State and Force Estimation on a Rotating Helicopter Blade through a Kalman-Based Approach

Abstract

1. Introduction

2. Methodologies: Theoretical Background

2.1. Multibody Structural Model

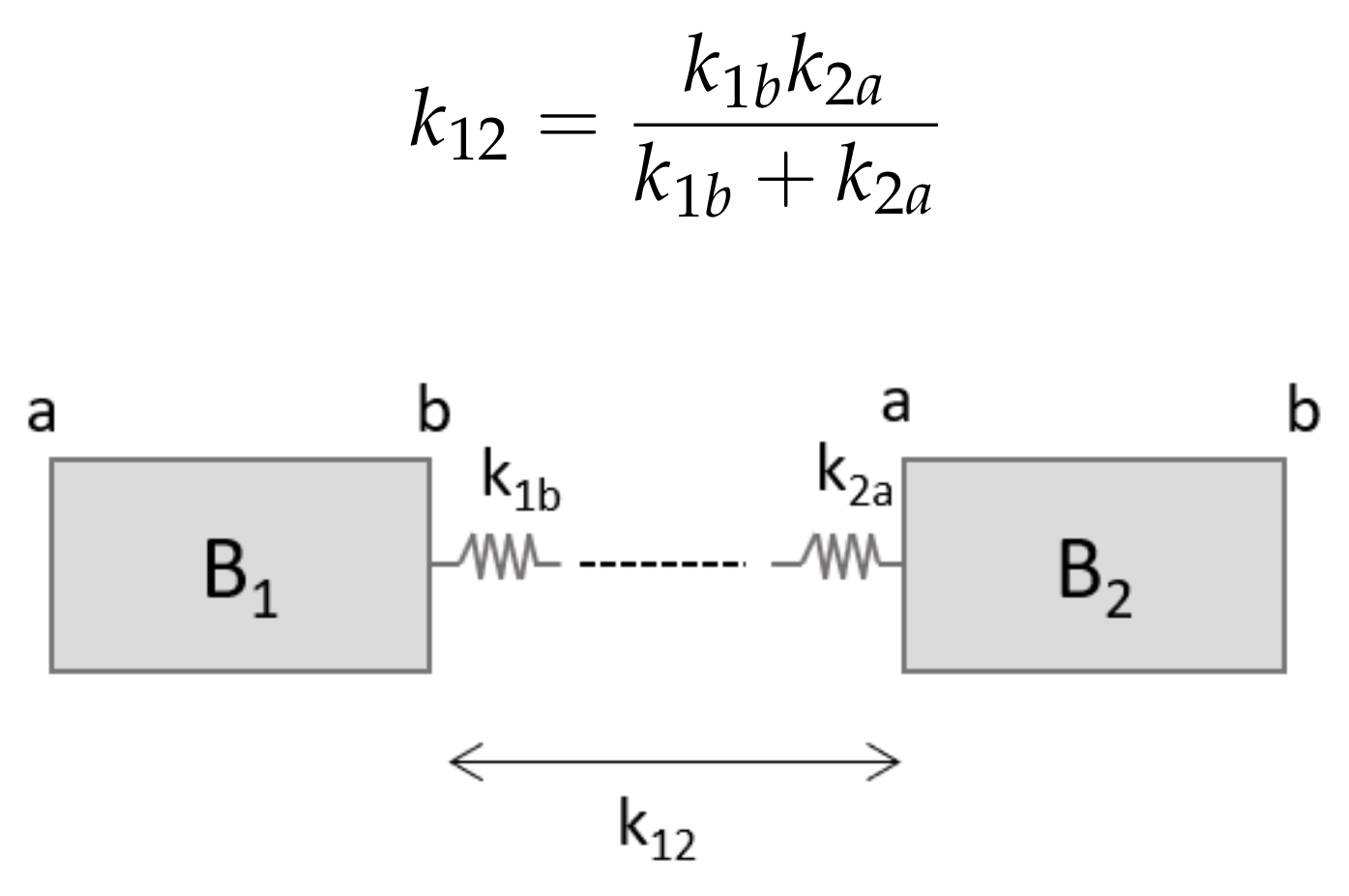

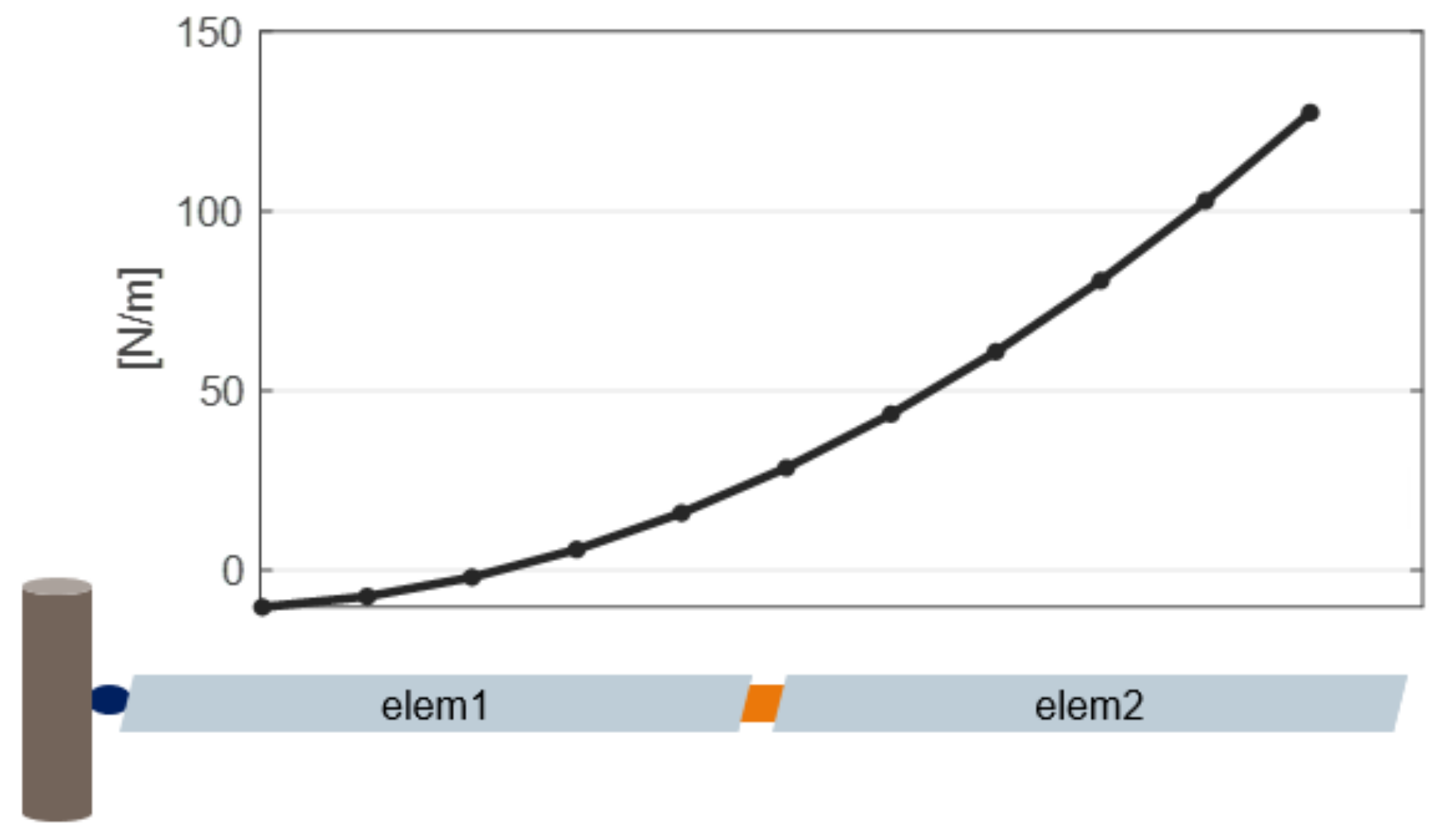

2.1.1. Finite Segment Beam Formulation

2.2. Aerodynamic Model

2.2.1. Aerodynamic Loads

- is the air density.

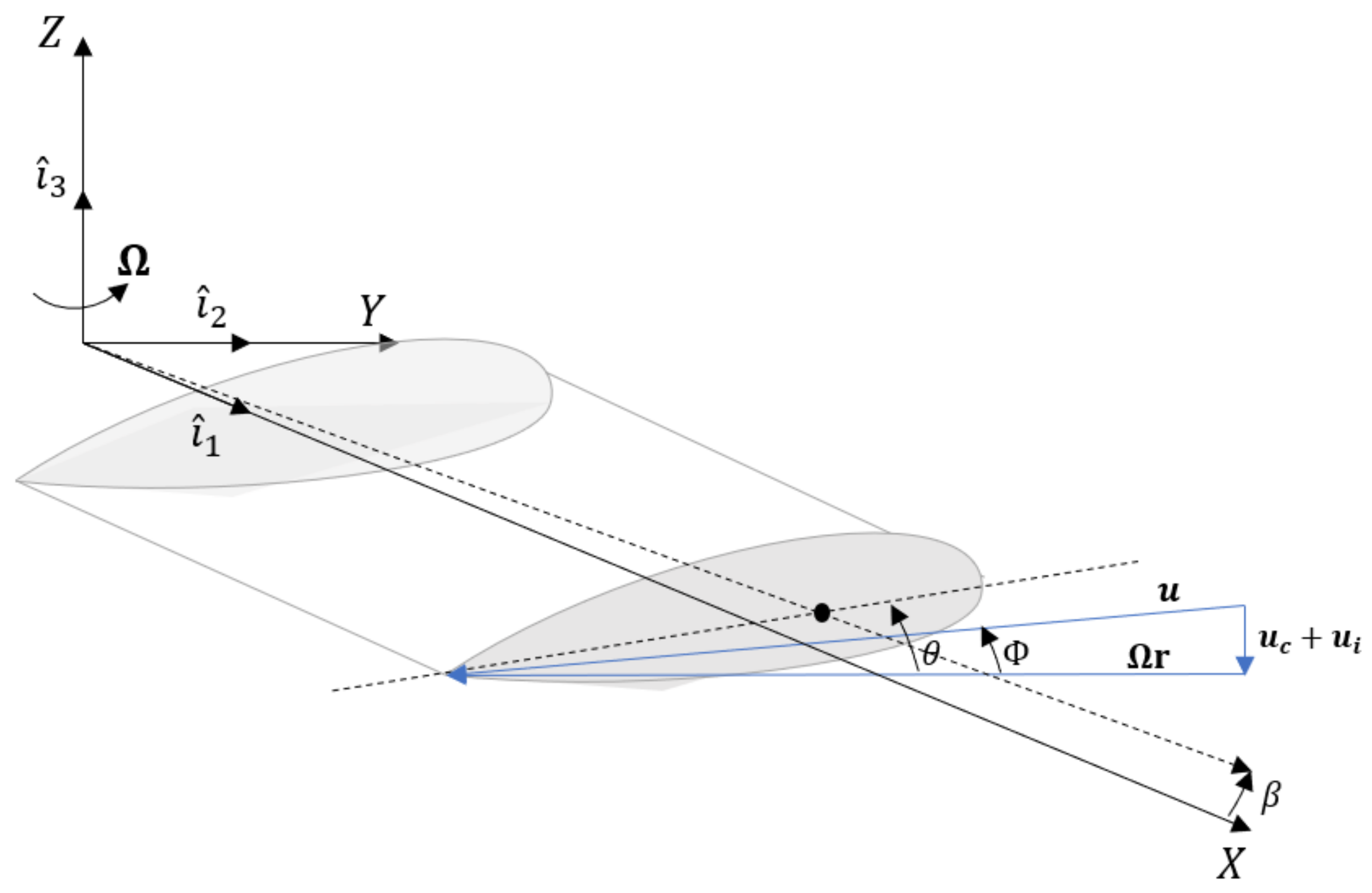

- is the velocity vector evaluated at the stage . Considering the blade modeled as a rigid body, is expressed as:where is the flapping velocity, which is defined as the time-derivative of the angle shown in Figure 2. are the components of the air velocity. In hovering flight, the air velocity is reduced to only the vertical contribution along , naming the inflow velocity . If the point resides on an axis parallel to , then:

- and are the aerodynamic coefficients; in general, they are tabular values for a given airfoil. Important for the evaluation of the total thrust produced by the rotating blades is the expression of the lift coefficient . This contribution focuses on small angles of attack and low values of the Mach number, such that a linear relation is guaranteed, with a representing the lift slope of the section, and (Figure 2). and are respectively the pitch and inflow angles of the section. More details about the derivation of are given in Section 2.2.2.

