Object-Based Thermal Image Segmentation for Fault Diagnosis of Reciprocating Compressors

Abstract

1. Introduction

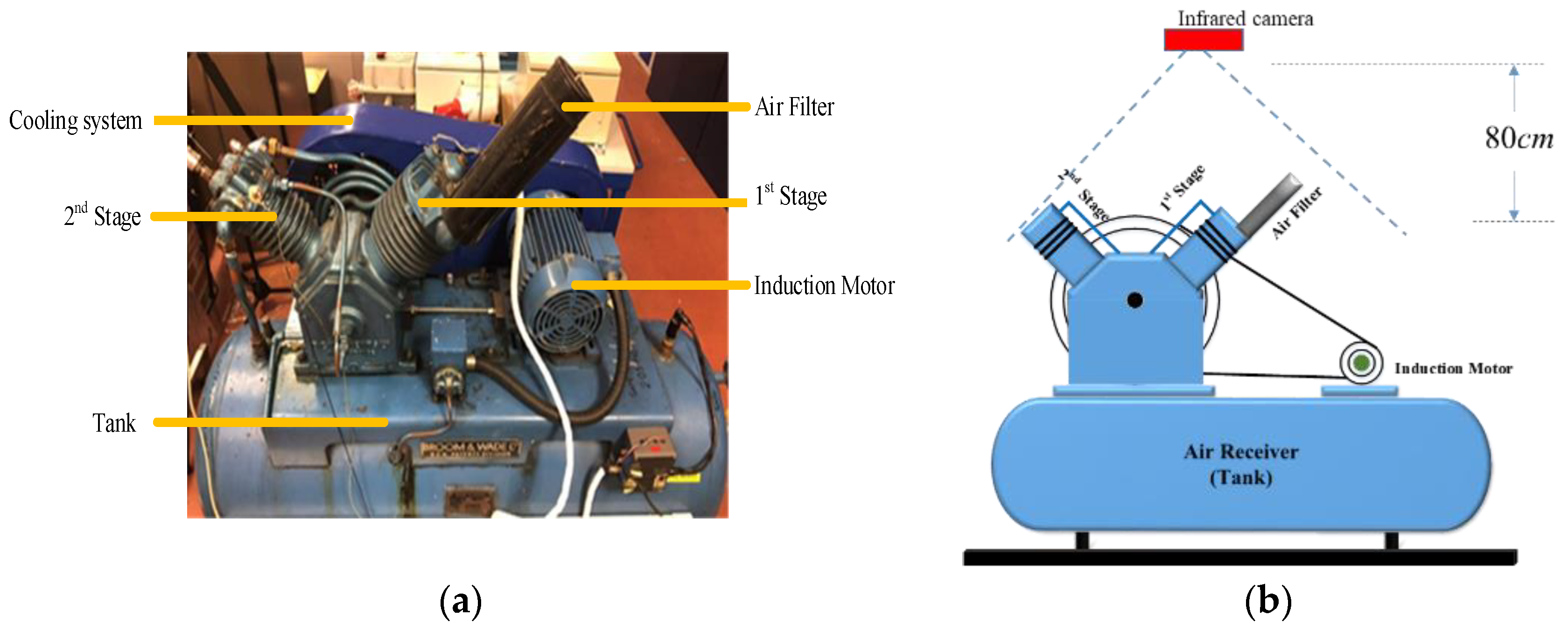

