Time-Frequency Distribution Map-Based Convolutional Neural Network (CNN) Model for Underwater Pipeline Leakage Detection Using Acoustic Signals

Abstract

1. Introduction

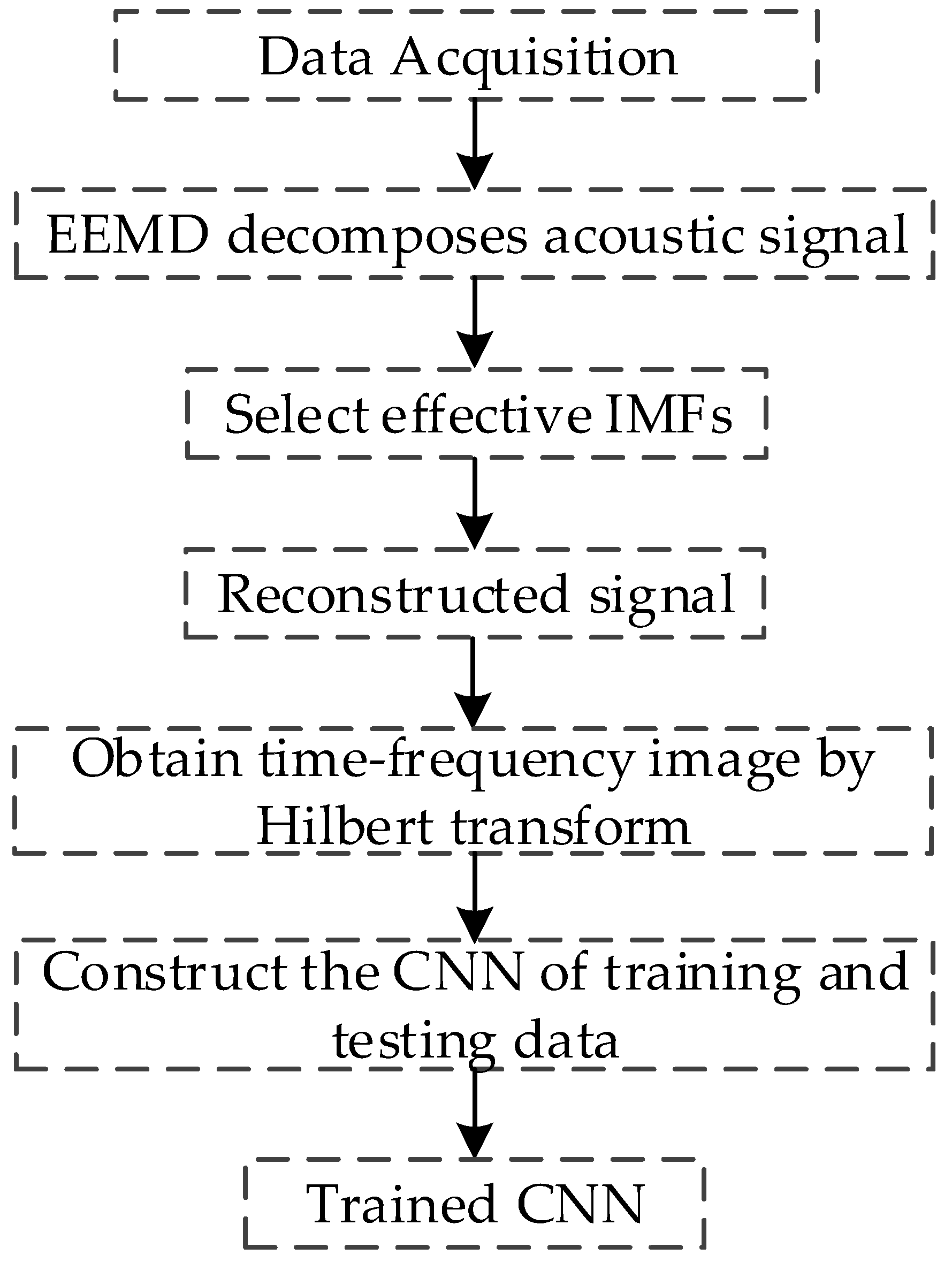

- The structure of the jet generated by the underwater pipeline leakage is studied.

- The influence of the pipe pressure and leakage hole size on the radiated noise is analyzed.

- Radiated noise signals are demonstrated in the time-frequency domain through the EEMD algorithm, and the pipeline leakage degree is identified by HHT-CNN.

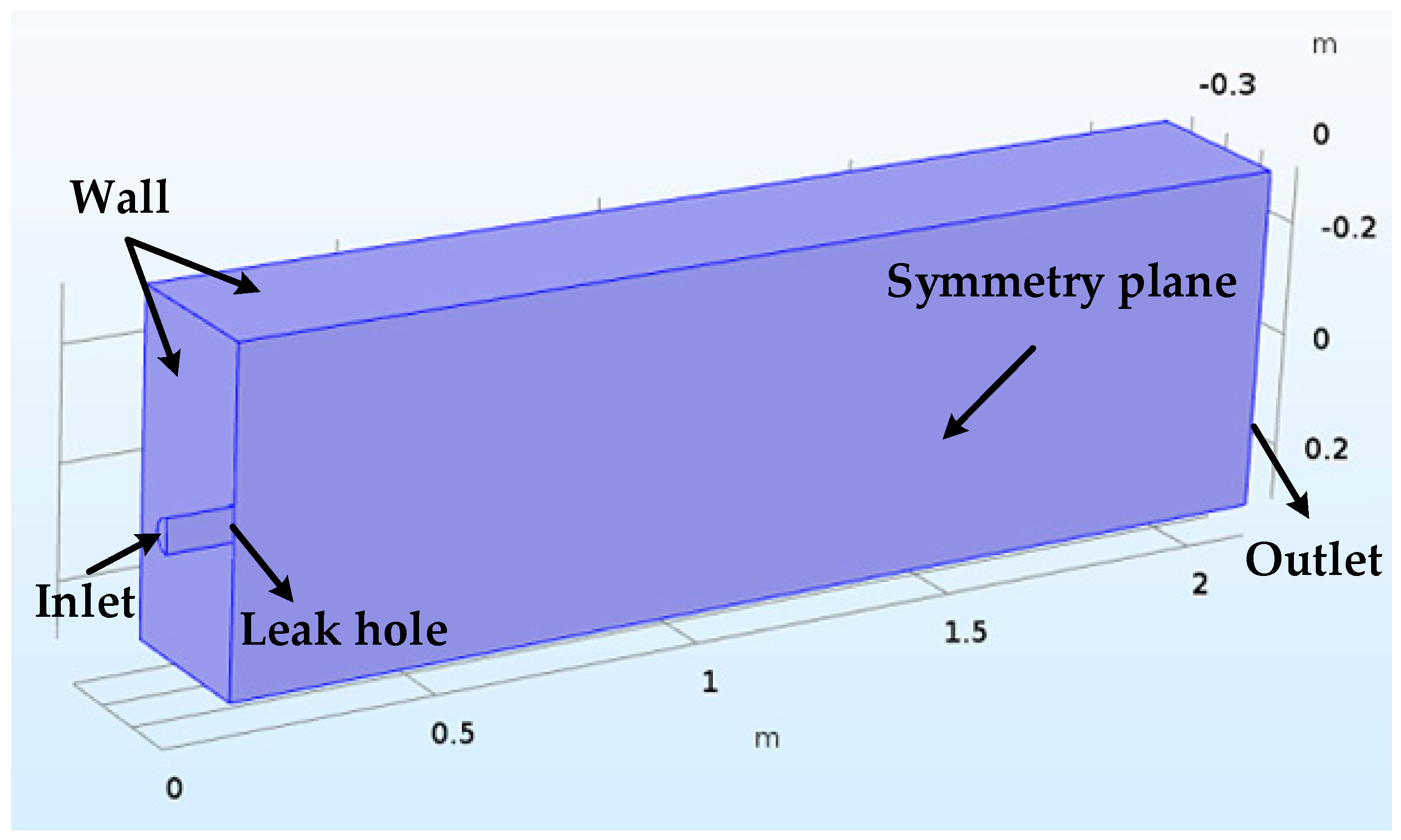

2. Simulation of the Underwater Pipeline Leak

- The high-velocity jet fluid is injected into static or relatively low-speed fluid media. The two-fluid media are rapidly mixed due to a large velocity difference. Therefore, turbulent pulsation will produce strong jet noise in the boundary layer.

