In-Situ Measurement of Fresh Produce Respiration Using a Modular Sensor-Based System

Abstract

1. Introduction

2. Materials and Methods

2.1. Plant Materials and Controlled Atmosphere (CA) Facility

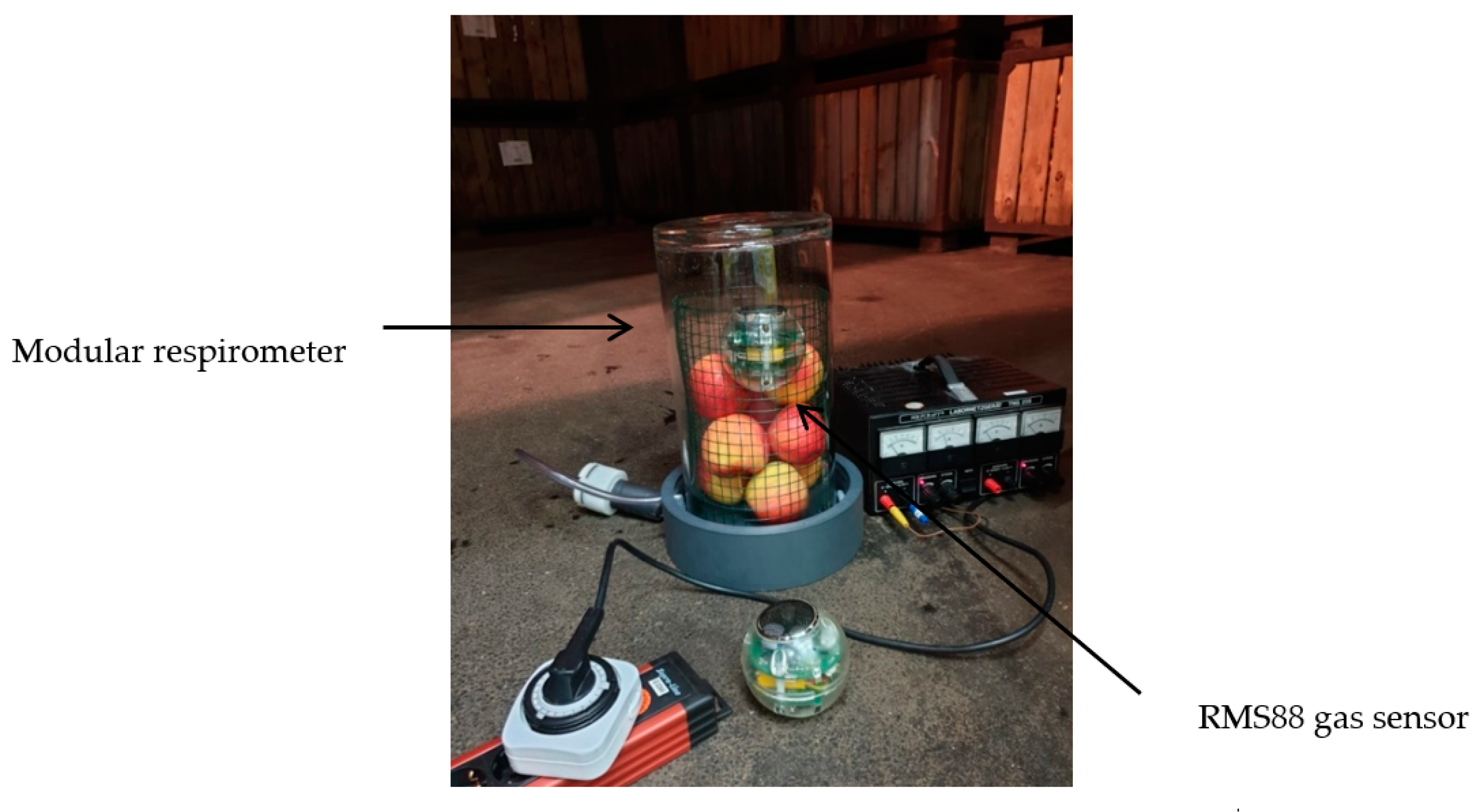

2.2. Construction of Respiration Measuring Gas Sensor

2.3. Modular Respirometer

2.4. Calculation of Respiration Rate

3. Results

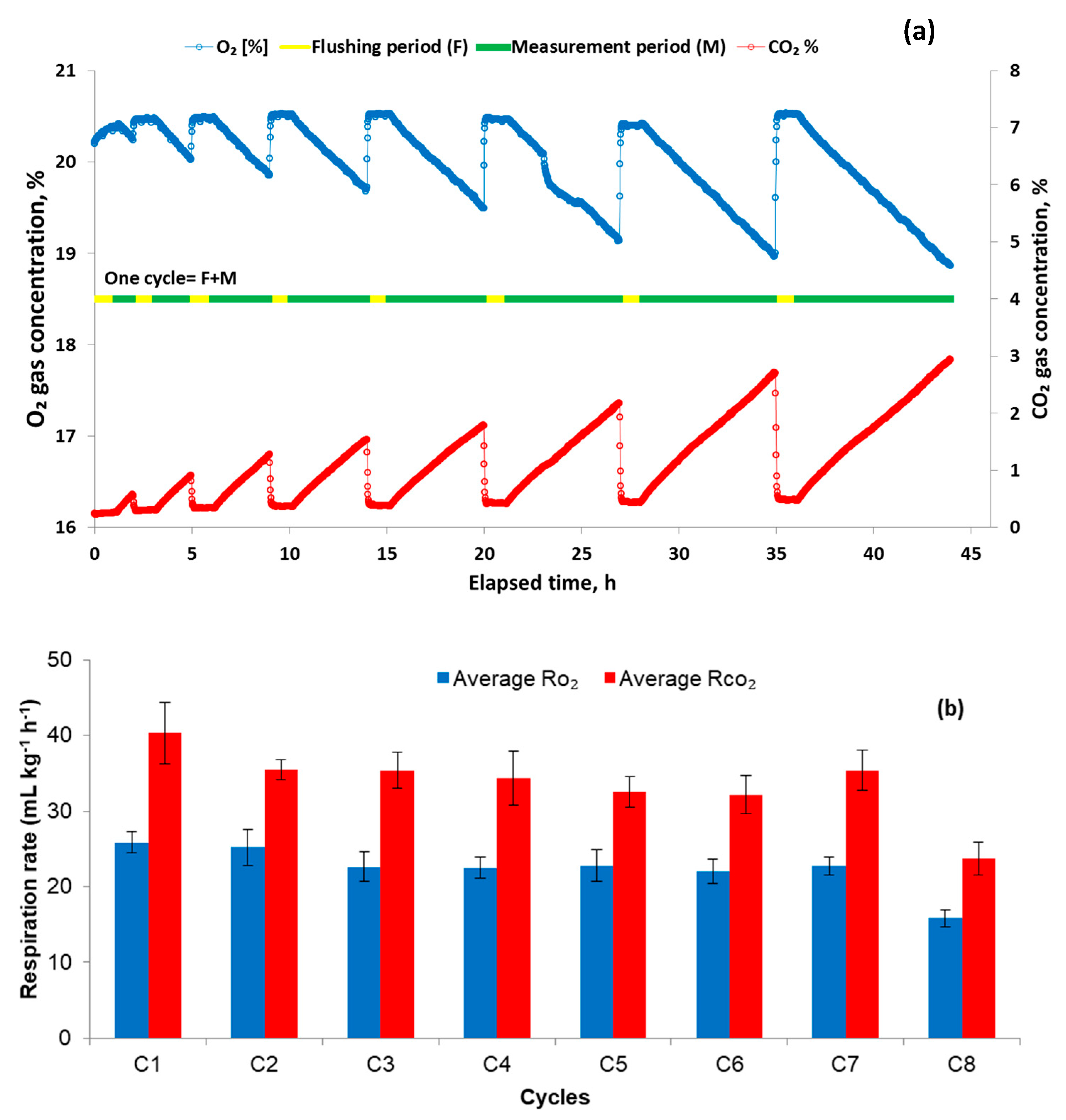

