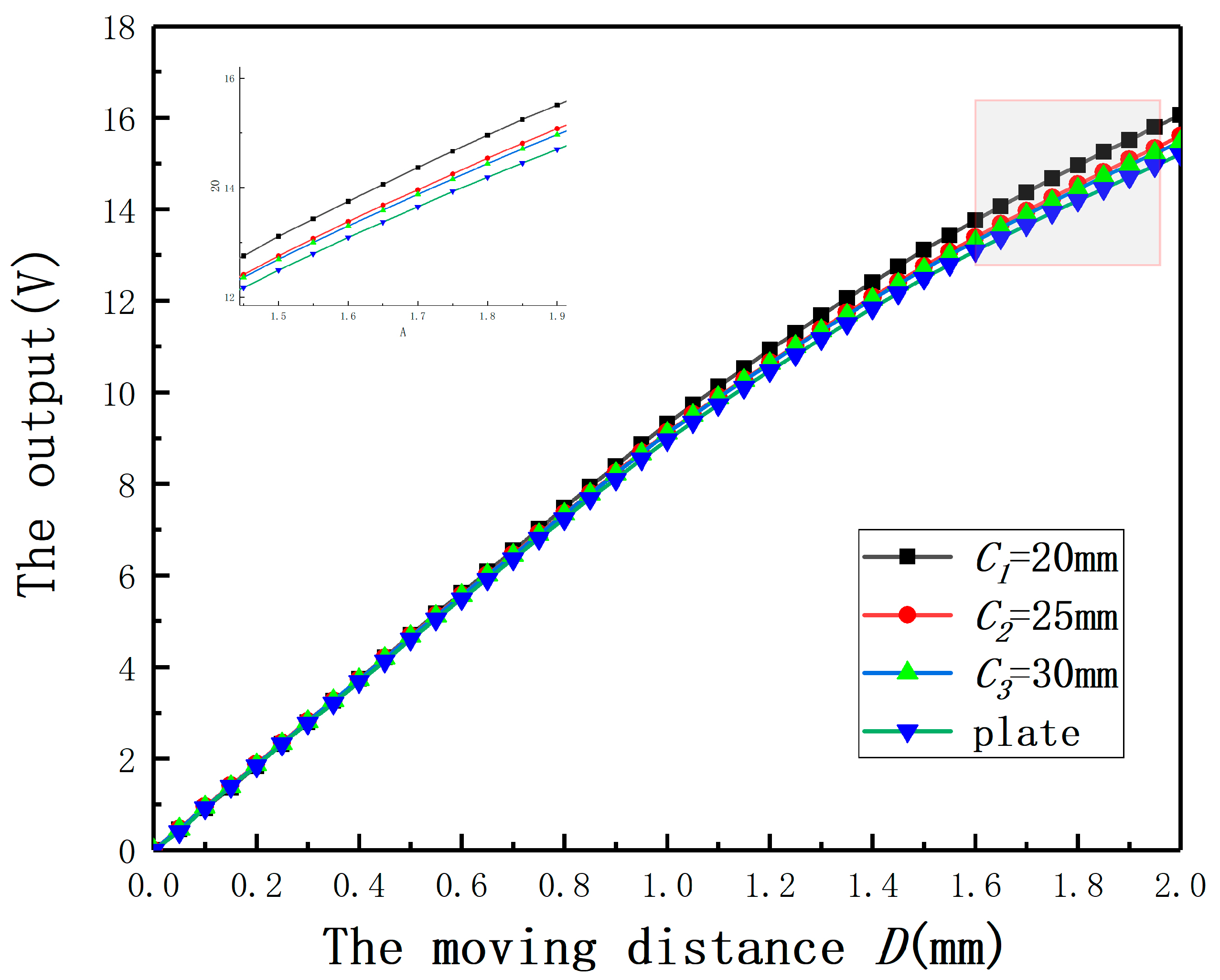

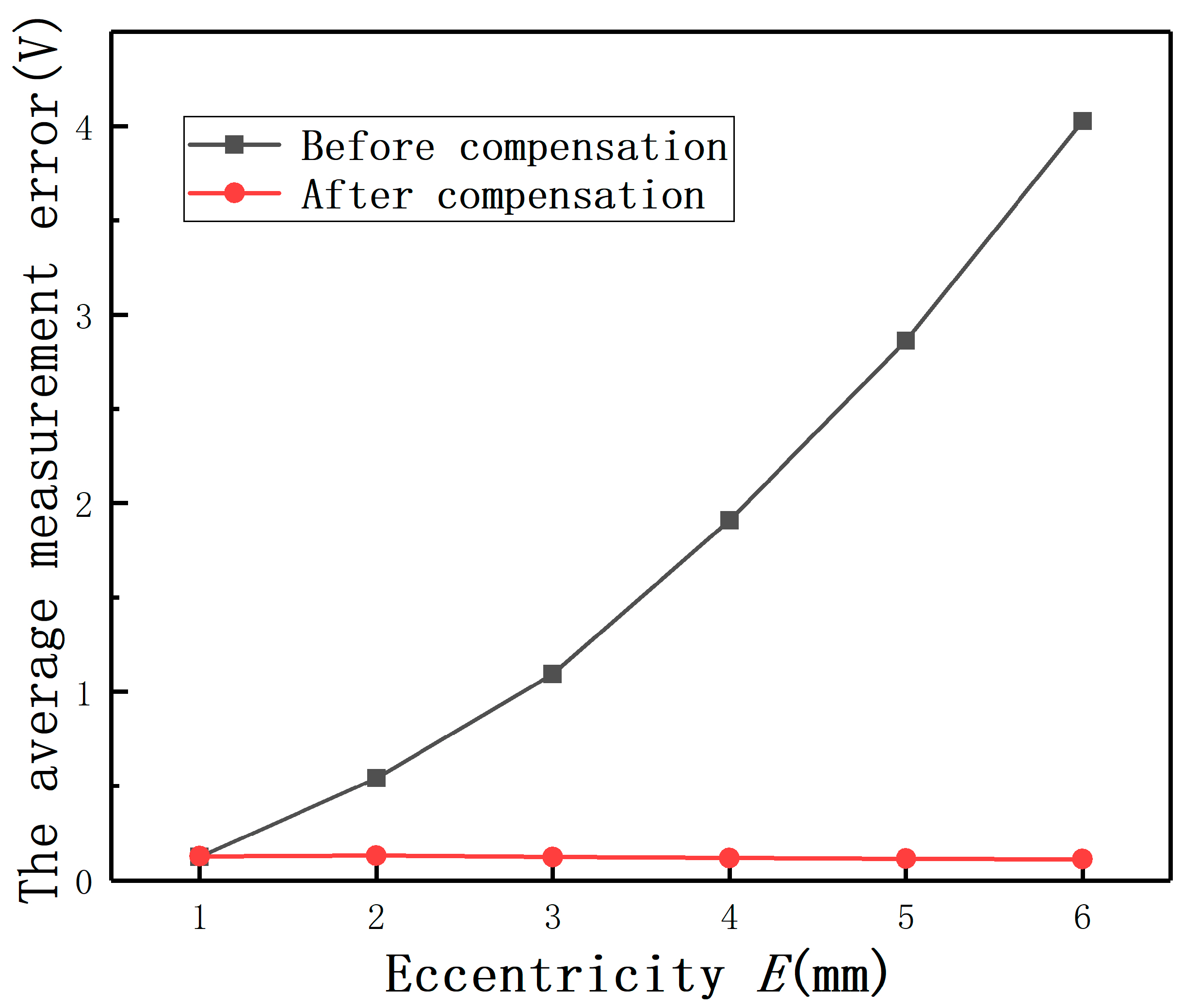

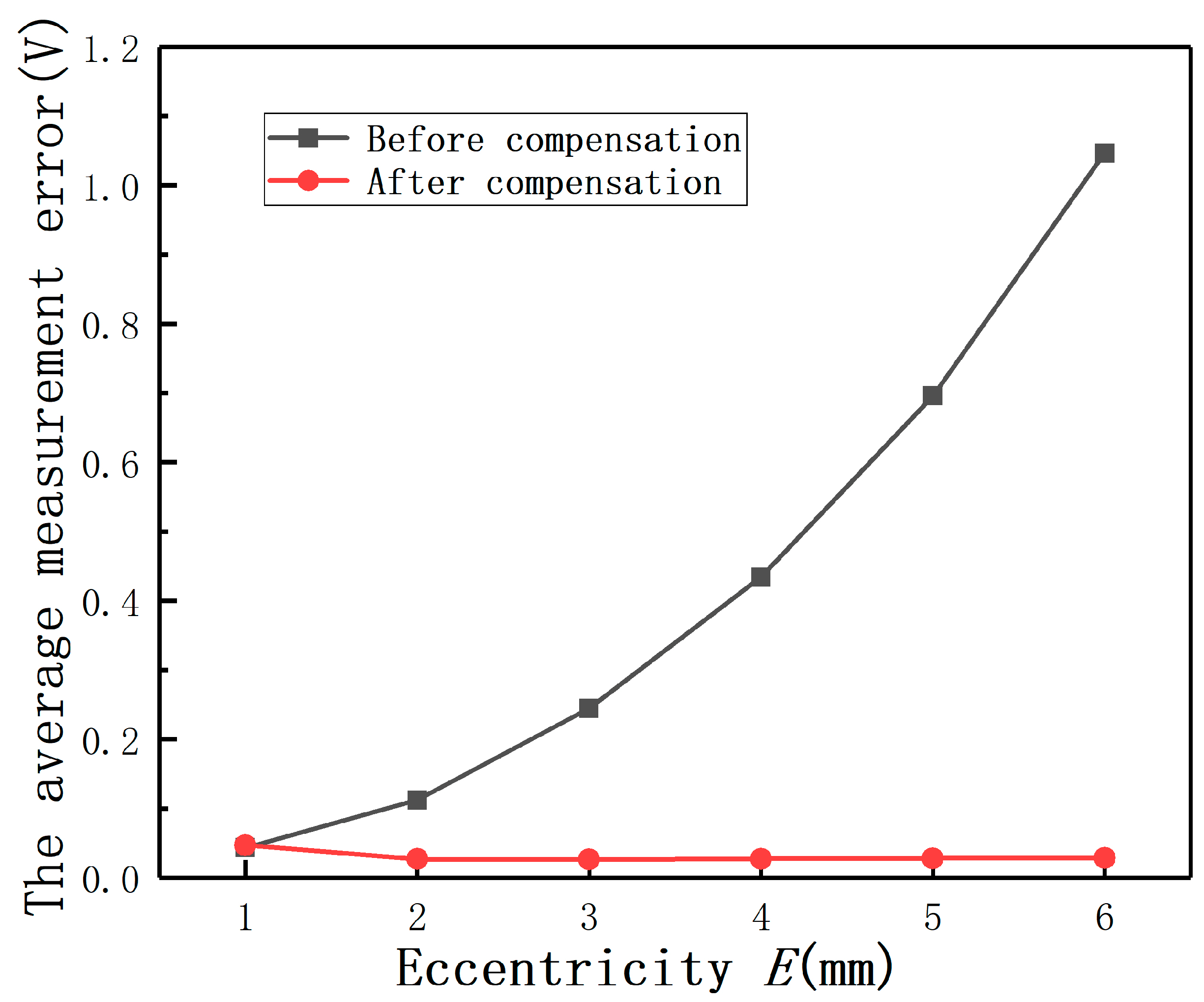

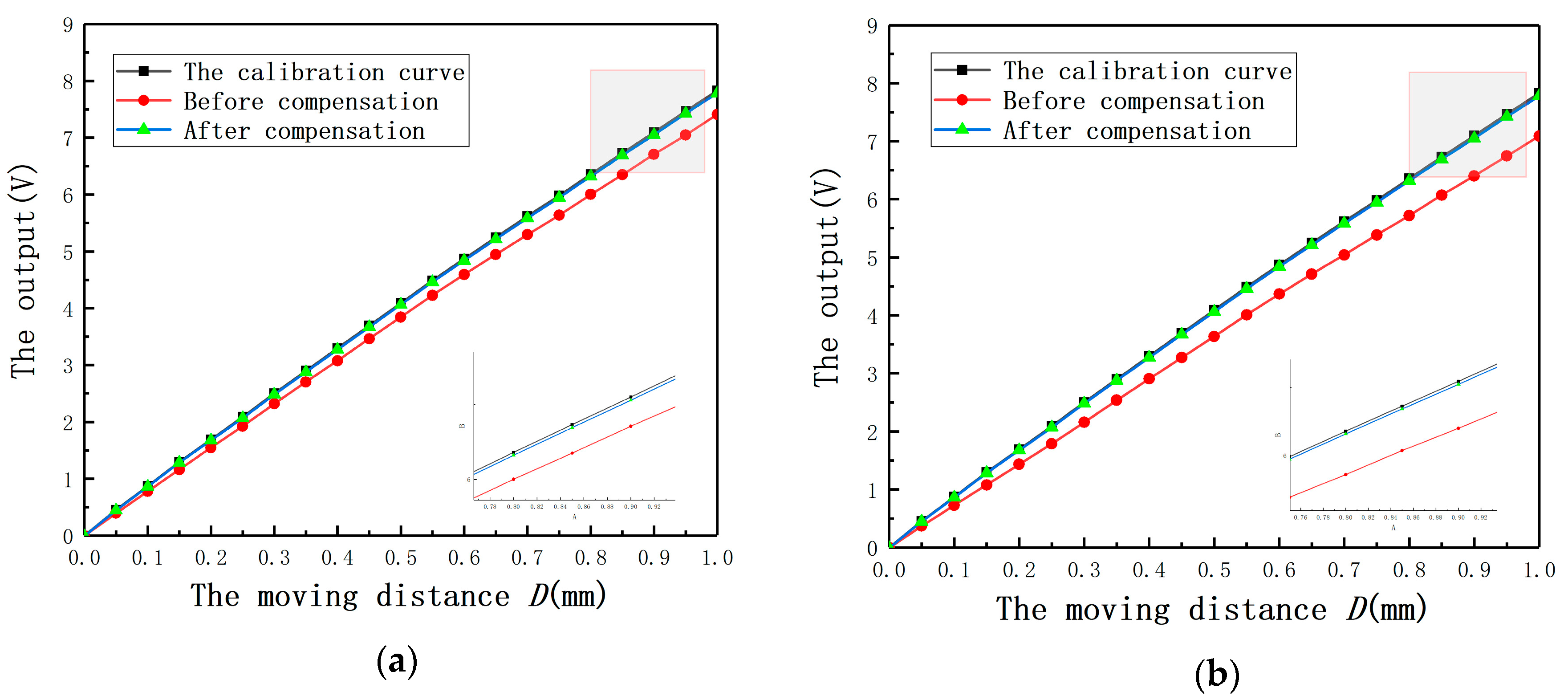

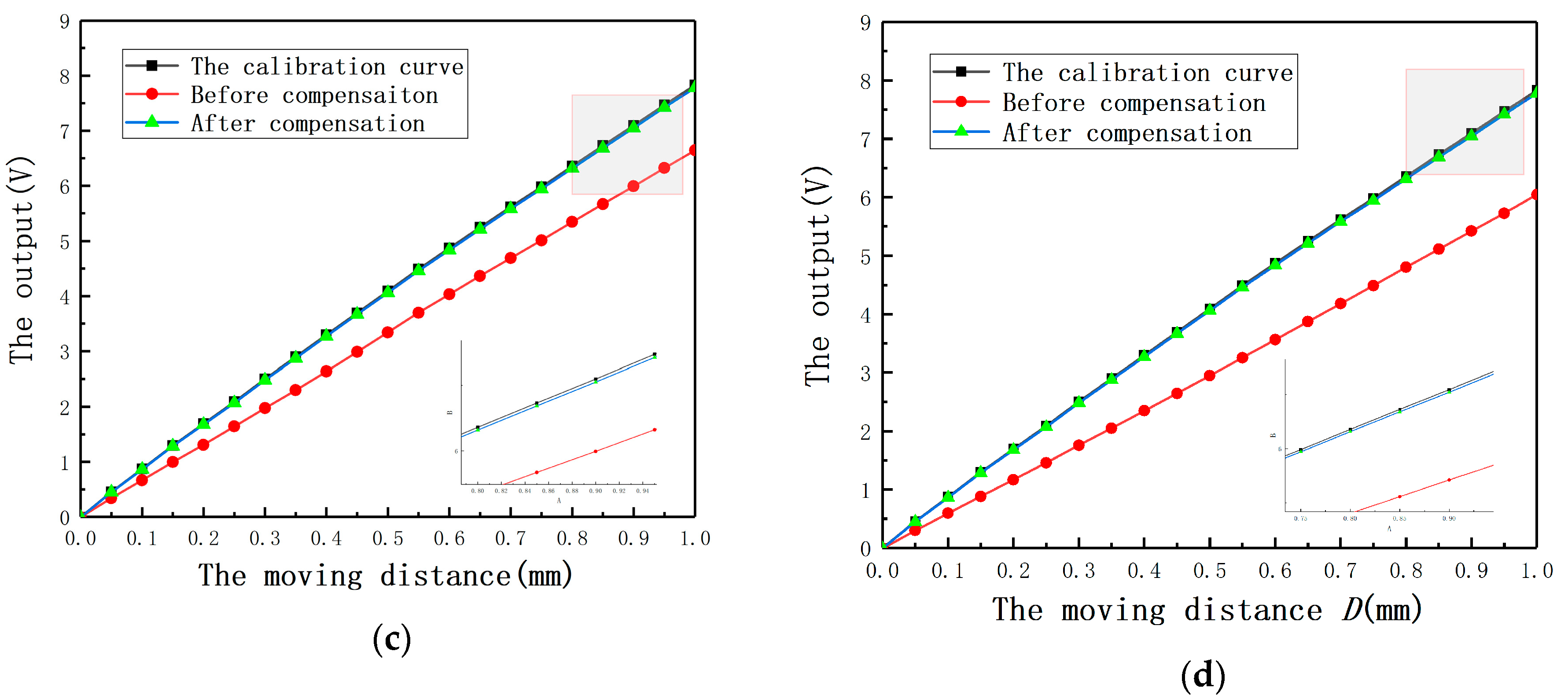

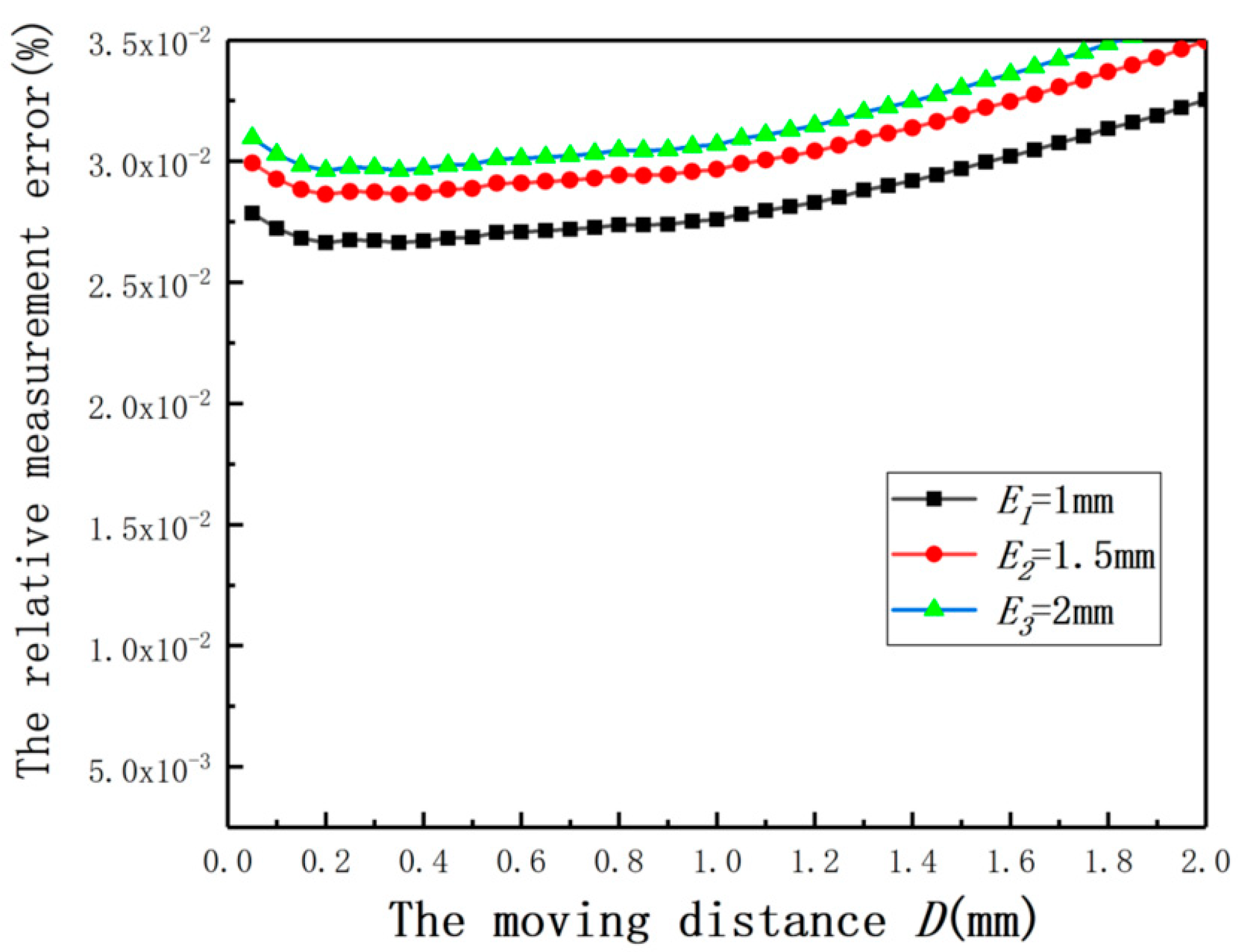

5. Application of Compensation Method in Magnetic Suspension Motor

The length of air gap has a great influence on the performance and reliability of a magnetic suspension motor. If the air gap is too large, the magnetic resistance will increase. The excitation current required to achieve the same magnetic field strength will increase greatly, and the excitation loss will also increase greatly. The power factor of the motor will decrease significantly, and the performance of the motor will deteriorate. In order to reduce the excitation current and improve the power factor, the air gap should be minimized. Generally, the air gap of a magnetic suspension motor is about 2 mm and the radial position control accuracy is 5‰. However, if the rotor radius is 30 mm, when the air gap is within 2 mm, the hardware compensation accuracy of the differential structure is 2.49%, which is difficult to meet the control accuracy, as shown in

