Magnetic Ring Multi-Defect Stereo Detection System Based on Multi-Camera Vision Technology †

Abstract

1. Introduction

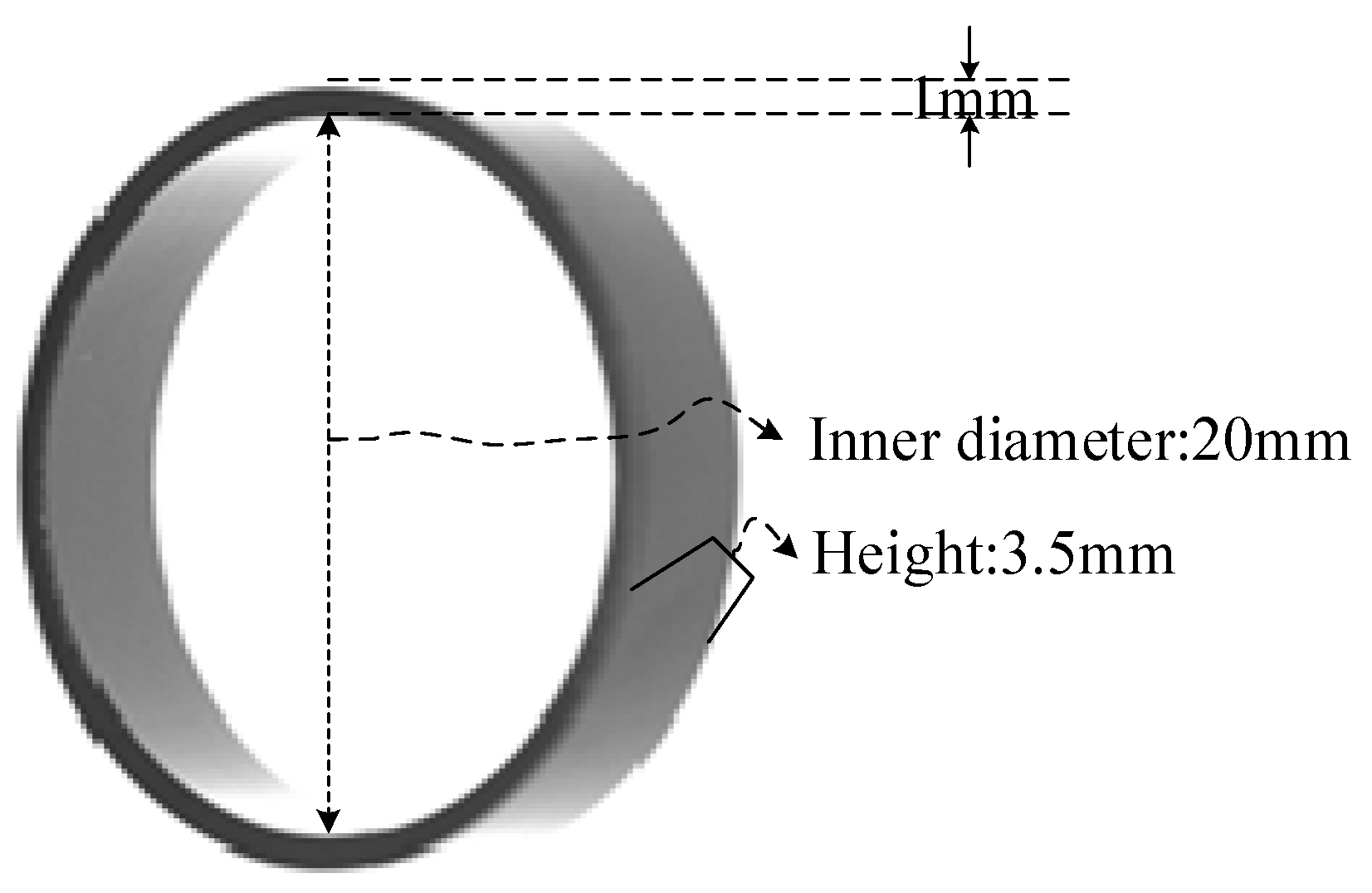

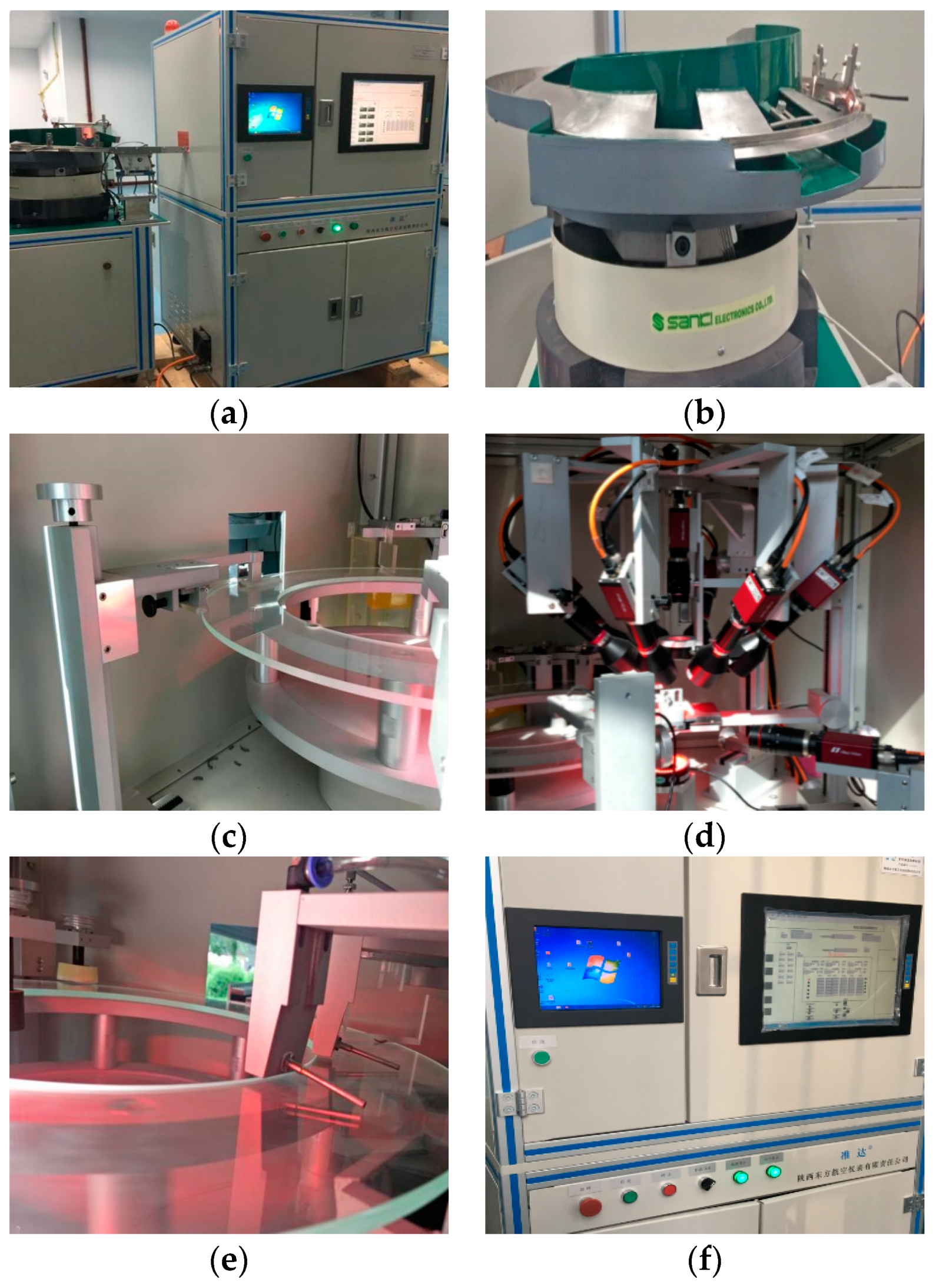

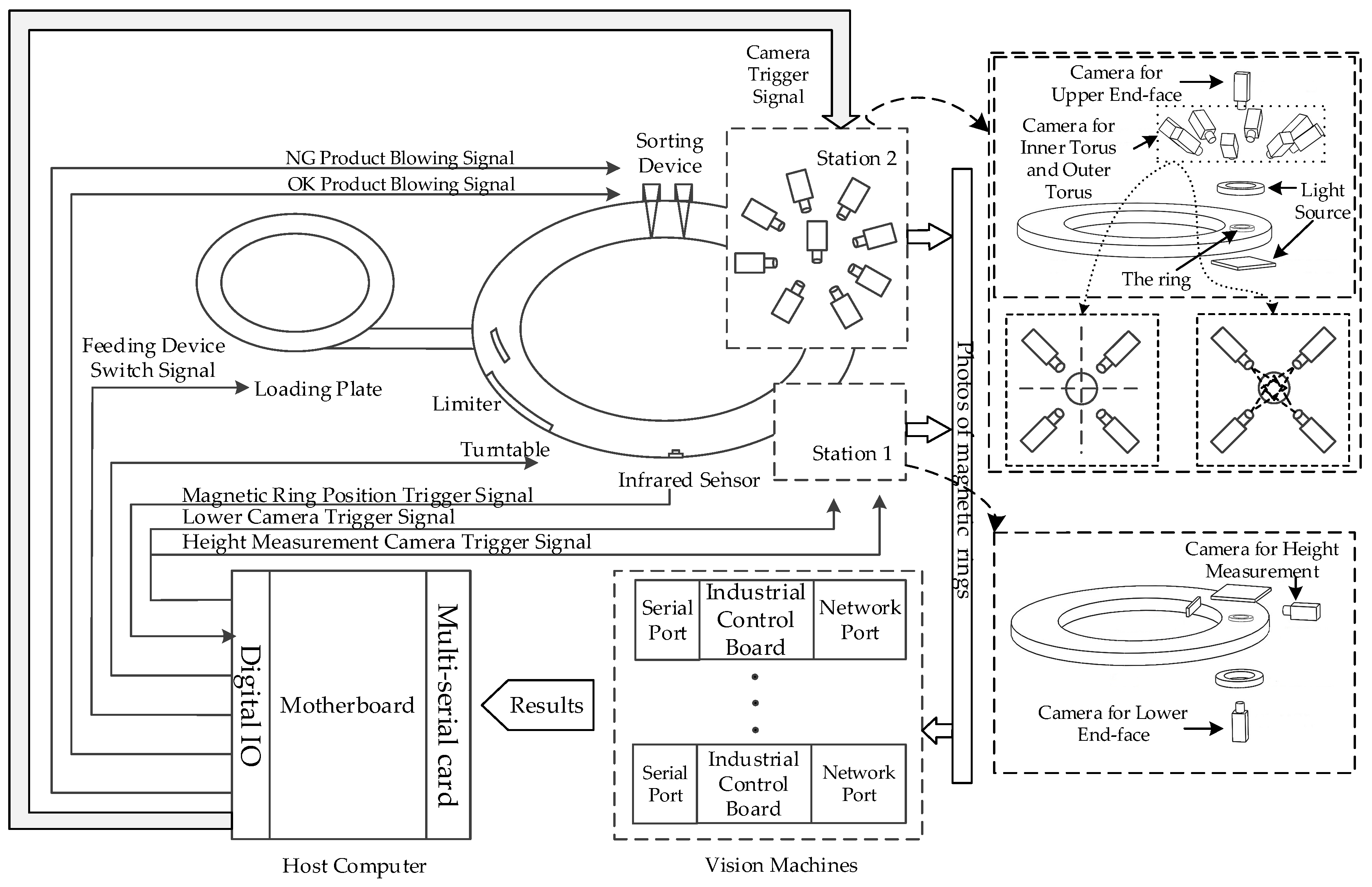

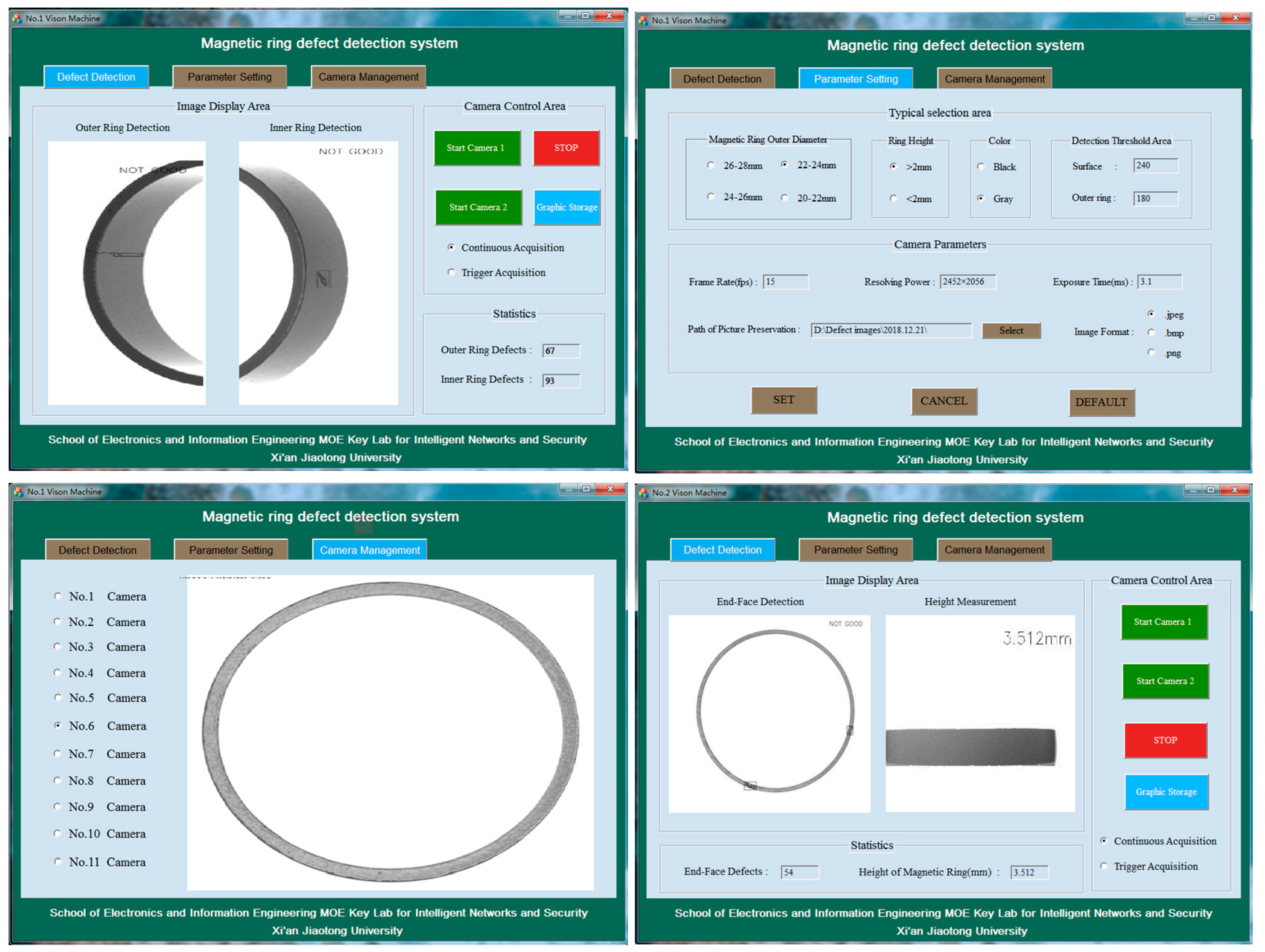

2. System Design

2.1. Hardware Design

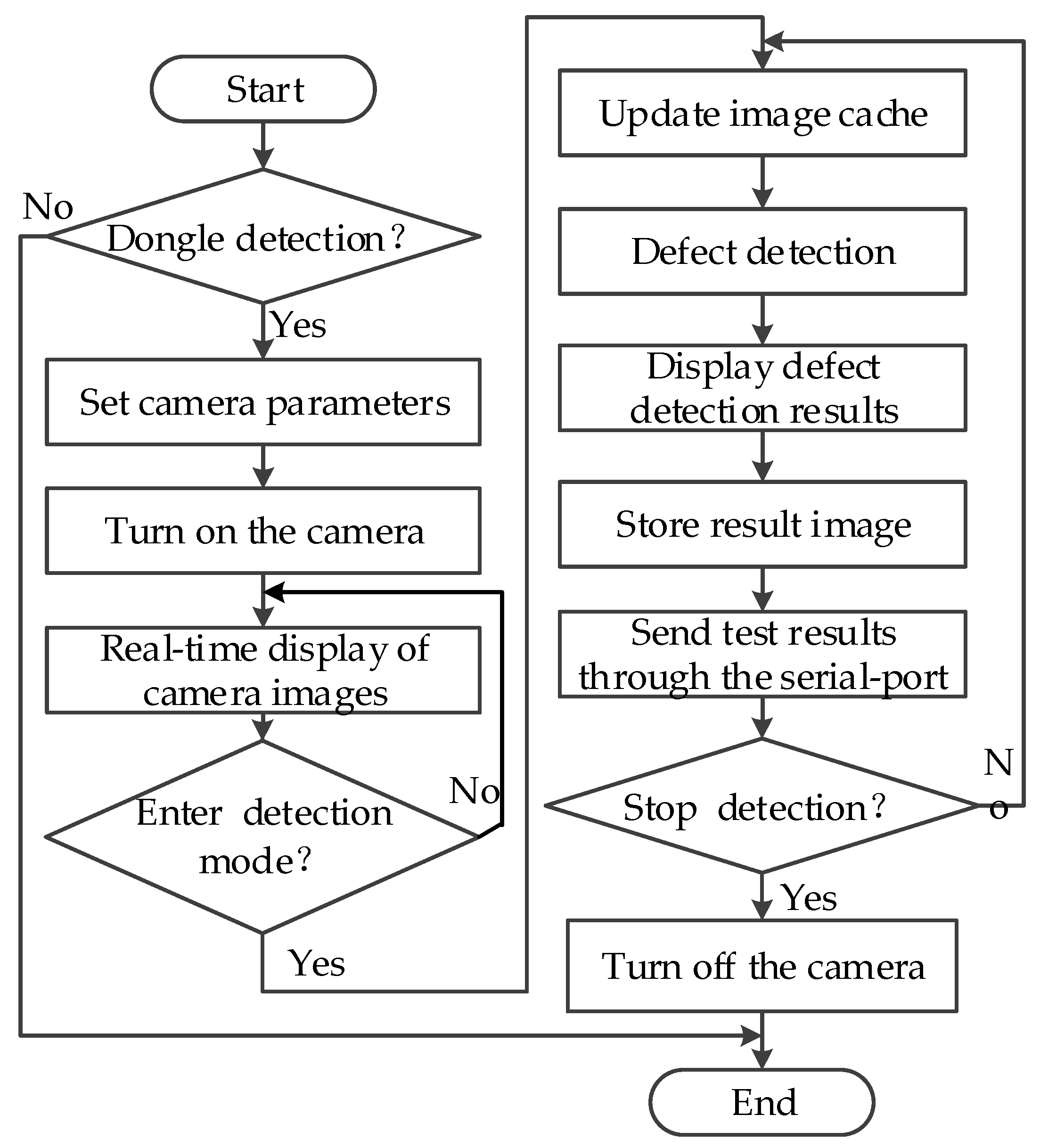

2.2. Software Design

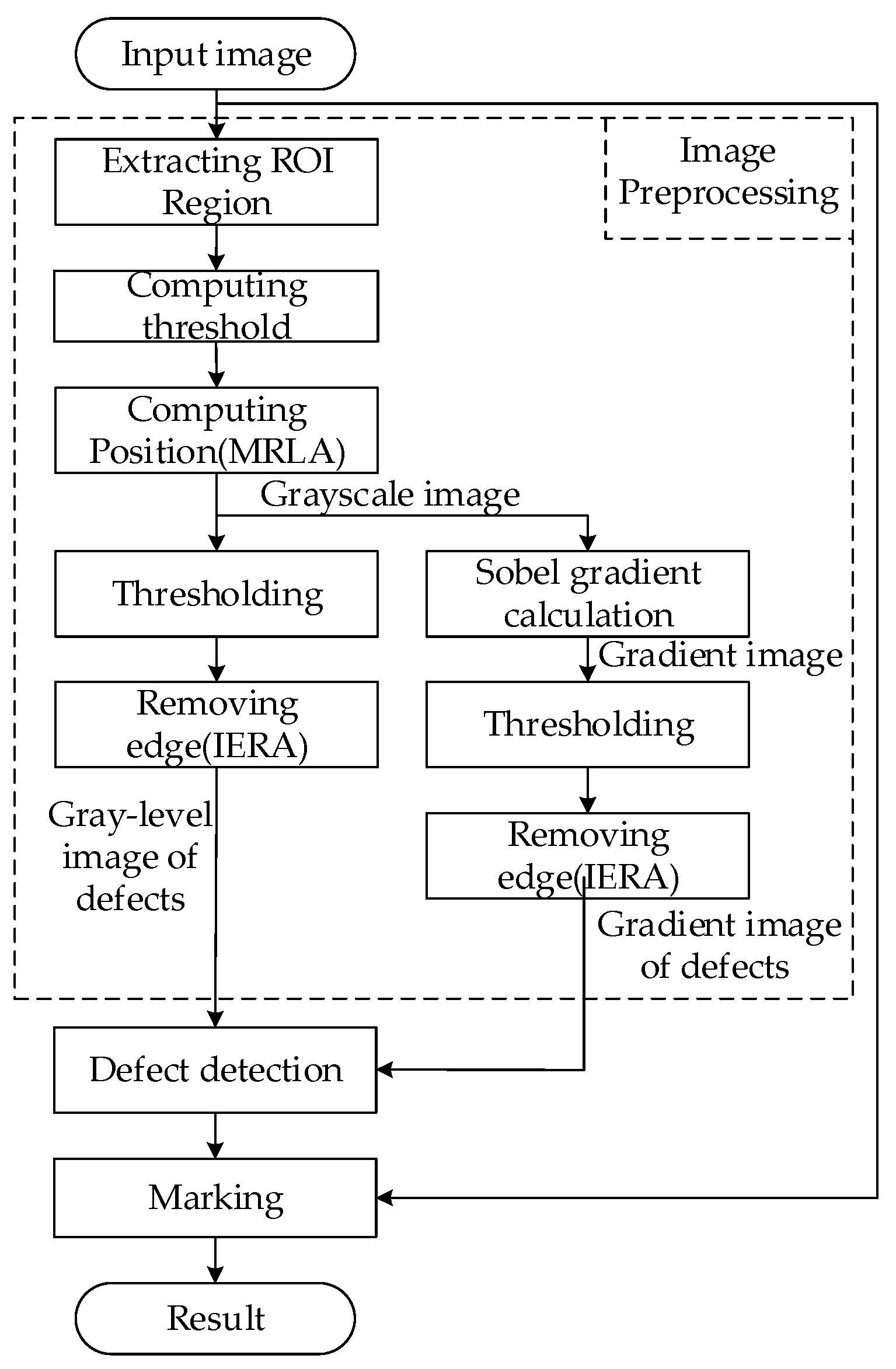

3. Methods

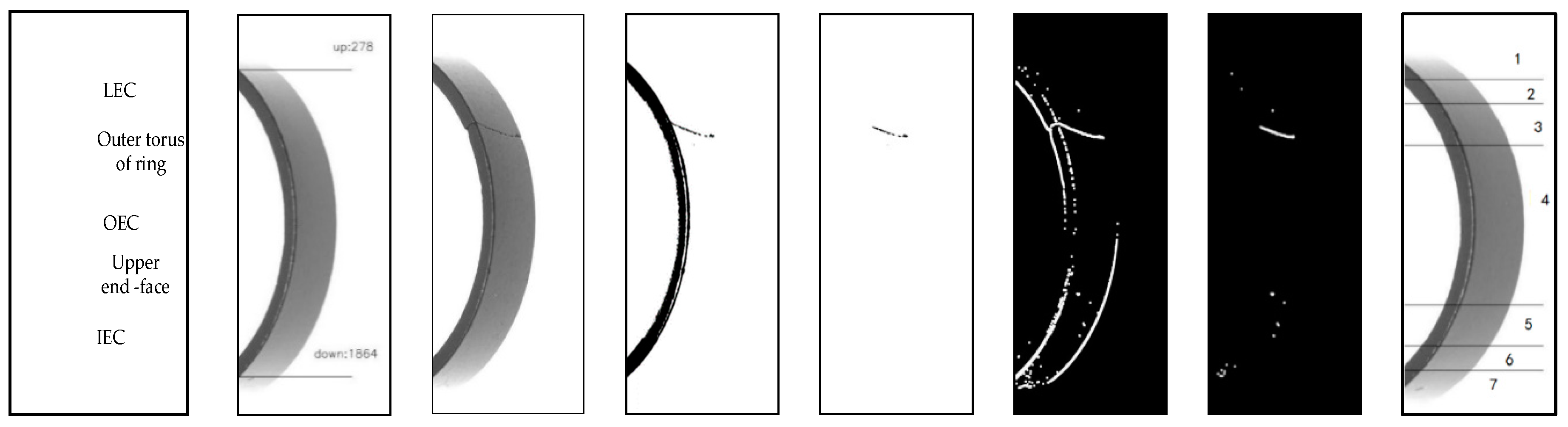

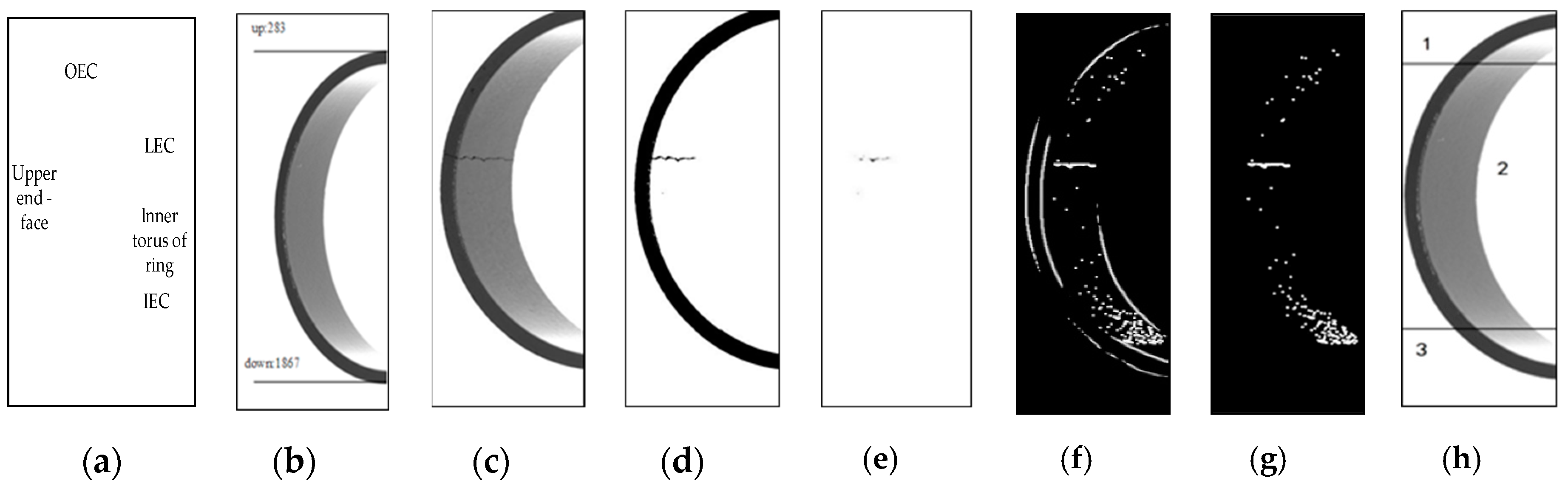

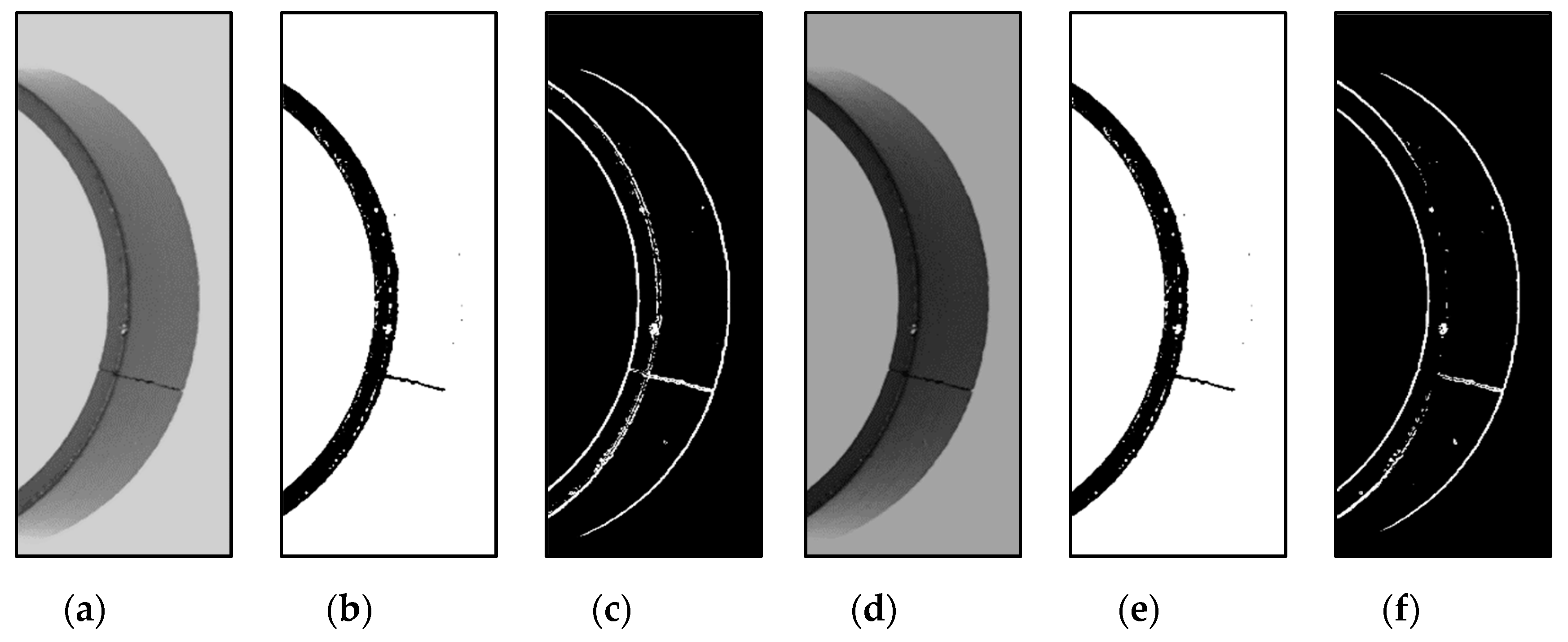

3.1. Image Preprocessing

