Design, Construction and Testing of IoT Based Automated Indoor Vertical Hydroponics Farming Test-Bed in Qatar

Abstract

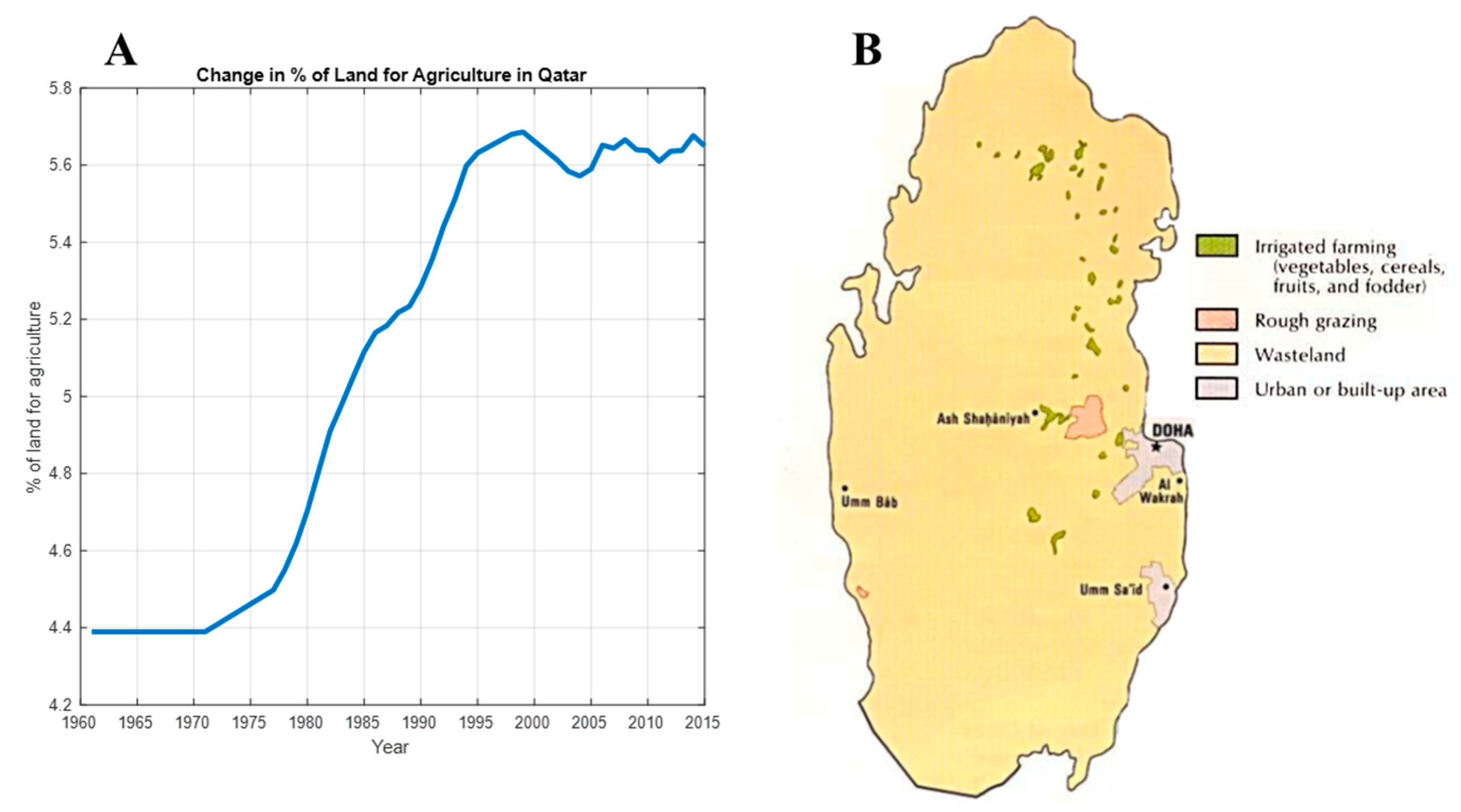

1. Introduction

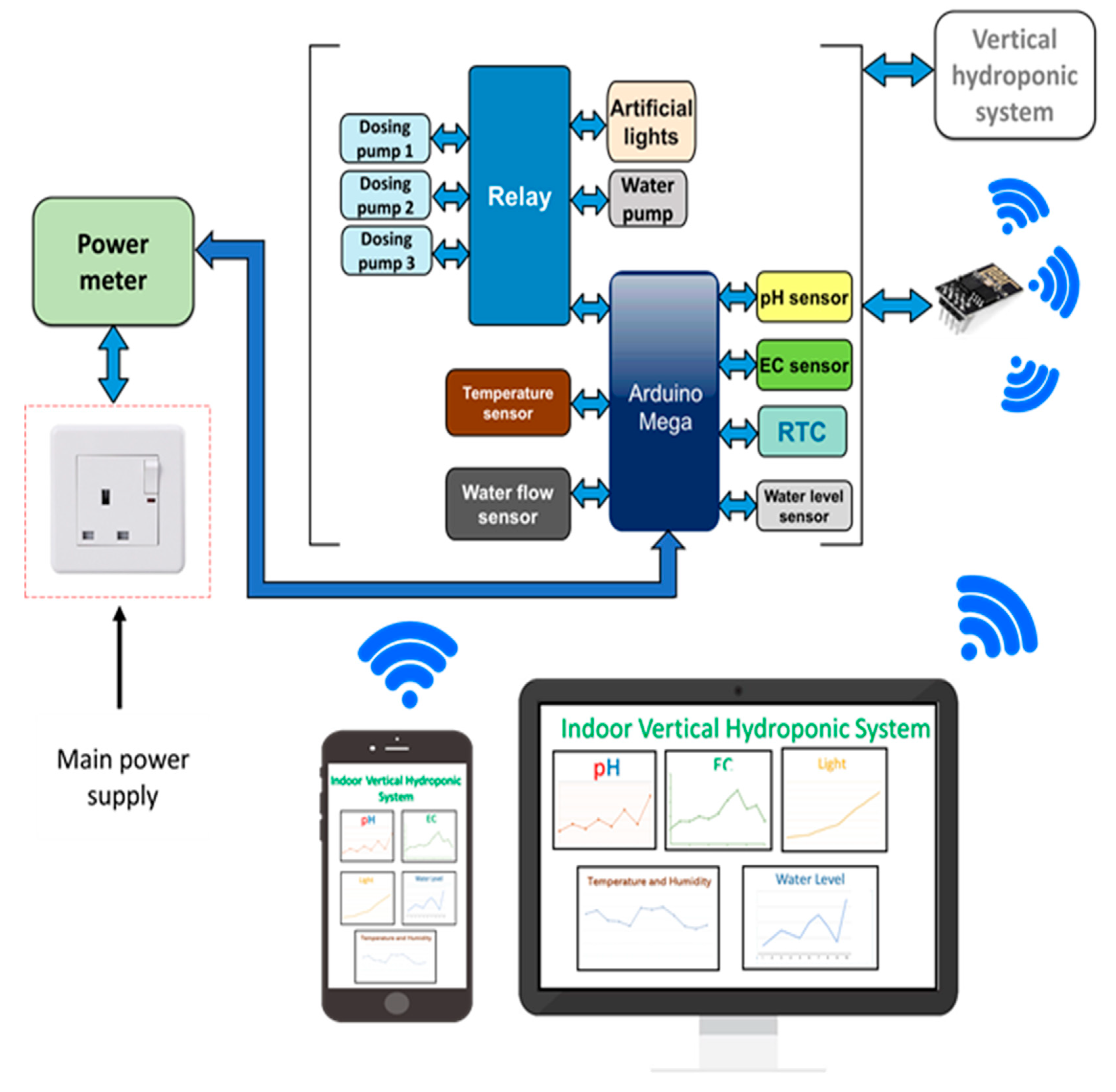

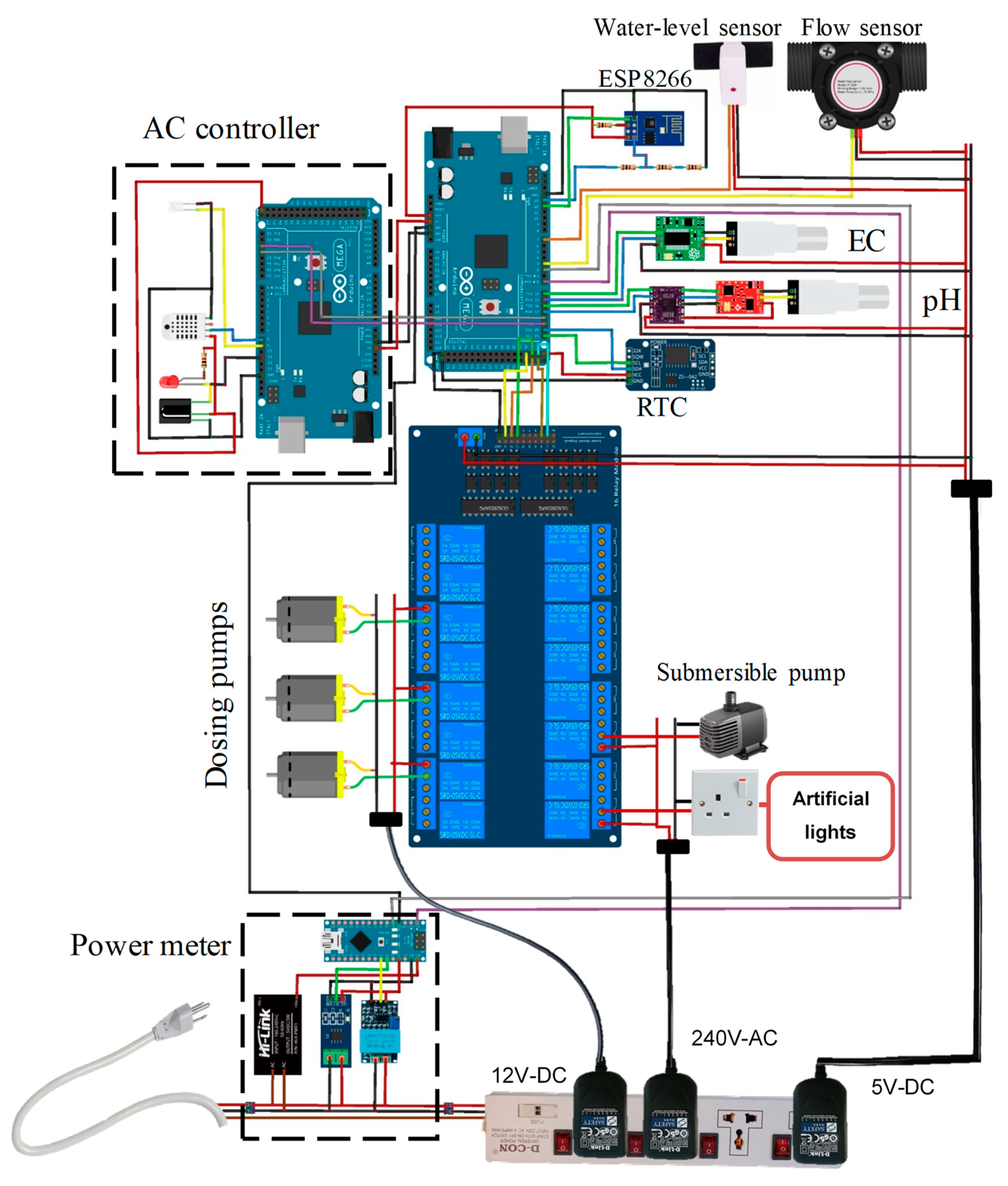

2. Materials and Methods

- NFT structure and essential components

- Water flow path

- Nutrition and pH controlling system

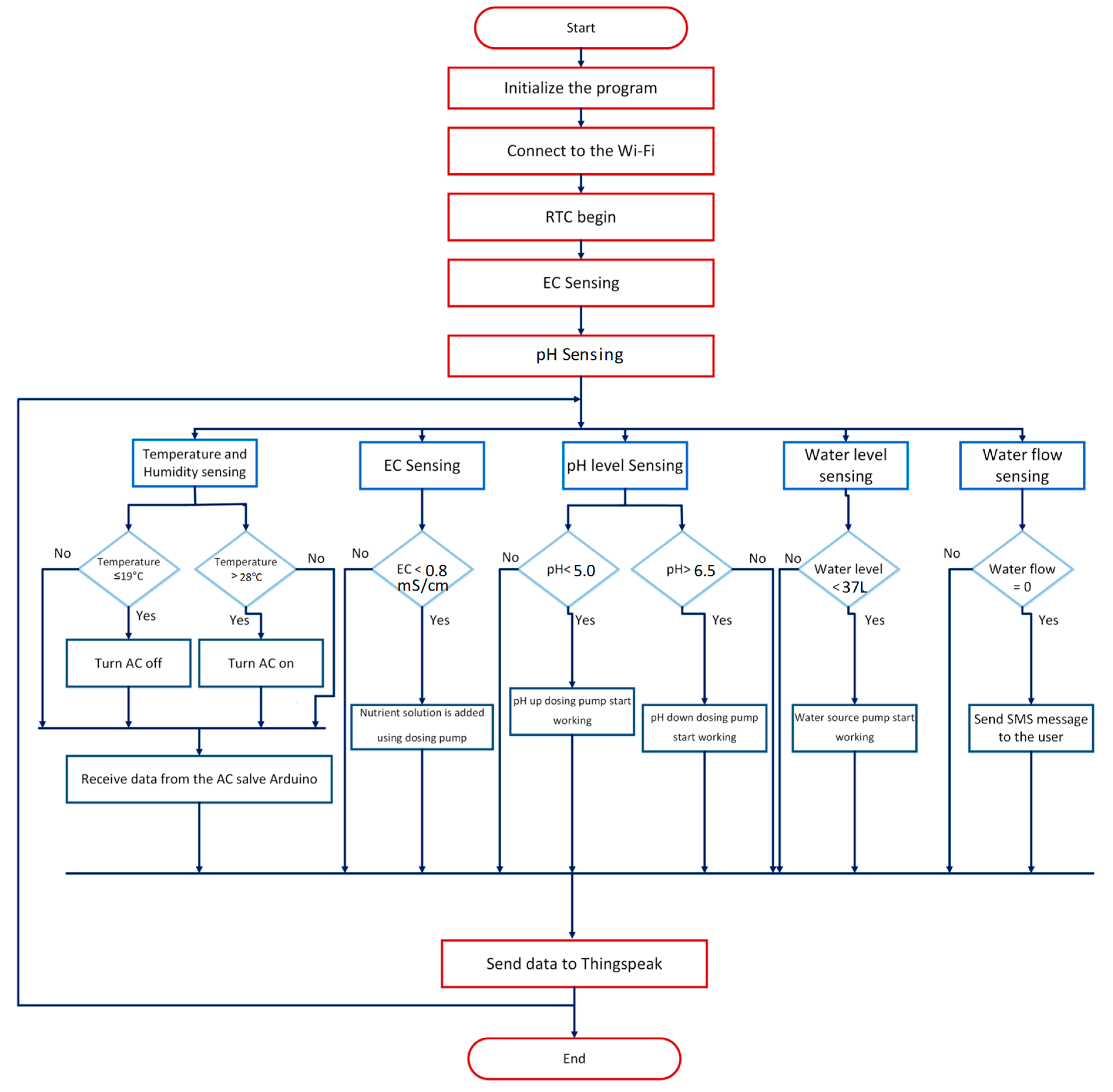

- Internet of Things (IoT) platform

2.1. NFT Structure and Essential Components

2.1.1. Nutrients’ Container

2.1.2. Water Pump

2.1.3. Artificial Lights

2.1.4. Nutrients and pH

2.1.5. Isolation Circuit

2.1.6. RTC Circuit

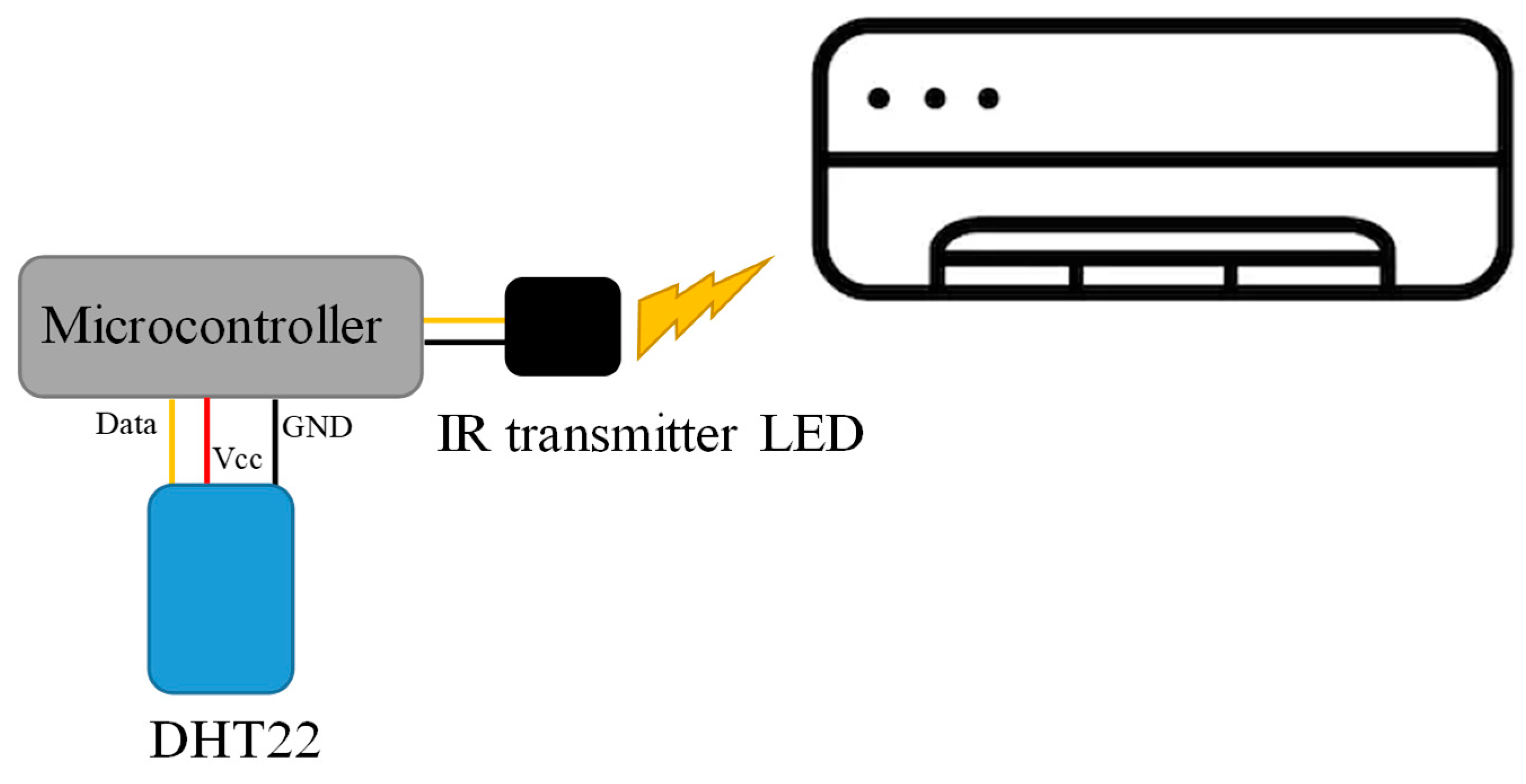

2.1.7. Air Conditioner (AC) Controlling Subsystem

2.1.8. Power Consumption Monitoring Subsystem

2.2. Water Flow Path

2.3. Nutrition and pH Controlling System

2.4. Internet of Things (IoT) Platform

3. Testing and Validation

3.1. Testing of Electronic Sensors

3.1.1. EC and pH Sensor

3.1.2. Water Flow Sensors

