Artificial Intelligence Applied to a Robotic Dairy Farm to Model Milk Productivity and Quality based on Cow Data and Daily Environmental Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Site, Robotic Dairy Farm, and Data Acquisition

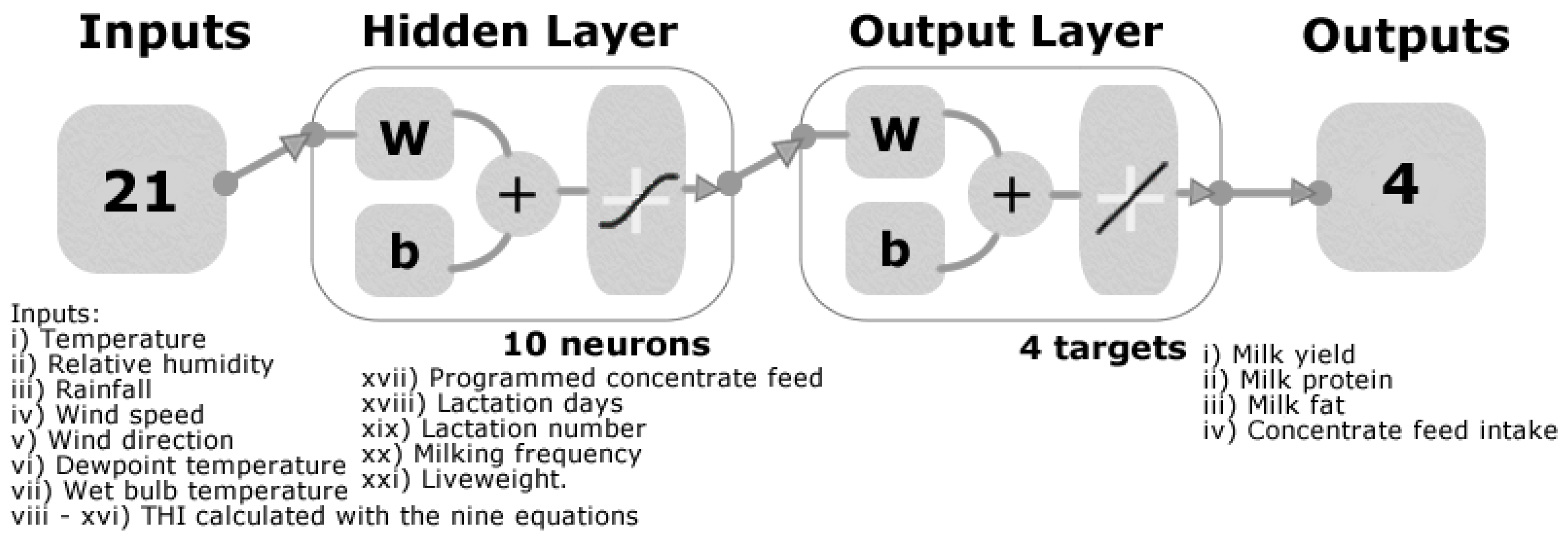

2.2. Statistical Data and Machine Learning Modeling

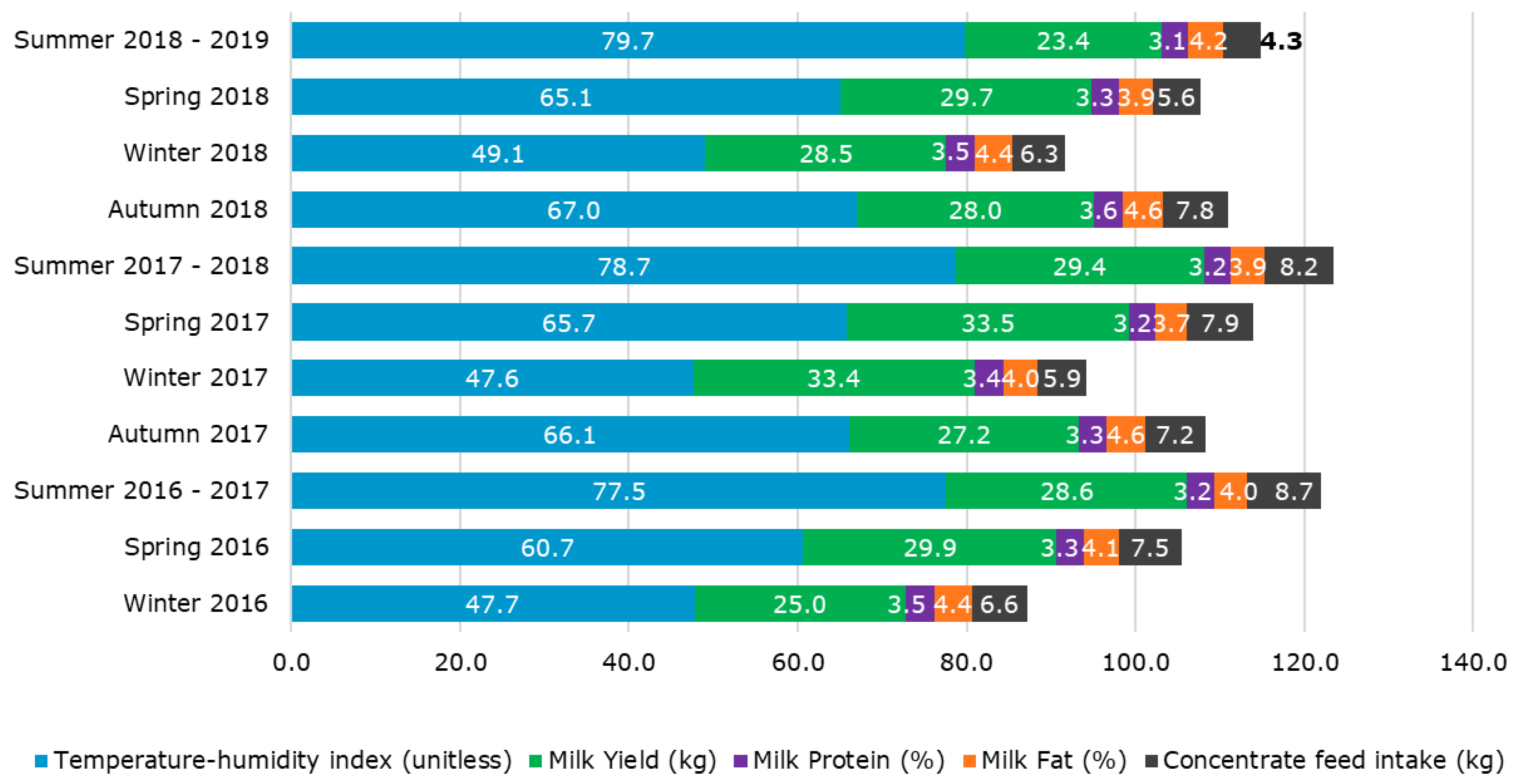

3. Results

4. Discussion

4.1. Seasonality and Milk Yield

4.2. Machine Learning Models

4.3. Artificial Intelligence to Manage Heat Stress and Milk Productivity

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Britt, J.; Cushman, R.; Dechow, C.D.; Dobson, H.; Humblot, P.; Hutjens, M.; Jones, G.; Ruegg, P.; Sheldon, I.; Stevenson, J. Invited review: Learning from the future—A vision for dairy farms and cows in 2067. J. Dairy Sci. 2018, 101, 3722–3741. [Google Scholar] [CrossRef] [PubMed]

- Hostiou, N.; Fagon, J.; Chauvat, S.; Turlot, A.; Kling-Eveillard, F.; Boivin, X.; Allain, C. Impact of precision livestock farming on work and human-animal interactions on dairy farms. A review. Biotechnol. Agron. Soc. Environ. 2017, 21, 268–275. [Google Scholar]

- McCullough, C. Global dairy outlook by 2030: Industry. The Dairy Mail 2019, 26, 12–15. [Google Scholar]

- Bear, C.; Holloway, L. Beyond resistance: Geographies of divergent more-than-human conduct in robotic milking. Geoforum 2019, 104, 212–221. [Google Scholar] [CrossRef]

- Heyden, T. The Cows That Queue up to Milk Themselves. Available online: https://robohub.org/the-cows-that-queue-up-to-milk-themselves-bbc-news/ (accessed on 3 May 2020).

