10 MHz Thin-Film PZT-Based Flexible PMUT Array: Finite Element Design and Characterization

Abstract

1. Introduction

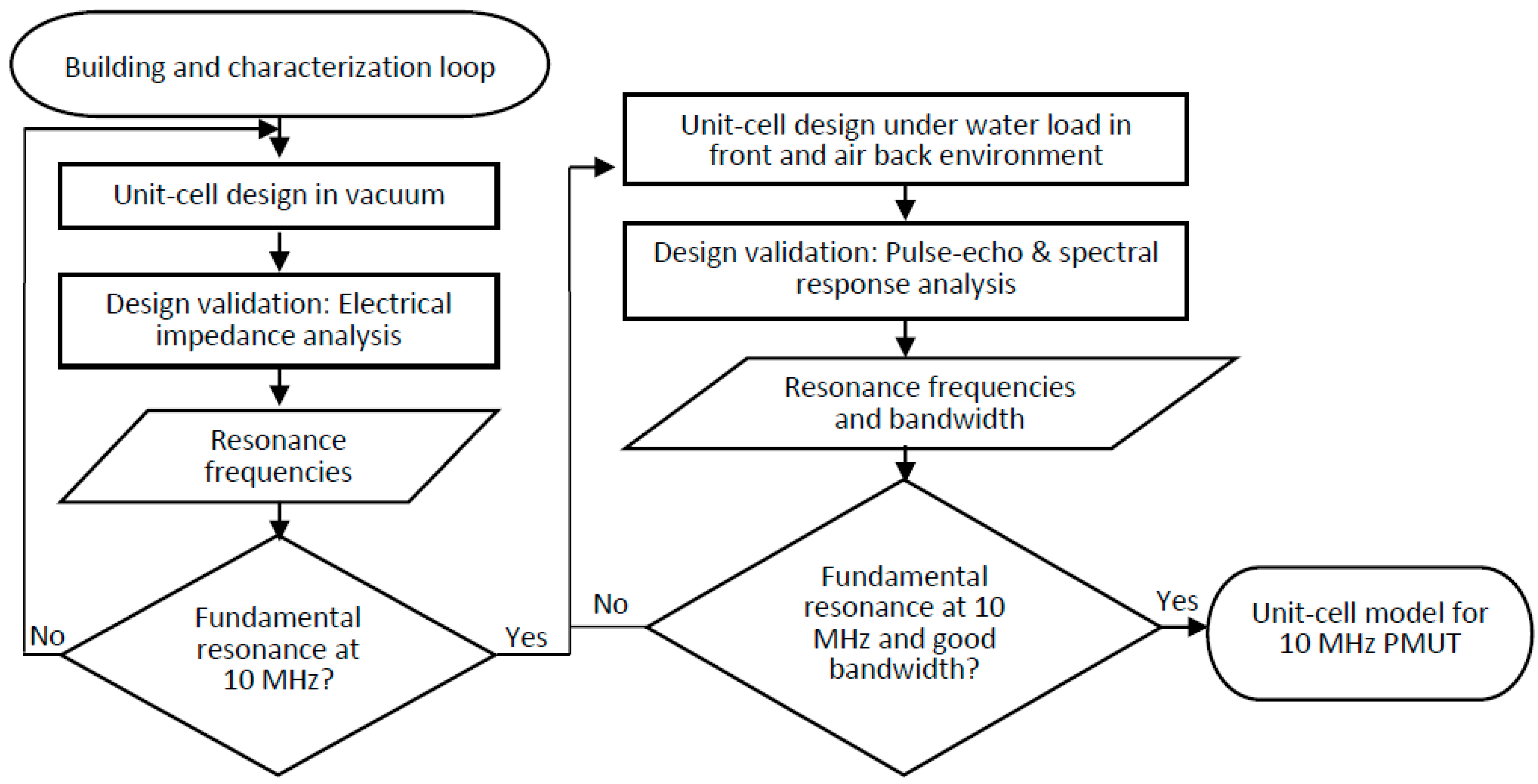

2. Unit-Cell Design

2.1. Unit-Cell Prototype 1

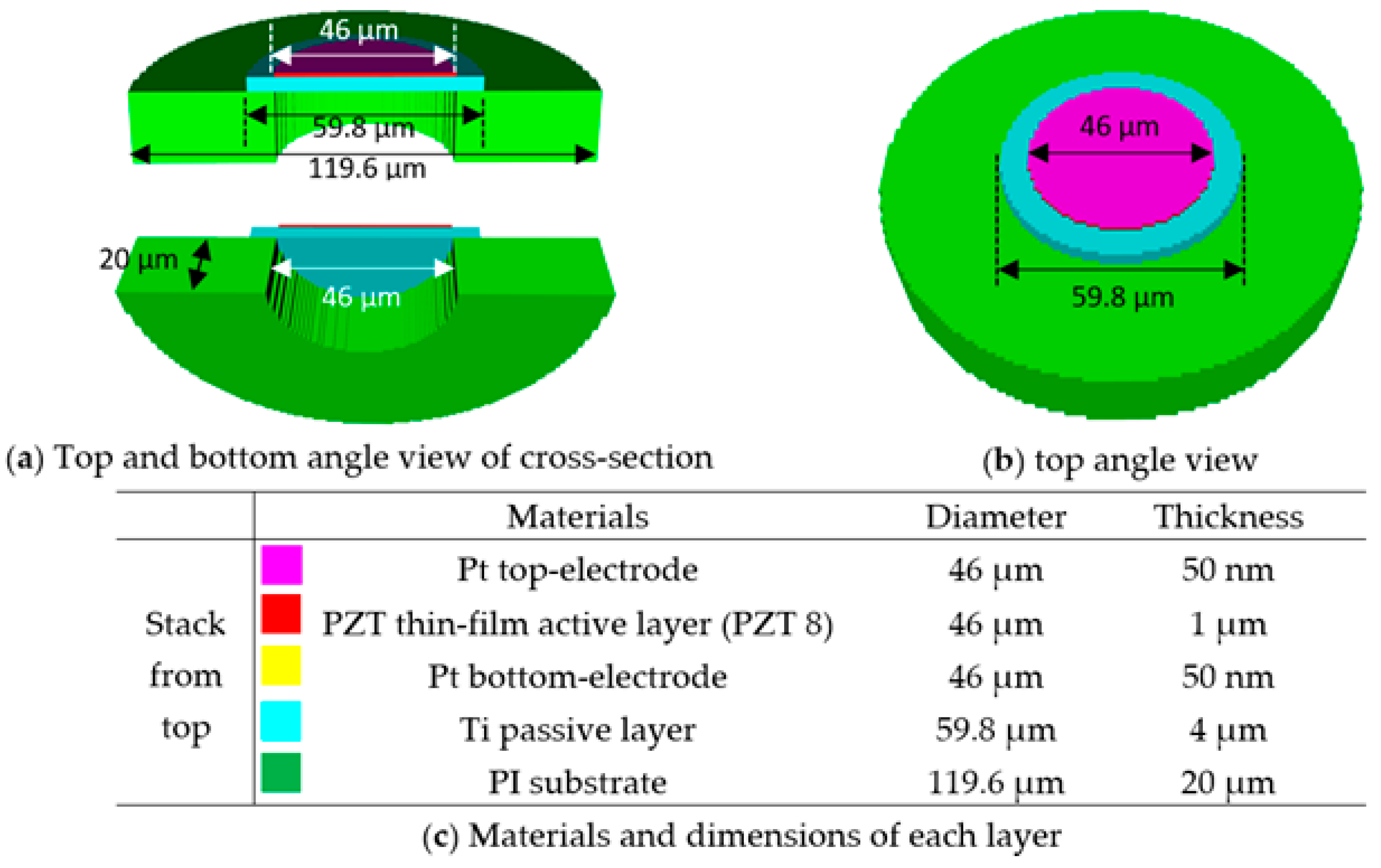

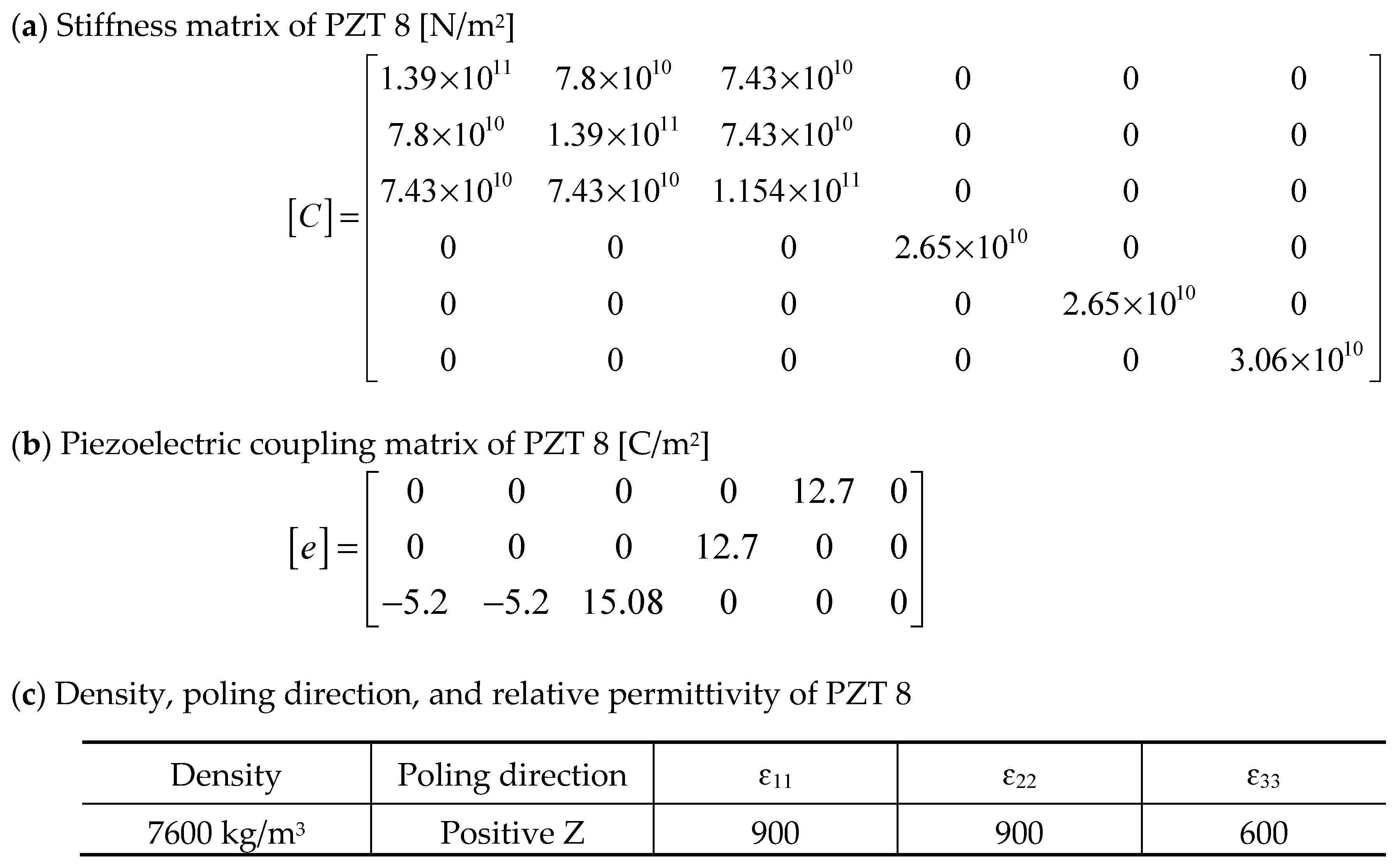

2.1.1. Dimensions and Material Properties

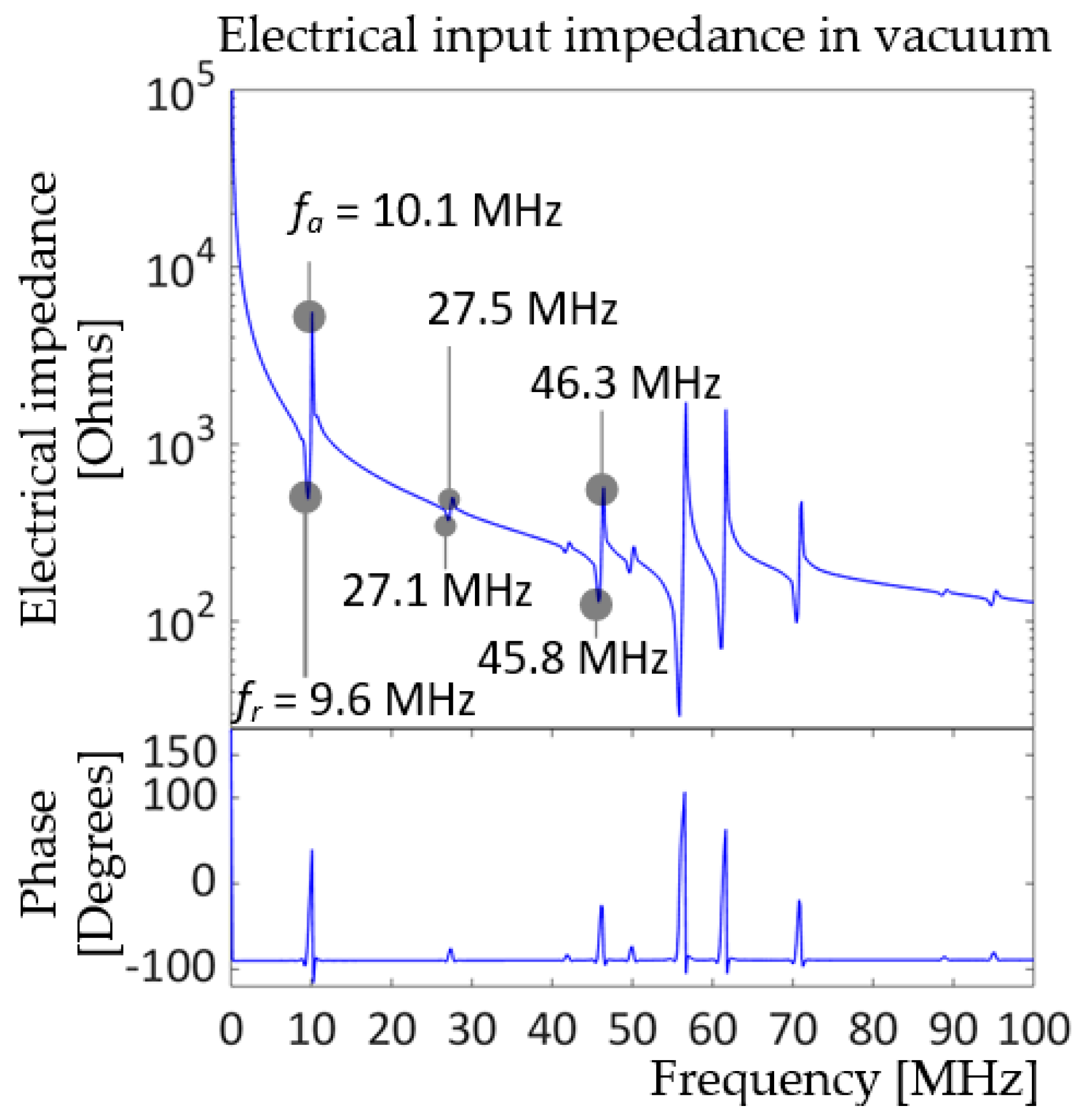

2.1.2. Validation with Electrical Input Impedance in Vacuum

2.1.3. Validation with Classic Plate Theory

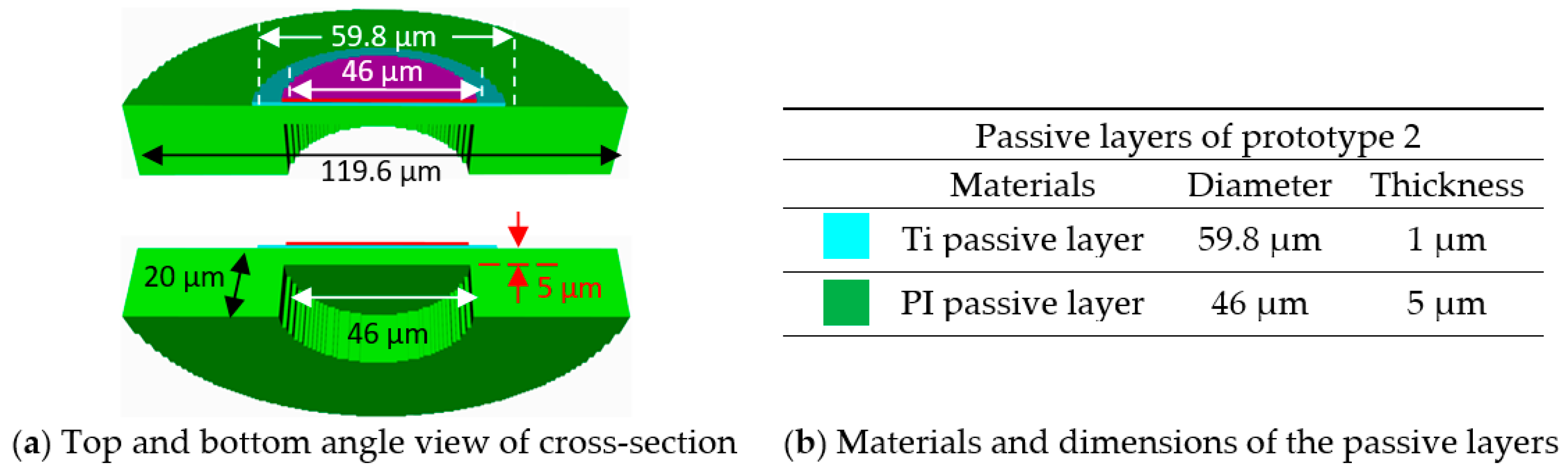

2.2. Unit-Cell Prototype 2

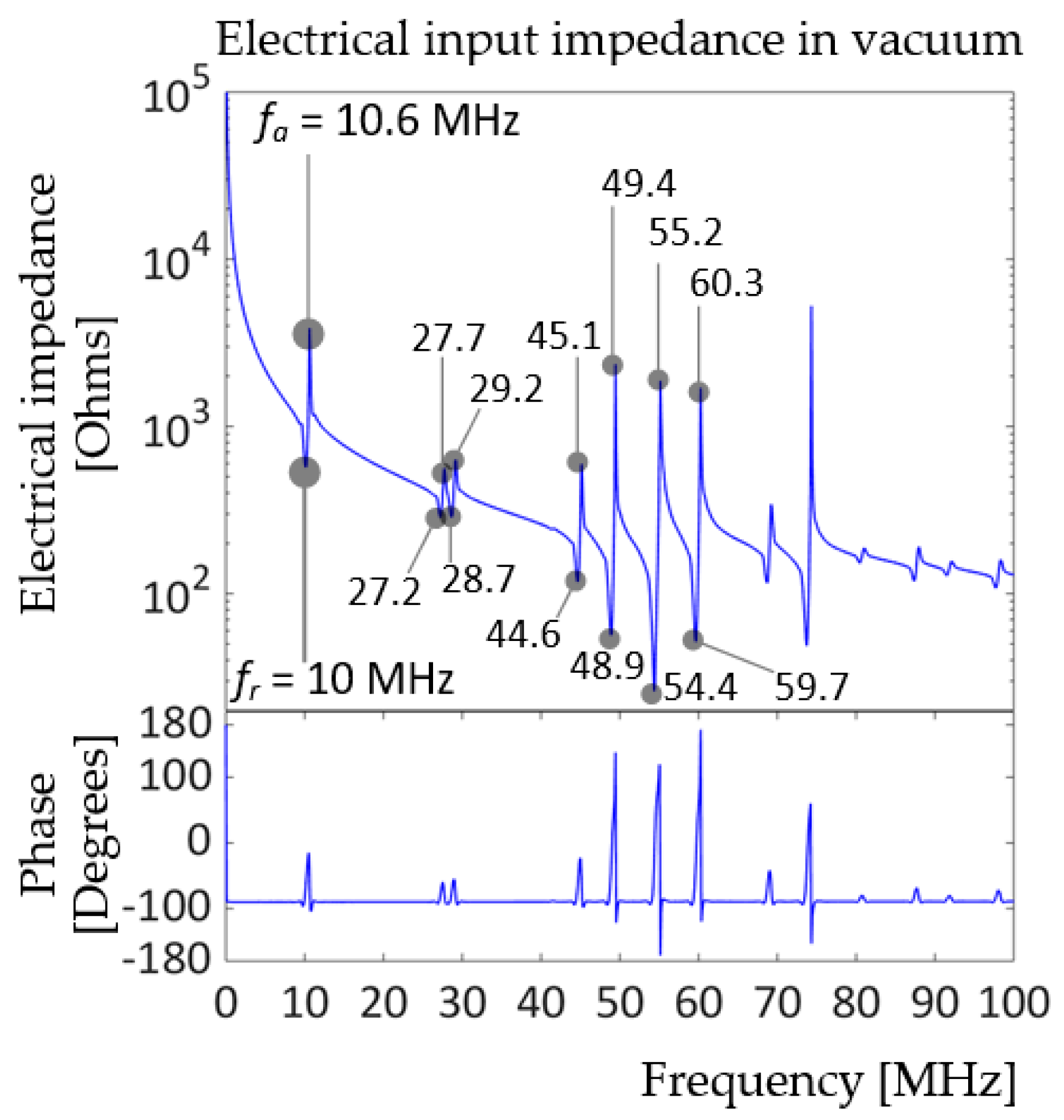

Validation with Electrical Input Impedance in Vacuum

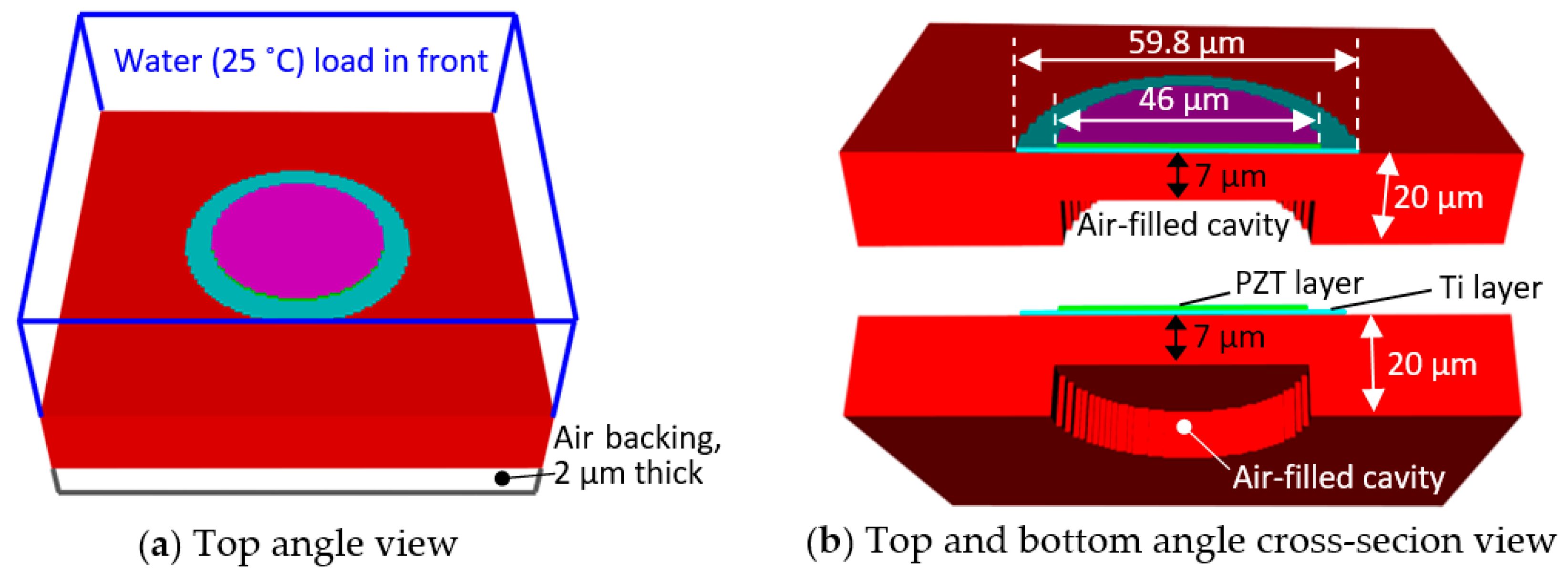

2.3. Unit-Cell with Water Load and Air-Backing

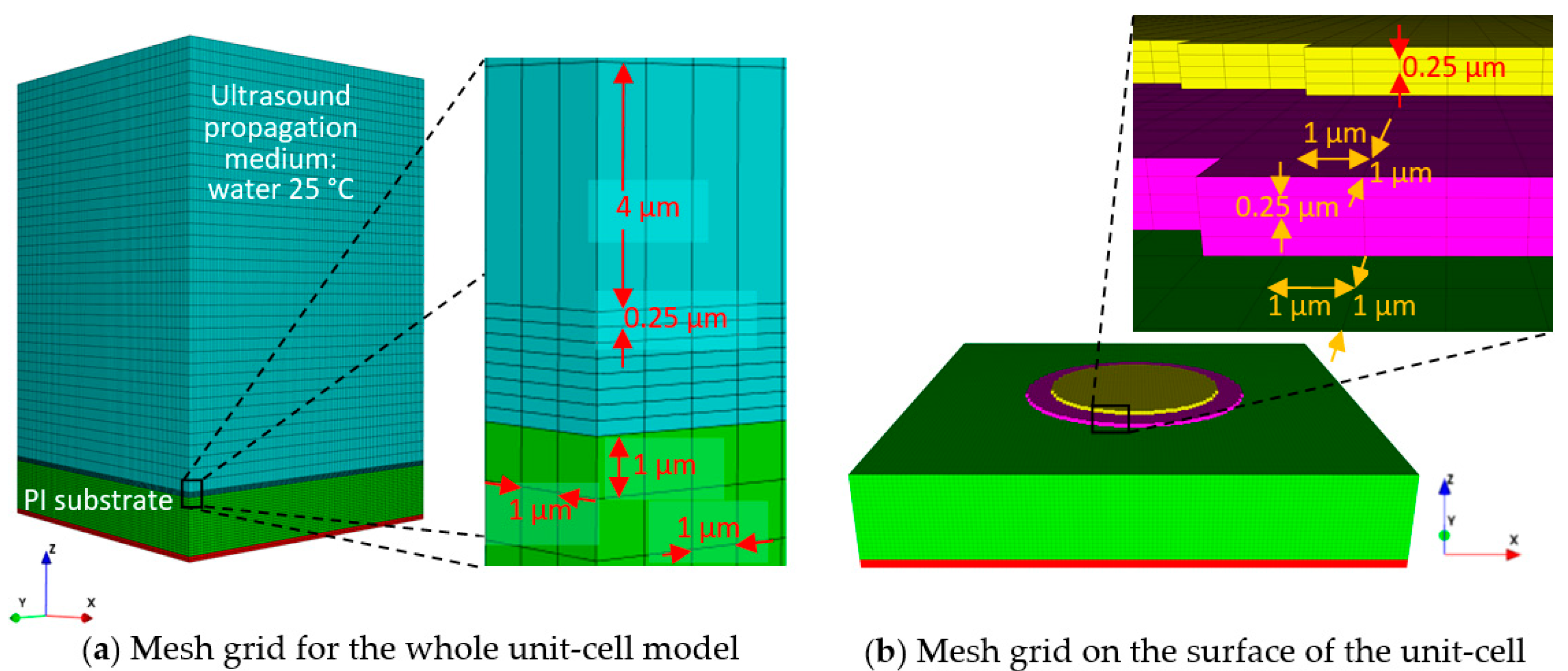

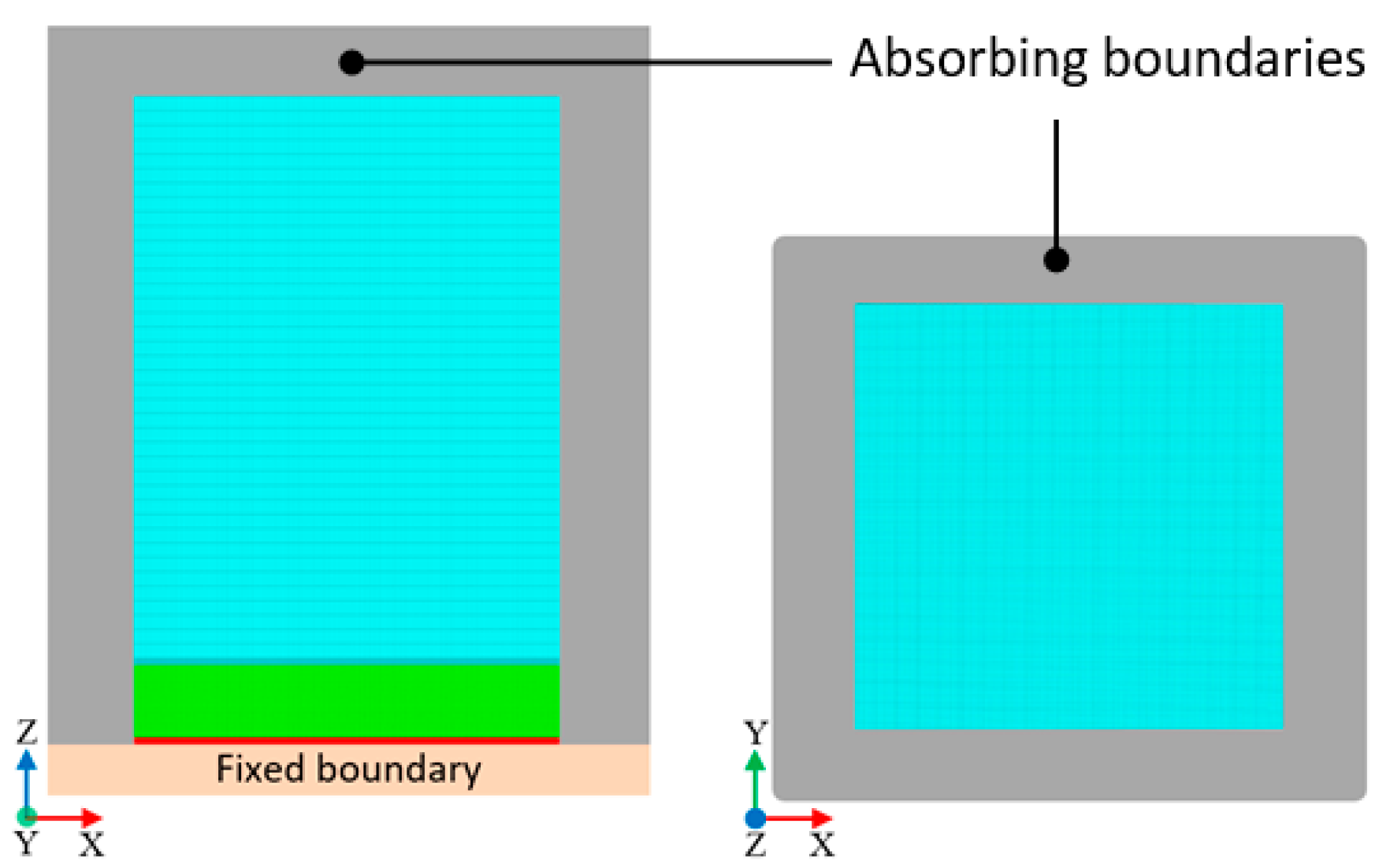

2.3.1. Boundary Conditions and Mesh for Unit-Cell Model

2.3.2. Pulse-Echo and Spectral Responses

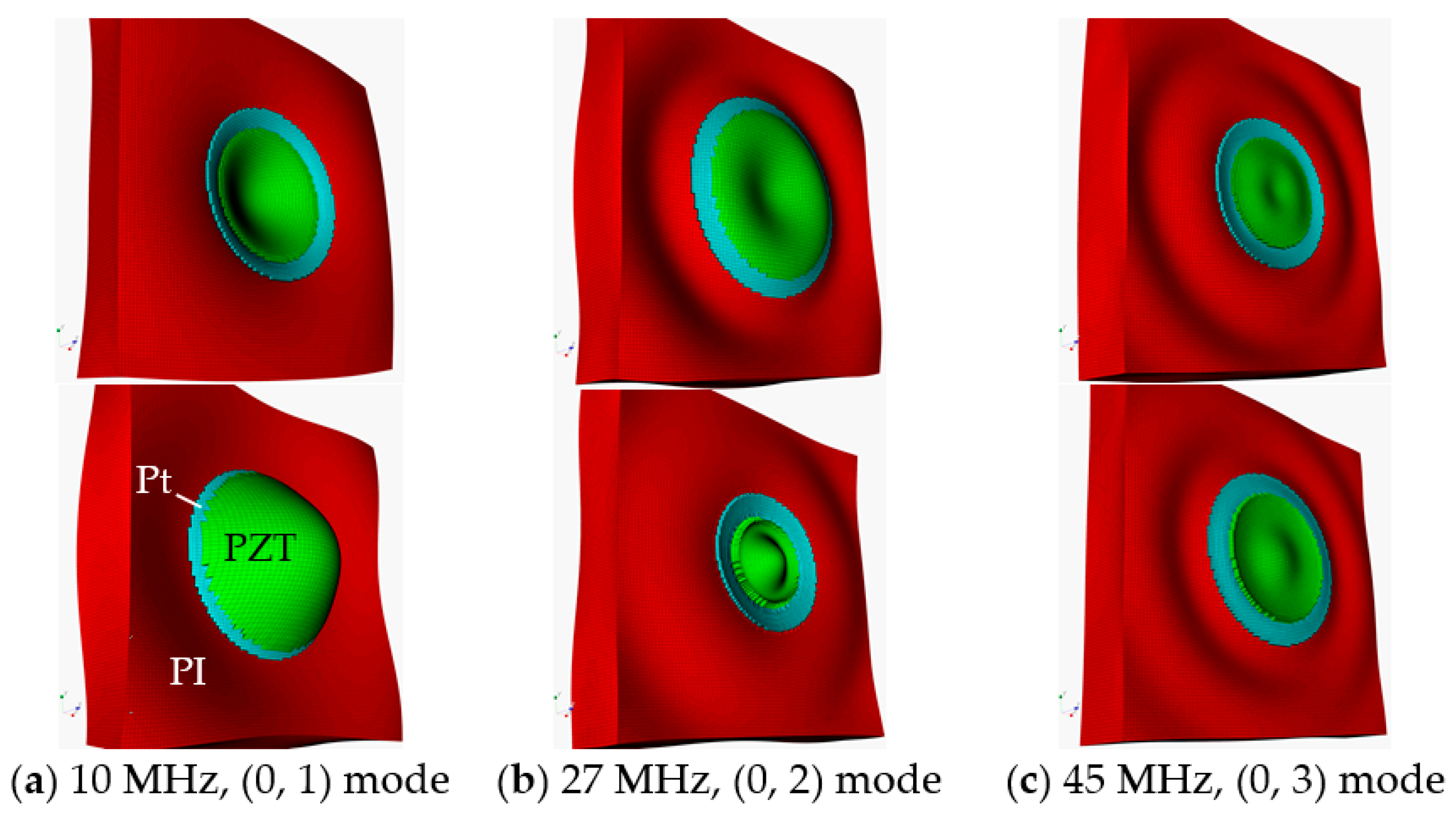

2.3.3. Mode Shape Profiles

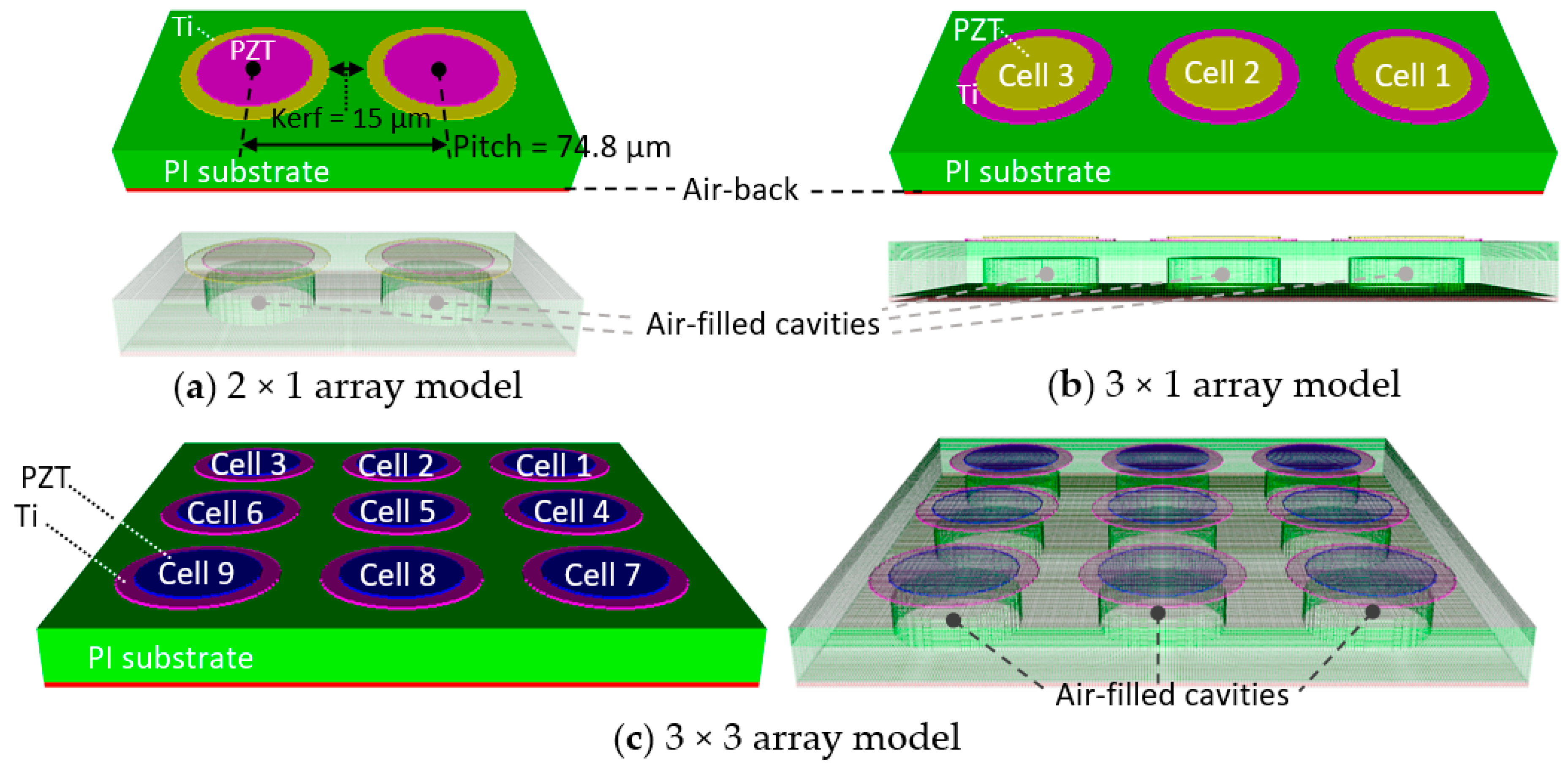

3. Characterization of Small Arrays

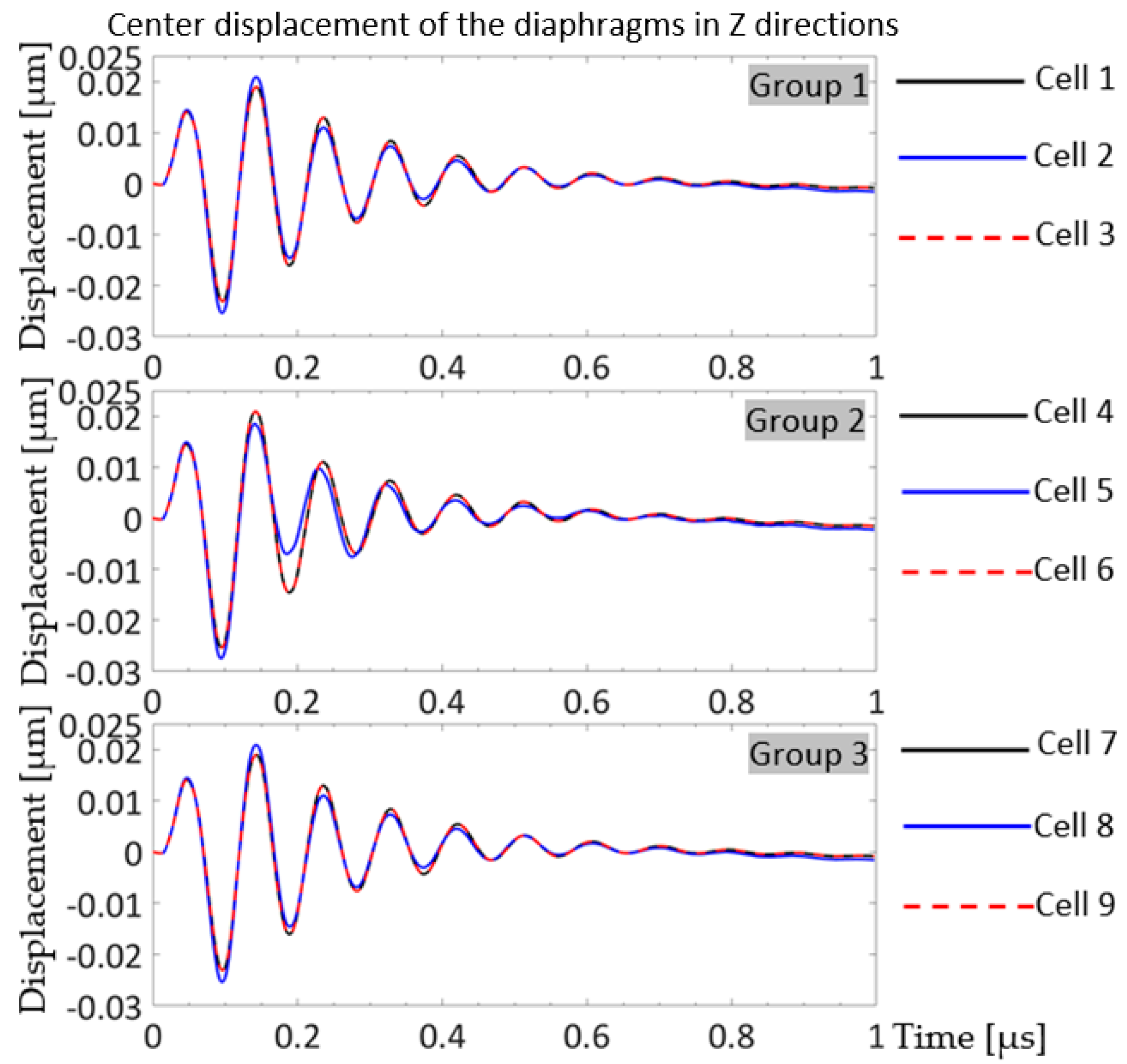

3.1. Displacement Synchronization and Oscillation Decay