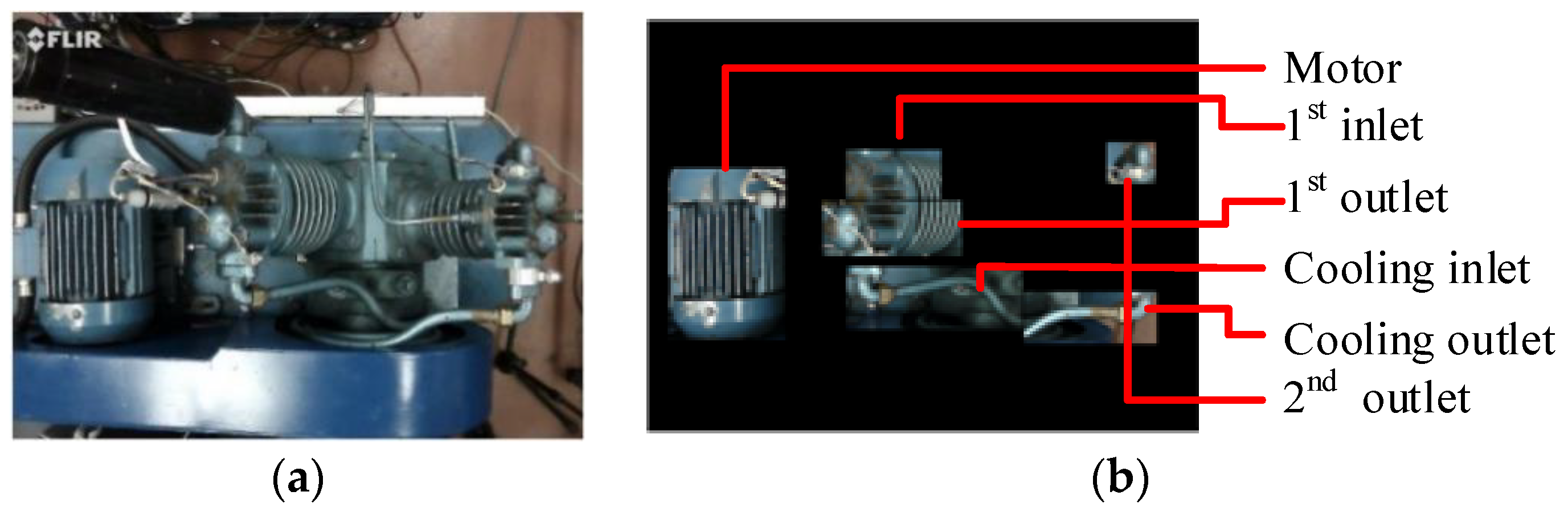

2. Experimental Facilities

2.1. Test Rig

2.2. Fault Simulation

3. Analysis of Temperature Change of Reciprocating Compressor

