Optimized CNT-PDMS Flexible Composite for Attachable Health-Care Device

Abstract

1. Introduction

2. Methods

2.1. Materials

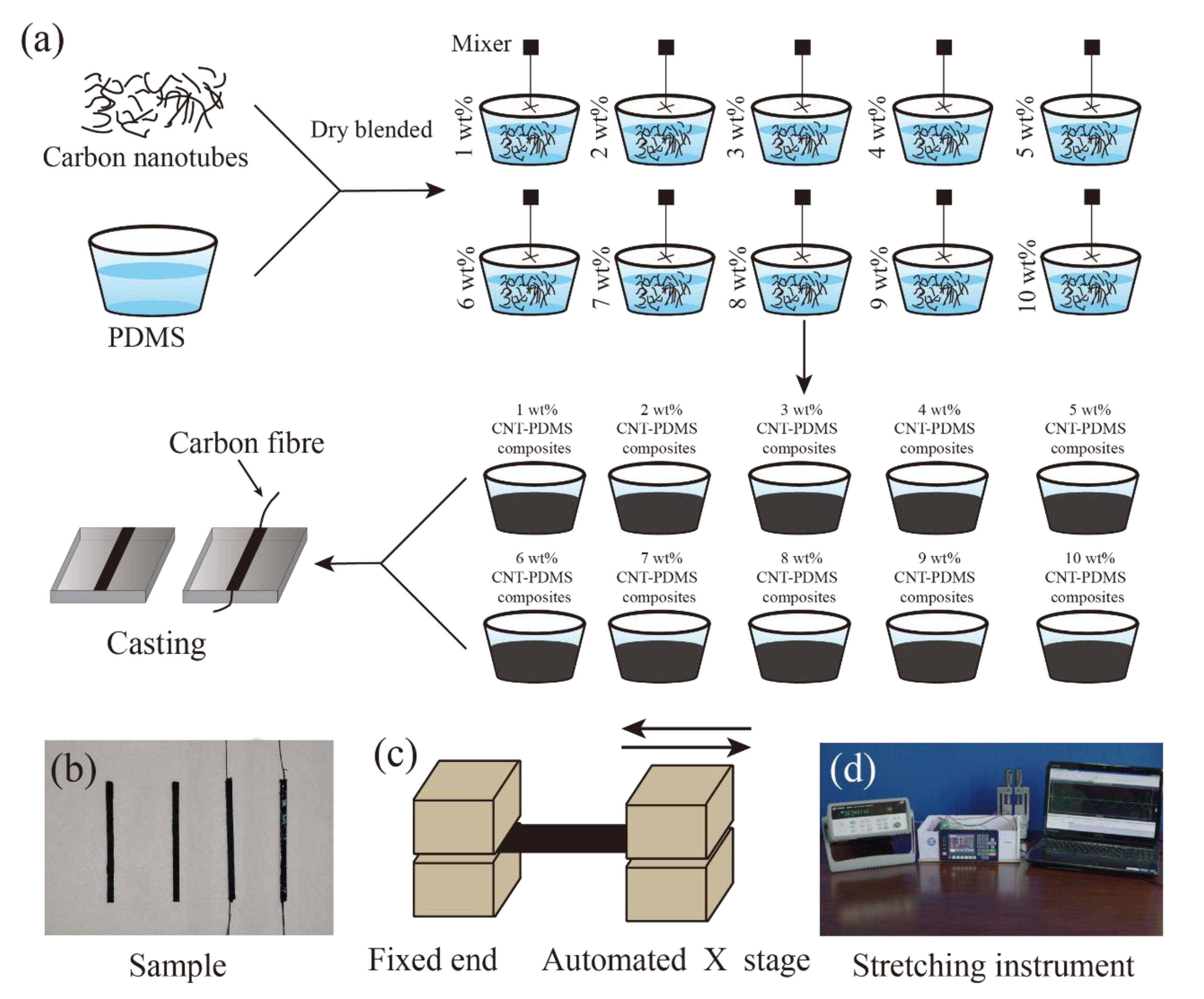

2.2. Preparation of Different Weight Ratio CNT-PDMS Composites

2.3. Measurement of Electrical Properties of the CNT-PDMS

2.4. Morphological Characterization of the CNT-PDMS Composite

2.5. Tensile Testing of the CNT-PDMS Composite

2.6. Piezoresistive Measurement of the CNT-PDMS Composite

3. Results and Discussions

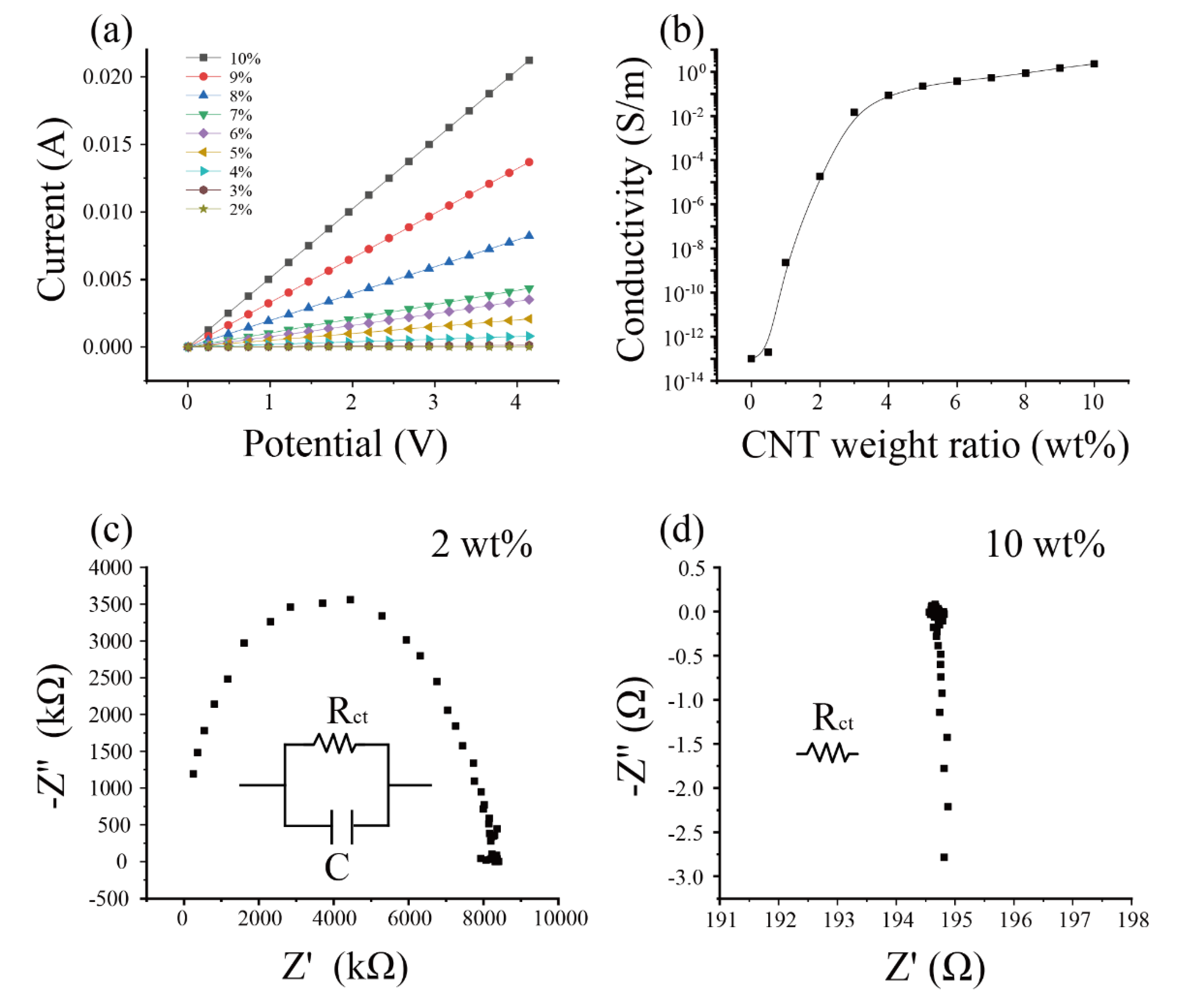

3.1. Electrical Properties of CNT-PDMS in Different Weight Ratios

3.1.1. Electrical Resistance of CNT-PDMS in Different Weight Ratios

3.1.2. Electrical Conductivities of CNT-PDMS in Different Weight Ratios

3.1.3. Electrical Impedance of the Different Weight Ratio the CNT-PDMS Composite in Alternating Current Mode

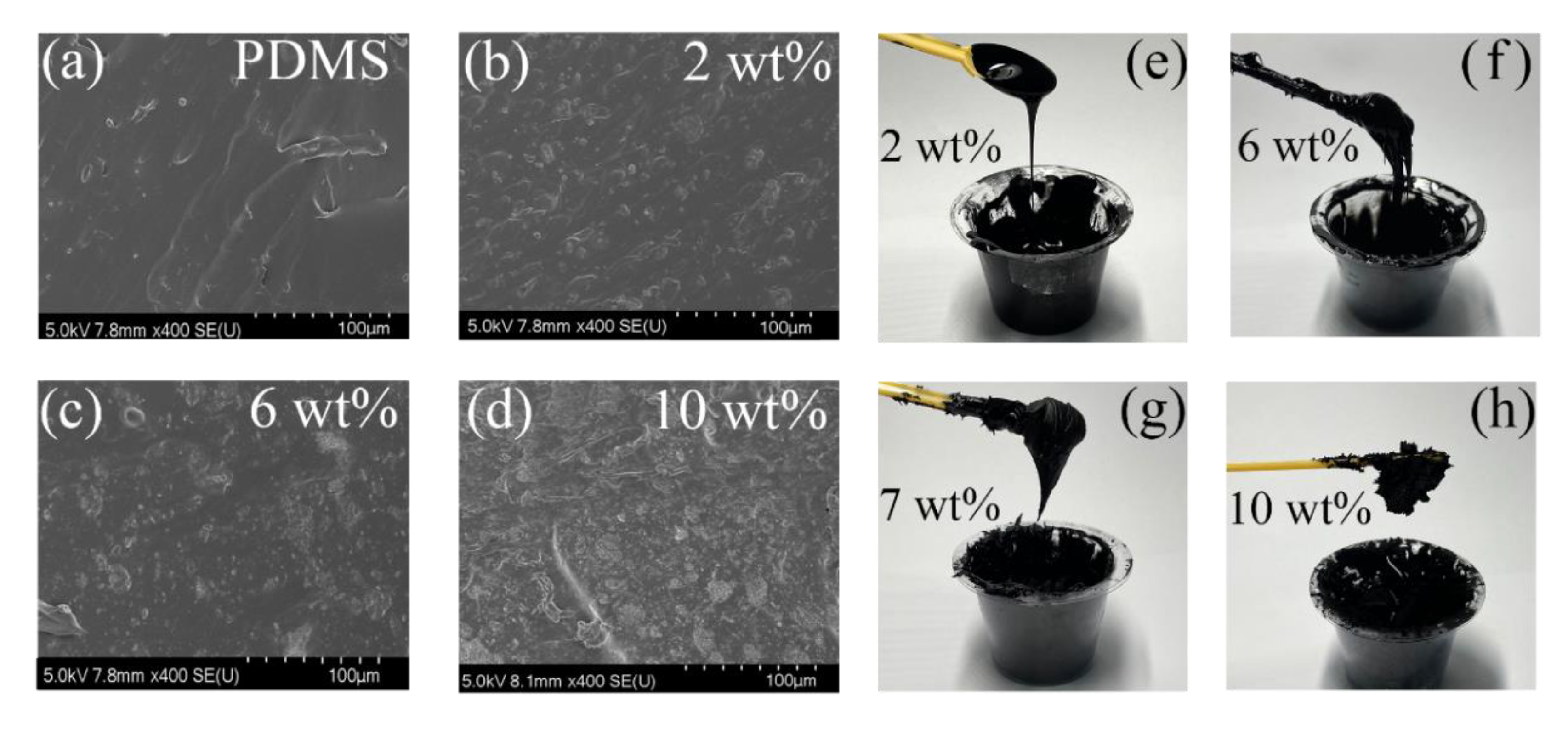

3.2. Morphologies of the CNT-PDMS Composites

