Design of a High Precision Ultrasonic Gas Flowmeter

Abstract

1. Introduction

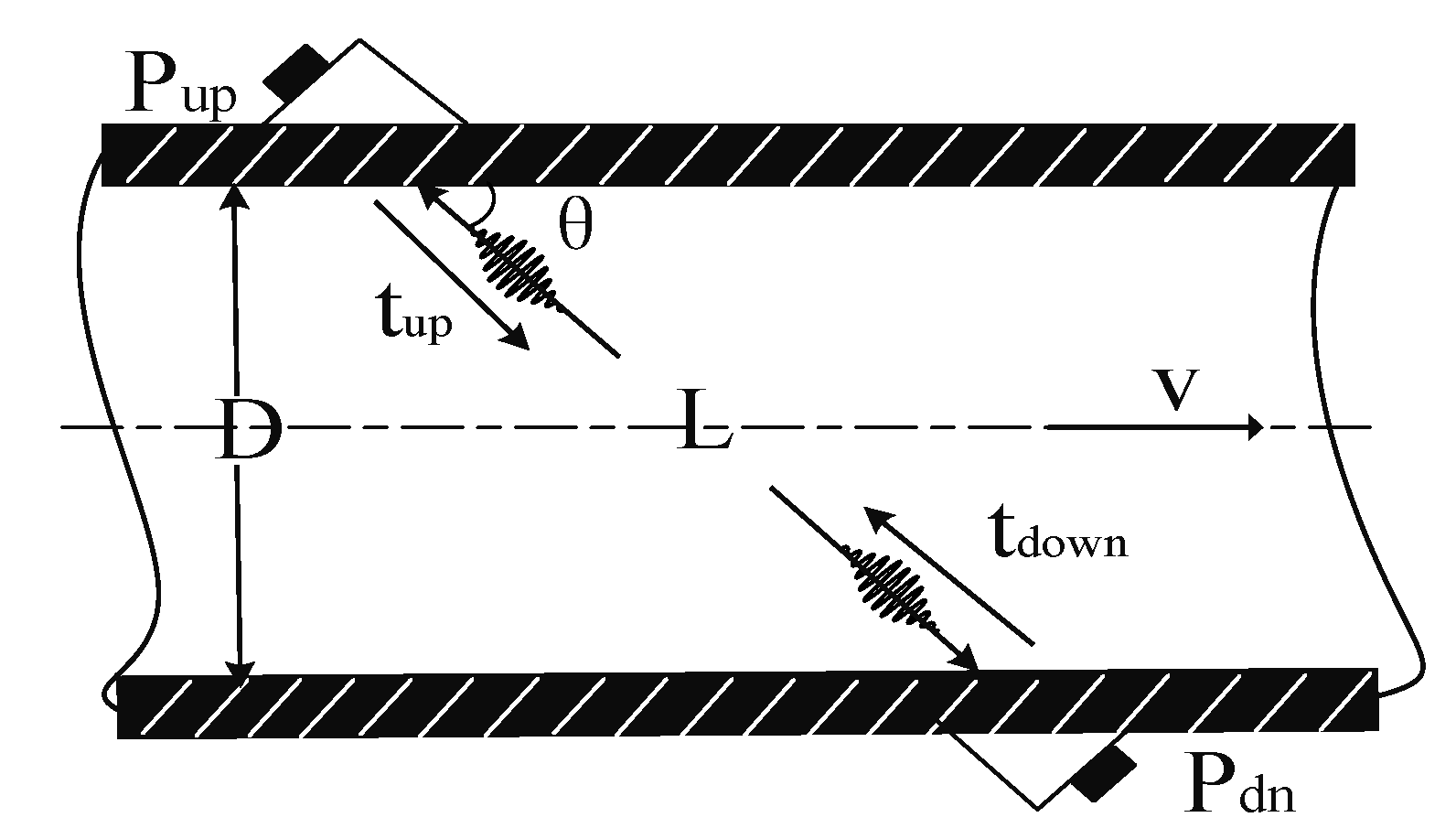

2. Method of Time-Difference Measurement

Principle of Time Difference Measurement

3. Hardware Design and Signal-Processing Process

3.1. Overall Hardware Design

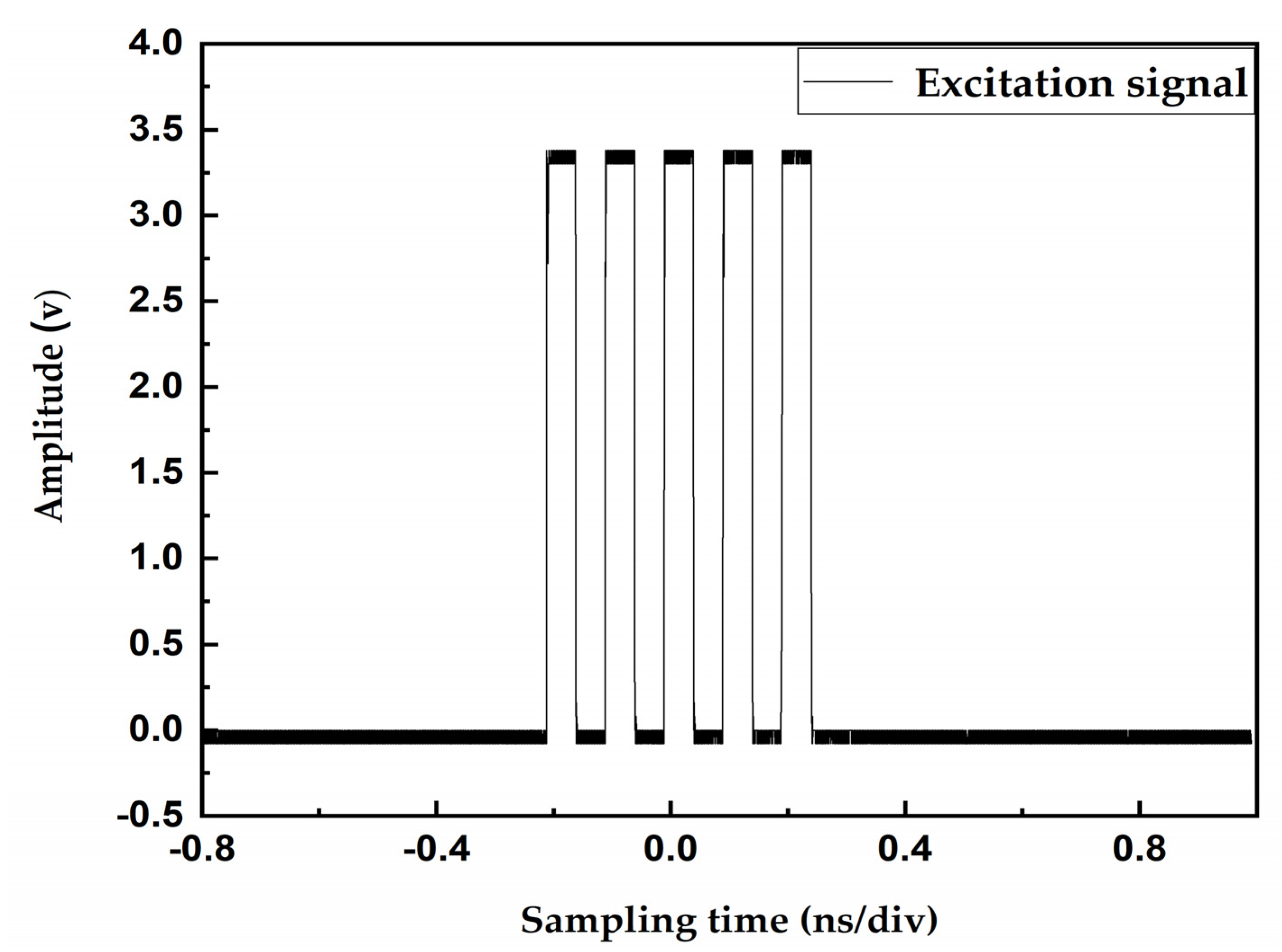

3.2. TDC-GP22 Circuit Generates an Excitation Signal

3.3. The Amplified Excitation Signal by the Amplifier Circuit

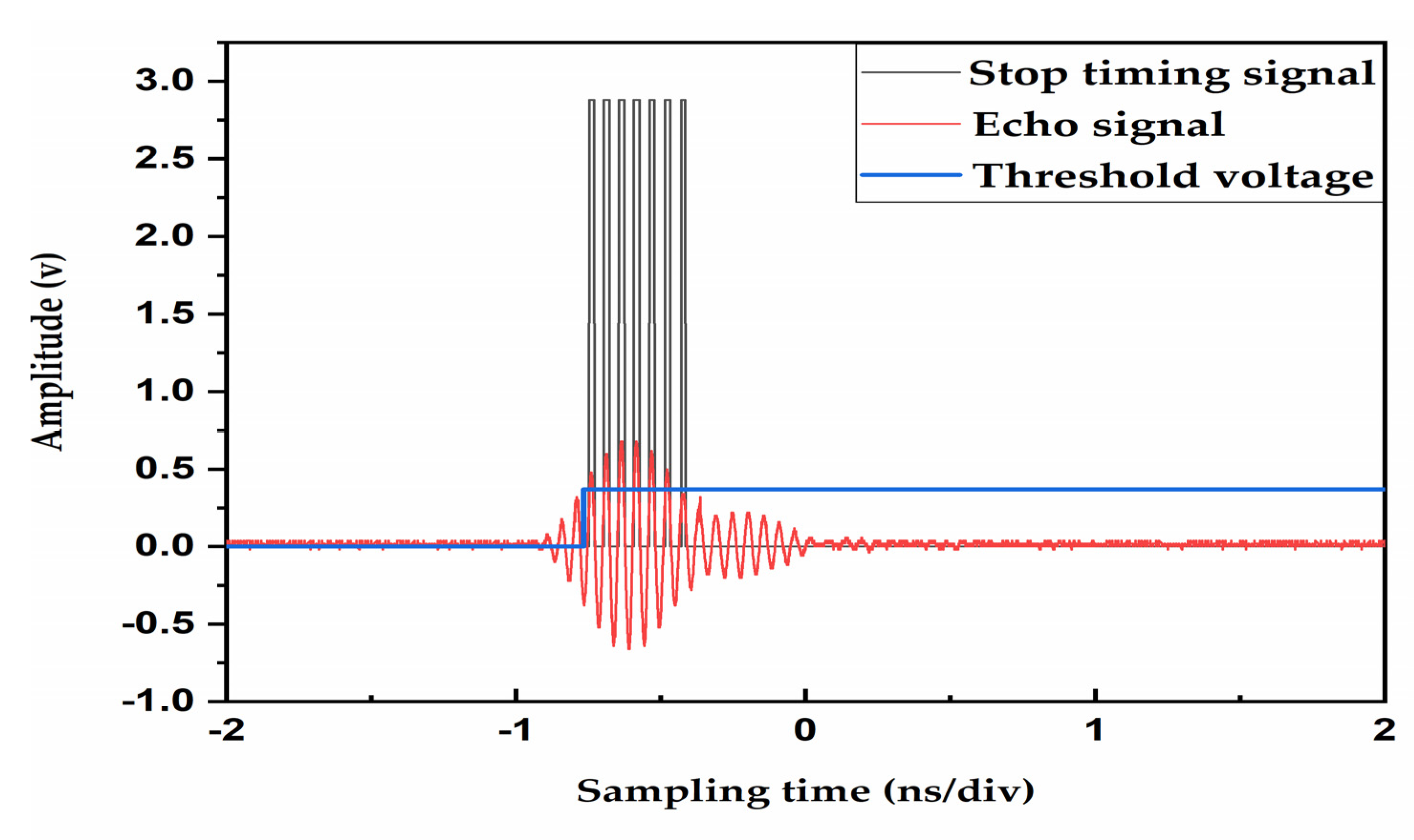

3.4. The Receiving Circuit Processes the Echo Signal

3.5. Threshold and Zero-Crossing Comparison Circuit Generates Stop Timing Signal

4. Software Design

4.1. Software System Design