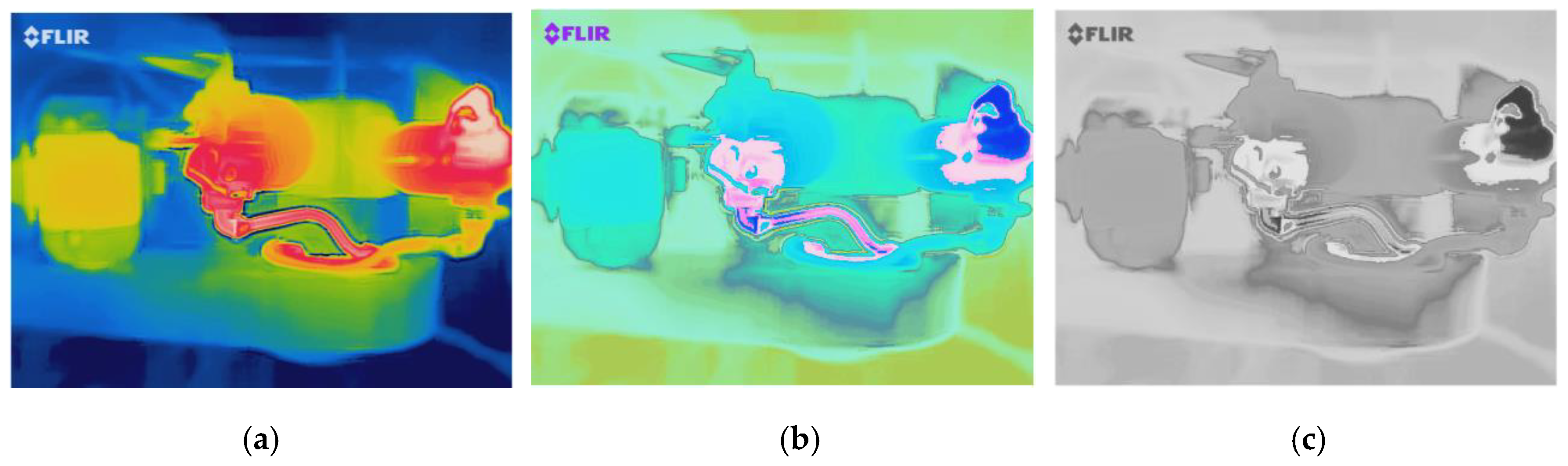

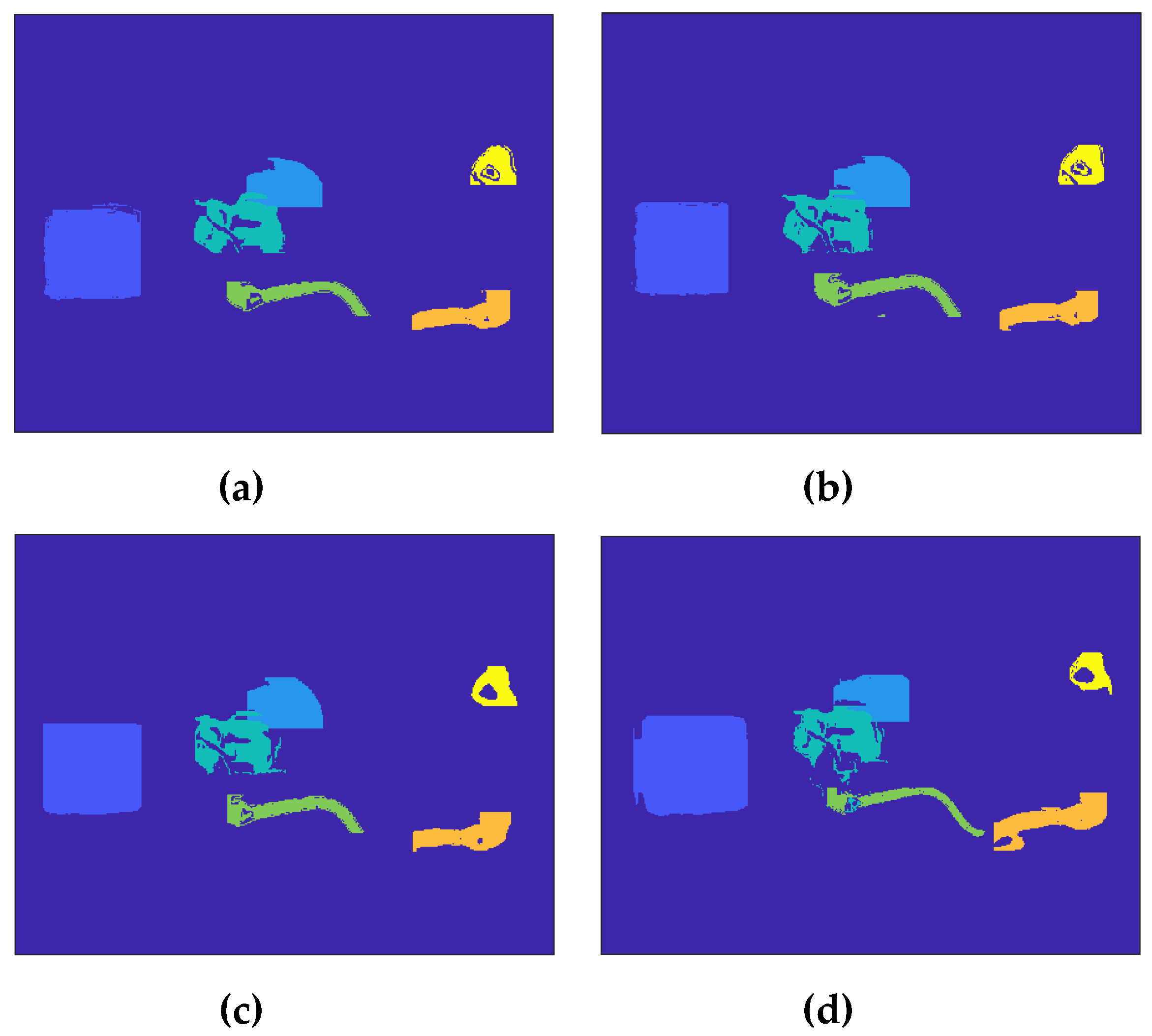

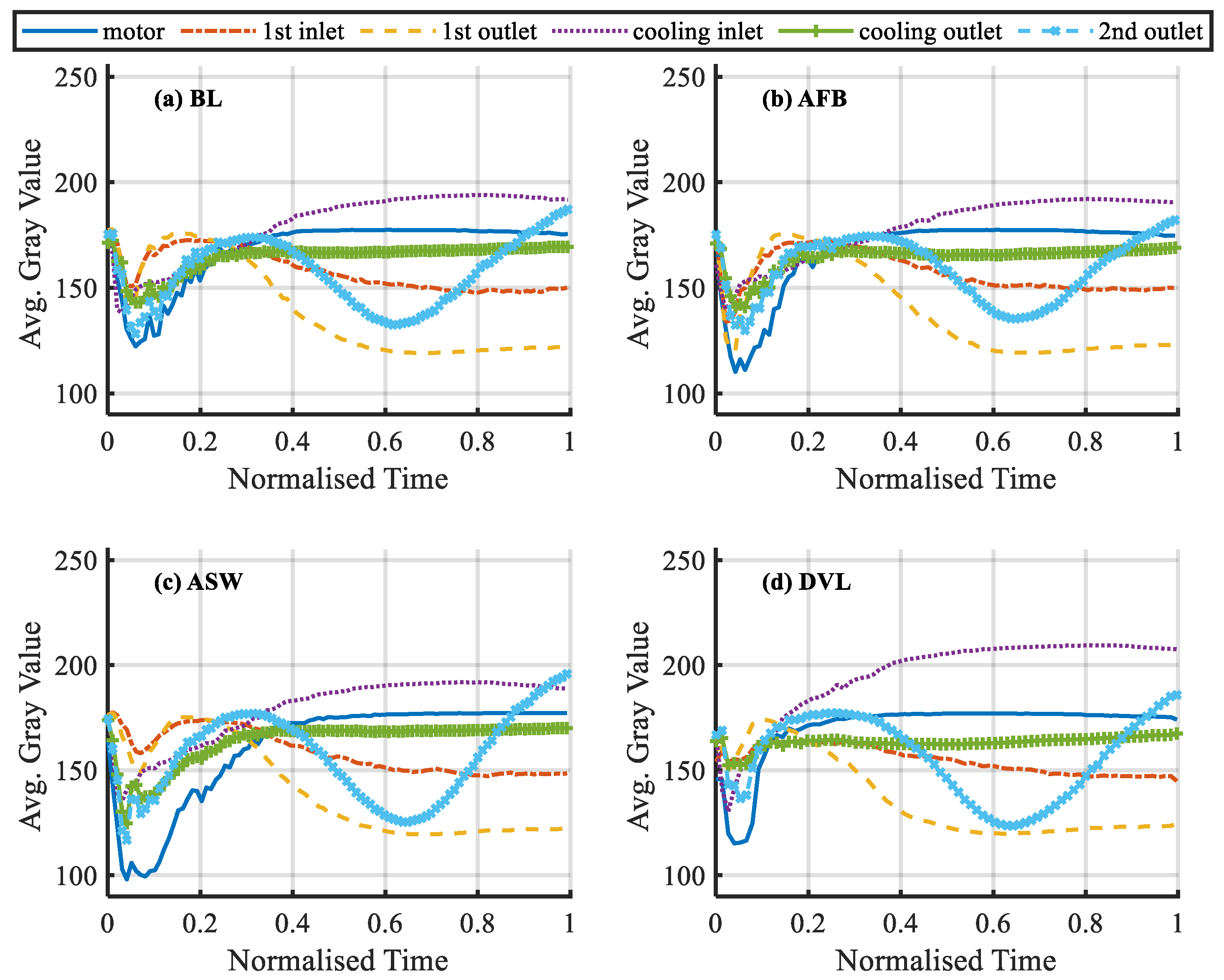

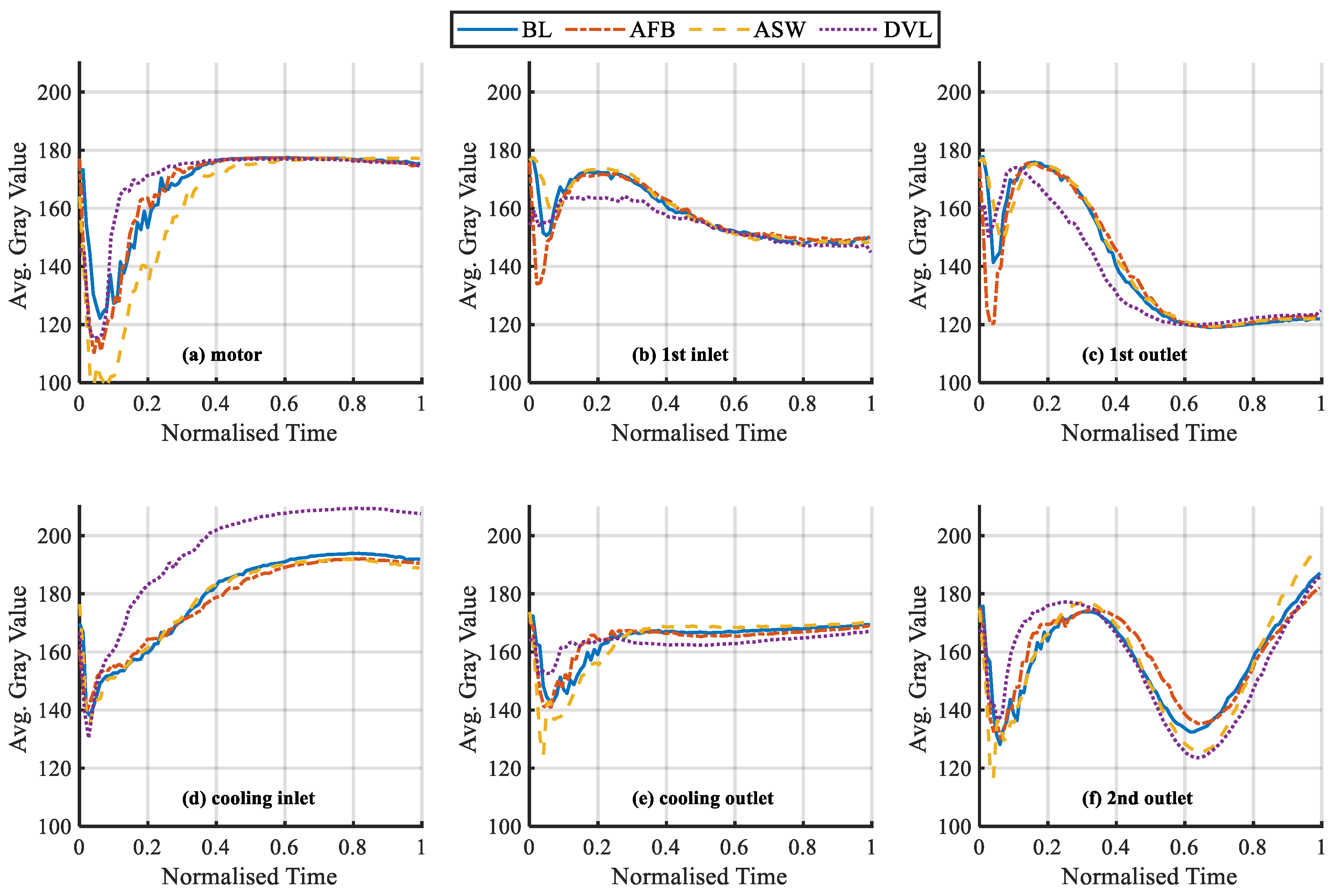

3.1. Temperature Change