3.1.3. Water Level Sensor

3.2. Dosing Pumps

3.3. Power Meter Subsystem

4. Results

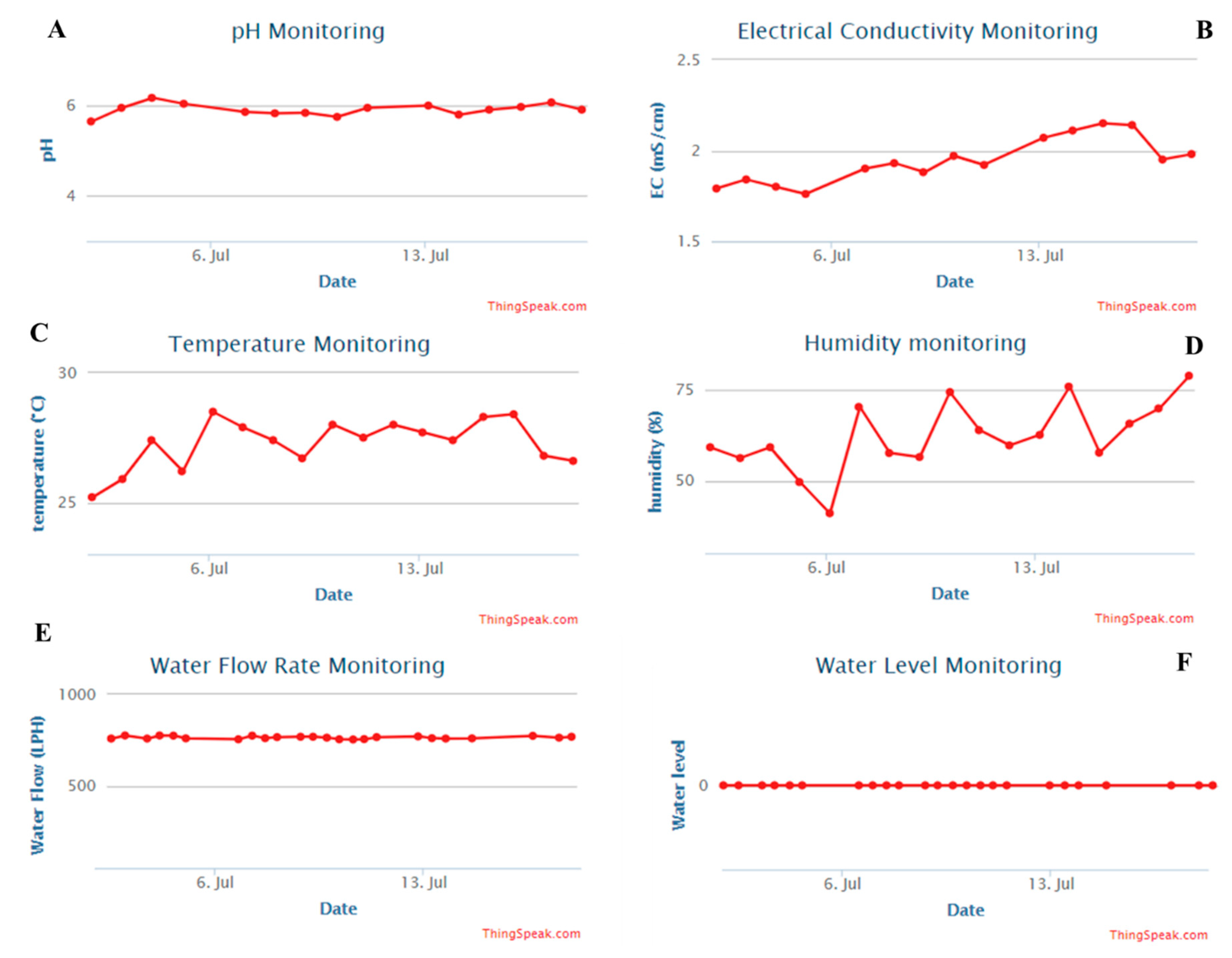

4.1. IoT Based Web and Mobile Interface

4.2. Alerting the User When an Intervention Is Required

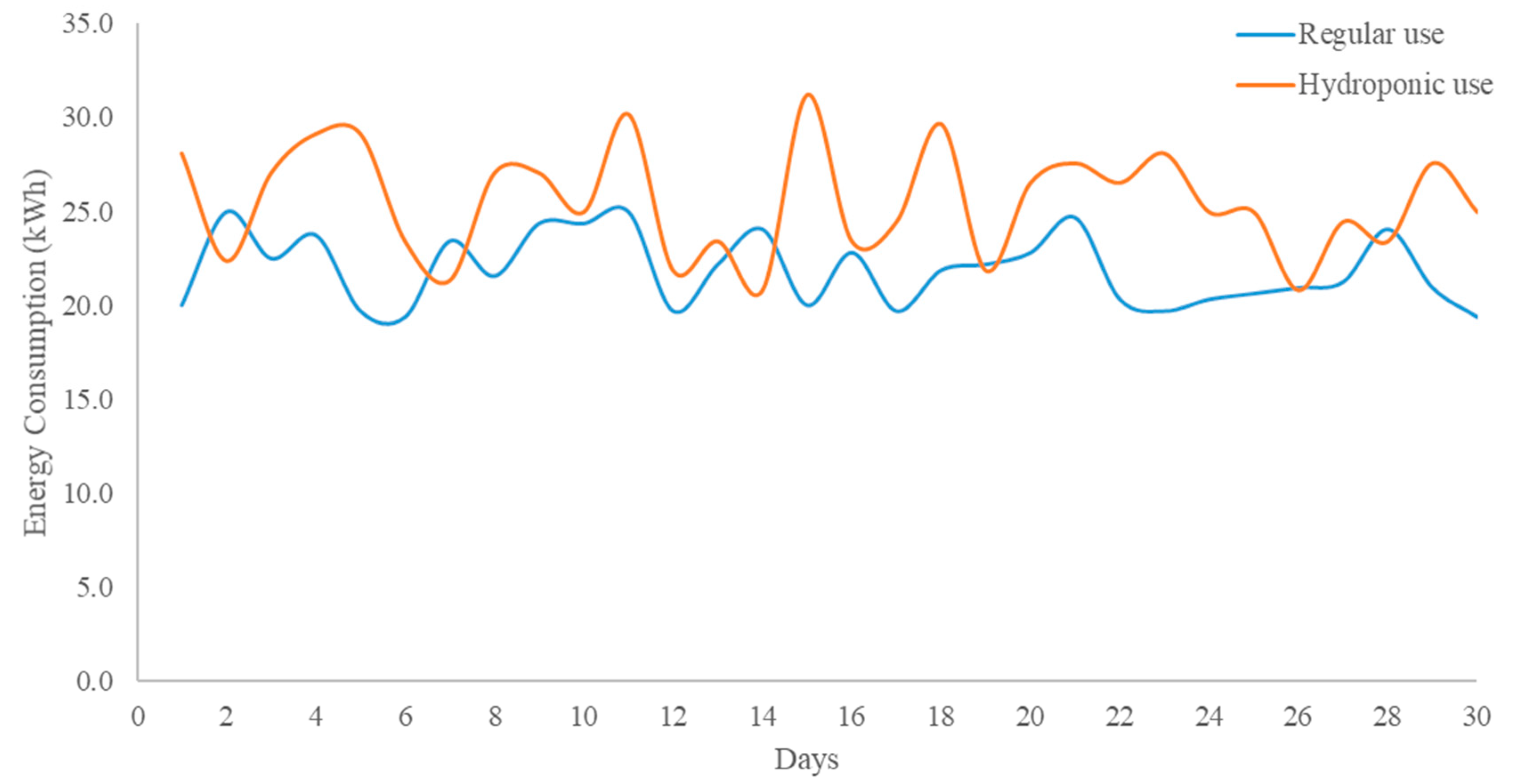

4.3. Power Consumption of the Overall System

4.4. Water Consumption and Volume Circulation per Month

4.5. Comparison with Other Similar Research Projects and Commerical Products

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Resh, H.M. Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardener and the Commercial Hydroponic Grower; 19 April 2016; CRC Press: Boca Raton, FL, USA, 2016; ISBN 1439878676. [Google Scholar]

- Abdullah, N.-O. Vertical-horizontal regulated soilless farming via advanced hydroponics for domestic food production in Doha, Qatar. Res. Ideas Outcomes 2016, 2, e8134. [Google Scholar] [CrossRef]