3.2. Pulse-Echo and Spectral Responses

3.3. PI Substrate vs. Si Substrate

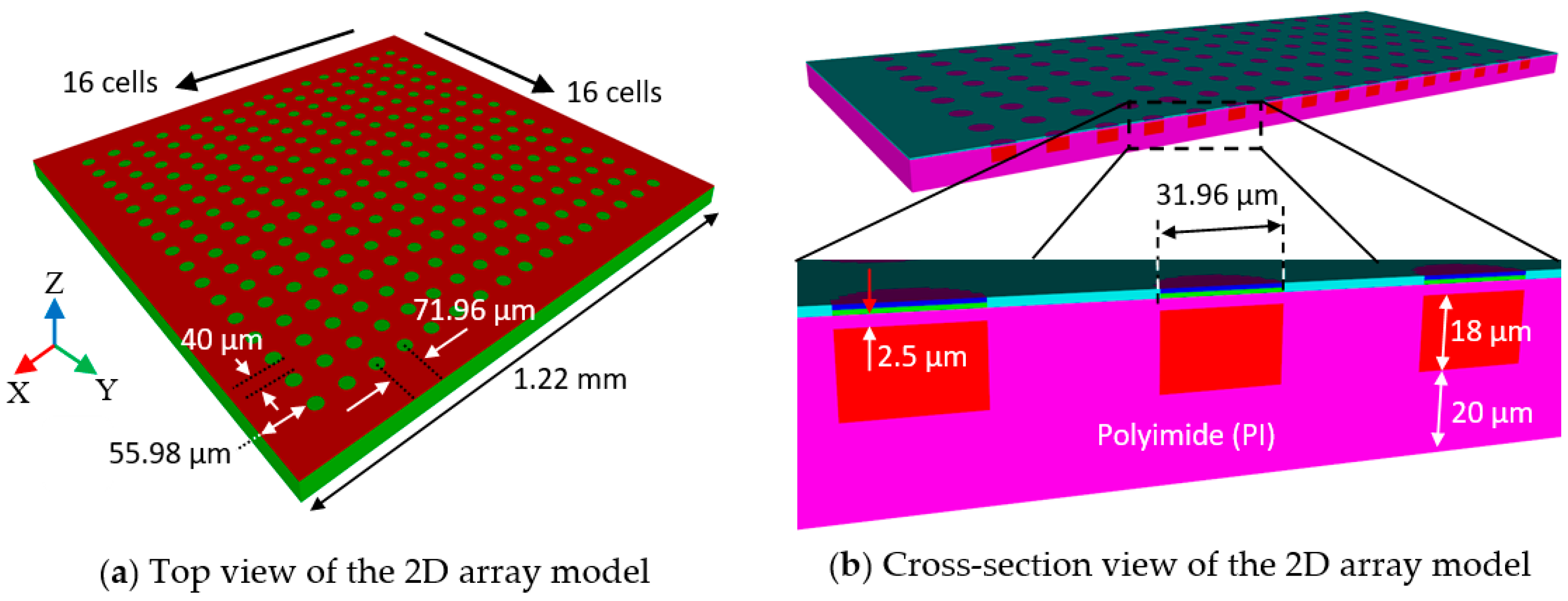

4. 16 × 16 2D Array

4.1. Construction of the 16 × 16 Array

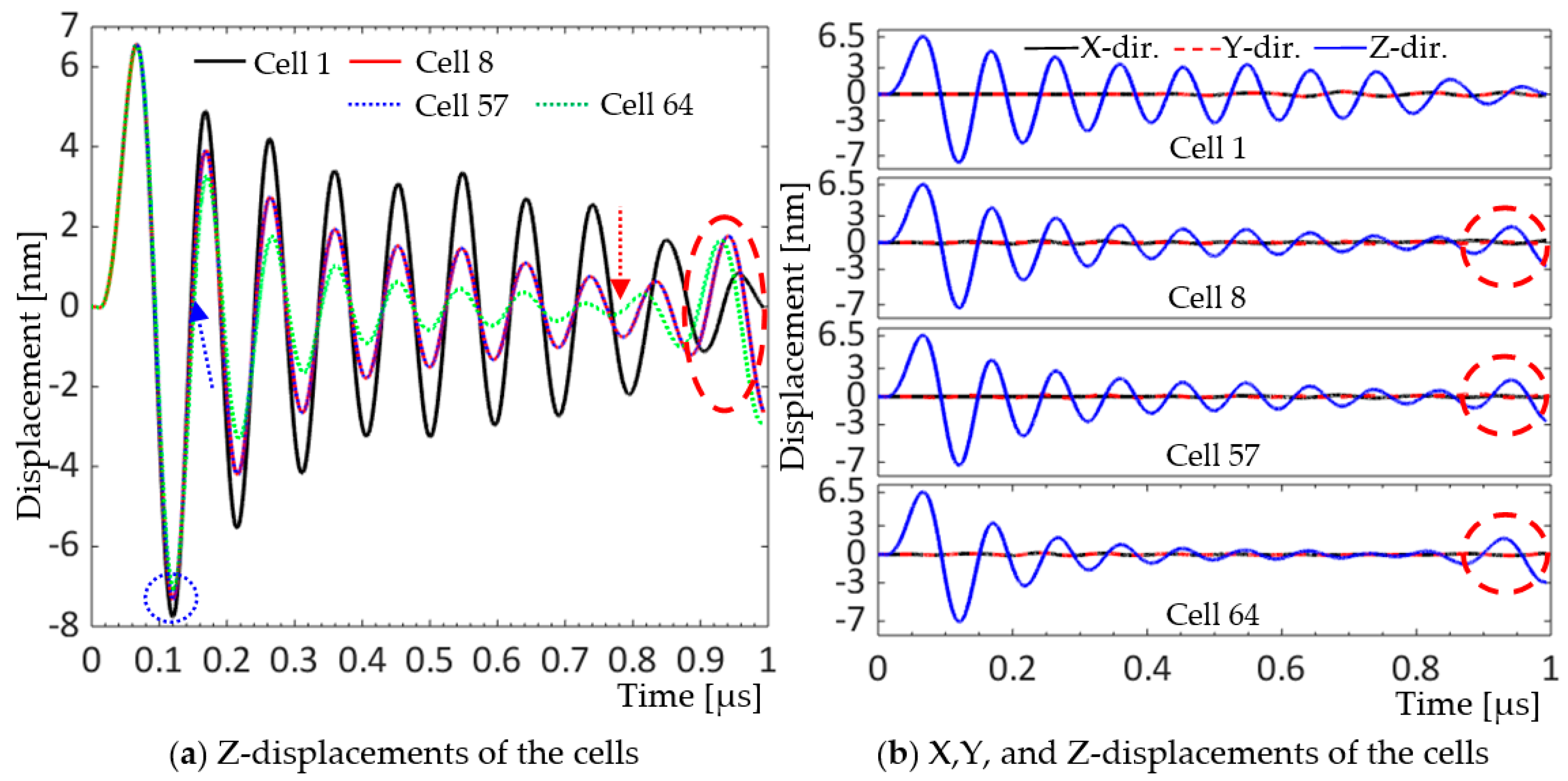

4.2. Surface Displacement Profile

4.3. Pulse-Echo and Spectral Responses

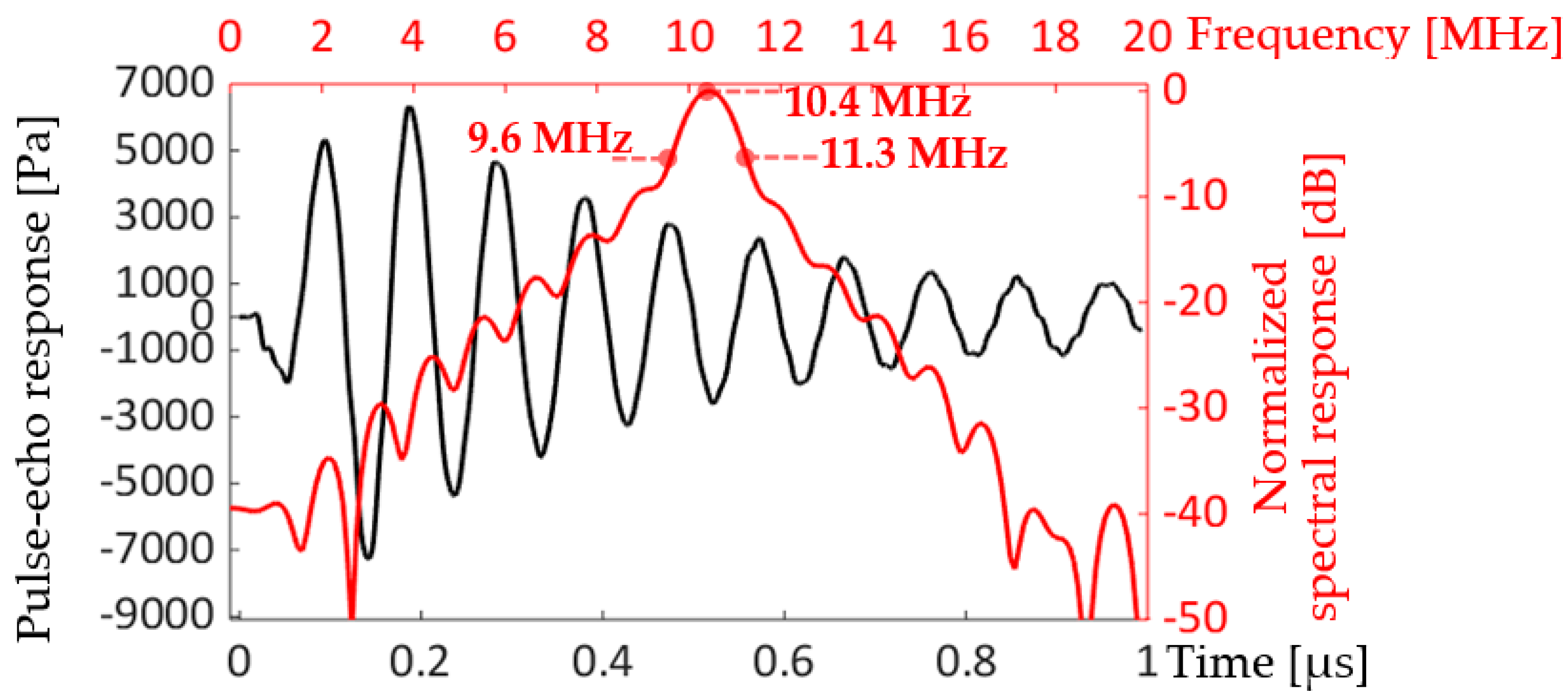

4.4. Beam Propagation Profile

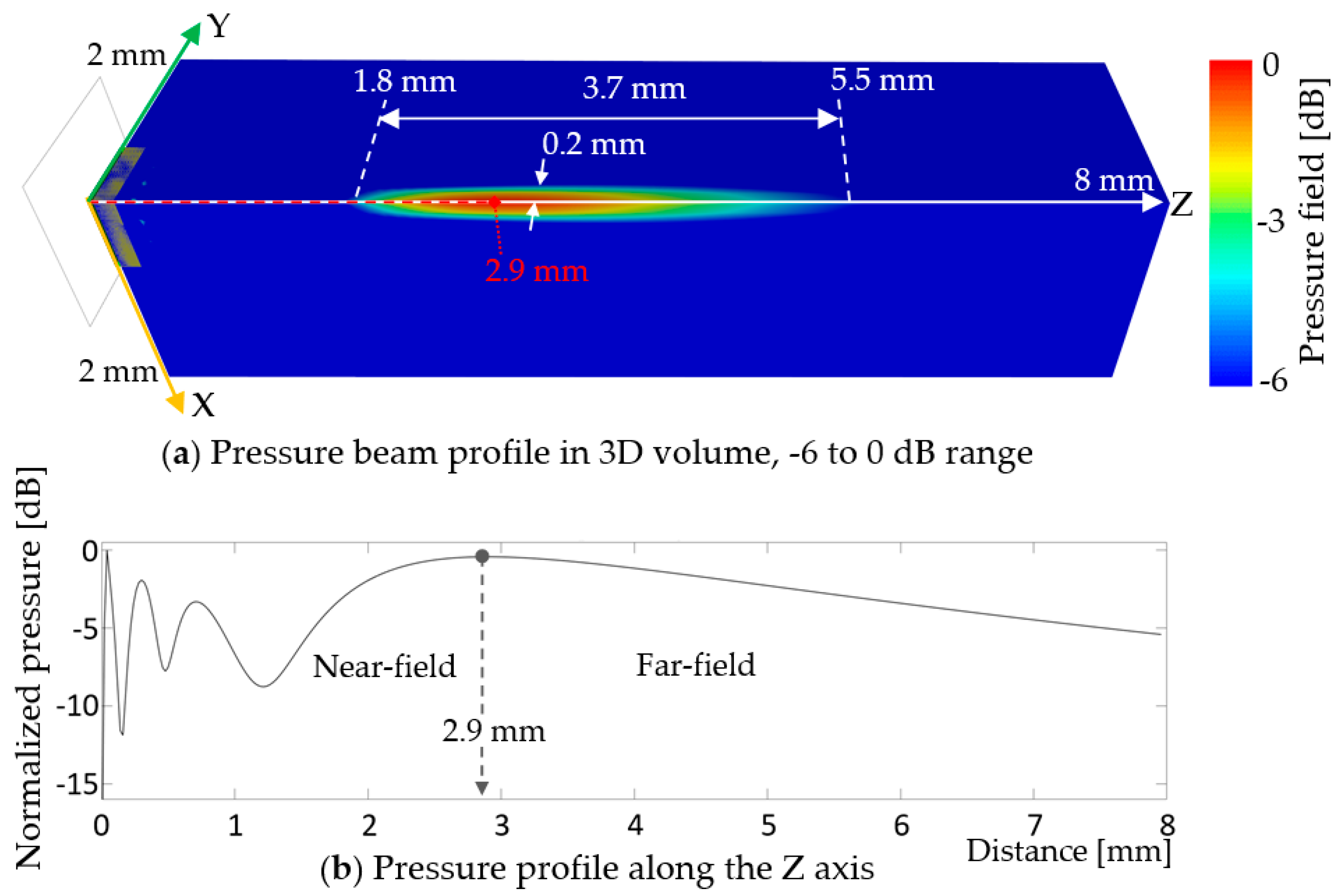

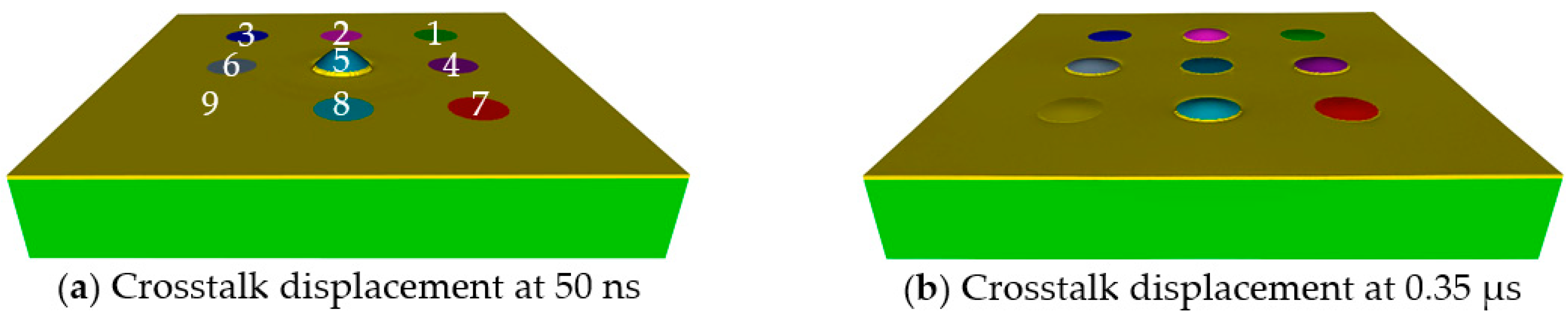

4.5. Crosstalk

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mina, I.G.; Kim, H.; Kim, I.; Park, S.K.; Choi, K.; Jackson, T.N.; Tutwiler, R.L.; Trolier-McKinstry, S. High Frequency Piezoelectric MEMS Ultrasound Transducers; IEEE: Piscataway, NJ, USA, 2007. [Google Scholar]

- Griggio, F.; Demore, C.E.; Kim, H.; Gigliotti, J.; Qiu, Y.; Jackson, T.N.; Choi, K.; Tutwiler, R.L.; Cochran, S.; Trolier-McKinstry, S. Micromachined Diaphragm Transducers for Miniaturised Ultrasound Arrays. In Proceedings of the 2012 IEEE International Ultrasonics Symposium (IUS), Dresden, Germany, 7–10 October 2012. [Google Scholar]