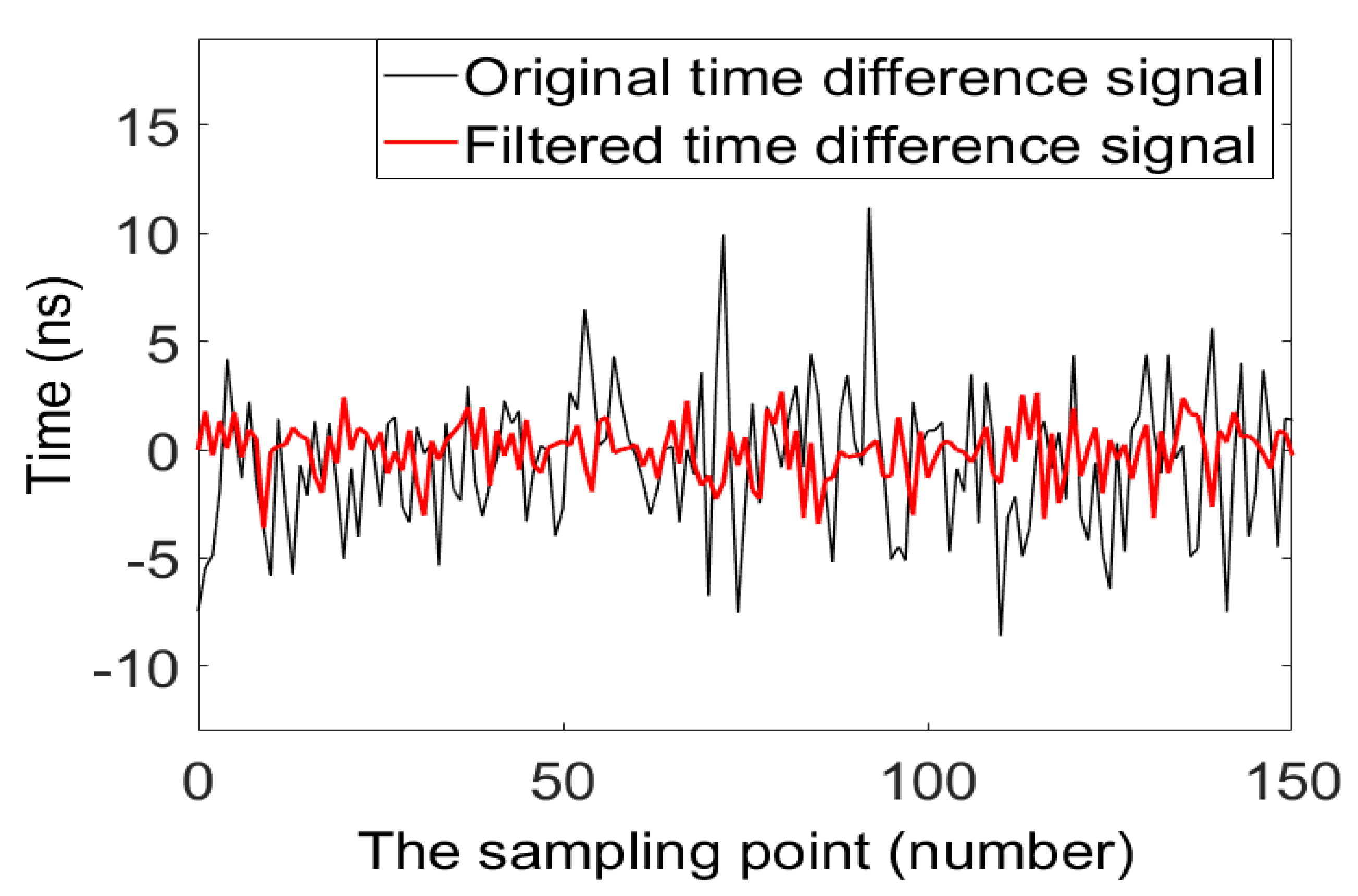

4.2. Data Filtering

4.2.1. Kalman Filtering Algorithm

- Predict the current state:

- The covariance of prior estimation errors:

- Gain calculation:

- Status estimate update:

- The covariance of posterior estimation error:

4.2.2. Filter Algorithm Combining Kalman and Arithmetic Average

5. Results and Discussion

5.1. Experimental Device

5.2. Zero-Drift Discussion

5.3. Experimental Data

5.4. Data Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hamouda, A.; Manck, O.; Hafiane, M.L.; Bouguechal, N.E. An Enhanced Technique for Ultrasonic Flow Metering Featuring Very Low Jitter and Offset. Sensors 2016, 16, 1008. