A Resonant Pressure Microsensor with the Measurement Range of 1 MPa Based on Sensitivities Balanced Dual Resonators

Abstract

1. Introduction

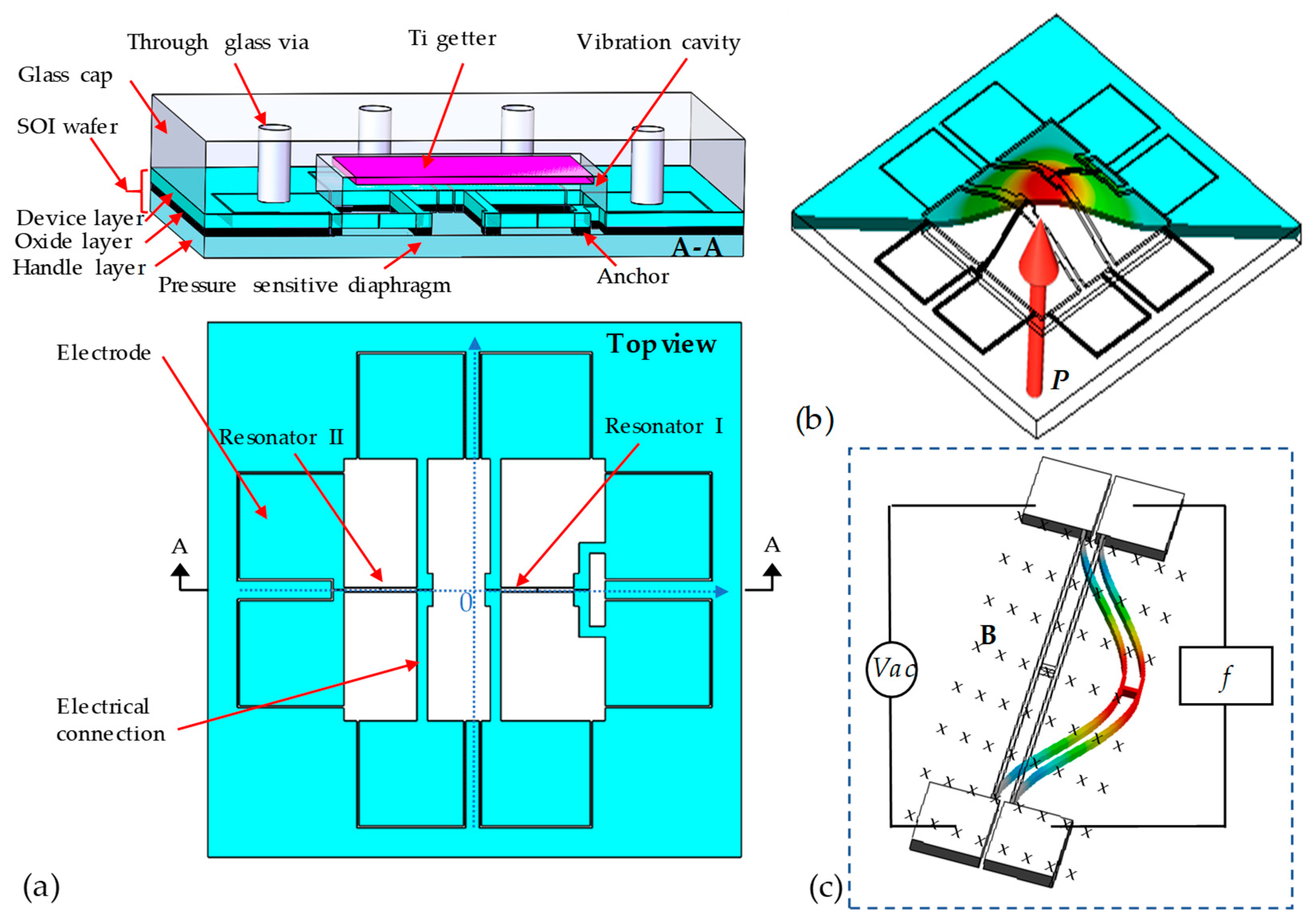

2. Design

2.1. Working Principle

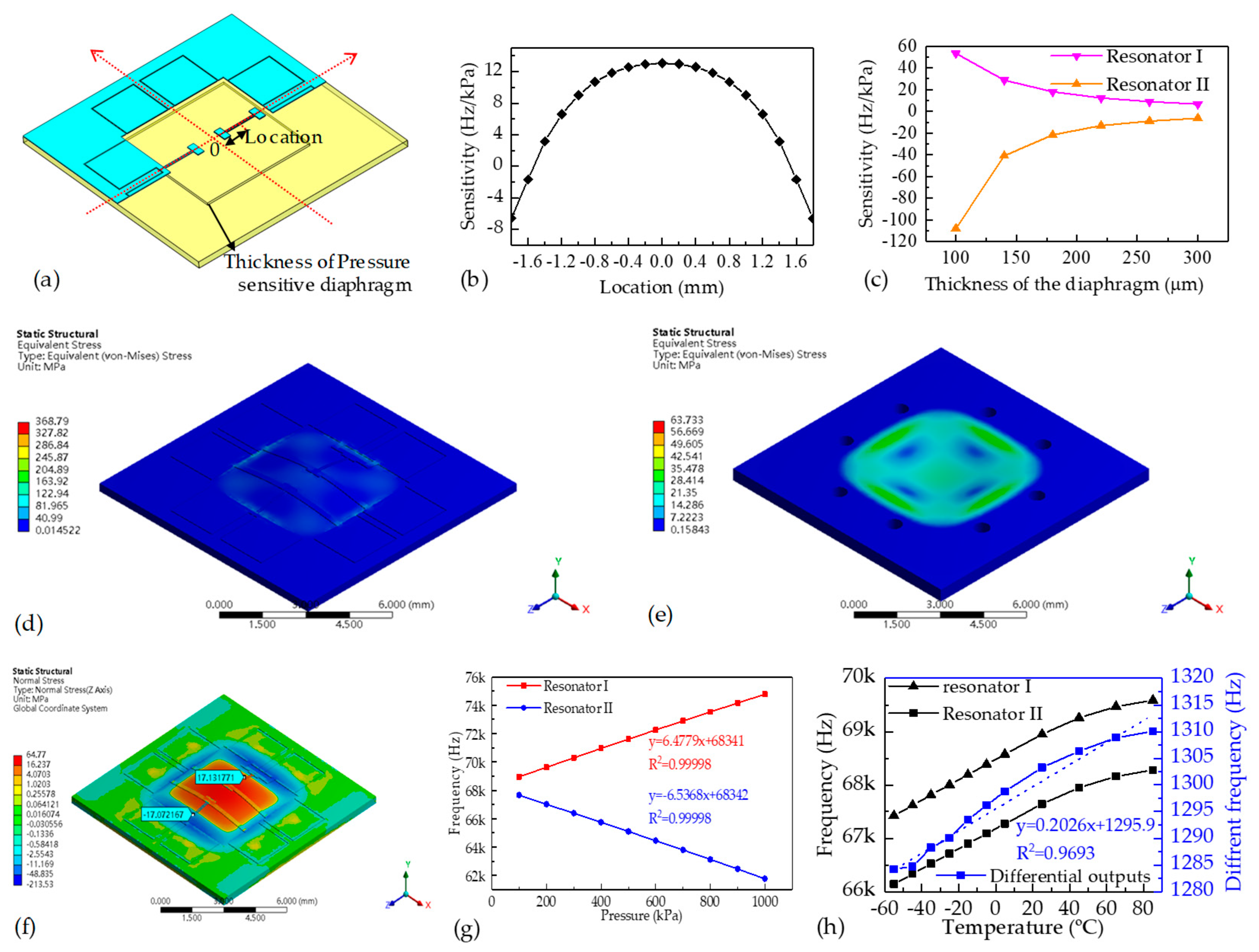

2.2. FEA Simulations