- Zhu, B.; Chan, N.Y.; Dai, J.; Shung, K.K.; Takeuchi, S.; Zhou, Q. New Fabrication of High-Frequency (100-MHz) Ultrasound PZT Film Kerfless Linear Array; IEEE: Piscataway, NJ, USA, 2013. [Google Scholar]

- Qiu, Y.; Gigliotti, J.V.; Wallace, M.; Griggio, F.; Demore, C.E.; Cochran, S.; Trolier-McKinstry, S. Piezoelectric micromachined ultrasound transducer (PMUT) arrays for integrated sensing, actuation and imaging. Sensors 2015, 15, 8020–8041. [Google Scholar] [CrossRef] [PubMed]

- Nakazawa, M.; Tabaru, M.; Takayasu, T.; Aoyagi, T.; Nakamura, K. 100-MHz ultrasonic linear array transducers based on polyurea-film. Acoust. Sci. Technol. 2015, 36, 139–148. [Google Scholar] [CrossRef]

- Cheng, C.Y.; Dangi, A.; Ren, L.; Tiwari, S.; Benoit, R.R.; Qiu, Y.; Lay, H.S.; Agrawal, S.; Pratap, R.; Kothapalli, S.R.; et al. Thin Film PZT-Based PMUT Arrays for Deterministic Particle Manipulation. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2019, 66, 1606–1615. [Google Scholar] [CrossRef]

- Sadeghpour, S.; Lips, B.; Kraft, M.; Puers, R. Bendable Piezoelectric Micromachined Ultrasound Transducer (PMUT) Arrays Based on Silicon-On-Insulator (SOI) Technology. J. Microelectromech. Syst. 2020, 29. [Google Scholar] [CrossRef]

