1. Introduction

Recently, wind energy as an inexhaustible and fast-growing clean renewable energy source has received considerable attention. As critical equipment for wind power generation, wind turbines have been widely distributed around the world. In practice, these turbines are usually situated in far-flung regions and always suffer from harsh operating environments, which can easily cause various failures and even shutdowns in severe cases [

1]. Specifically, sensors, such as pitch angle, power, and speed sensors, which are widely equipped in wind turbines for monitoring and controlling the operation of the entire turbine, are extremely prone to various faults. Statistically, sensor failures account for approximately 15% of the total wind turbine failures [

2]. Furthermore, sensor failures can cause signal corruption for condition monitoring and fault diagnosis, which in turn affect the health status of other key subassemblies, thereby reducing the reliability of the turbine and increasing economic losses [

3,

4]. As a result, it is particularly important and challenging to research effective and valuable fault detection approaches for wind turbine sensors.

Up to now, numerous fault detection techniques for wind turbine sensors have been proposed and discussed. On the one hand, physical-model based approaches have been proved to be effective and commonly adopted, typically including constrained Kalman filter [

5], Takagi–Sugeno fuzzy model [

6], and observed-based approaches [

7,

8]. Nevertheless, in practical engineering, it is unrealistic to establish a detailed mathematical model due to the complex electromechanical system construction and highly dynamic operating condition of wind turbines, which limits the further development and application of physical-model based methods, to a large extent. On the other hand, with the advent of advanced sensor technology, instead of requiring physical knowledge or accurate mathematical models, data-driven methods relying only on measured data have become quite attractive in fault detection of wind turbine sensors.

Practically, modern large-scale wind turbines have deployed supervisory control and data acquisition (SCADA) systems to acquire and record a vast amount of rich operational status data [

9]. Consequently, due to the availability and economy of SCADA data, sensor fault detection based on SCADA data has been considered as a feasible and valuable method, and, until now, numerous analysis approaches have been extensively studied in the literature. These methods mainly include artificial neural networks (ANN) [

10,

11], power curve-based method [

12,

13], support vector machine [

14,

15,

16], and classifier fusion-based method [

17]. However, these traditional methods cannot fully capture the complicated non-linear mapping between sensor variables due to their typical shallow structure, and, accordingly, can only achieve limited detection performance [

18]. In addition, these studies did not mine the sensor data from the perspective of the multivariate time series, nor was the co-relationship between multivariate was well considered.

Alternatively, as a novel type of machine learning, deep learning has attracted extensive attention from academic and industry community, which aims to extract abstract and valuable information from data via stacking multiple non-linear processing layers in hierarchical architectures, and therefore, is more powerful than those traditional intelligent methods [

19]. In recent years, this emerging method has been extensively used in a variety of challenging regression and classification tasks, such as speech recognition [

20], affect recognition [

21,

22], image classification [

23], and wind speed prediction [

24]. Moreover, deep learning-based wind turbine fault detection and diagnosis has witnessed an emerging research [

25,

26]. In particular, convolutional deep belief network (CDBN), a powerful hierarchical generative method, was proposed by Lee [

27], which has the unique advantages of the weight sharing and nonlinear feature learning and has been successfully introduced into the vibration-based fault diagnosis of bearings [

28,

29].

However, there are some challenges in applying conventional CDBN to detect wind turbine faults based on SCADA data. Specifically, sensor measurements from wind turbine SCADA systems are multivariate and closely related because of the mutual coupling and interaction between various components in a wind turbine [

