Deep Quality Assessment of a Solar Reflector Based on Synthetic Data: Detecting Surficial Defects from Manufacturing and Use Phase

Abstract

1. Introduction

2. State of the Art

3. Approach

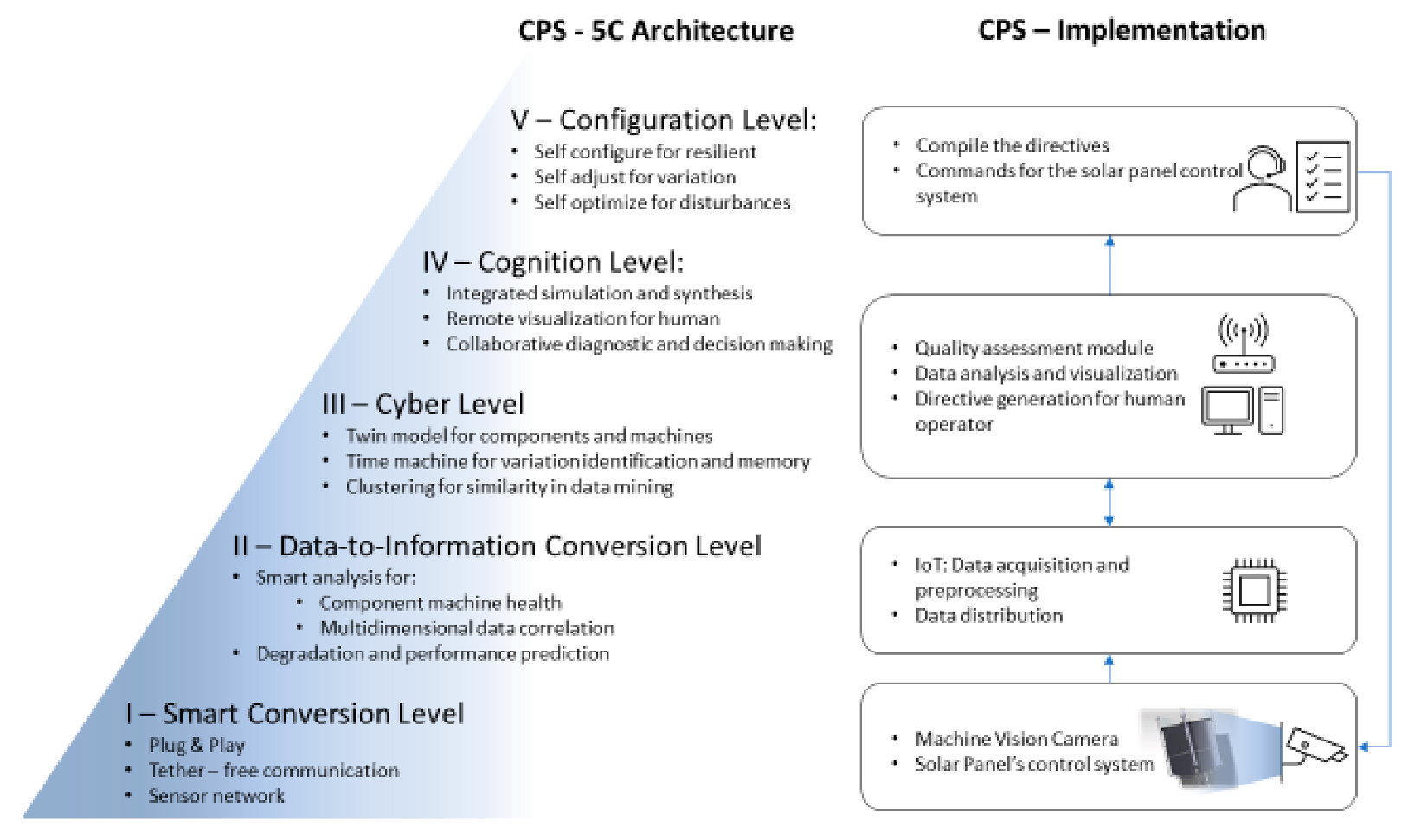

3.1. Quality Control System Design Approach Based On 5C Architecture

3.2. Acceleration of the Quality Assessment Algorithm’s Development

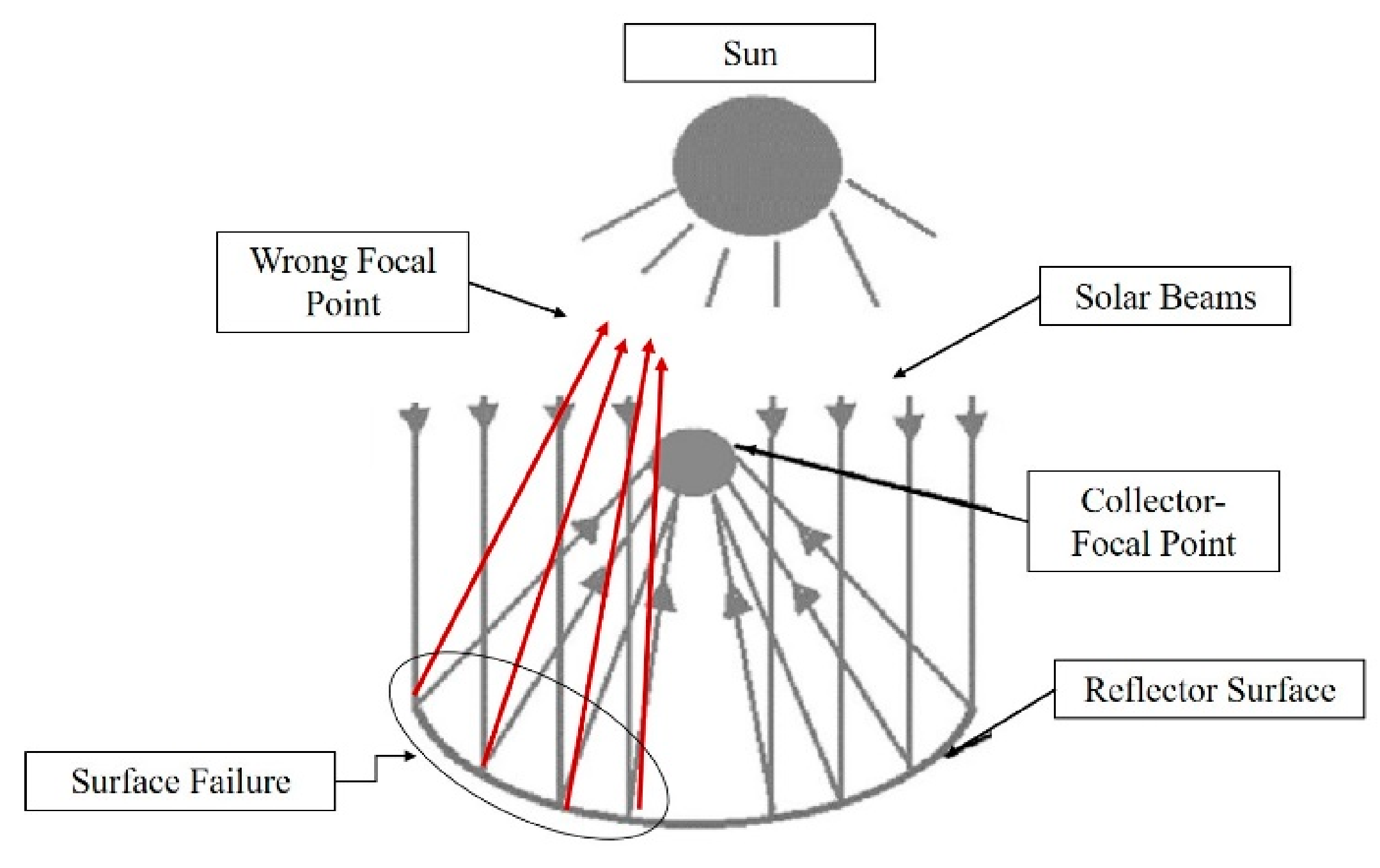

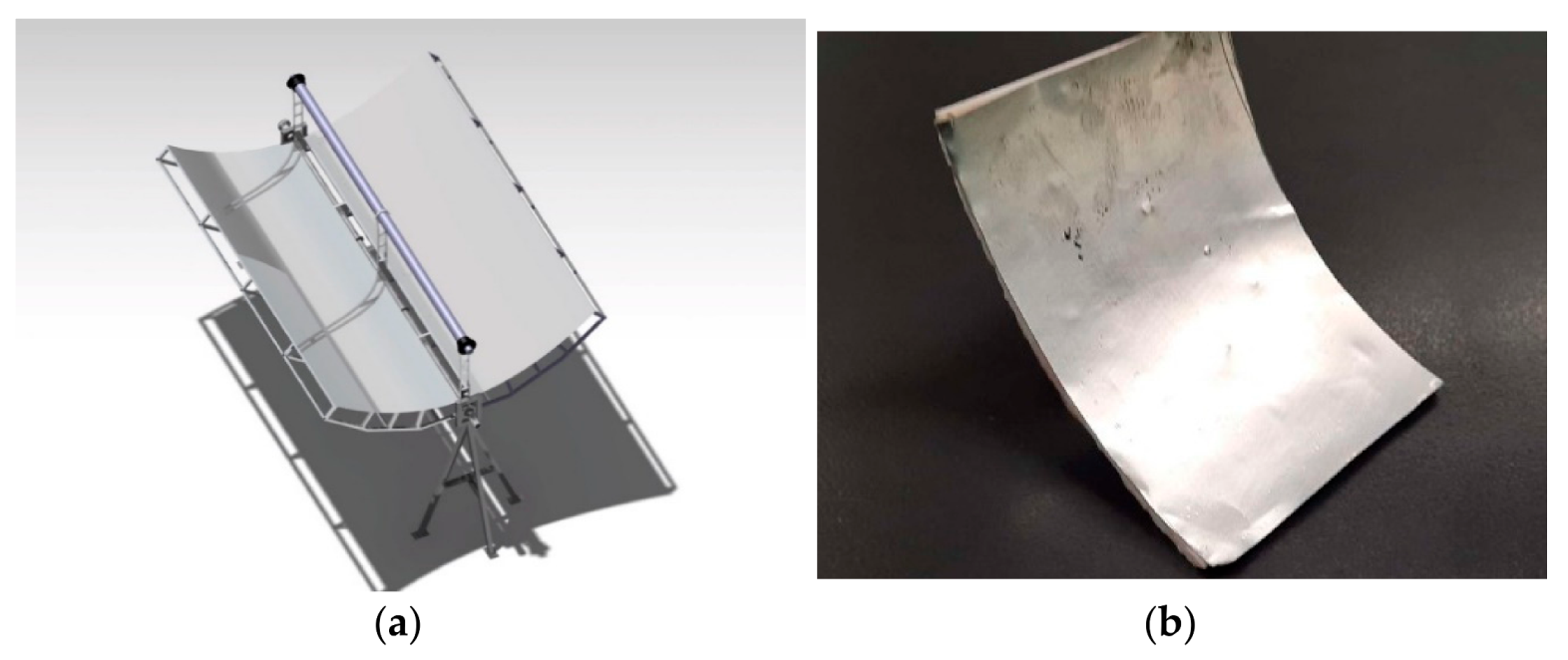

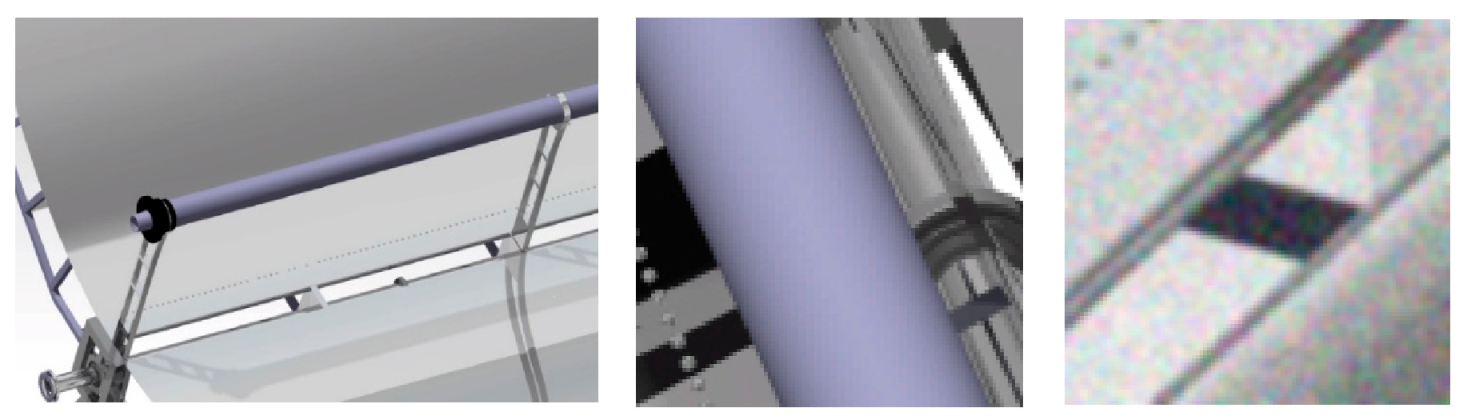

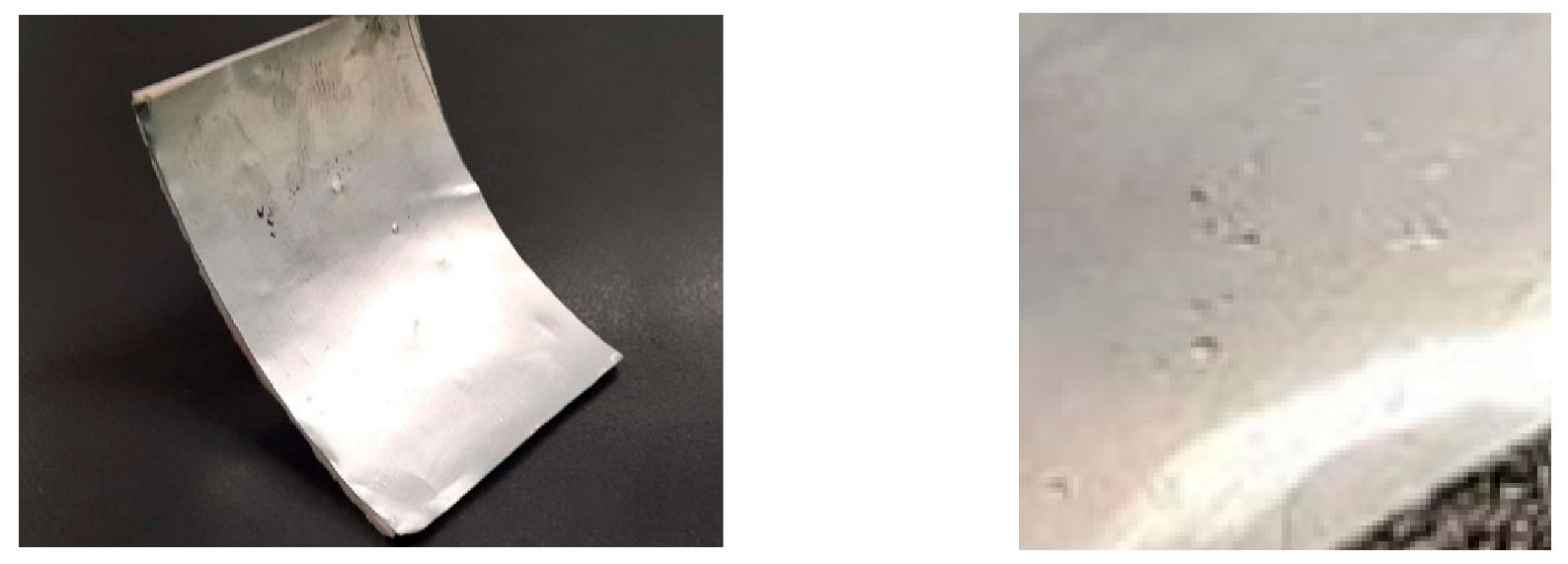

3.3. Case Study & Experimental Setup

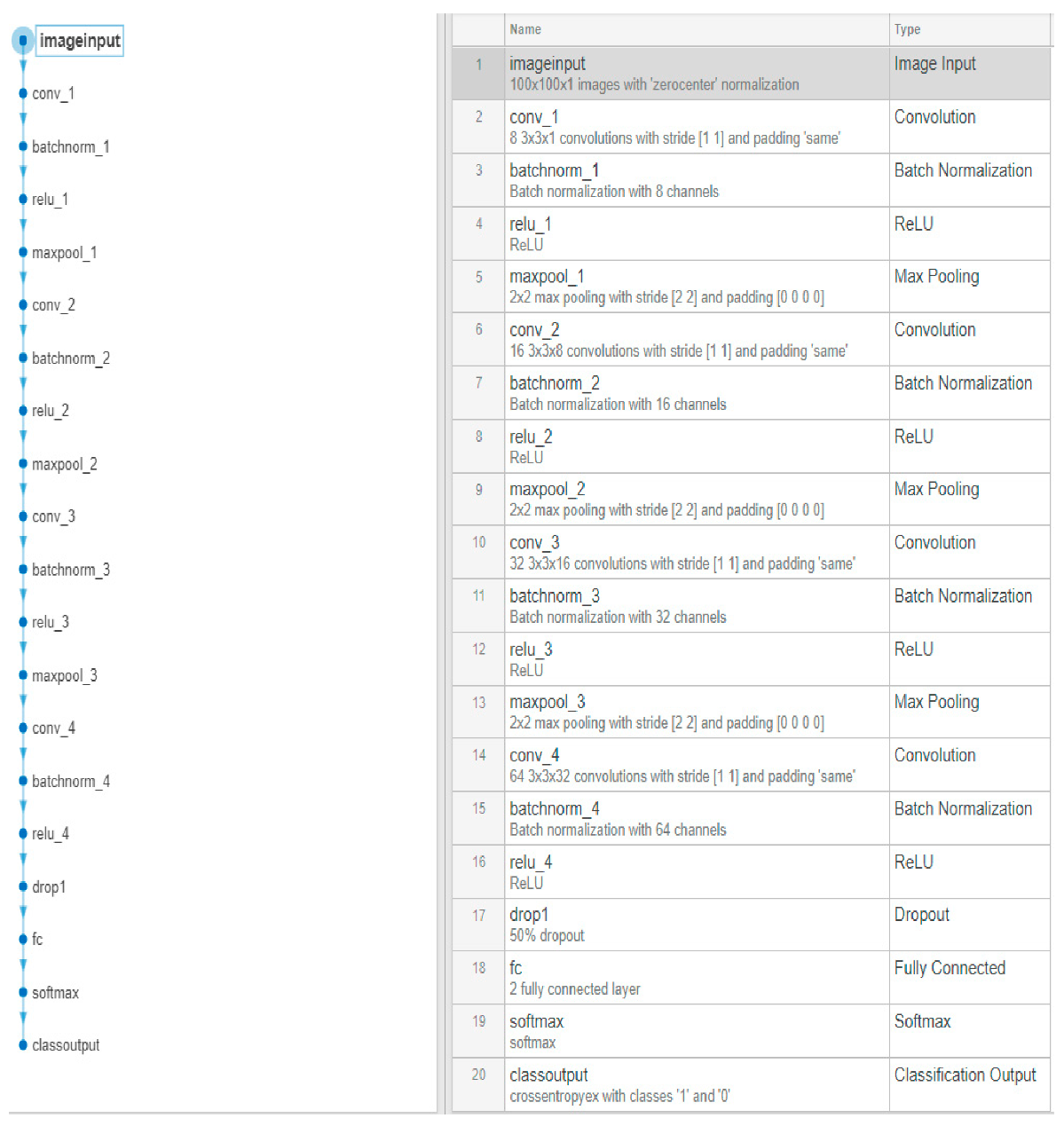