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z. Study on Key Technology of Multi-Channel Ultrasonic Gas Flowmeter Signal Processing Based on Zero-Crossing Detection. Master’s Thesis, Hefei University of Technology, Hefei, China, 2017. (In Chinese). [Google Scholar]

- Yan, J.; Bian, K. Design and realization of ultrasonic gas meter. Ind. Metrol. 2013, 23, 46–48. (In Chinese) [Google Scholar]

- Luca, A.; Fodil, K.; Zerarka, A. Full-wave numerical simulation of ultrasonic transit-time gas flowmeters. In Proceedings of the IEEE Ultrasonics Symposium, Tours, France, 18–21 September 2016; pp. 1–4. [Google Scholar]

- Arpino, F.; Dell’Isola, M.; Ficco, G.; Vigo, P. Unaccounted for gas in natural gas transmission networks: Prediction model and analysis of the solutions. J. Nat. Gas Sci. Eng. 2014, 17, 58–70. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, C.W.; Lin, J. Effects of Velocity Profiles on Measuring Accuracy of Transit-Time Ultrasonic Flowmeter. Appl. Sci. 2019, 9, 1648. [Google Scholar] [CrossRef]

- Rajita, G.; Mandal, N. Review on transit time ultrasonic flowmeter. In Proceedings of the International Conference on Control, Instrumentation, Energy & Communication, Kolkata, India, 28–30 January 2016; pp. 88–92. [Google Scholar]

- Zheng, D.D.; Mei, J.Q.; Wang, M. Improvement of gas ultrasonic flowmeter measurement non-linearity based on ray tracing method. IET Sci. Meas. Technol. 2016, 10, 602–606. [Google Scholar] [CrossRef]

- Zheng, D.D.; Zhang, P.Y.; Xu, T.S. Study of acoustic transducer protrusion and recess effects on ultrasonic flowmeter measurement by numerical simulation. Flow Meas. Instrum. 2011, 22, 488–493. [Google Scholar] [CrossRef]

- Guo, L.; Sun, Y.; Liu, L.; Shen, Z.; Gao, R.; Zhao, K. The flow field analysis and flow calculation of ultrasonic flowmeter based on the fluent software. Abstr. Appl. Anal. 2014, 2014, 528–602. [Google Scholar] [CrossRef]

- Zhao, X. Development of Single-Path Ultrasonic Flowmeter. Master’s Thesis, China Jiliang University, Hangzhou, China, 2013. (In Chinese). [Google Scholar]