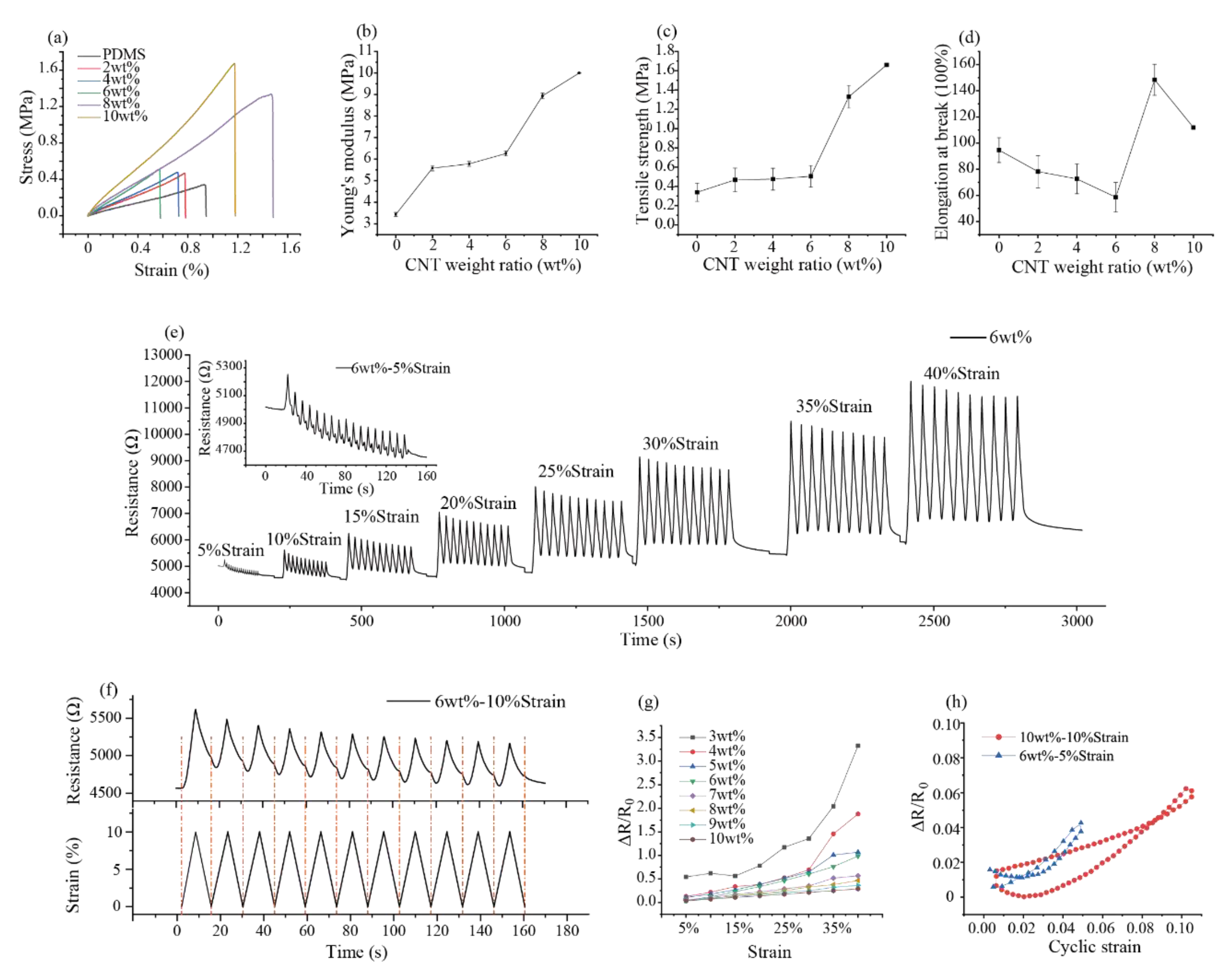

3.3. Mechanical Properties of the CNT-PDMS Composites

3.4. Piezoresistive Behavior of the CNT-PDMS Composites

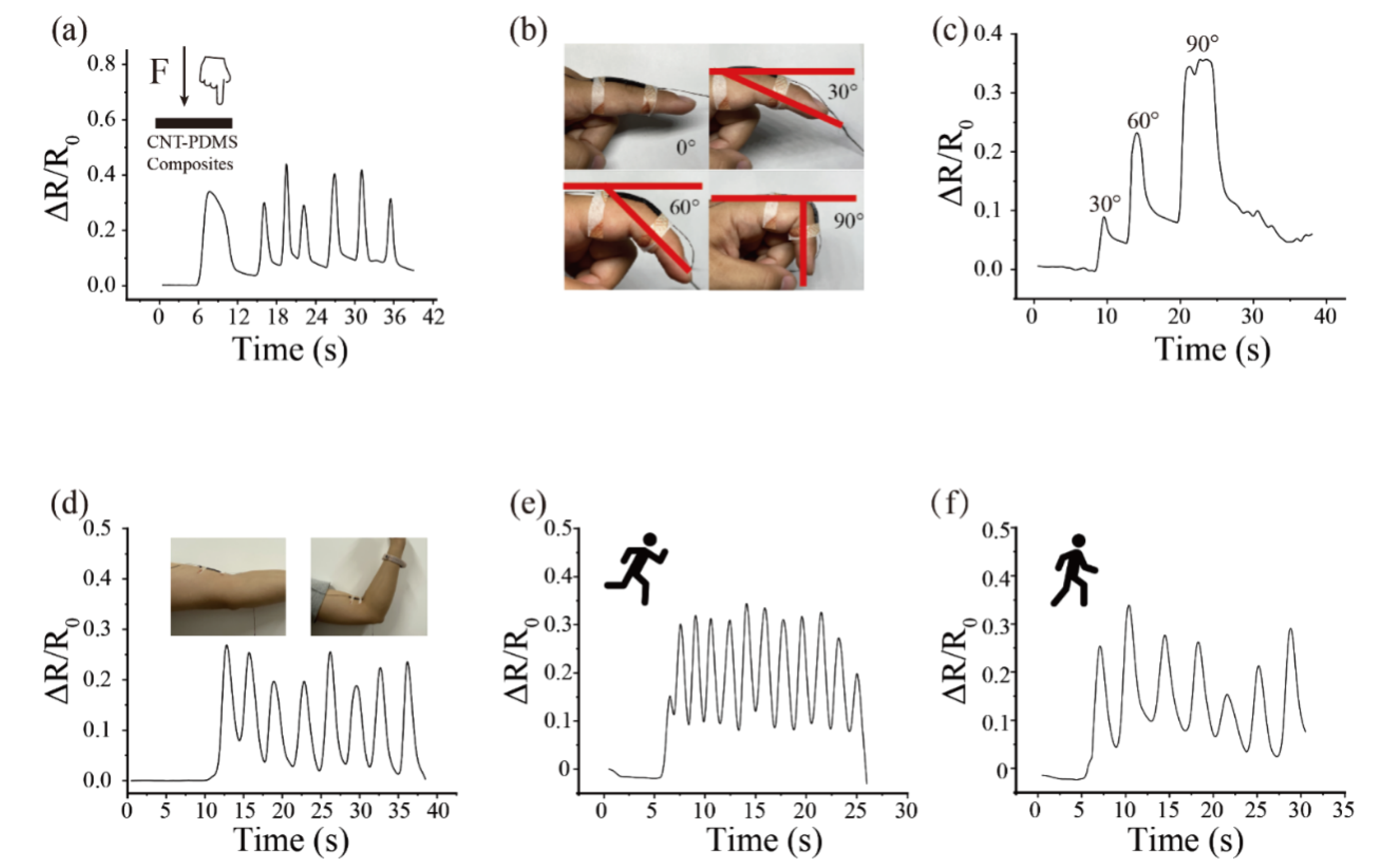

3.5. Application of the CNT-PDMS Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lou, Z.; Chen, S.; Wang, L.; Shi, R.; Li, L.; Jiang, K.; Chen, D.; Shen, G. Ultrasensitive and ultraflexible e-skins with dual functionalities for wearable electronics. Nano Energy 2017, 38, 28–35. [Google Scholar] [CrossRef]

- Marwick, T.H. Measurement of Strain and Strain Rate by Echocardiography. J. Am. Coll. Cardiol. 2006, 47, 1313–1327. [Google Scholar] [CrossRef]

- Lind, J.U.; Busbee, T.A.; Valentine, A.D.; Pasqualini, F.S.; Yuan, H.; Yadid, M.; Park, S.; Kotikian, A.; Nesmith, A.P.; Campbell, P.H.; et al. Instrumented cardiac microphysiological devices via multimaterial three-dimensional printing. Nat. Mater. 2017, 16, 303–308. [Google Scholar] [CrossRef]