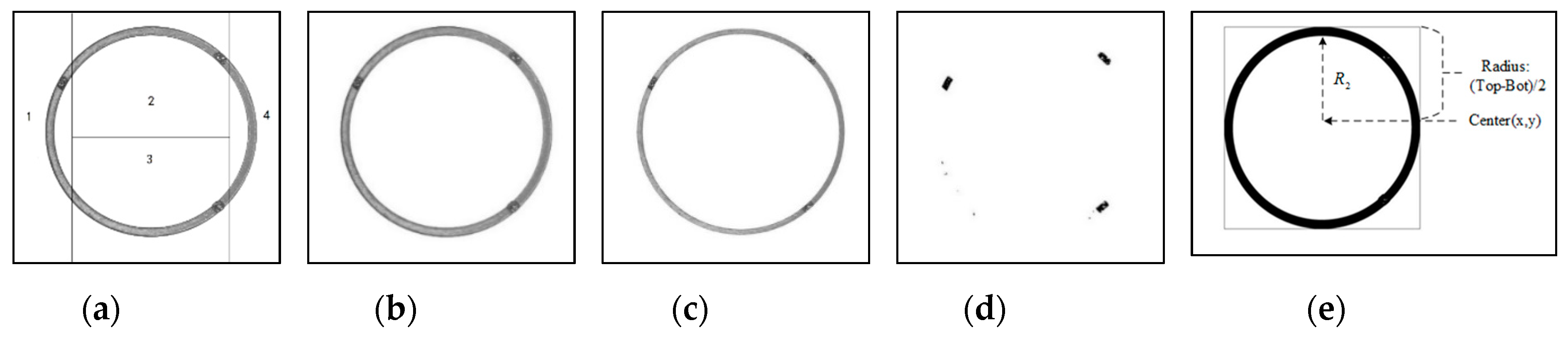

3.2. Magnetic Ring Location Algorithm

| Algorithm 1 Magnetic Ring Location Algorithm |

| 1: Given a grayscale torus image . |

| 2: Use sub-region gray threshold segmentation to obtain a binary image . |

| 3: for I = 0, …, M do |

| 4: Scan from top to bottom. |

| 5: Count the number of black dots. |

| 6: if |

| 7: Get the up position . |

| 8: end |

| 9: end |

| 10: for I = 0, …, M do |

| 11: Scan from bottom to top. |

| 12: Count the number of black dots. |

| 13: if |

| 14: Get the down position . |

| 15: end |

| 16: end |