Characteristics of Reciprocating Compressor Based on Pseudo-Color Analysis

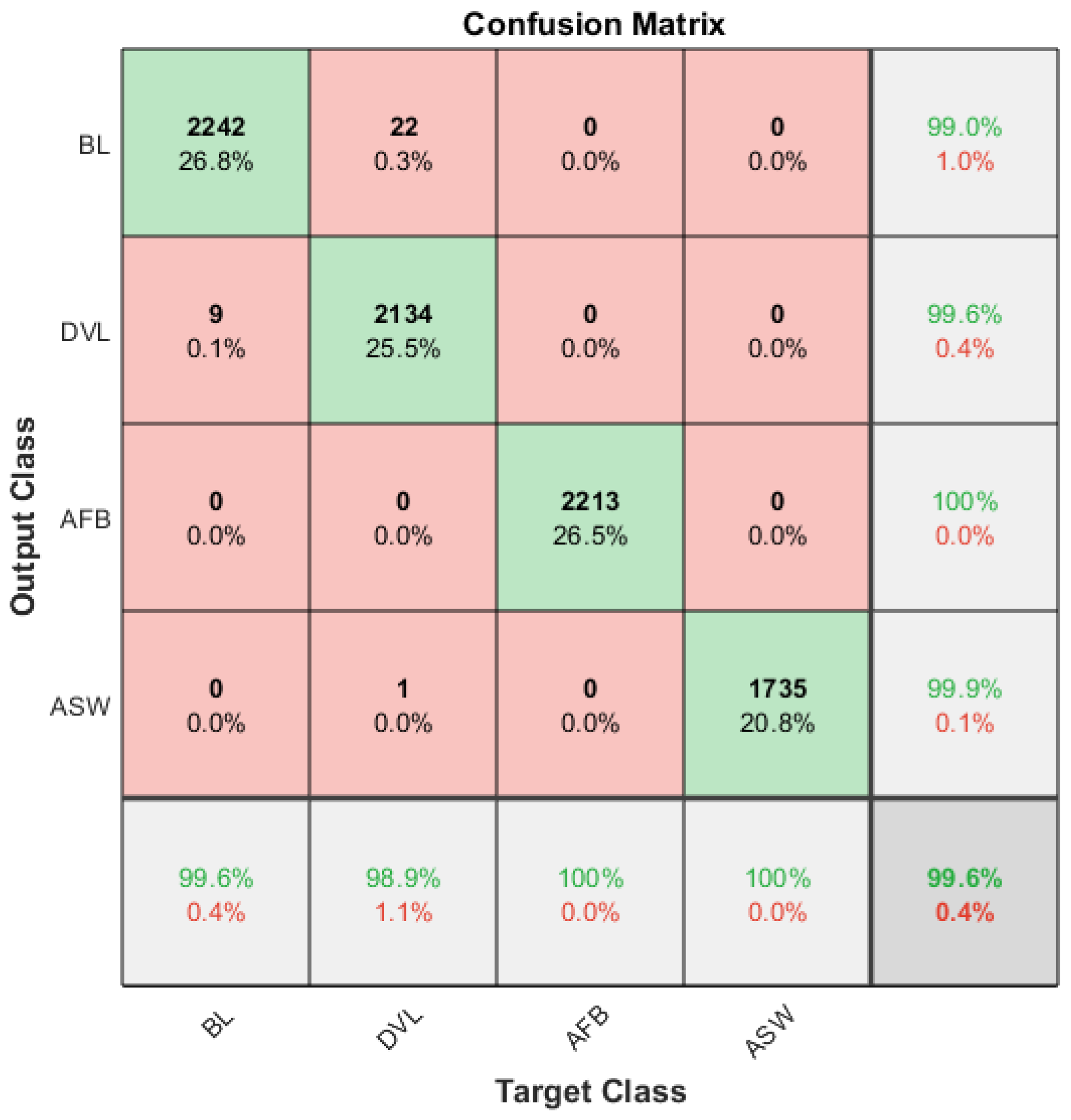

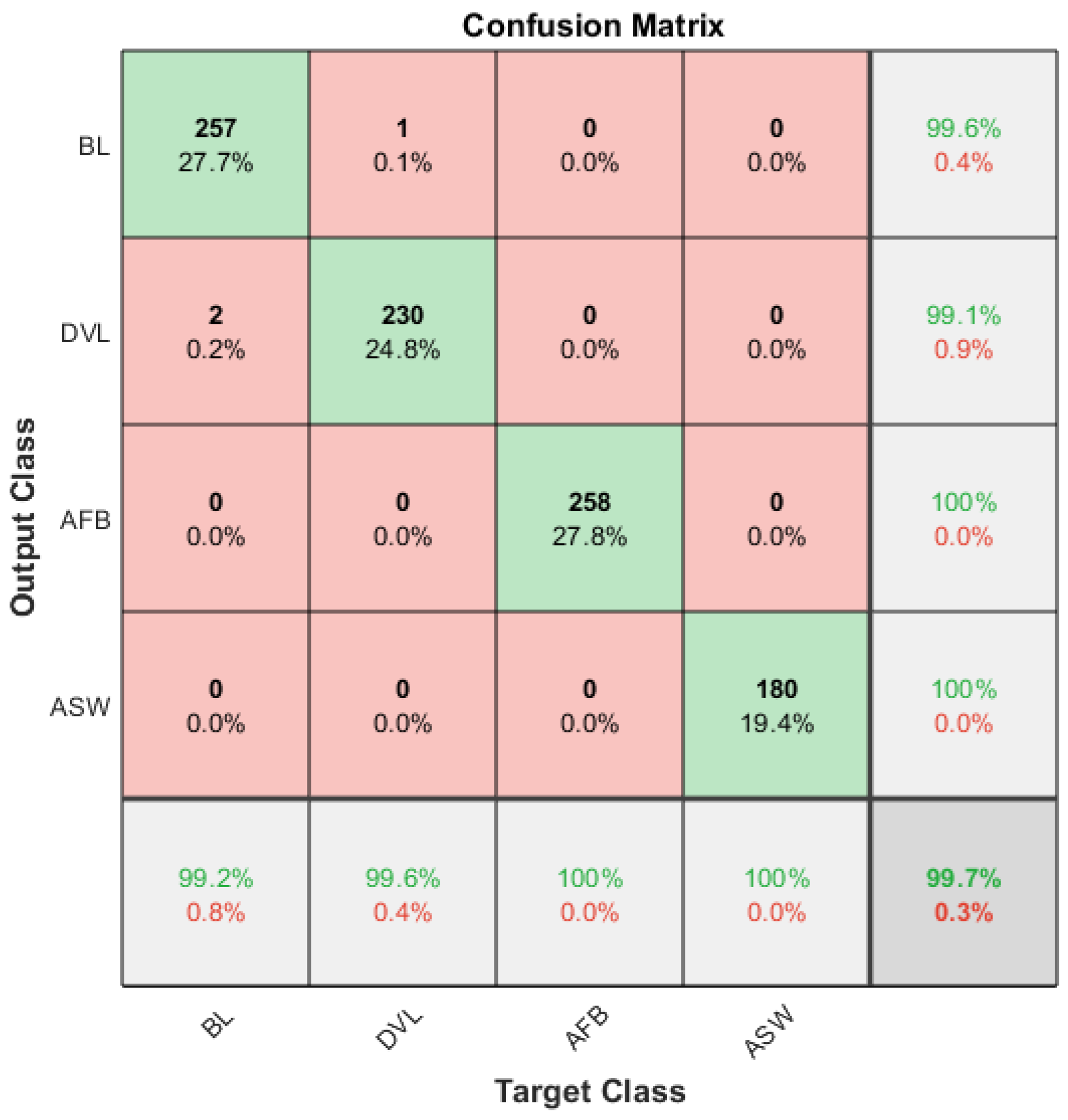