- Chu, M.; Nguyen, T.; Pandey, V.; Zhou, Y.; Pham, H.N.; Bar-Yoseph, R.; Radom-Aizik, S.; Jain, R.; Cooper, D.M.; Khine, M. Respiration rate and volume measurements using wearable strain sensors. NPJ Digit. Med. 2019, 2, 8–9. [Google Scholar] [CrossRef]

- Ren, M.; Zhou, Y.; Wang, Y.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Highly stretchable and durable strain sensor based on carbon nanotubes decorated thermoplastic polyurethane fibrous network with aligned wave-like structure. Chem. Eng. J. 2019, 360, 762–777. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, L.; Fan, L.; Deng, H.; Fu, Q. Fabrication of Highly Stretchable, Washable, Wearable, Water-Repellent Strain Sensors with Multi-Stimuli Sensing Ability. ACS Appl. Mater. Interfaces 2018, 10, 31655–31663. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Chen, H.; Chen, X.; Wu, H.; Guo, H.; Cheng, X.; Meng, B.; Zhang, H. All-in-one piezoresistive-sensing patch integrated with micro-supercapacitor. Nano Energy 2018, 53, 189–197. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Y.; Dai, K.; Wang, Y.; Zheng, G.; Liu, C.; Shen, C. A highly stretchable and stable strain sensor based on hybrid carbon nanofillers/polydimethylsiloxane conductive composites for large human motions monitoring. Compos. Sci. Technol. 2018, 156, 276–286. [Google Scholar] [CrossRef]

- Bin, W.; Hossain, M.M.; Kong, S.H. PDMS-based two-axis inclinometer with a 360-degree measuring range. Sens. Actuators A Phys. 2016, 239, 54–60. [Google Scholar] [CrossRef]

- Sapra, G. CNT/Polymer Composite Strain Sensors. Available online: https://www.krishisanskriti.org/vol_image/08Jul201510074132%20%20%20%20%20%20%20%20Gaurav%20Sapra%20%20%20%20%20279-282.pdf (accessed on 11 August 2020).

- Boland, C.S.; Khan, U.; Ryan, G.; Barwich, S.; Charifou, R.; Harvey, A.; Backes, C.; Li, Z.; Ferreira, M.S.; Möbius, M.E.; et al. Sensitive electromechanical sensors using viscoelastic graphene-polymer nanocomposites. Science 2016, 354, 1257–1260. [Google Scholar] [CrossRef] [PubMed]

- Schneider, F.; Draheim, J.; Kamberger, R.; Wallrabe, U. Process and material properties of polydimethylsiloxane (PDMS) for Optical MEMS. Sens. Actuators A Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- Raczkowska, J.; Prauzner-Bechcicki, S.; Lukes, J.; Sepitka, J.; Bernasik, A.; Awsiuk, K.; Paluszkiewicz, C.; Pabijan, J.; Lekka, M.; Budkowski, A. Physico-chemical properties of PDMS surfaces suitable as substrates for cell cultures. Appl. Surf. Sci. 2016, 389, 247–254. [Google Scholar] [CrossRef]

- Khosla, A.; Gray, B.L. Fabrication of multiwalled carbon nanotube polydimethylsiloxne nanocomposite polymer flexible microelectrodes for microfluidics and MEMS. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 7–11 March 2010. [Google Scholar]