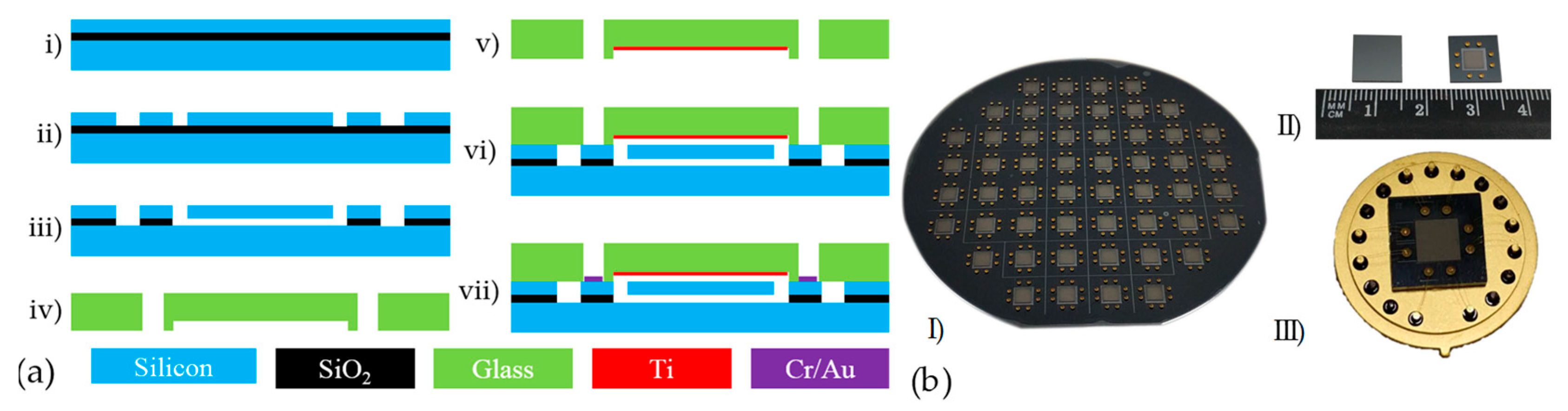

3. Fabrication

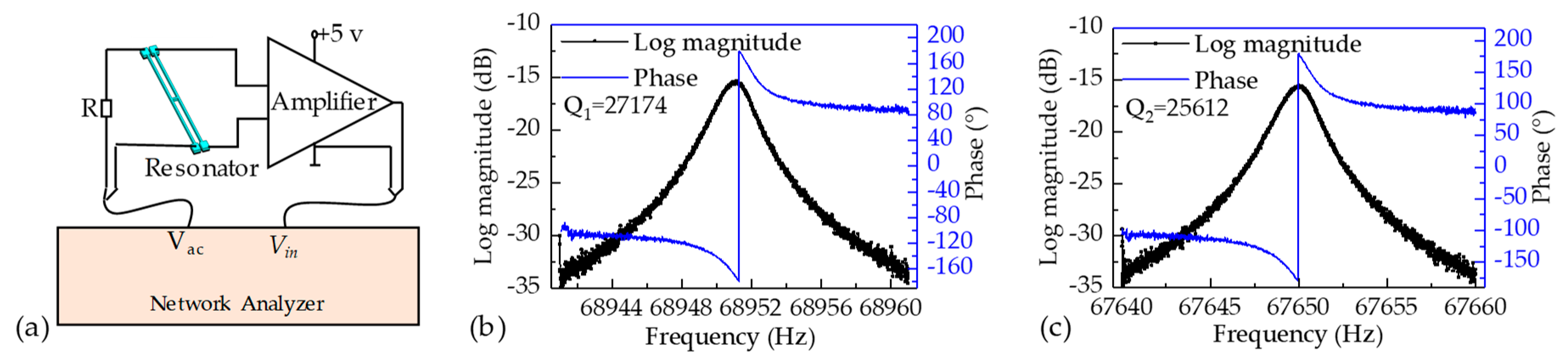

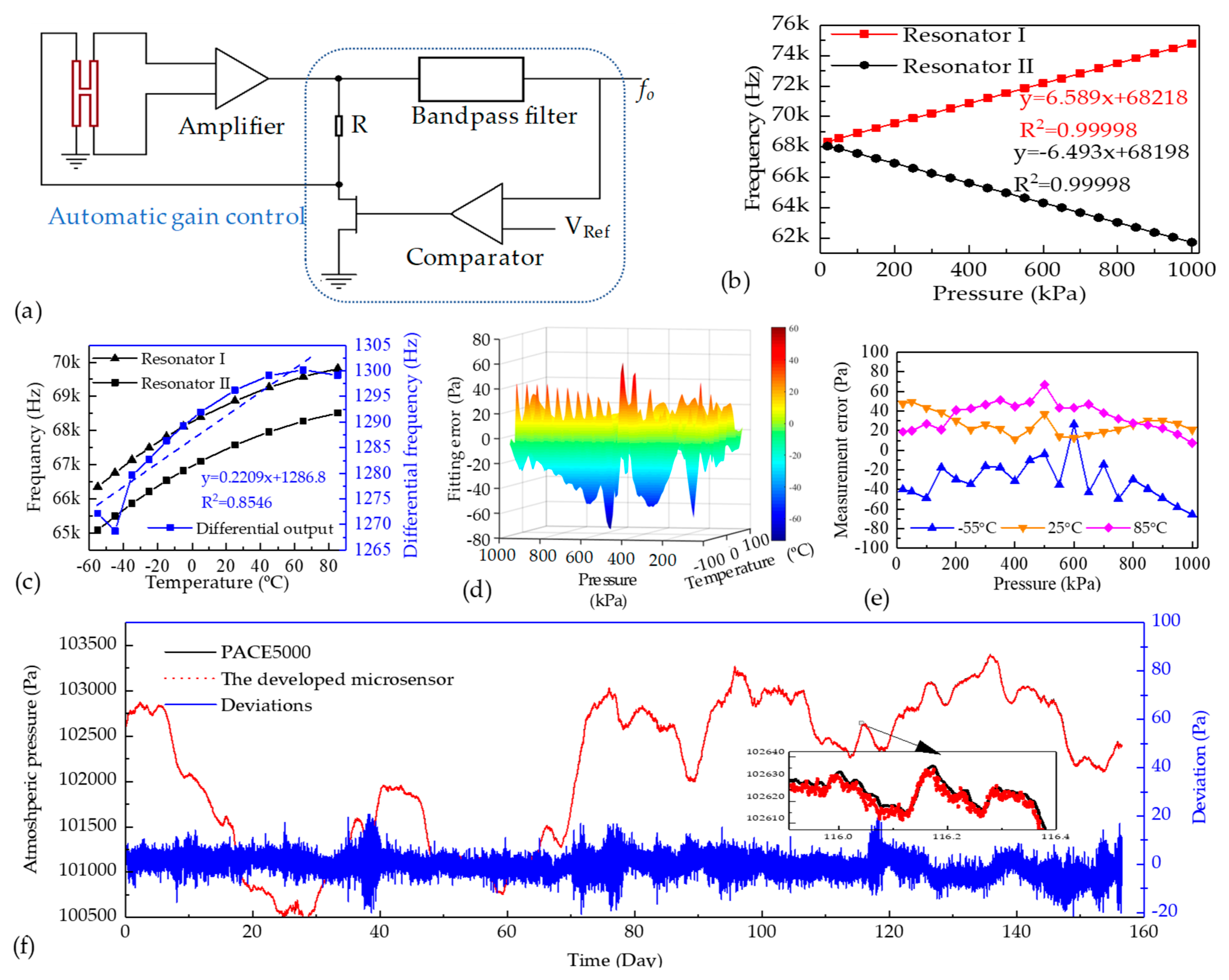

4. Experimental Characterizations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Eaton, W.P.; Smith, J.H. Micromachined pressure sensors: Review and recent developments. Smart Mater. Struct. 1997, 6, 530–539. [Google Scholar] [CrossRef]

- Beeby, S.P.; Ensel, G.; Kraft, M.; White, N.M. MEMS Mechanical Sensors; Artech House Inc.: London, UK, 2008; pp. 97–112. [Google Scholar]

- Wang, J.B.; Chen, D.Y.; Xie, B.; Chen, J.; Zhu, L.; Lu, Y.L. A micromachined silicon resonant pressure sensor. In Micro Electro Mechanical Systems; Huang, Q.A., Ed.; Springer: Singapore, 2017; pp. 1–34. [Google Scholar]

- Greenwood, J.; Wray, T. High accuracy pressure measurement with a silicon resonant sensor. Sens. Actuators A Phys. 1993, 37, 82–85. [Google Scholar] [CrossRef]

