Complementary Metamaterial Sensor for Nondestructive Evaluation of Dielectric Substrates

Abstract

1. Introduction

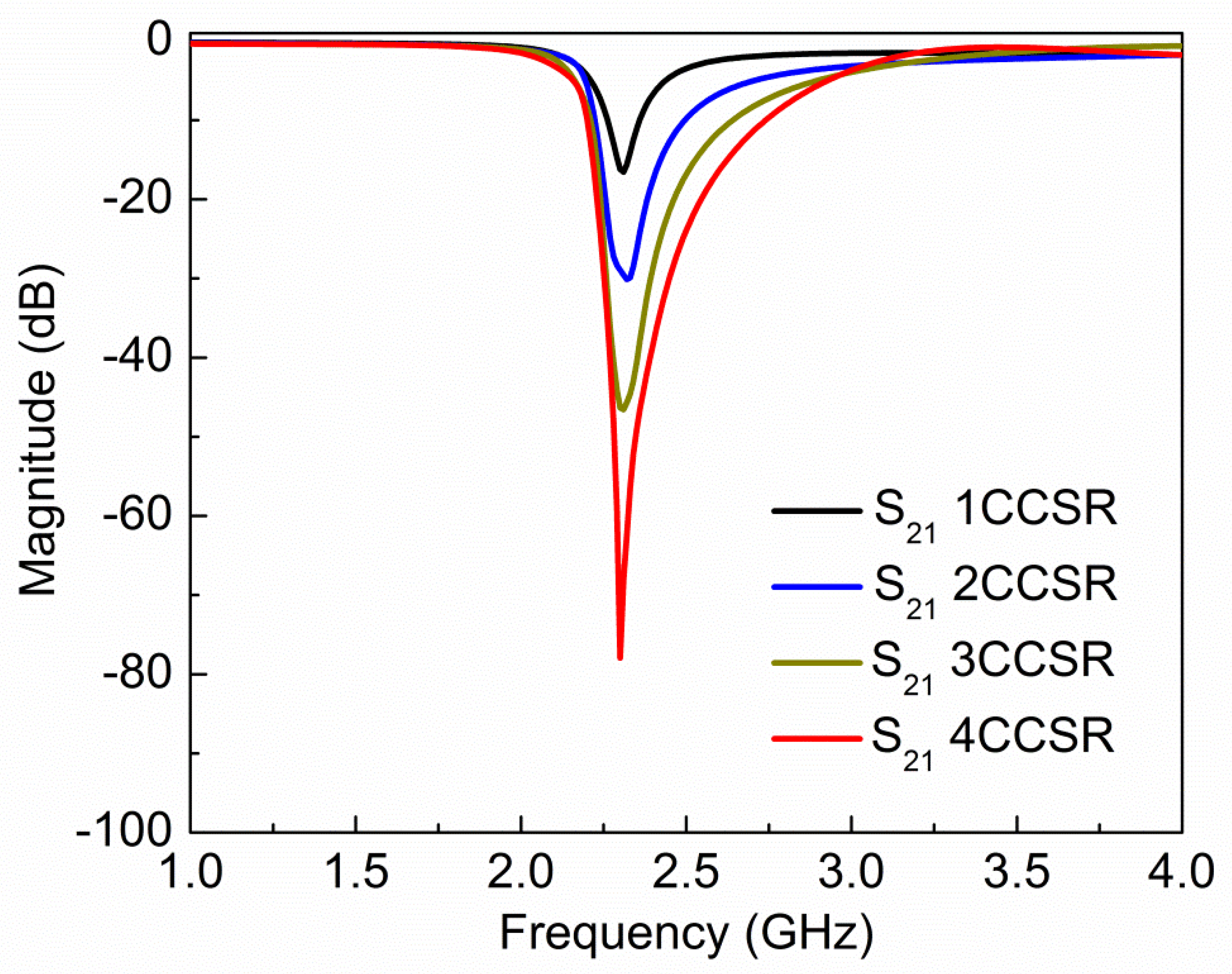

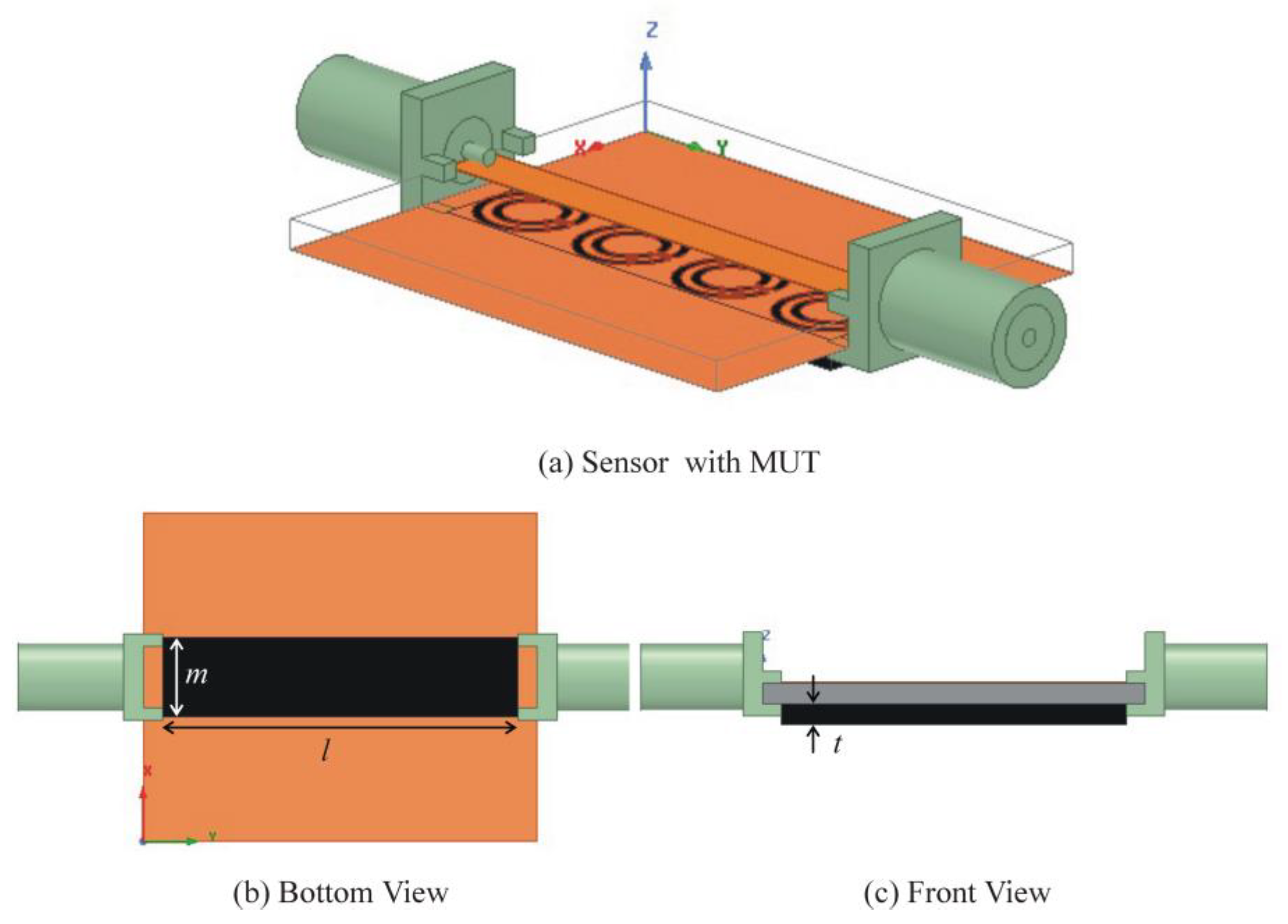

2. Sensor Design

3. Sensitivity Analysis