| 17: Output the location result and . |

3.3. Image Edge Removal Algorithm

| Algorithm 2 Image Edge Removal Algorithm | ||

| Part I | 1: Given a grayscale image . | |

| 2: Process and get gray binary image . | ||

| 3: for I = 0, …, M do | ||

| 4: Set the array of IEC to , set the array of OEC to . | ||

| 5: for j = 0, …, N − 2 do | ||

| 6: if | ||

| 7: Get . | ||

| 8: end | ||

| 9: end | ||

| 10: for j = , …, N − 4 do | ||

| 11: if | ||

| 12: Get . | ||

| 13: end | ||

| 14: end | ||

| 15: for j = 0, …, N do | ||

| 16: if | ||

| 17: Set | ||

| 18: end | ||

| 19: end | ||

| 20: end | ||

| 21: Output the edge-removed gray binary image . | ||

| Part II | 1: | Given a grayscale image . |

| 2: | Obtain a binary image and an image with high threshold binarization. Use Sobel operator to obtain gradient binary image . | |

| 3: | for i = 0, …, M do | |

| 4: | Set the array of IEC to , set the array of LEC and set the array of OEC to . | |

| 5: | for j = 0, …, N − 4 do | |

| 7: | if | |

| 8: | Get . | |

| 9: | end | |

| 10: | end | |

| 11: | for j = , …, N − 4 do | |

| 13: | if | |

| 14: | Get . | |

| 15: | if | |

| 16: | Get . | |

| 17: | end | |

| 18: | end | |

| 19: | for j = 0, …, N do | |

| 20: | if or | |

| 21: | Set . | |

| 22: | end | |

| 23: | end | |

| 24: | end | |

| 25: | Output the edge-removed torus gradient image . | |

| Part III | 1: | Given a grayscale end face image . |

| 2: | Process and get binary image . | |

| 3: | Create a white circle with as its center, radius and line width, respectively. | |

| 4: | forj = y, y − 1, …,4 do | |

| 5: | Scan upward from . | |

| 6: | if | |

| 7: | Get . | |

| 8: | end | |

| 9: | end | |

| 10: | Create a white circle with as its center, radius and line width, respectively. | |