- c indicates the chord of the blade at stage r.

2.2.2. Uniform Inflow Model

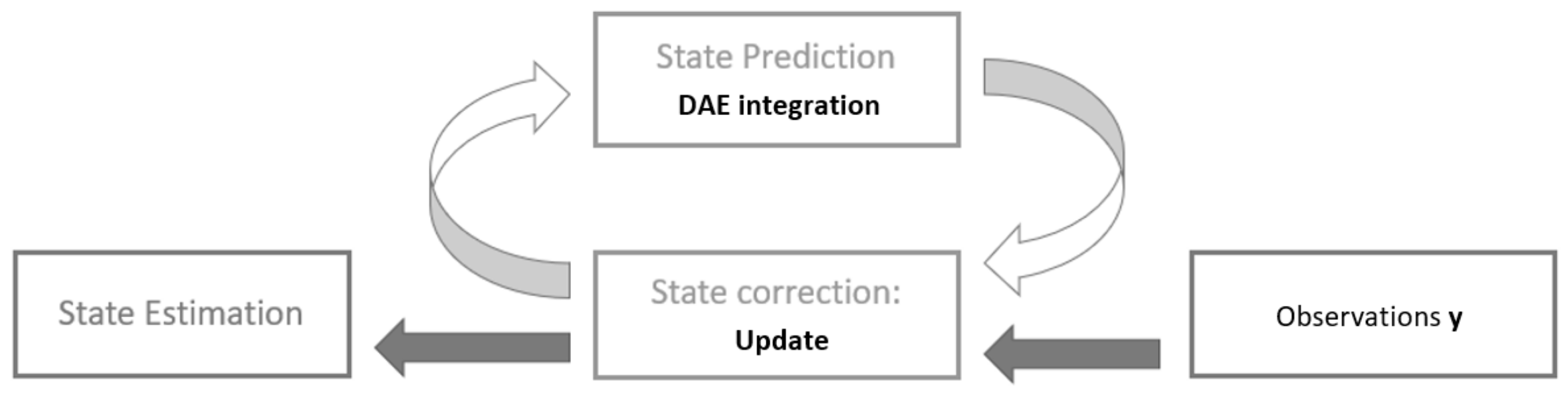

2.3. Kalman Filter for Implicit Scheme

- Correction—updating of the solution of the previous step with the available observations :where is the Kalman gain, obtained in the definition of the filter by minimizing the estimation covariance. Further details on the derivation of and on the update of the covariance matrices during the estimation can be found in [16].

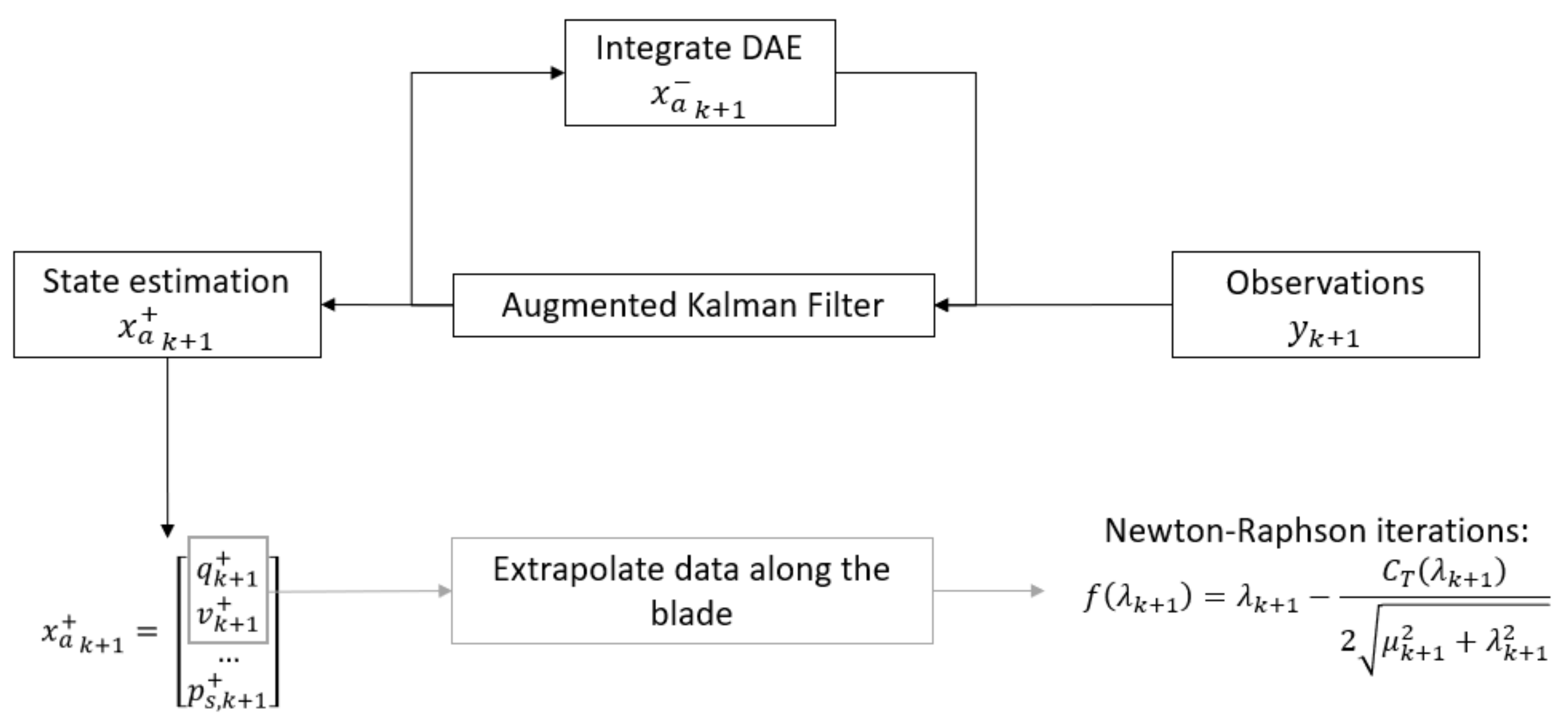

3. Workflow for Estimation of States and Loads on a Rotor Blade

- Writing the vector in Equation (19) as a function of and , i.e., the orientation and velocity of a given point;

- Modeling the aerodynamic forces as external loads without explicit dependence on the states.

