Temperature Compensation Method for Raster Projectors Used in 3D Structured Light Scanners

Abstract

:1. Introduction

2. The Test Stand

3. Preliminary Studies

- -

- The first experiment was related to registration of the temperature and time to reach the projector’s thermal equilibrium; and

- -

- The scope of the second experiment was to register the thermal drift and the deformation of the projected image.

3.1. The Warming-Up Process—Thermal Equilibrium

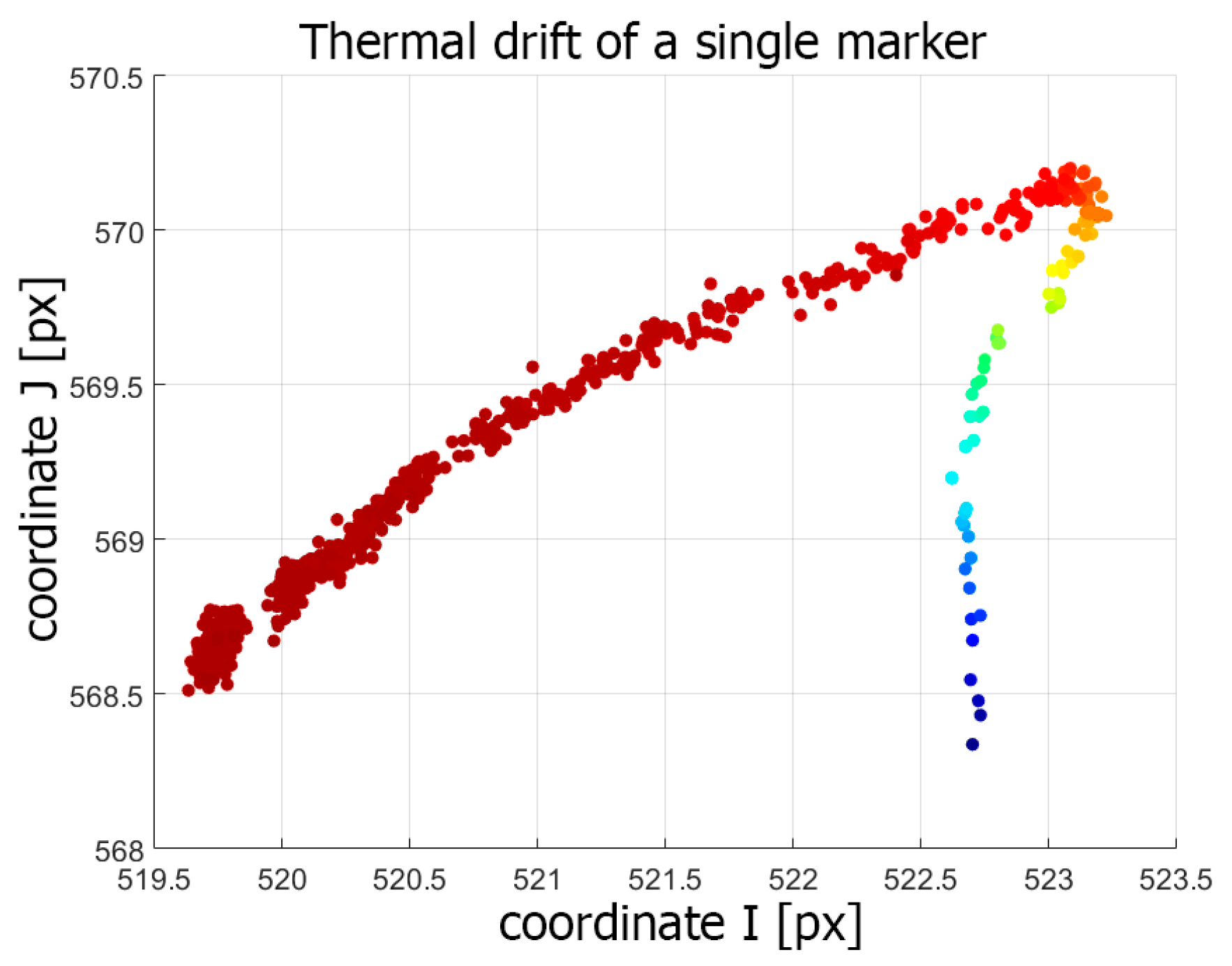

3.2. The Warming-Up Process—Thermal Drift and Deformation of the Projected Image

4. Compensation

4.1. Tests in the Thermal Chamber

4.2. The Compensation Model

4.3. The Verification Experiment

4.4. Results

5. Discussion and Conclusions

Funding

Conflicts of Interest

References

- Sitnik, R.; Kujawińska, M. From cloud-of-point coordinates to three-dimensional virtual environment: The data conversion system. Opt. Eng. 2002, 41, 12–41. [Google Scholar] [CrossRef]

- Sitnik, R. Odwzorowanie Kształtu Obiektów Trójwymiarowych z Wykorzystaniem Oświetlenia Strukturalnego; Oficyna Wydawnicza Politechniki Warszawskiej: Warszawa, Poland, 2010; ISBN 0137-2335. [Google Scholar]

- Sładek, J.; Sitnik, R.; Kupiec, M.; Błaszczyk, P.; Sładek, R.J.; Sitnik, M.; Kupiec, P.B. The hybrid coordinate measurement system as a response to industrial requirements. Metrol. Meas. Syst. 2010, XVII, 537–547. [Google Scholar] [CrossRef]

- Geng, J. Structured-light 3D surface imaging: A tutorial. Adv. Opt. Photon. 2011, 3, 128–160. [Google Scholar] [CrossRef]