- Wang, L.; Dou, W.; Malhi, M.; Zhu, M.; Liu, H.; Plakhotnik, J.; Xu, Z.; Zhao, Q.; Chen, J.; Chen, S.; et al. Microdevice Platform for Continuous Measurement of Contractility, Beating Rate, and Beating Rhythm of Human-Induced Pluripotent Stem Cell-Cardiomyocytes inside a Controlled Incubator Environment. ACS Appl. Mater. Interfaces 2018, 10, 21173–21183. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhai, T.; Zhan, C.; Fu, Q.; Ma, C. Actuation Behavior of Multilayer Graphene Nanosheets/Polydimethylsiloxane Composite Films. Polymers 2018, 10, 1243. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef]

- Gökaltun, A.; Kang, Y.B.; Yarmush, M.L.; Usta, O.B.; Asatekin, A. Simple Surface Modification of Poly(dimethylsiloxane) via Surface Segregating Smart Polymers for Biomicrofluidics. Sci. Rep. 2019, 9. [Google Scholar] [CrossRef]

- Wen, Z.; Chen, J.; Yeh, M.; Guo, H.; Li, Z.; Fan, X.; Zhang, T.; Zhu, L.; Wang, Z.L. Blow-driven triboelectric nanogenerator as an active alcohol breath analyzer. Nano Energy 2015, 16, 38–46. [Google Scholar] [CrossRef]

- Jung, H.; Moon, J.; Baek, D.; Lee, J.; Choi, Y.; Hong, J.; Lee, S. CNT/PDMS composite flexible dry electrodes for long-term ECG monitoring. IEEE Trans. Biomed. Eng. 2012, 59, 1472–1479. [Google Scholar] [CrossRef]

- Lu, S.; Tian, C.; Wang, X.; Zhang, L.; Du, K.; Ma, K.; Xu, T. Strain sensing behaviors of GnPs/epoxy sensor and health monitoring for composite materials under monotonic tensile and cyclic deformation. Compos. Sci. Technol. 2018, 158, 94–100. [Google Scholar] [CrossRef]

- Song, Y.; Wang, H.; Cheng, X.; Li, G.; Chen, X.; Chen, H.; Miao, L.; Zhang, X.; Zhang, H. High-efficiency self-charging smart bracelet for portable electronics. Nano Energy 2019, 55, 29–36. [Google Scholar] [CrossRef]

- Khosla, A.; Gray, B.L. Preparation, characterization and micromolding of multi-walled carbon nanotube polydimethylsiloxane conducting nanocomposite polymer. Mater. Lett. 2009, 63, 1203–1206. [Google Scholar] [CrossRef]

- Xia, Y.; Whitesides, G.M. Soft lithography. Angew. Chem. Int. Ed. 1998, 37, 550–575. [Google Scholar] [CrossRef]

- Wu, C.; Lin, H.; Hsu, J.; Yip, M.; Fang, W. Static and dynamic mechanical properties of polydimethylsiloxane/carbon nanotube nanocomposites. Thin Solid Films 2009, 517, 4895–4901. [Google Scholar] [CrossRef]

- Pyo, S.; Lee, J.; Kim, M.; Chung, T.; Oh, Y.; Lim, S.; Park, J.; Kim, J. Development of a flexible three-axis tactile sensor based on screen-printed carbon nanotube-polymer composite. J. Micromech. Microeng. 2014, 24, 75012. [Google Scholar] [CrossRef]

- Hassan, S.; Yusof, M.S.; Ding, S.; Maksud, M.I.; Nodin, M.N.; Mamat, K.A.; Sazali, M.S.; Rahim, M.Z. Investigation of Carbon Nanotube Ink with PDMS Printing Plate on Fine Solid Lines Printed by Micro-flexographic Printing Method. IOP Conf. Ser. Mater. Sci. Eng. 2017, 203, 12017. [Google Scholar] [CrossRef]

- Yu, L.; Shearer, C.; Shapter, J. Recent Development of Carbon Nanotube Transparent Conductive Films. Chem. Rev. 2016, 116, 13413–13453. [Google Scholar] [CrossRef]

- Wang, X.; Li, G.; Liu, R.; Ding, H.; Zhang, T. Reproducible layer-by-layer exfoliation for free-standing ultrathin films of single-walled carbon nanotubes. J. Mater. Chem. 2012, 22, 21824. [Google Scholar] [CrossRef]

- Jeon, D.; Kim, H.; Lee, M.W.; Park, S.J.; Kim, G. Piezo-impedance response of carbon nanotube/polydimethylsiloxane nanocomposites. APL Mater. 2019, 7, 041118. [Google Scholar] [CrossRef]

- Sun, X.; Liu, X.; Shen, X.; Wu, Y.; Wang, Z.; Kim, J. Graphene foam/carbon nanotube/poly(dimethyl siloxane) composites for exceptional microwave shielding. Compos. Part A Appl. Sci. Manuf. 2016, 85, 199–206. [Google Scholar] [CrossRef]