3.1. Respiration Measured over Varying Respiration Measurement Periods (Experiment I)

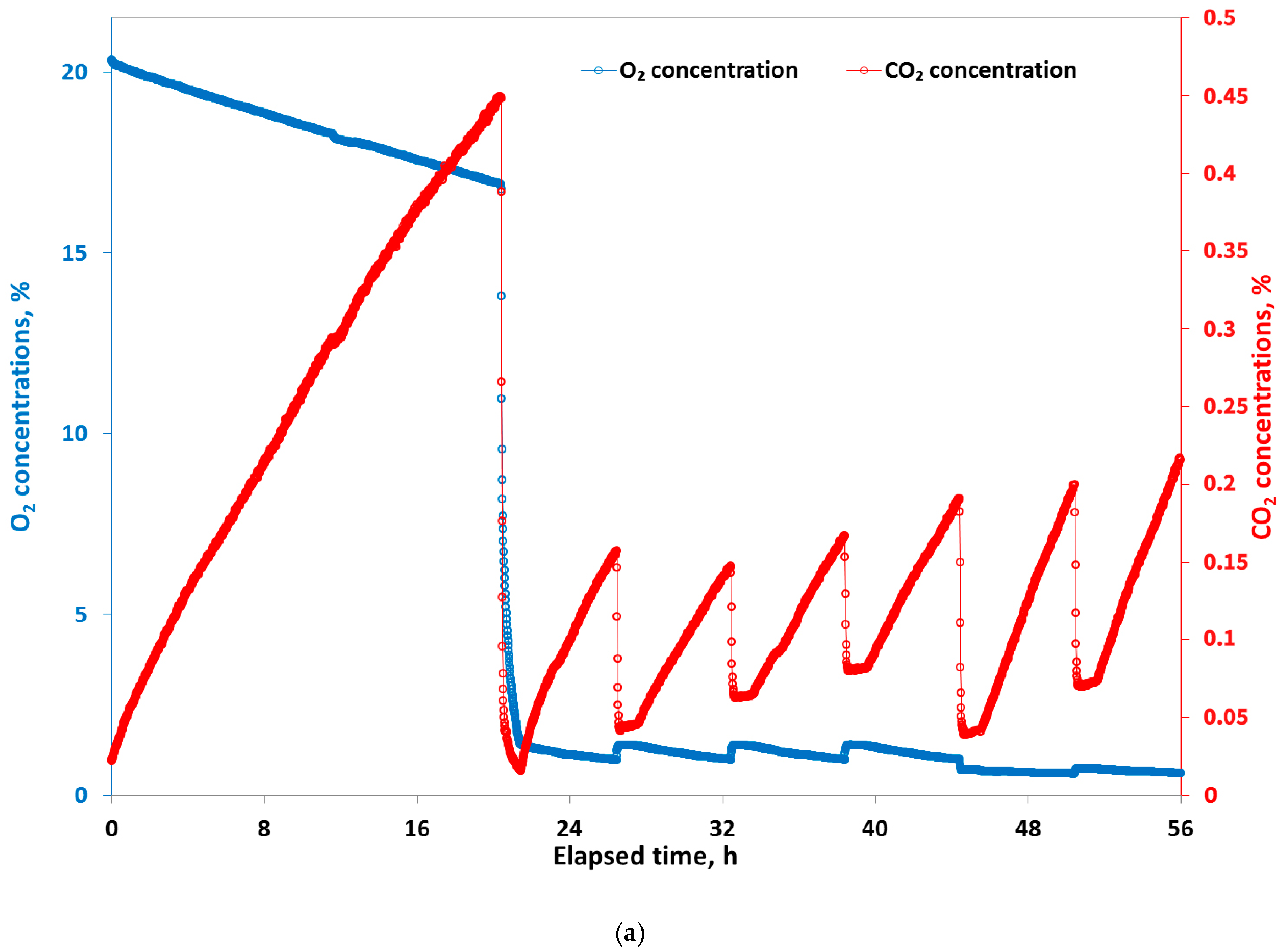

3.2. Respiration Measured under Controlled Atmosphere (Experiment II)

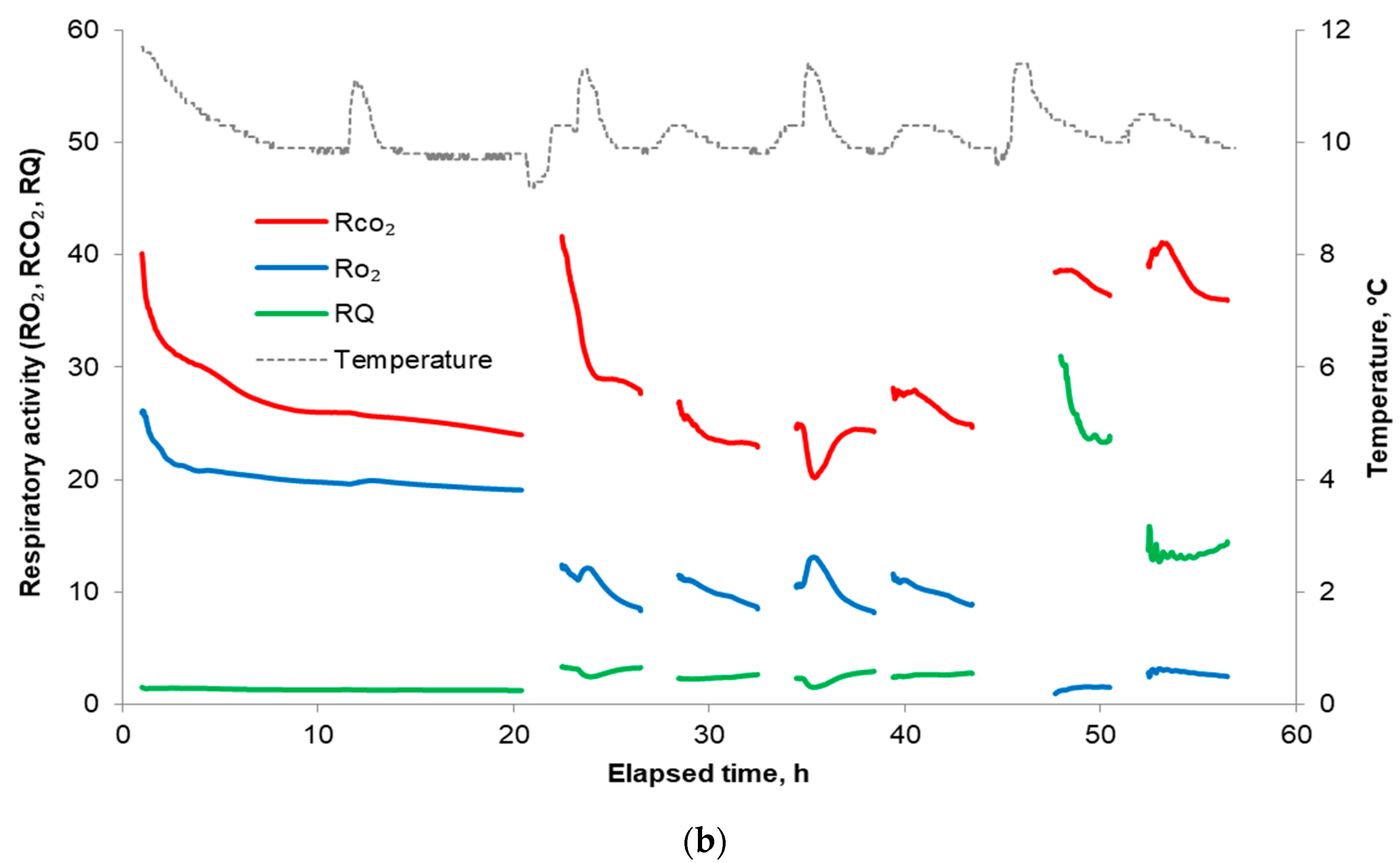

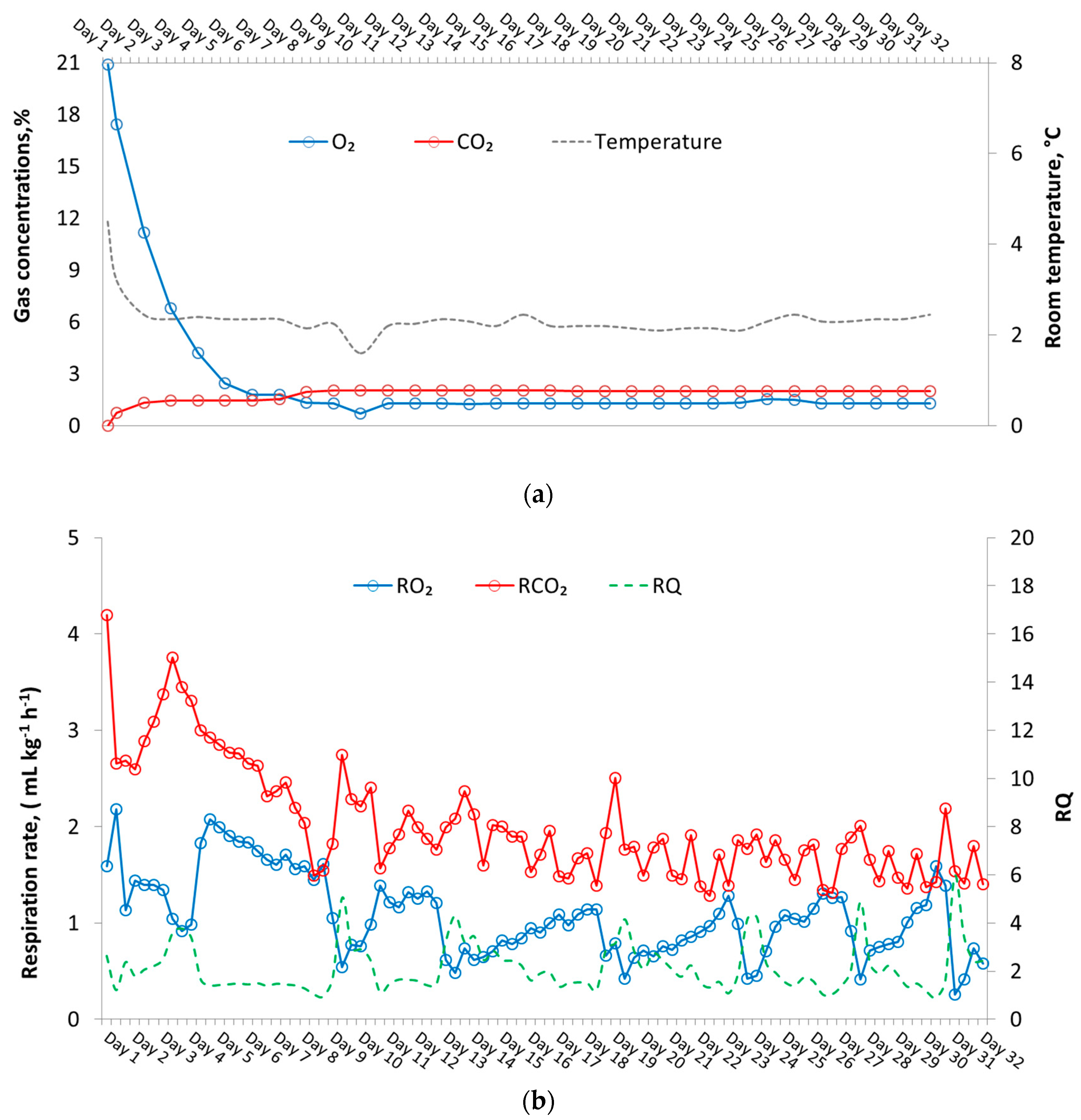

3.3. Respiration Measured in Commercial Apple CA Storage (Experiment III)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alves, J.A.; Júnior, R.A.B.; Boas, E.V.B.V. Identification