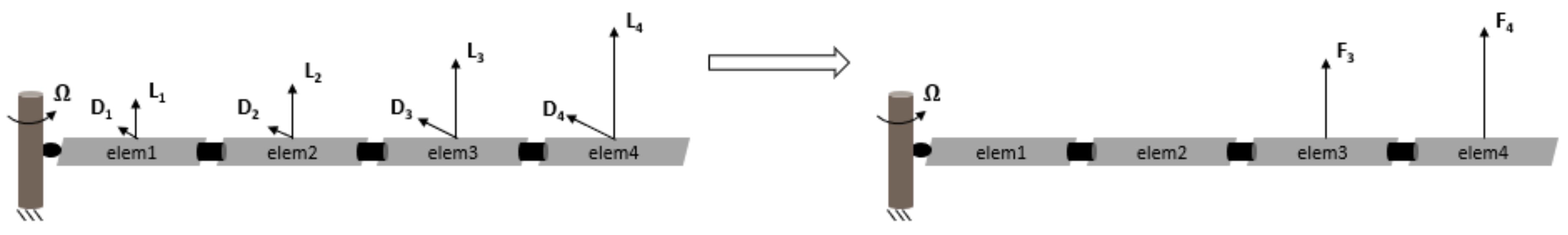

- Definition of the set of loads. This decision should be made in conjunction with the previous step. For multiple distributed loads, the definition of a subset of loads could be useful to reduce the number of observations needed. For the case in Figure 5, the full input vector is ; a good choice could be the selection of loads close to the tip , because their contributions to the dynamics of the blade are higher.

- Extrapolation of along the blade span. The components of the velocity vector along the blade can be approximated as a linear function of the position r:

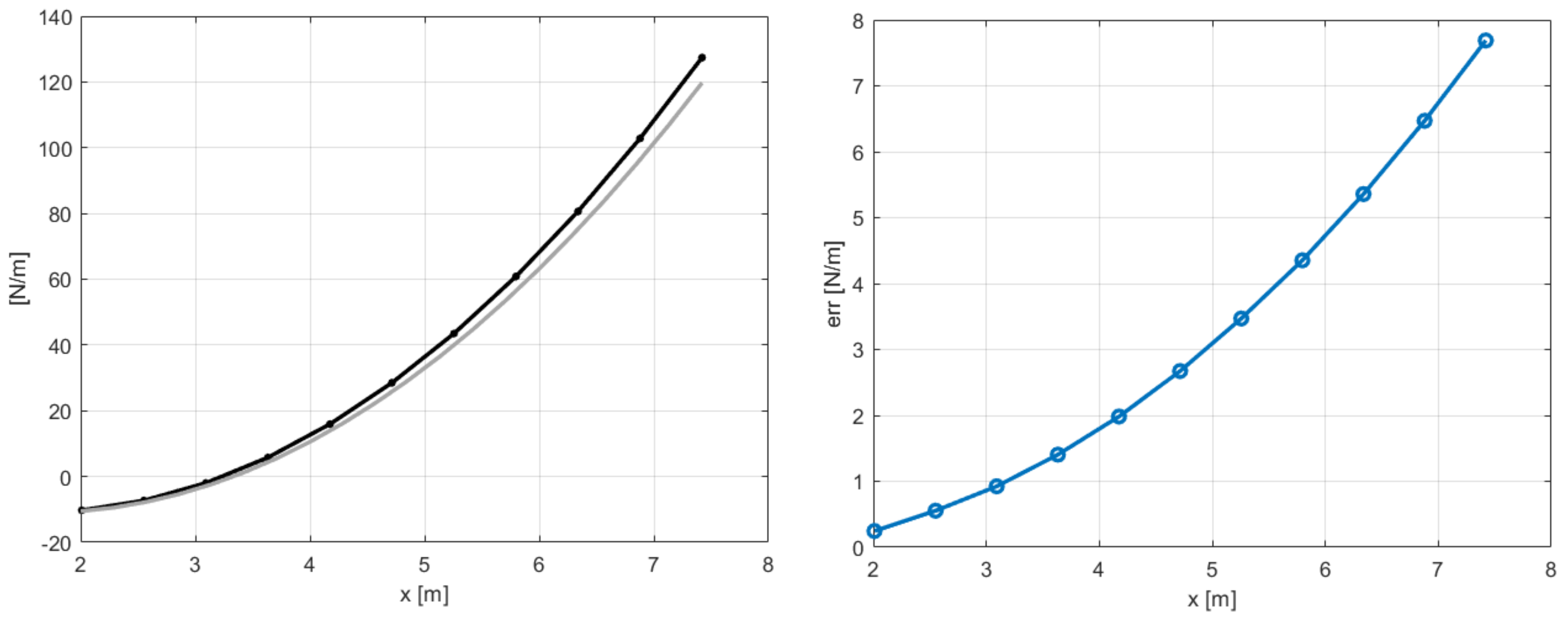

- Evaluation of the lift distribution along the blade span. Recalling Equation (5), and given a certain flight condition with known pitch angle , the only unknown in the elemental lift will be the inflow angle :The iterative process in Section 2.2 can thus be applied to find the exact value of at each time-step.

4. Numerical Validation on a 2-Blade Rotor Model

- Noisy reference observation data generated in Python code by simulating the coupled structural-aerodynamic model. Estimation of a subset of lumped loads on the same structural model without aerodynamic and subsequent distributed load evaluations.

- Reference observation data generated in MBDyn on a similar, but independently-formulated structural-aerodynamic model. Estimation of a subset of lumped loads on the structural Python model and subsequent evaluation of distributed loads.