- Gorthi, S.S.; Rastogi, P. Fringe projection techniques: Whither we are? Opt. Lasers Eng. 2010, 48, 133–140. [Google Scholar] [CrossRef] [Green Version]

- Owczarek, D.; Ostrowska, K.; Sładek, J. Examination of optical coordinate measurement systems in the conditions of their operation. Maint. Probl. 2017, 4, 7–19. [Google Scholar]

- Siebke, I.; Campana, L.; Ramstein, M.; Furtwängler, A.; Hafner, A.; Lösch, S. The application of different 3D-scan-systems and photogrammetry at an excavation—A Neolithic dolmen from Switzerland. Digit. Appl. Archaeol. Cult. Herit. 2018, 10, e00078. [Google Scholar] [CrossRef]

- Adamczyk, M.; Sieniło, M.; Sitnik, R.; Woźniak, A. Hierarchical, Three-Dimensional Measurement System for Crime Scene Scanning. J. Forensic Sci. 2017, 62, 889–899. [Google Scholar] [CrossRef]

- Ostrowska, K.; Szewczyk, D.; Sładek, J. Wzorcowanie systemów optycznych zgodnie z normami ISO i zaleceniami VDI/VDE. Czas. Tech. Mech. 2012, 109, 167–179. [Google Scholar]

- VDI/VDE 2634 Blatt 3 The Guideline Applies to Optical 3-D-Measuring Systems Based on Area Scanning, Whose Function is Based on Triangulation and Applies to the Measuring of Three-Dimensional Objects in Multi Views. Available online: http://www.vdi.eu/guidelines/vdivde_2634_blatt_3-optische_3_d_messsysteme_bildgebende_systeme_mit_flaechenhafter_antastung (accessed on 12 October 2020).

- ISO 10360-2:2009: Geometrical Product Specifications (GPS)–Acceptance and Reverification Tests for Coordinate Measuring Machines (CMM). Part 2: CMMs Used for Measuring Linear Dimensions. Available online: https://www.iso.org/standard/40954.html (accessed on 12 October 2020).

