A Review of the Real-Time Monitoring of Fluid-Properties in Tubular Architectures for Industrial Applications

Abstract

1. Introduction

2. Pipe Monitoring Sensors

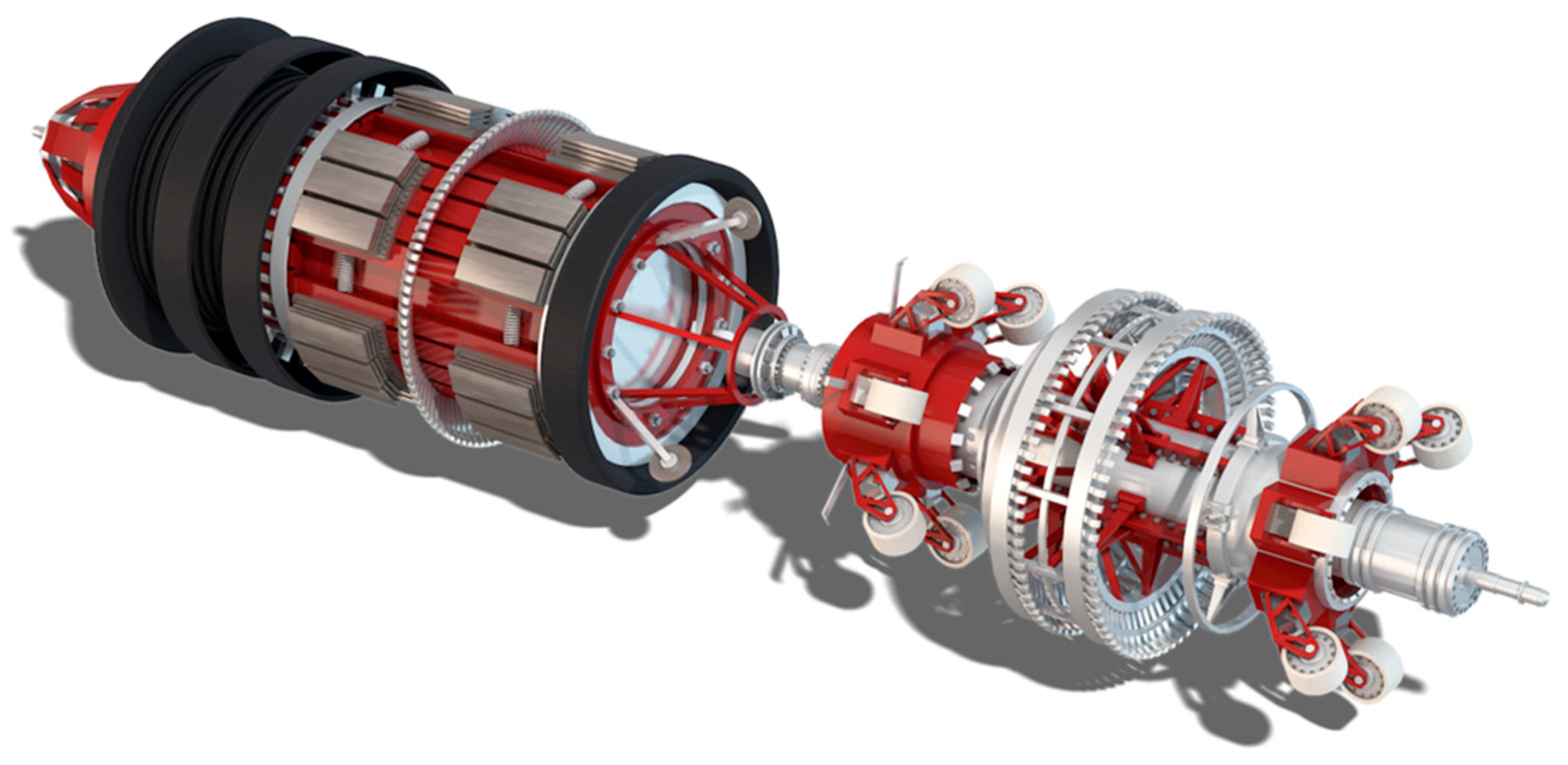

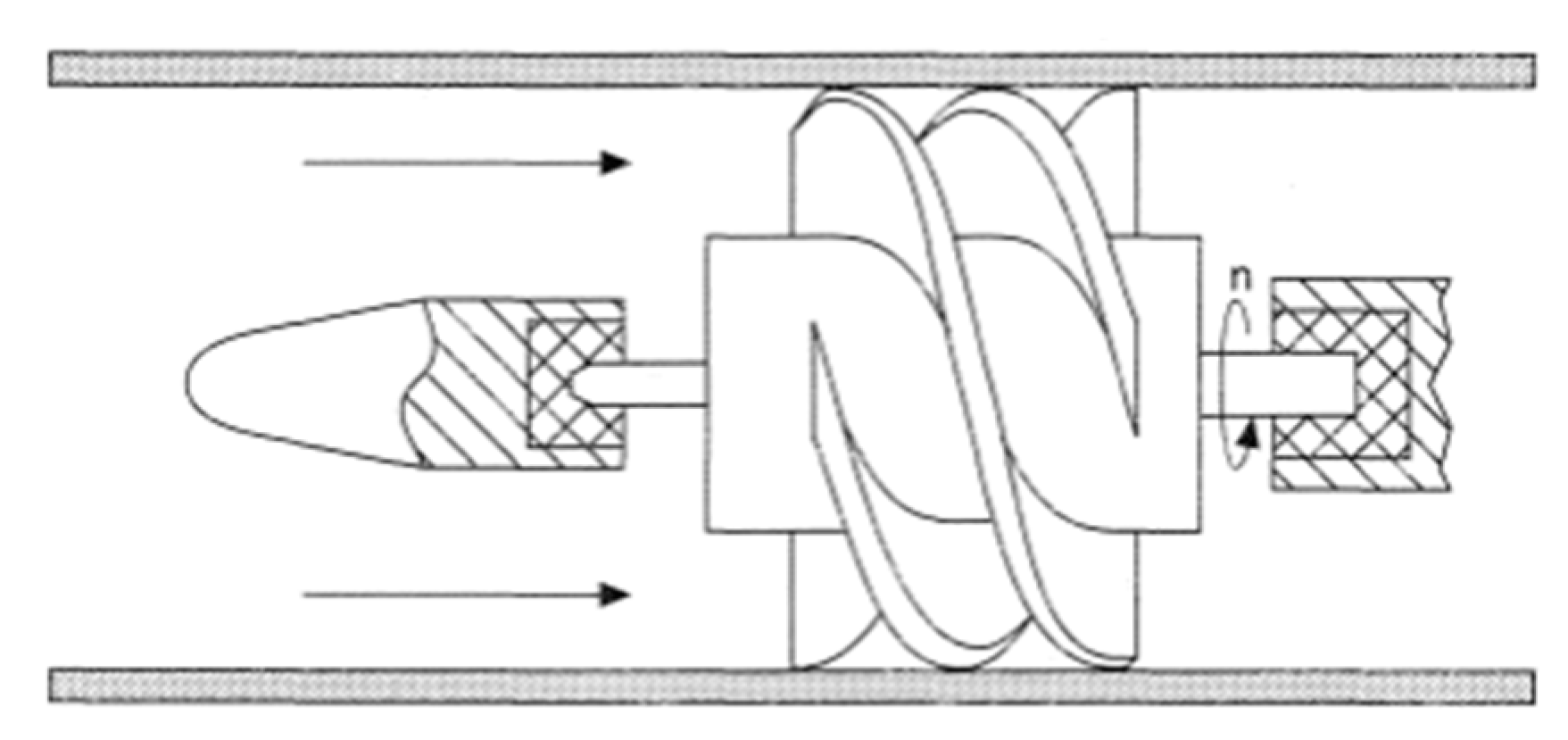

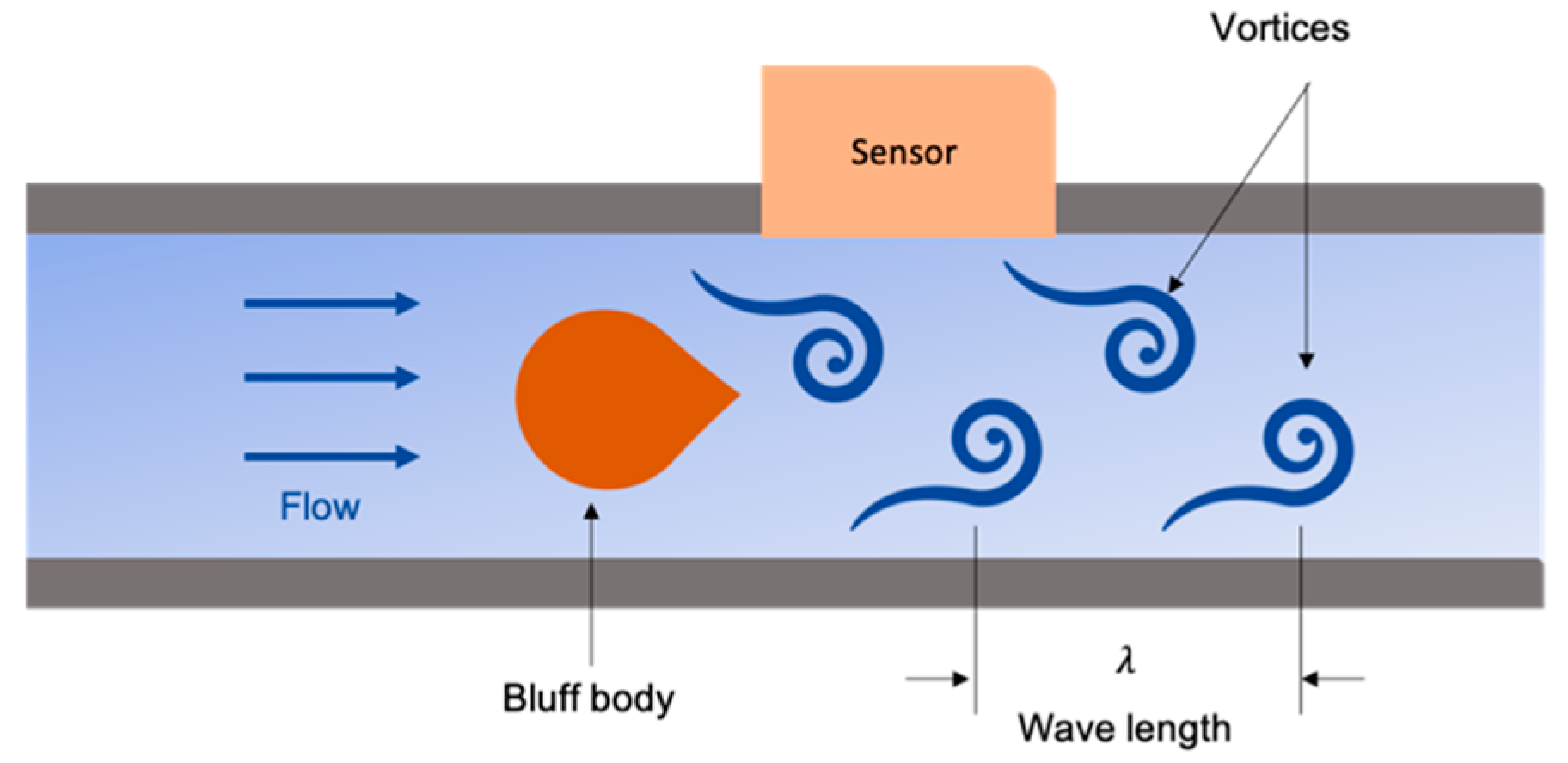

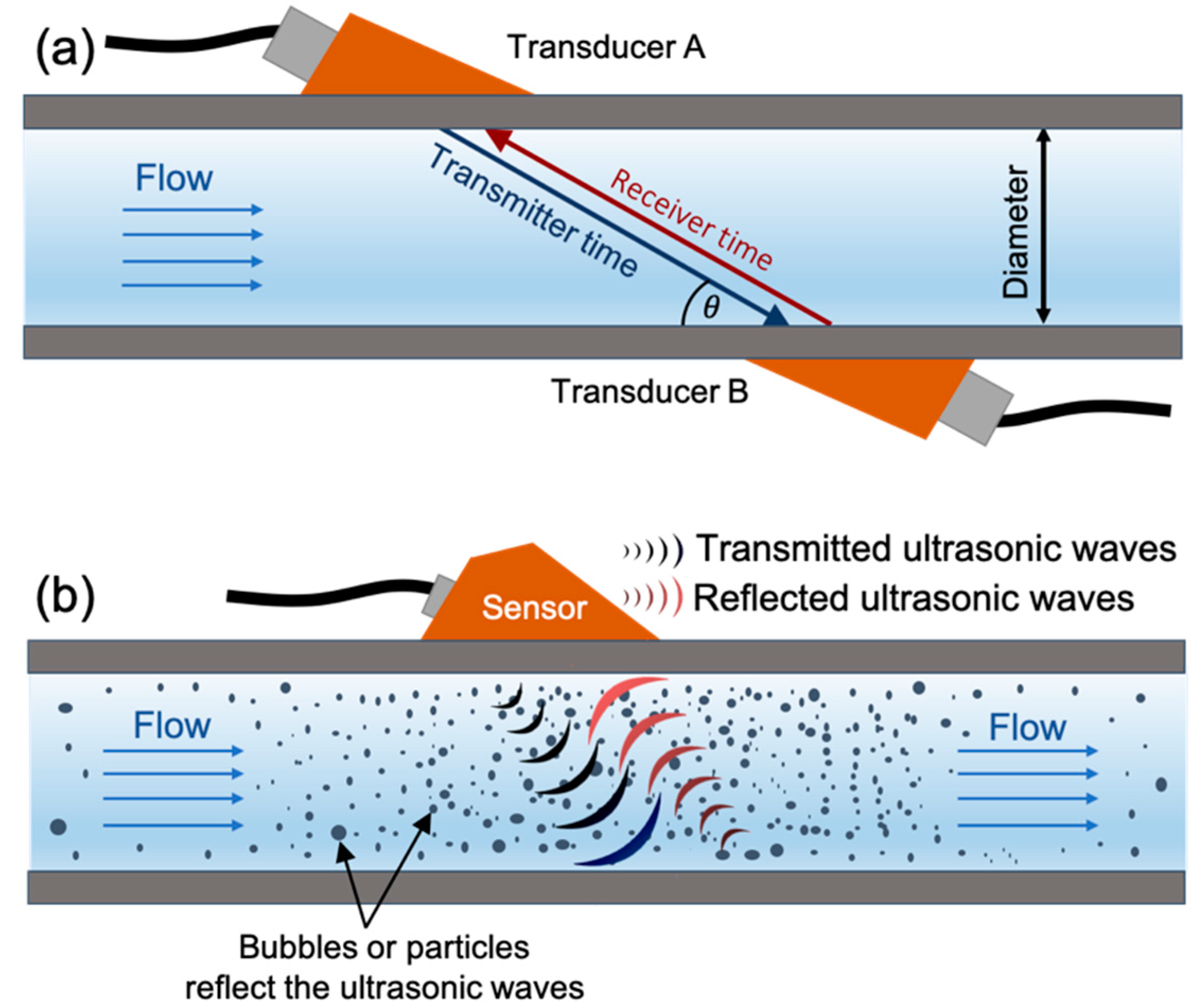

3. Pipes Flow Sensors

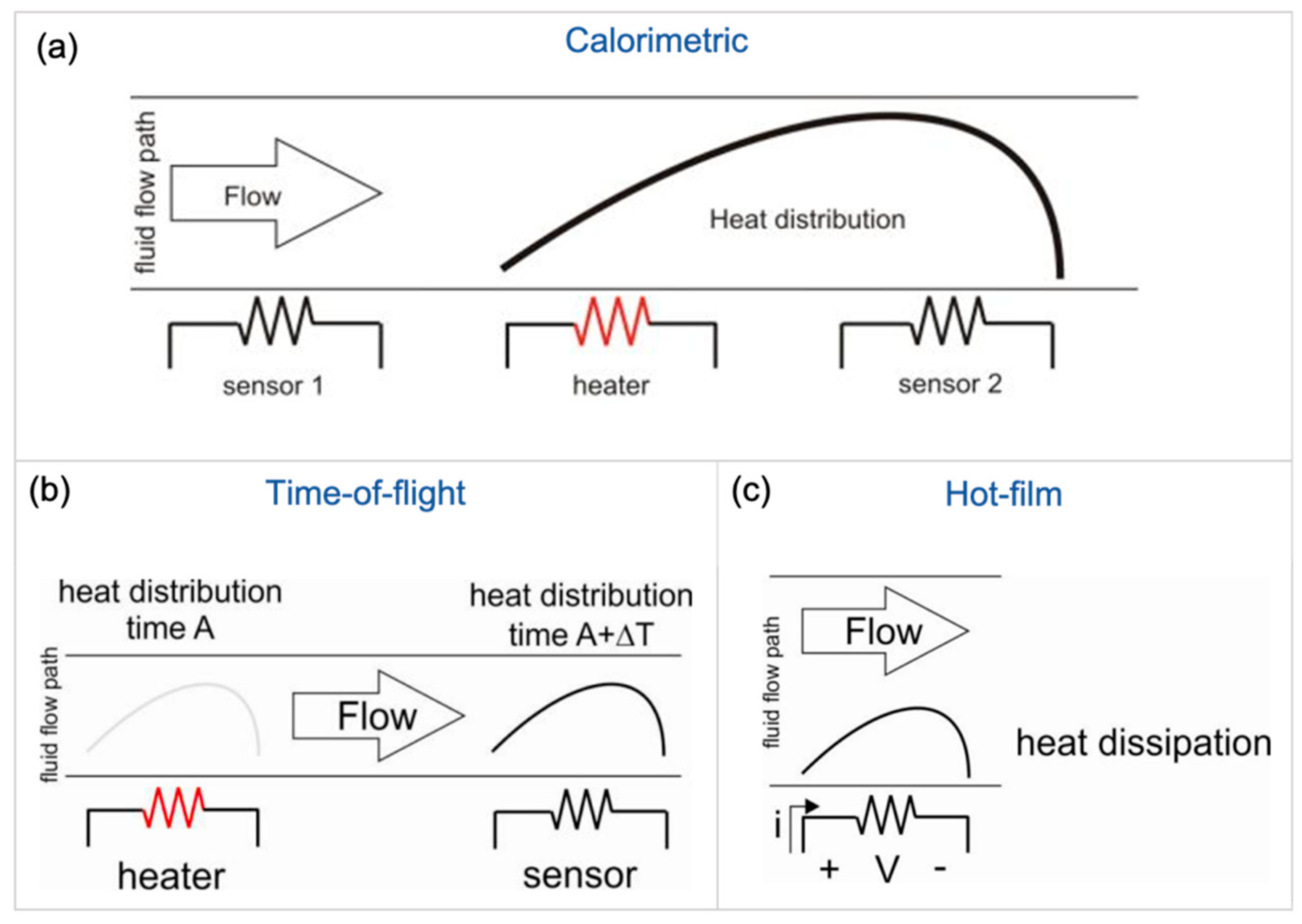

Microfluidic Flow Sensors

4. Viscosity Sensors

Microfluidic Viscometers

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bernasconi, G.; Del Giudice, S.; Giunta, G.; Dionigi, F. Advanced pipeline vibroacoustic monitoring. In Proceedings of the Pressure Vessels and Piping Conference, Paris, France, 14–18 July 2013. [Google Scholar]

- Lambrou, T.P.; Anastasiou, C.C.; Panayiotou, C.G.; Polycarpou, M.M. A low-cost sensor network for real-time monitoring and contamination detection in drinking water distribution systems. IEEE Sens. J. 2014, 14, 2765–2772. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Gabbar, H.A. Review of pipeline integrity management practices. Int. J. Press. Vessel. Pip. 2010, 87, 373–380. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. A high throughput inductive pulse sensor for online oil debris monitoring. Tribol. Int. 2011, 44, 175–179. [Google Scholar] [CrossRef]

- Caputo, A.C.; Pelagagge, P.M. An inverse approach for piping networks monitoring. J. Loss Prev. Process Ind. 2002, 15, 497–505. [Google Scholar] [CrossRef]

- Shibata, S.; Niimi, Y.; Shikida, M. Flexible thermal MEMS flow sensor based on Cu on polyimide substrate. Proc. IEEE Sens. 2014, 2014, 424–427. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, P.; Vuran, M.C.; Al-Rodhaan, M.A.; Al-Dhelaan, A.M.; Akyildiz, I.F. MISE-PIPE: Magnetic induction-based wireless sensor networks for underground pipeline monitoring. Ad Hoc Netw. 2011, 9, 218–227. [Google Scholar] [CrossRef]

- Galindo-Rosales, F.J. Complex fluid-flows in microfluidics. In Complex Fluid-Flows Microfluidics; Springer: Cham, Switzerland, 2018; pp. 1–23. [Google Scholar] [CrossRef]

- Meniconi, S.; Brunone, B.; Ferrante, M.; Massari, C. Transient tests for locating and sizing illegal branches in pipe systems. J. Hydroinform. 2011, 13, 334–345. [Google Scholar] [CrossRef]