- Jorquera-Chavez, M.; Fuentes, S.; Dunshea, F.R.; Warner, R.D.; Poblete, T.; Jongman, E.C. Modelling and Validation of Computer Vision Techniques to Assess Heart Rate, Eye Temperature, Ear-Base Temperature and Respiration Rate in Cattle. Animals 2019, 9, 1089. [Google Scholar] [CrossRef] [PubMed]

- Ji, B.; Banhazi, T.; Ghahramani, A.; Bowtell, L.; Wang, C.; Li, B. Modelling of heat stress in a robotic dairy farm. Part 3: Rumination and milking performance. Biosyst. Eng. 2020. [Google Scholar] [CrossRef]

- Ji, B.; Banhazi, T.; Ghahramani, A.; Bowtell, L.; Wang, C.; Li, B. Modelling of heat stress in a robotic dairy farm. Part 2: Identifying the specific thresholds with production factors. Biosyst. Eng. 2019. [Google Scholar] [CrossRef]

- Ji, B.; Banhazi, T.; Ghahramani, A.; Bowtell, L.; Wang, C.; Li, B. Modelling of heat stress in a robotic dairy farm. Part 1: Thermal comfort indices as the indicators of production loss. Biosyst. Eng. 2019. [Google Scholar] [CrossRef]

- Ekine-Dzivenu, C.; Mrode, R.A.; Ojango, J.M.; Okeyo Mwai, A. Evaluating the impact of heat stress as measured by temperature-humidity index (THI) on test-day milk yield of dairy cattle in Tanzania. In Proceedings of the Seventh All Africa conference on Animal Agriculture, Accra, Ghana, 29 July–2 August 2019. [Google Scholar]

- Nascimento, F.G.d.O.; Aguiar, H.C.P.; Rodrigues, G.M.; Guimarães, E.C.; Nascimento, M.R.B.d.M. What is the best temperature-humidity index equation to indicate heat stress in crossbred dairy calves in a tropical environment? Ciência Rural 2019, 49, e20180132. [Google Scholar] [CrossRef]

- Berman, A.; Horovitz, T.; Kaim, M.; Gacitua, H. A comparison of THI indices leads to a sensible heat-based heat stress index for shaded cattle that aligns temperature and humidity stress. Int. J. Biometeorol. 2016, 60, 1453–1462. [Google Scholar] [CrossRef]

- Carolan, M. Automated agrifood futures: Robotics, labor and the distributive politics of digital agriculture. J. Peasant Stud. 2020, 47, 184–207. [Google Scholar] [CrossRef]

- Dunshea, F.R.; Oluboyede, K.; DiGiacomo, K.; Leury, B.J.; Cottrell, J.J. Betaine improves milk yield in grazing dairy cows supplemented with concentrates at high temperatures. Animals 2019, 9, 57. [Google Scholar] [CrossRef] [PubMed]

- Bolton, D. The computation of equivalent potential temperature. Mon. Weather Rev. 1980, 108, 1046–1053. [Google Scholar] [CrossRef]

- Goodwin, R. Wet Bulb, Matlab Central File Exchange. Available online: https://www.mathworks.com/matlabcentral/fileexchange/50785-wet-bulb (accessed on 20 April 2020).

- Gonzalez Viejo, C.; Torrico, D.; Dunshea, F.; Fuentes, S. Development of Artificial Neural Network Models to Assess Beer Acceptability Based on Sensory Properties Using a Robotic Pourer: A Comparative Model Approach to Achieve an Artificial Intelligence System. Beverages 2019, 5, 33. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Bowman, P.J.; Haile-Mariam, M.; Nieuwhof, G.J.; Hayes, B.J.; Pryce, J.E. Implementation of a breeding value for heat tolerance in Australian dairy cattle. J. Dairy Sci. 2017, 100, 7362–7367. [Google Scholar] [CrossRef]

- Ouellet, V.; Cabrera, V.; Fadul-Pacheco, L.; Charbonneau, É. The relationship between the number of consecutive days with heat stress and milk production of Holstein dairy cows raised in a humid continental climate. J. Dairy Sci. 2019, 102, 8537–8545. [Google Scholar] [CrossRef]

- Gunn, K.M.; Holly, M.A.; Veith, T.L.; Buda, A.R.; Prasad, R.; Rotz, C.A.; Soder, K.J.; Stoner, A.M. Projected heat stress challenges and abatement opportunities for US milk production. PLoS ONE 2019, 14. [Google Scholar] [CrossRef]

- Summer, A.; Lora, I.; Formaggioni, P.; Gottardo, F. Impact of heat stress on milk and meat production. Anim. Front. 2019, 9, 39–46. [Google Scholar] [CrossRef]

- Sigdel, A.; Abdollahi-Arpanahi, R.; Aguilar, I.; Peñagaricano, F. Whole Genome Mapping Reveals Novel Genes and Pathways Involved in Milk Production Under Heat Stress in US Holstein Cows. Front. Genet. 2019, 10, 928. [Google Scholar] [CrossRef]