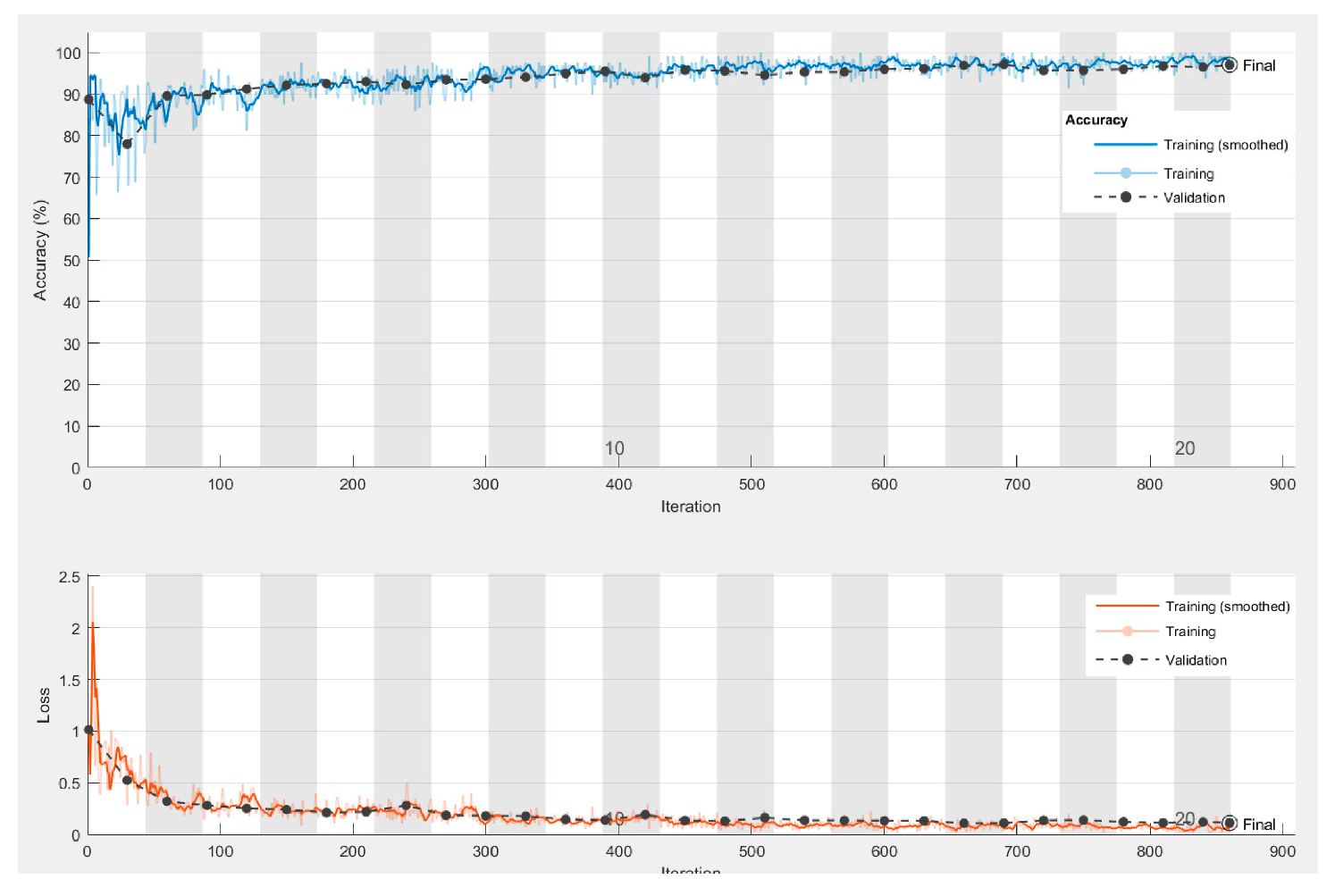

3.4. Model Selection

3.5. Model Development Utilizing a Synthetic Dataset

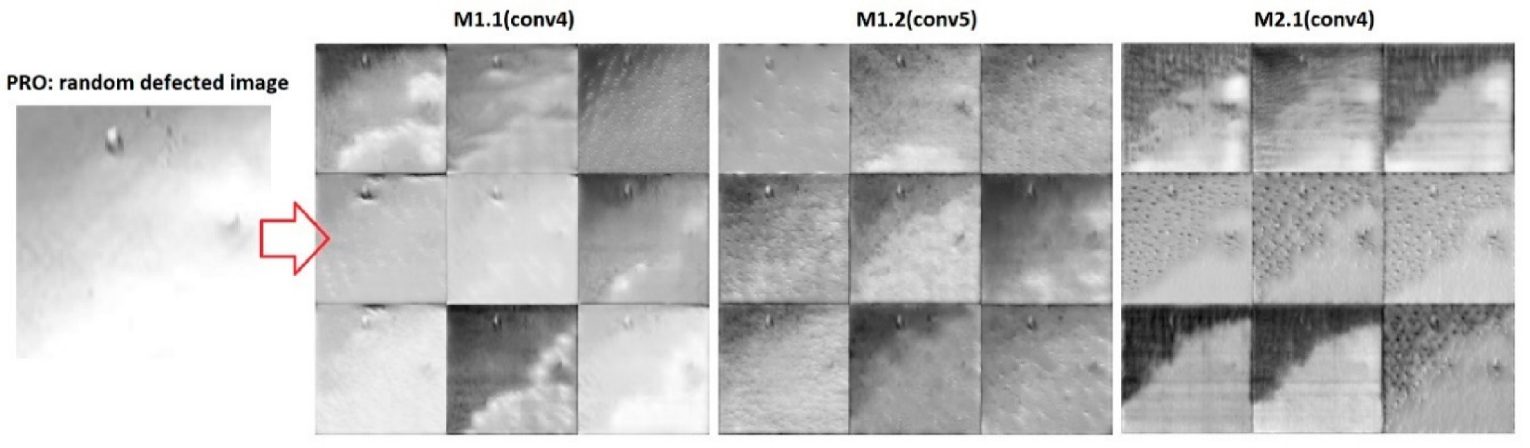

3.6. Transfer Learning Using the Trained CNN

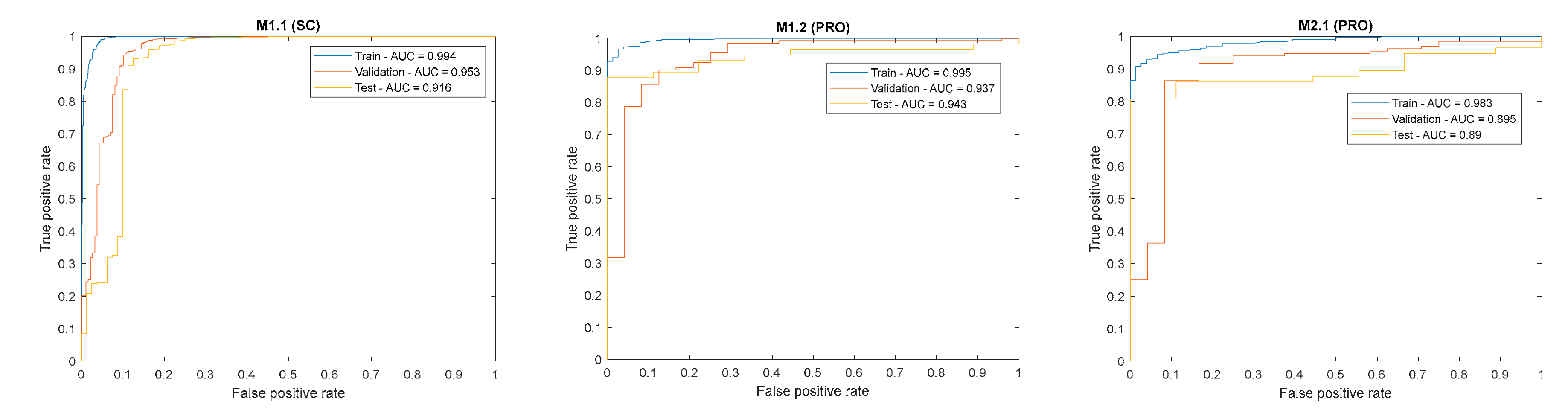

4. Results

5. Conclusions and Future Outlooks

Author Contributions

Funding

|

Conflicts of Interest

References

- Rajala, R.; Westerlund, M.; Lampikoski, T. Environmental sustainability in industrial manufacturing: Re-examining the greening of Interface’s business model. J. Clean. Prod. 2016, 115, 52–61. