Moving Accelerometers to the Tip: Monitoring of Wind Turbine Blade Bending Using 3D Accelerometers and Model-Based Bending Shapes

Abstract

:1. Introduction

1.1. Relevance

1.2. Related Literature

1.3. Approach and Objective

2. Method

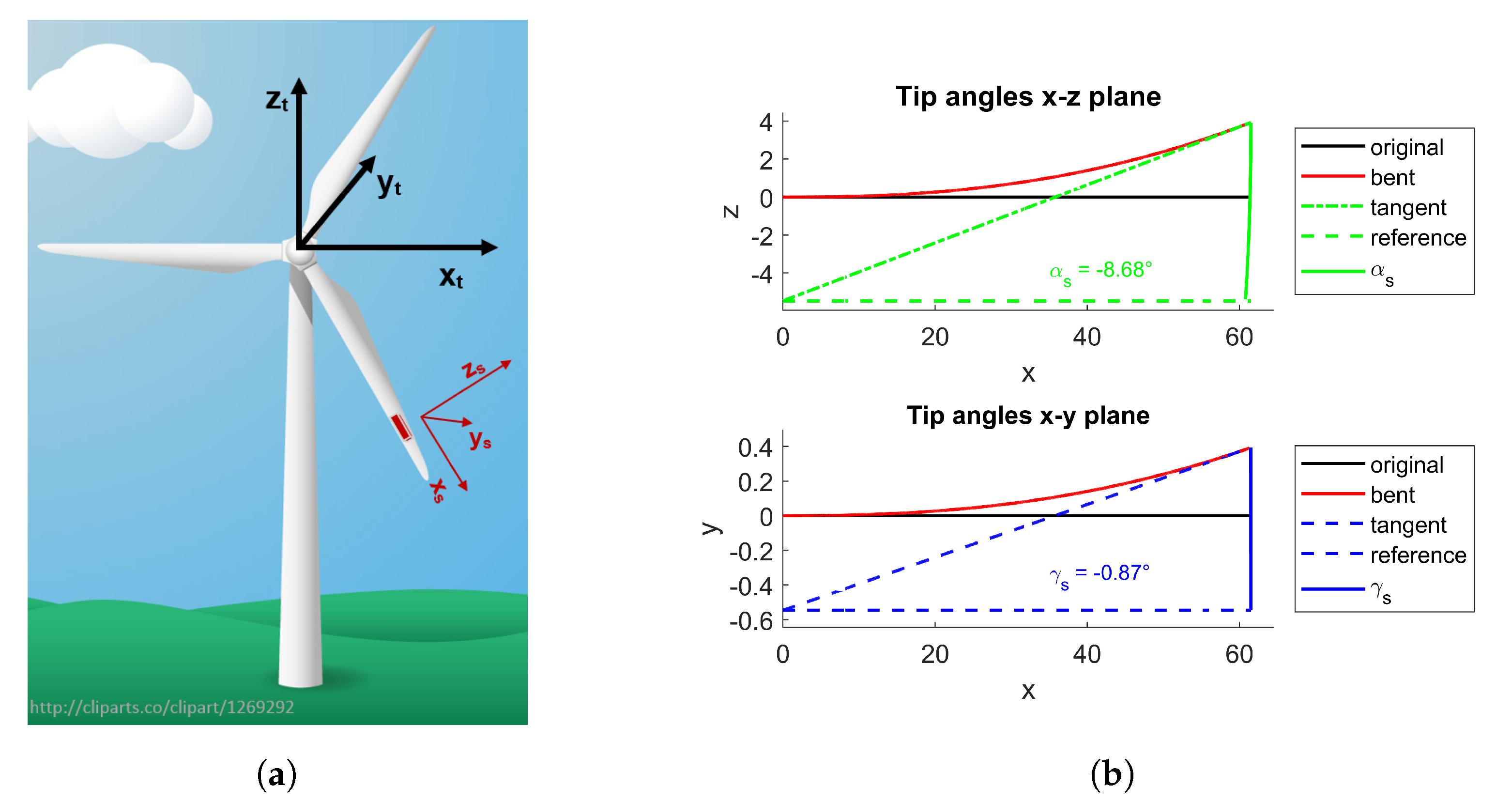

2.1. Model of Acceleration Measurements

- : rotation around the -axis due to rotational movement of the blade.

- : pitch angle of the blade around the -axis.

- : orientation of the blade around the -axis, e.g., due to bending.