- Alba, D.F.; Campigotto, G.; Cazarotto, C.J.; dos Santos, D.S.; Gebert, R.R.; Reis, J.H.; Souza, C.F.; Baldissera, M.D.; Gindri, A.L.; Kempka, A.P. Use of grape residue flour in lactating dairy sheep in heat stress: Effects on health, milk production and quality. J. Therm. Biol. 2019, 82, 197–205. [Google Scholar] [CrossRef]

- dos Santos, D.d.S.; Klauck, V.; Campigotto, G.; Alba, D.F.; Dos Reis, J.H.; Gebert, R.R.; Souza, C.F.; Baldissera, M.D.; Schogor, A.L.B.; Santos, I.D. Benefits of the inclusion of açai oil in the diet of dairy sheep in heat stress on health and milk production and quality. J. Therm. Biol. 2019, 84, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Hall, L.; Dunshea, F.; Allen, J.; Rungruang, S.; Collier, J.; Long, N.; Collier, R.J. Evaluation of dietary betaine in lactating Holstein cows subjected to heat stress. J. Dairy Sci. 2016, 99, 9745–9753. [Google Scholar] [CrossRef] [PubMed]

- Gonzalez-Rivas, P.A.; Sullivan, M.; Cottrell, J.J.; Leury, B.J.; Gaughan, J.B.; Dunshea, F.R. Effect of feeding slowly fermentable grains on productive variables and amelioration of heat stress in lactating dairy cows in a sub-tropical summer. Trop. Anim. Health Prod. 2018, 50, 1763–1769. [Google Scholar] [CrossRef] [PubMed]

- Coppock, C.E. Reduce Heat Stress in High-Producing Dairy Cows with Feeding and Nutrition Management. In Dairy Science Handbook; CRC Press: Boca Raton, FL, USA, 2019; pp. 315–324. [Google Scholar]

- Dunshea, F.R.; Leury, B.J.; Fahri, F.; DiGiacomo, K.; Hung, A.; Chauhan, S.; Clarke, I.J.; Collier, R.; Little, S.; Baumgard, L. Amelioration of thermal stress impacts in dairy cows. Anim. Prod. Sci. 2013, 53, 965–975. [Google Scholar] [CrossRef]

- Ahmad, M.; Bhatti, J.A.; Abdullah, M.; Ullah, R.; ul Ain, Q.; Hasni, M.S.; Ali, M.; Rashid, A.; Qaisar, I.; Rashid, G. Different ambient management intervention techniques and their effect on milk production and physiological parameters of lactating NiliRavi buffaloes during hot dry summer of subtropical region. Trop. Anim. Health Prod. 2019, 51, 911–918. [Google Scholar] [CrossRef]

- Yao, C.; Shi, Z.; Zhao, Y.; Ding, T. Effect of Mixed-Flow Fans with a Newly Shaped Diffuser on Heat Stress of Dairy Cows Based on CFD. Energies 2019, 12, 4315. [Google Scholar] [CrossRef]

- Tresoldi, G.; Schütz, K.E.; Tucker, C.B. Cooling cows with sprinklers: Effects of soaker flow rate and timing on behavioral and physiological responses to heat load and production. J. Dairy Sci. 2019, 102, 528–538. [Google Scholar] [CrossRef]

- Sruthi, S.; Sasidharan, M.; Anil, K.; Harikumar, S.; Simon, S. Effect of automated intermittent wetting and forced ventilation on the physiological parameters and milk production of Murrah buffaloes in humid tropics. Pharma Innov. J. 2019, 8, 315–319. [Google Scholar]

- Imbabi, T.; Hassan, T.; Radwan, A.; Soliman, A. Production, haematological and biochemical metabolites of Egyptian buffaloes (Bubalus bubalis) during the hot summer months in Egypt. Slovak J. Anim. Sci. 2019, 52, 152–159. [Google Scholar]

- Pinto, S.; Hoffmann, G.; Ammon, C.; Heuwieser, W.; Levit, H.; Halachmi, I.; Amon, T. Effect of two cooling frequencies on respiration rate in lactating dairy cows under hot and humid climate conditions. Annal. Anim. Sci. 2019, 19, 821–834. [Google Scholar] [CrossRef]

- Meteorology, B.O. BoM Automated Data Services. Available online: http://www.bom.gov.au/catalogue/data-feeds.shtml (accessed on 10 February 2020).