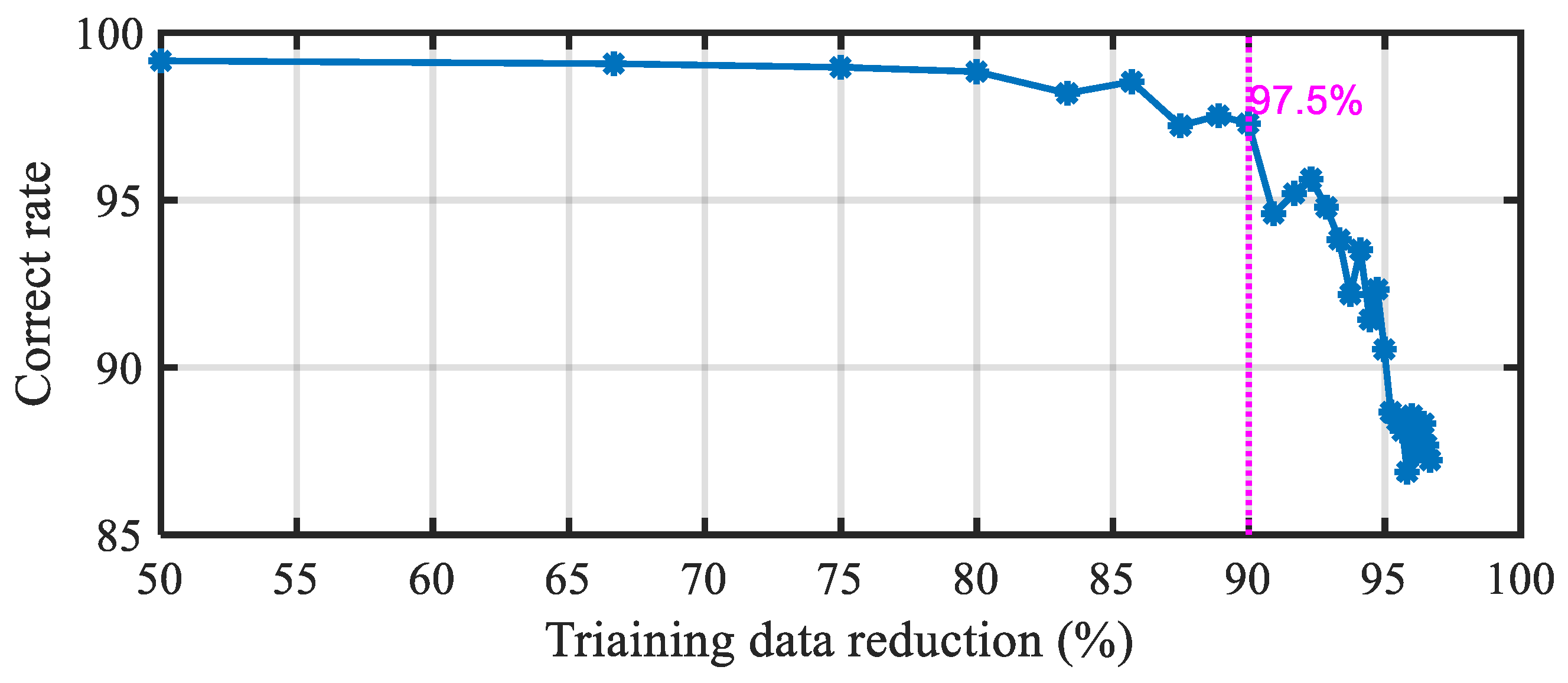

3.2. Fault Type Classification Using Support Vector Machine (SVM)

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Martini, A.; Troncossi, M.; Vincenzi, N. Structural and electrodynamic analysis of rotary transfer machines by Finite Element model. J. Serb. Soc. Comput. Math. 2017, 11, 1–16. [Google Scholar] [CrossRef]