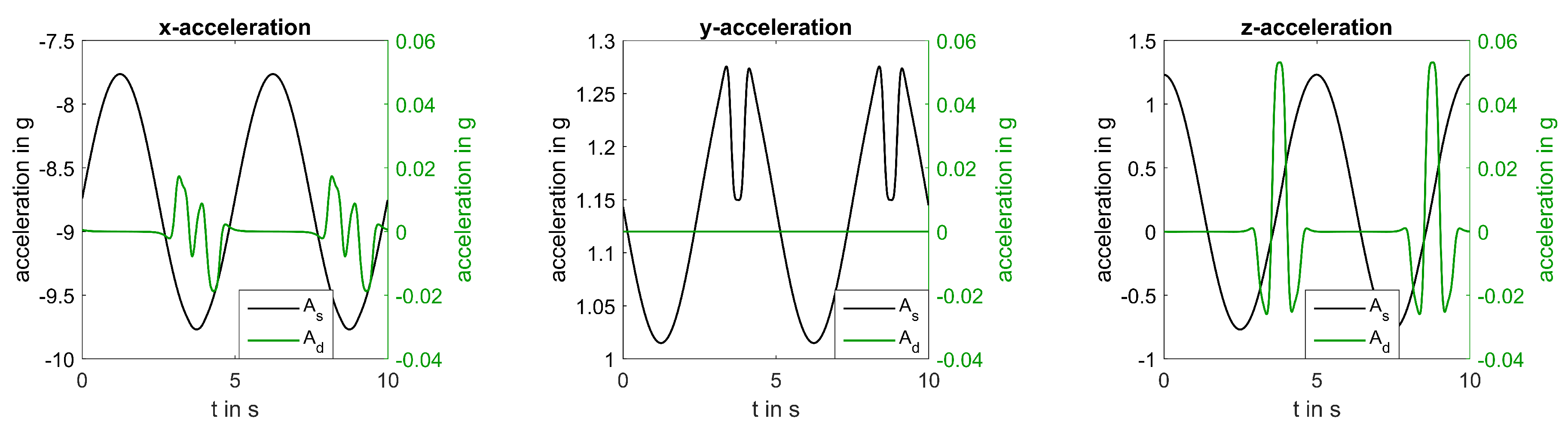

2.1.1. Static Acceleration

2.1.2. Dynamic Acceleration

2.1.3. Overall Model

2.2. Bending Shapes

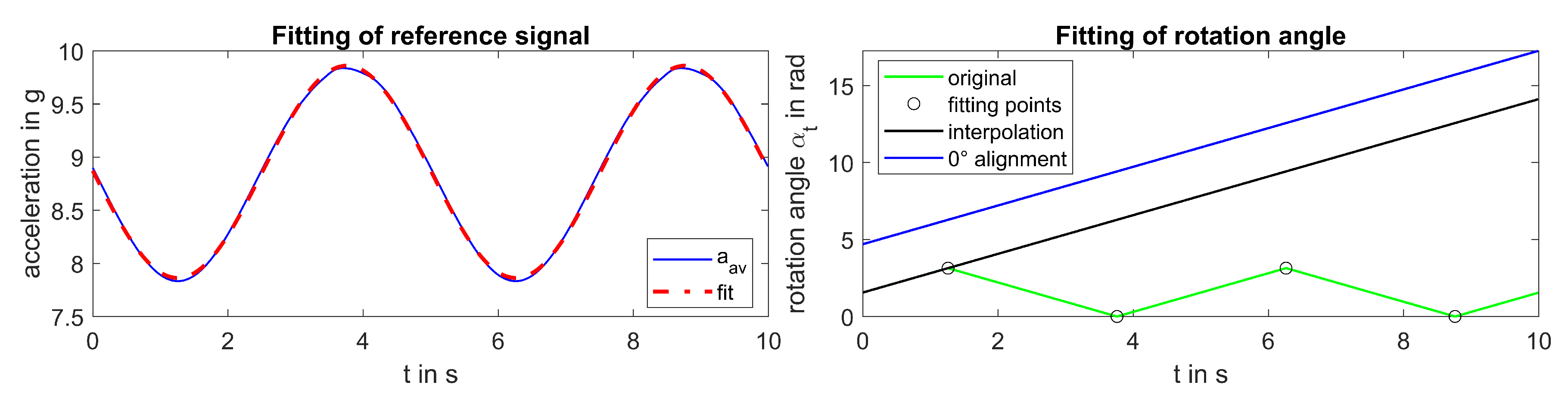

2.2.1. Estimation of the Rotation Angle

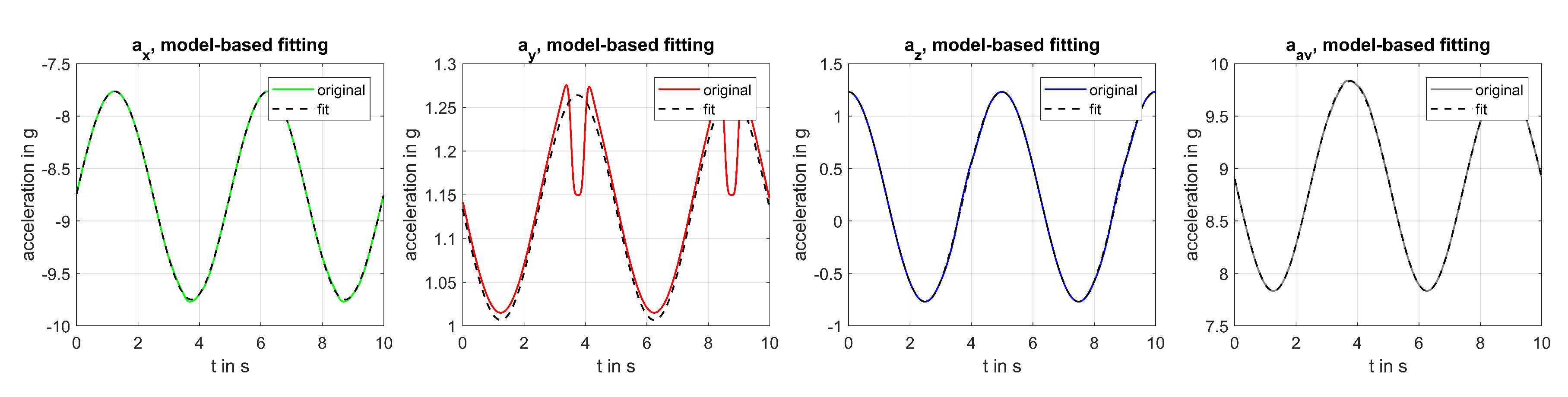

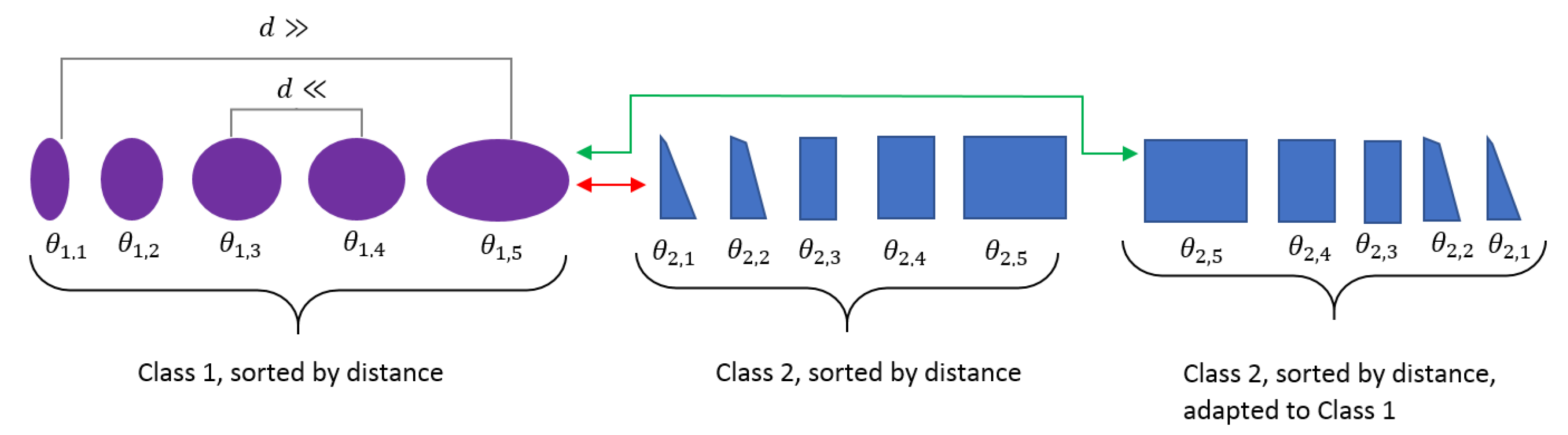

2.2.2. Model Fitting

2.2.3. Shape Computation

2.3. Pattern Recognition and Morphing Circle

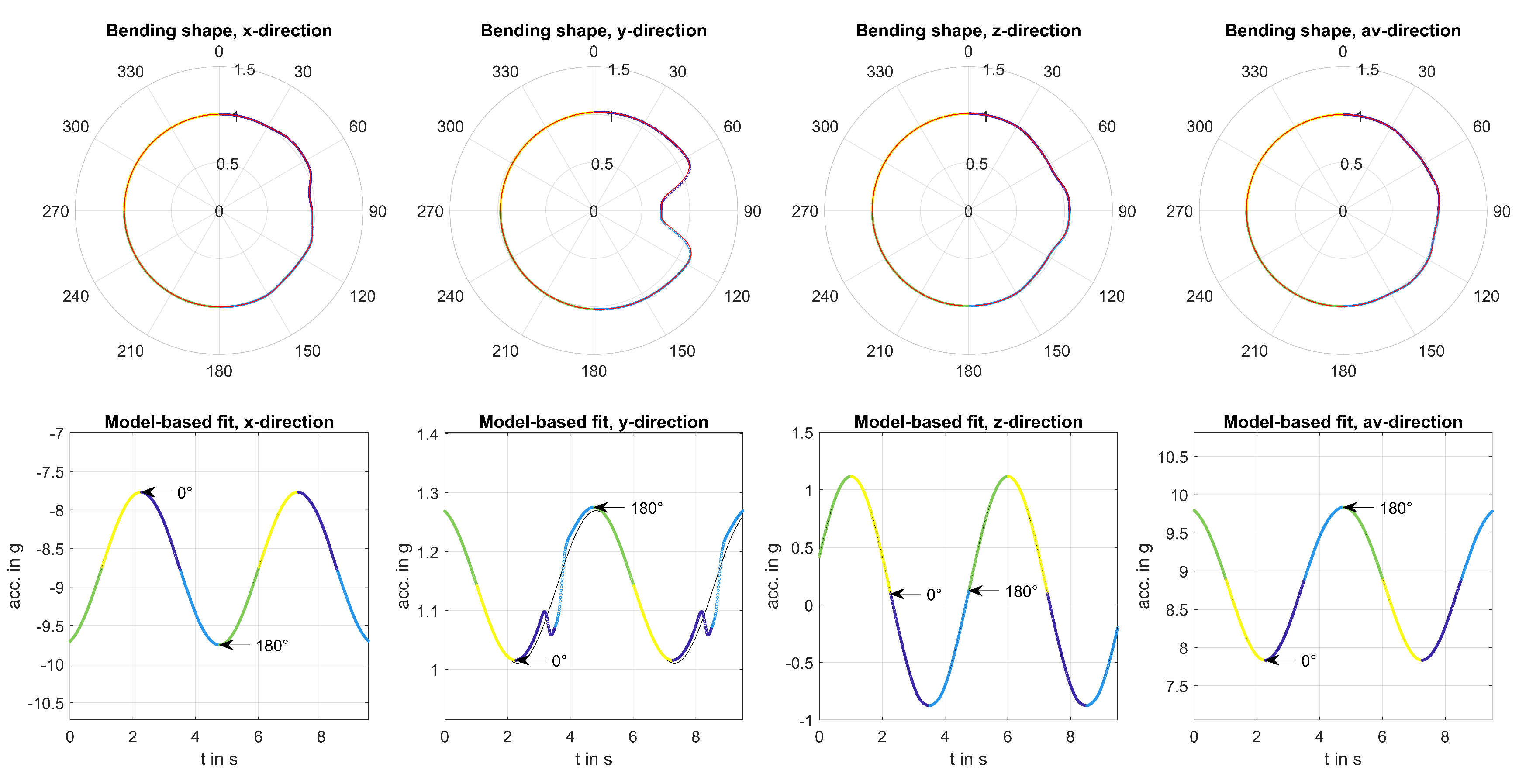

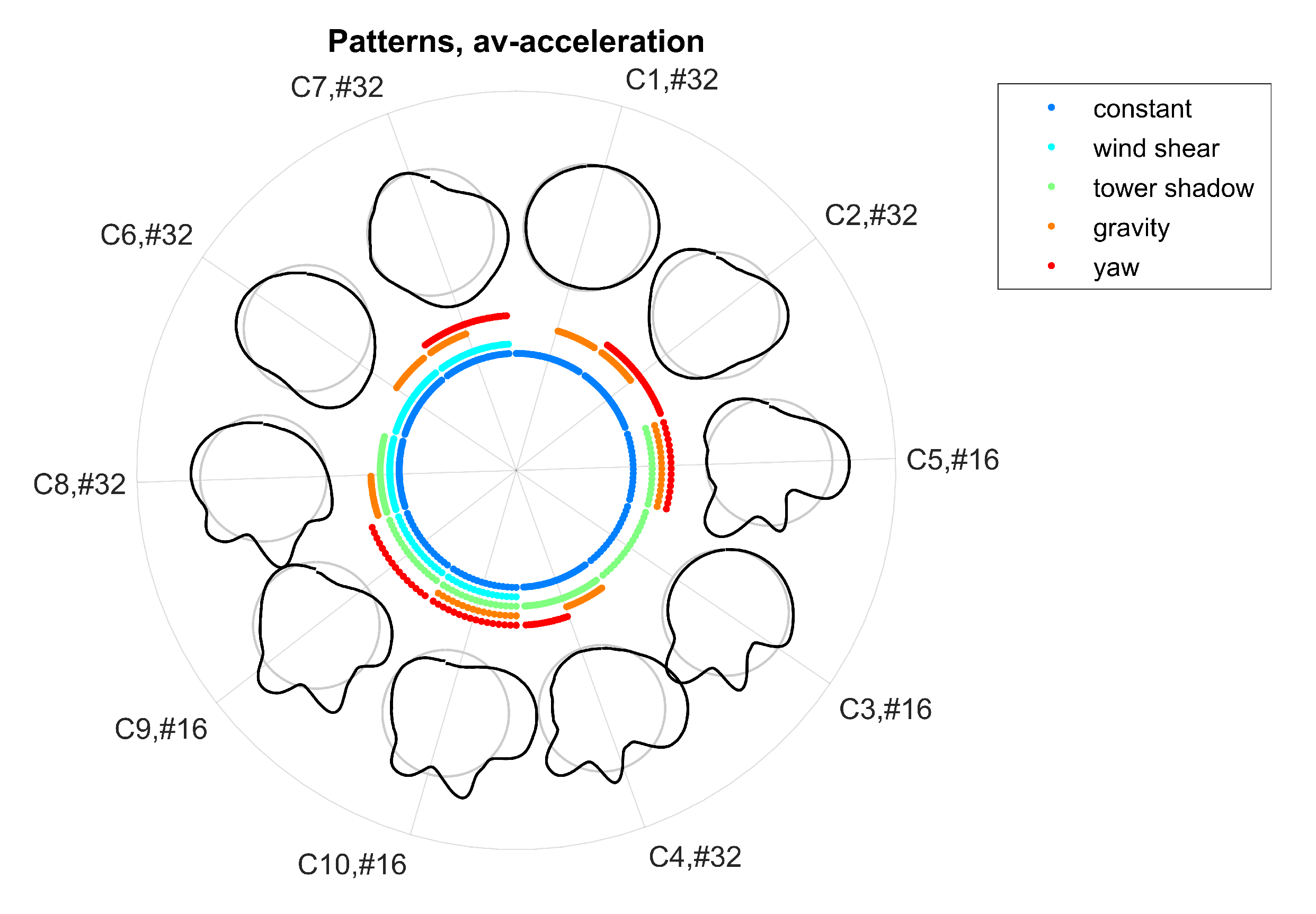

- Unsorted Shapes:Identified bending shapes of varying environmental conditions (bending effects) and operational settings (mounting position of the sensor) were collected and normalised separately for each measurement direction as described in Section 2.2.3. Part 1 of Figure 9 displays the identified bending shapes as single elements, with colour representing affiliation to different classes.

- Hierarchical Clustering:

- (a)

- Hierarchical clustering was used for assigning shapes to different classes by using a similarity measure [27]. The average Euclidean distance across all positions between each pair of shapes was used as a distance measure. Agglomerate clustering was used, which uses bottom-up clustering by first treating all elements as single classes and then continuously merges classes. Part 2 of Figure 9 shows an example of assigning elements to four different classes.

- (b)