| 11: | Use and to remove edges. | |

| 12: | Output the edge-removed grayscale end face image. | |

3.4. Connected Domain Filtering Method

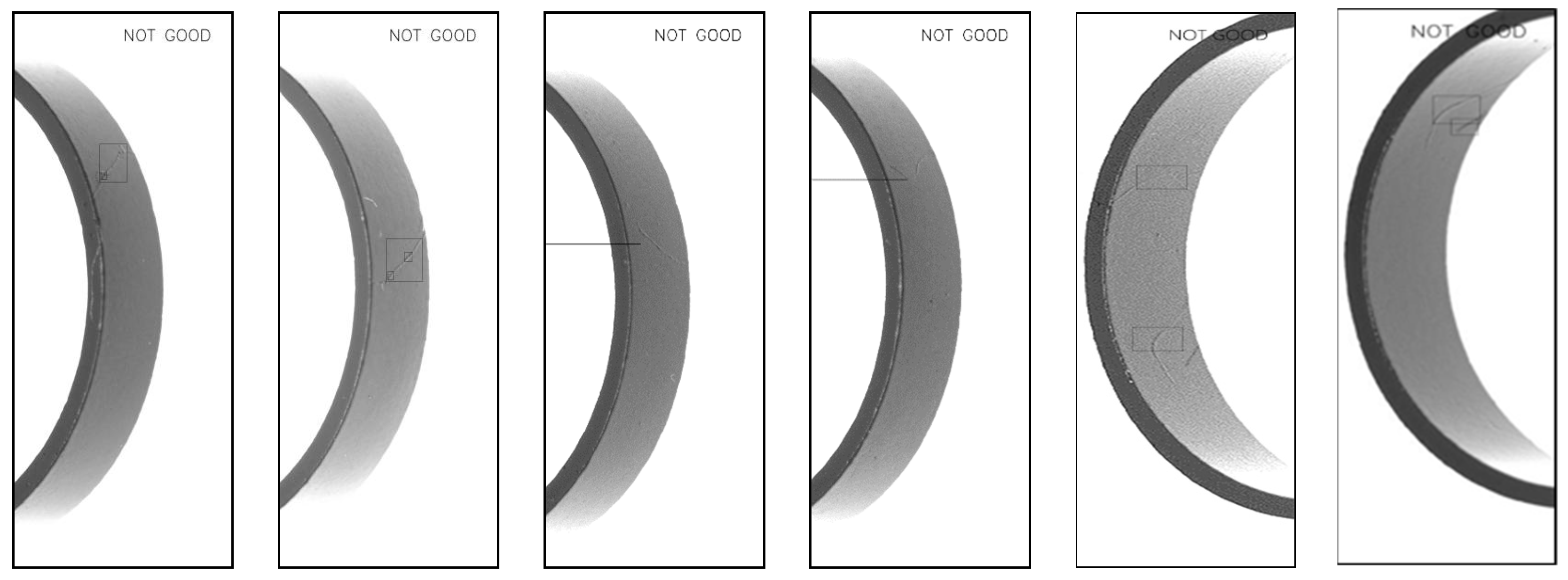

- Crack defect: It can be categorized into obvious crack and recessive crack. The obvious crack is shown as a thick line in the image and has a strong contrast with the torus region. The recessive crack is opposite to the obvious crack.

- Large-area defect: It is characterized by obvious protrusion or depression, a strong contrast with the surrounding area and a large defect area.

- Fiber defect: It has the characteristics of low gray-level discrimination with the surrounding area, inconspicuous protrusion, irregular shape, and fine lines.

| Algorithm 3 Connected Domain Filtering Method | ||

| Part I | 1: | Give a gray binary image or a gradient binary image . |

| 2: | Process and get ’s anti-color image . | |

| 3: | Get the connected domain set and the number k of the connected domain. | |

| 4: | fori = 1, …, k do | |

| 5: | Get the area of the connected domain , the minimum bounding rectangle (with length and width ). | |

| 6: | Set each value of . | |

| 7: | if is satisfied | |

| 8: | is judged to be a defect. | |

| 9: | end | |

| 10: | end | |

| 11: | Output the results. | |

| Part II | 1: | Given a gradient binary image . |

| 2: | Get the width of . | |

| 3: | Set the step length and a rectangular search box with a width of and a length of . Set number of connected domains . | |

| 4: | fori = 1, …, …, do | |

| 5: | Use to traverse from top to bottom in steps of . | |

| 6: | For the , get k connected domains. | |

| 7: | for j = 1, …, k do | |

| 8: | Get the area of the connected domain , the minimum bounding rectangle (with length and width ). | |