- Due to the high velocity of injection, the jet flow will generate many vortices to form turbulence. Thus, the jet fluid will produce strong turbulence noise, which eventually becomes the radiation noise source.

- In the vicinity of the leakage port, the turbulent noise is generated due to the existence of a high-velocity gradient region.

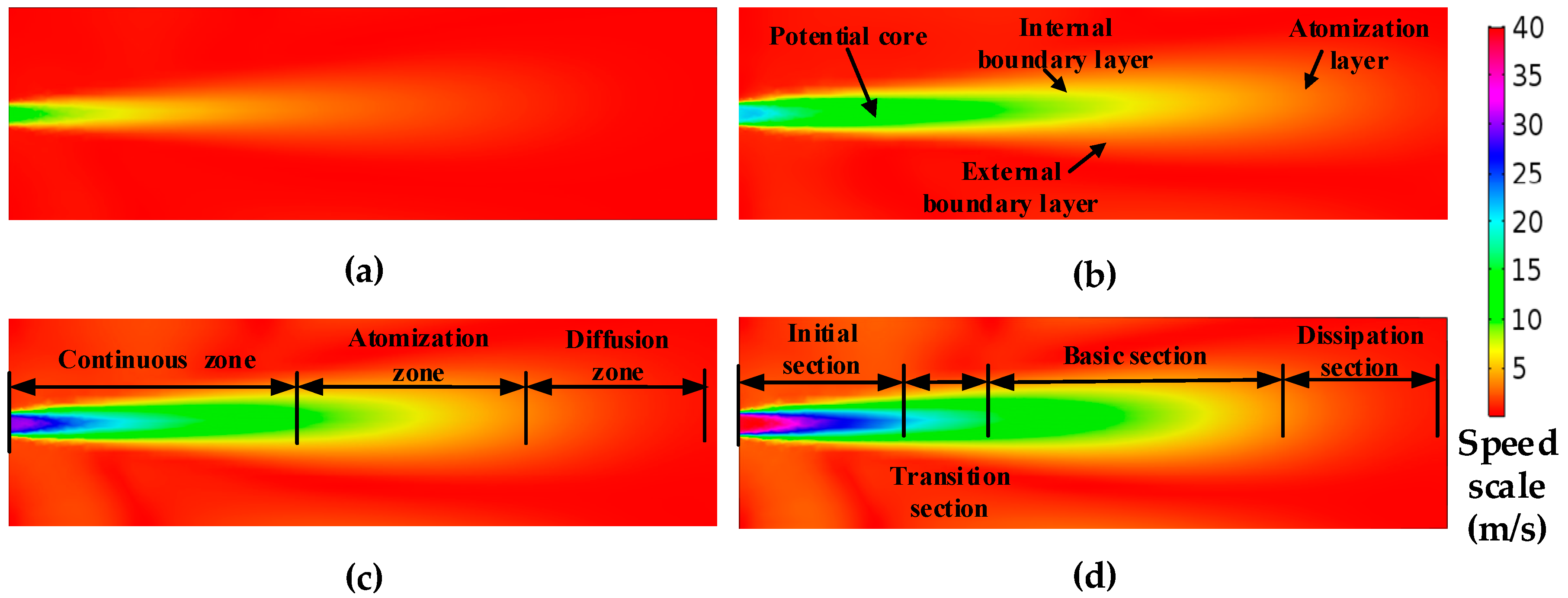

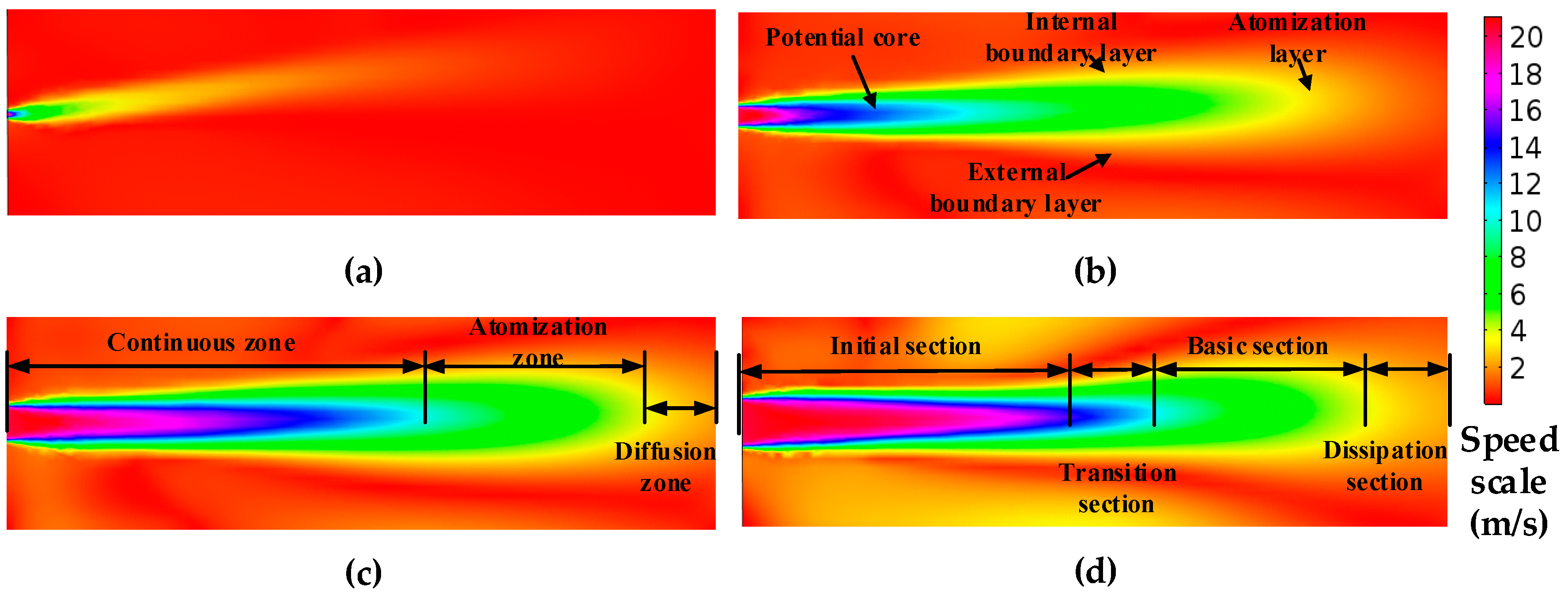

- The flow field structure of the underwater jet can be divided into three flow zones: Continuous flow zone: this zone is located from the jet nozzle to five diameters away from the jet nozzle. The center is the core of the jet, and the core is intensely mixed with the static fluid with high turbulence intensity and high-frequency radiation noise. Atomization flow zone: this zone is from the end of the core of the jet to the radius 10 times from the jet hole. The turbulence intensity and flow velocity decrease with the increase of distance, also the frequency of radiation noise decreases. Diffusion flow zone: following the atomization flow zone, the turbulence intensity and flow velocity continue to decrease.

- From Figure 2 and Figure 3, the acoustic radiation comes mainly from the core of the jet, and the high-velocity fluid mixes with the absorbed fluid to form a highly turbulent and directional fluid. In the continuous flow area, the velocity gradient from the core to the mixing boundary is large, and there are complex and changeable stresses in the fluid, with high turbulence intensity, and the flow velocity and pressure of the fluid vary rapidly, thus producing strong radiation noise.