- Denkmann, W.; Nickell, R.; Stickler, D. Analysis of structural-acoustic interactions in metal-ceramic transducers. IEEE Trans. Audio Electroacoust 1973, 21, 317–324. [Google Scholar] [CrossRef]

- Bernstein, J.J.; Houston, K.; Niles, L.C.; Li, K.K.; Chen, H.D.; Cross, L.E.; Udayakumar, K. Integrated ferroelectric monomorph transducers for acoustic imaging. Integr. Ferroelectr. 1997, 15, 289–307. [Google Scholar] [CrossRef]

- Bernstein, J.J.; Finberg, S.L.; Houston, K.; Niles, L.C.; Chen, H.D.; Cross, L.E.; Li, K.K.; Udayakumar, K. Micromachined high frequency ferroelectric sonar transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1997, 44, 960–969. [Google Scholar] [CrossRef]

- Percin, G.; Khuri-Yakub, B.T. Micromachined 2-D array piezoelectrically actuated flextensional transducers. IEEE Int. Ultrason. Symp. 1997, 2, 959–962. [Google Scholar]

- Bernstein, J.J.; Bottari, J.; Houston, K.; Kirkos, G.; Miller, R.; Xu, B.; Ye, Y.; Cross, L.E. Advanced MEMS ferroelectric ultrasound 2D arrays. IEEE Int. Ultrason. Symp. 1999, 2, 1145–1153. [Google Scholar]