- Martini, A.; Troncossi, M. Upgrade of an automated line for plastic cap manufacture based on experimental vibration analysis. Case Stud. Mech. Syst. Signal Process. 2016, 3, 28–33. [Google Scholar] [CrossRef]

- Wang, T.; Han, Q.; Chu, F.; Feng, Z. Vibration based condition monitoring and fault diagnosis of wind turbine planetary gearbox: A review. Mech. Syst. Sig. Process. 2019, 126, 662–685. [Google Scholar] [CrossRef]

- Abaszade, M.; Effati, S. Stochastic support vector machine for classifying and regression of random variables. Neural Process. Lett. 2018, 48, 1–29. [Google Scholar] [CrossRef]

- Verma, N.K.; Sevakula, R.K.; Dixit, S.; Salour, A. Intelligent condition based monitoring using acoustic signals for air compressors. IEEE Trans. Reliab. 2015, 65, 291–309. [Google Scholar] [CrossRef]

- Townsend, J.; Badar, M.A.; Szekerces, J. Updating temperature monitoring on reciprocating compressor connecting rods to improve reliability. Eng. Sci. Technol. Int. J. 2016, 19, 566–573. [Google Scholar] [CrossRef]

- Munari, E.; D’Elia, G.; Morini, M.; Mucchi, E.; Pinelli, M.; Spina, P.R. Experimental Investigation of Vibrational and Acoustic Phenomena for Detecting the Stall and Surge of a Multistage Compressor. J. Eng. Gas Turbines Power 2018, 140, 092605. [Google Scholar] [CrossRef]

- Ali, S.M.; Hui, K.H.; Hee, L.M.; Leong, M.S.; Abdelrhman, A.M.; Al-Obaidi, M.A. Observations of changes in acoustic emission parameters for varying corrosion defect in reciprocating compressor valves. Ain Shams Eng. J. 2019, 10, 253–265. [Google Scholar] [CrossRef]

- Li, X.; Chen, J.; Wang, Z.; Jia, X.; Peng, X. A non-destructive fault diagnosis method for a diaphragm compressor in the hydrogen refueling station. Int. J. Hydrogen Energy 2019, 44, 24301–24311. [Google Scholar] [CrossRef]

- Sim, H.Y.; Ramli, R.; Saifizul, A.; Soong, M.F. Detection and estimation of valve leakage losses in reciprocating compressor using acoustic emission technique. Measurement 2020, 152, 107315. [Google Scholar] [CrossRef]

- Li, X.; Peng, X.; Zhang, Z.; Jia, X.; Wang, Z. A new method for nondestructive fault diagnosis of reciprocating compressor by means of strain-based p–V diagram. Mech. Syst. Sig. Process. 2019, 133, 106268. [Google Scholar] [CrossRef]

- Feng, G.; Hu, N.; Mones, Z.; Gu, F.; Ball, A. An investigation of the orthogonal outputs from an on-rotor MEMS accelerometer for reciprocating compressor condition monitoring. Mech. Syst. Sig. Process. 2016, 76, 228–241. [Google Scholar] [CrossRef]

- Haba, U.; Shaeboub, A.; Mones, Z.; Gu, F.; Ball, A. Diagnosis of Compound Faults in Reciprocating Compressors Based on Modulation Signal Bispectrum of Current Signals. In Proceedings of the 2nd International Conference on Maintenance Engineering, IncoME-II 2017, Manchester, UK, 5–6 September 2017. [Google Scholar]

- Qi, G.; Zhu, Z.; Erqinhu, K.; Chen, Y.; Chai, Y.; Sun, J. Fault-diagnosis for reciprocating compressors using big data and machine learning. Simul. Modell. Pract. Theory 2018, 80, 104–127. [Google Scholar] [CrossRef]

- Pichler, K.; Lughofer, E.; Pichler, M.; Buchegger, T.; Klement, E.P.; Huschenbett, M. Fault detection in reciprocating compressor valves under varying load conditions. Mech. Syst. Sig. Process. 2016, 70, 104–119. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, J.; Ma, B. Fault diagnosis of reciprocating compressor using a novel ensemble empirical mode decomposition-convolutional deep belief network. Measurement 2020, 107619. [Google Scholar] [CrossRef]

- Cabrera, D.; Guamán, A.; Zhang, S.; Cerrada, M.; Sánchez, R.V.; Cevallos, J.; Long, J.; Li, C. Bayesian approach and time series dimensionality reduction to LSTM-based model-building for fault diagnosis of a reciprocating compressor. Neurocomputing 2020, 380, 51–66. [Google Scholar] [CrossRef]

- Loukopoulos, P.; Zolkiewski, G.; Bennett, I.; Sampath, S.; Pilidis, P.; Duan, F.; Sattar, T.; Mba, D. Reciprocating compressor prognostics of an instantaneous failure mode utilising temperature only measurements. Appl. Acoust. 2019, 147, 77–86. [Google Scholar] [CrossRef]