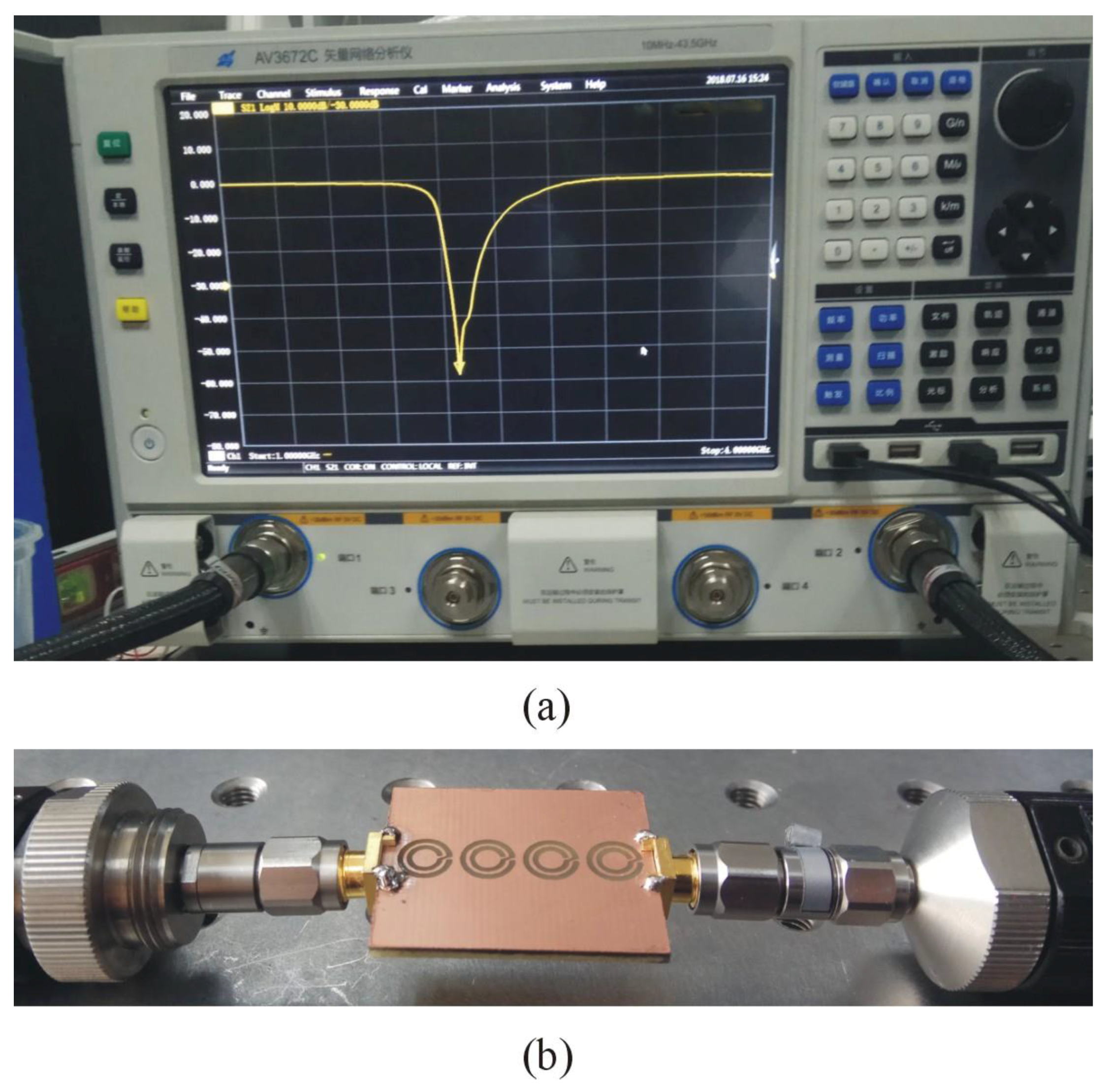

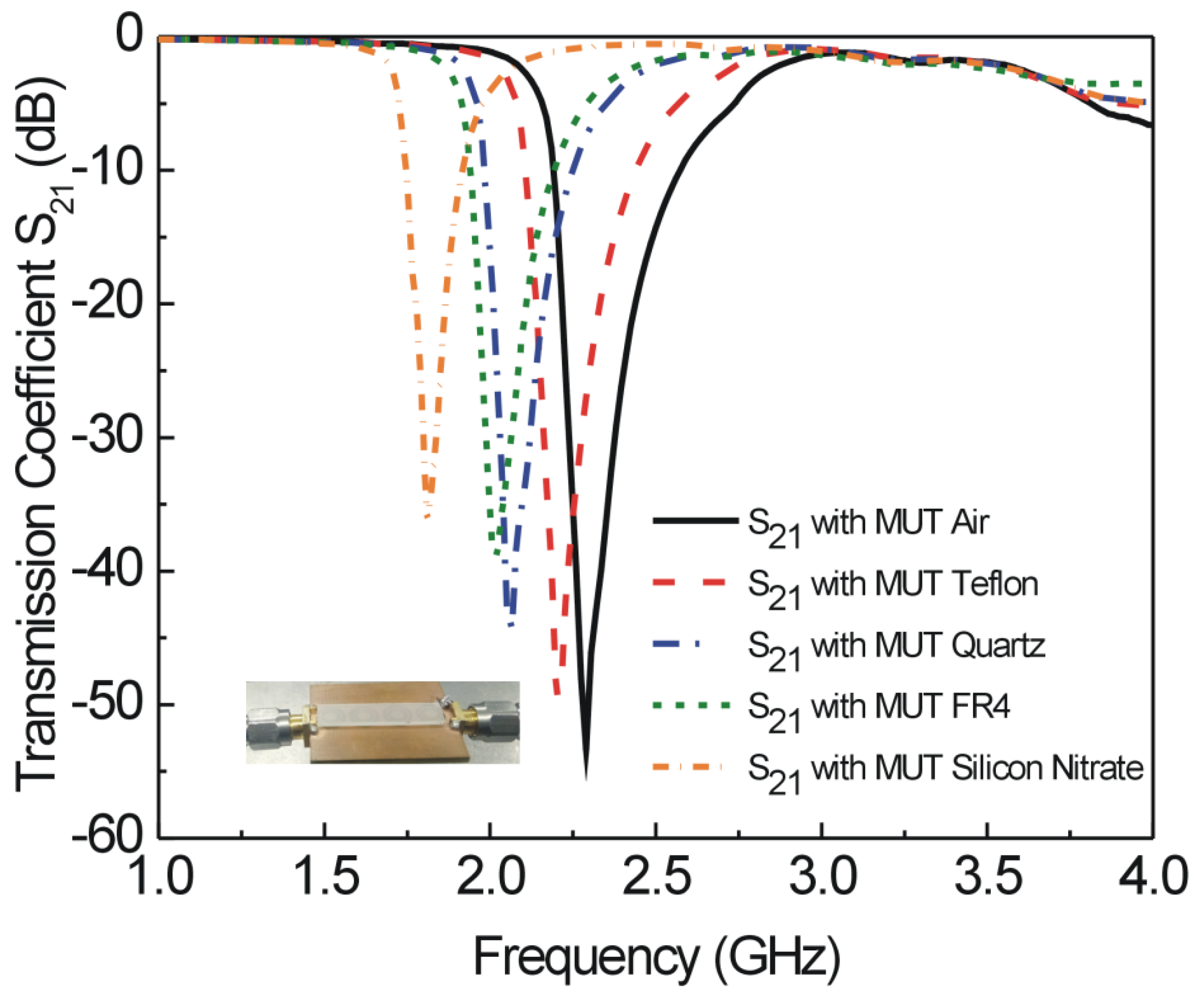

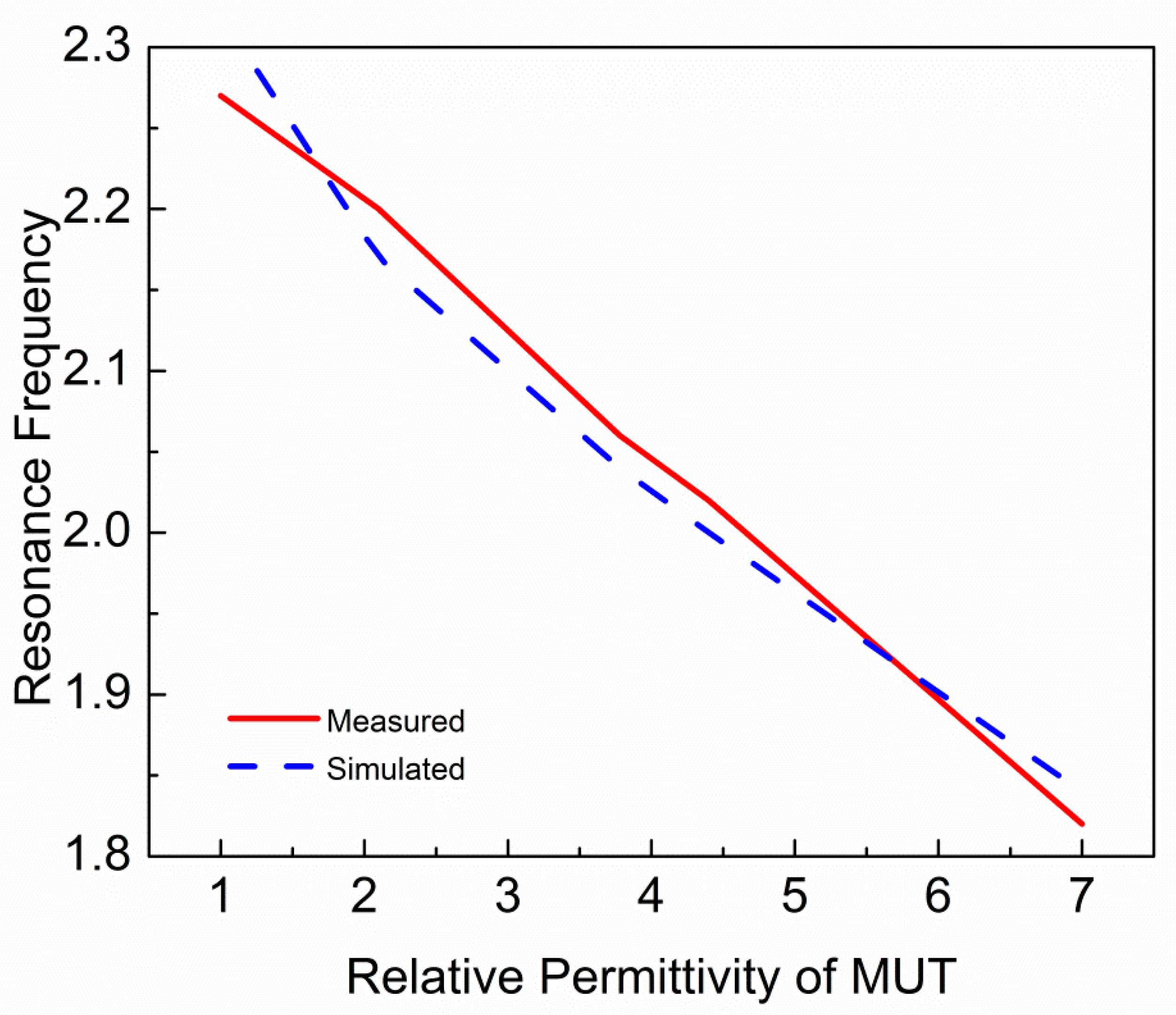

4. Fabrication and Measurement