- The minimum number of elements per class was set to in order to exclude one-time events and to solely find classes representative of particular environmental or operational conditions. In case a class with a smaller number of elements was created, these elements were saved to a separate outlier class. We set the number of classes to , which resulted in a total of 11 classes including the outlier class . Iterative clustering was conducted as long as any class consisting of fewer elements than was created.

- (c)

- Finally, all elements of the outlier class were tested regarding their affiliation to any of the regular classes. For each class , pair-wise Euclidean distances between all elements were used to form a distance group and the distances from any element of the outlier class to all elements of class were used to form a distance group .Then, the significance of the affiliation of distances to groups and was tested by conducting an analysis of variances (ANOVA) withwhich tested the mean square (MS) within groups and against the mean square between both groups. The mean square was defined as the sum of squared deviations from the mean divided by the degrees of freedom [28]. In case elements from both groups stemmed from the same distribution, the F-score was small and the corresponding significance level p was large. The significance level was calculated for all classes . If the highest significance level (largest p-value) exceeded , the tested element of the outlier class was moved to the respective regular class .

- Circle Arrangement:The median of all class elements represented the bending pattern of each class. For visualisation, all patterns were arranged in a circle by minimising the Euclidean distances between patternsPart 3 of Figure 9 displays a circle along which classes are arranged, with coloured bows representing the arrangement of classes along the circle.

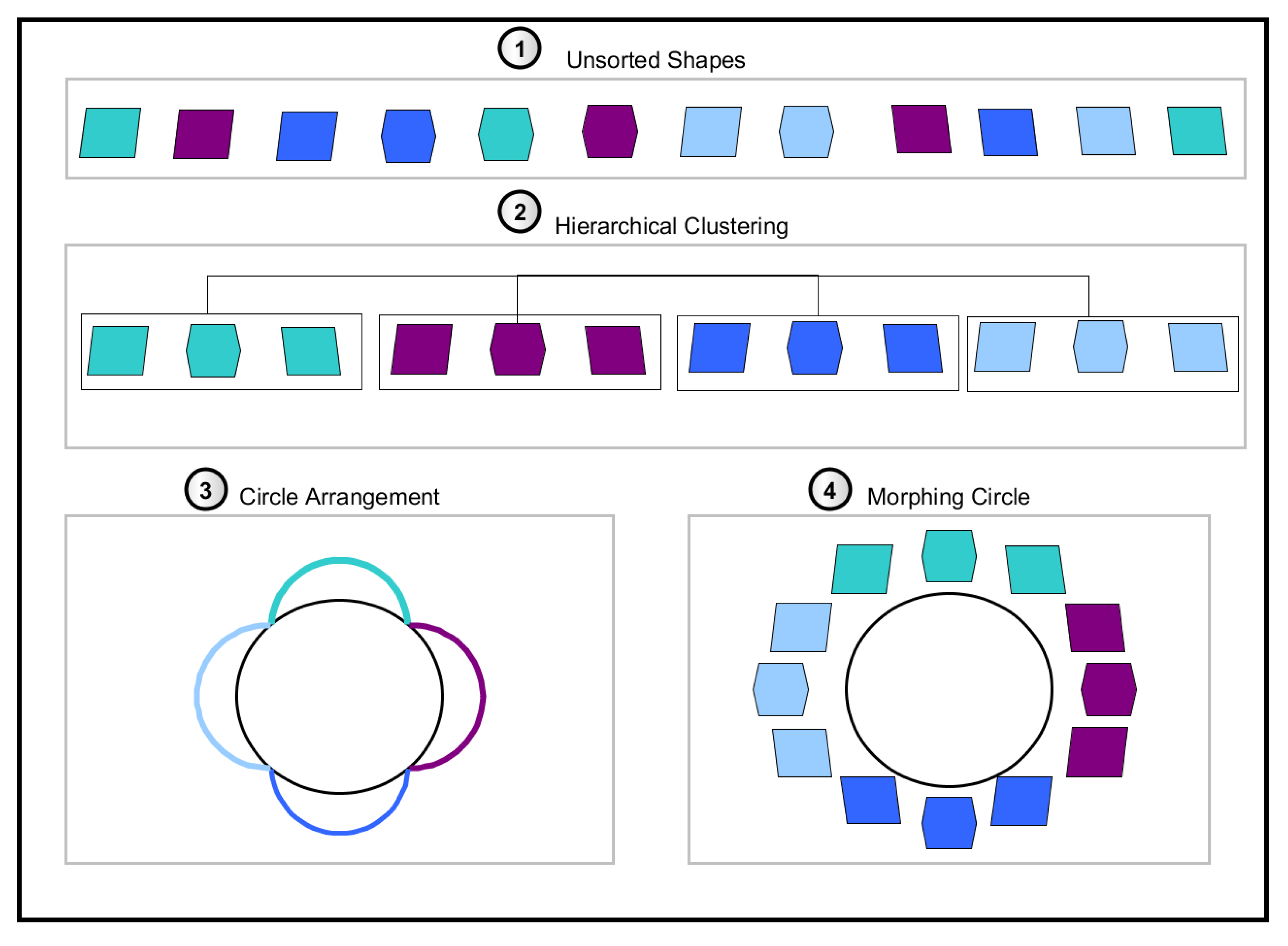

- Morphing Circle:Finally, all elements of each class were sorted by their Euclidean distances (see Figure 10). Elements were arranged within each class so that similar elements were located in the centre and the remaining elements were arranged to both sides with the first and last element having the largest distances between each other. This resulted in a morphing procedure from one bending shape to the other. At class boundaries, the order was either kept or reversed to align elements with the smallest distances, as shown in Figure 10. This arrangement could then be used for jointly visualising patterns and reference data. Part 4 of Figure 9 visualises the single elements along the morphing circle, with colour corresponding to different classes and shapes of single elements corresponding to varying properties of bending shapes.