4.1. Kalman-Based Estimation

- The aerodynamic loads give higher contribution in the proximity of the blade tip;

- The in-plane loads are much smaller than the out-of-plane ones, namely, ,

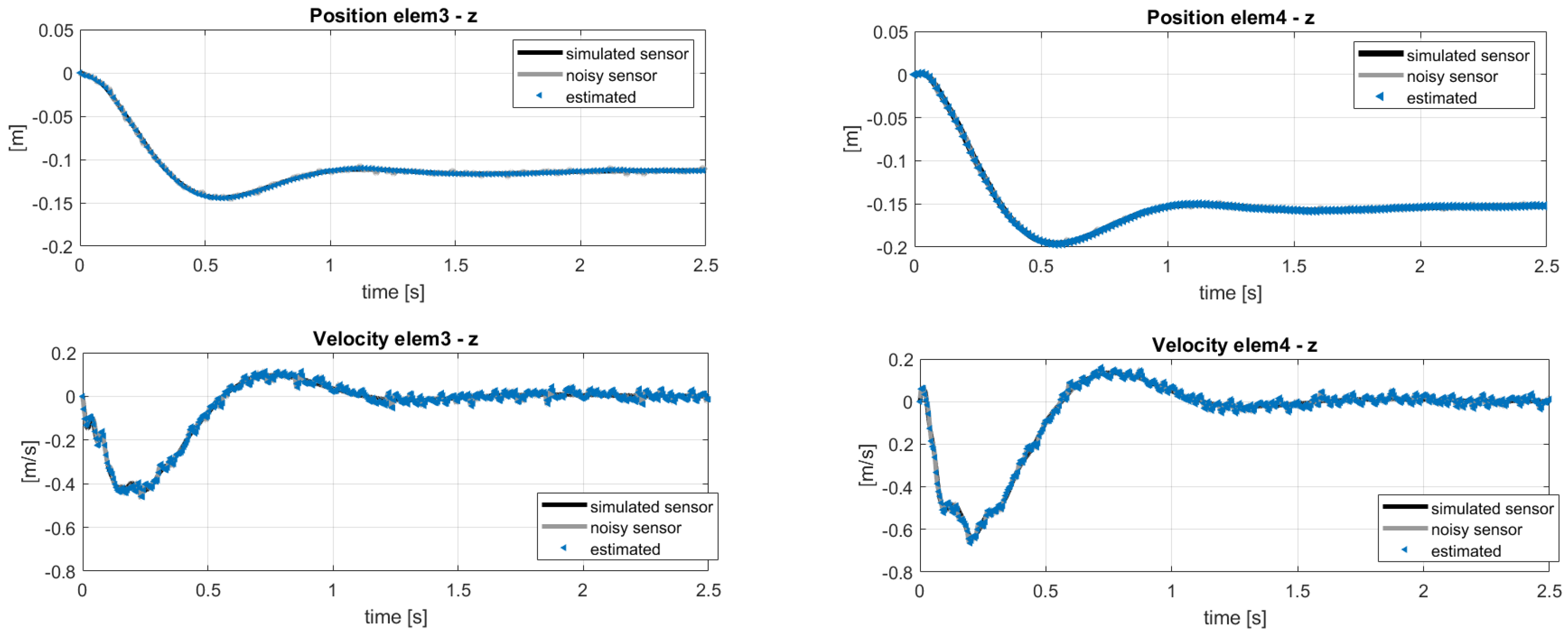

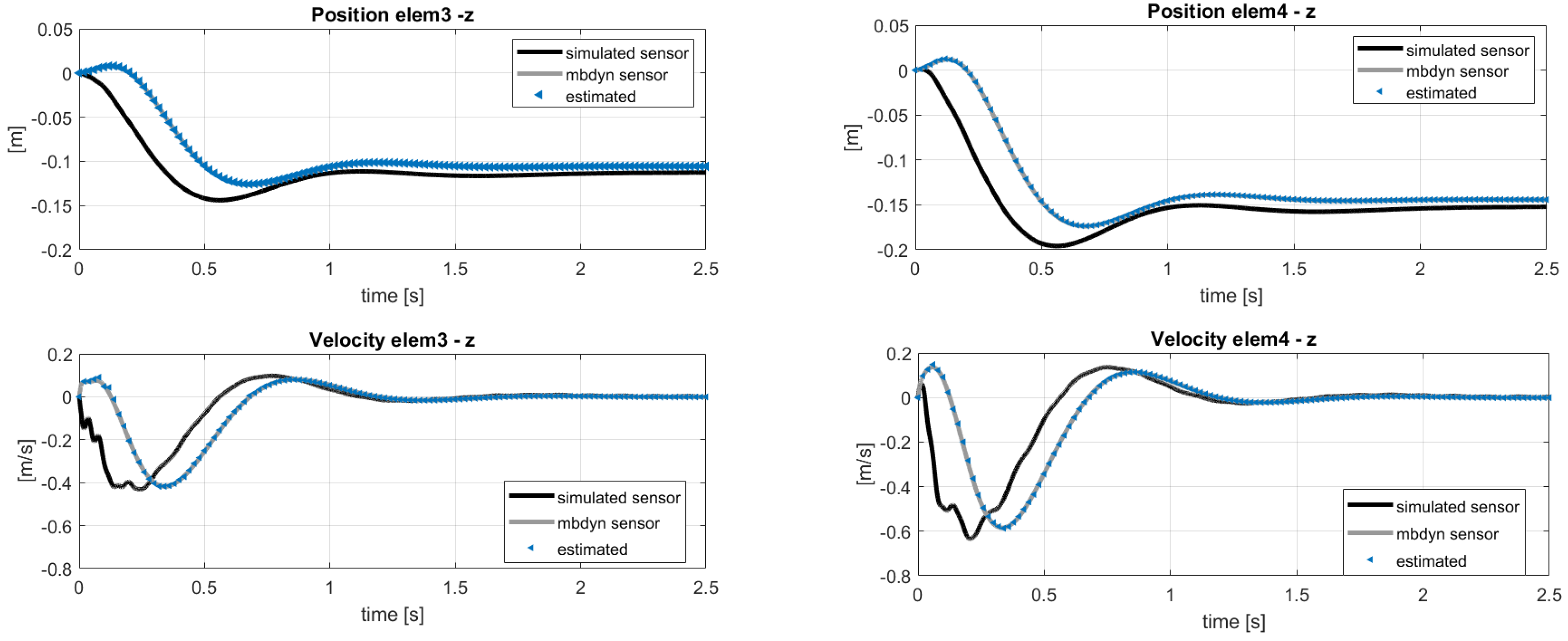

4.1.1. Reference Noisy Data

- The sensor layout does not include in-plane quantities, e.g., position sensors in direction.

