A Novel Tangential Electric-Field Sensor Based on Electric Dipole and Integrated Balun for the Near-Field Measurement Covering GPS Band

Abstract

:1. Introduction

2. Theory and Methods

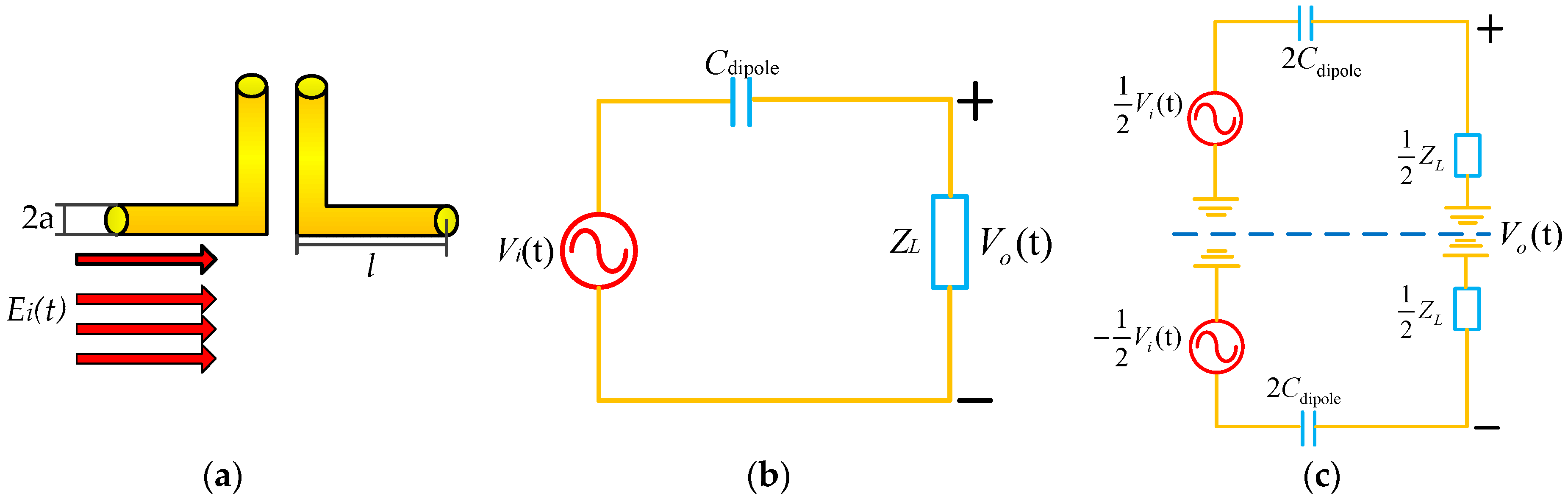

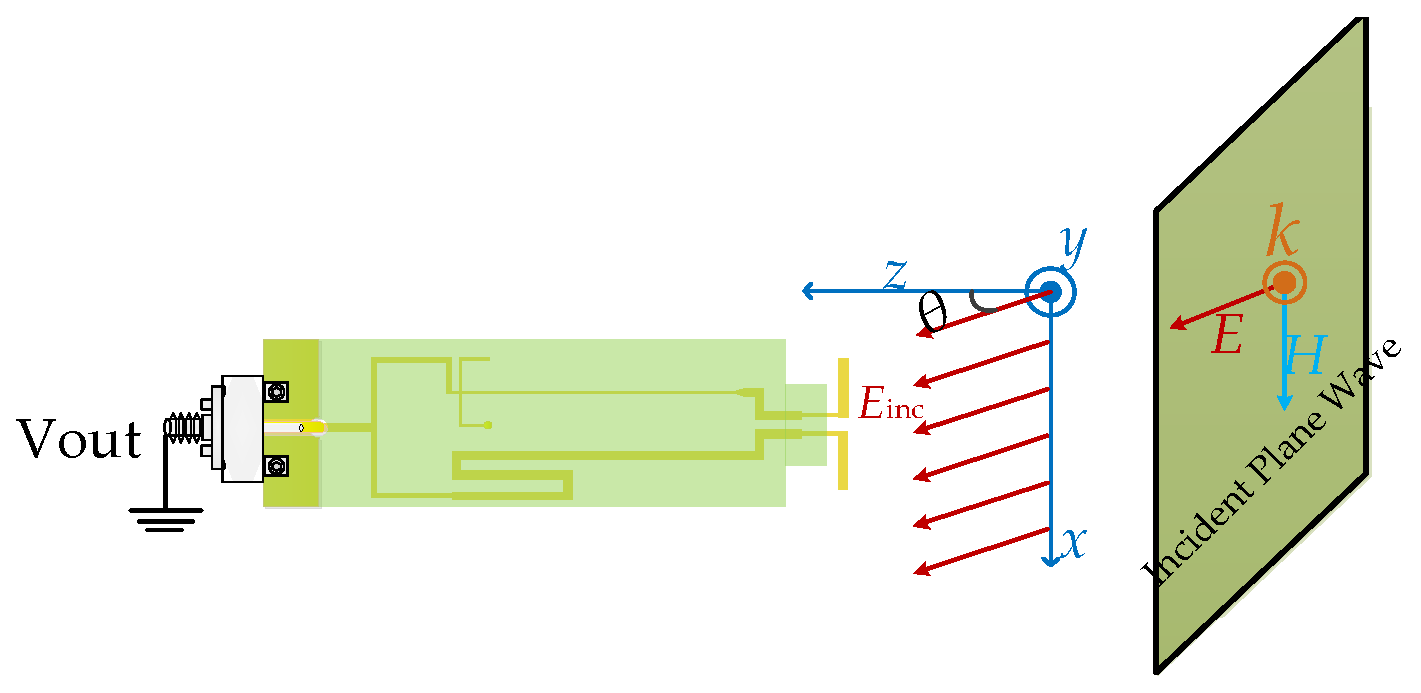

2.1. Reception Mechanism of the Sensor