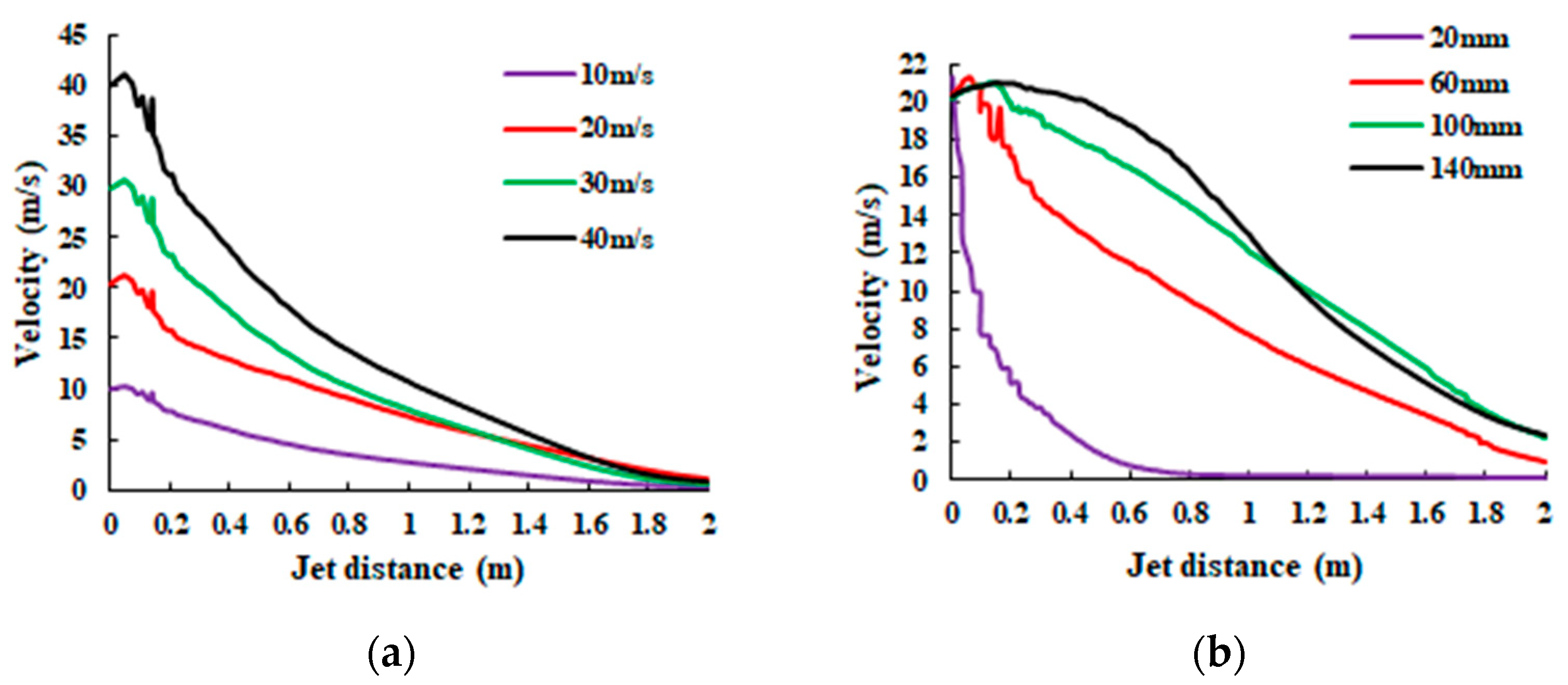

- In Figure 4, the velocity of the fluid in the direction of the jet decreases gradually as the volume of the fluid increases, but a small amount of high-speed fluid is retained at the jet outlet, and its velocity still keeps the outlet velocity of the leak outlet, which becomes the core of the jet. The instantaneous velocity of the leak at the same pressure increases with the leak diameter.