- Wygant, I.O.; Kupnik, M.; Khuri-Yakub, B.T. An analytical model for capacitive pressure transducers with circular geometry. J. Microelectromech. Syst. 2018, 27, 448–456. [Google Scholar] [CrossRef]

- Unigarro, E.; Bohorquez, J.C.; Achury, A.; Ramirez, F.; Sacristan, J.; Segura-Quijano, F. Differential capacitive pressure sensor design based on standard CMOS. Electron. Lett. 2017, 53, 741–742. [Google Scholar] [CrossRef]

- Mosser, V.; Suski, J.; Goss, J.; Obermeier, E. Piezoresistive pressure sensors based on polycrystalline silicon. Sens. Actuators A Phys. 1991, 28, 113–132. [Google Scholar] [CrossRef]

- Li, C.; Xie, J.B.; Cordovilla, F.; Zhou, J.Q.; Jagdheesh, R.; Ocana, J.L. Design, fabrication and characterization of an annularly grooved membrane combined with rood beam piezoresistive pressure sensor for low pressure measurements. Sens. Actuators A Phys. 2018, 17, 525–536. [Google Scholar] [CrossRef]

- Yang, F.; Kong, D.R.; Kong, L. Accurate measurement of high-frequency blast waves through dynamic compensation of miniature piezoelectric pressure sensors. Sens. Actuators A Phys. 2018, 280, 14–23. [Google Scholar] [CrossRef]

- Xu, F.J.; Ma, T.H. Modeling and Studying Acceleration-Induced Effects of Piezoelectric Pressure Sensors Using System Identification Theory. Sensors 2019, 19, 1052. [Google Scholar] [CrossRef]

- Shi, H.; Gong, J.Z.; Cook, P.R.; Arkwright, J.W.; Png, G.M.; Lambert, M.F.; Zecchin, A.C.; Simpson, A.R. Wave separation and pipeline condition assessment using in-pipe fibre optic pressure sensors. J. Hydroinform. 2019, 21, 371–379. [Google Scholar] [CrossRef]

- Li, W.W.; Liang, T.; Jia, P.G.; Lei, C.; Hong, Y.P.; Li, Y.W.; Yao, Z.; Liu, W.Y.; Xiong, J.J. Fiber-optic Fabry-Perot pressure sensor based on sapphire direct bonding for high-temperature applications. Appl. Opt. 2019, 58, 1662–1666. [Google Scholar] [CrossRef]

- Ikeda, K.; Kuwayama, H.; Kobayashi, T.; Watanabe, T.; Nishikawa, T.; Yoshida, T.; Harada, K. 3-dimensional micromachining of silicon pressure sensor integrating resonant strain-gauge on diaphragm. Sens. Actuators A Phys. 1990, 23, 1007–1010. [Google Scholar] [CrossRef]

- Harada, K.; Ikeda, K.; Kuwayama, H.; Murayama, H. Various applications of resonant pressure sensor chip based on 3-D micromachining. Sens. Actuators A Phys. 1999, 73, 261–266. [Google Scholar] [CrossRef]

- Christopher, J.W.; Greenwood, J.; Bertioli, M.M. A high accuracy resonant pressure sensor by fusion bonding and trench etching. Sens. Actuators A Phys. 1999, 76, 298–304. [Google Scholar]

- Kinnell, P.K.; Craddock, R. Advances in Silicon Resonant Pressure Transducers. Procedia Chem. 2009, 1, 104–107. [Google Scholar] [CrossRef]

- Greenwood, J.C. Etched silicon vibrating sensor. J. Phys. E Sci. Instrum. 1984, 17, 650–652. [Google Scholar] [CrossRef]

- Petersen, K.; Pourahmadi, F.; Brown, J.; Parsons, P.; Skinner, M.; Tudor, M. Resonant Beam Pressure Sensor Fabricated with Silicon Fusion Bonding. In Proceedings of the Transducers ’91, International Conference on Solid State Sensors and Actuators, San Francisco, CA, USA, 24–27 June 1991; pp. 664–667. [Google Scholar]

- Welham, C.J.; Gardner, J.W.; Greenwood, J. A laterally driven micromachined resonant pressure sensor. Sens. Actuators A Phys. 1996, 52, 86–91. [Google Scholar] [CrossRef]