of respiration rate and water activity change in fresh-cut carrots using biospeckle laser and frequency approach. Postharvest Biol. Technol. 2013, 86, 381–386. [Google Scholar] [CrossRef]

- Iqbal, T.; Rodrigues, F.A.; Mahajan, P.V.; Kerry, J.P. Mathematical modeling of the influence of temperature and gas composition on the respiration rate of shredded carrots. J. Food Eng. 2009, 91, 325–332. [Google Scholar] [CrossRef]

- Mahajan, P.V.; Luca, A.; Edelenbos, M. Development of a small and flexible sensor-based respirometer for real-time determination of respiration rate, respiratory quotient and low O2 limit of fresh produce. Comput. Electron. Agric. 2016, 121, 347–353. [Google Scholar] [CrossRef]

- Keshri, N.; Weltzien, C.; Mahajan, P.V. Sensors for Measurement of Respiratory Gases in Fresh Produce Packaging and Storage. Ref. Module Food Sci. 2019. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, Z.; Li, L.; Wang, Y.; Zhao, H.; Hu, M.; Li, M.; Zhang, Z. Effect of controlled atmospheres with varying O2/CO2 levels on the postharvest senescence and quality of broccoli (Brassica oleracea L. var. italica) florets. Eur. Food Res. Technol. 2013, 237, 943–950. [Google Scholar] [CrossRef]