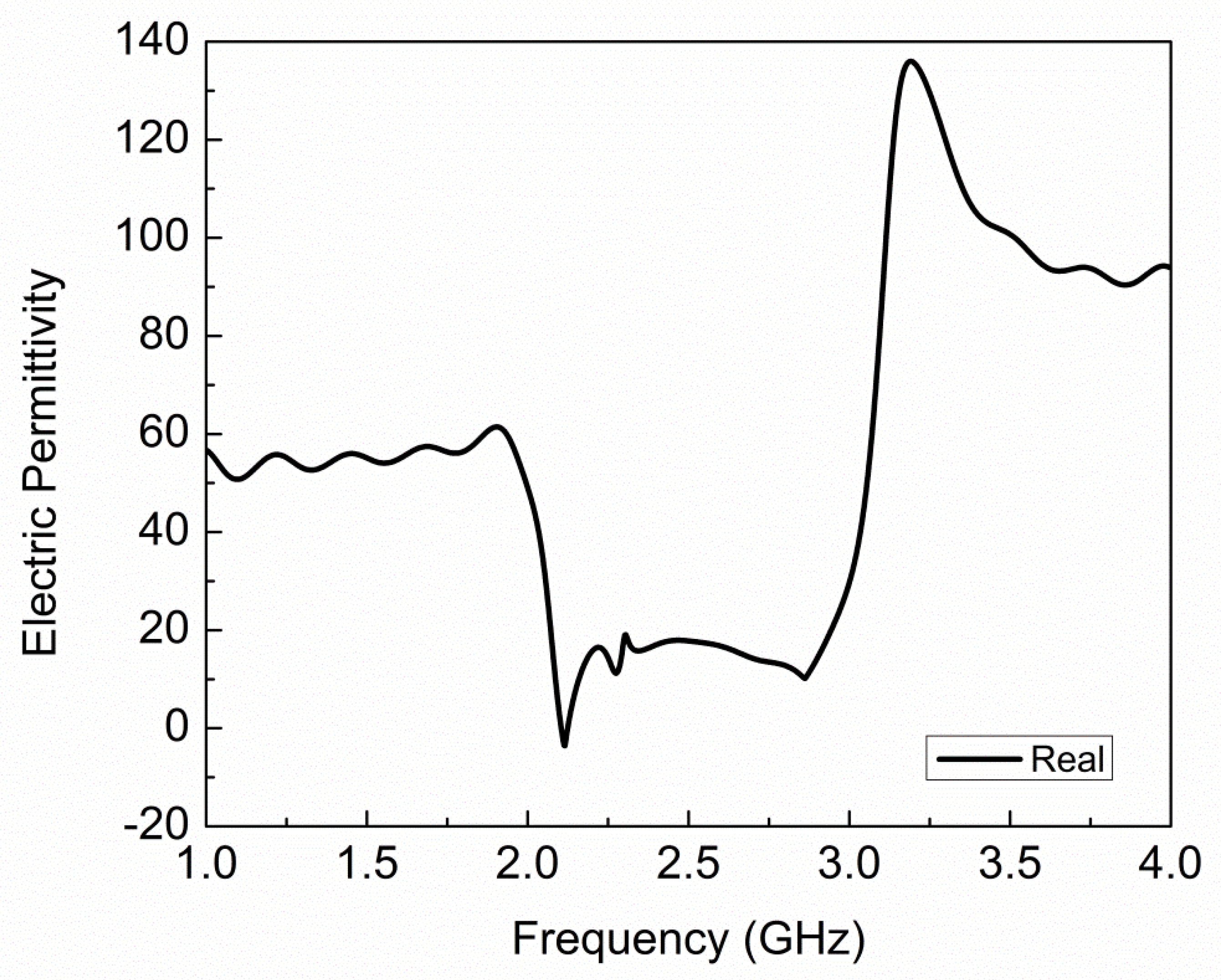

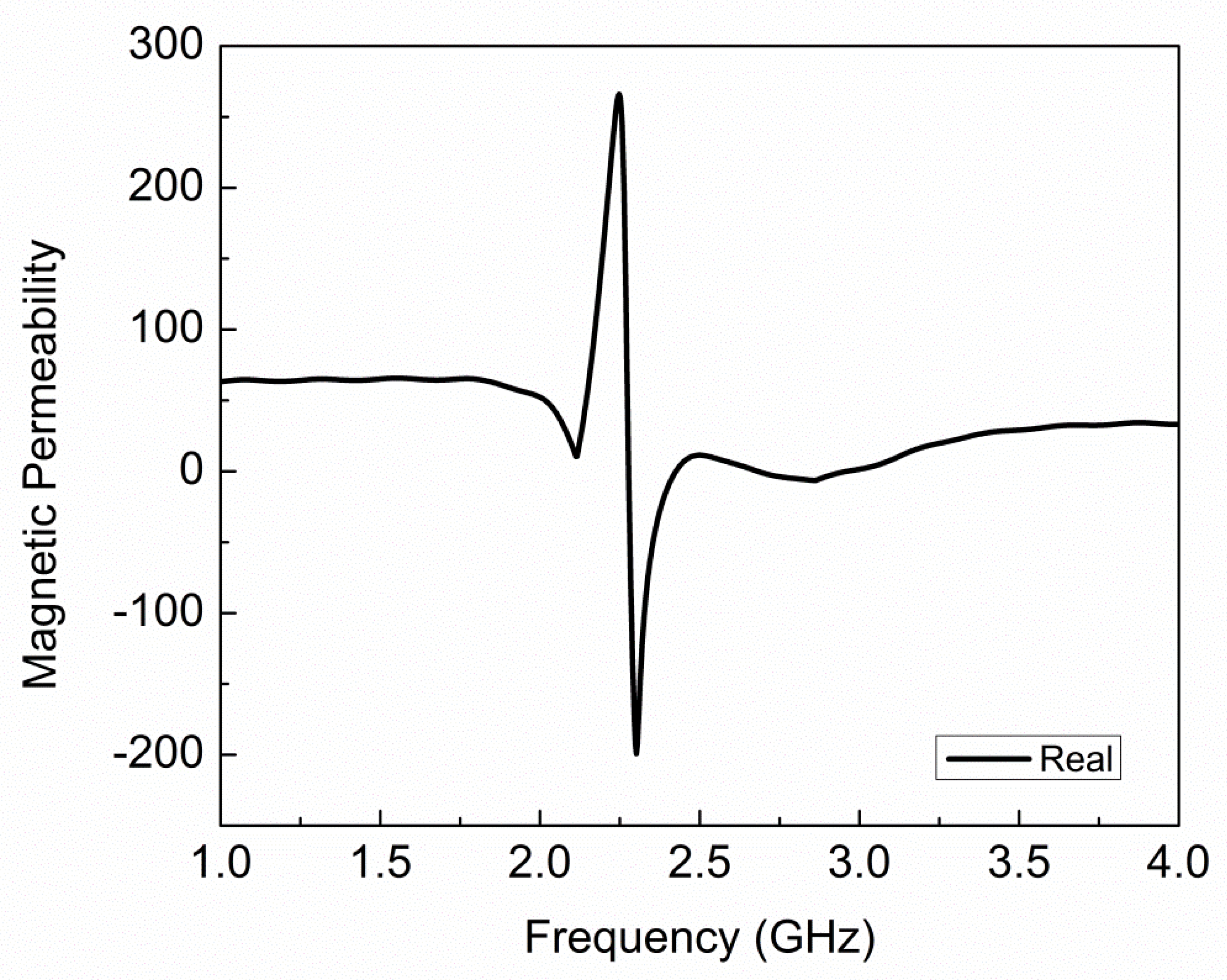

5. Formulation

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tiwari, N.K.; Singh, S.P.; Akhtar, M.J. Novel Improved sensitivity planar microwave probe for adulteration detection in edible oils. IEEE Microw. Wirel. Components Lett. 2019, 29, 164–166. [Google Scholar] [CrossRef]