- Li, Y. Ultrasonic Flowmeter Structure Design Based on Structure and Flow Field Analysis. Master’s Thesis, Zhejiang University, Hangzhou, China, 2015. (In Chinese). [Google Scholar]

- Chen, H.X.; Zuo, M.J.; Wang, X.D.; Hoseini, M.R. An adaptive Morlet wavelet filter for time-of-flight estimation in ultrasonic damage assessment. Measurement 2010, 43, 570–585. [Google Scholar] [CrossRef]

- Yao, P. Measurement Accuracy Improvement Method of Gas Ultrasonic Flowmeter in Complex Flow Field. Master’s Thesis, Zhejiang University, Hangzhou, China, 2018. (In Chinese). [Google Scholar]

- Willatzen, M.; Kamath, H. Nonlinearities in ultrasonic flow measurement. Flow Meas. Instrum. 2008, 19, 79–84. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Y.; Chen, X. Acoustic propagation in viscous fluid with uniform flow and a novel design methodology for ultrasonic flowmeter. Ultrasonics 2013, 53, 595–606. [Google Scholar] [CrossRef]

- Chen, Q.; Li, W.; Wu., J. Realization of a multipath ultrasonic gas flowmeter based on transit-time technique. Ultrasonics 2014, 54, 285–290. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Kim, S.; Park, S. Two-dimensional ultrasonic anemometer using the directivity angle of an ultrasonic sensor. Microelectron. J. 2008, 39, 1195–1199. [Google Scholar] [CrossRef]

- Iooss, B.; Lhuillier, C.; Jeanneau, H. Numerical simulation of transit-time ultrasonic flowmeters: Uncertainties due to flow profile and fluid turbulence. Ultrasonics 2002, 40, 1009–1015. [Google Scholar] [CrossRef]

- Li, W.H.; Chen, Q.; Wu, J.T. Double threshold ultrasonic distance measurement technique and its application. Rev. Sci. Instrum. 2014, 85, 044905. [Google Scholar] [CrossRef] [PubMed]

- Tiwari, K.A.; Raisutis, R.; Samaitis, V. Hybrid signal processing technique to improve the defect estimation in ultrasonic non-destructive testing of composite structures. Sensors 2017, 17, 2858. [Google Scholar] [CrossRef]

- Zahiri-Azar, R.; Salcudean, S.E. Time-Delay Estimation in Ultrasound Echo Signals Using Individual Sample Tracking. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 2640–2650. [Google Scholar] [CrossRef]

- Ding, F.; Zhang, X.; Xu, L. The innovation algorithms for multivariable state-space models. Int. J. Adapt. Control Signal Process. 2019, 33, 1601–1608. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, L.; Ding, F.; Hayat, T. Combined state and parameter estimation for a bilinear state space system with moving average noise. J. Frankl. Inst. 2018, 355, 3079–3103. [Google Scholar] [CrossRef]

- Buchner, H.; Kellermann, W. Improved Kalman gain computation for multichannel frequency-domain adaptive filtering and application to acoustic echo cancellation. In Proceedings of the 2002 IEEE International Conference on Acoustics, Speech, and Signal Processing, Orlando, FL, USA, 13–17 May 2002. [Google Scholar]

- Kumar, G.; Prasad, D.; Singh, R.P. Target tracking using adaptive Kalman Filter. In Proceedings of the 2017 International Conference on Smart grids, Power and Advanced Control Engineering, Bangalore, India, 17–19 August 2017; pp. 376–380. [Google Scholar]

- Li, L.; Hua, C.; Yang, H. A new adaptive unscented Kalman filter based on covariance matching technique. In Proceedings of the 2014 International Conference on Mechatronics and Control, Jinzhou, China, 3–5 July 2014; pp. 1308–1313. [Google Scholar]