- Daga, R.; Samal, M.K. Real-time monitoring of high temperature components. Procedia Eng. 2013, 55, 421–427. [Google Scholar] [CrossRef][Green Version]

- Rizzo, P. Water and wastewater pipe nondestructive evaluation and health monitoring: A review. Adv. Civ. Eng. 2010, 2010, 13. [Google Scholar] [CrossRef]

- Wang, J.; Jang, Y.; Wan, G.; Giridharan, V.; Song, G.L.; Xu, Z.; Koo, Y.; Qi, P.; Sankar, J.; Huang, N.; et al. Flow-induced corrosion of absorbable magnesium alloy: In-situ and real-time electrochemical study. Corros. Sci. 2016, 104, 277–289. [Google Scholar] [CrossRef]

- Feng, Q.; Kong, Q.; Huo, L.; Song, G. Crack detection and leakage monitoring on reinforced concrete pipe. Smart Mater. Struct. 2015. [Google Scholar] [CrossRef]

- Hiltscher, G.; Mühlthaler, W.; Smits, J. Industrial Pigging Technology; Hiltscher, G., Muhlthaler, W., Smits, J., Eds.; Wiley-VCH: Weinheim, Germany, 2003; ISBN 9783527306350. [Google Scholar]

- Gupta, A.; Sircar, A. Introduction to pigging & a case study on pigging of an onshore crude oil trunkline. Int. J. Latest Technol. Eng. 2016, 5, 18–25. [Google Scholar]

- Metje, N.; Chapman, D.N.; Cheneler, D.; Ward, M.; Thomas, A.M. Smart pipes—Instrumented water pipes, can this be made a reality? Sensors 2011, 11, 7455–7475. [Google Scholar] [CrossRef] [PubMed]

- Tiratsoo, J.N.H. Pipeline Pigging Technology, 2nd ed.; Gulf Professional Publishing: Accrington, UK, 1992. [Google Scholar]

- Alnaimat, F.; Ziauddin, M. Wax deposition and prediction in petroleum pipelines. J. Pet. Sci. Eng. 2020, 184, 106385. [Google Scholar] [CrossRef]

- Brower, D.V.; Prescott, C.N.; Zhang, J.; Howerter, C.; Rafferty, D. Real-time flow assurance monitoring with non-intrusive fiber optic technology. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2005. [Google Scholar]

- Smith, A.; Dixon, N.; Fowmes, G. Monitoring buried pipe deformation using acoustic emission: quantification of attenuation. Int. J. Geotech. Eng. 2017, 11, 418–430. [Google Scholar] [CrossRef]

- Liu, Z.; Kleiner, Y. State-of-the-art review of technologies for pipe structural health monitoring. IEEE Sens. J. 2012, 12, 1987–1992. [Google Scholar] [CrossRef]