- Nilchian, A.; Li, C. Mechanical and electrochemical characterization of CNT/PDMS composited soft and stretchable electrodes fabricated by an efficient solution-based fabrication method. J. Electroanal. Chem. 2016, 781, 166–173. [Google Scholar] [CrossRef]

- Zhang, X.; Han, M.; Meng, B.; Zhang, H. High performance triboelectric nanogenerators based on large-scale mass-fabrication technologies. Nano Energy 2015, 11, 304–322. [Google Scholar] [CrossRef]

- Rasel, M.S.; Maharjan, P.; Salauddin, M.; Rahman, M.T.; Cho, H.O.; Kim, J.W.; Park, J.Y. An impedance tunable and highly efficient triboelectric nanogenerator for large-scale, ultra-sensitive pressure sensing applications. Nano Energy 2018, 49, 603–613. [Google Scholar] [CrossRef]

- Monteiro-Riviere, N.A.; Nemanich, R.J.; Inman, A.O.; Wang, Y.Y.; Riviere, J.E. Multi-walled carbon nanotube interactions with human epidermal keratinocytes. Toxicol. Lett. 2005, 155, 377–384. [Google Scholar] [CrossRef]

- Huang, N.; Zang, J.; Zhang, G.; Guan, L.; Li, S.; Zhao, L.; Tang, L. Efficient interfacial interaction for improving mechanical properties of polydimethylsiloxane nanocomposites filled with low content of graphene oxide nanoribbons. RSC Adv. 2017, 7, 22045–22053. [Google Scholar] [CrossRef]

- Leyva Egurrola, S.; Del Castillo Castro, T.; Castillo Ortega, M.M.; Encinas, J.C.; Herrera Franco, P.J.; Bonilla Cruz, J.; Lara Ceniceros, T.E. Electrical, mechanical, and piezoresistive properties of carbon nanotube-polyaniline hybrid filled polydimethylsiloxane composites. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Kohlmeyer, R.R.; Javadi, A.; Pradhan, B.; Pilla, S.; Setyowati, K.; Chen, J.; Gong, S. Electrical and Dielectric Properties of Hydroxylated Carbon Nanotube−Elastomer Composites. J. Phys. Chem. C 2009, 113, 17626–17629. [Google Scholar] [CrossRef]

- Liu, C.; Choi, J. Strain-Dependent Resistance of PDMS and Carbon Nanotubes Composite Microstructures. IEEE Trans. Nanotechnol. 2010, 9, 590–595. [Google Scholar] [CrossRef]

- Liu, C.; Choi, J. Improved Dispersion of Carbon Nanotubes in Polymers at High Concentrations. Nanomaterials 2012, 2, 329–347. [Google Scholar] [CrossRef]

- Zhu, L.; Zhou, X.; Liu, Y.; Fu, Q. Highly Sensitive, Ultrastretchable Strain Sensors Prepared by Pumping Hybrid Fillers of Carbon Nanotubes/Cellulose Nanocrystal into Electrospun Polyurethane Membranes. ACS Appl. Mater. Interfaces 2019, 11, 12968–12977. [Google Scholar] [CrossRef]

- Lu, J.; Lu, M.; Bermak, A.; Lee, Y. Study of piezoresistance effect of carbon nanotube-PDMS composite materials for nanosensors. In Proceedings of the 2007 7th IEEE Conference on Nanotechnology (IEEE NANO), Hong Kong, China, 2–5 August 2007; pp. 1240–1243. [Google Scholar]

- Liu, C.; Choi, J. Patterning conductive PDMS nanocomposite in an elastomer using microcontact printing. J. Micromech. Microeng. 2009, 19, 085019. [Google Scholar] [CrossRef]

- Akhtarian, S.; Veladi, H.; Mohammadi Aref, S. Fabrication and characterization of conductive poly(dimethylsiloxane)-carbon nanotube nanocomposites for potential microsensor applications. Sens. Rev. 2019, 39, 1–9. [Google Scholar] [CrossRef]

- Zhang, Y.; Ge, Y.; Du, Y.; Yang, L. Monitoring of Compression and Bending Process of Reactive Powder Concrete Using MWCNTs/PDMS Composite Sensors. IEEE Sens. J. 2017, 17, 6153–6159. [Google Scholar] [CrossRef]

- Stampfer, C.; Helbling, T.; Obergfell, D.; Schöberle, B.; Tripp, M.K.; Jungen, A.; Roth, S.; Bright, V.M.; Hierold, C. Fabrication of Single-Walled Carbon-Nanotube-Based Pressure Sensors. Nano Lett. 2006, 6, 233–237. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.; Lee, J.; Kim, G.; Kim, Y.; Kang, S.; Cho, S.; Kim, S.; Kim, J.; Lee, W.; Kim, D.; et al. Rough-Surface-Enabled Capacitive Pressure Sensors with 3D Touch Capability. Small 2017, 13, 1700368. [Google Scholar] [CrossRef] [PubMed]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Nankali, M.; Nouri, N.M.; Geran Malek, N.; Sanjari Shahrezaei, M.A. Electrical properties of stretchable and skin–mountable PDMS/MWCNT hybrid composite films for flexible strain sensors. J. Compos. Mater. 2018, 53, 3047–3060. [Google Scholar] [CrossRef]