| Parameter/Year | 2016 * | 2017 | 2018 | 2019 * | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Mean | SD | Min | Max | Mean | SD | Min | Max | Mean | SD | Min | Max | Mean | SD | |

| T (°C) | 7.9 | 37.8 | 19.3 | 7.15 | 8.3 | 42.0 | 22.2 | 8.27 | 8.9 | 43.3 | 22.6 | 7.90 | 16.3 | 44.9 | 31.7 | 6.07 |

| RH (%) | 66.0 | 100 | 95.6 | 6.20 | 56.2 | 100 | 92.3 | 9.27 | 44.2 | 100 | 87.9 | 11.67 | 39.2 | 92.6 | 69.2 | 12.13 |

| Tdp (°C) | 3.8 | 24.9 | 11.6 | 3.40 | 2.1 | 22.8 | 11.5 | 3.97 | 1.6 | 22.1 | 10.2 | 3.75 | 4.3 | 21.2 | 13.5 | 3.79 |

| Twet (°C) | 6.6 | 25.3 | 13.8 | 3.56 | 6.8 | 25.3 | 14.7 | 4.20 | 5.9 | 24.5 | 14.1 | 3.97 | 11.3 | 24.1 | 18.6 | 3.11 |

| Rainfall (mm day−1) | 0.0 | 34.0 | 3.9 | 6.76 | 0.0 | 31.6 | 1.86 | 4.55 | 0.0 | 37.8 | 1.4 | 4.07 | 0.0 | 5.0 | 0.3 | 0.99 |

| Wind speed (km h−1) | 5.2 | 38.3 | 15.1 | 5.22 | 5.8 | 34.3 | 15.3 | 5.19 | 5.1 | 38.0 | 16.2 | 5.82 | 9.4 | 39.8 | 19.5 | 6.14 |

| Wind direction (°) | 127.7 | 360.0 | 344.0 | 26.54 | 247.2 | 360.0 | 345.1 | 23.76 | 112.2 | 360.0 | 341.8 | 32.81 | 241.7 | 360.0 | 338.9 | 30.62 |

| THI1 | 57.2 | 89.6 | 70.6 | 7.37 | 58.4 | 94.6 | 73.3 | 8.72 | 58.7 | 92.9 | 73.3 | 8.34 | 67.3 | 96.3 | 82.8 | 6.25 |

| THI2 | 44.5 | 78.6 | 58.1 | 7.08 | 45.4 | 81.2 | 60.2 | 8.42 | 44.5 | 79.2 | 59.6 | 8.01 | 54.9 | 80.5 | 68.6 | 6.06 |

| THI3 | 44.7 | 81.1 | 60.0 | 8.24 | 46.0 | 86.8 | 62.9 | 9.79 | 46.3 | 83.8 | 62.6 | 9.34 | 56.3 | 87.8 | 73.2 | 6.99 |

| THI4 | 50.8 | 83.2 | 64.2 | 7.37 | 52.0 | 88.2 | 66.9 | 8.72 | 52.3 | 86.5 | 66.9 | 8.34 | 60.9 | 89.9 | 76.4 | 6.25 |

| THI5 | 47.1 | 82.2 | 63.4 | 8.15 | 47.5 | 86.5 | 66.5 | 9.13 | 49.0 | 84.3 | 66.9 | 8.48 | 60.4 | 87.5 | 76.2 | 5.55 |

| THI6 | 59.1 | 91.5 | 72.0 | 7.33 | 60.2 | 97.0 | 74.7 | 8.75 | 60.5 | 94.4 | 74.6 | 8.39 | 68.7 | 98.7 | 84.3 | 6.56 |

| THI7 | 50.8 | 83.6 | 63.9 | 7.40 | 51.9 | 89.1 | 66.6 | 8.84 | 52.2 | 86.5 | 66.5 | 8.47 | 60.6 | 90.9 | 76.3 | 6.62 |

| THI8 | 47.1 | 82.0 | 63.4 | 8.09 | 47.5 | 86.3 | 66.5 | 9.07 | 49.0 | 84.0 | 66.8 | 8.41 | 60.4 | 87.2 | 76.0 | 5.49 |

| THI9 | 33.4 | 86.6 | 58.8 | 12.45 | 33.4 | 92.6 | 63.7 | 13.73 | 36.5 | 89.4 | 64.4 | 12.61 | 55.4 | 93.7 | 78.1 | 7.83 |

| Programmed concentrate feed (kg day−1) | 0.0 | 15.0 | 8.9 | 3.03 | 0.0 | 23.0 | 8.5 | 3.11 | 0.0 | 15.7 | 7.8 | 3.15 | 0.0 | 8.0 | 5.1 | 2.30 |