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Alexopoulos, H.; Papacharalampopoulos, A.; Mourtzis, D. Automotive weather strip manufacturing: Process modeling and extrudate dimensional accuracy evaluation. Procedia CIRP 2018, 72, 375–380. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Nandini, V.; Vishal, R.D.; Prakash, C.A.; Aishwarya, S. A Review on Applications of Machine Vision Systems in Industries. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Prakash, A. Vision Algorithm for Seam Tracking in automatic Welding System. Int. J. Recent Adv. Mech. Eng. 2015, 4, 125–131. [Google Scholar] [CrossRef]

- Derbel, N.; Ghommam, J.; Zhu, Q. Diagnosis, Fault Detection & Tolerant Control; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Davies, E. Machine vision in the food industry. In Robotics and Automation in the Food Industry; Elsevier: Amsterdam, The Netherlands, 2013; pp. 75–110. [Google Scholar]

- Chen, T.Q.; Zhang, J.; Zhou, Y.; Murphey, Y.L. A Smart Machine Vision System for PCB Inspection. Comput. Vis. 2001, 2070, 513–518. [Google Scholar]

- Zhang, X.W.; Ding, Y.Q.; Lv, Y.; Shi, A.; Liang, R. A vision inspection system for the surface defects of strongly reflected metal based on multi-class SVM. Expert Syst. Appl. 2011, 36, 5930–5939. [Google Scholar]