- Akasheh, F.; Myers, T.; Fraser, J.D.; Bose, S.; Bandyopadhyay, A. Development of piezoelectric micromachined ultrasonic transducers. Sens. Actuators A 2004, 111, 275–287. [Google Scholar] [CrossRef]

- Choi, H.S.; Ding, J.L.; Bandyopadhyay, A.; Anderson, M.J.; Bose, S. Characterization and modeling of a piezoelectric micromachined ultrasonic transducer with a very large length/width aspect ratio. J. Micromech. Microeng. 2008, 18, 025037. [Google Scholar] [CrossRef]

- Sammoura, F.; Kim, S.G. Theoretical modeling and equivalent electric circuit of a bimorph piezoelectric micromachined ultrasonic transducer. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 990–998. [Google Scholar] [CrossRef] [PubMed]

- Sammoura, F.; Smyth, K.; Bathurst, S.; Kim, S.G. October. An analytical analysis of the sensitivity of circular piezoelectric micromachined ultrasonic transducers to residual stress. IEEE Int. Ultrason. Symp. 2012, 580–583. [Google Scholar] [CrossRef]

- Yang, Y.; Tian, H.; Wang, Y.F.; Shu, Y.; Zhou, C.J.; Sun, H.; Zhang, C.H.; Chen, H.; Ren, T.L. An ultra-high element density pMUT array with low crosstalk for 3-D medical imaging. Sensors 2013, 13, 9624–9634. [Google Scholar] [CrossRef]