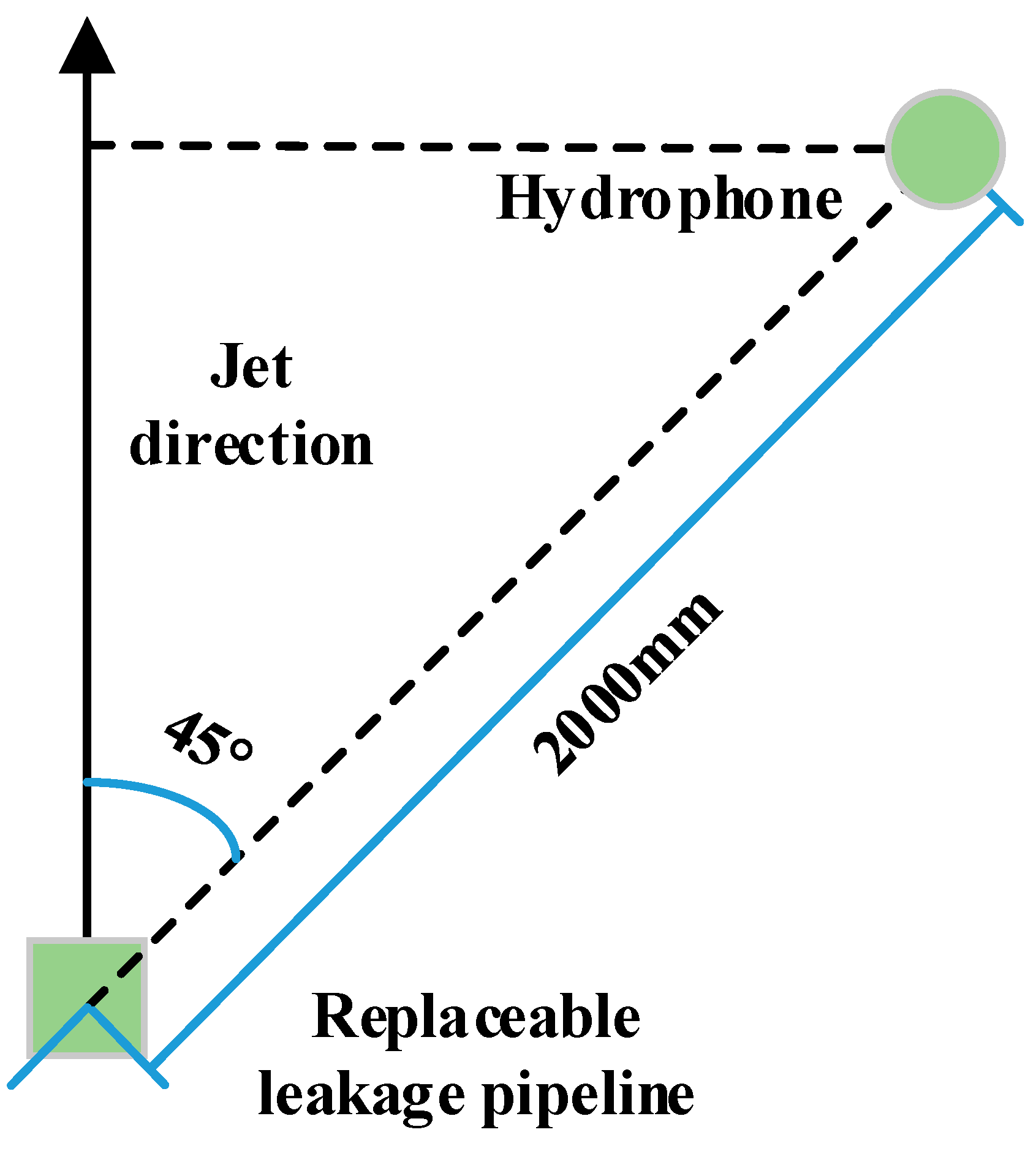

3. Acoustics Image Acquisition

4. The Underwater Experiment of Radiation Noise

5. Analysis and Results

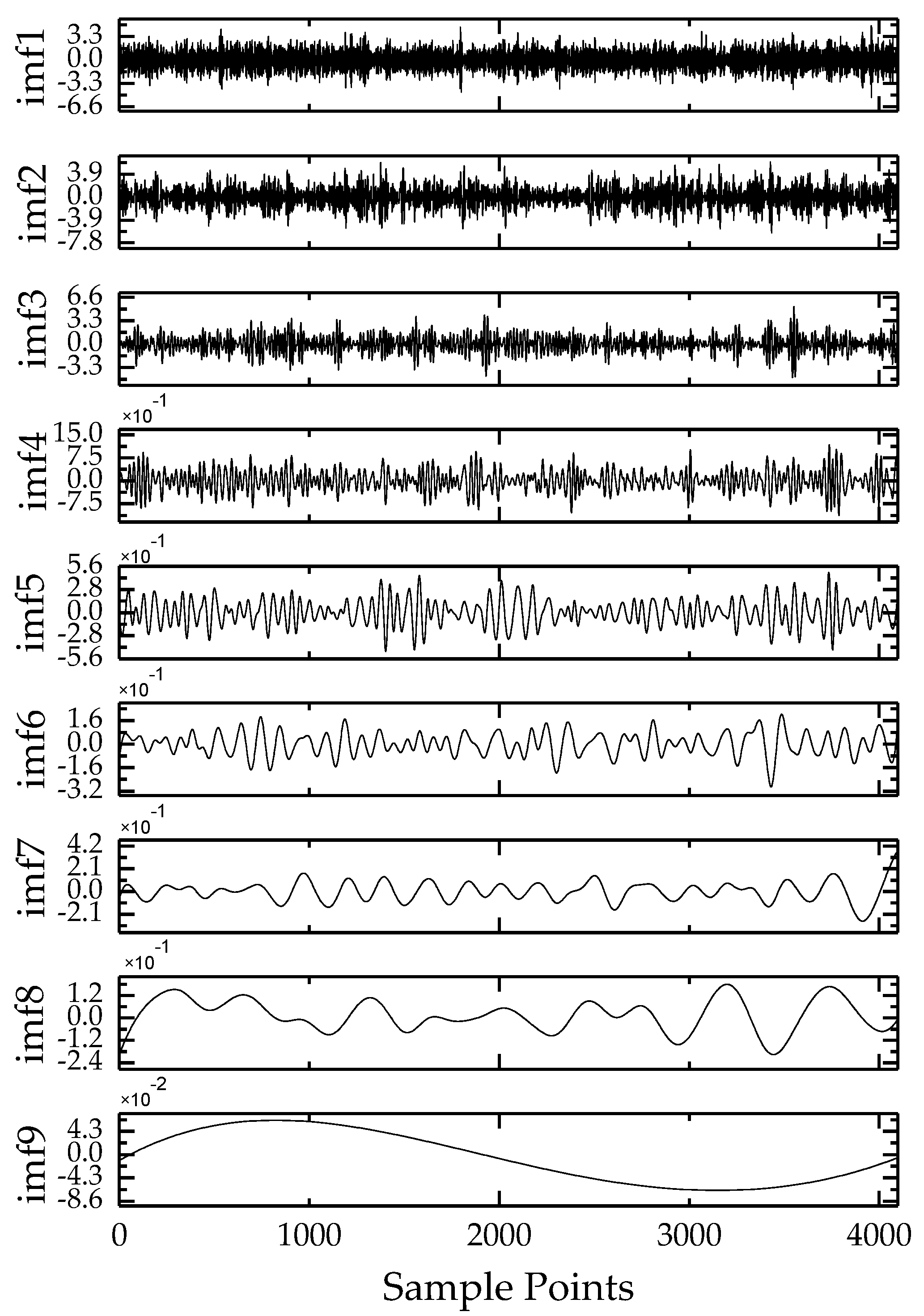

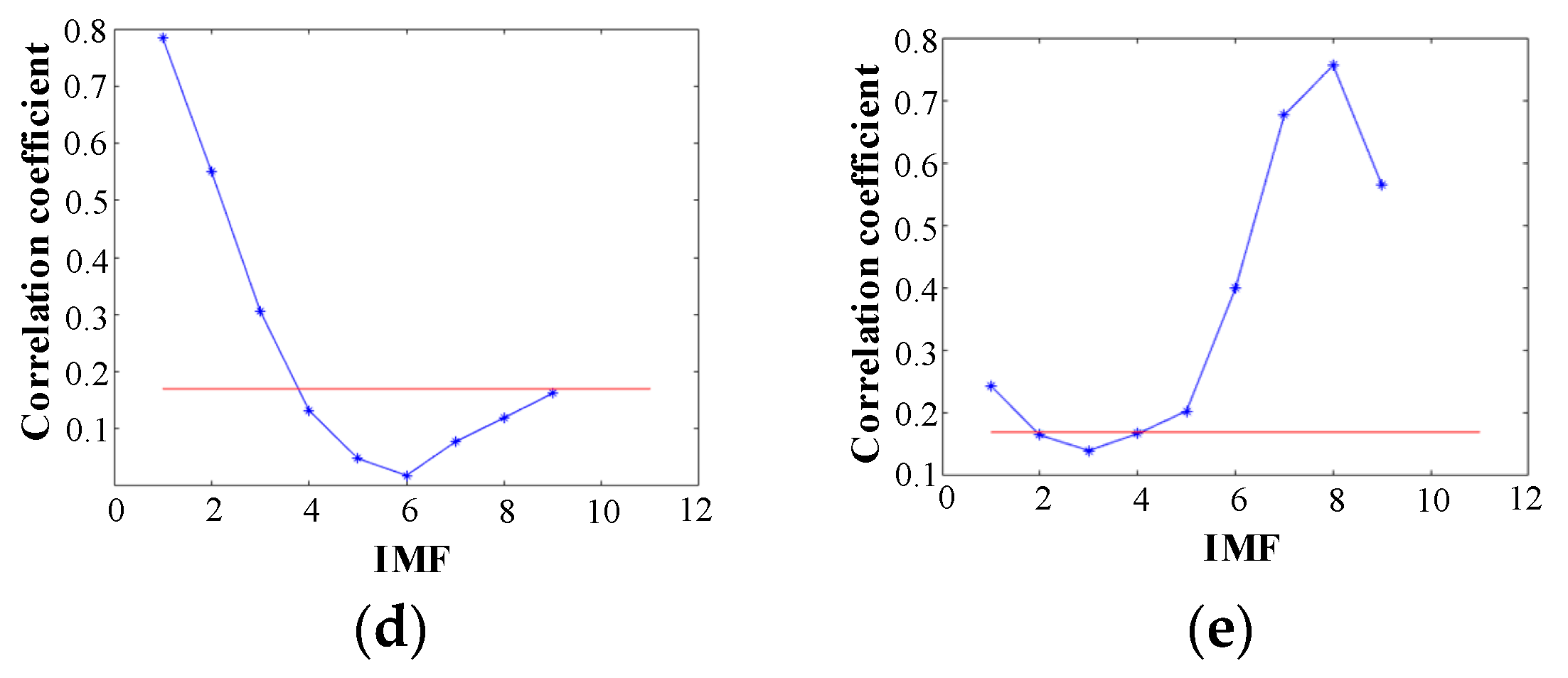

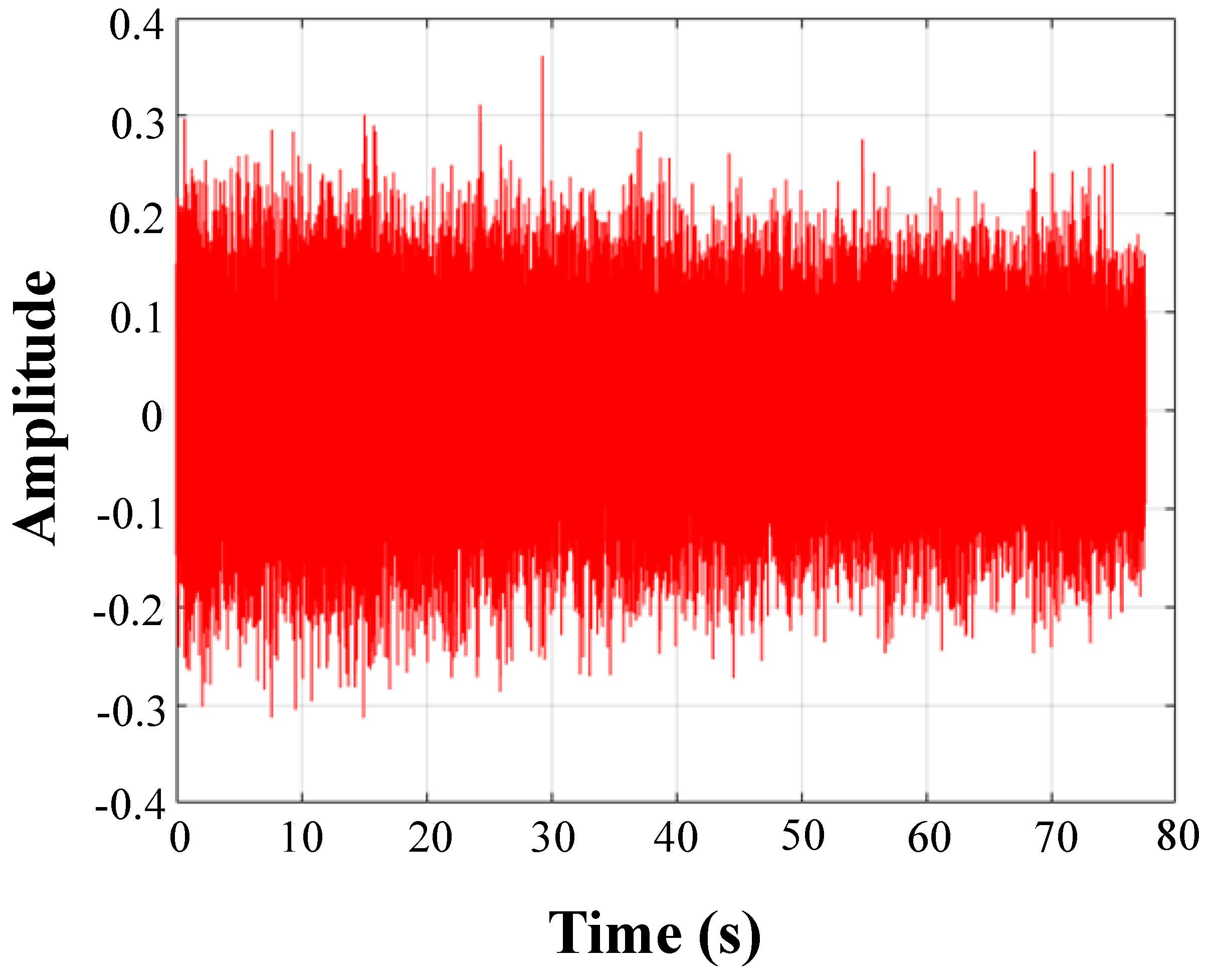

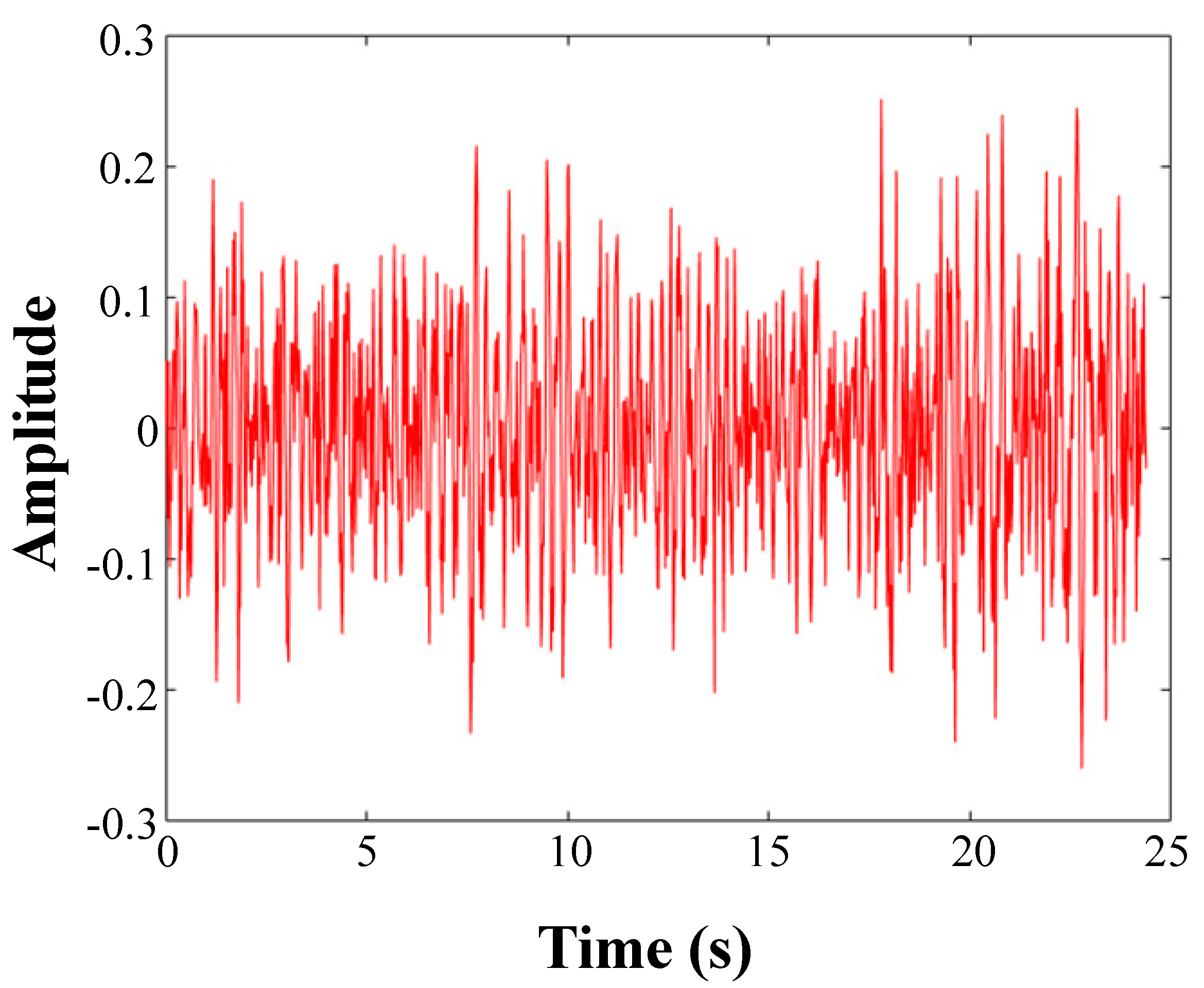

5.1. Signal Decomposition

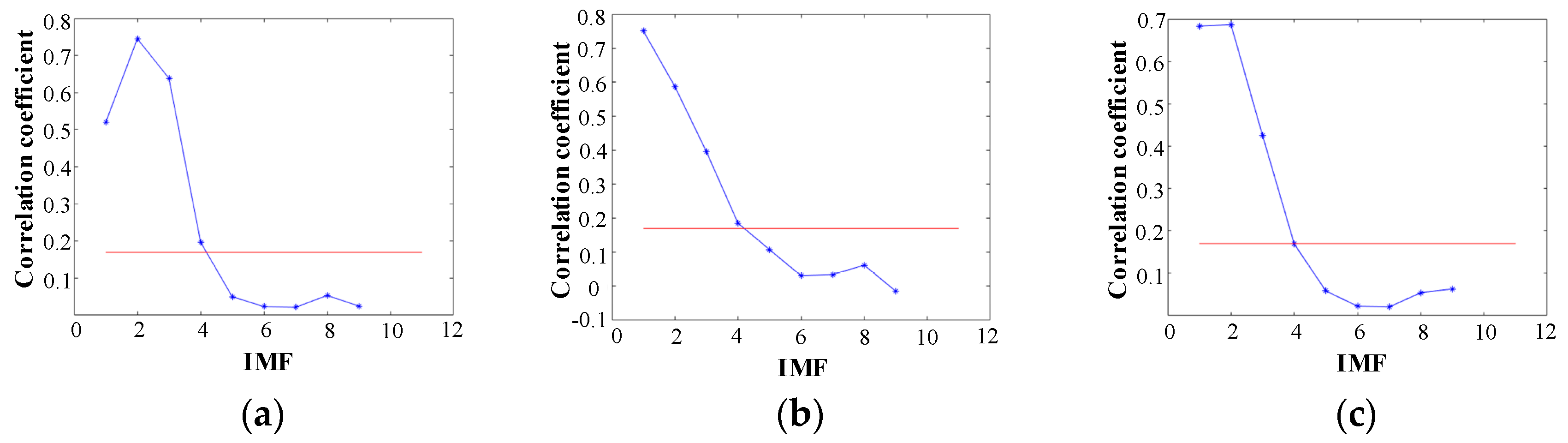

5.2. Filtering and Refactoring

5.3. Time-Frequency Map

5.4. Results and Analysis of Underwater Pipeline Leakage Noise

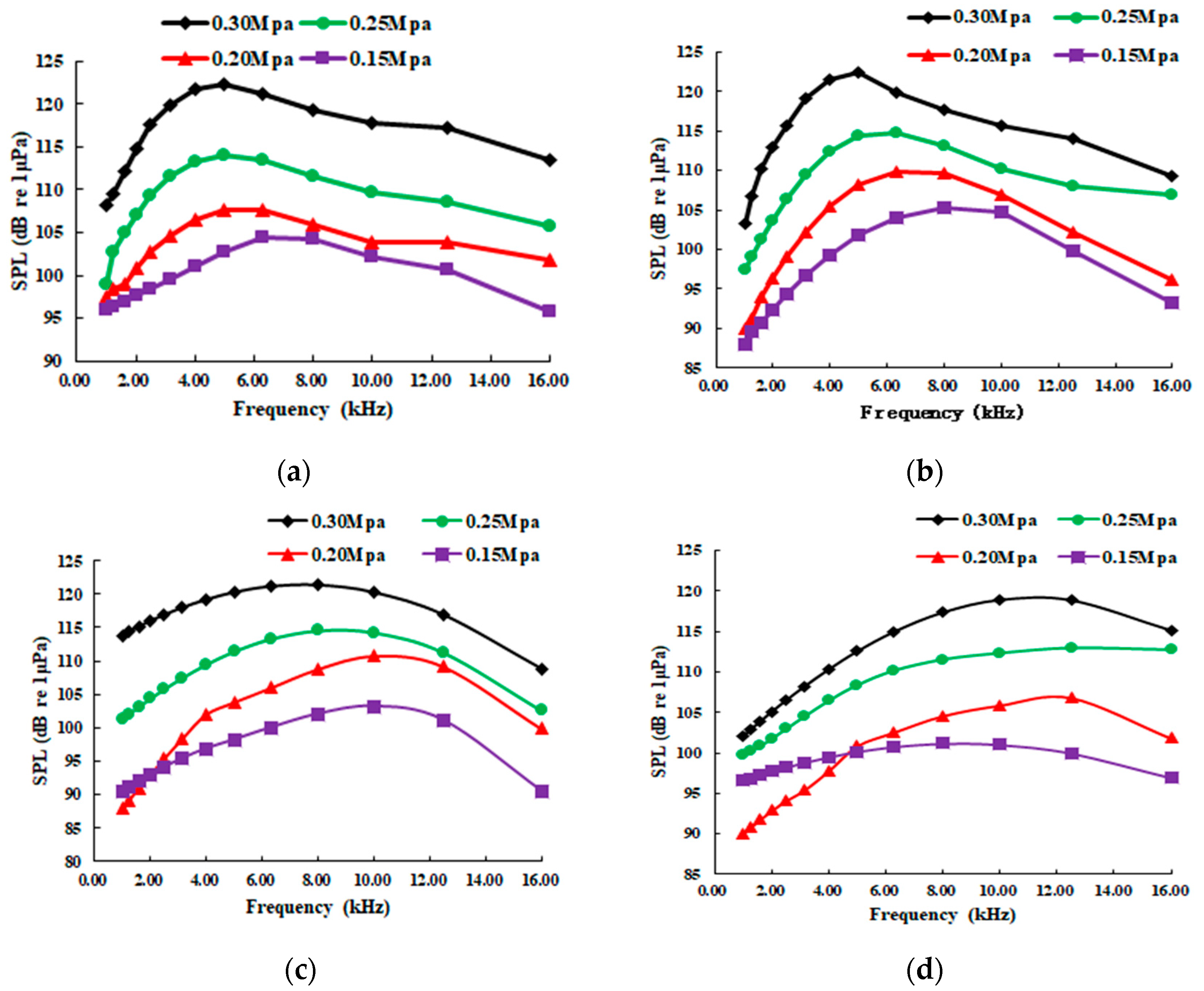

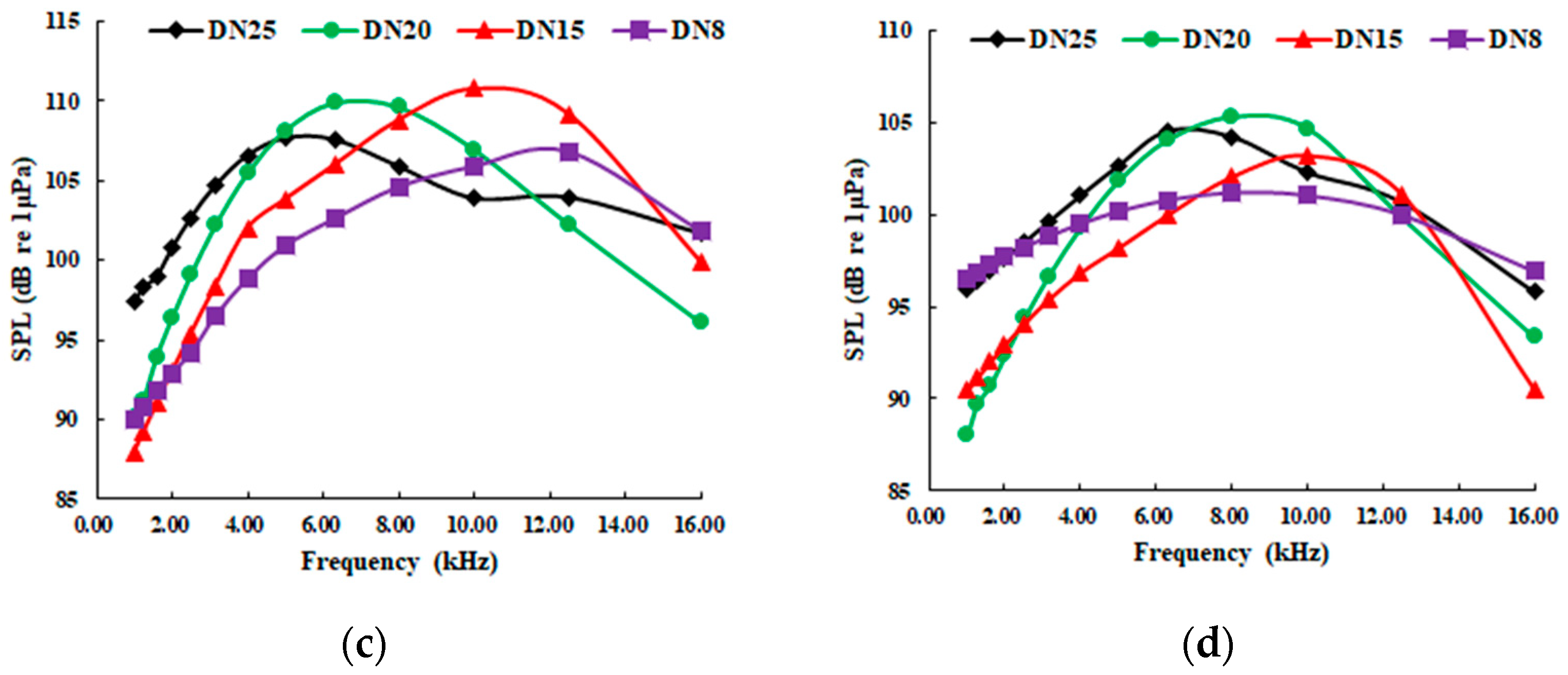

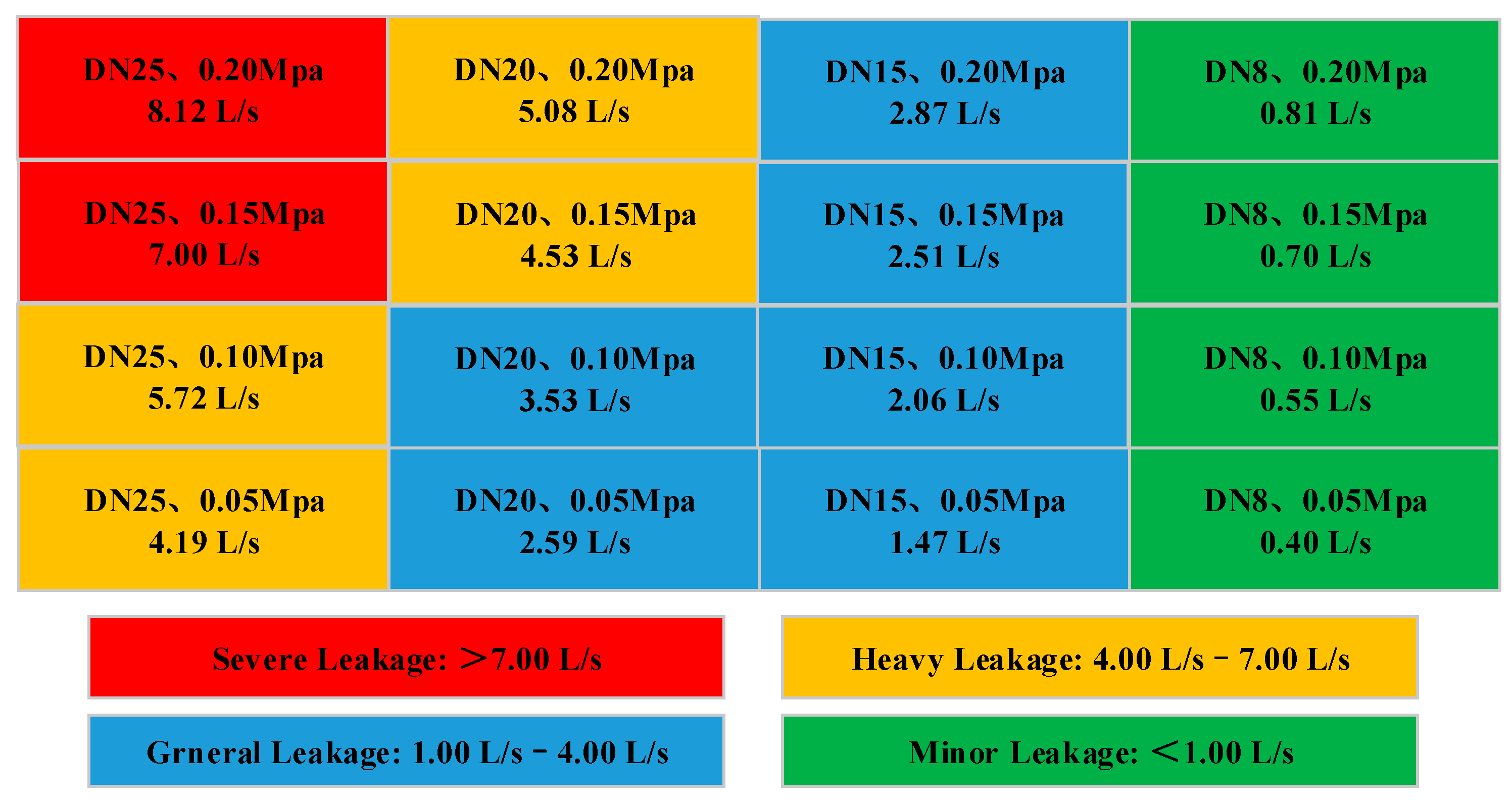

5.4.1. Effect of Different Leakage Pressures on the Sound Pressure Level of Jet Radiation

5.4.2. Effect of Different Leakage Diameters on Jet Radiation Sound Pressure Level

6. Identification of Time-Frequency Images

7. Conclusions

- It is found that the radiation noise generated by the pipeline leakage is mid–high-frequency continuous spectrum noise. The increase of the pipeline pressure and the pipeline leakage diameter will cause the narrowing of the frequency bandwidth, and its center frequency moves toward the low-frequency direction. Under the same conditions, the pressure has a greater influence on the amplitude. For every 0.15 MPa increase in the pressure, the radiation sound pressure level increases by 6–7 dB.