- Crisnapati, P.N.; Wardana, I.N.K.; Aryanto, I.K.A.A.; Hermawan, A. Hommons: Hydroponic management and monitoring system for an IOT based NFT farm using web technology. In Proceedings of the 2017 5th International Conference on Cyber and IT Service Management (CITSM), Denpasar, Indonesia, 8–10 August 2017; pp. 1–6. [Google Scholar]

- Mehra, M.; Saxena, S.; Sankaranarayanan, S.; Tom, R.J.; Veeramanikandan, M. IoT based hydroponics system using Deep Neural Networks. Comput. Electron. Agric. 2018, 155, 473–486. [Google Scholar] [CrossRef]

- Baabood, A. Qatar’s Resilience Strategy and Implications for State-Society Relations; Istituto Affari Internazionali (IAI): Rome, Italy, 2017. [Google Scholar]

- Chowdhury, M.E.; Khandakar, A.; Hossain, B.; Abouhasera, R. A low-cost closed-loop solar tracking system based on the sun position algorithm. J. Sens. 2019, 2019, 1–11. [Google Scholar]

- Khandakar, A.; EH Chowdhury, M.; Khoda Kazi, M.; Benhmed, K.; Touati, F.; Al-Hitmi, M.; Gonzales, J.S. Machine learning based photovoltaics (PV) power prediction using different environmental parameters of Qatar. Energies 2019, 12, 2782. [Google Scholar] [CrossRef]