- Kumari, R.; Patel, P.N.; Yadav, R. An ENG-inspired microwave sensor and functional technique for label-free detection of aspergillus Niger. IEEE Sens. J. 2018, 18, 3932–3939. [Google Scholar] [CrossRef]

- Trabelsi, S.; Nelson, S.O. Microwave sensing of quality attributes of agricultural and food products. IEEE Instrum. Meas. Mag. 2016, 19, 36–41. [Google Scholar] [CrossRef]

- Abdolrazzaghi, M.; Khan, S.; Daneshmand, M. A Dual-Mode Split-Ring Resonator to Eliminate Relative Humidity Impact. IEEE Microw. Wirel. Components Lett. 2018, 28, 939–941. [Google Scholar] [CrossRef]

- Chuma, E.L.; Iano, Y.; Fontgalland, G.; Bravo Roger, L.L. Microwave sensor for liquid dielectric characterization based on metamaterial complementary split ring resonator. IEEE Sens. J. 2018, 18, 9978–9983. [Google Scholar] [CrossRef]

- Falcone, F.; Lopetegi, T.; Baena, J. Effective negative epsilon stopband microstrip lines based on complementary split ring resonators. IEEE Microw. Wirel. Components Lett. 2004, 14, 280–282. [Google Scholar] [CrossRef]

- Pendry, J.B.; Holden, A.J.; Robbins, D.J.; Stewart, W.J. Magnetism from conductors and enhanced nonlinear phenomena. IEEE Microw. Wirel. Components Lett. 1999, 47, 2075–2084. [Google Scholar] [CrossRef]

- Baena, J.D.; Bonache, J.; Martín, F.; Sillero, R.M.; Falcone, F.; Lopetegi, T.; Laso, M.A.G.; García-García, J.; Gil, I.; Portillo, M.F.; et al. Equivalent-circuit models for split-ring resonators and complementary split-ring resonators coupled to planar transmission lines. IEEE Trans. Microw. Theory Tech. 2005, 53, 1451–1460. [Google Scholar] [CrossRef]

- Zarifi, M.H.; Deif, S.; Abdolrazzaghi, M.; Chen, B.; Ramsawak, D.; Amyotte, M.; Vahabisani, N.; Hashisho, Z.; Chen, W.; Daneshmand, M. A microwave ring resonator sensor for early detection of breaches in pipeline coatings. IEEE Trans. Ind. Electron. 2017, 65, 1626–1635. [Google Scholar] [CrossRef]

- Mohd Bahar, A.A.; Zakaria, Z.; Ab Rashid, S.R.; Isa, A.A.M.; Alahnomi, R.A. High-efficiency microwave planar resonator sensor based on bridge split ring topology. IEEE Microw. Wirel. Components Lett. 2017, 27, 545–547. [Google Scholar] [CrossRef]

- Puentes, M.; Maasch, M.; Schubler, M.; Jakoby, R. Frequency multiplexed 2-dimensional sensor array based on split-ring resonators for organic tissue analysis. IEEE Trans. Microw. Theory Tech. 2012, 60, 1720–1727. [Google Scholar] [CrossRef]

- Boybay, M.S.; Ramahi, O.M. Material characterization using complementary split-ring resonators. IEEE Trans. Instrum. Meas. 2012, 61, 3039–3046. [Google Scholar] [CrossRef]

- Haq, T.U.; Ruan, C.; Ullah, S.; Kosar, A. Reconfigurable Ultra Wide Band Notch Filter based on Complementary Metamaterial. In Proceedings of the 2018 IEEE Asia-Pacific Conference on Antennas and Propagation (APCAP), Auckland, New Zealand, 5–8 August 2018. [Google Scholar]

- Lee, C.S.; Yang, C.L. Thickness and permittivity measurement in multi-layered dielectric structures using complementary split-ring resonators. IEEE Sens. J. 2014, 14, 695–700. [Google Scholar] [CrossRef]