- Keshri, N.; Truppel, I.; Herppich, W.B.; Geyer, M.; Weltzien, C.; Mahajan, P.V. Development of sensor system for real-time measurement of respiration rate of fresh produce. Comput. Electron. Agric. 2019, 157, 322–328. [Google Scholar] [CrossRef]

- Bessemans, N.; Verboven, P.; Verlinden, B.; Nicolaï, B. A novel type of dynamic controlled atmosphere storage based on the respiratory quotient (RQ-DCA). Postharvest Biol. Technol. 2016, 115, 91–102. [Google Scholar] [CrossRef]

- Borchert, N.B.; Cruz-Romero, M.C.; Mahajan, P.V.; Ren, M.; Papkovsky, D.B.; Kerry, J.P. Application of gas sensing technologies for non-destructive monitoring of headspace gases (O2 and CO2) during chilled storage of packaged mushrooms (Agaricus bisporus) and their correlation with product quality parameters. Food Packag. Shelf Life 2014, 2, 17–29. [Google Scholar] [CrossRef]

- Jo, Y.H.; Kim, N.Y.; An, D.S.; Lee, H.J.; Lee, D.S. Modified atmosphere container equipped with gas diffusion tube automatically controlled in response to real-time gas concentration. Biosyst. Eng. 2013, 115, 250–259. [Google Scholar] [CrossRef]

- Løkke, M.M.; Seefeldt, H.F.; Edwards, G.; Green, O. Novel wireless sensor system for monitoring oxygen, temperature and respiration rate of horticultural crops post harvest. Sensors 2011, 11, 8456–8468. [Google Scholar] [CrossRef] [PubMed]

- Veltman, R.H. Method and Apparatus for Controlling the Atmosphere in a Space Filled with Agricultural or Horticultural Products. WO2013125944A1, 24 February 2012. Available online: https://patents.google.com/patent/WO2013125944A1/en (accessed on 1 April 2020).

- Ortiz, J.; Terry, L.; Collings, E.; García Cas, J. A New Real-Time Automated Method for Measuring in Situ Respiration Rates of Fresh Produce. In Proceedings of the VII International Postharvest Symposium 1012, Kuala Lumpur, Malaysia, 25–29 June 2012; pp. 1151–1157. [Google Scholar]

- Bessemans, N.; Verboven, P.; Verlinden, B.; Nicolai, B. Model based leak correction of real-time RQ measurement for dynamic controlled atmosphere storage. Postharvest Biol. Technol. 2018, 136, 31–41. [Google Scholar] [CrossRef]

- Brackmann, A. Control Apparatus for Controlled Atmosphere Cells for Storing Perishable Items. EP2918179A1, 3 December 2014. Available online: https://patents.google.com/patent/EP2918179A1/en (accessed on 1 April 2020).

- Delele, M.A.; Nicolai, B.; Verboven, P.; Verlinden, B. Storage of Respiratory Produce. EP2547213B1, 17 March 2010. Available online: https://patents.google.com/patent/EP2547213B1 (accessed on 1 April 2020).

- Schaefer, J.C.; Bishop, D.J. Dynamic Control System and Method for Controlled Atmosphere Room. U.S. Patent 20120097050A1, 26 October 2010. Available online: https://patents.google.com/patent/US20120097050A1/en (accessed on 1 April 2020).

- Weber, A.; Brackmann, A.; Both, V.; Pavanello, E.P.; Anese, R.O.; Thewes, F.R. Respiratory quotient: Innovative method for monitoring ‘Royal Gala’apple storage in a dynamic controlled atmosphere. Sci. Agric. 2015, 72, 28–33. [Google Scholar] [CrossRef]

- Falagán, N.; Terry, L.A. Recent Advances in Controlled and Modified Atmosphere of Fresh Produce. Johns. Matthey Technol. Rev. 2018, 62, 107–117. [Google Scholar] [CrossRef]

- Van Schaik, A.C.R.; Geijn, F.; Verschoor, J.; Veltman, R. A new interactive storage concept: Dynamic control of respiration. Acta Hortic. 2015, 1071, 245–251. [Google Scholar] [CrossRef]