- Sun, X.D.; Yuan, W.Z.; Qiao, D.Y.; Sun, M.; Ren, S. Design and Analysis of a New Tuning Fork Structure for Resonant Pressure Sensor. Micromachines 2016, 7, 148. [Google Scholar] [CrossRef]

- Du, X.H.; Liu, Y.F.; Li, A.L.; Zhou, Z.; Sun, D.H.; Wang, L.Y. Laterally Driven Resonant pressure sensor with etched silicon dual diaphragms and combined beams. Sensors 2016, 16, 158. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Chen, D.Y.; Wang, J.B.; Li, Y.N.; Chen, J. A High-Q Resonant Pressure Microsensor with Through-Glass Electrical Interconnections Based on Wafer-Level MEMS Vacuum Packaging. Sensors 2014, 14, 24244–24257. [Google Scholar] [CrossRef]

- Xie, B.; Xing, Y.H.; Wang, Y.S.; Chen, J.; Chen, D.Y.; Wang, J.B. A Lateral Differential Resonant Pressure Microsensor Based on SOI-Glass Wafer-Level Vacuum Packaging. Sensors 2015, 15, 24257–24268. [Google Scholar] [CrossRef]

- Shi, X.Q.; Lu, Y.L.; Xie, B.; Li, Y.D.; Wang, J.B.; Chen, D.Y.; Chen, J. A resonant pressure microsensor based on double-ended tuning fork and electrostatic excitation/piezoresistive detection. Sensors 2018, 18, 2494. [Google Scholar] [CrossRef]

- Li, Y.N.; Wang, J.B.; Luo, Z.Y.; Chen, D.Y.; Chen, J. A Resonant Pressure Microsensor Capable of Self-Temperature Compensation. Sensors 2015, 15, 10048–10058. [Google Scholar] [CrossRef]

| Reference | Q-Factor | Pressure Range | Temperature Range | Temperature Sensitivity | Accuracy |

|---|---|---|---|---|---|

| Peterson [18] | >100,000 | 10~130 kPa | −40~125 °C | ~2 Hz/°C | 0.01% FS |

| Welham [19] | 50 in air | 0~350 kPa | - | - | - |

| Sun [20] | 10,000 | 20~280 kPa | −40~80 °C | 2 Hz/°C | 0.05% FS |

| Du [21] | 20,000 | 30~190 kPa | 30~75 °C | - | 0.03% FS |

| Luo [22] | 22,000 | 50~100 kPa | −40~70 °C | −0.33 Hz/°C | 0.02% FS |

| Xie [23] | 11,000 | 50~110 kPa | −40~70 °C | - | 0.02% FS |

| Shi [24] | 10,000 | 10~150 kPa | −35~85 °C | −0.30 Hz/°C | 0.01% FS |

| This sensor | >25,000 | 20~1000 kPa | −55~85 °C | +0.22 Hz/°C | 0.01% FS |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Yan, P.; Xiang, C.; Chen, D.; Wang, J.; Xie, B.; Chen, J. A Resonant Pressure Microsensor with the Measurement Range of 1 MPa Based on Sensitivities Balanced Dual Resonators. Sensors 2019, 19, 2272. https://doi.org/10.3390/s19102272

Lu Y, Yan P, Xiang C, Chen D, Wang J, Xie B, Chen J. A Resonant Pressure Microsensor with the Measurement Range of 1 MPa Based on Sensitivities Balanced Dual Resonators. Sensors. 2019; 19(10):2272. https://doi.org/10.3390/s19102272

Chicago/Turabian StyleLu, Yulan, Pengcheng Yan, Chao Xiang, Deyong Chen, Junbo Wang, Bo Xie, and Jian Chen. 2019. "A Resonant Pressure Microsensor with the Measurement Range of 1 MPa Based on Sensitivities Balanced Dual Resonators" Sensors 19, no. 10: 2272. https://doi.org/10.3390/s19102272

APA StyleLu, Y., Yan, P., Xiang, C., Chen, D., Wang, J., Xie, B., & Chen, J. (2019). A Resonant Pressure Microsensor with the Measurement Range of 1 MPa Based on Sensitivities Balanced Dual Resonators. Sensors, 19(10), 2272. https://doi.org/10.3390/s19102272