A Comparison Study of Fatigue Behavior of Hard and Soft Piezoelectric Single Crystal Macro-Fiber Composites for Vibration Energy Harvesting

Abstract

1. Introduction

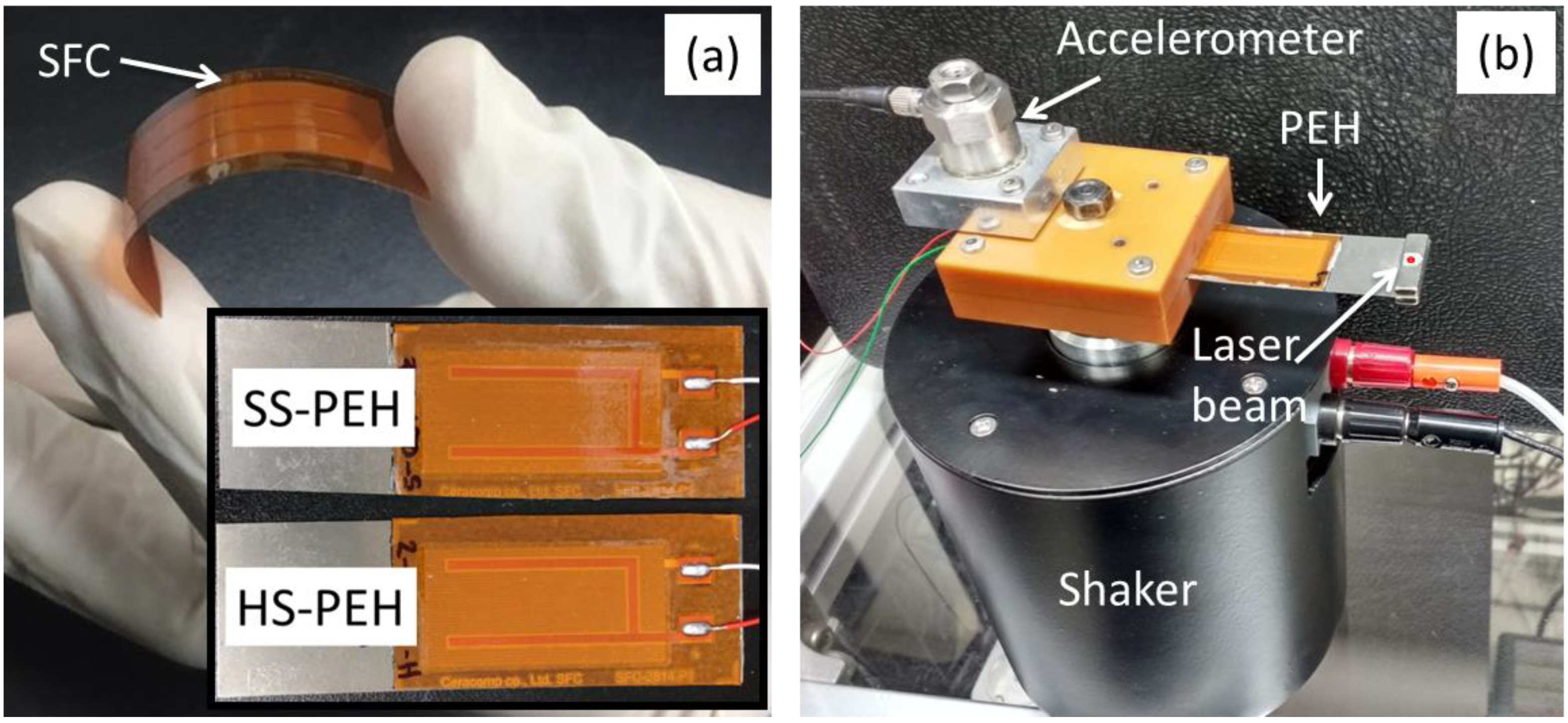

2. Experimental details

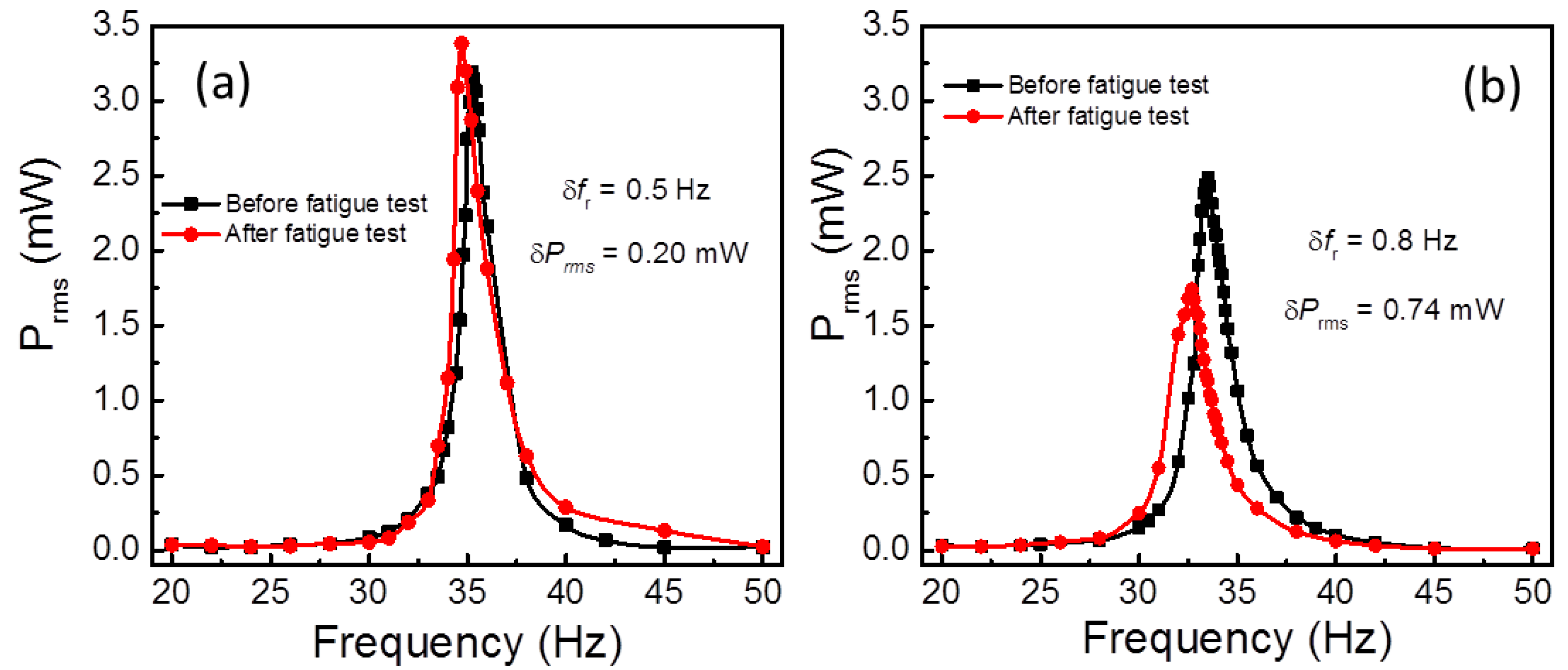

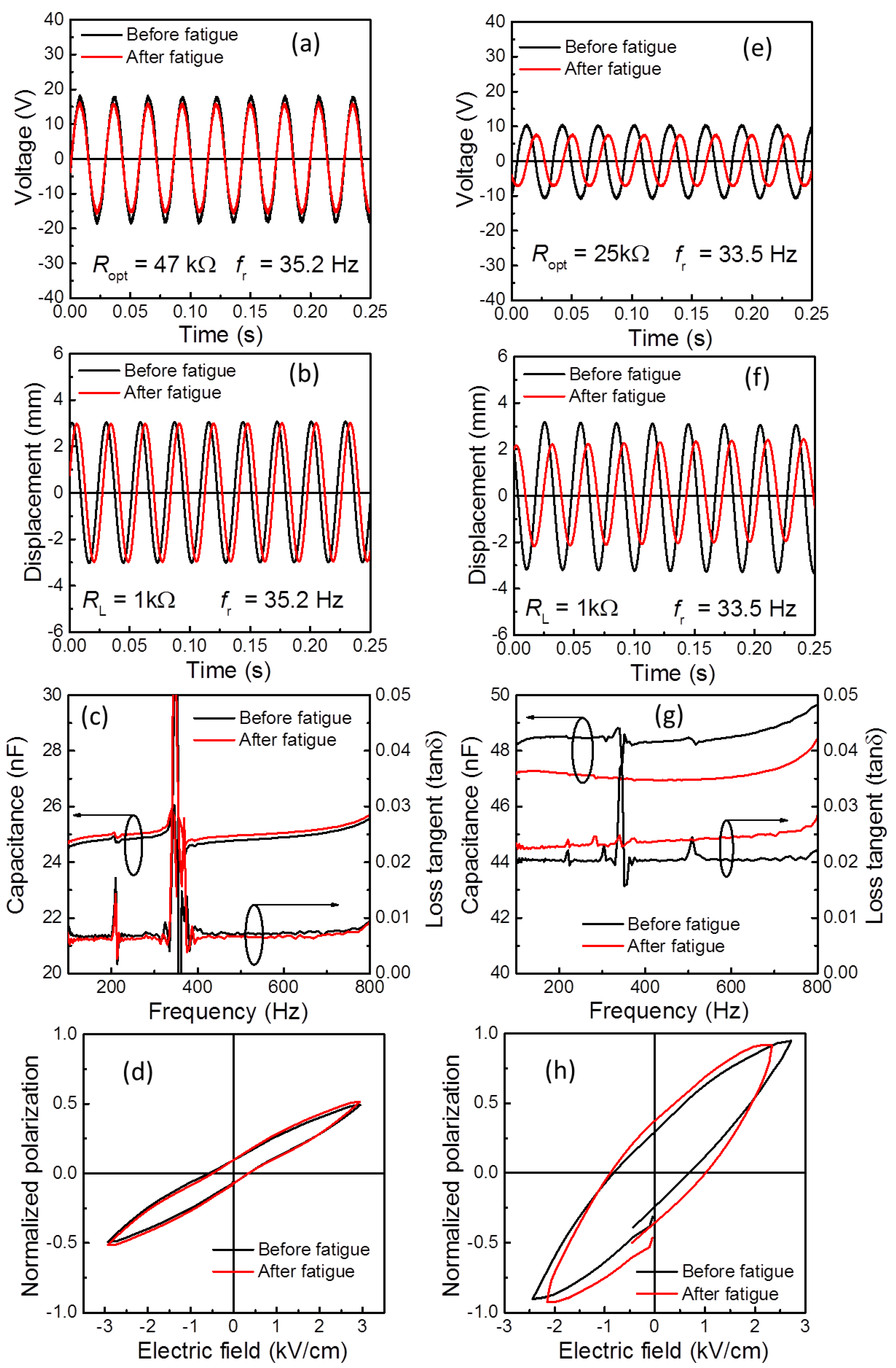

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Alper, E.; Inman, D.J. Piezoelectric Energy Harvesting; Wiley: Chichester, UK, 2011. [Google Scholar]

- Romero, E.; Warrington, R.O.; Neuman, M.R. Energy scavenging sources for biomedical sensors. Physiol. Meas. 2009, 30, R35. [Google Scholar] [CrossRef]

- Steven, R.A.; Henry, A.S. A review of power harvesting using piezoelectric materials (2003–2006). Smart Mater. Struct. 2007, 16, R1. [Google Scholar]

- Priya, S.; Song, H.-C.; Zhou, Y.; Varghese, R.; Chopra, A.; Kim, S.-G.; Kanno, I.; Wu, L.; Ha Dong, S.; Ryu, J.; et al. A Review on Piezoelectric Energy Harvesting: Materials, Methods, and Circuits. Energy Harvest. Syst. 2017, 4, 3–39. [Google Scholar] [CrossRef]