- Weber, A.; Thewes, F.R.; de Oliveira Anese, R.; Both, V.; Pavanello, E.P.; Brackmann, A. Dynamic controlled atmosphere (DCA): Interaction between DCA methods and 1-methylcyclopropene on ‘Fuji Suprema’apple quality. Food Chem. 2017, 235, 136–144. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations. Prevention of Post-Harvest Food Losses: Fruits, Vegetables and Root Crops: A Training Manual; FAO: Rome, Italy, 1989. [Google Scholar]

- Fonseca, S.C.; Oliveira, F.A.; Brecht, J.K. Modelling respiration rate of fresh fruits and vegetables for modified atmosphere packages: A review. J. Food Eng. 2002, 52, 99–119. [Google Scholar] [CrossRef]

- Kader, A.A.; Saltveit, M.E. Respiration and gas exchange. Postharvest Physiol. Pathol. Veg. 2003, 2, 7–29. [Google Scholar]

- Hernandez-Munoz, P.; Almenar, E.; Del Valle, V.; Velez, D.; Gavara, R. Effect of chitosan coating combined with postharvest calcium treatment on strawberry (Fragaria× ananassa) quality during refrigerated storage. Food Chem. 2008, 110, 428–435. [Google Scholar] [CrossRef] [PubMed]

- Mitcham, E.; Crisosto, C.; Kader, A. Produce facts. Strawberry. Recommendations for maintaining postharvest quality. Perish. Handl. Newsl. 1996, 87, 21–22. [Google Scholar]

- Woodward, J.; Topping, A. The influence of controlled atmospheres on the respiration rates and storage behaviour of strawberry fruits. J. Hortic. Sci. 1972, 47, 547–553. [Google Scholar] [CrossRef]

- Mitcham, E.; Crisosto, C.; Kader, A. Apple, Red Delicious: Recommendations for Maintaining Postharvest Quality. 1999. Available online: http://postharvest.ucdavis.edu/Commodity_Resources/Fact_Sheets/Datastores/Fruit_English/?uid=5&ds=798 (accessed on 27 March 2020).

- Gasser, F.; Eppler, T.; Naunheim, W.; Gabioud, S.; Hoehn, E. Control of the Critical Oxygen Level During Dynamic CA Storage of Apples by Monitoring Respiration as well as Chlorophyll Fluorescence. In Proceedings of the International Conference on Ripening Regulation and Postharvest Fruit Quality 796, Weingarten, Germany, 11–13 November 2007; pp. 69–76. [Google Scholar]

| Experiment | Produce | Sample Mass (g) | Temperature (°C) | Gas Composition | Flushing Cycles | Storage Duration | |

|---|---|---|---|---|---|---|---|

| Measurement Period (h) | Number of Cycles/Day | ||||||

| I | Strawberries | 280 | 10 | Air | Varying | Varying | 44 h |

| II | Strawberries | 260 | 10 | Air, then 1% O2 | 5 | 4 | 56 h |

| III | Pinova apples | 1436 | 2 | 2% O2 + 1.3% CO2, N2-balanced | 7 | 3 | 32 d |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keshri, N.; Truppel, I.; Herppich, W.B.; Geyer, M.; Weltzien, C.; Mahajan, P.V. In-Situ Measurement of Fresh Produce Respiration Using a Modular Sensor-Based System. Sensors 2020, 20, 3589. https://doi.org/10.3390/s20123589

Keshri N, Truppel I, Herppich WB, Geyer M, Weltzien C, Mahajan PV. In-Situ Measurement of Fresh Produce Respiration Using a Modular Sensor-Based System. Sensors. 2020; 20(12):3589. https://doi.org/10.3390/s20123589

Chicago/Turabian StyleKeshri, Nandita, Ingo Truppel, Werner B. Herppich, Martin Geyer, Cornelia Weltzien, and Pramod V. Mahajan. 2020. "In-Situ Measurement of Fresh Produce Respiration Using a Modular Sensor-Based System" Sensors 20, no. 12: 3589. https://doi.org/10.3390/s20123589

APA StyleKeshri, N., Truppel, I., Herppich, W. B., Geyer, M., Weltzien, C., & Mahajan, P. V. (2020). In-Situ Measurement of Fresh Produce Respiration Using a Modular Sensor-Based System. Sensors, 20(12), 3589. https://doi.org/10.3390/s20123589