- Rizzo, P.; Marzani, A.; Bruck, J. Ultrasonic guided waves for nondestructive evaluation/structural health monitoring of trusses. Meas. Sci. Technol. 2010, 21, 045701. [Google Scholar] [CrossRef]

- Honarvar, F.; Salehi, F.; Safavi, V.; Mokhtari, A.; Sinclair, A.N. Ultrasonic monitoring of erosion/corrosion thinning rates in industrial piping systems. Ultrasonics 2013, 53, 1251–1258. [Google Scholar] [CrossRef]

- Ewert, U.; Tschaikner, M.; Hohendorf, S.; Bellon, C.; Haith, M.I.; Huthwaite, P.; Lowe, M.J.S. Corrosion monitoring with tangential radiography and limited view computed tomography. AIP Conf. Proc. 2016, 1706, 110003. [Google Scholar]

- Rakvin, M.; Markučic, D.; Hižman, B. Evaluation of pipe wall thickness based on contrast measurement using Computed Radiography (CR). Procedia Eng. 2014, 69, 1216–1224. [Google Scholar] [CrossRef]

- Machado, M.A.; Rosado, L.; Pedrosa, N.; Vostner, A.; Miranda, R.M.; Piedade, M.; Santos, T.G. Novel eddy current probes for pipes: Application in austenitic round-in-square profiles of ITER. NDT E Int. 2017, 87, 111–118. [Google Scholar] [CrossRef]

- Adegboye, M.A.; Fung, W.K.; Karnik, A. Recent advances in pipeline monitoring and oil leakage detection technologies: Principles and approaches. Sensors 2019, 19, 2548. [Google Scholar] [CrossRef] [PubMed]

- Nikles, M.; Vogel, B.H.; Briffod, F.; Grosswig, S.; Sauser, F.; Luebbecke, S.; Bals, A.; Pfeiffer, T. Leakage detection using fiber optics distributed temperature monitoring. In Smart Structures and Materials 2004: Smart Sensor Technology and Measurement Systems; Udd, E., Inaudi, D., Eds.; SPIE: San Diego, CA, USA, 2004; Volume 5384, p. 18. [Google Scholar]

- Rajeev, P.; Kodikara, J.; Chiu, W.K.; Kuen, T. Distributed optical fibre sensors and their applications in pipeline monitoring. Key Eng. Mater. 2013, 558, 424–434. [Google Scholar] [CrossRef]

- Boukhanouf, R.; Haddad, A.; North, M.T.; Buffone, C. Experimental investigation of a flat plate heat pipe performance using IR thermal imaging camera. Appl. Therm. Eng. 2006, 26, 2148–2156. [Google Scholar] [CrossRef]

- Brunone, B.; Ferrante, M.; Meniconi, S.; Massari, C. Effectiveness sssessment of pipe systems by means of transient test-based techniques. Procedia Environ. Sci. 2013, 19, 814–822. [Google Scholar] [CrossRef][Green Version]