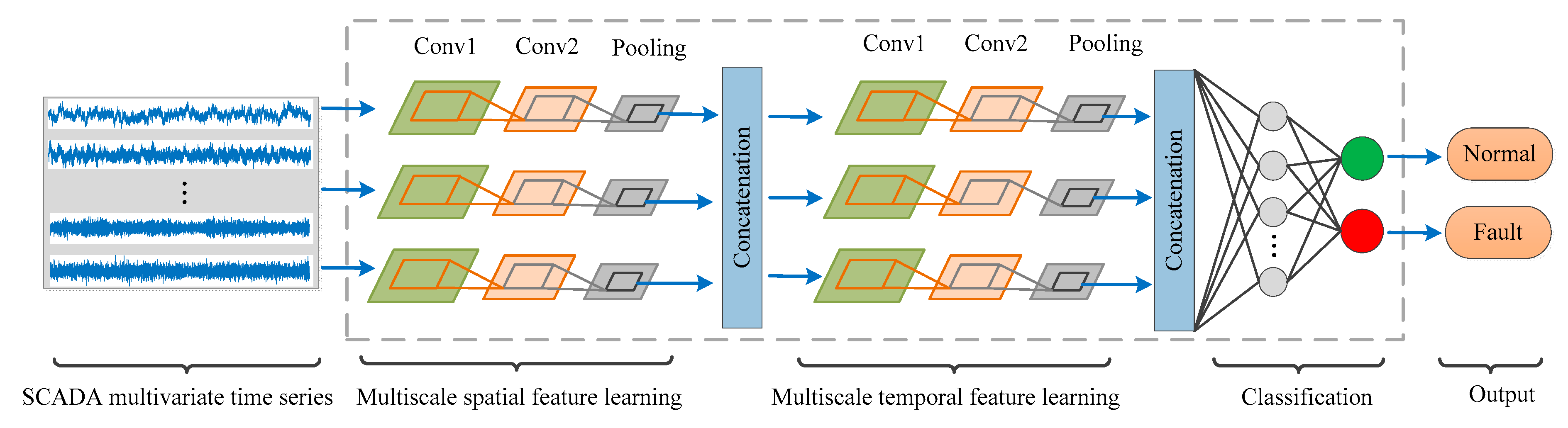

30]. Moreover, these sensor variables are time series in nature, incorporating the temporal and spatial correlation information simultaneously. This paper proposes a novel classification-based fault detection method for wind turbine sensors. In particular, a multiscale spatio-temporal CDBN (MSTCDBN) is developed to extract the interactions and inherent spatio-temporal characteristics of the SCADA multivariate time series. The proposed method can improve the feature learning capability and, thus, enhance fault detection performance. The main contributions of this paper are summarized as follows.

A novel MSTCDBN method is proposed to overcome the limitations of traditional CDBN that lack the ability to capture the spatio-temporal correlations inherent in multivariate time series and cannot realize multiscale feature learning. In other words, the proposed MSTCDBN has the superiorities of spatio-temporal dependence extraction and multiscale feature characterization, simultaneously. At the same time, as far as we know, this is the first time CDBN has been applied to the analysis and processing of multivariate time series.

Specifically, the spatio-temporal dependences hidden in the multivariate time series are considered by designing different forms of convolution kernels in a cascade way. Furthermore, the interactive and complementary representations between sensor variables are extracted at multiple different scales of filters in a parallel fashion. The proposed MSTCDBN with the multiscale spatio-temporal feature learning ability enables us to enhance the classification performance greatly.

A generic wind turbine benchmark model is utilized to evaluate the effectiveness of the proposed method in the fault detection of wind turbine sensors, and comparative studies are performed.

The reminder of this paper is organized as follows.

Section 2 briefly describes the theory of standard CDBN and introduces the proposed MSTCDBN approach for fault detection of wind turbine sensors in detail. A systematic description of the experiment and the acquisition and preprocessing of multivariate time series signals are proposed in

Section 3.

Section 4 gives the comparative detection results to evaluate the effectiveness of the proposed method. Conclusions are provided in

Section 5.

4. Results

In this section, in order to verify the effectiveness of the proposed approach and overcome the influence of randomness in the model training process on the detection results, ten trials were conducted for evaluating the overall performance. Meanwhile, the advantage of the proposed MSTCDBN fault detection method was proved by comparing with traditional CDBN and its other variants. Here, four commonly adopted evaluation metrics, classification accuracy, precision, recall, and F1 score were used for performance evaluation and comparison, which can be defined as follows

where TP refers to the number of correctly classified as positive samples, TN is the number of correctly classified as negative samples, FP is the number of misclassified as positive samples, and FN is the number of misclassified as negative samples, respectively.