- Peng, L.H.; Zhang, B.W.; Zhao, H.C.; Stephane, S.A.; Ishikawa, H.; Shimizu, K. Data integration method for multipath ultrasonic flowmeter. IEEE Sens. J. 2012, 12, 2866–2874. [Google Scholar] [CrossRef]

- Raine, A.B.; Aslam, N.; Underwood, C.P.; Danaher, S. Development of an ultrasonic airflow measurement device for ducted air. Sensors 2015, 15, 10705–10722. [Google Scholar] [CrossRef]

- Wang, Y.J.; Ding, F.; Wu, M.H. Recursive parameter estimation algorithm for multivariate output-error systems. J. Frankl. Inst. 2018, 355, 5163–5181. [Google Scholar] [CrossRef]

| Average Value of the Standard Flowmeter (m3/h) | The Value of the Verified Flowmeter (m3/h) | Average Value of the Verified Flowmeter (m3/h) | Relative Error (%) |

|---|---|---|---|

| 0.0250 | 0.0253 | 0.0257 | 2.7404 |

| 0.0259 | |||

| 0.0258 | |||

| 0.4000 | 0.3975 | 0.3933 | −1.6731 |

| 0.3922 | |||

| 0.3902 | |||

| 1.6000 | 1.6477 | 1.6174 | 1.0901 |

| 1.6233 | |||

| 1.5813 | |||

| 4.0000 | 3.9530 | 3.9705 | −0.7364 |

| 3.9348 | |||

| 4.0238 |

| Number | Difference between Maximum and Minimum (ns) | Standard Deviation (ns) |

|---|---|---|

| Sample 1 | 17.258 | 2.8873 |

| Sample 2 | 7.893 | 1.3232 |

| Particular Flow Point in the Low Zone Time Difference Data (μs) | Relative Error (%) | Particular Flow Point in the High Zone Time Difference Data (μs) | Relative Error (%) |

|---|---|---|---|

| 0.2978 | −9.4558 | 1.6293 | 0.1332 |

| 0.3561 | 8.2700 | 1.6136 | −0.8317 |

| 0.3328 | 1.1858 | 1.6385 | 0.6986 |

| Particular Flow Point in the Low Zone Time Difference Data (μs) | Relative Error (%) | Particular Flow Point in the High Zone Time Difference Data (μs) | Relative Error (%) |

|---|---|---|---|

| 0.2625 | −0.2407 | 1.5698 | −0.1950 |

| 0.2612 | −0.7347 | 1.5723 | −0.0360 |

| 0.2657 | 0.9754 | 1.5765 | 0.2310 |

| Before Data Filtering | After Data Filtering | |

|---|---|---|

| Sample average of a particular flow point in the low zone (μs) | 0.3289 | 0.2631 |

| Sample average of a particular flow point in the high zone (μs) | 1.6271 | 1.5729 |

| Relative error ΔE in the low zone | 17.7258% | 1.7101% |

| Relative error ΔE in the high zone | 1.5303% | 0.4260% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zhang, K.; Wang, L.; Yang, M. Design of a High Precision Ultrasonic Gas Flowmeter. Sensors 2020, 20, 4804. https://doi.org/10.3390/s20174804

Chen J, Zhang K, Wang L, Yang M. Design of a High Precision Ultrasonic Gas Flowmeter. Sensors. 2020; 20(17):4804. https://doi.org/10.3390/s20174804

Chicago/Turabian StyleChen, Jianfeng, Kai Zhang, Leiyang Wang, and Mingyue Yang. 2020. "Design of a High Precision Ultrasonic Gas Flowmeter" Sensors 20, no. 17: 4804. https://doi.org/10.3390/s20174804

APA StyleChen, J., Zhang, K., Wang, L., & Yang, M. (2020). Design of a High Precision Ultrasonic Gas Flowmeter. Sensors, 20(17), 4804. https://doi.org/10.3390/s20174804