- Meniconi, S.; Brunone, B.; Ferrante, M.; Capponi, C.; Carrettini, C.A.; Chiesa, C.; Segalini, D.; Lanfranchi, E.A. Anomaly pre-localization in distribution-transmission mains by pump trip: Preliminary field tests in the Milan pipe system. J. Hydroinform. 2015, 17, 377–389. [Google Scholar] [CrossRef]

- Capponi, C.; Meniconi, S.; Lee, P.J.; Brunone, B.; Cifrodelli, M. Time-domain analysis of laboratory experiments on the transient pressure damping in a leaky polymeric pipe. Water Resour. Manag. 2020, 34, 501–514. [Google Scholar] [CrossRef]

- Sadeghioon, A.M.; Metje, N.; Chapman, D.; Anthony, C. Water pipeline failure detection using distributed relative pressure and temperature measurements and anomaly detection algorithms. Urban Water J. 2018, 15, 287–295. [Google Scholar] [CrossRef]

- Yazdekhasti, S.; Piratla, K.R.; Atamturktur, S.; Khan, A. Experimental evaluation of a vibration-based leak detection technique for water pipelines. Struct. Infrastruct. Eng. 2018, 14, 46–55. [Google Scholar] [CrossRef]

- Chen, X.; Ding, T. Flexible eddy current sensor array for proximity sensing. Sens. Actuators A Phys. 2007, 135, 126–130. [Google Scholar] [CrossRef]

- Kobayashi, M.; Jen, C.K.; Lévesque, D. Flexible ultrasonic transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2006, 53, 1478–1486. [Google Scholar] [CrossRef] [PubMed]

- Shih, J.L.; Kobayashi, M.; Jen, C.K. Flexible ultrasonic transducers for structural health monitoring of pipes at high temperatures. In Proceedings of the 2009 IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009. [Google Scholar]

- Van Hieu, B.; Choi, S.; Kim, Y.U.; Park, Y.; Jeong, T. Wireless transmission of acoustic emission signals for real-time monitoring of leakage in underground pipes. KSCE J. Civ. Eng. 2011, 15, 805–812. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kwon, Y.E. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef]

- Pernía, A.M.; Mayor, H.A.; Prieto, M.J.; Villegas, P.J.; Nuño, F.; Martín-Ramos, J.A. Magnetostrictive sensor for blockage detection in pipes subjected to high temperatures. Sensors 2019, 19, 2382. [Google Scholar] [CrossRef]

- Okosun, F.; Cahill, P.; Hazra, B.; Pakrashi, V. Vibration-based leak detection and monitoring of water pipes using output-only piezoelectric sensors. Eur. Phys. J. Spec. Top. 2019, 228, 1659–1675. [Google Scholar] [CrossRef]

- Maharaj, C.; Dear, J.P.; Morris, A. A review of methods to estimate creep damage in low-alloy steel power station steam pipes. Strain 2009, 45, 316–331. [Google Scholar] [CrossRef]

- Shih, J.L.; Kobayashi, M.; Jen, C.K. Flexible metallic ultrasonic transducers for structural health monitoring of pipes at high temperatures. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 2103–2110. [Google Scholar] [CrossRef]

- Paolozzi, A.; Paris, C.; Vendittozzi, C.; Felli, F.; Mongelli, M.; De Canio, G.; Colucci, A.; Asanuma, H. Test of FBG sensors for monitoring high pressure pipes. In Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2017; Lynch, J.P., Ed.; SPIE: Portland, OR, USA, 2017; Volume 10168, p. 101681Q. [Google Scholar]

- Ho, M.; El-Borgi, S.; Patil, D.; Song, G. Inspection and monitoring systems subsea pipelines: A review paper. Struct. Heal. Monit. 2020, 19, 606–645. [Google Scholar] [CrossRef]

- Nestleroth, J.B. Pipeline in-line inspection—Challenges to NDT. Insight Non-Destr. Test. Cond. Monit. 2006, 48, 524–528. [Google Scholar] [CrossRef][Green Version]

- Carvalho, A.A.; Rebello, J.M.A.; Souza, M.P.V.; Sagrilo, L.V.S.; Soares, S.D. Reliability of non-destructive test techniques in the inspection of pipelines used in the oil industry. Int. J. Press. Vessel. Pip. 2008, 85, 745–751. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Rajita, G.; Mandal, N. Review on transit time ultrasonic flowmeter. In Proceedings of the 2016 2nd International Conference on Control, Instrumentation, Energy and Communication (CIEC 2016), Kolkata, India, 28–30 January 2016; pp. 88–92. [Google Scholar]

- Abdul Wahab, Y.; Abdul Rahim, R.; Fazalul Rahiman, M.H.; Ridzuan Aw, S.; Mohd Yunus, F.R.; Goh, C.L.; Abdul Rahim, H.; Ling, L.P. Non-invasive process tomography in chemical mixtures—A review. Sens. Actuators B Chem. 2015, 210, 602–617. [Google Scholar] [CrossRef]

- Takashima, S.; Asanuma, H.; Niitsuma, H. A water flowmeter using dual fiber Bragg grating sensors and cross-correlation technique. Sens. Actuators A Phys. 2004, 116, 66–74. [Google Scholar] [CrossRef]

- Lu, X.; Kujundzic, E.; Mizrahi, G.; Wang, J.; Cobry, K.; Peterson, M.; Gilron, J.; Greenberg, A.R. Ultrasonic sensor control of flow reversal in RO desalination-Part 1: Mitigation of calcium sulfate scaling. J. Membr. Sci. 2012, 419, 20–32. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Hamed, M.H.; Omara, Z.M.; Sharshir, S.W. Water desalination using a humidification-dehumidification technique—A detailed review. Nat. Resour. 2013, 04, 286–305. [Google Scholar] [CrossRef]

- Liu, Z.; Hong, T.; Zhang, W.; Li, Z.; Chen, H. Novel liquid flow sensor based on differential pressure method. Rev. Sci. Instrum. 2007, 78, 015108. [Google Scholar] [CrossRef] [PubMed]

- Son, B.H.; Park, J.Y.; Lee, S.; Ahn, Y.H. Suspended single-walled carbon nanotube fluidic sensors. Nanoscale 2015, 7, 15421–15426. [Google Scholar] [CrossRef]

- Zheng, Y.; Liu, Q. Review of techniques for the mass flow rate measurement of pneumatically conveyed solids. Meas. J. Int. Meas. Confed. 2011, 44, 589–604. [Google Scholar] [CrossRef]

- Gorak, A.; Schoenmakers, H. Distillation, 1st ed.; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Huijsing, J.H.; van Dorp, A.L.C.; Loos, P.J.G. Thermal mass-flow meter. J. Phys. E 1988, 21, 994. [Google Scholar] [CrossRef]

- Otakane, K.; Sakai, K.; Seto, M. Development of the thermal flow meter. SICE 2003 Annu. Conf. 2003, 3, 3080–3083. [Google Scholar]

- Abdullahi, S.I.; Malik, N.A.; Habaebi, M.H.; Salami, A.B. Miniaturized turbine flow sensor: design and simulation. In Proceedings of the 2018 7th International Conference on Computer and Communication Engineering (ICCCE), Kuala Lumpur, Malaysia, 19–20 September 2018; 2018; pp. 38–43. [Google Scholar] [CrossRef]

- Edwards, P.K. Turbine Flow Monitoring Device. U.S. Patent No. 6,487,919, 3 December 2002. [Google Scholar]

- Gianchandani, Y.B.; Takahata, K. Electromagnetic Flow Sensor Device. U.S. Patent No. 7,922,667, 12 April 2011. [Google Scholar]

- Spong, E.; Reizes, J. Efficiency improvements of electromagnetic flow control. In CHT-04—Advances in Computational Heat Transfer III, Proceedings of the Third International Symposium; Begell House: Sydney, Australia, 2004; p. 25. [Google Scholar]

- Pankanin, G.L. The vortex flowmeter: various methods of investigating phenomena. Meas. Sci. Technol. 2005, 16, R1. [Google Scholar] [CrossRef]

- Cheng, L.K.; Schiferli, W.; Nieuwland, R.A.; Franzen, A.; den Boer, J.J.; Jansen, T.H. Development of a FBG vortex flow sensor for high-temperature applications. In Proceedings of the 21st International Conference on Optical Fiber Sensors, Ottawa, ON, Canada, 17 May 2011; Volume 7753, p. 77536V. [Google Scholar]

- Lynnworth, L.C.; Liu, Y. Ultrasonic flowmeters: Half-century progress report, 1955–2005. Ultrasonics 2006, 44, e1371–e1378. [Google Scholar] [CrossRef] [PubMed]

- Tezuka, K.; Mori, M.; Suzuki, T.; Kanamine, T. Ultrasonic pulse-Doppler flow meter application for hydraulic power plants. Flow Meas. Instrum. 2008, 19, 155–162. [Google Scholar] [CrossRef]