As described in

Section 2, in order to extract interactive spatio-temporal features for sensor fault detection, six different forms of CDBN were designed in the proposed MSTCDBN method. Each CDBN module consists of two hidden layers and a pooling layer, and the number of filter groups for two hidden layers were set to 9 and 16, respectively. The detailed structures are listed in

Table 4. In addition, in the process of model training, the batch sizes of each CDBN were 100 and 10, and the stride length was selected as 1 by 1. In the final classification phase, the output size of the MSTCDBN was two, which corresponds to the normal and fault conditions of the sensor, respectively.

In addition, herein, several structures of CDBN from different perspectives were investigated to deeply explore the capability of the presented method in the wind turbine sensor fault detection, including standard CDBN, single-scale temporal CDBN (STCDBN), single-scale spatial CDBN (SSCDBN), single-scale spatio-temporal CDBN (SSTCDBN), multiscale temporal CDBN (MTCDBN), and multiscale spatial CDBN (MSCDBN). Specifically, the first three methods all contain one CDBN module and only consider the correlations on a single scale. For the standard CDBN, conventional square filters are adopted. The filters of STCDBN and SSCDBN are specified to slide only along the time and spatial axes, respectively. In terms of the SSTCDBN, it contains two cascaded CDBN modules, taking into account the correlations in both temporal and spatial dimensions on a single scale. For the latter two methods, MTCDBN and MSCDBN consist of three parallel CDBN modules, extracting temporal and spatial information on multiple scales, respectively. In these experiments, the same input, two-layer structures CDBN and softmax classifier as the proposed method was used, and the stride length and batch sizes were also set to 1 by 1 and 100 and 10, respectively. The detailed structures are shown in

Table 5. Moreover, all models with the running environment Intel Core (TM) i5-4300 CPU and 8-GB RAM using the Matlab software. The average testing performance (mean

standard deviation) of all methods over ten trials are given in

Figure 4 and the average testing time is shown in

Table 6.

It can be easily seen from

Figure 4 that the first six methods yield similar detection performance. However, compared with standard CDBN with conventional square filter, STCDBN and SSCDBN have better performance, which shows the ability of temporal and spatial information extraction. Moreover, in terms of the mean value, it can be seen that MTCDBN is superior to STCDBN in all evaluation metrics. Although MSCDBN is slightly inferior to SSCDBN, the proposed method obviously outperforms these two methods and other structures of CDBN. This is mainly because MSTCDBN with different scales of filters can extract and learn the interactive spatio-temporal correlation information that is beneficial for classification. Specifically, better and more stable improvements from other variants of CDBN to MSTCDBN can be observed for accuracy, precision, and F1-score. Overall, the method presented in this paper results in an enhanced fault detection performance. Likewise, it is not difficult to find from

Table 6 that although the structure of the proposed method is relatively complex, it costs less computing time than the MTCDBN and MSCDBN due to the introduction of pooling operation and need for the fewer number of filter groups.

From another perspective, in order to better understand the classification performance of different approaches, the testing classification results over ten trials using the confusion matrix are given in

Figure 5. The 0 and 1 represent normal and fault conditions, respectively. It can be observed that the confusion matrix comprehensively describes the number of correctly classified samples and misclassified samples for normal and fault conditions, the percentage of each condition that is correctly classified and incorrectly classified, and the percentage of correctly classified and misclassified in each predicted label. Obviously, compared with other methods, fewer total samples are misclassified when employing proposed MSTCDBN method, resulting in better detection performance.

According to

Section 3, six health conditions of sensors are mainly focused on this paper, including the normal condition and five different patterns of faults. Therefore, it is necessary to quantitatively evaluate the detection performance of an individual condition based on the overall detection results. The comparative results with average classification accuracy are given in

Table 7.