- Lin, Y.H.; Lee, W.S.; Wu, C.Y. Automated fault classification of reciprocating compressors from vibration data: A case study on optimization using genetic algorithm. Procedia Eng. 2014, 79, 355–361. [Google Scholar] [CrossRef][Green Version]

- Lin, Y.H.; Wu, H.C.; Wu, C.Y. Automated condition classification of a reciprocating compressor using time–frequency analysis and an artificial neural network. Smart Mater. Struct. 2006, 15, 1576. [Google Scholar] [CrossRef]

- AlThobiani, F.; Ball, A. An approach to fault diagnosis of reciprocating compressor valves using Teager–Kaiser energy operator and deep belief networks. Expert Syst. Appl. 2014, 41, 4113–4122. [Google Scholar]

- Tran, V.T.; AlThobiani, F.; Tinga, T.; Ball, A.; Niu, G. Single and combined fault diagnosis of reciprocating compressor valves using a hybrid deep belief network. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2018, 232, 3767–3780. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Khoshnazar, H. Valve fault detection for single-stage reciprocating compressors. J. Nat. Gas Sci. Eng. 2016, 35, 1239–1248. [Google Scholar] [CrossRef]

- Liu, H.; Bao, C.; Xie, T.; Gao, S.; Song, X.; Wang, W. Research on the intelligent diagnosis method of the server based on thermal image technology. Infrared Phys. Technol. 2019, 96, 390–396. [Google Scholar] [CrossRef]

- Younus, A.M.; Yang, B.S. Intelligent fault diagnosis of rotating machinery using infrared thermal image. Expert Syst. Appl. 2012, 39, 2082–2091. [Google Scholar] [CrossRef]

- Liu, H.; Ran, J.; Xie, T.; Gao, S. Thermal feature extraction of servers in a datacenter using thermal image registration. Infrared Phys. Technol. 2017, 85, 133–140. [Google Scholar] [CrossRef]

- Janssens, O.; Schulz, R.; Slavkovikj, V.; Stockman, K.; Loccufier, M.; Van de Walle, R.; Van Hoecke, S. Thermal image based fault diagnosis for rotating machinery. Infrared Phys. Technol. 2015, 73, 78–87. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, Z. Diagnosis of the three-phase induction motor using thermal imaging. Infrared Phys. Technol. 2017, 81, 7–16. [Google Scholar] [CrossRef]

- Al-Musawi, A.K.; Anayi, F.; Packianather, M. Three-phase induction motor fault detection based on thermal image segmentation. Infrared Phys. Technol. 2020, 104, 103140. [Google Scholar] [CrossRef]

- Lo, N.G.; Flaus, J.M.; Adrot, O. Review of Machine Learning Approaches in Fault Diagnosis Applied to IoT Systems. In Proceedings of the 2019 International Conference on Control, Automation and Diagnosis (ICCAD), Grenoble, France, 2–4 July 2019. [Google Scholar]

- Yang, H.-B.; Zhang, J.-A.; Chen, L.-L.; Zhang, H.-L.; Liu, S.-L. Fault Diagnosis of Reciprocating Compressor Based on Convolutional Neural Networks with Multisource Raw Vibration Signals. Math. Prob. Eng. 2019, 2019, 6921975. [Google Scholar] [CrossRef]

| Fault Modes | Frame Rate | Duration | Number of Images | Ambient Temperature (°C) |

|---|---|---|---|---|

| BL | 4.04 frame/s | 10′22″ | 2515 | 23.5 |

| AFB | 4.09 frame/s | 10′04″ | 2393 | 23.1 |

| ASW | 3.92 frame/s | 10′10″ | 2469 | 20.5 |

| DVL | 3.02 frame/s | 10′31″ | 1907 | 24.7 |

| Region | Hue Range | Saturation Range | Value Range |

|---|---|---|---|

| moto | —— | —— | >0.8 |

| 1st inlet | <0.1 | —— | —— |

| 1st outlet | >0.95 | —— | —— |

| Cooling inlet | <0.1 | —— | —— |

| Cooling outlet | <0.2 | —— | >0.7 |

| 2nd outlet | <0.09 | <0.6 | —— |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, R.; Lin, Y.; Tang, W.; Gu, F.; Ball, A. Object-Based Thermal Image Segmentation for Fault Diagnosis of Reciprocating Compressors. Sensors 2020, 20, 3436. https://doi.org/10.3390/s20123436

Deng R, Lin Y, Tang W, Gu F, Ball A. Object-Based Thermal Image Segmentation for Fault Diagnosis of Reciprocating Compressors. Sensors. 2020; 20(12):3436. https://doi.org/10.3390/s20123436

Chicago/Turabian StyleDeng, Rongfeng, Yubin Lin, Weijie Tang, Fengshou Gu, and Andrew Ball. 2020. "Object-Based Thermal Image Segmentation for Fault Diagnosis of Reciprocating Compressors" Sensors 20, no. 12: 3436. https://doi.org/10.3390/s20123436

APA StyleDeng, R., Lin, Y., Tang, W., Gu, F., & Ball, A. (2020). Object-Based Thermal Image Segmentation for Fault Diagnosis of Reciprocating Compressors. Sensors, 20(12), 3436. https://doi.org/10.3390/s20123436