- Ahmad, N.; Khandakar, A.; El-Tayeb, A.; Benhmed, K.; Iqbal, A.; Touati, F. Novel design for thermal management of PV cells in harsh environmental conditions. Energies 2018, 11, 3231. [Google Scholar] [CrossRef]

- Khandakar, A.; Touati, A.; Touati, F.; Abdaoui, A.; Bouallegue, A. Experimental setup to validate the effects of major environmental parameters on the performance of FSO communication link in Qatar. Appl. Sci. 2018, 8, 2599. [Google Scholar] [CrossRef]

- Touati, F.; Khandakar, A.; Chowdhury, M.E.; Antonio, S., Jr.; Sorino, C.K.; Benhmed, K. Photo-Voltaic (PV) monitoring system, performance analysis and power prediction models in Doha, Qatar. In Renewable Energy; IntechOpen: London, UK, 2020. [Google Scholar]

- Wellesley, L. How Qatar’s Food System Has Adapted to the Blockade. Available online: https://www.chathamhouse.org/expert/comment/how-qatar-s-food-system-has-adapted-blockade (accessed on 5 July 2020).

- Qatar-Agricultural Land (% of Land Area). Available online: https://www.indexmundi.com/facts/qatar/indicator/AG.LND.AGRI.ZS (accessed on 5 July 2020).

- Ataullah, S. New Farm Projects to Raise Self-Sufficiency in Vegetables. Available online: https://thepeninsulaqatar.com/article/16/02/2019/New-farm-projects-to-raise-self-sufficiency-in-vegetables?__cf_chl_captcha_tk__=e0c66d3b892848125f0796025c153001022636c2-1598343477-0-AW5ZoI2fkykJ--WiNCGMg3RHrO1NM1igfEWNQ0SXKNpaT7O8ndt8AWoqJj_bIThdatHPcST1_7aTMD2vr5OuGamQbgoVAGrwET5TMT7_NBq6xsSrww0eWF-YalWiqWx_adGjZ40jIGk3gh4lKFB7UKeyAkG5m-yS1VPHLMLl3wGLLitEngc2BmCXmTF1OjQNcsSrrBhDkqgA9ixew3spqklsFPoGvIkS78KKoXmi8x6Bk93BoU13neK3YjVFIPrRDvzohcbEcFLiPPSh5QHb4LQciI2SYKdl1QJSlPFG5Z4Y2TzKjstM775xBCVtvKe-IoCKespQxsm-ZJibgzMLAs1_4bioA2xpJ2tcyEPTxX8dcBHLbEHkbHxxl9A8UvfHNmGJsylzJF5y4_3zXAZIUWPYfeTGlWheL7dE3a7Z-7i_XpgYwODkCTkfyOsnKHTL5CM8toOs9LvShZN2YFddhsLoBWKPvJjx2t9QADxZDcmn7dn6RY9yXDrRLNv6v4gyIay5kT41f6OGzsU1OVkBeo3H3IX-82KmrjOzOy-zg3sNN_TdTuj7nCP8vgc9LcxH9sjri9BP-fZCBjKtFyrL2V4 (accessed on 5 July 2020).