As can be observed from

Table 7 that in terms of normal condition, fault types three and four, all methods achieved relatively good performance, with the classification accuracy of above 98%, 93%, and 92%, respectively. Moreover, the proposed method and SSTCDBN outperform the other models in classifying fault type one. As far as fault type five was concerned, the recognition accuracy of MSCDBN was only 62.8%, which is significantly lower than other methods. It is worth mentioning that as for fault type two, the approach presented in this paper achieved the highest classification accuracy of 83.6%. However, with respect to other variants of CDBN, the best result was only 60.4%, which clearly shows the advantage of the proposed method in fault identification. Moreover, it also indirectly indicates that fault type two is probably the most difficult of the six health conditions to detect. In a word, the method incorporating multiscale and spatio-temporal feature learning capability presented in this paper plays an important role in sensor fault detection and finally obtains the highest overall accuracy.

In order to further demonstrate the ability of the proposed method in fault detection of wind turbine sensors, a comparison with traditional ANN and deep belief network (DBN) is carried out. For these two networks, the four-layer structures consisting of an input layer, two hidden layers, and an output layer are used for classification. It should be noted that different from the CDBN model, DBN, and ANN deal with data on the one-dimensional input structure.

Table 8 shows the average comparison results between the proposed MSTCDBN and the two methods in terms of four evaluation metrics over ten trails.

It can be easily found from

Table 8 that the accuracy, precision, recall, and F1-score generated by the proposed MSTCDBN method was higher than the ANN and DBN models. It means that the proposed method achieves the best overall performance compared to the other two methods, indicating the superiority of the proposed method in fault detection. Furthermore, it can also be seen that the DBN performs better than the ANN. This is mainly because compared with the ANN model, DBN has powerful unsupervised feature learning ability, which can handle complex relationships between variables, thus resulting in relatively better performance. However, this model ignores the two-dimensional structure of the input, making it difficult to extract the spatio-temporal correlations hidden in the multivariate time series. In contrast, the proposed MSTCDBN method takes into account spatio-temporal features at different filter scales, which contributions to the enhancement of the fault detection performance.

In summary, since the sensor measurements generated by the benchmark model can truly reflect the wind turbine SCADA data, the proposed MSTCDBN method has the potential to be an alternative method for sensor fault detection in real wind farms. Meanwhile, in practice, it is reasonable to train an independent model for each turbine due to the different operating conditions and environments of each turbine. Likewise, the condition labels which are helpful for fault detection should be carefully labeled so that the proposed method is widespread adopted.

5. Conclusions

In this paper, a novel MSTCDBN approach is presented to address the challenging task of fault detection of wind turbine sensors by considering the temporal and spatial correlations hidden in the multivariate time series. Firstly, a major feature of the presented approach is that different forms of convolution kernels are designed to extract the spatio-temporal characteristics between sensor variables in a cascade way. Secondly, another contribution is to learn interactive and rich fault features by incorporating different scales of filters in a parallel manner. Accordingly, the proposed method can enhance the feature learning capacity and fault detection performance. Furthermore, the effectiveness of the MSTCDBN model was investigated by comparing with traditional CDBN and its other variants, as well as ANN and DBN methods. In particular, the developed method combing spatio-temporal feature extraction and multiscale learning is better than other models in terms of classification performance, which provides a new insight for detecting wind turbine sensor faults and can be extended to other research applications.

However, due to the limited SCADA data, this study is only validated on a generic benchmark model. In future work, the developed MSTCDBN will further be spread to real wind turbine sensors, and other critical components in wind turbines will be discussed. From the perspective of pattern recognition, a fault diagnosis system can quickly identify and locate fault categories when abnormalities occur in the wind turbine. Therefore, the proposed method will be further used for the sensor fault diagnosis to identify the specific fault type of the sensor. Based on the sensor fault detection and diagnosis, it is necessary to adopt corresponding fault-tolerant control strategies to ensure that the turbine is in normal operation, thereby improving the safety and reliability of the turbine. Meanwhile, more advanced feature extraction and learning approaches will be established to further mine the spatio-temporal correlations in SCADA multivariate time series. In this paper, the data-driven method is used to realize the fault detection, and the combination of data-driven and model-based methods is expected to become a new research direction [

41].