- Anklin, M.; Drahm, W.; Rieder, A. Coriolis mass flowmeters: Overview of the current state of the art and latest research. Flow Meas. Instrum. 2006, 17, 317–323. [Google Scholar] [CrossRef]

- Apple, C.; Anklin, M.; Drahm, W. Mass flowmeters, coriolis. In Instrument Engineers’ Handbook: Process Measurement and Analysis, 4th ed.; CRC Press: Boca Raton, FL, USA, 2003; ISBN 9781420064025. [Google Scholar]

- Venugopal, A.; Agrawal, A.; Prabhu, S.V. Review on vortex flowmeter—Designer perspective. Sens. Actuators A Phys. 2011, 170, 8–23. [Google Scholar] [CrossRef]

- Świsulski, D.; Hanus, R.; Zych, M.; Petryka, L. Methods of measurement signal acquisition from the rotational flow meter for frequency analysis. EPJ Web Conf. 2017, 143, 02124. [Google Scholar] [CrossRef]

- Baker, R.C. Turbine and related flowmeters: I. Industrial practice. Flow Meas. Instrum. 1991, 2, 147–161. [Google Scholar] [CrossRef]

- Rensing, M.; Cunningham, T.J. Coriolis flowmeter verification via embedded modal analysis. In Conference Proceedings of the Society for Experimental Mechanics Series; Springer: New York, NY, USA, 2011; Volume 3, pp. 851–860. [Google Scholar]

- Bobovnik, G.; Kutin, J.; Bajsić, I. The effect of flow conditions on the sensitivity of the Coriolis flowmeter. Flow Meas. Instrum. 2004, 15, 69–76. [Google Scholar] [CrossRef]

- Wang, T.; Baker, R. Coriolis flowmeters: A review of developments over the past 20 years, and an assessment of the state of the art and likely future directions. Flow Meas. Instrum. 2014, 40, 99–123. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, H. Neural networks approach for prediction of gas–liquid two-phase flow pattern based on frequency domain analysis of vortex flowmeter signals. Meas. Sci. Technol. 2008, 19, 015401. [Google Scholar] [CrossRef]

- Zyłka, P.; Modrzyński, P.; Janus, P. Vortex anemometer using MEMS cantilever sensor. J. Microelectromech. Syst. 2010, 19, 1485–1489. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, H.; Zhou, J. Investigation of the pressure probe properties as the sensor in the vortex flowmeter. Sens. Actuators A Phys. 2007, 136, 646–655. [Google Scholar] [CrossRef]

- Venugopal, A.; Agrawal, A.; Prabhu, S.V. Frequency detection in vortex flowmeter for low Reynolds number using piezoelectric sensor and installation effects. Sens. Actuators A Phys. 2012, 184, 78–85. [Google Scholar] [CrossRef]

- Schena, E.; Massaroni, C.; Saccomandi, P.; Cecchini, S. Flow measurement in mechanical ventilation: A review. Med. Eng. Phys. 2015, 37, 257–264. [Google Scholar] [CrossRef] [PubMed]

- Takeda, Y.; Mori, M. Doppler Ultrasonic Flowmeter. U.S. Patent No. 6,931,945, 23 August 2005. [Google Scholar]

- Li, B.; Lu, J.; Chen, J.; Chen, S. Study on transit-Time ultrasonic flow meter with waveform analysis. In Proceedings of the 2nd International Conference on Information System and Data Mining, New York, NY, USA, 9–11 April 2018. [Google Scholar]

- Jenkins, A. Mass Flow Measurement Techniques across the Spectrum. Available online: https://www.alicat.com/mass-flow-measurement-techniques-radar/ (accessed on 23 April 2020).

- Liu, P.; Zhu, R.; Que, R. A flexible flow sensor system and its characteristics for fluid mechanics measurements. Sensors 2009, 9, 9533–9543. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Miquet, E.E.; Perchoux, J.; Loubière, K.; Tronche, C.; Prat, L.; Sotolongo-Costa, O. Optical feedback interferometry for velocity measurement of parallel liquid-liquid flows in a microchannel. Sensors 2016, 16, 1233. [Google Scholar] [CrossRef] [PubMed]

- Anandharamakrishnan, C. Computational fluid dynamics applications in food processing. In Computational Fluid Dynamics Applications in Food Processing; Springer: New York, NY, USA, 2013; pp. 1–9. [Google Scholar]

- Patist, A.; Bates, D. Ultrasonic innovations in the food industry: From the laboratory to commercial production. Innov. Food Sci. Emerg. Technol. 2008, 9, 147–154. [Google Scholar] [CrossRef]

- Saeed, H.; Ali, S.; Rashid, S.; Qaisar, S.; Felemban, E. Reliable monitoring of oil and gas pipelines using wireless sensor network (WSN)—REMONG. In Proceedings of the 9th International Conference on System of Systems Engineering: The Socio-Technical Perspective (SoSE 2014), Adelade, SA, Australia, 9–13 June 2014; pp. 230–235. [Google Scholar]

- Ashauer, M.; Scholz, H.; Briegel, R.; Sandmaier, H.; Lang, W. Thermal flow sensors for very small flow rate. In Transducers ’01 Eurosensors XV; Springer: Berlin/Heidelberg, Germany, 2001; pp. 1436–1439. [Google Scholar] [CrossRef]

- Thorat, S.; Thibodeau, C.; Collier, B.; Ngo, H. Leveraging control and monitoring technologies. IEEE Ind. Appl. 2017, 23, 62–73. [Google Scholar] [CrossRef]

- Valinoti, A.C.; Neves, B.G.; Da Silva, E.M.; Maia, L.C. Surface degradation of composite resins by acidic medicines and pH-cycling. J. Appl. Oral Sci. 2008, 16, 257–265. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Lee, C.-Y.; Chiang, C.-M. A MEMS-based air flow sensor with a free-standing micro-cantilever structure. Sensors 2007, 7, 2389–2401. [Google Scholar] [CrossRef]

- Czaplewski, D.A.; Ilic, B.R.; Zalalutdinov, M.; Olbricht, W.L.; Zehnder, A.T.; Craighead, H.G.; Michalske, T.A. A micromechanical flow sensor for microfluidic applications. J. Microelectromech. Syst. 2004, 13, 576–585. [Google Scholar] [CrossRef]

- Smith, R.; Sparks, D.R.; Riley, D.; Najafi, N. A MEMS-based coriolis mass flow sensor for industrial applications. IEEE Trans. Ind. Electron. 2009, 56, 1066–1071. [Google Scholar] [CrossRef]

- Yu, Y.; Zong, G. Design and simulation of an ultrasonic flow meter for thin pipe. In Proceedings of the 2011 IEEE International Conference on Mechatronics and Automation (ICMA 2011), Beijing, China, 7–10 August 2011; pp. 1115–1119. [Google Scholar]

- Noeth, N.; Keller, S.S.; Boisen, A. Fabrication of a cantilever-based microfluidic flow meter with nL min−1 resolution. J. Micromechan. Microeng. 2011, 21, 15007. [Google Scholar] [CrossRef]

- Lien, V.; Vollmer, F. Microfluidic flow rate detection based on integrated optical fiber cantilever. Lab Chip 2007, 7, 1352–1356. [Google Scholar] [CrossRef] [PubMed]

- Cheri, M.S.; Latifi, H.; Sadeghi, J.; Moghaddam, M.S.; Shahraki, H.; Hajghassem, H. Real-time measurement of flow rate in microfluidic devices using a cantilever-based optofluidic sensor. Analyst 2013, 139, 431–438. [Google Scholar] [CrossRef]

- Pinto, R.M.R.; Chu, V.; Conde, J.P. Label-free biosensing of DNA in microfluidics using amorphous silicon capacitive micro-cantilevers. IEEE Sens. J. 2020, 1. [Google Scholar] [CrossRef]

- Amírola, J.; Rodríguez, A.; Castañer, L.; Santos, J.P.; Gutiérrez, J.; Horrillo, M.C. Micromachined silicon microcantilevers for gas sensing applications with capacitive read-out. Sens. Actuators B Chem. 2005, 111, 247–253. [Google Scholar] [CrossRef]

- Mutharasan, R.; Maraldo, D.R. Detection and quantification of biomarkers via a piezoelectric cantilever sensor. Mod. Pathol. 2011, 15, 1236–1237. [Google Scholar]

- Mutharasan, R.; David, R.; Maraldo, G. Detection and quantification of bomarkers vaapiezoelectric cantilever sensor. U.S. Patent No. 7,993,854, 9 August 2011. [Google Scholar]

- Radhakrishnan, S.; Lal, A. Scalable microbeam flowsensors with electronic readout. J. Microelectromech. Syst. 2005, 14, 1013–1022. [Google Scholar] [CrossRef]

- Gass, V.; van der Schoot, B.H.; de Rooij, N.F. Nanofluid handling by micro-flow-sensor based on drag force measurements. In Proceedings of the IEEE Micro Electro Mechanical Systems, Fort Lauderdale, FL, USA, 10 February 1993; pp. 167–172. [Google Scholar]