- Ghandali, P.; Khameneifar, F.; Mayer, J.R.R. A pseudo-3D ball lattice artifact and method for evaluating the metrological performance of structured-light 3D scanners. Opt. Lasers Eng. 2019, 121, 87–95. [Google Scholar] [CrossRef]

- Martínez-Pellitero, S.; Cuesta, E.; Giganto, S.; Barreiro, J. New procedure for qualification of structured light 3D scanners using an optical feature-based gauge. Opt. Lasers Eng. 2018, 110, 193–206. [Google Scholar] [CrossRef]

- Geometrical Product Specifications (GPS)—Acceptance and Reverification Tests for coordinate Measuring Systems (CMS)—Part 8: CMMs with Optical Distance Sensors. Available online: https://docs.opencv.org/2.4/modules/calib3d/doc/camera_calibration_and_3d_reconstruction.html (accessed on 12 October 2020).

- Adamczyk, M.; Kamiński, M.; Sitnik, R.; Bogdan, A.; Karaszewski, M. Effect of temperature on calibration quality of structured-light three-dimensional scanners. Appl. Opt. 2014, 53, 5154. [Google Scholar] [CrossRef] [PubMed]

- Kruth, J.-P.; Zhou, L.; Vanherck, P. Thermal Error Analysis and Compensation of an LED-CMOS Camera 3D Measuring System. Science 2003, 3, 5–8. [Google Scholar]

- Kruth, J.-P.; Zhou, L.; Vanherck, P. Behaviour And Accuracy Specification - Study On An LED-CMOS Camera 3D Measuring System. WIT Trans. Eng. Sci. 2003, 44, 10. [Google Scholar]

- Handel, H. Analyzing the influence of camera temperature on the image acquisition process. In Proceedings of the SPIE, Electronic Imaging, San Jose, CA, USA, 25 February 2008; Volume 6805, pp. 1–8. [Google Scholar]

- Handel, H. Analyzing the influences of camera warm-up effects on image acquisition. IPSJ Trans. Comput. Vis. Appl. 2009, 1, 12–20. [Google Scholar] [CrossRef] [Green Version]

- Handel, H. Compensation of thermal errors in vision based measurement systems using a system identification approach. In Proceedings of the 2008 9th International Conference on Signal Processing; IEEE: Beijing, China, 2008; pp. 1329–1333. [Google Scholar]

- Podbreznik, P.; Potočnik, B. Assessing the influence of temperature variations on the geometrical properties of a low-cost calibrated camera system by using computer vision procedures. Mach. Vis. Appl. 2012, 23, 953–966. [Google Scholar] [CrossRef]

- Yu, Q.; Chao, Z.; Jiang, G.; Shang, Y.; Fu, S.; Liu, X.; Zhu, X.; Liu, H. The effects of temperature variation on videometric measurement and a compensation method. Image Vis. Comput. 2014, 32, 1021–1029. [Google Scholar] [CrossRef]

- Elias, M.; Eltner, A.; Liebold, F.; Maas, H.G. Assessing the influence of temperature changes on the geometric stability of smartphone-and raspberry Pi cameras. Sensors 2020, 20, 643. [Google Scholar] [CrossRef] [Green Version]

- Adamczyk, M.; Liberadzki, P.; Sitnik, R. Temperature Compensation Method for Digital Cameras in 2D and 3D Measurement Applications. Sensors 2018, 18, 3685. [Google Scholar] [CrossRef] [Green Version]

- Adamczyk, M.; Liberadzki, P.; Sitnik, R. Temperature compensation method for mechanical base of 3D-structured light scanners. Sensors 2020, 20, 362. [Google Scholar] [CrossRef] [Green Version]

- Zhou, G.; Lee, C. Optical MEMS, Nanophotonics, and Their Applications; Series in Optics and Optoelectronics; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781351647601. [Google Scholar]

- Sontheimer, A.B.; Mehrl, D.J. Effects of operating conditions on DMD hinge memory lifetime. In Proceedings of the 2003 IEEE International Reliability Physics Symposium Proceedings, 2003, 41st Annual, Dallas, TX, USA, 30 March–4 April 2003; Volume 2003, pp. 473–477. [Google Scholar]

- Douglass, M.R. Lifetime estimates and unique failure mechanisms of the Digital Micromirror Device (DMD). In Proceedings of the 1998 IEEE International Reliability Physics Symposium Proceedings, 36th Annual (Cat. No.98CH36173), Reno, NV, USA, 31 March–2 April 1998; pp. 9–16. [Google Scholar]