- Di Leo, G.; Liguori, C.; Pietrosanto, A.; Sommella, P. A vision system for the online quality monitoring of industrial manufacturing. Opt. Lasers Eng. 2017, 89, 162–168. [Google Scholar] [CrossRef]

- Chang, M.; Chen, B.-C.; Gabayno, J.L.; Chen, M.-F. Development of an optical inspection platform for surface defect detection in touch panel glass. Int. J. Optomechatronics 2016, 10, 63–72. [Google Scholar] [CrossRef]

- Çelik, H.I.; Dülger, L.; Topalbekiroğlu, M. Development of a machine vision system: Real-time fabric defect detection and classification with neural networks. J. Text. Inst. 2013, 105, 575–585. [Google Scholar] [CrossRef]

- Athanasopoulou, L.; Papacharalampopoulos, A.; Stavropoulos, P. Context awareness system in the use phase of a smart mobility platform: A vision system for a light-weight approach. Procedia CIRP 2020, 88, 560–564. [Google Scholar] [CrossRef]

- Jordan, M.; Kleinberg, J.; Schölkopf, B. Pattern Recognition and Machine Learning; Springer: New York, NY, USA, 2006. [Google Scholar]

- Sun, J.; Wang, P.; Luo, Y.-K.; Li, W. Surface Defects Detection Based on Adaptive Multiscale Image Collection and Convolutional Neural Networks. IEEE Trans. Instrum. Meas. 2019, 68, 4787–4797. [Google Scholar] [CrossRef]