- According to the characteristics of the pipeline leakage acoustic signal, the signal is preprocessed. Through time-frequency analysis, a time-frequency image is obtained, which can accurately describe the characteristics of the signal. A simple two-layer network is built to train these images, and its recognition accuracy is validated at the degree of pipeline leakage.

- The combination of CNN and the visualization of underwater acoustic signals in the time-frequency domain provides a novel insight for fault identification of underwater pipelines.

- This method is mainly used to collect and analyze the jet noise generated by pipeline leakage, which is limited by the sensitivity of hydrophones in the working distance, and the acting depth is limited by transmission cable length. In the marine environment, if the leakage hole is too small, the generated noise may be drowned by the environmental noise, which induces the difficulty of identification. Therefore, it is necessary to select equipment according to local conditions, and the hydrophone should be not far away from the pipeline during testing.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Y.; Tang, W.; Du, J. Development of subsea production system and its control system. In Proceedings of the ICCSS 2017—2017 4th International Conference on Information, Cybernetics and Computational Social Systems (ICCSS), Dalian, China, 24–26 July 2017; pp. 117–122. [Google Scholar]

- Hong, C.; Estefen, S.F.; Wang, Y.; Lourenço, M.I. An integrated optimization model for the layout design of a subsea production system. Appl. Ocean. Res. 2018, 77, 1–13. [Google Scholar] [CrossRef]

- Wang, Z.M.; Zhang, J. Corrosion of multiphase flow pipelines: The impact of crude oil. Corros. Rev. 2016, 34, 17–40. [Google Scholar] [CrossRef]

- Vralstad, T.; Melbye, A.G.; Carlsen, I.M.; Llewelyn, D. Comparison of leak-detection technologies for continuous monitoring of subsea-production templates. SPE Proj. Facil. Constr. 2011, 6, 96–103. [Google Scholar] [CrossRef]

- Mahmutoglu, Y.; Turk, K. A passive acoustic based system to locate leak hole in underwater natural gas pipelines. Digit. Signal. Process. A Rev. J. 2018, 76, 59–65. [Google Scholar] [CrossRef]

- Zhu, J.; Ren, L.; Ho, S.C.; Jia, Z.; Song, G. Gas pipeline leakage detection based on PZT sensors. Smart Mater. Struct. 2017, 26. [Google Scholar] [CrossRef]