- Alfadhel, A.; Li, B.; Zaher, A.; Yassine, O.; Kosel, J. A magnetic nanocomposite for biomimetic flow sensing. Lab Chip 2014, 14, 4362–4369. [Google Scholar] [CrossRef]

- Droogendijk, H.; Groenesteijn, J.; Haneveld, J.; Sanders, R.G.P.; Wiegerink, R.J.; Lammerink, T.S.J.; Lötters, J.C.; Krijnen, G.J.M. Parametric excitation of a micro Coriolis mass flow sensor. Appl. Phys. Lett. 2012, 101, 99–102. [Google Scholar] [CrossRef]

- Kuo, J.T.W.; Yu, L.; Meng, E. Micromachined thermal flow sensors-A review. Micromachines 2012, 3, 550–573. [Google Scholar] [CrossRef]

- Petropoulos, A.; Pagonis, D.N.; Kaltsas, G. Flexible PCB-MEMS flow sensor. Procedia Eng. 2012, 47, 236–239. [Google Scholar] [CrossRef]

- Sturm, H.; Lang, W. Membrane-based thermal flow sensors on flexible substrates. Sens. Actuators A Phys. 2013, 195, 113–122. [Google Scholar] [CrossRef]

- Ashauer, M.; Glosch, H.; Hedrich, F.; Hey, N.; Sandmaier, H.; Lang, W. Thermal flow sensor for liquids and gases. Am. Soc. Mech. Eng. Dyn. Syst. Control Div. DSC 1998, 66, 427–432. [Google Scholar] [CrossRef]

- Cubukcu, A.S.; Zernickel, E.; Buerklin, U.; Urban, G.A. A 2D thermal flow sensor with sub-mW power consumption. Sens. Actuators A Phys. 2010, 163, 449–456. [Google Scholar] [CrossRef]

- Tanaka, H.; Terao, M.; Tanaka, Y. Non-wetted thermal micro flow sensor. In Proceedings of the 2012 Proceedings of SICE Annual Conference (SICE), Akita, Japan, 20–23 August 2012; pp. 10–15. [Google Scholar]

- Arevalo, A.; Byas, E.; Foulds, I.G. Simulation of thermal transport based flow meter for microfluidics applications. In Proceedings of the Comsol Conference, Rotterdam, The Netherlands, 23–25 October 2013; Volume 2, pp. 1–5. [Google Scholar]

- Mistry, K.K.; Mahapatra, A. Design and simulation of a thermo transfer type MEMS based micro flow sensor for arterial blood flow measurement. Microsyst. Technol. 2012, 18, 683–692. [Google Scholar] [CrossRef]

- Kim, T.H.; Kim, S.J. Development of a micro-thermal flow sensor with thin-film thermocouples. J. Micromech. Microeng. 2006, 16, 2502–2508. [Google Scholar] [CrossRef]

- Tabata, O. Fast-response silicon flow sensor with an on-chip fluid temperature sensing element. IEEE Trans. Electr. Dev. 1986, 33, 361–365. [Google Scholar] [CrossRef]

- Randjelović, D.; Petropoulos, A.; Kaltsas, G.; Stojanović, M.; Lazić, Ž.; Djurić, Z.; Matić, M. Multipurpose MEMS thermal sensor based on thermopiles. Sens. Actuators A Phys. 2008, 141, 404–413. [Google Scholar] [CrossRef]

- Mizuno, Y.; Liger, M.; Tai, Y.C. Nanofluidic flowmeter using carbon sensing element. In Proceedings of the 17th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Maastricht, The Netherlands, 25–29 January 2004; pp. 322–325. [Google Scholar]

- Shen, G.P.; Qin, M.; Huang, Q.A.; Zhang, H.; Wu, J. A FCOB packaged thermal wind sensor with compensation. Microsyst. Technol. 2010, 16, 511–518. [Google Scholar] [CrossRef]

- Liu, J.; Tai, Y.C.; Ho, C.M. MEMS for pressure distribution studies of gaseous flows in microchannels. In Proceedings of the IEEE Micro Electro Mechanical Systems, Amsterdam, The Netherlands, 29 Januare–2 February 1995; pp. 209–215. [Google Scholar] [CrossRef]

- Kohl, M.J.; Abdel-Khalik, S.I.; Jeter, S.M.; Sadowski, D.L. A microfluidic experimental platform with internal pressure measurements. Sens. Actuators A Phys. 2005, 118, 212–221. [Google Scholar] [CrossRef]

- Martinelli, M.; Viktorov, V. A mini fluidic oscillating flowmeter. Flow Meas. Instrum. 2011, 22, 537–543. [Google Scholar] [CrossRef]

- Song, W.; Psaltis, D. Optofluidic membrane interferometer: An imaging method for measuring microfluidic pressure and flow rate simultaneously on a chip ARTICLES YOU MAY BE INTERESTED IN. Biomicrofluidics 2011, 5, 44110. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Xu, F. A review on optical microfibers in fluidic applications. J. Micromech. Microeng. 2017, 27, 093001. [Google Scholar] [CrossRef]

- Yan, S.; Liu, Z.; Li, C.; Ge, S.; Xu, F.; Lu, Y. “Hot-wire” microfluidic flowmeter based on a microfiber coupler. Opt. Lett. 2016, 41, 5680. [Google Scholar] [CrossRef]

- Caldas, P.; Jorge, P.A.S.; Rego, G.; Frazão, O.; Santos, J.L.; Ferreira, L.A.; Araújo, F. Fiber optic hot-wire flowmeter based on a metallic coated hybrid long period grating/fiber Bragg grating structure. Appl. Opt. 2011, 50, 2738–2743. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, Q.F.; Zhang, C.L.; Wu, Y.; Rao, Y.J.; Peng, G.D. Microfluidic Flow Rate Detection with a Large Dynamic Range by Optical Manipulation. IEEE Photonics Technol. Lett. 2015, 27, 2508–2511. [Google Scholar] [CrossRef]

- Gong, Y.; Qiu, L.; Zhang, C.; Wu, Y.; Rao, Y.J.; Peng, G.D. Dual-Mode Fiber Optofluidic Flowmeter with a Large Dynamic Range. J. Light. Technol. 2017, 35, 2156–2160. [Google Scholar] [CrossRef]

- Kuswandi, B.; Huskens, J.; Verboom, W. Optical sensing systems for microfluidic devices: A review. Anal. Chim. Acta 2007, 601, 141–155. [Google Scholar] [CrossRef]

- Vanarase, A.U.; Alcalà, M.; Jerez Rozo, J.I.; Muzzio, F.J.; Romañach, R.J. Real-time monitoring of drug concentration in a continuous powder mixing process using NIR spectroscopy. Chem. Eng. Sci. 2010, 65, 5728–5733. [Google Scholar] [CrossRef]

- Abdallah, A.; Heinisch, M.; Jakoby, B. Measurement error estimation and quality factor improvement of an electrodynamic-acoustic resonator sensor for viscosity measurement. Sens. Actuators A Phys. 2013, 199, 318–324. [Google Scholar] [CrossRef]

- Hasan, S.W.; Ghannam, M.T.; Esmail, N. Heavy crude oil viscosity reduction and rheology for pipeline transportation. Fuel 2010, 89, 1095–1100. [Google Scholar] [CrossRef]

- Muñoz, J.A.D.; Ancheyta, J.; Castañeda, L.C. Required viscosity values to ensure proper transportation of crude oil by pipeline. Energy Fuels 2016, 30, 8850–8854. [Google Scholar] [CrossRef]

- Zhu, J.; Yoon, J.M.; He, D.; Bechhoefer, E. Online particle-contaminated lubrication oil condition monitoring and remaining useful life prediction for wind turbines. Wind Energy 2015, 18, 1131–1149. [Google Scholar] [CrossRef]

- Appleby, M.; Choy, F.K.; Du, L.; Zhe, J. Oil debris and viscosity monitoring using ultrasonic and capacitance/inductance measurements. Lubr. Sci. 2013, 25, 507–524. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring—A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Agoston, A.; Ötsch, C.; Jakoby, B. Viscosity sensors for engine oil condition monitoring—Application and interpretation of results. Sens. Actuators A Phys. 2005, 121, 327–332. [Google Scholar] [CrossRef]

- Zhang, Y.; He, M.G.; Xue, R.; Wang, X.F.; Zhong, Q.; Zhang, X.X. A new method for liquid viscosity measurements: Inclined-tube viscometry. Int. J. Thermophys. 2008, 29, 483–504. [Google Scholar] [CrossRef]

- Qin, L.; Chen, Q.; Cheng, H.; Chen, Q.; Li, J.F.; Wang, Q.M. Viscosity sensor using ZnO and AlN thin film bulk acoustic resonators with tilted polar c-axis orientations. J. Appl. Phys. 2011, 110, 094511. [Google Scholar] [CrossRef]

- Huebner, H.; Tauber, G.; Hofbauer, P.; Glatzer, R.; Beintze, G.; Wagner, D.; Riege, G. Capillary viscometer. U.S. Patent No. 4,685,328, 11 August 1987. [Google Scholar]