Figure 25. To further illustrate why

E cannot be ignored in the displacement measurement of magnetic suspension motor, the effect of

E on the displacement measurement is described by the relative measurement error. The relative measurement error is defined as

. As shown in

Figure 30 and

Figure 31, it can be found that the relative measurement error cannot be ignored.

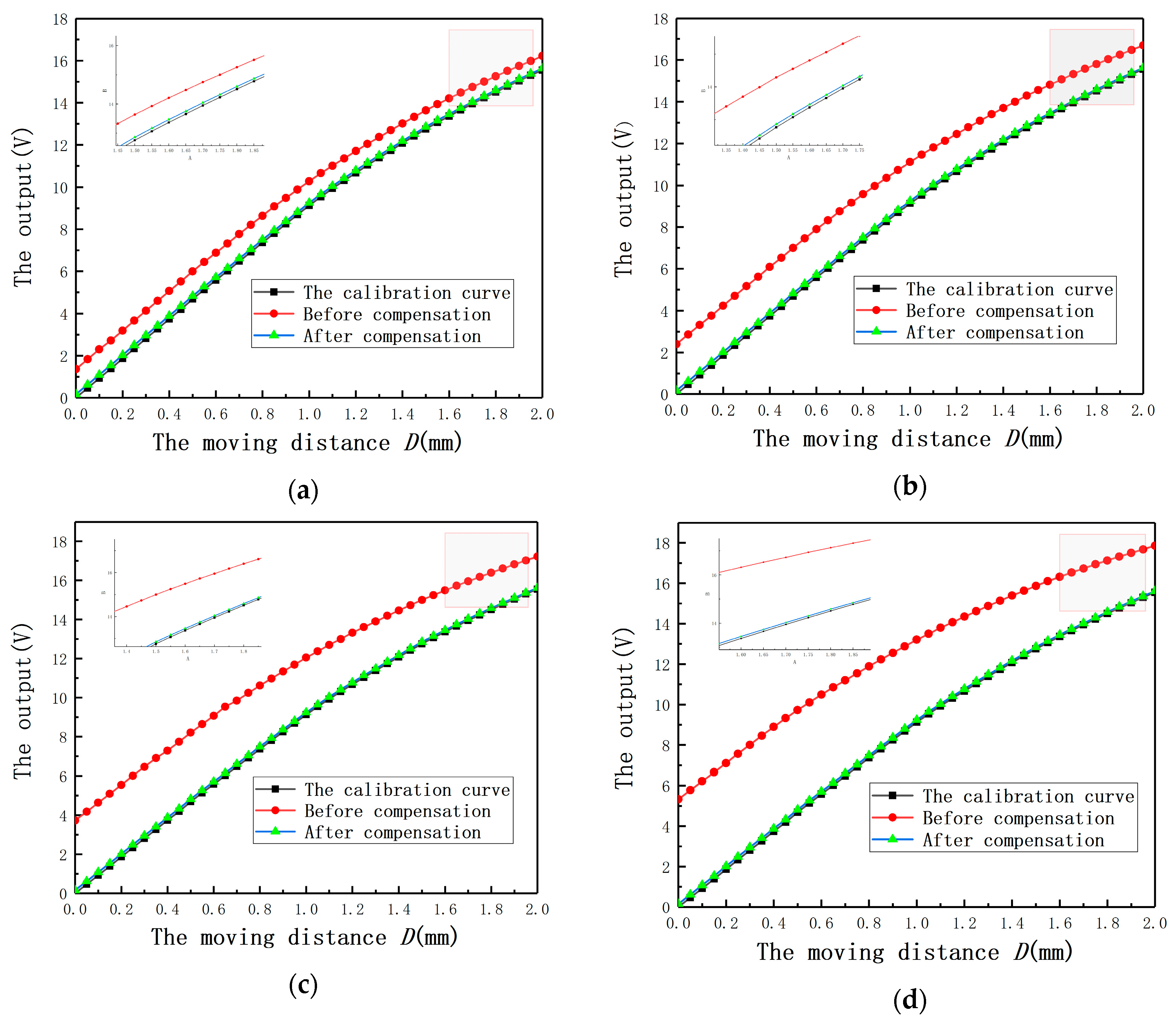

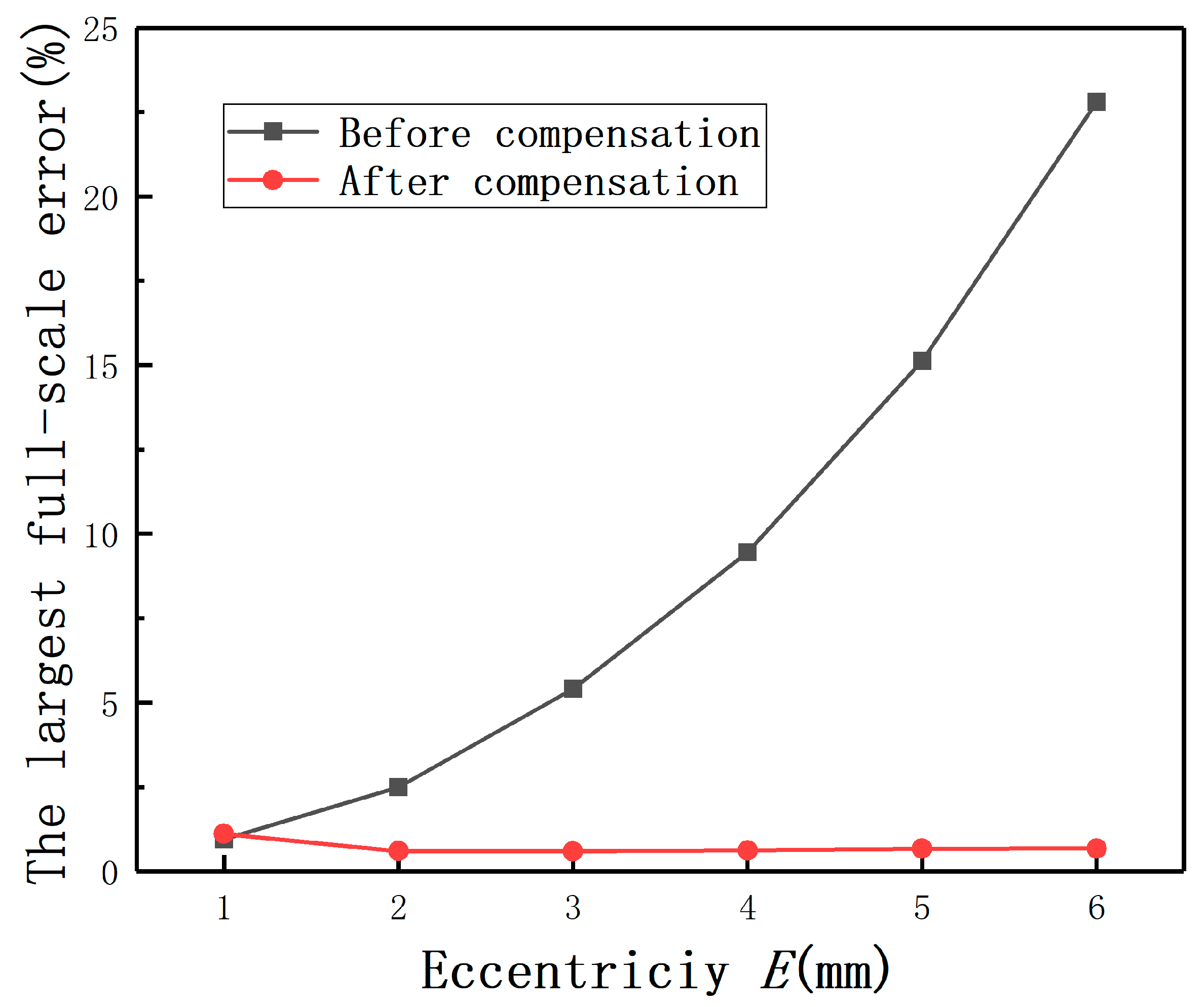

Equation (14) is mainly for large eccentricity, so a compensation equation for small eccentricity is needed. The radius of measured cylinder was 30 mm.

E was set as 1, 1.5, and 2 mm, respectively. The compensation method for small eccentricity is the same as the method of

Section 4.3. The compensation equation is:

In order to validate the effectiveness of Equation (16), the relative measurement errors under different

E after compensation are shown in

Figure 32. The results prove that Equation (16) is effective to compensate for the measurement errors under small eccentricity.