- Michael, W.S.; Matthew, B.; Ephrahim, G. Designing maximum power output into piezoelectric energy harvesters. Smart Mater. Struct. 2012, 21, 085008. [Google Scholar]

- Miso, K.; John, D.; Brian, L.W. Efficiency of piezoelectric mechanical vibration energy harvesting. Smart Mater. Struct. 2015, 24, 055006. [Google Scholar]

- Dhakar, L.; Liu, H.; Tay, F.E.H.; Lee, C. A new energy harvester design for high power output at low frequencies. Sens. Actuators A Phys. 2013, 199, 344–352. [Google Scholar] [CrossRef]

- Aboulfotoh, N.; Twiefel, J. On developing an optimal design procedure for a bimorph piezoelectric cantilever energy harvester under a predefined volume. Mech. Syst. Signal Process. 2018, 106, 1–12. [Google Scholar] [CrossRef]

- Wu, M.; Ou, Y.; Mao, H.; Li, Z.; Liu, R.; Ming, A.; Ou, W. Multi-resonant wideband energy harvester based on a folded asymmetric M-shaped cantilever. AIP Adv. 2015, 5, 077149. [Google Scholar] [CrossRef]

- Song, H.-C.; Kumar, P.; Sriramdas, R.; Lee, H.; Sharpes, N.; Kang, M.-G.; Maurya, D.; Sanghadasa, M.; Kang, H.-W.; Ryu, J.; et al. Broadband dual phase energy harvester: Vibration and magnetic field. Appl. Energy 2018, 225, 1132–1142. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, S.; Li, D.; Jin, L.; Wu, Q.; Liu, F. Frequency up-converted piezoelectric energy harvester for ultralow-frequency and ultrawide-frequency-range operation. Appl. Phys. Lett. 2018, 112, 163902. [Google Scholar] [CrossRef]

- Li, W.G.; He, S.; Yu, S. Improving Power Density of a Cantilever Piezoelectric Power Harvester Through a Curved L-Shaped Proof Mass. IEEE Trans. Ind. Electron. 2010, 57, 868–876. [Google Scholar] [CrossRef]

- Yeo, H.G.; Trolier-McKinstry, S. Effect of piezoelectric layer thickness and poling conditions on the performance of cantilever piezoelectric energy harvesters on Ni foils. Sens. Actuators A Phys. 2018, 273, 90–97. [Google Scholar] [CrossRef]

- Lee, M.-S.; Kim, C.-I.; Yun, J.-S.; Park, W.-I.; Hong, Y.-W.; Paik, J.-H.; Cho, J.-H.; Park, Y.-H.; Jeong, Y.-H. Comparison of Energy Harvesting Characteristics in Trapezoidal Piezoelectric Cantilever Generator with PZT Laminate Film by Longitudinal (3-3) Mode and Transverse (3-1) Mode. J. Korean Inst. Electr. Electron. Mater. Eng. 2017, 30, 768–775. [Google Scholar]

- Yeo, H.G.; Ma, X.; Rahn, C.; Trolier-McKinstry, S. Efficient Piezoelectric Energy Harvesters Utilizing (001) Textured Bimorph PZT Films on Flexible Metal Foils. Adv. Funct. Mater. 2016, 26, 5940–5946. [Google Scholar] [CrossRef]

- Lee, L.T.; Mohamed, M.A.; Yahya, I.; Kulothungan, J.; Muruganathan, M.; Mizuta, H. Comparison of piezoelectric energy harvesting performance using silicon and graphene cantilever beam. Microsyst. Technol. 2018, 24, 3783–3789. [Google Scholar] [CrossRef]

- Palosaari, J.; Leinonen, M.; Juuti, J.; Jantunen, H. The effects of substrate layer thickness on piezoelectric vibration energy harvesting with a bimorph type cantilever. Mech. Syst. Signal Process. 2018, 106, 114–118. [Google Scholar] [CrossRef]

- Du, S.; Jia, Y.; Chen, S.-T.; Zhao, C.; Sun, B.; Arroyo, E.; Seshia, A.A. A new electrode design method in piezoelectric vibration energy harvesters to maximize output power. Sens. Actuators A Phys. 2017, 263, 693–701. [Google Scholar] [CrossRef]