- Gassmann, H.U.; Mugnier, M. Capillary Viscometer. U.S. Patent No. 3,699,804, 24 October 1972. [Google Scholar]

- Stankovská, M.; Šoltés, L.; Vikartovská, A.; Mendichi, R.; Lath, D.; Molnárová, M.; Gemeiner, P. Study of hyaluronan degradation by means of rotational viscometry: Contribution of the material of viscometer. Chem. Pap. 2004, 58, 348–352. [Google Scholar]

- Casaretto, C.; Martínez Sarrasague, M.; Giuliano, S.; Rubin de Celis, E.; Gambarotta, M.; Carretero, I.; Miragaya, M. Evaluation of Lama glama semen viscosity with a cone-plate rotational viscometer. Andrologia 2012, 44, 335–341. [Google Scholar] [CrossRef] [PubMed]

- Davis, A.M.J.; Brenner, H. The falling-needle viscometer. Phys. Fluids 2001, 13, 3086–3088. [Google Scholar] [CrossRef]

- Mustafaev, M.R. The theory of falling-hollow-cylinder viscometer. High Temp. 2006, 44, 633–636. [Google Scholar] [CrossRef]

- Brizard, M.; Megharfi, M.; Mahé, E.; Verdier, C. Design of a high precision falling-ball viscometer. Rev. Sci. Instrum. 2005, 76, 025109. [Google Scholar] [CrossRef]

- Yabuno, H.; Higashino, K.; Kuroda, M.; Yamamoto, Y. Self-excited vibrational viscometer for high-viscosity sensing. J. Appl. Phys. 2014, 116, 124305. [Google Scholar] [CrossRef]

- Akpek, A.; Youn, C.; Maeda, A.; Fujisawa, N.; Kagawa, T. Effect of thermal convection on viscosity measurement in vibrational viscometer. J. Flow Control Meas. Vis. 2014, 02, 12–17. [Google Scholar] [CrossRef]

- Caetano, F.J.P.; Correia Da Mata, J.L.; Fareleira, J.M.N.A.; Oliveira, C.M.B.P.; Wakeham, W.A. Viscosity measurements of liquid toluene at low temperatures using a dual vibrating-wire technique. Int. J. Thermophys. 2004, 25, 1–11. [Google Scholar] [CrossRef]

- Svedin, N.; Stemme, E.; Stemme, G. A static turbine flow meter with a micromachined silicon torque sensor. J. Microelectromech. Syst. 2003, 12, 937–946. [Google Scholar] [CrossRef]

- Srivastava, N.; Davenport, R.D.; Burns, M.A. Nanoliter viscometer for analyzing blood plasma and other liquid samples. Anal. Chem. 2005, 77, 383–392. [Google Scholar] [CrossRef]

- Cullen, P.J.; Duffy, A.P.; O’Donnell, C.P. In-line consistency monitoring of tomato based products using vibrational process viscometry. J. Food Process. Preserv. 2001, 25, 337–351. [Google Scholar] [CrossRef]

- Kawatra, S.K.; Bakshi, A.K. On-line viscometry in particulate processing. Miner. Process. Extr. Metall. Rev. 1995, 14, 249–273. [Google Scholar] [CrossRef]

- Cullen, P.J.; Duffy, A.P.; O’Donnell, C.P.; O’Callaghan, D.J. Process viscometry for the food industry. Trends Food Sci. Technol. 2000, 11, 451–457. [Google Scholar] [CrossRef]

- O’Shea, N.; O’Callaghan, T.F.; Tobin, J.T. The application of process analytical technologies (PAT) to the dairy industry for real time product characterization—process viscometry. Innov. Food Sci. Emerg. Technol. 2019, 55, 48–56. [Google Scholar] [CrossRef]

- Wiklund, J.; Stading, M. Application of in-line ultrasound Doppler-based UVP-PD rheometry method to concentrated model and industrial suspensions. Flow Meas. Instrum. 2008, 19, 171–179. [Google Scholar] [CrossRef]

- Rahman, M.; Håkansson, U.; Wiklund, J. In-line rheological measurements of cement grouts: Effects of water/cement ratio and hydration. Tunn. Undergr. Sp. Technol. 2015, 45, 34–42. [Google Scholar] [CrossRef]

- Wiklund, J.; Shahram, I.; Stading, M. Methodology for in-line rheology by ultrasound Doppler velocity profiling and pressure difference techniques. Chem. Eng. Sci. 2007, 62, 4277–4293. [Google Scholar] [CrossRef]

- Mohammed, A. Suitability of viscosity measurement methods for liquid food variety and applicability in food industry-A review. J. Food Agric. Environ. 2010, 8, 100–107. [Google Scholar]

- Han, Z.; Tang, X.; Zheng, B. A PDMS viscometer for microliter Newtonian fluid. J. Micromech. Microeng. 2007, 17, 1828–1834. [Google Scholar] [CrossRef]

- Dewar, R.J.; Joyce, M.J. The quartz crystal microbalance as a microviscometer for improved rehabilitation therapy of dysphagic patients. In Proceedings of the 2005 IEEE Engineering in Medicine and Biology 27th Annual Conference, Shanghai, China, 17–18 January 2006; Volume 7, pp. 2511–2515. [Google Scholar]

- Sinn, I.; Albertson, T.; Kinnunen, P.; Breslauer, D.N.; McNaughton, B.H.; Burns, M.A.; Kopelman, R. Asynchronous magnetic bead rotation microviscometer for rapid, sensitive, and label-free studies of bacterial growth and drug sensitivity. Anal. Chem. 2012, 84, 5250–5256. [Google Scholar] [CrossRef]

- Yang, K.; Chu, G.; Shao, L.; Xiang, Y.; Zhang, L.; Chen, J. Micromixing efficiency of viscous media in micro-channel reactor. Chin. J. Chem. Eng. 2009, 17, 546–551. [Google Scholar] [CrossRef]

- Cakmak, O.; Elbuken, C.; Ermek, E.; Mostafazadeh, A.; Baris, I.; Erdem Alaca, B.; Kavakli, I.H.; Urey, H. Microcantilever based disposable viscosity sensor for serum and blood plasma measurements. Methods 2013, 63, 225–232. [Google Scholar] [CrossRef] [PubMed]

- Riesch, C.; Reichel, E.K.; Jachimowicz, A.; Schalko, J.; Hudek, P.; Jakoby, B.; Keplinger, F. A suspended plate viscosity sensor featuring in-plane vibration and piezoresistive readout. J. Micromech. Microeng. 2009, 19. [Google Scholar] [CrossRef]

- Cerimovic, S.; Beigelbeck, R.; Antlinger, H.; Schalko, J.; Jakoby, B.; Keplinger, F. Sensing viscosity and density of glycerol-water mixtures utilizing a suspended plate MEMS resonator. Microsyst. Technol. 2012, 18, 1045–1056. [Google Scholar] [CrossRef][Green Version]

- Heinisch, M.; Reichel, E.K.; Dufour, I.; Jakoby, B. Tunable resonators in the low kHz range for viscosity sensing. Sens. Actuators A Phys. 2012, 186, 111–117. [Google Scholar] [CrossRef]

- Kang, K.; Lee, L.J.; Koelling, K.W. High shear microfluidics and its application in rheological measurement. Exp. Fluids 2005, 38, 222–232. [Google Scholar] [CrossRef]

- Pipe, C.J.; McKinley, G.H. Microfluidic rheometry. Mech. Res. Commun. 2009, 36, 110–120. [Google Scholar] [CrossRef]

- Han, K.; Zhu, K.; Bahl, G. Opto-mechano-fluidic viscometer. Appl. Phys. Lett. 2014, 105, 014103. [Google Scholar] [CrossRef]

- Haidekker, M.A.; Theodorakis, E.A. Molecular rotors—Fluorescent biosensors for viscosity and flow. Org. Biomol. Chem. 2007, 5, 1669–1678. [Google Scholar] [CrossRef]

- Choi, S.; Moon, W.; Lim, G. A micro-machined viscosity-variation monitoring device using propagation of acoustic waves in microchannels. J. Micromech. Microeng. 2010, 20, 085034. [Google Scholar] [CrossRef]

- Choi, S.; Jang, H.; Lee, H.; Park, J.; Cha, Y.; Shin, D.; Lee, K. Design and fabriction of micro-viscometer using the propagation of acoustic waves in micro-channel. In Proceedings of the 2012 IEEE 25th International Conference on Micro Electro Mechanical Systems (MEMS), Paris, France, 29 January–2 February 2012; pp. 804–807. [Google Scholar]

- Chen, P.C.; Lal, A. Ultrasonic viscometer with integrated depth measurement. In Proceedings of the 2015 IEEE International Ultrasonics Symposium (IUS 2015), Taipei, Taiwan, 21–24 October 2015. [Google Scholar]