3. Simulation

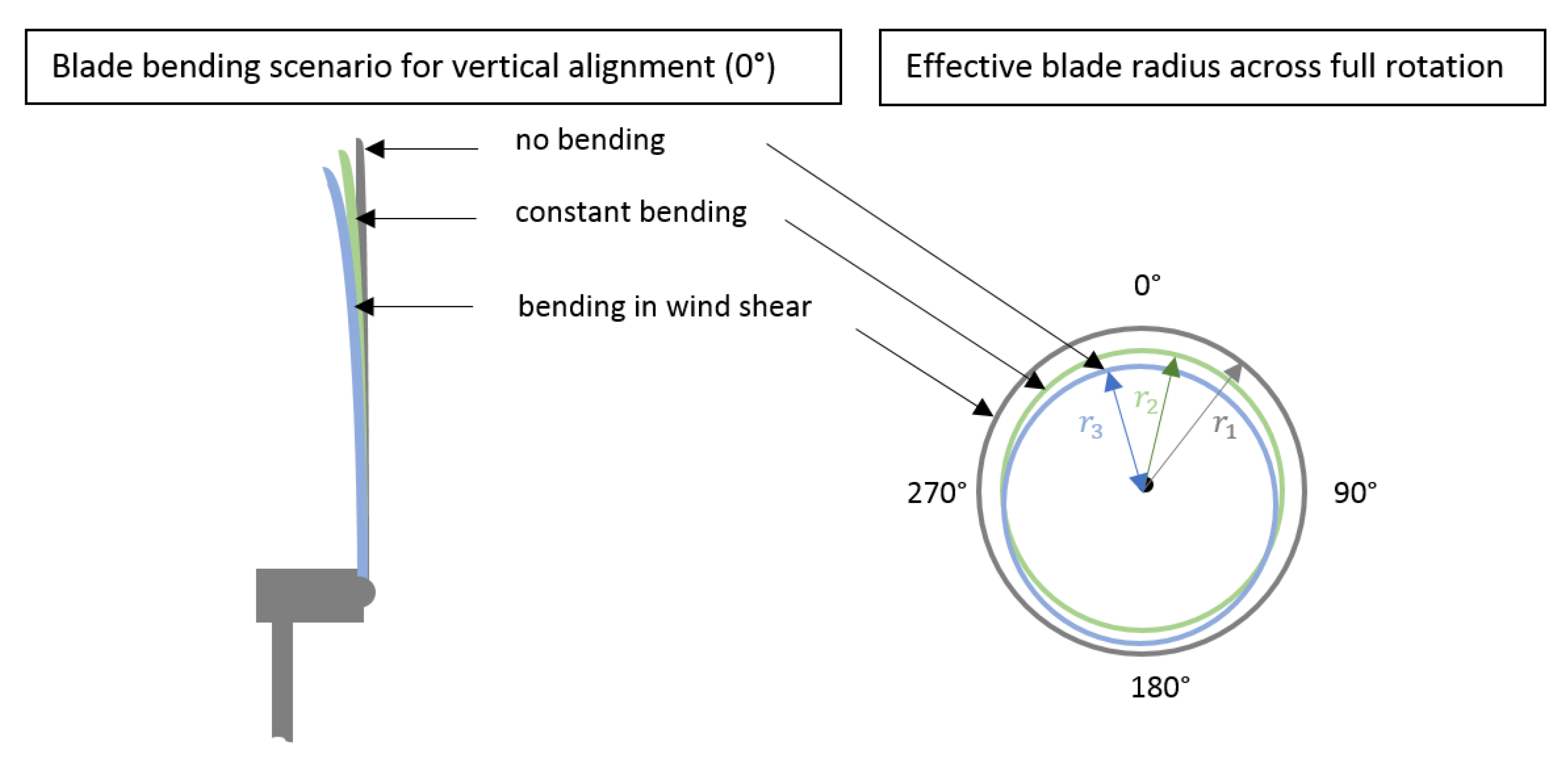

3.1. Alternate Bending Effects

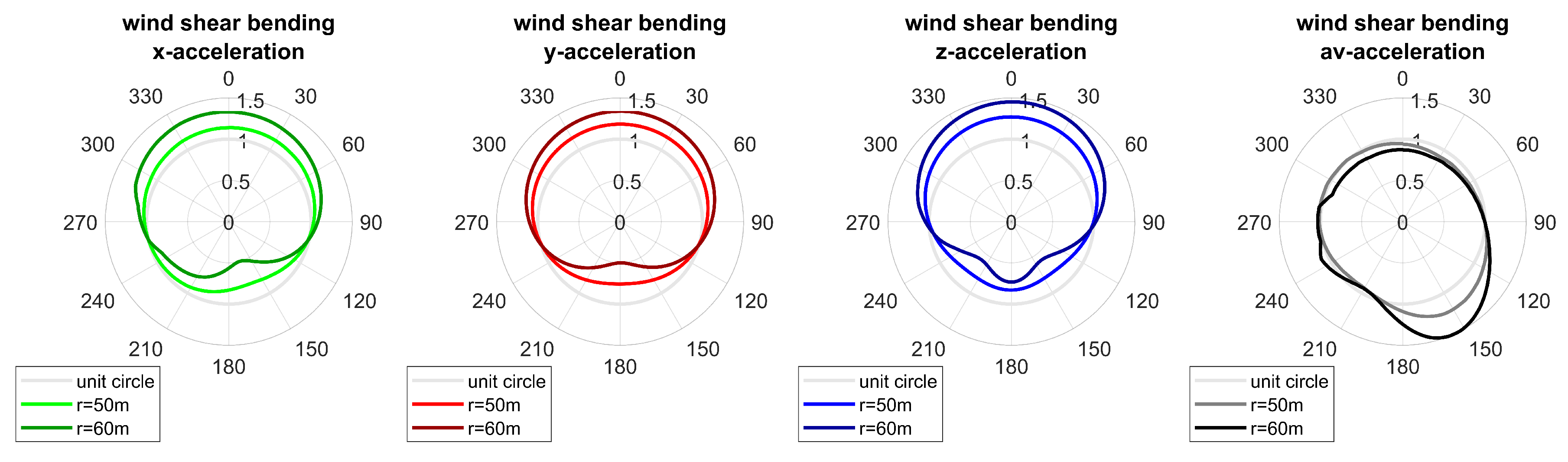

- Wind shear: depending on the surface conditions on site, a nonuniform wind profile leads to an increase in wind speed with height; hence, the blade encounters different wind speeds across the rotation angle . Wind speed was simulated as , with being the wind speed at hub height H, being the empirical wind shear exponent set to in the simulation, and being the effective blade height at rotation angle and blade radius R [11].