- Adedeji, K.B.; Hamam, Y.; Abe, B.T.; Abu-Mahfouz, A.M. Towards Achieving a Reliable Leakage Detection and Localization Algorithm for Application in Water Piping Networks: An Overview. IEEE Access 2017, 5, 20272–20285. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Q.; Bai, Y.; Bai, Q. Chapter 6—Leak Detection Systems. Subsea Pipeline Integr. Risk Manag. 2014, 125–143. [Google Scholar] [CrossRef]

- Lu, H.; Iseley, T.; Behbahani, S.; Fu, L. Leakage detection techniques for oil and gas pipelines: State-of-the-art. Tunn. Undergr. Sp. Technol. 2020, 98. [Google Scholar] [CrossRef]

- Chen, Y.; Kuo, T.; Kao, W.; Tsai, J.; Chen, W.; Fan, K. An improved method of soil-gas sampling for pipeline leak detection: Flow model analysis and laboratory test. J. Nat. Gas. Sci. Eng. 2017, 42, 226–231. [Google Scholar] [CrossRef]

- Murvay, P.S.; Silea, I. A survey on gas leak detection and localization techniques. J. Loss Prev. Process. Ind. 2012, 25, 966–973. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Q.; Shi, L.; Yang, Q. Underwater gas pipeline leakage source localization by distributed fiber-optic sensing based on particle swarm optimization tuning of the support vector machine. Appl. Opt. 2016, 55, 242. [Google Scholar] [CrossRef] [PubMed]