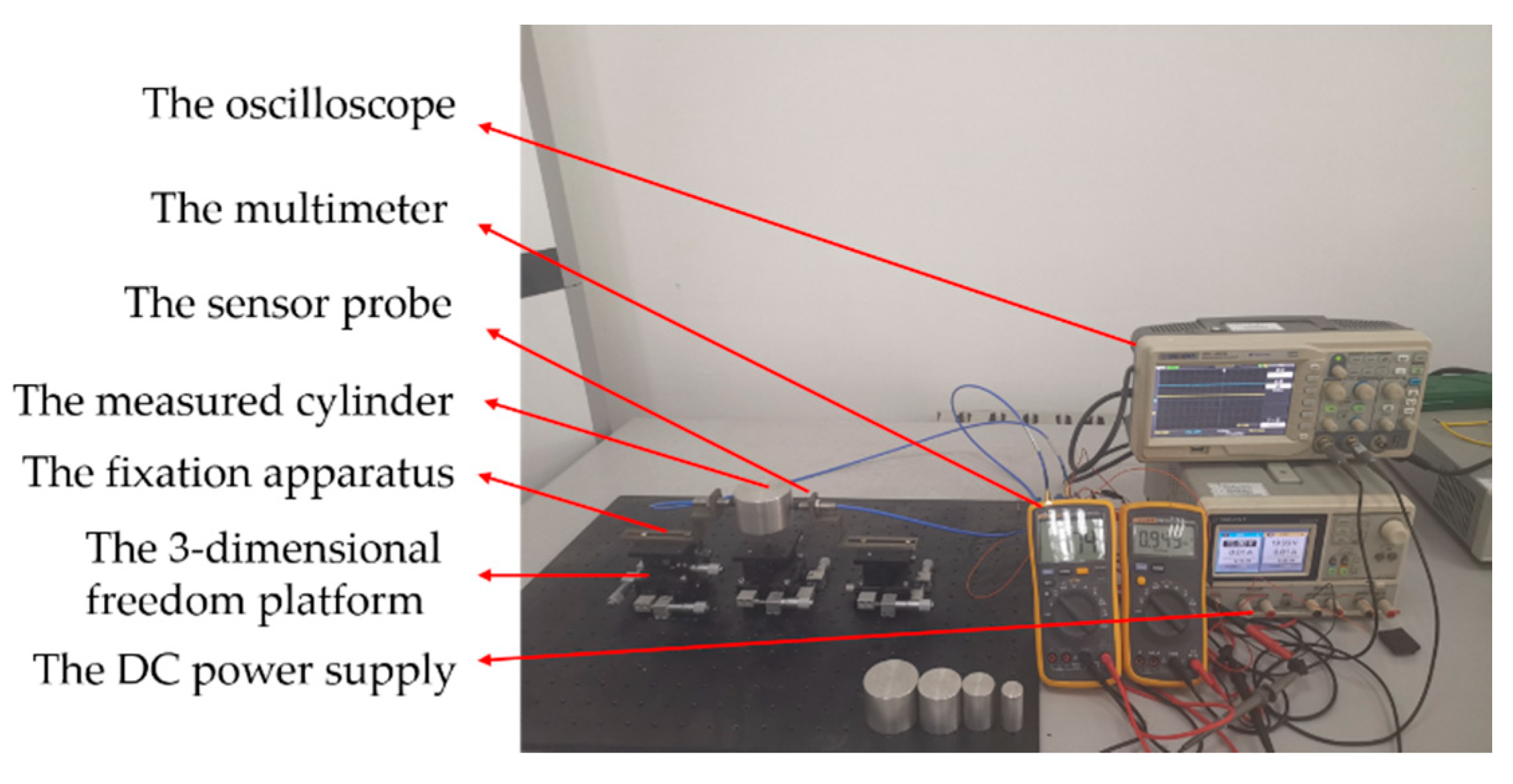

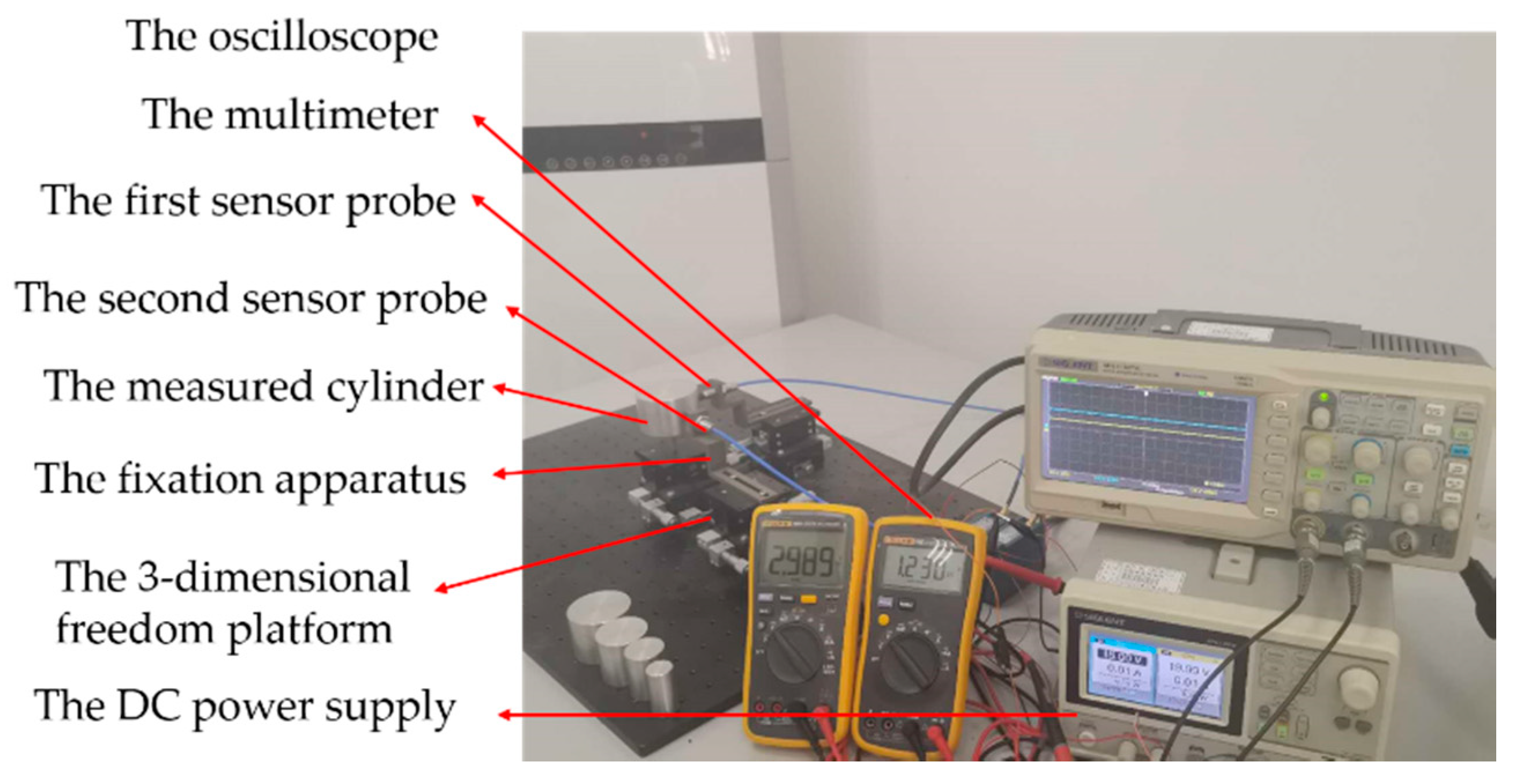

The paper puts forward the compensation method to realize the eccentricity compensation, but the compensation method is based on a known eccentricity. Obviously, the compensation equation cannot be directly applied to the displacement measurement of the magnetic suspension motor system. To obtain the value of eccentricity, as shown in

Figure 33, the system had two sensors and they were separated by 90 degrees. The sensors arranged in

X and

Y directions were used to detect the radial displacement in both directions, respectively, and the measured value of each other was used as the eccentricity of the other side to compensate the measurement errors. In theory, the effect of measurement error caused by eccentricity can be reduced.

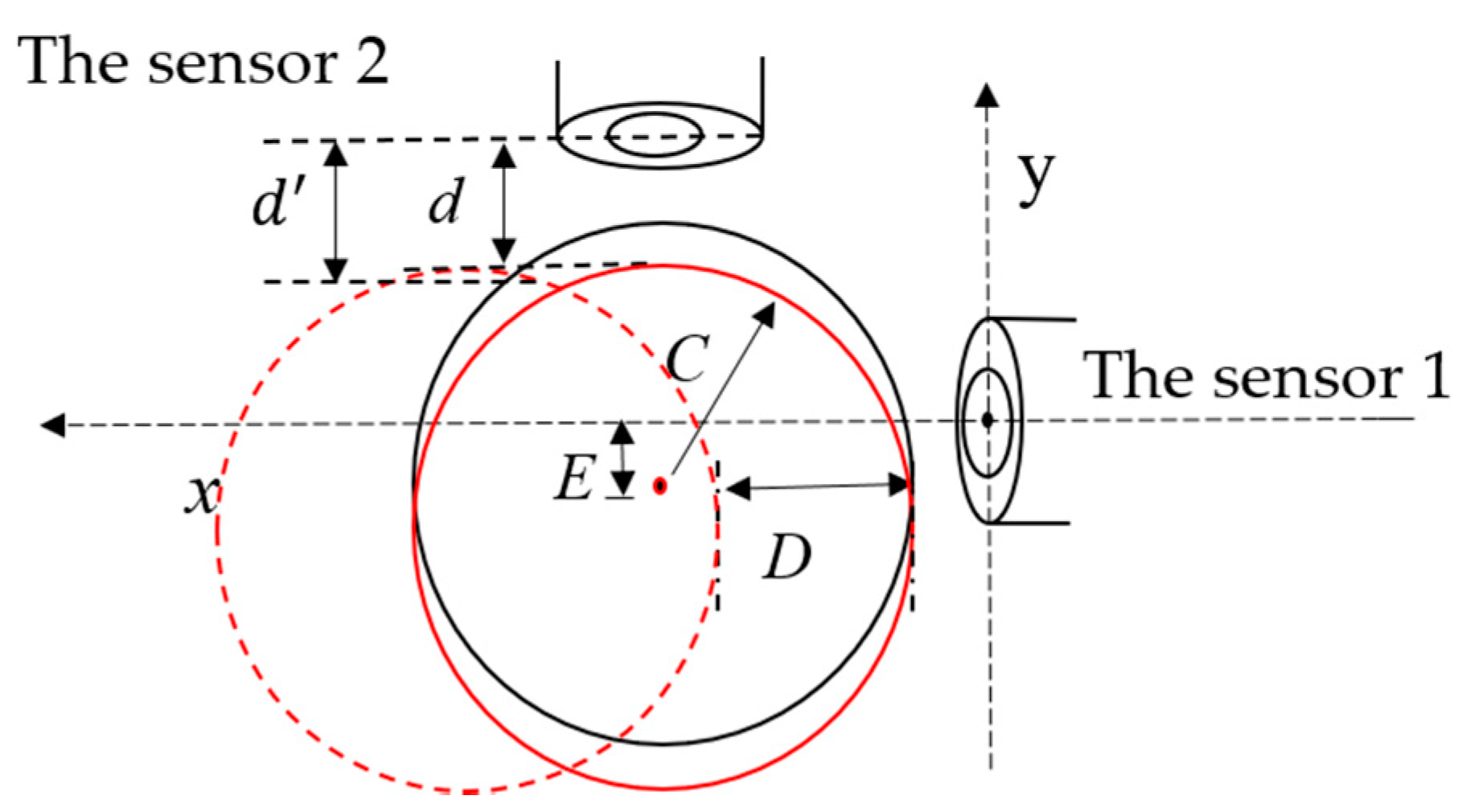

In order to analyze the effect of the measured cylinder eccentricity in one direction on the output of the other sensor, a mathematical model diagram of the orthogonal structure was established, as shown in

Figure 34. Assuming that the measured cylinder has an eccentricity in

Y axis direction, and the measured cylinder is still moving in

X axis direction, the output of the sensor 2 will inevitably change. The fluctuation of the sensor 2 output is directly related to whether the measured value of the sensor 2 can be regarded as the eccentric value of the sensor 1, especially when the displacement of the measured cylinder in both directions is very small. After the measured cylinder has an eccentricity in

Y axis direction,

d represents the distance from the sensor 2 to the measured cylinder. When the measured cylinder is moving in

X axis direction,

represents the distance from the sensor 2 to the measured cylinder.