- Lu, Y.; Horsley, D.A. Modeling, fabrication, and characterization of piezoelectric micromachined ultrasonic transducer arrays based on cavity SOI wafers. J. Microelectromech. Syst. 2015, 24, 1142–1149. [Google Scholar] [CrossRef]

- Dangi, A.; Pratap, R. System level modeling and design maps of PMUTs with residual stresses. Sens. Actuators A Phys. 2017, 262, 18–28. [Google Scholar] [CrossRef]

- Massimino, G.; Colombo, A.; Ardito, R.; Quaglia, F.; Corigliano, A. On the Effects of Package on the PMUTs Performances—Multiphysics Model and Frequency Analyses. Micromachines 2020, 11, 307. [Google Scholar] [CrossRef]

- Kim, J.N. Closed-Loop Finite Element Design of Array Ultrasonic Transducers for High. Frequency Applications; The Pennsylvania State University: State College, PA, USA, 2019. [Google Scholar]

- Liu, T.; Wallace, M.; Trolier-McKinstry, S.E.; Jackson, T.N. High-temperature crystallized thin-film PZT on thin polyimide substrates. J. Appl. Phys. 2017, 122, 164103. [Google Scholar] [CrossRef]

- Liu, T.; Kim, J.N.; Trolier-McKinstry, S.E.; Jackson, T.N. Flexible Thin-Film PZT Ultrasonic Transducers. In Proceedings of the 2018 76th Device Research Conference (DRC), Santa Barbara, CA, USA, 24–27 June 2018; pp. 1–2. [Google Scholar]