- Fu, H.; Chen, G.; Bai, N. Electrode Coverage Optimization for Piezoelectric Energy Harvesting from Tip Excitation. Sensors 2018, 18, 804. [Google Scholar] [CrossRef]

- Erturk, A.; Lee, H.-Y.; Inman, D.J. Investigation of Soft and Hard Ceramics and Single Crystals for Resonant and Off-Resonant Piezoelectric Energy Harvesting. In Proceedings of the ASME 2010 Conference on Smart Materials, Adaptive Structures and Intelligent Systems SMASIS2010, Philadelphia, PA, USA, 28 September–1 October 2010; The American Society of Mechanical Engineers: Philadelphia, PA, USA, 2010; pp. 589–596. [Google Scholar]

- Zhao, S.; Erturk, A. Deterministic and band-limited stochastic energy harvesting from uniaxial excitation of a multilayer piezoelectric stack. Sens. Actuators A Phys. 2014, 214, 58–65. [Google Scholar] [CrossRef]

- Shahab, S.; Zhao, S.; Erturk, A. Soft and Hard Piezoelectric Ceramics and Single Crystals for Random Vibration Energy Harvesting. Energy Technol. 2018, 6, 935–942. [Google Scholar] [CrossRef]

- Harne, R.L.; Wang, K.W. A review of the recent research on vibration energy harvesting via bistable systems. Smart Mater. Struct. 2013, 22, 023001. [Google Scholar] [CrossRef]

- Stanton, S.C.; McGehee, C.C.; Mann, B.P. Nonlinear dynamics for broadband energy harvesting: Investigation of a bistable piezoelectric inertial generator. Physica D 2010, 239, 640–653. [Google Scholar] [CrossRef]

- Kathpalia, B.; Tan, D.; Stern, I.; Erturk, A. An experimentally validated model for geometrically nonlinear plucking-based frequency up-conversion in energy harvesting. Smart Mater. Struct. 2017, 27, 015024. [Google Scholar] [CrossRef]

- Gu, L.; Livermore, C. Impact-driven, frequency up-converting coupled vibration energy harvesting device for low frequency operation. Smart Mater. Struct. 2011, 20, 045004. [Google Scholar] [CrossRef]

- Dauksevicius, R.; Gaidys, R.; Ostasevicius, V.; Lockhart, R.; Vásquez Quintero, A.; de Rooij, N.; Briand, D. Nonlinear piezoelectric vibration energy harvester with frequency-tuned impacting resonators for improving broadband performance at low frequencies. Smart Mater. Struct. 2019, 28, 025025. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.-H.; Kim, J. A review of piezoelectric energy harvesting based on vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Yaowen, Y.; Lihua, T.; Hongyun, L. Vibration energy harvesting using macro-fiber composites. Smart Mater. Struct. 2009, 18, 115025. [Google Scholar]

- Hyun Jeong, S.; Choi, Y.-T.; Wereley, N.M.; Purekar, A.S. Energy Harvesting Devices Using Macro-fiber Composite Materials. J. Intell. Mater. Syst. Struct. 2010, 21, 647–658. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, B.; Luo, Y.; Miao, W.; Xu, M. An Enhanced Piezoelectric Vibration Energy Harvesting System with Macro Fiber Composite. Shock Vib. 2015, 2015, 7. [Google Scholar] [CrossRef]

- Peddigari, M.; Lim, K.-W.; Kim, M.; Park, C.H.; Yoon, W.-H.; Hwang, G.-T.; Ryu, J. Effect of elastic modulus of cantilever beam on the performance of unimorph type piezoelectric energy harvester. APL Mater. 2018, 6, 121107. [Google Scholar] [CrossRef]

- Kim, G.-Y.; Peddigari, M.; Lim, K.-W.; Hwang, G.-T.; Yoon, W.-H.; Choi, H.; Lee, J.W.; Ryu, J. Effect of Thickness Ratio in Piezoelectric/Elastic Cantilever Structure on the Piezoelectric Energy Harvesting Performance. Electron. Mater. Lett. 2019, 15, 61–69. [Google Scholar] [CrossRef]