- Lu, J.; Thomas, J.R.; Plunkett, R.K.; Claesson, M.A.; Ernstsson, P.M.; Rutland, M.; Langmuir, M.; Hanley, L.; Kornienko, O.; Ada, E.T.; et al. In situ evaluation of density, viscosity, and thickness of adsorbed soft layers by combined surface acoustic wave and surface plasmon resonance. Phys. Chem. Biol. Interfaces 2000, 19, 4200. [Google Scholar] [CrossRef]

- Jiang, C.; Chen, Y.; Cho, C. A three-dimensional finite element analysis model for SH-SAW torque sensors. Sensors 2019, 19, 4290. [Google Scholar] [CrossRef] [PubMed]

- Morita, T.; Sugimoto, M.; Kondoh, J. Measurements of standard-viscosity liquids using shear horizontal surface acoustic wave sensors. Jpn. J. Appl. Phys. 2009, 48, 432–8561. [Google Scholar] [CrossRef][Green Version]

- Jakoby, B.; Beigelbeck, R.; Keplinger, F.; Lucklum, F.; Niedermayer, A.; Reichel, E.K.; Riesch, C.; Voglhuber-Brunnmaier, T.; Weiss, B. Miniaturized sensors for the viscosity and density of liquids—Performance and issues. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 111–120. [Google Scholar] [CrossRef] [PubMed]

- Jakoby, B.; Klinger, F.P.; Svasek, P. A novel microacoustic viscosity sensor providing integrated sample temperature control. Sens. Actuators A Phys. 2005, 123, 274–280. [Google Scholar] [CrossRef]

- Markova, L.V.; Myshkin, N.K.; Kong, H.; Han, H.G. On-line acoustic viscometry in oil condition monitoring. Tribol. Int. 2011, 44, 963–970. [Google Scholar] [CrossRef]

- Reichel, E.K.; Riesch, C.; Keplinger, F.; Kirschhock, C.E.A.; Jakoby, B. Analysis and experimental verification of a metallic suspended plate resonator for viscosity sensing. Sens. Actuators A Phys. 2010, 162, 418–424. [Google Scholar] [CrossRef]

- Lee, J.; Tripathi, A. Intrinsic viscosity of polymers and biopolymers measured by microchip. Anal. Chem. 2005, 77, 7137–7147. [Google Scholar] [CrossRef]

- Bird, R.B. Transport phenomena. Appl. Mech. Rev. 2002, 55, R1–R4. [Google Scholar] [CrossRef]

- Silber-Li, Z.H.; Tan, Y.P.; Weng, P.F. A microtube viscometer with a thermostat. Exp. Fluids 2004, 36, 586–592. [Google Scholar] [CrossRef]

- Ody, C.P. Capillary contributions to the dynamics of discrete slugs in microchannels. Microfluid. Nanofluid. 2010, 9, 397–410. [Google Scholar] [CrossRef]

- Digilov, R.M.; Reiner, M. Weight-controlled capillary viscometer. Am. J. Phys. 2005, 73, 1020. [Google Scholar] [CrossRef]

- Viscometer/Rheometer-On-a-Chip, VROC Technology. Available online: https://www.rheosense.com/technology (accessed on 19 May 2020).

- Solomon, D.E.; Abdel-Raziq, A.; Vanapalli, S.A. A stress-controlled microfluidic shear viscometer based on smartphone imaging. Rheol. Acta 2016, 55, 727–738. [Google Scholar] [CrossRef]

- Lee, S.C.; Heo, J.; Woo, H.C.; Lee, J.A.; Seo, Y.H.; Lee, C.L.; Kim, S.; Kwon, O.P. Fluorescent molecular rotors for viscosity sensors. Chem. A Eur. J. 2018, 24, 13706–13718. [Google Scholar] [CrossRef]

- Kang, D.; Gai, B.; Thompson, B.; Lee, S.M.; Malmstadt, N.; Yoon, J. Flexible opto-fluidic fluorescence sensors based on heterogeneously integrated micro-VCSELS and silicon photodiodes. ACS Photonics 2016, 3, 912–918. [Google Scholar] [CrossRef]

- Raut, S.; Kimball, J.; Fudala, R.; Doan, H.; Maliwal, B.; Sabnis, N.; Lacko, A.; Gryczynski, I.; Dzyuba, S.V.; Gryczynski, Z. A homodimeric BODIPY rotor as a fluorescent viscosity sensor for membrane-mimicking and cellular environments. Phys. Chem. Chem. Phys. 2014, 16, 27037–27042. [Google Scholar] [CrossRef]

- Degré, G.; Joseph, P.; Tabeling, P.; Lerouge, S.; Cloitre, M.; Ajdari, A. Rheology of complex fluids by particle image velocimetry in microchannels. Appl. Phys. Lett. 2006, 89, 024104. [Google Scholar] [CrossRef]

- Gupta, S.; Wang, W.S.; Vanapalli, S.A. Microfluidic viscometers for shear rheology of complex fluids and biofluids. Biomicrofluidics 2016, 10, 043402. [Google Scholar] [CrossRef]

- Bamshad, A.; Nikfarjam, A.; Sabour, M.H. Capillary-based micro-optofluidic. Meas. Sci. Technol. 2018, 29, 095901. [Google Scholar] [CrossRef]

- Borst, J.W.; Hink, M.A.; Van Hoek, A.; Visser, A.J.W.G. Effects of refractive index and viscosity on fluorescence and anisotropy decays of enhanced cyan and yellow fluorescent proteins. J. Fluoresc. 2005, 15, 153–160. [Google Scholar] [CrossRef]

- Hosny, N.A.; Mohamedi, G.; Rademeyer, P.; Owen, J.; Wu, Y.; Tang, M.X.; Eckersley, R.J.; Stride, E.; Kuimova, M.K. Mapping microbubble viscosity using fluorescence lifetime imaging of molecular rotors. Proc. Natl. Acad. Sci. USA 2013, 110, 9225–9230. [Google Scholar] [CrossRef] [PubMed]

- Cakmak, O.; Ermek, E.; Urey, H.; Yaralioglu, G.G.; Kilinc, N. MEMS based blood plasma viscosity sensor without electrical connections. In Proceedings of the IEEE Sensors, Baltimore, MD, USA, 3–6 November 2013. [Google Scholar]

| Differential Pressure | Turbine | Electromagnetic | Ultrasonic | Vortex | Coriolis | |

|---|---|---|---|---|---|---|

| Real-Time | Yes | Yes | Yes | Yes | Yes | Yes |

| Pressure Drop | High | High | No | No | High | High |

| Size | Large | Bulky | Large | Large | Bulky | Bulky |

| Flexible Electronics | Potential | N/A | Reported | Reported | No | N/A |

| Invasive | Yes | Yes | No | No | Yes | Yes |

| Pressure Difference | Optical | Thermal | MEMS | |

|---|---|---|---|---|

| Real-Time Measurements | Yes | Yes | Yes | Yes |

| Tubular Application Potential | Yes | No | Yes | Yes |

| Flexible Electronics Potential | Yes | No | Yes | No |

| Power Consumption | Low | High | High | High |

| Capillary | Falling Objects | Rotational | Vibrational | |

|---|---|---|---|---|

| Sample Size | L-ml | L-ml | L-ml | ml-μL |

| Accuracy | Very high | High | High | High |

| Real-Time Potential | Yes | No | Yes | Yes |

| Flexible Electronics | Yes | No | No | Yes |

| Rotational | Vibrational | Tube Velocity | |

|---|---|---|---|

| Real-Time | Yes | Yes | Yes |

| Pressure Drop | Yes | Yes | No |

| Size | Bulky | Large | Small |

| Invasive Installation | Yes | Yes | No |

| Accuracy | High | High | Low |

| Flexible Electronics Potential | No | Yes | Yes |

| Flow Type | All | All | Laminar |

| MEMS | TSM | SAW | Optical | Capillary | |

|---|---|---|---|---|---|

| Real-Time | Yes | Yes | Near | Yes | Yes |

| Potential for Tubular Application | No | Yes | No | No | Yes |

| Flexible Electronics | No | Yes | Yes | No | Yes |

| Power Consumption | High | Low | Low | High | Low |

| Electronics Complexity | Simple | Complex | Complex | Very complex | Very simple |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

A. Nour, M.; M. Hussain, M. A Review of the Real-Time Monitoring of Fluid-Properties in Tubular Architectures for Industrial Applications. Sensors 2020, 20, 3907. https://doi.org/10.3390/s20143907

A. Nour M, M. Hussain M. A Review of the Real-Time Monitoring of Fluid-Properties in Tubular Architectures for Industrial Applications. Sensors. 2020; 20(14):3907. https://doi.org/10.3390/s20143907

Chicago/Turabian StyleA. Nour, Maha, and Muhammad M. Hussain. 2020. "A Review of the Real-Time Monitoring of Fluid-Properties in Tubular Architectures for Industrial Applications" Sensors 20, no. 14: 3907. https://doi.org/10.3390/s20143907

APA StyleA. Nour, M., & M. Hussain, M. (2020). A Review of the Real-Time Monitoring of Fluid-Properties in Tubular Architectures for Industrial Applications. Sensors, 20(14), 3907. https://doi.org/10.3390/s20143907