- Wojcik, G.L.; Vaughan, D.K.; Abboud, N.; Mould, J.J. Electromechanical Modeling using Explicit Time-Domain Finite Elements, Proceedings of the IEEE International Ultrasonics Symposium 1993, Baltimore, MD, USA, 31 October–3 November 1993; IEEE: New York, NY, USA, 1993; pp. 1107–1112. [Google Scholar]

- PZFlex Support Group. PZFlex User Manual 2014: PZFlex Modeling Guide; PZFlex Support Group, Weidlinger Associates, Inc.: Mountain View, CA, USA, 2014; p. 1. [Google Scholar]

- Trolier-McKinstry, S.; Muralt, P. Thin film piezoelectrics for MEMS. J. Electroceram. 2004, 12, 7–17. [Google Scholar] [CrossRef]

- PZFlex Support Group. PZFlex 2018 Embedded Database (ver. 2018); OnScale (formerly PZFlex): Redwood City, CA, USA, 2018. [Google Scholar]

- PI-2600 Series—Low Stress Application. Product Bulletin, HD MicroSystems, 250 Cheesequake Road, Parlin, NJ, USA. Available online: http://www.dupont.com/content/dam/dupont/products-and-services/electronic-and-electrical-materials/semiconductor-fabrication-and-packaging-materials/documents/PI-2600_ProcessGuide.pdf (accessed on 10 April 2019).