- Only out-of-plane loads are considered in the estimation, even if the reference sensors come from a coupled multibody-aerodynamic simulation which includes lift and drag forces. The choice to not estimate the drag forces was because the resulting magnitude would be comparatively small with respect to the computed lift.

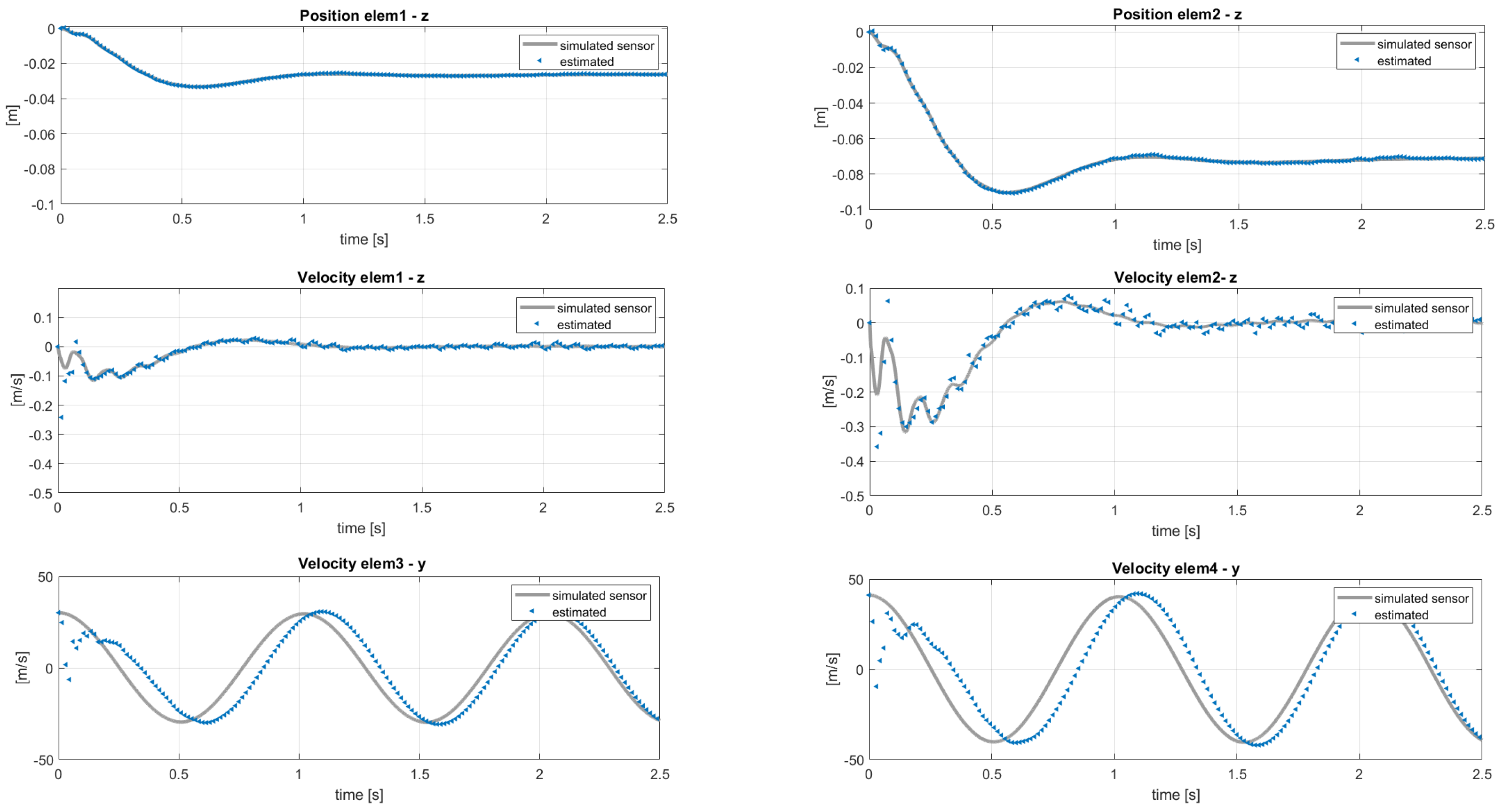

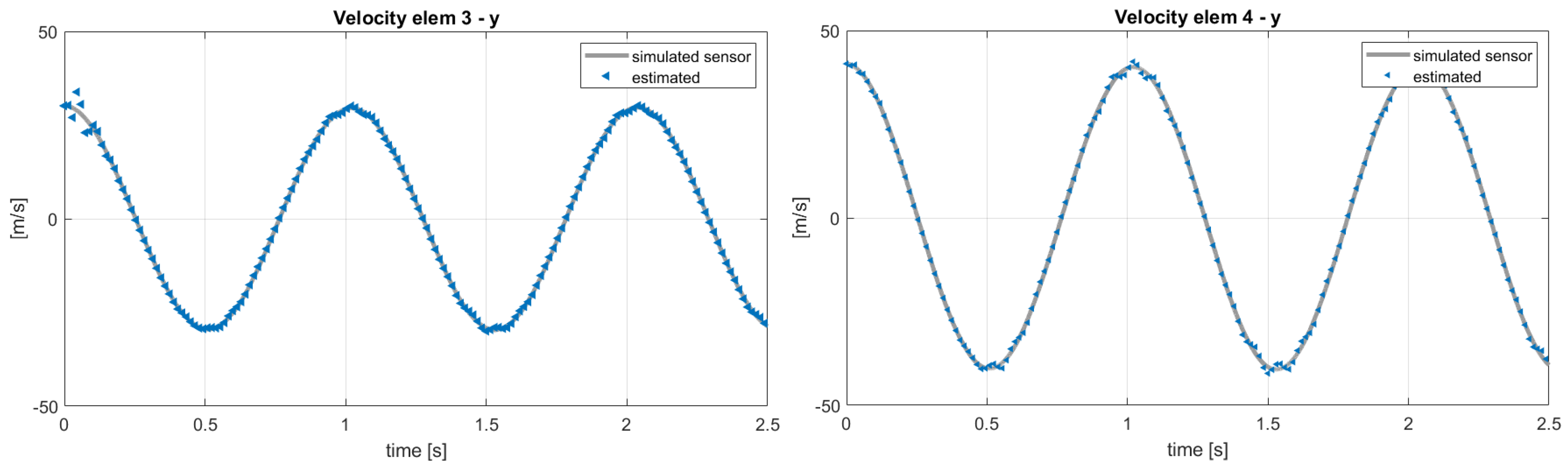

4.1.2. Reference Data from Mbdyn

- Finite segment: ;

- Finite volume: .

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pawar, P.M.; Ganguli, R. Helicopter rotor health monitoring—A review. J. Aerosp. Eng. 2007, 221, 631–647. [Google Scholar] [CrossRef]

- Ganguli, R.; Chopra, I.; Haas, D.J. Formulation of a Helicopter Rotor System Damage Detection Methodology. J. Am. Helicopter Soc. 1996, 41, 302–312. [Google Scholar] [CrossRef]

- Ganguli, R.; Chopra, I.; Haas, D.J. Simulation of helicopter rotor-system structural damage, blade mistracking, friction and freeplay. J. Aircr. 1998, 35, 591–597. [Google Scholar] [CrossRef]

- Haas, D.J.; Flitter, L.; Milano, J. Helicopter Flight Data Feature Extraction or Component Load Monitoring. J. Aircr. 1996, 33, 37–45. [Google Scholar] [CrossRef]

- Ganguli, R.; Chopra, I.; Haas, D.J. Detection of helicopter rotor system simulated faults using neural networks. J. Am. Helicopter Soc. 1997, 42, 161–171. [Google Scholar] [CrossRef]

- Ganguli, R.; Chopra, I.; Haas, D.J. Helicopter rotor system fault detection using physics based model and neural networks. AIAA J. 1998, 36, 1078–1086. [Google Scholar] [CrossRef]

- Sarego, G.; Zaccariotto, M.; Galvanetto, U. Artificial neural networks for impact force reconstruction on composite plates and relevant uncertainty propagation. IEEE Aerosp. Electron. Syst. Mag. 2018, 33, 38–47. [Google Scholar] [CrossRef]

- Ghajari, M.; Sharif-Khodaei, Z.; Aliabadi, M.H.; Apicella, A. Identification of impact force for smart composite stiffened panels. Smart Mater. Struct. 2013, 22, 085014. [Google Scholar] [CrossRef]

- Bhatnagar, S.; Afshar, Y.; Pan, S.; Duraisamy, K.; Kaushik, S. Prediction of aerodynamic flow fields using convolutional neural networks. Comput. Mech. 2019, 64, 525–545. [Google Scholar] [CrossRef]

- Bagherzadeh, S.A. Nonlinear aircraft system identification using artificial neural networks enhanced by empirical mode decomposition. Aerosp. Sci. Technol. 2018, 75, 155–171. [Google Scholar] [CrossRef]