- Mendoza, M.; Carrillo, A.; Márquez, A. New distributed optical sensor for detection and localization of liquid hydrocarbons: Part II: Optimization of the elastomer performance. Sens. Actuators A Phys. 2004, 111, 154–165. [Google Scholar] [CrossRef]

- Sheltami, T.R.; Bala, A.; Shakshuki, E.M. Wireless sensor networks for leak detection in pipelines: A survey. J. Ambient Intell. Humaniz. Comput. 2016, 7, 347–356. [Google Scholar] [CrossRef]

- Hauge, E.; Aamo, O.M.; Godhavn, J.M. Model-based monitoring and leak detection in oil and gas pipelines. SPE Proj. Facil. Constr. 2009, 4, 53–60. [Google Scholar] [CrossRef]

- Torres, L.; Verde, C.; Besancon, G.; Gonzalez, O. High-gain observers for leak location in subterranean pipelines of liquefied petroleum gas. Int. J. Robust Nonlinear Control 2014, 24, 1127–1141. [Google Scholar] [CrossRef]

- Piskur, P.; Szymak, P.; Jaskólski, K.; Flis, L.; Gąsiorowski, M. Hydroacoustic system in a biomimetic underwater vehicle to avoid collision with vessels with low- speed propellers in a controlled environment. Sensors 2020, 20, 968. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, H.; Duan, F.; Wang, X.; Fu, X.; Li, C.; Sun, Z.; Dong, X. Self-contained high-SNR underwater acoustic signal acquisition node and synchronization sampling method for multiple distributed nodes. Sensors 2019, 19, 4749. [Google Scholar] [CrossRef]

- Enguix, I.F.; Egea, M.S.; González, A.G.; Serrano, D.A. Underwater acoustic impulsive noise monitoring in port facilities: Case study of the port of cartagena. Sensors 2019, 19, 4672. [Google Scholar] [CrossRef]

- De Luna, D.R.; Palitó, T.T.C.; Assagra, Y.A.O.; Altafim, R.A.P.; Carmo, J.P.; Altafim, R.A.C.; Carneiro, A.A.O.; De Sousa, V.A. Ferroelectret-based hydrophone employed in oil identification-A machine learning approach. Sensors 2020, 20, 2979. [Google Scholar] [CrossRef]

- Egorov, E.; Shabalina, A.; Zaitsev, D.; Kurkov, S.; Gueorguiev, N. Frequency response stabilization and comparative studies of MET hydrophone at marine seismic exploration systems. Sensors 2020, 20, 1944. [Google Scholar] [CrossRef]

- Praczyk, T.; Szymak, P.; Naus, K.; Pietrukaniec, L.; Hożyń, S. Report on Research with Biomimetic Autonomous Underwater Vehicle—Navigation and Autonomous Operation. Zesz. Nauk. Akad. Mar. Wojennej 2019, 213, 53–67. [Google Scholar] [CrossRef][Green Version]

- Kumar, A.; Gandhi, C.P.; Zhou, Y.; Kumar, R.; Xiang, J. Variational mode decomposition based symmetric single valued neutrosophic cross entropy measure for the identification of bearing defects in a centrifugal pump. Appl. Acoust. 2020, 165, 107294. [Google Scholar] [CrossRef]

- Kumar, A.; Gandhi, C.P.; Zhou, Y.; Kumar, R.; Xiang, J. Improved deep convolution neural network (CNN) for the identification of defects in the centrifugal pump using acoustic images. Appl. Acoust. 2020, 167, 107399. [Google Scholar] [CrossRef]

- Shen, S.; Yang, H.; Yao, X.; Li, J.; Xu, G.; Sheng, M. Ship type classification by convolutional neural networks with auditory-like mechanisms. Sensors 2020, 20, 253. [Google Scholar] [CrossRef]

- Meltzer, G.; Ivanov, Y.Y. Fault detection in gear drives with non-stationary rotational speed - Part I: The time-frequency approach. Mech. Syst. Signal Process. 2003, 17, 1033–1047. [Google Scholar] [CrossRef]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Snin, H.H.; Zheng, Q.; Yen, N.C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hubert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Kuo, C.; Lin, W.S.; Dressel, C.A.; Chiu, A.W.L. Ensemble Empirical Mode Decomposition. Source 2011, 55, 6281–6284. [Google Scholar]

- Jin, H.; Zhang, L.; Liang, W.; Ding, Q. Integrated leakage detection and localization model for gas pipelines based on the acoustic wave method. J. Loss Prev. Process. Ind. 2014, 27, 74–88. [Google Scholar] [CrossRef]

- Wang, C.X.; Zhang, T.; Hou, G.X. Noise prediction of submerged free jet based on theory of vortex sound. Chuan Bo Li Xue/J. Sh. Mech. 2010, 14, 670–677. [Google Scholar]

- Lighthill, M.J. On Sound Generated Aerodynamically, II. Turbulence as a Source of Sound. Proc. R. Soc. Lond. Ser. A 1954, 222, 1–32. [Google Scholar]

- Lighthill, M.J. On Sound Generated Aerodynamically, I. General Theory. Proc. R. Soc. Lond. Ser. A 1952, 211, 564–587. [Google Scholar]

- Ayenu-prah, A.; Attoh-okine, N.I.I. A criterion for selecting relevant intrinsic mode functions in empirical mode decomposition. Analysis 2010, 2, 1–24. [Google Scholar] [CrossRef]

- Schmidhuber, J. Deep learning in neural networks. Neural Netw. 2015. [CrossRef]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2323. [Google Scholar] [CrossRef]

| Name | Range | Accuracy |

|---|---|---|

| DHP8501 Digital hydrophone | 20 Hz–20 kHz | ±1.5 dB |

| ZB-0.10/8B Air compressor | 0–0.8 MPa | – |

| WZB Pressure tank | 0–108 L | – |

| Self-priming pump | 0–30 m | – |

| Flowmeter | 0–50 m3/h | ±0.5% |

| Pressure gauge | 0–1 MPa | ±1% |

| Name | DN25 | DN20 | DN15 | DN8 |

|---|---|---|---|---|

| Diameter (mm) | 25 | 20 | 15 | 8 |

| Layer | Layer Name | Layer Size |

|---|---|---|

| 1 | Input | 875 × 656 × 3 |

| 2 | Reshape | 36 × 36 × 1 |

| 3 | Convolution1 | 5 × 5 × 16 |

| 4 | Max Pooling1 | 2 × 2 with stride 2 |

| 5 | Convolution2 | 3 × 3 × 32 |

| 6 | Max Pooling2 | 2 × 2 with stride 2 |

| 7 | Fully connected layer | 128 |

| 8 | Softmax | – |

| 9 | Classify output layer | – |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Y.; Xiao, Y.; Liu, X.; Liu, G.; Jiang, W.; Qin, J. Time-Frequency Distribution Map-Based Convolutional Neural Network (CNN) Model for Underwater Pipeline Leakage Detection Using Acoustic Signals. Sensors 2020, 20, 5040. https://doi.org/10.3390/s20185040

Xie Y, Xiao Y, Liu X, Liu G, Jiang W, Qin J. Time-Frequency Distribution Map-Based Convolutional Neural Network (CNN) Model for Underwater Pipeline Leakage Detection Using Acoustic Signals. Sensors. 2020; 20(18):5040. https://doi.org/10.3390/s20185040

Chicago/Turabian StyleXie, Yingchun, Yucheng Xiao, Xuyan Liu, Guijie Liu, Weixiong Jiang, and Jin Qin. 2020. "Time-Frequency Distribution Map-Based Convolutional Neural Network (CNN) Model for Underwater Pipeline Leakage Detection Using Acoustic Signals" Sensors 20, no. 18: 5040. https://doi.org/10.3390/s20185040

APA StyleXie, Y., Xiao, Y., Liu, X., Liu, G., Jiang, W., & Qin, J. (2020). Time-Frequency Distribution Map-Based Convolutional Neural Network (CNN) Model for Underwater Pipeline Leakage Detection Using Acoustic Signals. Sensors, 20(18), 5040. https://doi.org/10.3390/s20185040