- PZFlex Support Group. PZFlex User Manual 2014: FlexLab—An. IDE for PZFlex; PZFlex Support Group, Weidlinger Associates, Inc.: Mountain View, CA USA, 2014. [Google Scholar]

- Kinsler, L.E.; Austin, R.F.; Alan, B.C.; James, V.S. Fundamentals of Acoustics, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1999. [Google Scholar]

- Shackelford, J.F.; Alexander, W. Material Science and Engineering Handbook, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Hong, E.; Trolier-McKinstry, S.E.; Smith, R.; Krishnaswamy, S.V.; Freidhoff, C.B. Vibration of micromachined circular piezoelectric diaphragms. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 697–706. [Google Scholar] [CrossRef]

- Kim, K.J.; Yu, W.R.; Kim, M.S. Anisotropic creep modeling of coated textile membrane using finite element analysis. Compos. Sci. Technol. 2008, 68, 1688–1696. [Google Scholar] [CrossRef]

- Ten Thije, R.H.W.; Akkerman, R. A multi-layer triangular membrane finite element for the forming simulation of laminated composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 739–753. [Google Scholar] [CrossRef]

- Tasso, I.V.; Buscaglia, G.C. A finite element method for viscous membranes. Comput. Methods Appl. Mech. Eng. 2013, 255, 226–237. [Google Scholar] [CrossRef]

- Cenanovic, M.; Hansbo, P.; Larson, M.G. Cut finite element modeling of linear membranes. Comput. Methods Appl. Mech. Eng. 2016, 310, 98–111. [Google Scholar] [CrossRef]

- Nodargi, N.A.; Bisegna, P. A novel high-performance mixed membrane finite element for the analysis of inelastic structures. Comput. Struct. 2017, 182, 337–353. [Google Scholar] [CrossRef]

- Roohbakhshan, F.; Sauer, R.A. A finite membrane element formulation for surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2019, 566, 84–103. [Google Scholar] [CrossRef]

- Liu, T. (The Pennsylvania State University, State College, PA, USA). Personal Communication, 2018. [Google Scholar]

- PZFlex Support Group. PZFlex 2016 Embedded Tutorial: Transducer Modeling; PZFlex Support Group, Weidlinger Associates, Inc.: Mountain View, CA, USA, 2014. [Google Scholar]

- Kim, J.N.; Tutwiler, R.L.; Todd, J.A. Preliminary Design of a High-Frequency Phased-Array Acoustic Microscope Probe for Nondestructive Evaluation of Pressure Vessel and Piping Materials. J. Press. Vessel Technol. 2018, 140, 041502. [Google Scholar] [CrossRef]

- Layers of the Skin. SEER Training Modules, National Cancer Institute. Available online: https://training.seer.cancer.gov/melanoma/anatomy/layers.html (accessed on 25 June 2019).

- Kim, J.; Cho, D.I.D.; Muller, R.S. Why Is Silicon a Better Mechanical Material for MEMS. In Transducers’ 01 Eurosensors XV, Proceedings of the 11th International Conference on Solid-State Sensors and Actuators, Munich, Germany, 10–14 June 2001; Springer: Berlin/Heidelberg, Germany, 2001; pp. 662–665. [Google Scholar]

- Rogers, J.A.; Dhar, L.; Nelson, K.A. Accurate determination of mechanical properties in thin polyimide films with transverse isotropic symmetry using impulsive stimulated thermal scattering. J. Phys. IV 1994, 4, 7–217. [Google Scholar] [CrossRef]

- D’Astous, F.T.; Foster, F.S. Frequency dependence of ultrasound attenuation and backscatter in breast tissue. Ultrasound Med. Biol. 1986, 12, 795–808. [Google Scholar] [CrossRef]

- Culjat, M.O.; Goldenberg, D.; Tewari, P.; Singh, R.S. A review of tissue substitutes for ultrasound imaging. Ultrasound Med. Biol. 2010, 36, 861–873. [Google Scholar] [CrossRef]

- Choi, H.S.; Anderson, M.J.; Ding, J.L.; Bandyopadhyay, A. A two-dimensional electromechanical composite plate model for piezoelectric micromachined ultrasonic transducers (pMUTs). J. Micromech. Microeng. 2009, 20, 015013. [Google Scholar] [CrossRef]

- Yaacob, M.I.H.; Arshad, M.R.; Manaf, A.A. Modeling of circular piezoelectric micro ultrasonic transducer using CuAl10 Ni5Fe4 on ZnO film for sonar applications. Acoust. Phys. 2011, 57, 151. [Google Scholar] [CrossRef]

- Sammoura, F.; Smyth, K.; Kim, S.G. Optimizing the electrode size of circular bimorph plates with different boundary conditions for maximum deflection of piezoelectric micromachined ultrasonic transducers. Ultrasonics 2013, 53, 328–334. [Google Scholar] [CrossRef] [PubMed]

- McKeighen, R.E. Design Guidelines for Medical Ultrasonic Arrays. In Medical Imaging 1998, Proceedings of the Ultrasonic Transducer Engineering, San Diego, CA, USA, 25–26 February 1998; International Society for Optics and Photonics: Bellingham, WA, USA, 1998; pp. 2–18. [Google Scholar]

| Material | Mechanical | Damping (Viscoelastic) | |||

|---|---|---|---|---|---|

| Density | Bulk Velocity | Shear Velocity | Bulk Attenuation | Shear Attenuation | |

| Pt | 21,400 kg/m3 | 3260 m/s | 1730 m/s | 0.3 dB/MHz/cm | 0.9 dB/MHz/cm |

| Ti | 4480 kg/m3 | 6100 m/s | 3100 m/s | 0.3 dB/MHz/cm | 1.2 dB/MHz/cm |

| PI | 1082 kg/m3 | 3500 m/s | 2000 m/s | 9 dB/cm at 10 MHz | 13 dB/cm at 10 MHz |

| Unit-Cell | 2 × 1 | 3 × 1 | 2 × 2 | 3 × 3 | ||

|---|---|---|---|---|---|---|

| PI substrate | Low/Upper -6 dB [MHz] | 6.9/15.9 | 8.3/18.4 | 8.6/13.1 | 8.6/13.1 | 9.6/11.5 |

| Center freq. [MHz] | 10.4 | 11.1 | 11.1 | 10.8 | 10.4 | |

| Bandwidth (−6 dB) | 86.5% | 47.7% | 41.0% | 41.7% | 18.3% |

| Unit-Cell | 2 × 1 | 3 × 1 | 2 × 2 | 3 × 3 | ||

|---|---|---|---|---|---|---|

| Si substrate | Lower/Upper -6 dB [MHz] | 9.2/17.8 | 9.7/18.4 | 8.6/18.6 | 11.5/18.4 | 13.6/18.7 |

| Center freq. [MHz] | 13.8 | 15.1 | 14.9 | 15.3 | 16.7 | |

| Bandwidth (−6 dB) | 62.3% | 57.6% | 67.1% | 45.1% | 30.5% |

| PI | Si | |

|---|---|---|

| Bulk attenuation coefficients | 9 dB/cm | 0.1 dB/cm |

| Shear attenuation coefficients | 13 dB/cm | 0.3 dB/cm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.N.; Liu, T.; Jackson, T.N.; Choi, K.; Trolier-McKinstry, S.; Tutwiler, R.L.; Todd, J.A. 10 MHz Thin-Film PZT-Based Flexible PMUT Array: Finite Element Design and Characterization. Sensors 2020, 20, 4335. https://doi.org/10.3390/s20154335

Kim JN, Liu T, Jackson TN, Choi K, Trolier-McKinstry S, Tutwiler RL, Todd JA. 10 MHz Thin-Film PZT-Based Flexible PMUT Array: Finite Element Design and Characterization. Sensors. 2020; 20(15):4335. https://doi.org/10.3390/s20154335

Chicago/Turabian StyleKim, Jeong Nyeon, Tianning Liu, Thomas N. Jackson, Kyusun Choi, Susan Trolier-McKinstry, Richard L. Tutwiler, and Judith A. Todd. 2020. "10 MHz Thin-Film PZT-Based Flexible PMUT Array: Finite Element Design and Characterization" Sensors 20, no. 15: 4335. https://doi.org/10.3390/s20154335

APA StyleKim, J. N., Liu, T., Jackson, T. N., Choi, K., Trolier-McKinstry, S., Tutwiler, R. L., & Todd, J. A. (2020). 10 MHz Thin-Film PZT-Based Flexible PMUT Array: Finite Element Design and Characterization. Sensors, 20(15), 4335. https://doi.org/10.3390/s20154335