- Gravity: gravity counteracts bending due to wind load in case of a downwards movement of the blade and enhances bending due to wind load in case of an upwards movement of the blade. This leads to a sinusoidal increase and decrease of bending, which was simulated as for clockwise rotation with .

- Yaw: if the alignment of the turbine to the wind direction is not sufficiently exact, wind loads differ for the left and the right half-plane of the rotation circle. The yaw-afflicted wind profile was simulated following the definition in [9] as for a yaw angle of .

- Tower shadow: the simulation of tower shadow has already been discussed in detail in Section 2.1.3 and has been used as a test signal for visualising our method.

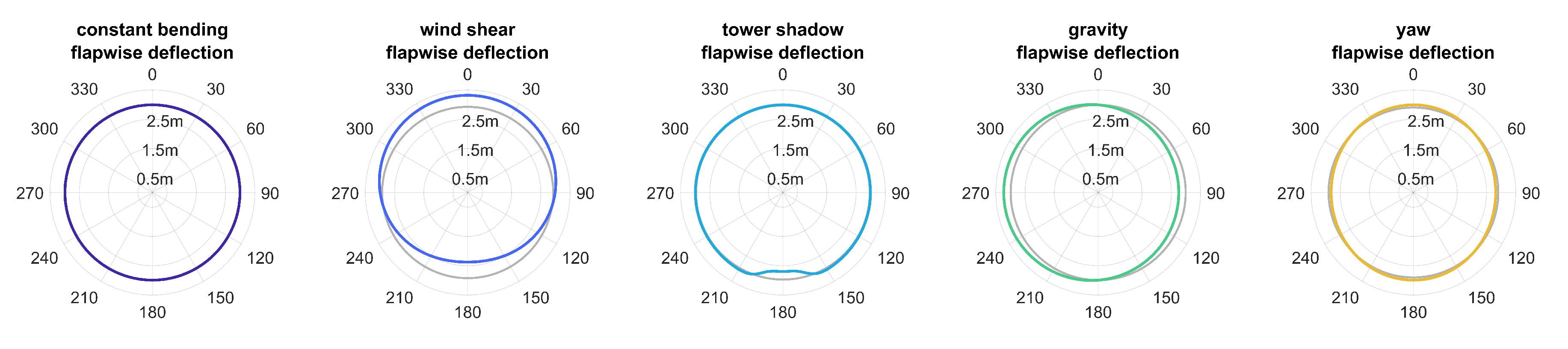

3.2. Simulated Bending Patterns

3.3. Resulting Bending Patterns

4. Real Data Experiment

4.1. Measurement Setup

4.2. Data Preprocessing

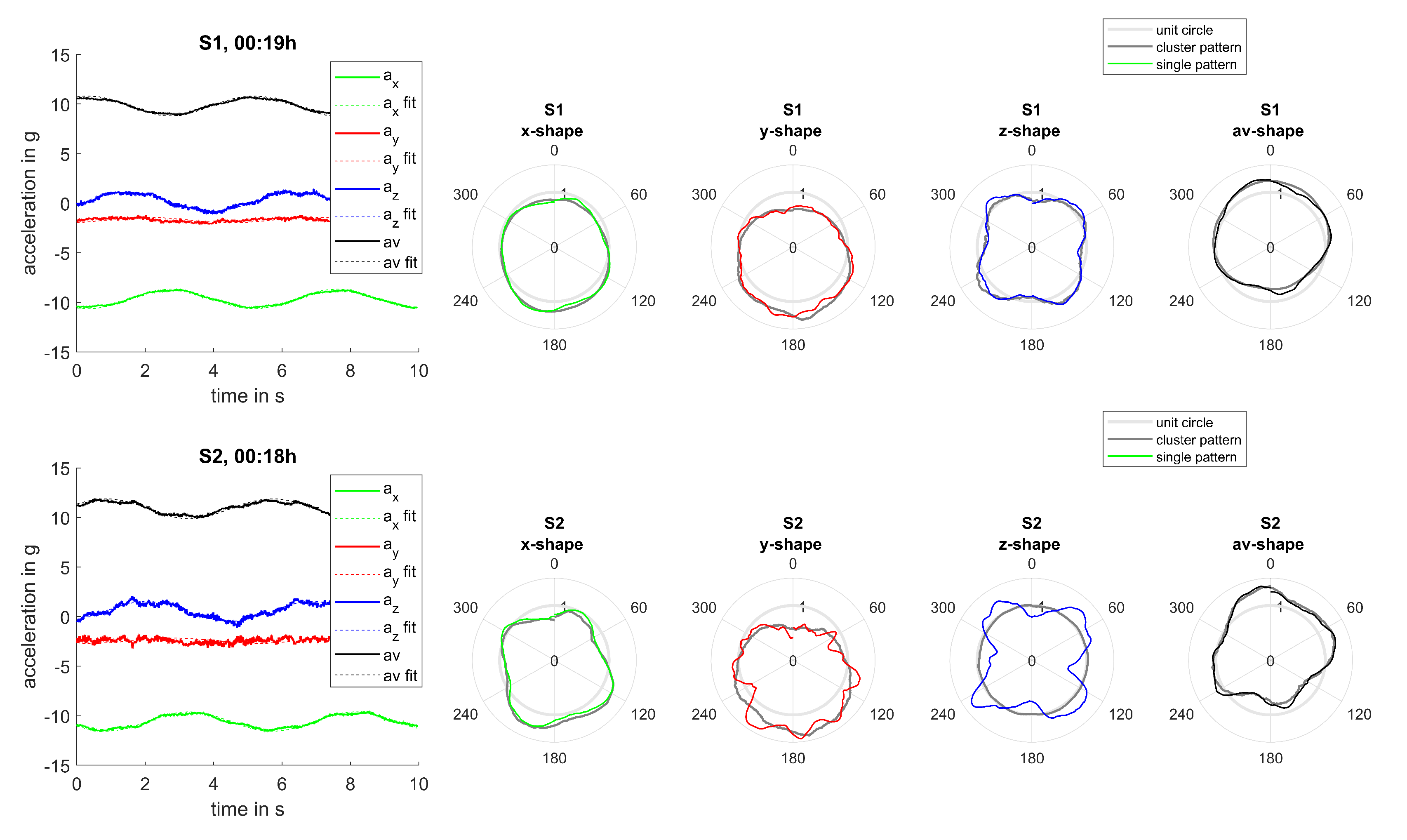

4.3. Results

4.3.1. Cluster Size

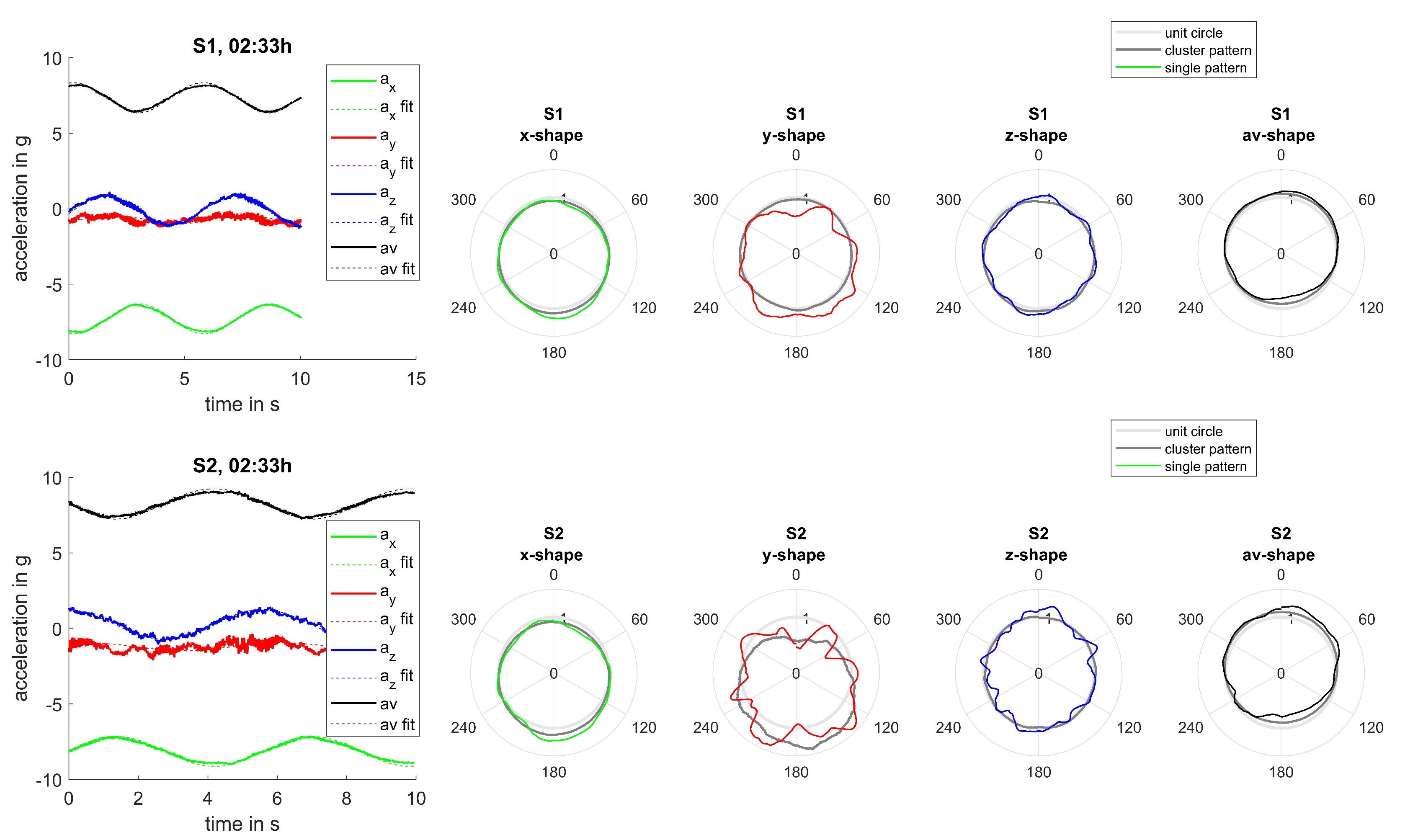

4.3.2. Evaluation of Sensors and

4.3.3. Evaluation of Sensor

4.3.4. Evaluation of Reference Data

4.3.5. Evaluation of the Bending Simulation

5. Discussion

6. Conclusions

- Accelerometers at the blade tip allow for a qualitative assessment of alternate bending at reasonable mounting effort.

- The sensors used in this study operate wirelessly and self-sufficiently; therefore, no restrictions on the mounting positions exist and sensors can even be used for retrofitting of existing turbines.

- No properties of the blade such as geometry and material, which are often not available by the operator, are needed.

- No environmental and operational parameters of the turbine are needed for evaluation. However, reference measurements at high accuracy are desirable for verification purposes.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ICP | Individual pitch control |

| UWB | Ultra-Wideband |

| ANOVA | Analysis of variance |

| MS | Mean square |

| MEMS | Micro-Electromechanical Systems |

| IMU | Inertial measurement unit |

References

- Lee, J.; Zhao, F. GWEC—Global Wind Report 2019; Technical Report; Global Wind Energy Council: Brussels, Belgium, 2019. [Google Scholar]

- DNV-GL. R&D Pathways for Supersized Wind Turbine Blades; Technical Report; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2019.

- 2018 Wind Technologies Market Report; Technical Report; U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy: Washington, DC, USA, 2018.

- GE Renewable Energy. Haliade-X 12 MW Offshore Wind Turbine Platform. Available online: https://www.ge.com/renewableenergy/wind-energy/offshore-wind/haliade-x-offshore-turbine (accessed on 19 May 2012).