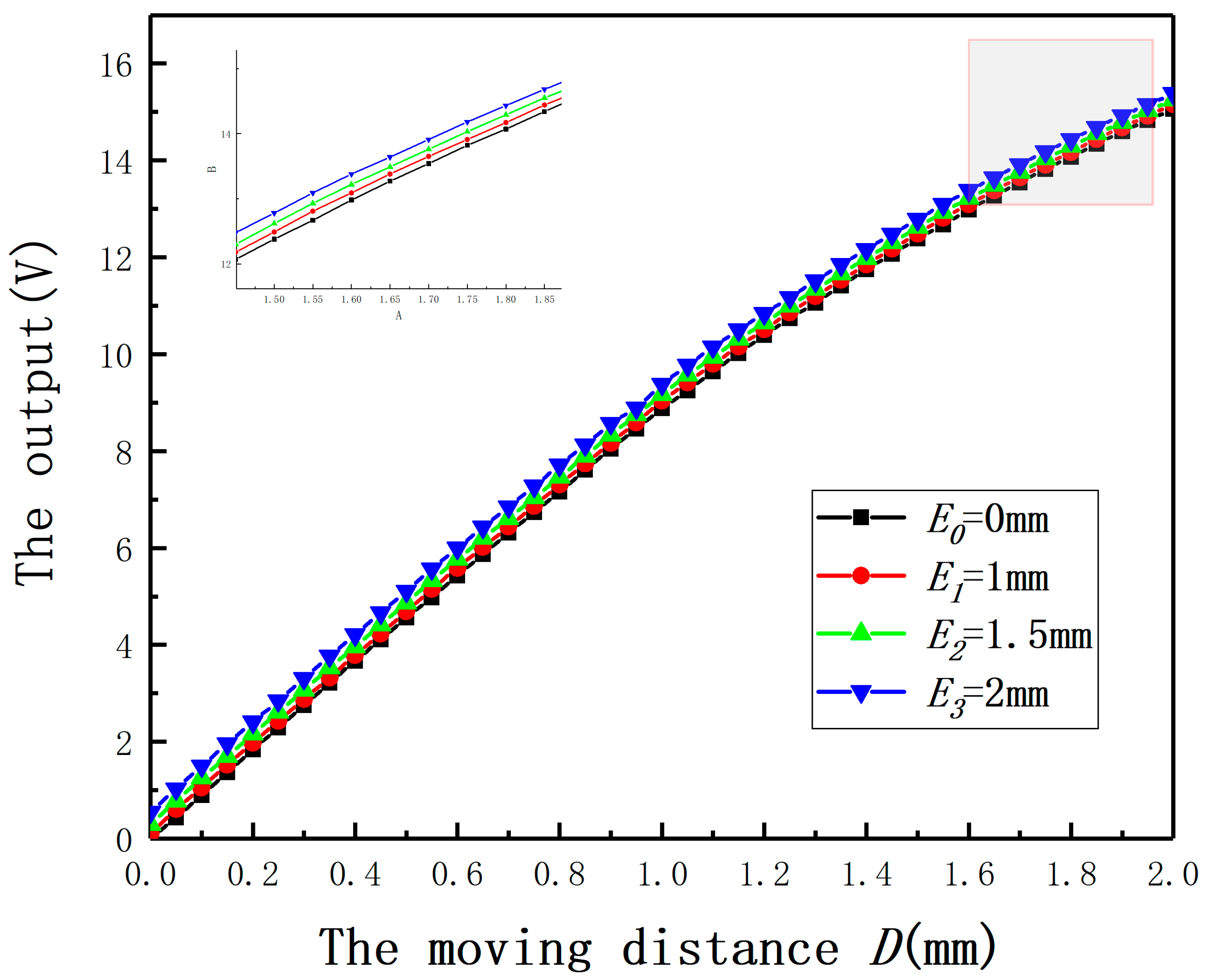

From the geometrical relation:

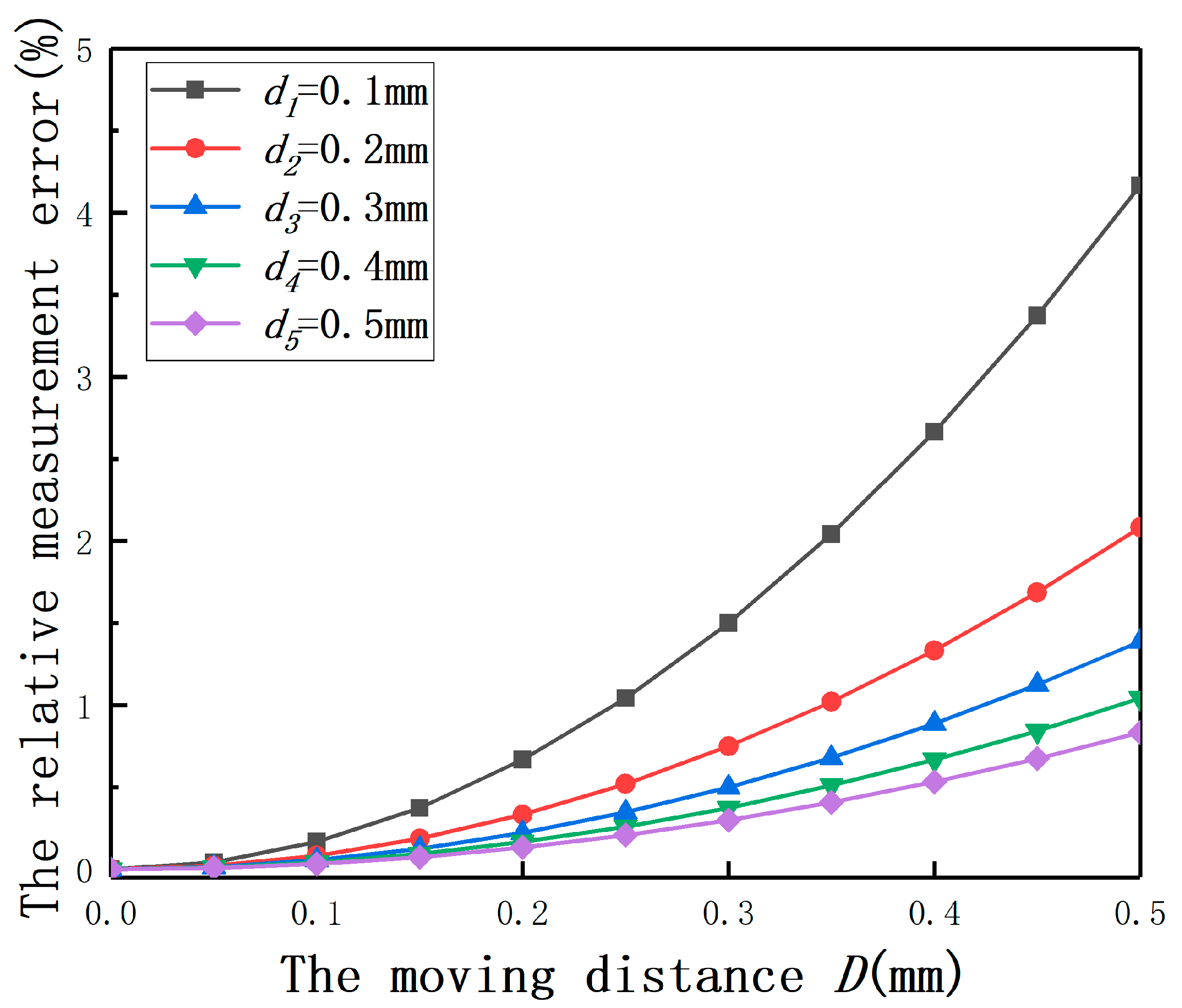

If the fluctuation of the sensor 2 is defined as

/

d, the relative measurement error is used to represent the fluctuation. The main influence on its control accuracy is the position detection accuracy of small displacement, so