- Abhishek, A. Analysis, Validation, Prediction and Fundamental Understanding of Rotor Blade Loads in an Unsteady Maneuver. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2010. [Google Scholar]

- Glaser, R.; Caccese, V.; Shahinpoor, M. Shape monitoring of a beam structure from measured strain or curvature. Exp. Mech. 2012, 52, 591–606. [Google Scholar] [CrossRef]

- Bogert, P.; Haugse, E.; Gehrki, R. Structural shape identification from experimental strains using a modal transformation technique. In Proceedings of the 44th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Norfolk, Virginia, 7–10 April 2003; p. 1626. [Google Scholar]

- Bernardini, G.; Porcelli, R.; Serafini, J.; Masarati, P. Rotor blade shape reconstruction from strain measurements. Aerosp. Sci. Technol. 2018, 79, 580–587. [Google Scholar] [CrossRef]

- Serafini, J.; Bernardini, G.; Porcelli, R.; Masarati, P. In-Flight Health Monitoring of Helicopter Blades via Differential Analysis. Aerosp. Sci. Technol. 2019, 88, 436–443. [Google Scholar] [CrossRef]

- Simon, D. Optimal State Estimation: Kalman, H Infinity, and Nonlinear Approaches; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Kalman, R.E. A new approach to linear filtering and prediction problems. J. Basic Eng. 1960, 82, 35–45. [Google Scholar] [CrossRef]

- Xie, L.; Soh, Y.C.; de Souza, C.E. Robust Kalman Filtering for Uncertain Discrete-Time Systems. IEEE Trans. Autom. Control 1994, 39, 1310–1314. [Google Scholar]

- Moheimani, S.R.; Savkin, A.V.; Petersen, I.R. Robust Filtering, Prediction, Smoothing, and Observability of Uncertain Systems. IEEE Trans. Circuits Syst. I Fundam. Theory Appl. 1998, 45, 446–457. [Google Scholar] [CrossRef]

- Yang, G.H.; Wang, J.L. Robust Nonfragile Kalman Filtering for Uncertain Linear Systems with Estimators Gain Uncertainty. IEEE Trans. Autom. Control 2001, 46, 343–348. [Google Scholar] [CrossRef]

- Alkahe, J.; Rand, O.; Oshman, Y. Helicopter health monitoring using an adaptive estimator. J. Am. Helicopter Soc. 2003, 48, 199–210. [Google Scholar] [CrossRef][Green Version]

- Heredia, G.; Ollero, A. Sensor fault detection in small autonomous helicopters using observer/Kalman filter identification. In Proceedings of the IEEE International Conference on Mechatronics, Malaga, Spain, 14–17 April 2009; pp. 1–6. [Google Scholar]

- Ebrahimian, H.; Astroza, R.; Conte, J.P.; Papadimitriou, C. Bayesian optimal estimation for output-only nonlinear system and damage identification of civil structures. Struct. Control Health Monit. 2018, 25, e2128. [Google Scholar] [CrossRef]