- Cooperman, A.; Martinez, M. Load Monitoring for Active Control of Wind Turbines. Renew. Sustain. Energy Rev. 2015, 41, 189–201. [Google Scholar] [CrossRef]

- Besnard, F.; Bertling, L. An approach for condition-based maintenance optimization applied to wind turbine blades. IEEE Trans. Sustain. Energy 2010, 1, 77–83. [Google Scholar] [CrossRef]

- Brouwer, S.R.; Al-Jibouri, S.H.; Cárdenas, I.C.; Halman, J.I. Towards analysing risks to public safety from wind turbines. Reliab. Eng. Syst. Saf. 2018, 180, 77–87. [Google Scholar] [CrossRef]

- Leishman, J.G. Challenges in Modelling the Unsteady Aerodynamics of Wind Turbines. Wind Energy 2002, 5, 85–132. [Google Scholar] [CrossRef]

- Kragh, K.A.; Hansen, M.H. Load alleviation of wind turbines by yaw misalignment. Wind Energy 2014, 17, 971–982. [Google Scholar] [CrossRef]

- Dai, L.; Zhou, Q.; Zhang, Y.; Yao, S.; Kang, S.; Wang, X. Analysis of wind turbine blades aeroelastic performance under yaw conditions. J. Wind Eng. Ind. Aerodyn. 2017, 171, 273–287. [Google Scholar] [CrossRef]

- Ke, S.; Wang, T.; Ge, Y.; Wang, H. Wind-induced fatigue of large HAWT coupled tower–blade structures considering aeroelastic and yaw effects. Struct. Des. Tall Spec. Build. 2018, 27, e1467. [Google Scholar] [CrossRef]

- Liew, J.; Lio, W.H.; Urbán, A.M.; Holierhoek, J.; Kim, T. Active tip deflection control for wind turbines. Renew. Energy 2020, 149, 445–454. [Google Scholar] [CrossRef] [Green Version]

- White, J.; Adams, D.; Rumsey, M. Updating of a wind turbine model for the evaluation of methods for operational monitoring using inertial measurements. In Proceedings of the 48th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2010; p. 1192. [Google Scholar]

- Adams, D.; White, J.; Rumsey, M.; Farrar, C. Structural health monitoring of wind turbines: Method and application to a HAWT. Wind Energy 2011, 14, 603–623. [Google Scholar] [CrossRef]

- Hansen, M.H.; Thomsen, K.; Fuglsang, P.; Knudsen, T. Two methods for estimating aeroelastic damping of operational wind turbine modes from experiments. Wind Energy Int. J. Prog. Appl. Wind Power Convers. Technol. 2006, 9, 179–191. [Google Scholar] [CrossRef] [Green Version]

- White, J.; Adams, D.; Rumsey, M.; Paquette, J. Estimation of wind turbine blade operational loading and deflection with inertial measurements. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; p. 1407. [Google Scholar]

- Loss, T.; Gerler, O.; Bergmann, A. Using MEMS Acceleration Sensors for Monitoring Blade Tip Movement of Wind Turbines. In Proceedings of the 2018 IEEE SENSORS, New Delhi, India, 28–31 October 2018. [Google Scholar]

- Fu, X.; He, L.; Qiu, H. MEMS gyroscope sensors for wind turbine blade tip deflection measurement. In Proceedings of the 2013 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Minneapolis, MN, USA, 6–9 May 2013; pp. 1708–1712. [Google Scholar]

- Zhang, S.; Jensen, T.L.; Franek, O.; Eggers, P.C.; Byskov, C.; Pedersen, G.F. Investigation of a UWB wind turbine blade deflection sensing system with a tip antenna inside a blade. IEEE Sens. J. 2016, 16, 7892–7902. [Google Scholar] [CrossRef]

- Moll, J.; Mälzer, M.; Simon, J.; Zadeh, A.T.; Krozer, V.; Dürr, M.; Kramer, C.; Friedmann, H.; Nuber, A.; Salman, R.; et al. Monitoring of Wind Turbine Blades Using Radar Technology: Results from a Field Study at a 2MW Wind Turbine. In Structural Health Monitoring 2019; DEStech Publishing Inc.: Lancaster, PA, USA, 2019. [Google Scholar]

- Grosse-Schwiep, M.; Piechel, J.; Luhmann, T. Measurement of rotor blade deformations of wind energy converters with laser scanners. J. Phys. Conf. Ser. 2014, 524, 012067. [Google Scholar] [CrossRef] [Green Version]

- Yuan, F. Structural Health Monitoring (SHM) in Aerospace Structures; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Hansen, M. Aerodynamic of Wind Turbines; Earthscan: London, UK; Sterling, VA, USA, 2008; pp. 103–106. [Google Scholar]

- Hansen, M.H. Aeroelastic instability problems for wind turbines. Wind Energy Int. J. Prog. Appl. Wind Power Convers. Technol. 2007, 10, 551–577. [Google Scholar] [CrossRef]

- Brizard, A.J. Motion in a Non-Inertial Frame. Available online: http://www.dartmouth.edu/~phys44/lectures/Chap_6.pdf (accessed on 17 September 2020).

- Dolan, D.S.; Lehn, P.W. Simulation Model of Wind Turbine 3p Torque Oscillations due to Wind Shear and Tower Shadow. IEEE Trans. Energy Convers. 2006, 21, 717–724. [Google Scholar] [CrossRef]

- Murtagh, F.; Contreras, P. Algorithms for hierarchical clustering: An overview. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2012, 2, 86–97. [Google Scholar] [CrossRef]

- Walde, J. Analysis of Variance, Lecture Notes; University of Innsbruck: Innsbruck, Austria, 1977. [Google Scholar]

- Analog Devices. 3-Axis, 2g/4g/8g/16g Digital Accelerometer. ADXL345. Rev. E. 2015. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL345.pdf (accessed on 17 September 2020).

- Eologix Sensor Technology. Available online: Https://www.eologix.com/en/solutions/windenergy/ (accessed on 28 May 2012).

- Loss, T.; Gerler, O.; Bergmann, A. Online Calibration of Accelerometers for Monitoring of Wind Turbine Blade Movement. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Dubrovnik, Croatia, 25–28 May 2020. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loss, T.; Bergmann, A. Moving Accelerometers to the Tip: Monitoring of Wind Turbine Blade Bending Using 3D Accelerometers and Model-Based Bending Shapes. Sensors 2020, 20, 5337. https://doi.org/10.3390/s20185337

Loss T, Bergmann A. Moving Accelerometers to the Tip: Monitoring of Wind Turbine Blade Bending Using 3D Accelerometers and Model-Based Bending Shapes. Sensors. 2020; 20(18):5337. https://doi.org/10.3390/s20185337

Chicago/Turabian StyleLoss, Theresa, and Alexander Bergmann. 2020. "Moving Accelerometers to the Tip: Monitoring of Wind Turbine Blade Bending Using 3D Accelerometers and Model-Based Bending Shapes" Sensors 20, no. 18: 5337. https://doi.org/10.3390/s20185337

APA StyleLoss, T., & Bergmann, A. (2020). Moving Accelerometers to the Tip: Monitoring of Wind Turbine Blade Bending Using 3D Accelerometers and Model-Based Bending Shapes. Sensors, 20(18), 5337. https://doi.org/10.3390/s20185337