- Maldonado, A.I.L.; Reyes, J.M.M.; Breceda, H.F.; Fuentes, H.R.; Contreras, J.A.V.; Maldonado, U.L. Automation and robotics used in hydroponic system. In Hydrocultural and Hydroponics Systems; IntechOpen: London, UK, 2019. [Google Scholar]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern plant cultivation technologies in agriculture under controlled environment: A review on aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Lakhiar, I.A.; Jianmin, G.; Syed, T.N.; Chandio, F.A.; Buttar, N.A.; Qureshi, W.A. Monitoring and control systems in agriculture using intelligent sensor techniques: A review of the aeroponic system. J. Sens. 2018, 2018. [Google Scholar] [CrossRef]

- Rius-Ruiz, F.X.; Andrade, F.J.; Riu, J.; Rius, F.X. Computer-operated analytical platform for the determination of nutrients in hydroponic systems. Food Chem. 2014, 147, 92–97. [Google Scholar] [CrossRef]

- Ibayashi, H.; Kaneda, Y.; Imahara, J.; Oishi, N.; Kuroda, M.; Mineno, H. A reliable wireless control system for tomato hydroponics. Sensors 2016, 16, 644. [Google Scholar] [CrossRef]

- Montoya, A.; Obando, F.; Morales, J.; Vargas, G. Automatic aeroponic irrigation system based on Arduino’s platform. In Proceedings of the Journal of Physics: Conference Series, Medelin, Colombia, 26–30 September 2016; p. 1. [Google Scholar]

- Eridani, D.; Wardhani, O.; Widianto, E.D. Designing and implementing the arduino-based nutrition feeding automation system of a prototype scaled nutrient film technique (NFT) hydroponics using total dissolved solids (TDS) sensor. In Proceedings of the 2017 4th International Conference on Information Technology, Computer, and Electrical Engineering (ICITACEE), Semarang, Indonesia, 18–19 October 2017; pp. 170–175. [Google Scholar]

- Ruengittinun, S.; Phongsamsuan, S.; Sureeratanakorn, P. Applied internet of thing for smart hydroponic farming ecosystem (HFE). In Proceedings of the 2017 10th International Conference on Ubi-media Computing and Workshops (Ubi-Media), Pattaya, Thailand, 1–4 August 2017; pp. 1–4. [Google Scholar]

- Palande, V.; Zaheer, A.; George, K. Fully automated hydroponic system for indoor plant growth. Procedia Comput. Sci. 2018, 129, 482–488. [Google Scholar] [CrossRef]

- Sirawattanakul, S. Smart Vertical Farm System (SVFS); The International Student Science Fair 2018: Aurora, IL, USA, 2018. [Google Scholar]

- Tagle, S.; Benoza, H.; Pena, R.; Oblea, A. Development of an indoor hydroponic tower for urban farming. In Proceedings of the 6th DLSU International Conference on Innovation and Technology Fair, Manila, Philippines, 22–23 November 2018; pp. 1–7. [Google Scholar]

- Cambra, C.; Sendra, S.; Lloret, J.; Lacuesta, R. Smart system for bicarbonate control in irrigation for hydroponic precision farming. Sensors 2018, 18, 1333. [Google Scholar] [CrossRef] [PubMed]

- Marques, G.; Aleixo, D.; Pitarma, R. Enhanced hydroponic agriculture environmental monitoring: An internet of things approach. In Proceedings of the International Conference on Computational Science, Faro, Portugal, 12–14 June 2019; pp. 658–669. [Google Scholar]

- Ruscio, F.; Paoletti, P.; Thomas, J.; Myers, P.; Fichera, S. Low-cost monitoring system for hydroponic urban vertical farms. Int. J. Agric. Biosyst. Eng. 2019, 13, 267–271. [Google Scholar]

- Van, L.-D.; Lin, Y.-B.; Wu, T.-H.; Lin, Y.-W.; Peng, S.-R.; Kao, L.-H.; Chang, C.-H. PlantTalk: A smartphone-based intelligent hydroponic plant box. Sensors 2019, 19, 1763. [Google Scholar] [CrossRef] [PubMed]

- Alipio, M.I.; Cruz, A.E.M.D.; Doria, J.D.A.; Fruto, R.M.S. On the design of Nutrient Film Technique hydroponics farm for smart agriculture. Eng. Agric. Environ. Food 2019, 12, 315–324. [Google Scholar] [CrossRef]

- Alipio, M.I.; Cruz, A.E.M.D.; Doria, J.D.A.; Fruto, R.M.S. A smart hydroponics farming system using exact inference in Bayesian network. In Proceedings of the 2017 IEEE 6th Global Conference on Consumer Electronics (GCCE), Osaka, Japan, 15–18 October 2019; pp. 1–5. [Google Scholar]

- Ferentinos, K.; Albright, L. Predictive neural network modeling of pH and electrical conductivity in deep-trough hydroponics. Trans. ASAE 2002, 45, 2007. [Google Scholar] [CrossRef]

- Khudoyberdiev, A.; Ahmad, S.; Ullah, I.; Kim, D. An optimization scheme based on fuzzy logic control for efficient energy consumption in hydroponics environment. Energies 2020, 13, 289. [Google Scholar] [CrossRef]

- Shaout, A.; Scott, S.G. IoT fuzzy logic aquaponics monitoring and control hardware real-time system. In Proceedings of the International Arab Conference on Information Technology, Yassmine Hammamet, Tunisia, 22–24 December 2017. [Google Scholar]

- Herman, H.; Adidrana, D.; Surantha, N.; Suharjito, S. Hydroponic nutrient control system based on internet of things. CommIT J. 2019, 13, 105–111. [Google Scholar] [CrossRef][Green Version]

- Abusin, S.A.; Mandikiana, B.W. Towards sustainable food production systems in Qatar: Assessment of the viability of aquaponics. Glob. Food Secur. 2020, 25, 100349. [Google Scholar] [CrossRef]

- Mahaidayu, M.G.; Nursyahid, A.; Setyawan, T.A.; Hasan, A. Nutrient Film Technique (NFT) hydroponic monitoring system based on wireless sensor network. In Proceedings of the 2017 IEEE International Conference on Communication, Networks and Satellite (Comnetsat), Jawa Tengah, Indonesia, 5–7 October 2017; pp. 81–84. [Google Scholar]

- Lee, S.; Lee, J. Beneficial bacteria and fungi in hydroponic systems: Types and characteristics of hydroponic food production methods. Sci. Hortic. 2015, 195, 206–215. [Google Scholar] [CrossRef]

- Kerns, S.C.; Lee, J.-L. Automated aeroponics system using IoT for smart farming. In Proceedings of the 8th International Scientific Forum, ISF, UNCP, Pembroke, NC, USA, 7–8 September 2017; pp. 7–8. [Google Scholar]

- We Are Transforming Agriculture. Available online: https://aerofarms.com/ (accessed on 6 July 2020).