- Lin, W.-Y.; Lin, C.-Y.; Chen, G.-S.; Hsu, C.-Y. Steel Surface Defects Detection Based on Deep Learning. In Advances in Intelligent Systems and Computing; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2018; Volume 789, pp. 141–149. [Google Scholar]

- Lee, J.; Bagheri, B.; Kao, H.-A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Vogel-Heuser, B.; Lee, J.; Leitão, P. Agents enabling cyber-physical production systems. At-Automatisierungstechnik 2015, 63, 777–789. [Google Scholar] [CrossRef]

- Han, D.; Liu, Q.; Fan, W. A new image classification method using CNN transfer learning and web data augmentation. Expert Syst. Appl. 2018, 95, 43–56. [Google Scholar] [CrossRef]

- Seshadrinathan, K.; Pappas, T.N.; Safranek, R.J.; Chen, J.; Wang, Z.; Sheikh, H.R.; Bovik, A.C. The Essential Guide to Image Processing; Academic Press: Cambridge, MA, USA, 2009; pp. 553–595. [Google Scholar]

- Khalid, S.; Khalil, T.; Nasreen, S. A survey of feature selection and feature extraction techniques in machine learning. In Proceedings of the 2014 Science and Information Conference, London, UK, 27–29 August 2014; pp. 372–378. [Google Scholar]

- Thanki, R.; Borra, S. Application of Machine Learning Algorithms for Classification and Security of Diagnostic Images; Academic Press: Cambridge, MA, USA, 2019; pp. 273–292. [Google Scholar]

- Nawi, N.M.; Atomi, W.H.; Rehman, M. The Effect of Data Pre-processing on Optimized Training of Artificial Neural Networks. Procedia Technol. 2013, 11, 32–39. [Google Scholar] [CrossRef]

- Nazari-Heris, M.; Mohammadi-Ivatloo, B. Application of heuristic algorithms to optimal PMU placement in electric power systems: An updated review. Renew. Sustain. Energy Rev. 2015, 50, 214–228. [Google Scholar] [CrossRef]

- Maunders, C.; Dwyer, C.; Tiemeijer, P.; Etheridge, J. Practical methods for the measurement of spatial coherence—A comparative study. Ultramicroscopy 2011, 111, 1437–1446. [Google Scholar] [CrossRef]

- Lenz, B.; Hasselbruch, H.; Großmann, H.; Mehner, A. Application of CNN networks for an automatic determination of critical loads in scratch tests on a-C:H:W coatings. Surf. Coat. Technol. 2020, 393, 125764. [Google Scholar] [CrossRef]

- Zhu, W.; Ma, Y.; Zhou, Y.; Benton, M.; Romagnoli, J.A. Deep Learning Based Soft Sensor and Its Application on a Pyrolysis Reactor for Compositions Predictions of Gas Phase Components. Comput. Aided Chem. Eng. 2018, 44, 2245–2250. [Google Scholar]

- Rawat, W.; Wang, Z. Deep convolutional neural networks for image classification: A comprehensive review. Neural Comput. 2017, 29, 2352–2449. [Google Scholar] [CrossRef] [PubMed]

- Kumagai, W.; Kanamori, T. Risk bound of transfer learning using parametric feature mapping and its application to sparse coding. Mach. Learn. 2019, 108, 1975–2008. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. In Advances in Neural Information Processing Systems Conference; Association for Computing Machinery (ACM): New York, NY, USA, 2012; pp. 1097–1105. [Google Scholar]

- Abu Mallouh, A.; Qawaqneh, Z.; Barkana, B. Utilizing CNNs and transfer learning of pre-trained models for age range classification from unconstrained face images. Image Vis. Comput. 2019, 88, 41–51. [Google Scholar] [CrossRef]

- Ying, X. An Overview of Overfitting and its Solutions. J. Phys. Conf. Ser. 2019, 1168, 022022. [Google Scholar] [CrossRef]

- Meng, Z.; Fan, X.; Chen, X.; Chen, M.; Tong, Y. Detecting Small Signs from Large Images. In Proceedings of the IEEE International Conference on Information Reuse and Integration (IRI), San Diego, CA, USA, 4–6 August 2017. [Google Scholar]

- Taherisadr, M.; Asnani, P.; Galster, S.; Dehzangi, O. ECG-based driver inattention identification during naturalistic driving using Mel-frequency cepstrum 2-D transform and convolutional neural networks. Smart Health 2018, 50–61. [Google Scholar] [CrossRef]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Tušar, T.; Gantar, K.; Koblar, V.; Ženko, B.; Filipič, B. A study of overfitting in optimization of a manufacturing quality control procedure. Appl. Soft Comput. 2017, 59, 77–87. [Google Scholar] [CrossRef]

- Wang, Z. A Hyperspectral Image Classification Example. In Semi-supervised Hyperspectral Classification using Task-driven Dictionary Learning with Regularization; Academic Press: Cambridge, MA, USA, 2019; pp. 9–29. [Google Scholar]

- Hu, K.; Zhang, Z.; Niu, X.; Zhang, Y.; Cao, C.; Xiao, F.; Gao, X. Retinal vessel segmentation of color fundus images using multiscale convolutional neural network with an improved cross-entropy loss function. Neurocomputing 2018, 309, 179–191. [Google Scholar] [CrossRef]

- Olah, C.; Mordvintsev, A.; Schubert, L. Feature visualization. Distill 2017, 2, e7. [Google Scholar] [CrossRef]