- Tan, D.; Yavarow, P.; Erturk, A. Resonant nonlinearities of piezoelectric macro-fiber composite cantilevers with interdigitated electrodes in energy harvesting. Nonlinear Dyn. 2018, 92, 1935–1945. [Google Scholar] [CrossRef]

- Annapureddy, V.; Na, S.-M.; Hwang, G.-T.; Kang, M.G.; Sriramdas, R.; Palneedi, H.; Yoon, W.-H.; Hahn, B.-D.; Kim, J.-W.; Ahn, C.-W.; et al. Exceeding milli-watt powering magneto-mechano-electric generator for standalone-powered electronics. Energy Environ. Sci. 2018, 11, 818–829. [Google Scholar] [CrossRef]

- Annapureddy, V.; Palneedi, H.; Yoon, W.-H.; Park, D.-S.; Choi, J.-J.; Hahn, B.-D.; Ahn, C.-W.; Kim, J.-W.; Jeong, D.-Y.; Ryu, J. A pT/√Hz sensitivity ac magnetic field sensor based on magnetoelectric composites using low-loss piezoelectric single crystals. Sens. Actuators A Phys. 2017, 260, 206–211. [Google Scholar] [CrossRef]

- Annapureddy, V.; Kim, M.; Palneedi, H.; Lee, H.-Y.; Choi, S.-Y.; Yoon, W.-H.; Park, D.-S.; Choi, J.-J.; Hahn, B.-D.; Ahn, C.-W.; et al. Low-Loss Piezoelectric Single-Crystal Fibers for Enhanced Magnetic Energy Harvesting with Magnetoelectric Composite. Adv. Energy Mater. 2016, 6, 1601244. [Google Scholar] [CrossRef]

- Annapureddy, V.; Lee, H.Y.; Yoon, W.-H.; Woo, H.-J.; Lee, J.-H.; Palneedi, H.; Kim, H.-J.; Choi, J.-J.; Jeong, D.-Y.; Yi, S.N.; et al. Enhanced magnetic energy harvesting properties of magneto-mechano-electric generator by tailored geometry. Appl. Phys. Lett. 2016, 109, 093901. [Google Scholar] [CrossRef]

- Wilkie, W.; High, J.; Bockman, J. Reliability Testing of NASA Piezocomposite Actuators. In Proceedings of the 8th international Conference on New Actuators, Bremen, Germany, 10–12 June 2002; NASA Langley Research Center: Hampton, VA, USA, 2002. [Google Scholar]

- Henslee, I.A.; Miller, D.A.; Tempero, T. Fatigue life characterization for piezoelectric macrofiber composites. Smart Mater. Struct. 2012, 21, 105037. [Google Scholar] [CrossRef]

- Upadrashta, D.; Yang, Y. Experimental investigation of performance reliability of macro fiber composite for piezoelectric energy harvesting applications. Sens. Actuators A Phys. 2016, 244, 223–232. [Google Scholar] [CrossRef]

- Avvari, P.V.; Yang, Y.; Soh, C.K. Long-term fatigue behavior of a cantilever piezoelectric energy harvester. J. Intell. Mater. Syst. Struct. 2016, 28, 1188–1210. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Ceracomp Co., Ltd. Available online: https://ceracomp.com (accessed on 4 February 2019).

- Zhao, J.; Zhang, Q.M. Effect of mechanical stress on the electromechanical performance of PZT and PMN-PT ceramics. In Proceedings of the ISAF ’96. Proceedings of the Tenth IEEE International Symposium on Applications of Ferroelectrics, East Brunswick, NJ, USA, 18–21 June 1996; Volume 2, pp. 971–974. [Google Scholar]

- Zhang, S.; Lee, S.-M.; Kim, D.-H.; Lee, H.-Y.; Shrout, T.R. Characterization of Mn-modified Pb(Mg1/3Nb2/3)O3–PbZrO3–PbTiO3 single crystals for high power broad bandwidth transducers. Appl. Phys. Lett. 2008, 93, 122908. [Google Scholar] [CrossRef]