- Van der Merwe, R. Sigma-Point Kalman Filters for Probabilistic Inference in Dynamic State-Space Models. Ph.D. Thesis, Oregon Health & Science University, Portland, OR, USA, 2004. [Google Scholar]

- Risaliti, E.; Tamarozzi, T.; Vermaut, M.; Cornelis, B.; Desmet, W. Multibody model based estimation of multiple loads and strain field on a vehicle suspension system. Mech. Syst. Signal Process. 2019, 123, 1–25. [Google Scholar] [CrossRef]

- Azam, S.E.; Chatzi, E.; Papadimitriou, C. A dual Kalman filter approach for state estimation via output-only acceleration measurements. Mech. Syst. Signal Process. 2015, 60, 866–886. [Google Scholar] [CrossRef]

- Cumbo, R.; Tamarozzi, T.; Janssens, K.; Desmet, W. Kalman-based load identification and full-field estimation analysis on industrial test case. Mech. Syst. Signal Process. 2018, 117, 771–785. [Google Scholar] [CrossRef]

- Wayne, J. Helicopter Theory; Princeton University Press: Princeton, NY, USA, 1980. [Google Scholar]

- Shabana, A.A. Dynamics of Multibody Systems; Cambridge University Press: New York, NY, USA, 2003. [Google Scholar]

- Connelly, J.D.; Huston, R.L. The dynamics of flexible multibody systems: A finite segment approach—I. Theoretical aspects. Comput. Struct. 1994, 50, 255–258. [Google Scholar] [CrossRef]

- MultiBody Dynamics. Available online: https://www.mbdyn.org/ (accessed on 27 July 2020).

- Glauert, H. Airplane Propellers; Aerodynamic Theory; Springer: Berlin/Heidelberg, Germany, 1935; pp. 169–360. [Google Scholar]

- Huang, E.J. Computer Aided Analysis and Optimization of Mechanical System Dynamics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Simeon, B. Computational flexible multibody dynamics. In A Differential-Algebraic Approach; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Gear, C.W.; Gupta, G.K.; Leimkuhler, B.J. Automatic integration of the Euler- Lagrange equations with constraints. J. Comput. Appl. Math. 1985, 12–13, 77–90. [Google Scholar] [CrossRef]

- Przemieniecki, J.S. Theory of Matrix Structural Analysis—Vol. 1; Courier Corporation: New York, NY, USA, 1968. [Google Scholar]

- Bramwell AR, S.; Balmford, D.; Done, G. Bramwell’s Helicopter Dynamics; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Peters, D.A. Hingeless Rotor Frequency Response with Unsteady Inflow. Available online: https://ntrs.nasa.gov/search.jsp?R=19740026377 (accessed on 27 July 2020).

- Leishman, G.J. Principles of Helicopter Aerodynamics; CambridgE University Press: New York, NY, USA, 2006. [Google Scholar]

- Lourens, E.; Reynders, E.; De Roeck, G.; Degrande, G.; Lombaert, G. An augmented Kalman filter for force identification in structural dynamics. Mech. Syst. Signal Process. 2012, 27, 446–460. [Google Scholar] [CrossRef]

- Naets, F.; Croes, J.; Desmet, W. An online coupled state/input/parameter estimation approach for structural dynamics. Comput. Methods Appl. Mech. Eng. 2015, 283, 1167–1188. [Google Scholar] [CrossRef]

- Ascher, U.M.; Petzold, L.R. Computer methods for ordinary differential equations and differential-algebraic equations. Siam 1998, 61. [Google Scholar]

- Maes, K. Filtering Techniques for Force Identification and Response Estimation in Structural Dynamics. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2016. [Google Scholar]

- Python. Available online: https://www.python.org/ (accessed on 27 July 2020).

- Ghiringhelli, G.L.; Masarati, P.; Mantegazza, P. Multibody implementation of finite volume C beams. AIAA J. 2000, 38, 131–138. [Google Scholar] [CrossRef]

| Blade Structural Properties | Blade Elastic Properties | ||||

|---|---|---|---|---|---|

| Total mass | 82.76 | kg | 5.69E8 | N | |

| Chord | 0.537 | m | 4.00E5 | Nm | |

| Total Length | 6.988 | m | 4.00E5 | Nm | |

| Radius | 7.420 | m | 8.40E5 | Nm/rad | |

| Root Hinges—Distance From Hub | Root Hinges—Elastic Properties | ||||

| Flap offset | 0.289 | m | Flap damping characteristic | 7.50E3 | Nms/rad |

| Lag offset | 0.269 | m | Lag damping characteristic | 7.00E3 | Nms/rad |

| Pitch offset | 0.432 | m |

| Position Sensors | Velocity Sensors | ||

|---|---|---|---|

| elem3 | z | elem3 | z |

| elem4 | z | elem4 | z |

| Position Sensors | Velocity Sensors | ||

|---|---|---|---|

| elem3 | z | elem3 | z |

| elem4 | z | elem4 | z |

| elem4 | y |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cumbo, R.; Tamarozzi, T.; Jiranek, P.; Desmet, W.; Masarati, P. State and Force Estimation on a Rotating Helicopter Blade through a Kalman-Based Approach. Sensors 2020, 20, 4196. https://doi.org/10.3390/s20154196

Cumbo R, Tamarozzi T, Jiranek P, Desmet W, Masarati P. State and Force Estimation on a Rotating Helicopter Blade through a Kalman-Based Approach. Sensors. 2020; 20(15):4196. https://doi.org/10.3390/s20154196

Chicago/Turabian StyleCumbo, Roberta, Tommaso Tamarozzi, Pavel Jiranek, Wim Desmet, and Pierangelo Masarati. 2020. "State and Force Estimation on a Rotating Helicopter Blade through a Kalman-Based Approach" Sensors 20, no. 15: 4196. https://doi.org/10.3390/s20154196

APA StyleCumbo, R., Tamarozzi, T., Jiranek, P., Desmet, W., & Masarati, P. (2020). State and Force Estimation on a Rotating Helicopter Blade through a Kalman-Based Approach. Sensors, 20(15), 4196. https://doi.org/10.3390/s20154196