| 9: | Set each value of . | |

| 10: | if is satisfied. | |

| 11: | and save the coordinate of the connected domain . | |

| 12: | end | |

| 13: | end | |

| 14: | Set and . | |

| 15: | if is satisfied. | |

| 16: | The contains defects. | |

| 17: | end | |

| 18: | end | |

| 19: | Output the results. | |

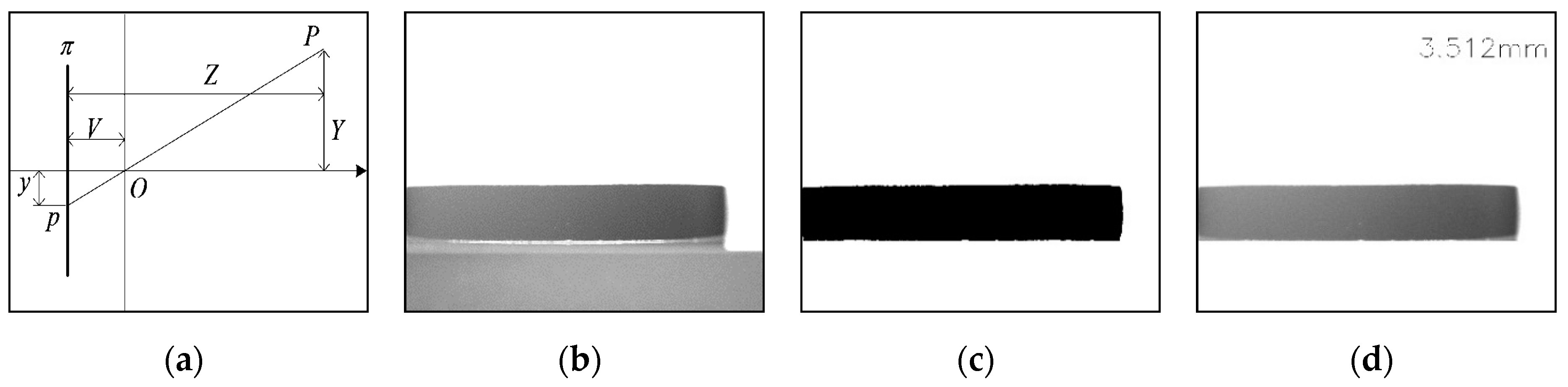

3.5. Measurement Method of Magnetic Ring Height

4. Experiments

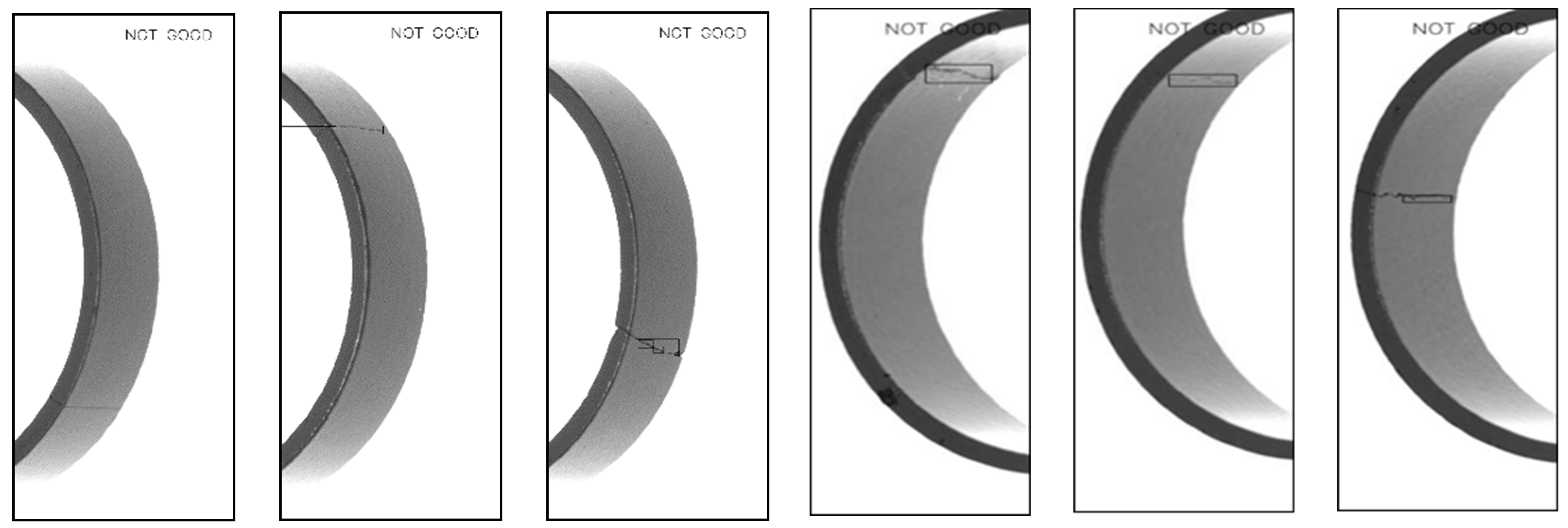

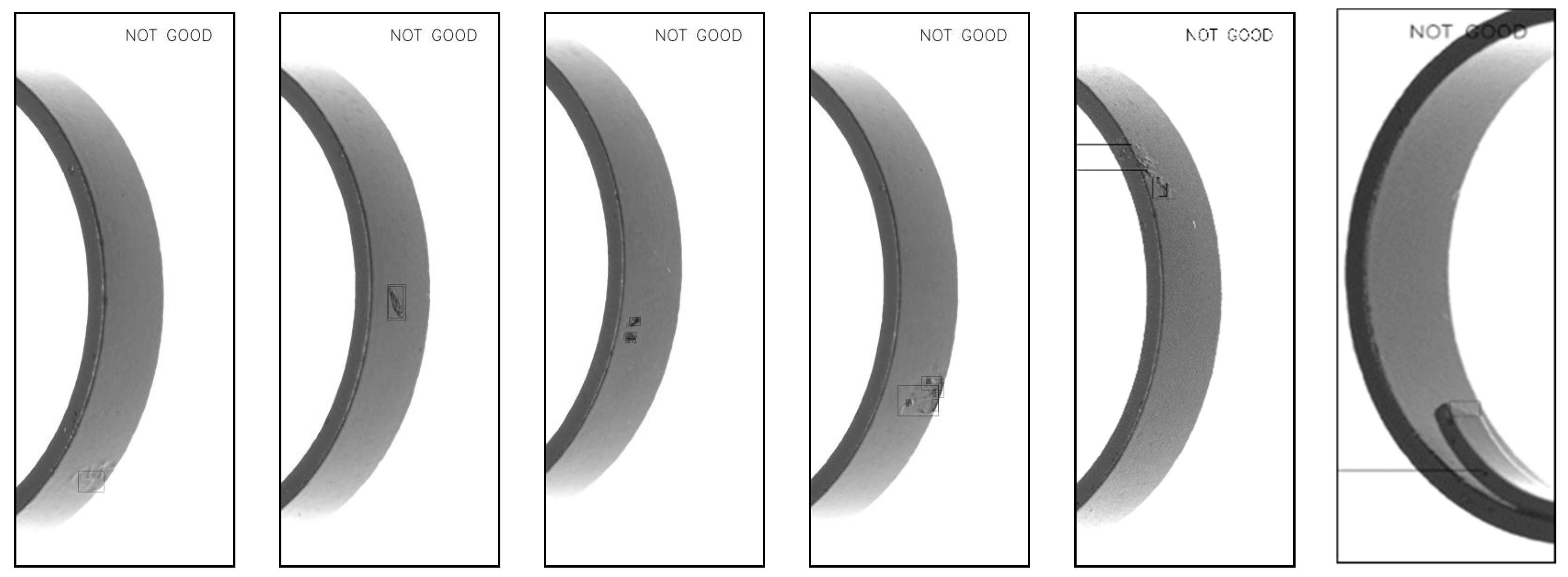

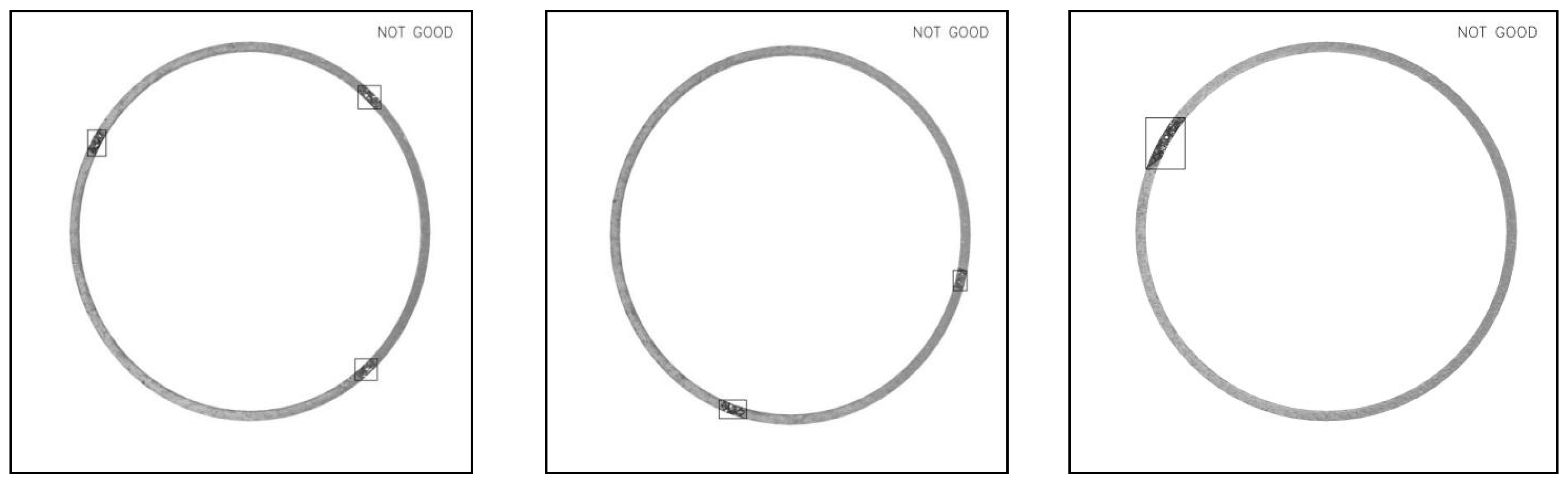

4.1. Examples of Defect Detection

4.2. Statistical Results of Defect Detection

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, L.J.; Wang, Y. Ferrite core appearance inspection using gray histogram and support vector machine. Chin. J. Sci. Instrum. 2006, 27, 840–844. [Google Scholar]