- Uchino, K. Chapter 17-High-Power Piezoelectrics and Loss Mechanisms. In Advanced Piezoelectric Materials, 2nd ed.; Uchino, K., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 647–754. [Google Scholar]

| Parameter | Symbol | Hard-Type SFC (Mn-doped PMN-PZT) | Soft-Type SFC (W-doped PMN-PZT) | Units |

|---|---|---|---|---|

| Density | ρ | 7800 | 7900 | kg/m3 |

| Volume | (l × b × h) | 28 × 14 × 0.2 | 28 × 14 × 0.2 | mm3 |

| Dielectric constant | ε33 | 2250 | 3962 | |

| Dielectric loss | tanδ | 0.0018 | 0.005 | |

| Mechanical loss | tanθ | 0.003 | 0.010 | |

| Electromechanical coupling factor | k32 | 0.697 | 0.726 | |

| Piezoelectric charge constant | d32 | −850 | −1850 | 10−12 C/N |

| Elastic compliance | s22E | 45.9 | 110.04 | 10−12 m2/N |

| Parameter | PEH Type | |

|---|---|---|

| HS-PEH | SS-PEH | |

| ΔPrms (mW) (at initial fr) | −6.9% | −23.6% |

| ΔPmax (mW) (at final fr) | +0.20 | −0.74 |

| Δfr (Hz) | −0.5 | −0.8 |

| NVPD (mW/cm3·Hz·g2) | +7.9% | −27.5% |

| Δdv (mm) (at initial fr) | −0.04 | −1.20 |

| ΔC (nF) (at 100 Hz) | +0.7% | −2.1% |

| PS (μC/cm2) | +4.7% | −3.4% |

| Dielectric loss | −16.2% | +11.2% |

| Hysteresis loss | +4.6% | +20.6% |

| Mechanical loss (damping ratio) | −0.3% | +27.5% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peddigari, M.; Kim, G.-Y.; Park, C.H.; Min, Y.; Kim, J.-W.; Ahn, C.-W.; Choi, J.-J.; Hahn, B.-D.; Choi, J.-H.; Park, D.-S.; et al. A Comparison Study of Fatigue Behavior of Hard and Soft Piezoelectric Single Crystal Macro-Fiber Composites for Vibration Energy Harvesting. Sensors 2019, 19, 2196. https://doi.org/10.3390/s19092196

Peddigari M, Kim G-Y, Park CH, Min Y, Kim J-W, Ahn C-W, Choi J-J, Hahn B-D, Choi J-H, Park D-S, et al. A Comparison Study of Fatigue Behavior of Hard and Soft Piezoelectric Single Crystal Macro-Fiber Composites for Vibration Energy Harvesting. Sensors. 2019; 19(9):2196. https://doi.org/10.3390/s19092196

Chicago/Turabian StylePeddigari, Mahesh, Ga-Yeon Kim, Chan Hee Park, Yuho Min, Jong-Woo Kim, Cheol-Woo Ahn, Jong-Jin Choi, Byung-Dong Hahn, Joon-Hwan Choi, Dong-Soo Park, and et al. 2019. "A Comparison Study of Fatigue Behavior of Hard and Soft Piezoelectric Single Crystal Macro-Fiber Composites for Vibration Energy Harvesting" Sensors 19, no. 9: 2196. https://doi.org/10.3390/s19092196

APA StylePeddigari, M., Kim, G.-Y., Park, C. H., Min, Y., Kim, J.-W., Ahn, C.-W., Choi, J.-J., Hahn, B.-D., Choi, J.-H., Park, D.-S., Hong, J.-K., Yeom, J.-T., Park, K.-I., Jeong, D.-Y., Yoon, W.-H., Ryu, J., & Hwang, G.-T. (2019). A Comparison Study of Fatigue Behavior of Hard and Soft Piezoelectric Single Crystal Macro-Fiber Composites for Vibration Energy Harvesting. Sensors, 19(9), 2196. https://doi.org/10.3390/s19092196