- What Grows Here Changes Everything. Available online: https://boweryfarming.com/ (accessed on 6 July 2020).

- Zero Pesticides. Just Picked. Craveable Flavor. Available online: https://www.plenty.ag/ (accessed on 6 July 2020).

- ThingSpeak for IoT Projects. Available online: https://thingspeak.com/ (accessed on 10 July 2020).

- WiFi Module ESP8266 SOC with 802.11 b/g/n and TCP/IP. Available online: https://www.robotgear.com.au/Product.aspx/Details/1028-WiFi-Module-ESP8266-SOC-with-802-11-b-g-n-and-TCP-IP (accessed on 5 July 2020).

- Resh, H.M. Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardener and the Commercial Hydroponic Grower; 9 August 2012; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9781439878675. [Google Scholar]

- Create Your Ecological World. Available online: http://www.koraylight.com/ (accessed on 11 July 2020).

- Brown, J. Nutrient Film Technique in the Hobby Greenhouse. Available online: https://www.cropking.com/blog/nutrient-film-technique-hobby-greenhouse (accessed on 5 July 2020).

- Storey, A. Sizing a Pump for Hydroponics or Aquaponics. Available online: https://university.upstartfarmers.com/blog/sizing-a-pump-hydroponics-aquaponics (accessed on 5 July 2020).

- Sunsun CHJ Series 600-6000L/H Submersible Aquarium Fish Tank Water Pump. Available online: https://www.ebay.com/itm/Sunsun-CHJ-Series-600-6000L-H-Submersible-Aquarium-Fish-Tank-Water-Pump-/164137332544?_trksid=p2385738.m4383.l4275.c10&var=463761153378 (accessed on 5 July 2020).

- Baker, N.R. Photoinhibition of photosynthesis. In Light as an Energy Source and Information Carrier in Plant Physiology; Springer: Cham, Switzerland, 1996; Volume 287, pp. 89–97. [Google Scholar]

- Fernandez, D. Choosing a LED Grow Light for your Hydroponic Crop. Available online: https://scienceinhydroponics.com/2010/05/choosing-a-led-grow-light-for-your-hydroponic-crop.html (accessed on 5 July 2020).

- Raine, R. How Long Should I Leave My Vegetable Seed Starts Under the Grow Light? Available online: https://homeguides.sfgate.com/long-should-leave-vegetable-seed-starts-under-grow-light-100569.html (accessed on 5 July 2020).

- pH Kit. Available online: https://atlas-scientific.com/kits/ph-kit/ (accessed on 12 July 2020).

- Conductivity K 1.0 Kit. Available online: https://atlas-scientific.com/kits/conductivity-k-1-0-kit/ (accessed on 12 July 2020).

- Media pH and EC Effects. Available online: https://gpnmag.com/article/media-ph-and-ec-effects/ (accessed on 5 July 2020).

- Guerra, L. One, Two, or Three-Part Nutrients? Available online: https://fifthseasongardening.com/one-two-or-three-part-nutrients (accessed on 5 July 2020).

- General Hydroponics pH Control Test Kit—GH 8 oz Up Down Adjustment Combo. Available online: https://www.amazon.com/General-Hydroponics-Control-Test-Kit/dp/B07QNDM853 (accessed on 5 July 2020).

- Basic EZO™ Inline Voltage Isolator. Available online: https://atlas-scientific.com/ezo-accessories/basic-ezo-inline-voltage-isolator/ (accessed on 5 July 2020).

- Dejan. Arduino and DS3231 Real Time Clock Tutorial. Available online: https://howtomechatronics.com/tutorials/arduino/arduino-ds3231-real-time-clock-tutorial/ (accessed on 5 July 2020).

- How to Grow Hydroponics: Temperature & Humidity. Available online: https://www.hydroponics-simplified.com/how-to-grow-hydroponics.html (accessed on 5 July 2020).

- What is the Right Humidity for Growing Plants Indoors? Available online: https://www.saferbrand.com/articles/humidity-hydroponics (accessed on 5 July 2020).

- Raj, A. Automatic AC Temperature Controller Using Arduino, DHT11 and IR Blaster. Available online: https://circuitdigest.com/microcontroller-projects/arduino-automatic-ac-temperature-control (accessed on 5 July 2020).

- Rouse, M. Internet of Things (IoT). Available online: https://internetofthingsagenda.techtarget.com/definition/Internet-of-Things-IoT (accessed on 5 July 2020).

- Al-Azba, M.; Cen, Z.; Remond, Y.; Ahzi, S. An optimal air-conditioner on-off control scheme under extremely hot weather conditions. Energies 2020, 13, 1021. [Google Scholar] [CrossRef]

- Saffouri, F.; Bayram, I.S.; Koç, M. Quantifying the cost of cooling in qatar. In Proceedings of the 2017 9th IEEE-GCC Conference and Exhibition (GCCCE), Manama, Bahrain, 8–11 May 2017; pp. 1–9. [Google Scholar]

- Alrawi, O.; Bayram, I.S.; Al-Ghamdi, S.G.; Koc, M. High-resolution household load profiling and evaluation of rooftop pv systems in selected houses in qatar. Energies 2019, 12, 3876. [Google Scholar] [CrossRef]

- Kameoka, T.; Kondo, H.; Isozaki, M.; Nakamura, T.; Kitamura, H.; Kimura, J. Environmental measurement for indoor plant factory with micro-miniature size wireless sensor. In Proceedings of the SICE Annual Conference 2011, Waseda University, Tokyo, Japan, 13–18 September 2011; pp. 2811–2816. [Google Scholar]

- Ijaz, F.; Siddiqui, A.A.; Im, B.K.; Lee, C. Remote management and control system for LED based plant factory using ZigBee and Internet. In Proceedings of the 2012 14th International Conference on Advanced Communication Technology (ICACT), Phoenix Park, PyeongChang, Korea, 19–22 February 2012; pp. 942–946. [Google Scholar]

- Sugano, M. Elemental technologies for realizing a fully-controlled artificial light-type plant factory. In Proceedings of the 2015 12th International Conference & Expo on Emerging Technologies for a Smarter World (CEWIT), Melville, NY, USA, 19–20 October 2015; pp. 1–5. [Google Scholar]

- AeroGarden. Available online: https://www.aerogarden.com/harvest-360.html (accessed on 18 July 2020).