- Gong, C.; Hogan, T. CMOS Compatible Fabrication Processes for the Digital Micromirror Device. IEEE J. Electron Devices Soc. 2014, 2, 27–32. [Google Scholar] [CrossRef]

- Qiao, Y.; Xu, X.; Pan, Y.; Li, Y. Research on DMD infrared scene projector with a high contrast ratio infrared prism design. Optik (Stuttg.) 2014, 125, 6854–6859. [Google Scholar] [CrossRef]

- Kwak, Y.; MacDonald, L. Characterisation of a desktop LCD projector. Displays 2000, 21, 179–194. [Google Scholar] [CrossRef]

- Sitnik, R. New method of structure light measurement system calibration based on adaptive and effective evaluation of 3D-phase distribution. Proc. SPIE Opt. Meas. Syst. Ind. Insp. IV 2005, 5856, 109–117. [Google Scholar] [CrossRef]

- Michoński, J.; Glinkowski, W.; Witkowski, M.; Sitnik, R. Automatic recognition of surface landmarks of anatomical structures of back and posture. J. Biomed. Opt. 2012, 17, 056015. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lenar, J.; Witkowski, M.; Carbone, V.; Kolk, S.; Adamczyk, M.; Sitnik, R.; van der Krogt, M.; Verdonschot, N. Lower body kinematics evaluation based on a multidirectional four-dimensional structured light measurement. J. Biomed. Opt. 2013, 18, 056014. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liberadzki, P.; Adamczyk, M.; Witkowski, M.; Sitnik, R. Structured-Light-Based System for Shape Measurement of the Human Body in Motion. Sensors 2018, 18, 2827. [Google Scholar] [CrossRef] [Green Version]

- Sitnik, R. Digital fringe projection system for large-volume 360-deg shape measurement. Opt. Eng. 2002, 41, 443. [Google Scholar] [CrossRef]

- Fang Chen Gordon, M.; Brown, M.S. Overview of 3-D shape measurement using optical methods. Opt. Eng. 2000, 39, 13–39. [Google Scholar] [CrossRef]

- Karaszewski, M.; Lech, K.; Bunsch, E.; Sitnik, R. In the Pursuit of Perfect 3D Digitization of Surfaces of Paintings: Geometry and Color Optimization. In Proceedings of the Digital Heritage. Progress in Cultural Heritage: Documentation, Preservation, and Protection; Ioannides, M., Magnenat-Thalmann, N., Fink, E., Žarnić, R., Yen, A.-Y., Quak, E., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 25–34. [Google Scholar]

- Karaszewski, M.; Adamczyk, M.; Sitnik, R.; Michoński, J.; Załuski, W.; Bunsch, E.; Bolewicki, P. Automated full-3D digitization system for documentation of paintings. In Proceedings of the SPIE-The International Society for Optical Engineering, Munich, Germany, 30 May 2013; Springer: Cham, Switzerland, 2013; Volume 87900X. [Google Scholar] [CrossRef]

- Bunsch, E.; Guzowska, A.; Sitnik, R. 3D scanning documentation of two different objects—The King’s Chinese Cabinet in Wilanow Palace Museum and a Roman gravestone from archeological excavations in Moesia Inferior as a part of multidisciplinary research. In Proceedings of the 2012 18th International Conference on Virtual Systems and Multimedia, Milan, Italy, 2–5 September 2012; pp. 633–636. [Google Scholar]

- DLPLCR4500EVM DLP LightCrafter 4500|TI.com. Available online: http://www.ti.com/tool/dlplcr4500evm (accessed on 12 October 2020).