| Lactation number | 1.0 | 6.0 | 2.7 | 0.97 | 1.0 | 7.0 | 3.0 | 1.24 | 1.0 | 7.0 | 2.3 | 1.61 | 1.0 | 8.0 | 3.0 | 1.75 |

| Lactation days | 0.0 | 736.0 | 225 | 158.17 | 0.0 | 668.0 | 198.1 | 139.28 | 0.0 | 705.0 | 228.3 | 142.26 | 0.0 | 755.0 | 227.5 | 144.01 |

| Milking frequency (per day) | 0.0 | 5.0 | 2.4 | 0.71 | 0.0 | 6.0 | 2.5 | 0.75 | 0.0 | 6.0 | 2.4 | 0.84 | 0.0 | 5.0 | 1.9 | 0.81 |

| Liveweight (kg) | 373.0 | 938.0 | 677.7 | 82.85 | 428.0 | 951.0 | 668.2 | 78.25 | 335.0 | 959.0 | 655.4 | 84.57 | 410.0 | 896.0 | 629.5 | 71.86 |

| Parameter/Year | 2016 * | 2017 | 2018 | 2019 * | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Mean | Min | Max | Mean | Min | Max | Mean | Min | Max | Mean | |

| Milk yield (kg day−1) | 0.0 | 65.4 | 28.1 | 0.0 | 60.2 | 30.7 | 0.0 | 61.2 | 28.8 | 0.0 | 52.1 | 21.2 |

| Milk protein (%) | 1.8 | 5.8 | 3.3 | 1.8 | 6.1 | 3.2 | 2.2 | 5.8 | 3.4 | 0.9 | 4.9 | 3.1 |

| Milk fat (%) | 1.0 | 10.7 | 4.2 | 0.8 | 10.2 | 4.0 | 0.7 | 10.3 | 4.2 | 0.7 | 10.9 | 4.3 |

| Concentrate feed intake (kg day−1) | 0.0 | 19.5 | 7.3 | 0.0 | 24.3 | 7.4 | 0.0 | 18.8 | 6.7 | 0.0 | 10.6 | 4.0 |

| Stage | Samples (Cows x Days) | Observations (Samples x Targets) | R | b | Performance (MSE) |

|---|---|---|---|---|---|

| Model 1 | |||||

| Training | 20,380 | 81,520 | 0.87 | 0.76 | 0.0186 |

| Testing | 8734 | 34,936 | 0.86 | 0.76 | 0.0189 |

| Overall | 29,114 | 116,456 | 0.87 | 0.76 | - |

| Model 2 | |||||

| Training | 116,521 | 466,084 | 0.86 | 0.74 | 0.0154 |

| Testing | 49,938 | 199,752 | 0.86 | 0.74 | 0.0157 |

| Overall | 166,459 | 665,836 | 0.86 | 0.74 | - |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fuentes, S.; Gonzalez Viejo, C.; Cullen, B.; Tongson, E.; Chauhan, S.S.; Dunshea, F.R. Artificial Intelligence Applied to a Robotic Dairy Farm to Model Milk Productivity and Quality based on Cow Data and Daily Environmental Parameters. Sensors 2020, 20, 2975. https://doi.org/10.3390/s20102975

Fuentes S, Gonzalez Viejo C, Cullen B, Tongson E, Chauhan SS, Dunshea FR. Artificial Intelligence Applied to a Robotic Dairy Farm to Model Milk Productivity and Quality based on Cow Data and Daily Environmental Parameters. Sensors. 2020; 20(10):2975. https://doi.org/10.3390/s20102975

Chicago/Turabian StyleFuentes, Sigfredo, Claudia Gonzalez Viejo, Brendan Cullen, Eden Tongson, Surinder S. Chauhan, and Frank R. Dunshea. 2020. "Artificial Intelligence Applied to a Robotic Dairy Farm to Model Milk Productivity and Quality based on Cow Data and Daily Environmental Parameters" Sensors 20, no. 10: 2975. https://doi.org/10.3390/s20102975

APA StyleFuentes, S., Gonzalez Viejo, C., Cullen, B., Tongson, E., Chauhan, S. S., & Dunshea, F. R. (2020). Artificial Intelligence Applied to a Robotic Dairy Farm to Model Milk Productivity and Quality based on Cow Data and Daily Environmental Parameters. Sensors, 20(10), 2975. https://doi.org/10.3390/s20102975