- Pei, C.; Fukuchi, T.; Zhu, H. A Study of Internal Defect Testing With the Laser-EMAT Ultrasonic Method. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2702–2708. [Google Scholar]

- Liu, S.; Dong, S.; Zhang, Y. Defect Detection in Cylindrical Cavity by Electromagnetic Ultrasonic Creeping Wave. IEEE Trans. Magn. 2017, 54, 6200305. [Google Scholar] [CrossRef]

- Wataru, Y.; Ryo, T.; Teruyoshi, S.; Keiji, E. Detection of Slit Defects on Backside of Steel Plate Using Low-Frequency Eddy-Current Testing. IEEE Trans. Magn. 2018, 54, 6202505. [Google Scholar]

- D’Angelo, G.; Laracca, M.; Rampone, S. Fast Eddy Current Testing Defect Classification Using Lissajous Figs. IEEE Trans. Instrum. Meas. 2018, 67, 821–830. [Google Scholar] [CrossRef]

- Cheng, L.; Tian, G.Y. Surface Crack Detection for Carbon Fiber Reinforced Plastic (CFRP) Materials Using Pulsed Eddy Current Thermography. IEEE Sens. J. 2011, 11, 3261–3268. [Google Scholar] [CrossRef]

- Tolba, A.S.; Raafat, H.M. Multiscale image quality measures for defect detection in thin films. Int. J. Adv. Manuf. Technol. 2015, 79, 113–122. [Google Scholar] [CrossRef]

- Boby, R.A.; Sonakar, P.S. Identification of defects on highly reflective ring components and analysis using machine vision. Int. J. Adv. Manuf. Technol. 2011, 52, 217–233. [Google Scholar] [CrossRef]

- Medina, R.; Gayubo, F. Automated visual classification of frequent defects in flat steel coils. Int. J. Adv. Manuf. Technol. 2011, 57, 1087–1097. [Google Scholar] [CrossRef]

- Gamage, P.; Xie, S.Q. A real-time vision system for defect inspection in cast extrusion manufacturing process. Int. J. Adv. Manuf. Technol. 2009, 40, 144–156. [Google Scholar] [CrossRef]

- Li, Q.; Ren, S. A Visual Detection System for Rail Surface Defects. IEEE Trans. Syst. 2012, 42, 1531–1542. [Google Scholar] [CrossRef]

- Tsai, D.M.; Hsieh, Y.C. Machine Vision-Based Positioning and Inspection Using Expectation-Maximization Technique. IEEE Trans. Instrum. Meas. 2017, 66, 2858–2868. [Google Scholar] [CrossRef]

- Chen, T.; Wang, Y.; Xiao, C.; Wu, Q.M.J. A Machine Vision Apparatus and Method for Can-End Inspection. IEEE Trans. Instrum. Meas. 2016, 65, 2055–2066. [Google Scholar] [CrossRef]

- Ko, J.S.; Rheem, J.Y. Defect detection of polycrystalline solar wafers using local binary mean. Int. J. Adv. Manuf. Technol. 2016, 82, 1753–1764. [Google Scholar] [CrossRef]

- Xu, H.; Hou, D.X.; Qiu, J.; Ye, S.L. Extracting crack signal of magnetic ring based on MAX262. In Proceedings of the Eighth International Symposium on Precision Engineering Measurement and Instrumentation, Chengdu, China, 8–11 August 2012. [Google Scholar]

- Yu, Z.J.; Li, X.Z.; Yu, H.D.; Xie, D. Research on surface defect inspection for small magnetic rings. In Proceedings of the 2009 International Conference on Mechatronics and Automation, Changchun, China, 9–12 August 2009. [Google Scholar]

- Li, J.F.; Zhang, Z.X.; Shen, J.M. Study on surface defect extraction of magnetic ring based on texture suppression. J. Optoelectron. Laser 2017, 28, 978–985. [Google Scholar]

- Wang, Y.N.; Chen, T.J.; He, Z.D.; Wu, C.Z. Review on the machine vision measurement and control technology for intelligent manufacturing equipment. Control Theory Appl. 2015, 32, 273–286. [Google Scholar]

- Otsu, N. Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Qian, K.; Li, F.; Wen, Y.M. Color and Space Distance Based Salient Region Detection Using Fixed Threshold Segmentation. Comput. Sci. 2016, 43, 103–106. [Google Scholar]

- Ren, R.; Hung, T.; Tan, K.C. Automatic Microstructure Defect Detection of Ti-6Al-4V Titanium Alloy by Regions-Based Graph. IEEE Trans. Emerg. Top. Comput. Intell. 2017, 1, 87–96. [Google Scholar] [CrossRef]

- Jiang, J.D.; Chen, P.Y.; Tong, Y.J.; Hoogmoed, W. Study on the defect inspection algorithm of touch switch pins based on machine vision. J. Zhejiang Univ. Technol. 2015, 43, 30–33. [Google Scholar]

| Number of Visual Machines | Detected Content | Maximum Time Consumption (ms) | Minimum Time Consumption (ms) | Average Time Consumption (ms) |

|---|---|---|---|---|

| 1 | Outer and inner rings | 510 | 395 | 436 |

| 2 | Lower end face | 470 | 412 | 425 |

| 3 | Inner ring | 260 | 180 | 220 |

| 4 | Outer ring, inner ring | 495 | 402 | 440 |

| 5 | Outer ring, inner ring | 490 | 406 | 443 |

| 6 | Outer ring, upper end surface | 500 | 420 | 455 |

| Number | Name | Total Number of Magnetic Rings | Number of Identifications | Recognition Rate |

|---|---|---|---|---|

| 1 | Crack | 200 | 200 | 100% |

| 2 | Adhesion | 200 | 200 | 100% |

| 3 | Hanger adhesion | 200 | 200 | 100% |

| 4 | Pitting | 200 | 200 | 100% |

| 5 | Foreign body | 200 | 185 | 92.5% |

| 6 | Fiber | 200 | 183 | 91.5% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Gong, W.; Xu, X. Magnetic Ring Multi-Defect Stereo Detection System Based on Multi-Camera Vision Technology. Sensors 2020, 20, 392. https://doi.org/10.3390/s20020392

Zhang X, Gong W, Xu X. Magnetic Ring Multi-Defect Stereo Detection System Based on Multi-Camera Vision Technology. Sensors. 2020; 20(2):392. https://doi.org/10.3390/s20020392

Chicago/Turabian StyleZhang, Xinman, Weiyong Gong, and Xuebin Xu. 2020. "Magnetic Ring Multi-Defect Stereo Detection System Based on Multi-Camera Vision Technology" Sensors 20, no. 2: 392. https://doi.org/10.3390/s20020392

APA StyleZhang, X., Gong, W., & Xu, X. (2020). Magnetic Ring Multi-Defect Stereo Detection System Based on Multi-Camera Vision Technology. Sensors, 20(2), 392. https://doi.org/10.3390/s20020392