- Saito, T.; Rehmsmeier, M. The Precision-Recall Plot Is More Informative than the ROC Plot When Evaluating Binary Classifiers on Imbalanced Datasets. PLoS ONE 2015, 10, e0118432. [Google Scholar] [CrossRef]

- Davis, J.; Goadrich, M. The relationship between Precision-Recall and ROC curves. In Proceedings of the 23rd International Conference on Machine Learning, Pittsburgh, PA, USA, 25–29 June 2006; pp. 233–240. [Google Scholar]

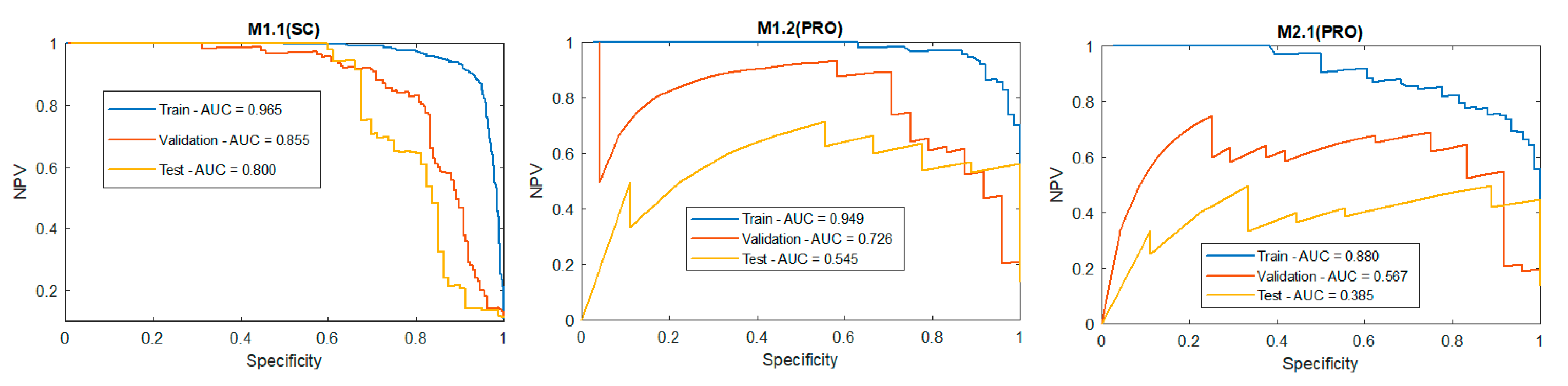

| Model | M1.1 (Trained with the Synthetic Dataset) | M1.2 (Extra Convolutional Layer, Retrained with Prototypes) | M2.1 (Initial Architecture, Trained with Prototypes) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dataset | SC | PRO | PRO | PRO | ||||||

| Partition | Train | Validation | Test | Complete | Train | Validation | Test | Train | Validation | Test |

| Metrics | ||||||||||

| Accuracy | 0.978 | 0.958 | 0.954 | 0.806 | 0.975 | 0.942 | 0.909 | 0.938 | 0.859 | 0.848 |

| Sensitivity | 0.995 | 0.987 | 0.992 | 0.884 | 0.993 | 0.984 | 0.964 | 0.984 | 0.962 | 0.947 |

| Specificity | 0.843 | 0.725 | 0.662 | 0.345 | 0.868 | 0.708 | 0.555 | 0.671 | 0.291 | 0.222 |

| Precision | 0.98 | 0.966 | 0.958 | 0.888 | 0.977 | 0.948 | 0.932 | 0.945 | 0.881 | 0.885 |

| F-Measure | 0.987 | 0.976 | 0.974 | 0.886 | 0.985 | 0.966 | 0.948 | 0.964 | 0.92 | 0.9153 |

| Geometric Mean | 0.916 | 0.846 | 0.810 | 0.552 | 0.928 | 0.835 | 0.732 | 0.812 | 0.5297 | 0.458 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papacharalampopoulos, A.; Tzimanis, K.; Sabatakakis, K.; Stavropoulos, P. Deep Quality Assessment of a Solar Reflector Based on Synthetic Data: Detecting Surficial Defects from Manufacturing and Use Phase. Sensors 2020, 20, 5481. https://doi.org/10.3390/s20195481

Papacharalampopoulos A, Tzimanis K, Sabatakakis K, Stavropoulos P. Deep Quality Assessment of a Solar Reflector Based on Synthetic Data: Detecting Surficial Defects from Manufacturing and Use Phase. Sensors. 2020; 20(19):5481. https://doi.org/10.3390/s20195481

Chicago/Turabian StylePapacharalampopoulos, Alexios, Konstantinos Tzimanis, Kyriakos Sabatakakis, and Panagiotis Stavropoulos. 2020. "Deep Quality Assessment of a Solar Reflector Based on Synthetic Data: Detecting Surficial Defects from Manufacturing and Use Phase" Sensors 20, no. 19: 5481. https://doi.org/10.3390/s20195481

APA StylePapacharalampopoulos, A., Tzimanis, K., Sabatakakis, K., & Stavropoulos, P. (2020). Deep Quality Assessment of a Solar Reflector Based on Synthetic Data: Detecting Surficial Defects from Manufacturing and Use Phase. Sensors, 20(19), 5481. https://doi.org/10.3390/s20195481