d is set as 0.1, 0.2, 0.3, 0.4, 0.5 mm and the range of

D is 0–0.5 mm. As shown in

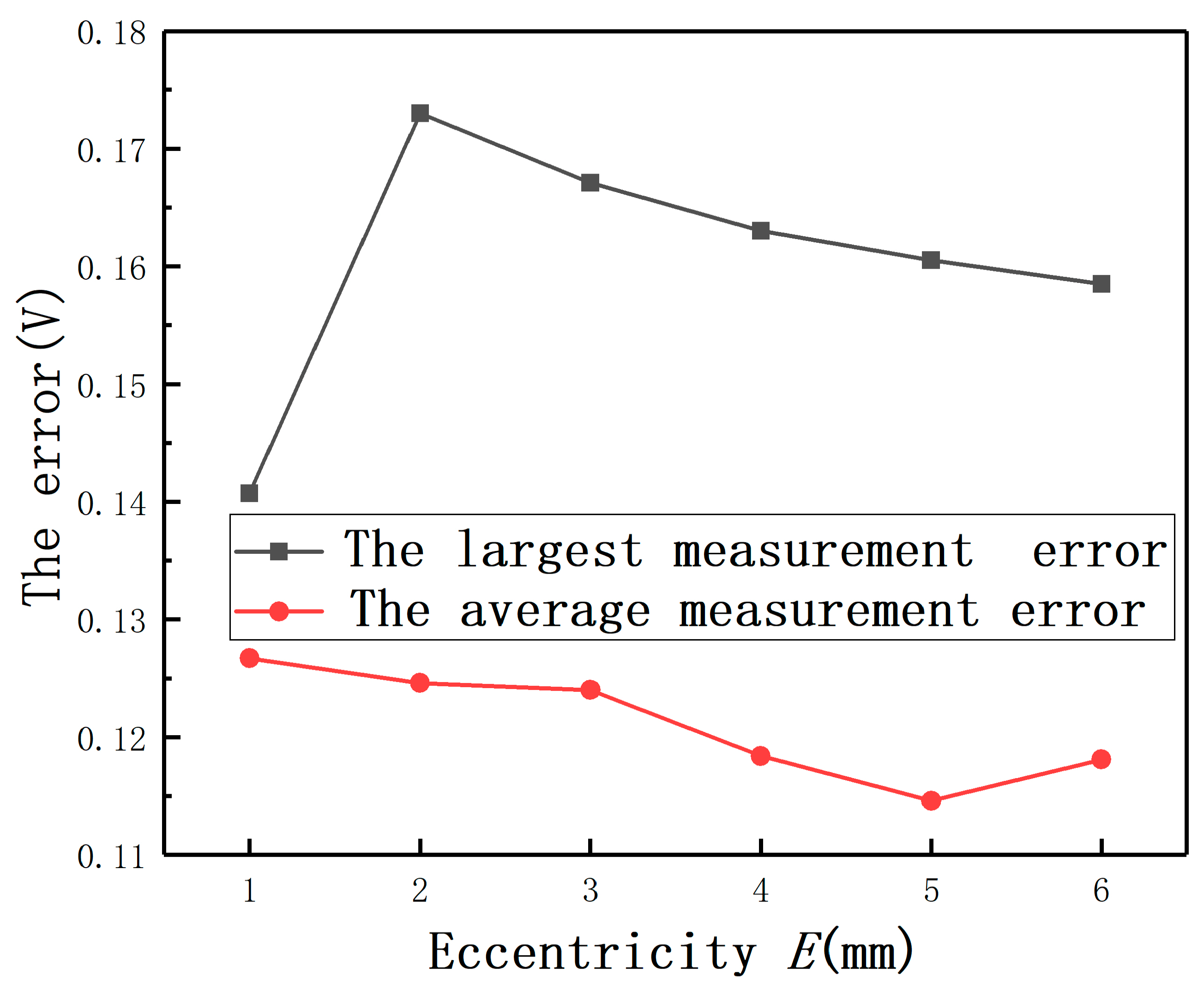

Figure 35, the fluctuation of the sensor 2 output will not be very large and can be controlled within 4.5%. This means that the measurement value of the sensor 2 can be regarded as the eccentricity of sensor 1.

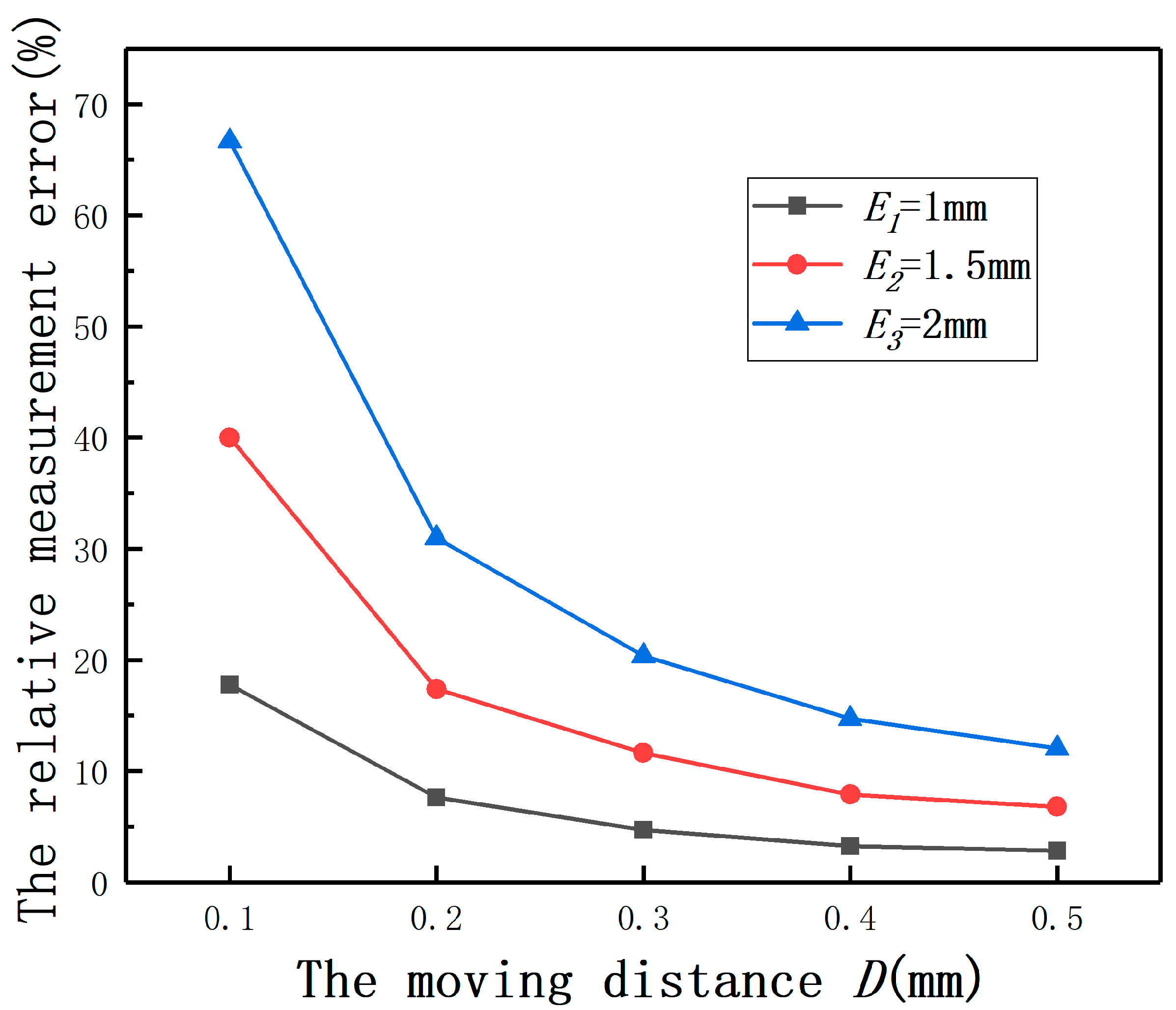

In the engineering application, when the rotor deviates during operation, the following situations will appear: (1) the output values of the two sensors are very small. (2) The output value of one sensor is large and the other is small. (3) The output values of the two sensors are very large.

For the first case, based on the previous analysis, the output value can be approximately seen to be true when the eccentricity is very small, so the output value of the first sensor can be directly provided to the second sensor as the eccentricity. The output value of the second sensor after compensation is used as the eccentricity of the first sensor. By adjusting 3-dimensional freedom platforms, the measured cylinder was moved to the position with small

E in both directions.