- FarmBot. Available online: https://farm.bot/ (accessed on 18 July 2020).

- Ecoslider. Available online: https://ecoslider.com/en/info/greenhouses-prices-models (accessed on 10 July 2020).

- Sheikh, B. Hydroponics: Key to sustain agriculture in water stressed and urban environment. Pak. J. Agric. Agril. Eng. Vet. Sci. 2006, 22, 53–57. [Google Scholar]

- Jones, J.B., Jr. Hydroponics: A Practical Guide for the Soilless Grower; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- AlShrouf, A. Hydroponics, aeroponic and aquaponic as compared with conventional farming. Am. Sci. Res. J. Eng. Technol. Sci. 2017, 27, 247–255. [Google Scholar]

- Bradley, P.; Marulanda, C. Simplified hydroponics to reduce global hunger. In Proceedings of the World Congress on Soilless Culture: Agriculture in the Coming Millennium, Ma’ale Hachamisha, Israel, 14–18 May 2000; pp. 289–296. [Google Scholar]

- Licamele, J.D. Biomass Production and Nutrient Dynamics in An Aquaponics System; The University of Arizona: Tuscon, AZ, USA, 2009. [Google Scholar]

- Steiner, A.A. Soilless culture. In Proceedings of the Sixth Colloquium on International Potash Institute; International Potash Insitute, Ed.; Wageningen University, Plant Physiological Research Centre: Wageningen, The Netherlands, 1968; pp. 324–341. [Google Scholar]

- Sardare, M.D.; Admane, S.V. A review on plant without soil-hydroponics. Int. J. Res. Eng. Technol. 2013, 2, 299–304. [Google Scholar]

- Þórarinsdóttir, R.I.; Kledal, P.R.; Skar, S.L.G.; Sustaeta, F.; Ragnarsdóttir, K.V.; Mankasingh, U.; Pantanella, E.; Ven, R.v.d.; Shultz, C. Aquaponics Guidelines. Available online: https://skemman.is/bitstream/1946/23343/1/Guidelines_Aquaponics_20151112.pdf (accessed on 5 July 2020).

- Nagayo, A.; Jamisola, R. Cloud-based wireless monitoring system and control of a smart solarpowered aquaponics greenhouse to promote sustainable agriculture and fishery in an arid region. In Proceedings of the BIUST Research and Innovation Forum 2017, Palapye, Botswana, 12–14 June 2017; pp. 144–151. [Google Scholar]

- Gonda, L.; Cugnasca, C.E. A proposal of greenhouse control using wireless sensor networks. In Proceedings of the Computers in Agriculture and Natural Resources, Orlando, FL, USA, 23–25 July 2006; p. 229. [Google Scholar]

| Modules | Voltage (V) | Current (A) | Power (W) | Power Consumption (kWh) per Month |

|---|---|---|---|---|

| pH sensor | 5 V DC | 0.0915 | 0.06588 | |

| EC sensor | 5 V DC | 0.25 | 0.18 | |

| Water pump (Nutrient) | 240 V AC | 0.033 | 7.92 | 5.7 |

| * 2 LED (6K3R4) | 240 V AC | 162.72 | 78.11 | |

| * 1 LED (K6) | 240 V AC | 0.311 | 74.64 | 35.83 |

| Water flow sensor | 5 V DC | 0.075 | 0.054 | |

| Water level sensor | 12 V DC | 0.05 | 0.6 | 0.432 |

| ** Water pump (Fresh water) | 12 V DC | 0.7 | 8.4 | Negligible |

| Humidity and temperature sensor | 5 V DC | 0.0054 | ||

| Relay | 5 V DC | 0.3 | 0.216 | |

| Total monthly power consumption (kWh) | 120.59 | |||

| Similar Work or Commercial Solution | Small (S) or Large (L) Scale | Soil(S) or Hydroponic(H) | IoT Solution | Light Monitoring (Yes/No) | Temperature Monitoring (M) and Control(C) | pH Monitoring (M) and Control(C) | Price Information | Power Consumption |

|---|---|---|---|---|---|---|---|---|

| KOMEOKA ET AL. [66] | L | S | No | Yes | M & C | None | ** ~1000$ | Not specified |

| IJAZ ET AL. [67] | L | H | No | Yes | M & C | None | ** ~1000$ | Not specified |

| SUGANO ET AL. [68] | L | H | No | Yes | M & C | C | ** ~1000$ | Not specified |

| AEROGAR-DEN [69] | S | H | Yes | Yes | None | None | ~100$ | Not specified |

| PLANTTALK [28] | S | H but not vertical | Yes | Yes | M & C | M & C | Not specified | Not specified |

| FARMBOT [70] | S | S | Yes | No | None | C | ~1000$ | Not available |

| * PROPOSED SOLUTION | S | H | Yes | Yes | M & C | M & C | ~400$ | Available |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, M.E.H.; Khandakar, A.; Ahmed, S.; Al-Khuzaei, F.; Hamdalla, J.; Haque, F.; Reaz, M.B.I.; Al Shafei, A.; Al-Emadi, N. Design, Construction and Testing of IoT Based Automated Indoor Vertical Hydroponics Farming Test-Bed in Qatar. Sensors 2020, 20, 5637. https://doi.org/10.3390/s20195637

Chowdhury MEH, Khandakar A, Ahmed S, Al-Khuzaei F, Hamdalla J, Haque F, Reaz MBI, Al Shafei A, Al-Emadi N. Design, Construction and Testing of IoT Based Automated Indoor Vertical Hydroponics Farming Test-Bed in Qatar. Sensors. 2020; 20(19):5637. https://doi.org/10.3390/s20195637

Chicago/Turabian StyleChowdhury, Muhammad E. H., Amith Khandakar, Saba Ahmed, Fatima Al-Khuzaei, Jalaa Hamdalla, Fahmida Haque, Mamun Bin Ibne Reaz, Ahmed Al Shafei, and Nasser Al-Emadi. 2020. "Design, Construction and Testing of IoT Based Automated Indoor Vertical Hydroponics Farming Test-Bed in Qatar" Sensors 20, no. 19: 5637. https://doi.org/10.3390/s20195637

APA StyleChowdhury, M. E. H., Khandakar, A., Ahmed, S., Al-Khuzaei, F., Hamdalla, J., Haque, F., Reaz, M. B. I., Al Shafei, A., & Al-Emadi, N. (2020). Design, Construction and Testing of IoT Based Automated Indoor Vertical Hydroponics Farming Test-Bed in Qatar. Sensors, 20(19), 5637. https://doi.org/10.3390/s20195637