- Lee, C.S.; Yang, C.L. Complementary split-ring resonators for measuring dielectric constants and loss tangents. IEEE Microw. Wirel. Components Lett. 2014, 24, 563–565. [Google Scholar] [CrossRef]

- Albishi, A.M.; Ramahi, O.M. Highly sensitive microwaves sensors for fluid concentration measurements. IEEE Microw. Wirel. Components Lett. 2018, 28, 287–289. [Google Scholar] [CrossRef]

- Zhang, X.; Ruan, C.; Haq, T.; Chen, K. High-Sensitivity Microwave Sensor for Liquid Characterization Using a Complementary Circular Spiral Resonator. Sensors 2019, 19, 787. [Google Scholar] [CrossRef] [PubMed]

- HONG, J.-S. Microstrip filters for RF/Microwave Applications; Wiley & Sons: New York, NY, USA, 2011; ISBN 9780470408773. [Google Scholar]

- Chen, X.; Grzegorczyk, T.M.; Wu, B.I.; Pacheco, J.; Kong, J.A. Robust method to retrieve the constitutive effective parameters of metamaterials. Phys. Rev. E Stat. Physics Plasmas Fluids Relat. Interdiscip. Top. 2004, 70, 7. [Google Scholar] [CrossRef]

- Lim, S.; Kim, C.Y.; Hong, S. Simultaneous Measurement of Thickness and Permittivity by Means of the Resonant Frequency Fitting of a Microstrip Line Ring Resonator. IEEE Microw. Wirel. Components Lett. 2018, 28, 539–541. [Google Scholar] [CrossRef]

| Analysis Area | Size | 25 × 30 × 50 mm3 |

| Boundary Condition | Radiation | |

| Cells | Number | 14,201 |

| Shape | Tetrahedron | |

| Feed | Wave port (50 Ω) | |

| Solution Type | Driven Model | |

| Convergence condition determination | Maximum number of passes; 20 Maximum delta S; 0.02 | |

| Number of CCSR in Ground Plane | Resonance Frequency (GHz) | Notch Depth (dB) | B.W at 3dB (GHz) |

|---|---|---|---|

| One | 2.32 | −16.54 | 0.36 |

| Two | 2.32 | −30.10 | 0.88 |

| Three | 2.32 | −46.54 | 1.01 |

| Four | 2.32 | −77.93 | 0.96 |

| Material Under Test (MUT) | Relative Permittivity of MUT | Simulated Resonance Frequency (GHz) | Measured Resonance Frequency (GHz) | Difference Between Simulation and Measurement |

|---|---|---|---|---|

| Air | 1 | 2.32 | 2.29 | 0.05 |

| Teflon | 2.1 | 2.17 | 2.20 | 0.03 |

| Quartz Glass | 3.78 | 2.04 | 2.06 | 0.02 |

| FR4 Epoxy | 4.4 | 2.0 | 2.02 | 0.02 |

| Silicon Nitrate | 7 | 1.84 | 1.82 | 0.02 |

| Material Under Test (MUT) | Relative Permittivity (εr’) | Equation (15) Calculation or εr’ |

|---|---|---|

| Air | 1 | 1.01 |

| Teflon | 2.1 | 2.11 |

| Quartz Glass | 3.78 | 3.88 |

| FR4 Epoxy | 4.4 | 4.41 |

| Silicon Nitrate | 7 | 7.15 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haq, T.u.; Ruan, C.; Zhang, X.; Ullah, S. Complementary Metamaterial Sensor for Nondestructive Evaluation of Dielectric Substrates. Sensors 2019, 19, 2100. https://doi.org/10.3390/s19092100

Haq Tu, Ruan C, Zhang X, Ullah S. Complementary Metamaterial Sensor for Nondestructive Evaluation of Dielectric Substrates. Sensors. 2019; 19(9):2100. https://doi.org/10.3390/s19092100

Chicago/Turabian StyleHaq, Tanveer ul, Cunjun Ruan, Xingyun Zhang, and Shahid Ullah. 2019. "Complementary Metamaterial Sensor for Nondestructive Evaluation of Dielectric Substrates" Sensors 19, no. 9: 2100. https://doi.org/10.3390/s19092100

APA StyleHaq, T. u., Ruan, C., Zhang, X., & Ullah, S. (2019). Complementary Metamaterial Sensor for Nondestructive Evaluation of Dielectric Substrates. Sensors, 19(9), 2100. https://doi.org/10.3390/s19092100