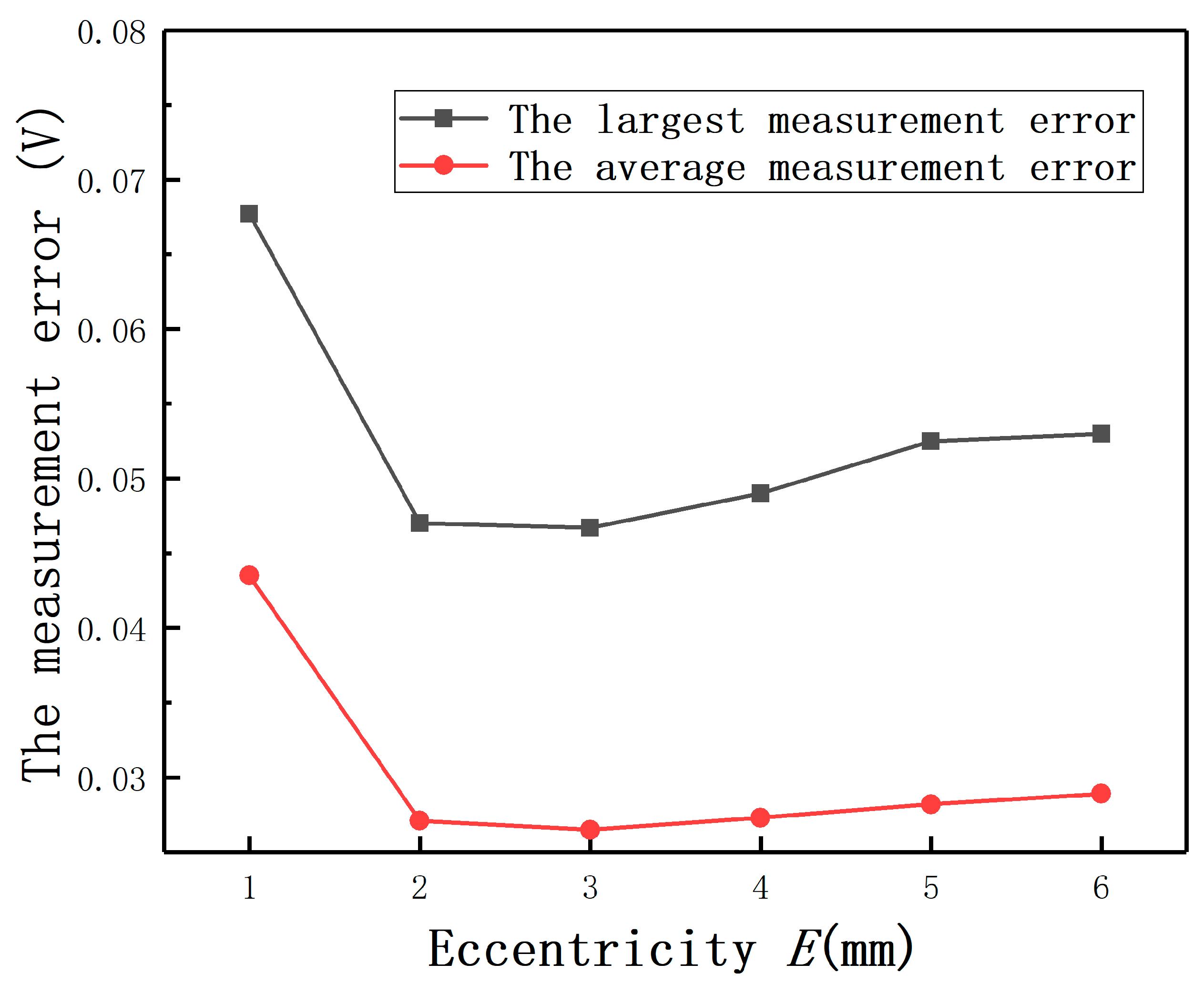

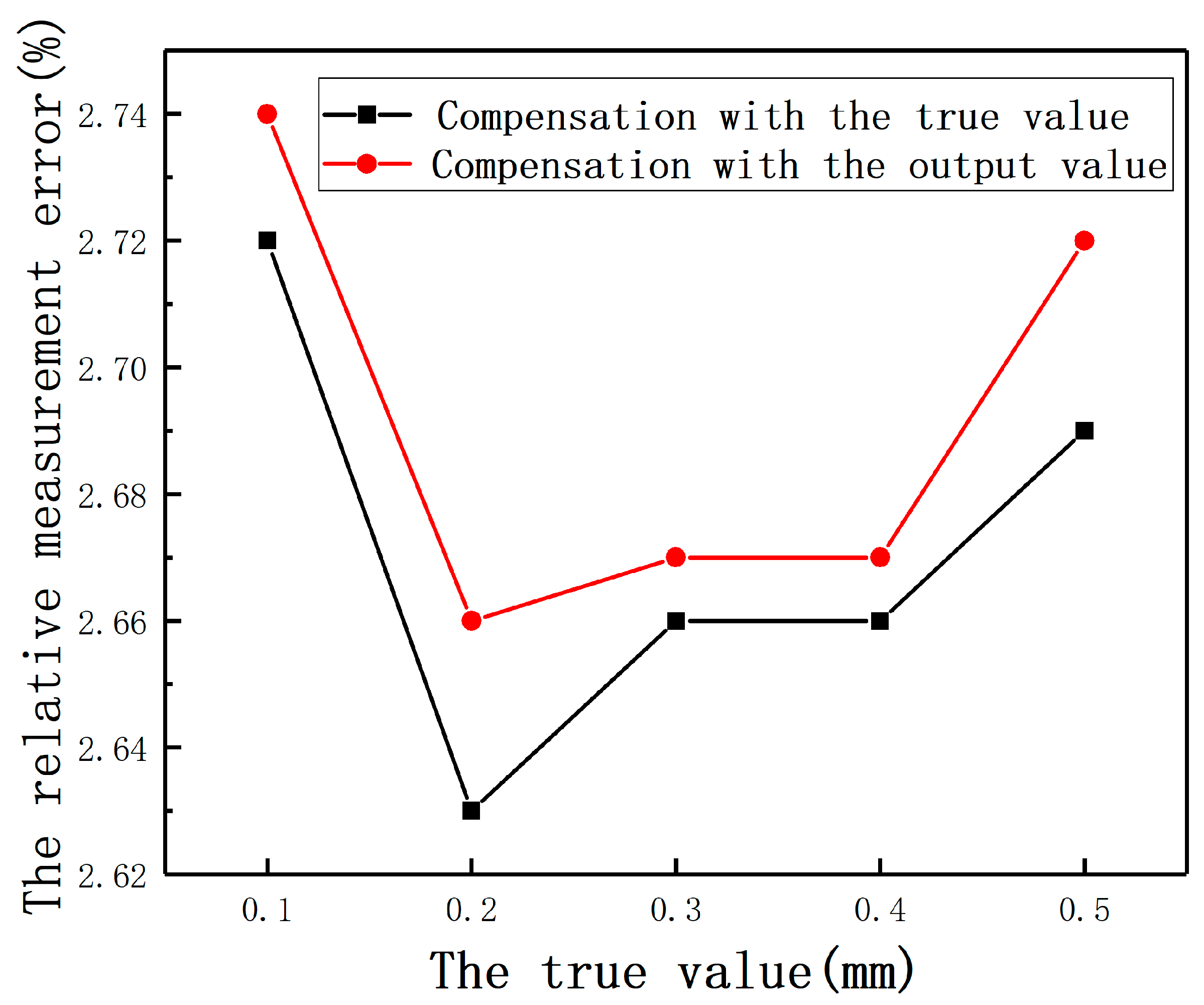

E was set as 0.1, 0.2, 0.3, 0.4, and 0.5 mm, respectively. As shown in

Figure 36, compared with the compensation effect of a known eccentricity, the error of using measured value instead of true value is acceptable.

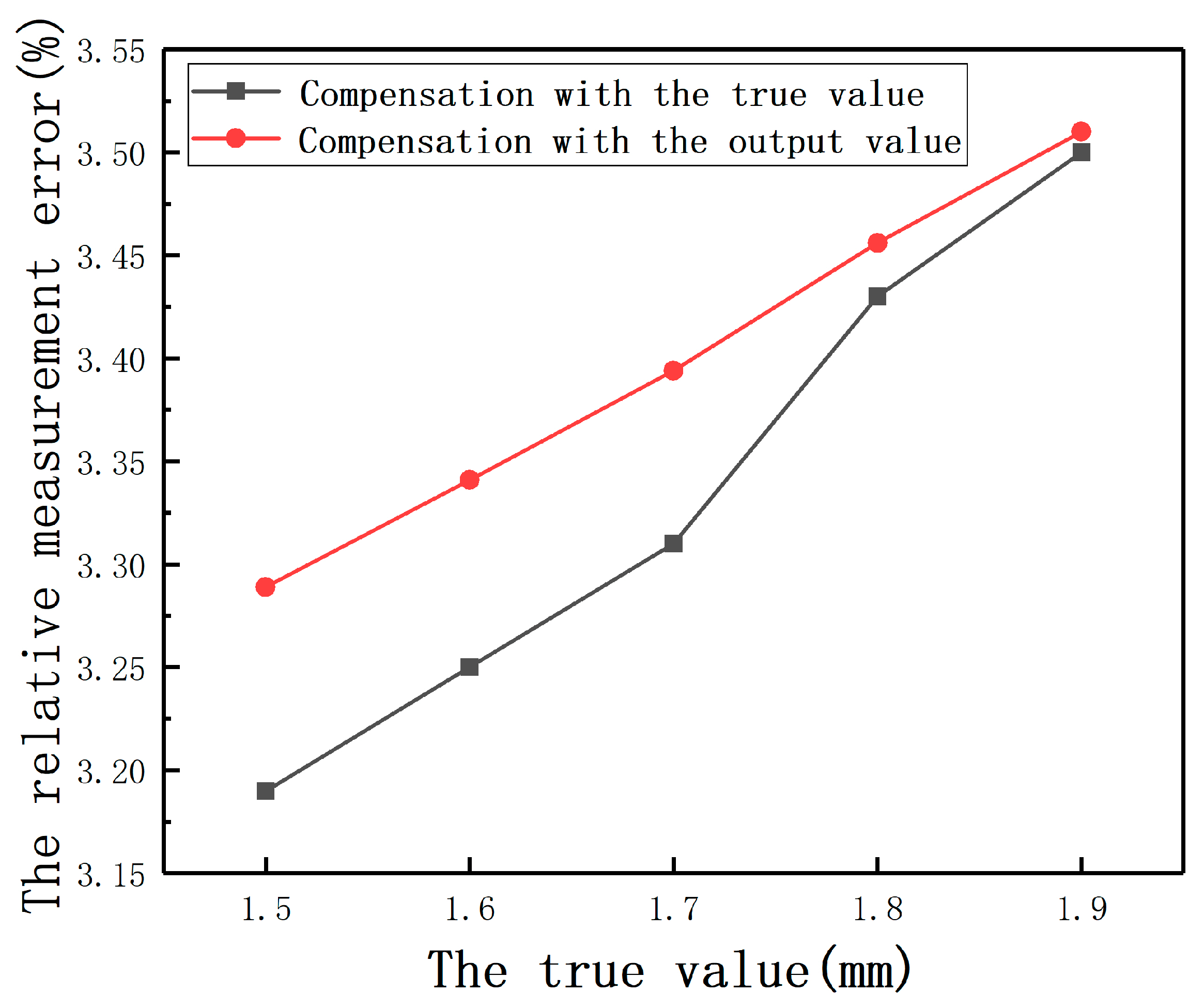

For the third case, according to the principle of closed-loop control, when the rotor is suspended in the equilibrium position, the main influence on its control accuracy is the position detection accuracy of small displacement. When the eccentricity of the rotor is large, the detection error mainly affects the dynamic performance of the control system. When the error is large, the speed of the control system is increased, which is acceptable for the control system. By adjusting 3-dimensional freedom platforms, in the direction of the first sensor probe,

E was set as 1.5, 1.6, 1.7, 1.8, and 1.9 mm, respectively. In the direction of the second sensor probe,

E was set as 1.5 mm. The output value of the second sensor can be directly provided to the first sensor as the eccentricity. As shown in

Figure 37, compared with the compensation effect of a known eccentricity, the error of using measured value instead of true value is also acceptable.