- Yang, L.; Li, E.; Long, T.; Fan, J.; Liang, Z. A Novel 3-D Path Extraction Method for Arc Welding Robot Based on Stereo Structured Light Sensor. IEEE Sens. J. 2019, 19, 763–773. [Google Scholar] [CrossRef]

- Yang, L.; Li, E.; Long, T.; Fan, J.; Liang, Z. A High-Speed Seam Extraction Method Based on the Novel Structured-Light Sensor for Arc Welding Robot: A Review. IEEE Sens. J. 2018, 18, 8631–8641. [Google Scholar] [CrossRef]

- Wen, X.; Song, K.-C. Three-Dimensional Shape Information Acquisition Using Binocular Stereo Vision for Reflective Steel Plate. In Proceedings of the Proceedings of the 2019 3rd International Conference on Graphics and Signal Processing, Hong Kong, China, 1–3 June 2019; ACM: New York, NY, USA, 2019; pp. 82–85. [Google Scholar]

- Wang, S.; Liang, J.; Li, X.; Su, F.; Zhao, Z. A calibration method on 3D measurement based on structured-light with single camera. In Proceedings of the 2019 International Conference on Optical Instruments and Technology: Optical Systems and Modern Optoelectronic Instruments; Nomura, T., Liu, J., Jia, B., Yao, X., Wang, Y., Eds.; SPIE: Beijing, China, 2020; p. 109. [Google Scholar]

- HP 3D Structured Light Scanner Pro S3-Product Leaflet. Available online: https://www8.hp.com/us/en/campaign/3Dscanner/overview.htmlhttps://www8.hp.com/us/en/campaign/3Dscanner/overview.html (accessed on 12 October 2020).

- SMARTTECH 3D Scanners-Proffessional 3D Scanning with Colour. Available online: http://smarttech3dscanner.com/ (accessed on 12 October 2020).

- XJ-A252-Slim Projectors|Casio USA. Available online: http://arch.casio-intl.com/asia-mea/en/projector/greenslim/xj_a256/ (accessed on 12 October 2020).

- Krause, D.; Bach, H. Low Thermal Expansion Glass Ceramics; Schott Series on Glass and Glass Ceramics; Springer: Berlin/Heidelberg, Germany, 2005; ISBN 9783540241119. [Google Scholar]

- Schott: ROBAX. Available online: https://www.schott.com/robax/english/manufacturer/viewing_panels/technical_properties.html#block365741 (accessed on 12 October 2020).

- Grasshopper 2.0 Mp Mono FireWire 1394b (Sony ICX274). Available online: https://www.ptgrey.com/grasshopper-2mp-mono-firewire-1394b-sony-icx274-camera (accessed on 12 October 2020).

- Flir Exx Series Datasheet. Available online: http://www.flir.com/uploadedFiles/Thermography_USA/Products/Product_Literature/flir-e-series-datasheet.pdf (accessed on 12 October 2020).

- MultiCon CMC-99-simex.pl. Available online: https://www.simex.pl/produkt/1285 (accessed on 12 October 2020).

- Press, W.H. Numerical Recipes 3rd Edition: The Art of Scientific Computing; Cambridge University Press: Cambridge, UK, 2007; ISBN 9780521880688. [Google Scholar]

- MATLAB-MathWorks-MATLAB & Simulink. Available online: https://uk.mathworks.com/products/matlab.html (accessed on 12 October 2020).

- Apply Geometric Transformation to Image - MATLAB Imwarp- MathWorks United Kingdom. Available online: https://uk.mathworks.com/help/images/ref/imwarp.html (accessed on 12 October 2020).

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamczyk, M. Temperature Compensation Method for Raster Projectors Used in 3D Structured Light Scanners. Sensors 2020, 20, 5778. https://doi.org/10.3390/s20205778

Adamczyk M. Temperature Compensation Method for Raster Projectors Used in 3D Structured Light Scanners. Sensors. 2020; 20(20):5778. https://doi.org/10.3390/s20205778

Chicago/Turabian StyleAdamczyk, Marcin. 2020. "Temperature Compensation Method for Raster Projectors Used in 3D Structured Light Scanners" Sensors 20, no. 20: 5778. https://doi.org/10.3390/s20205778

APA StyleAdamczyk, M. (2020). Temperature Compensation Method for Raster Projectors Used in 3D Structured Light Scanners. Sensors, 20(20), 5778. https://doi.org/10.3390/s20205778