- Skákalová, V.; Kaiser, A.B.; Woo, Y.S.; Roth, S. Electronic transport in carbon nanotubes: From individual nanotubes to thin and thick networks. Phys. Rev. B 2006, 74, 085403. [Google Scholar] [CrossRef]

- Simmons, J.G. Generalized Formula for the Electric Tunnel Effect between Similar Electrodes Separated by a Thin Insulating Film. J. Appl. Phys. 1963, 34, 1793–1803. [Google Scholar] [CrossRef]

- Fu, X.; Ramos, M.; Al-Jumaily, A.M.; Meshkinzar, A.; Huang, X. Stretchable strain sensor facilely fabricated based on multi-wall carbon nanotube composites with excellent performance. J. Mater. Sci. 2019, 54, 2170–2180. [Google Scholar] [CrossRef]

- Salvetat, J.; Briggs, G.; Bonard, J.; Bacsa, R.; Kulik, A.; Stöckli, T.; Burnham, N.; Forró, L. Elastic and Shear Moduli of Single-Walled Carbon Nanotube Ropes. Phys. Rev. Lett. 1999, 82, 944–947. [Google Scholar] [CrossRef]

- Bokobza, L. Multiwall carbon nanotube elastomeric composites: A review. Polymer 2007, 48, 4907–4920. [Google Scholar] [CrossRef]

- Caneba, G.T.; Axland, J. Electrical and Thermal Coatings from a Single-Walled Carbon Nanotube (SWCNT)/Polymer Composite. J. Miner. Mater. Charact. Eng. 2004, 3, 73–80. [Google Scholar] [CrossRef]

| Sample | Tensile Strength (MPa) | Young’s Modulus (MPa) | Elongation at the Break (%) |

|---|---|---|---|

| PDMS | 0.339 | 3.434 | 94.58 |

| PDMS-CNT (2 wt%) | 0.467 | 5.583 | 78.17 |

| PDMS-CNT (4 wt%) | 0.475 | 5.783 | 72.59 |

| PDMS-CNT (6 wt%) | 0.505 | 6.262 | 58.6 |

| PDMS-CNT (8 wt%) | 1.333 | 8.938 | 148.35 |

| PDMS-NT (10 wt%) | 1.669 | 10 | 111.8 |

| CNT Content | Linear Piezoresistive Range | Sensitivity in the Linear Range | R2 (in the Linear Range) | Initial Resistance R0 (Ω) | Conductivity (S/m) |

|---|---|---|---|---|---|

| 1 wt% | —— | —— | —— | —— | <10−9 |

| 2 wt% | —— | —— | —— | >40 MΩ | <3 × 10−5 |

| 3 wt% | 15–25% | 6.086 | 0.9737 | 35,682 | 0.0147 |

| 4 wt% | 0–30% | 2.1793 | 0.9741 | 9567.2 | 0.086 |

| 5 wt% | 0–30% | 2.1689 | 0.9867 | 3280.1 | 0.223 |

| 6 wt% | 0–30% | 1.5166 | 0.9789 | 8770.4 | 0.3774 |

| 7 wt% | 0–35% | 1.4321 | 0.9578 | 1395 | 0.5451 |

| 8 wt% | 0–40% | 1.2097 | 0.9921 | 529.14 | 0.8809 |

| 9 wt% | 0–40% | 0.9119 | 0.9937 | 492.06 | 1.4674 |

| 10 wt% | 0–40% | 0.7235 | 0.9997 | 344 | 2.275 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Wang, L.; Shi, Y.; Zhang, F.; Hu, S.; Liu, P.; Li, A.; Chen, J. Optimized CNT-PDMS Flexible Composite for Attachable Health-Care Device. Sensors 2020, 20, 4523. https://doi.org/10.3390/s20164523

Du J, Wang L, Shi Y, Zhang F, Hu S, Liu P, Li A, Chen J. Optimized CNT-PDMS Flexible Composite for Attachable Health-Care Device. Sensors. 2020; 20(16):4523. https://doi.org/10.3390/s20164523

Chicago/Turabian StyleDu, Jian, Li Wang, Yanbin Shi, Feng Zhang, Shiheng Hu, Pengbo Liu, Anqing Li, and Jun Chen. 2020. "Optimized CNT-PDMS Flexible Composite for Attachable Health-Care Device" Sensors 20, no. 16: 4523. https://doi.org/10.3390/s20164523

APA StyleDu, J., Wang, L., Shi, Y., Zhang, F., Hu, S., Liu, P., Li, A., & Chen, J. (2020). Optimized CNT-PDMS Flexible Composite for Attachable Health-Care Device. Sensors, 20(16), 4523. https://doi.org/10.3390/s20164523