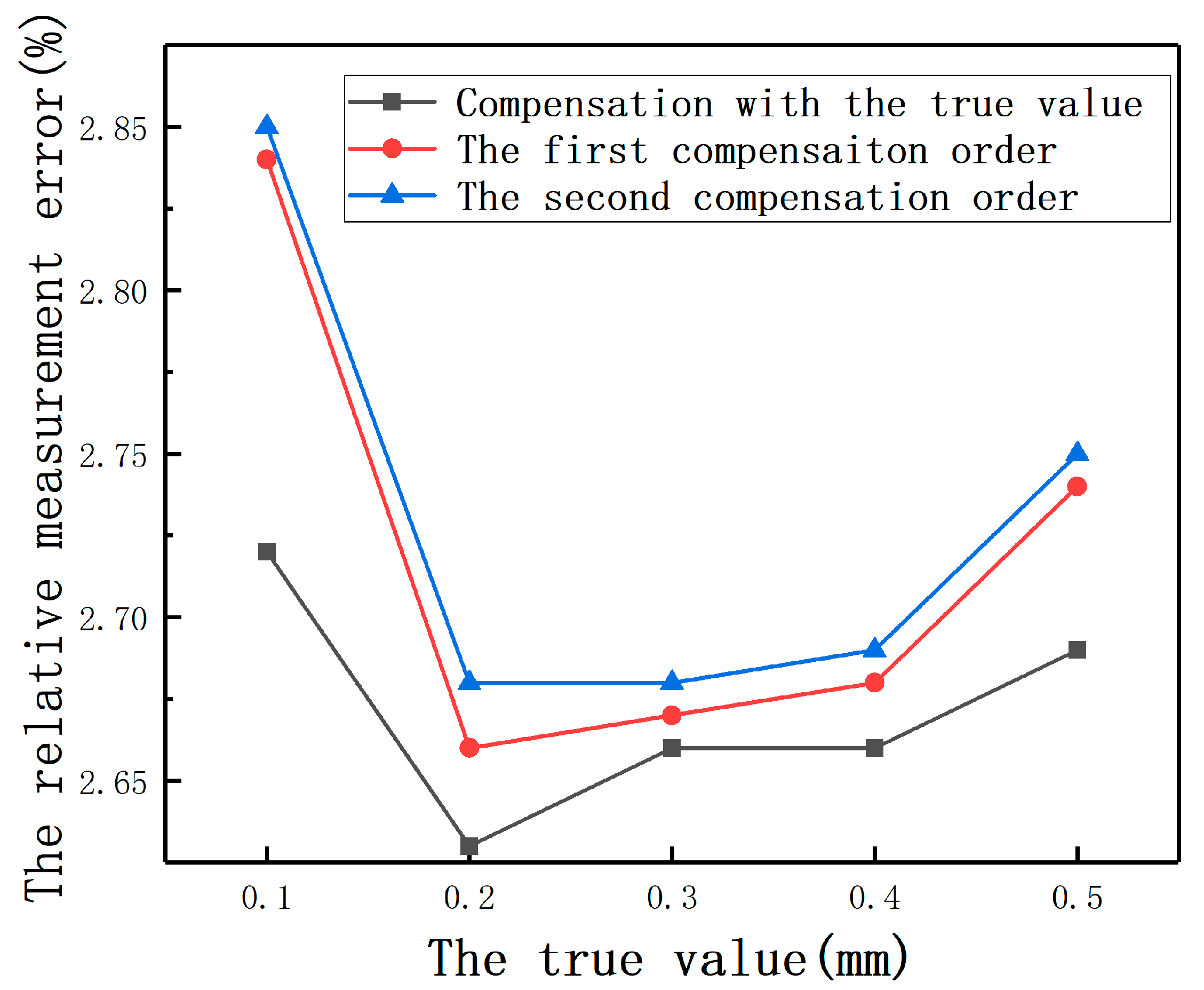

For the second case, the output value of one sensor is larger than another, which brings up a problem about the compensation order. To determine the compensation order, by adjusting 3-dimensional freedom platforms, in the direction of the first sensor,

E was set as 0.1, 0.2, 0.3, 0.4, and 0.5 mm, respectively. In the direction of the second sensor,

E was set as 1 mm. The first compensation order is that the small output value is used as the eccentricity of the large one. The output value after compensation is used as the eccentricity of the previous sensor. The second compensation order is contrary to the first one. The relative measurement error of the smaller true value is used as the standard of comparison. As shown in

Figure 38, the relative measurement errors of the first compensation order are smaller than that of the second order.

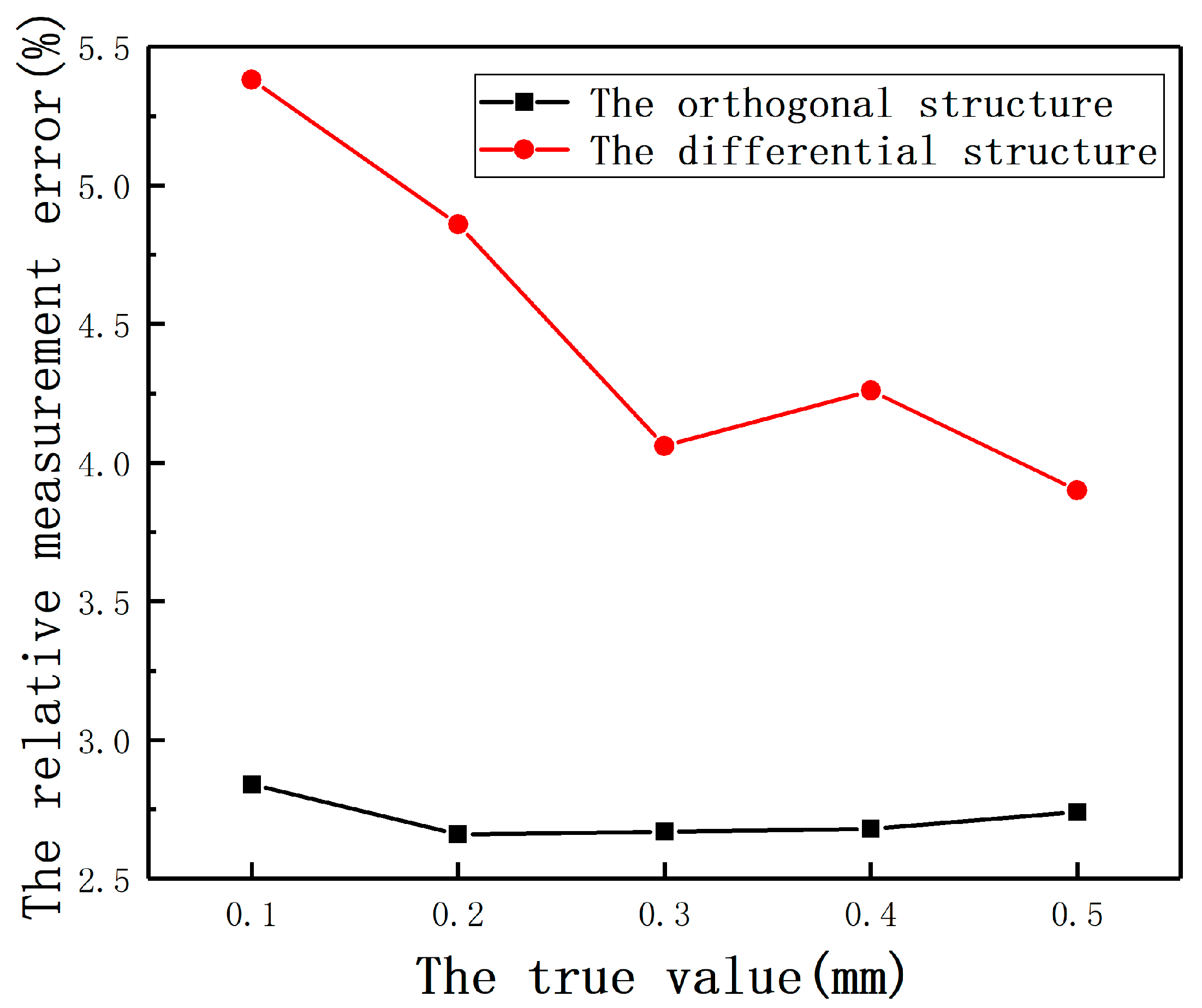

In the eddy current displacement measurement, in order to reduce the influence of

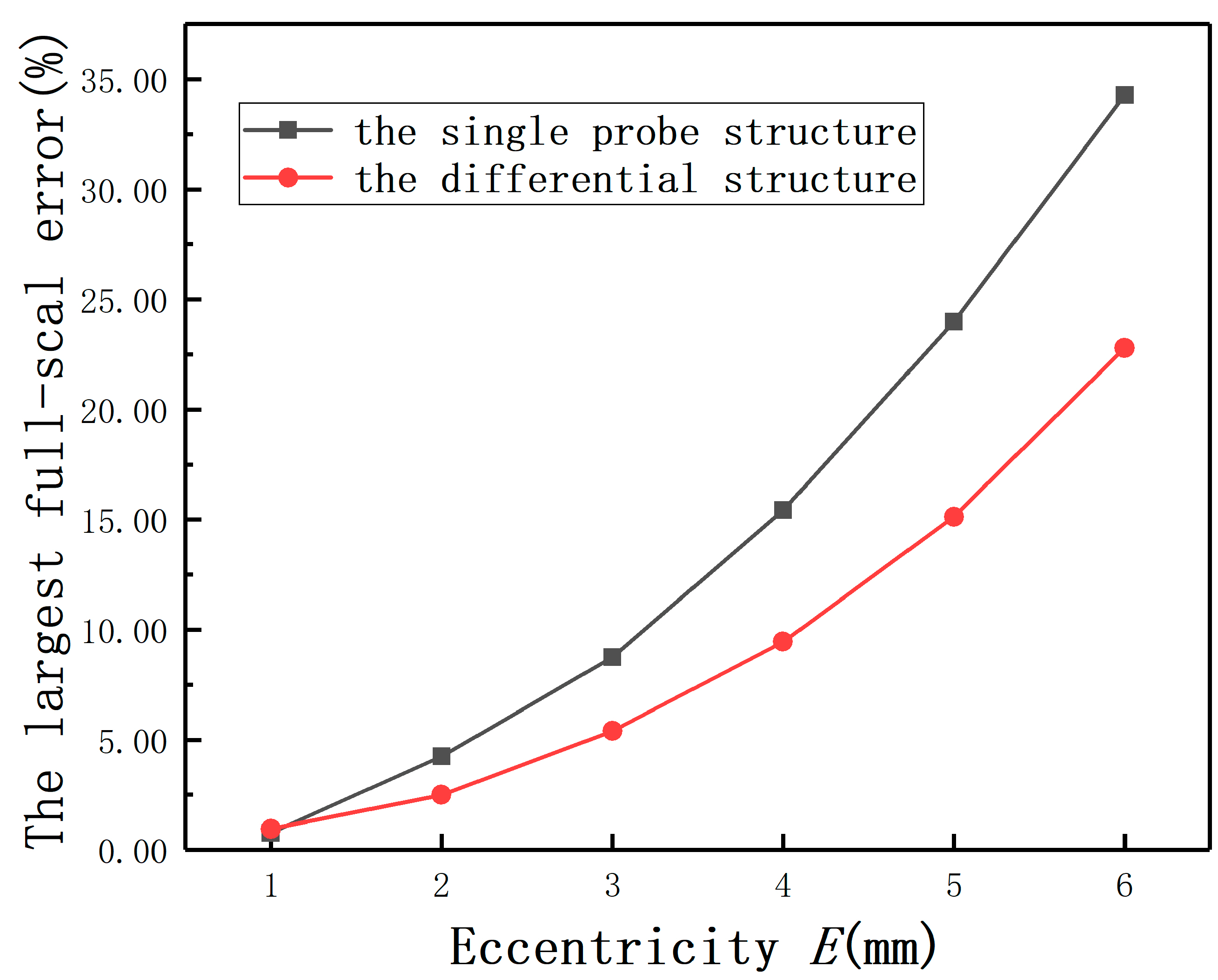

E, the differential structure is often used in the existing technology.

Figure 39 shows the compensation effect of the compensation method based on the orthogonal structure that uses the measured value in the orthogonal direction as the true value of

E and the hardware compensation effect of the differential structure. It can be seen from the result that the method proposed in this paper reduces the effect of

E more significantly. Meanwhile, if the differential structure is used to detect the rotor radial position, the position detection system needs to be equipped with four sensors, which easily causes the electromagnetic interference between each other. However, the compensation method proposed in this section can be applied to the orthogonal structure, which only needs only two sensors. If four sensors are used in the position detection system, the redundancy and reliability of the system can be improved.