2.2. Design of the Tangential Electric-Dipole Sensor

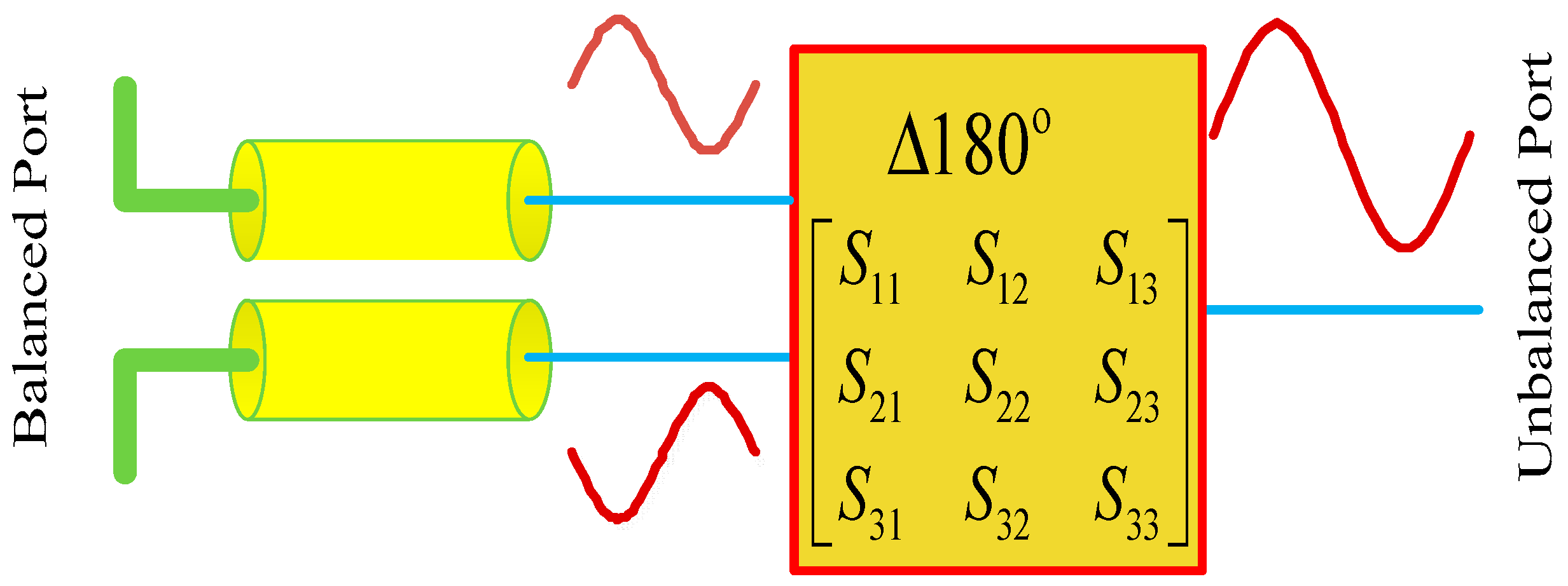

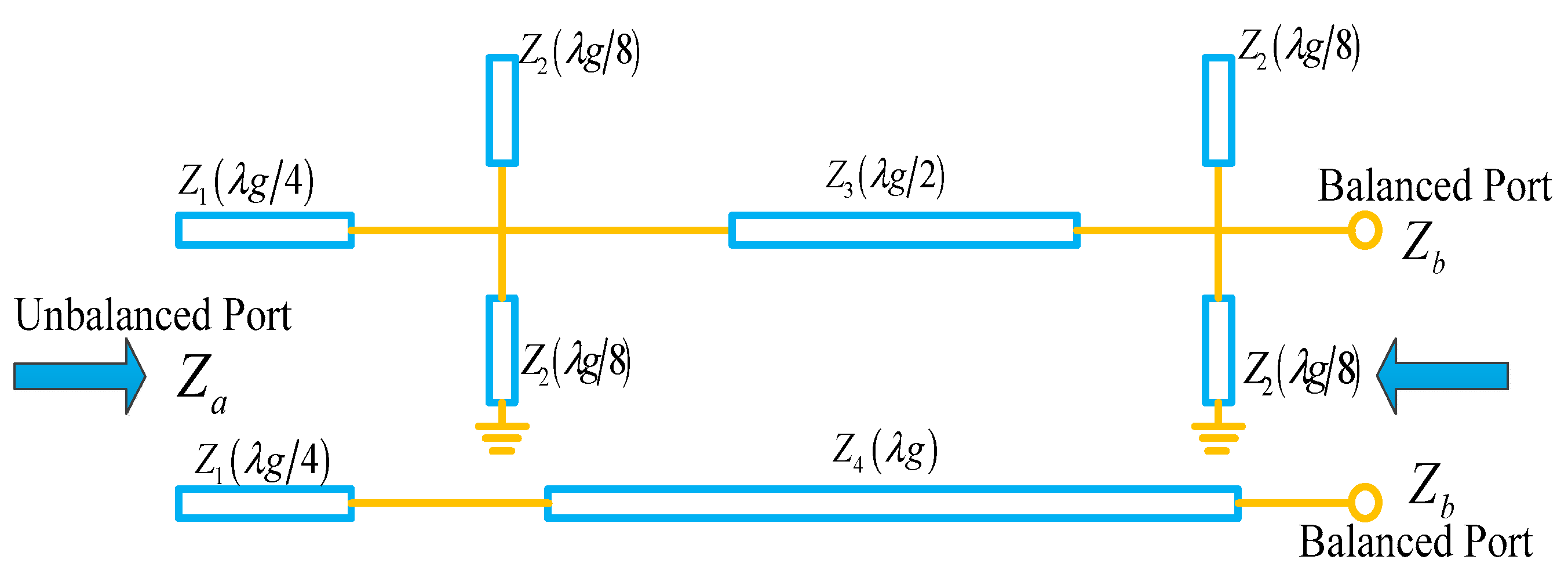

2.2.1. Integrated Balun

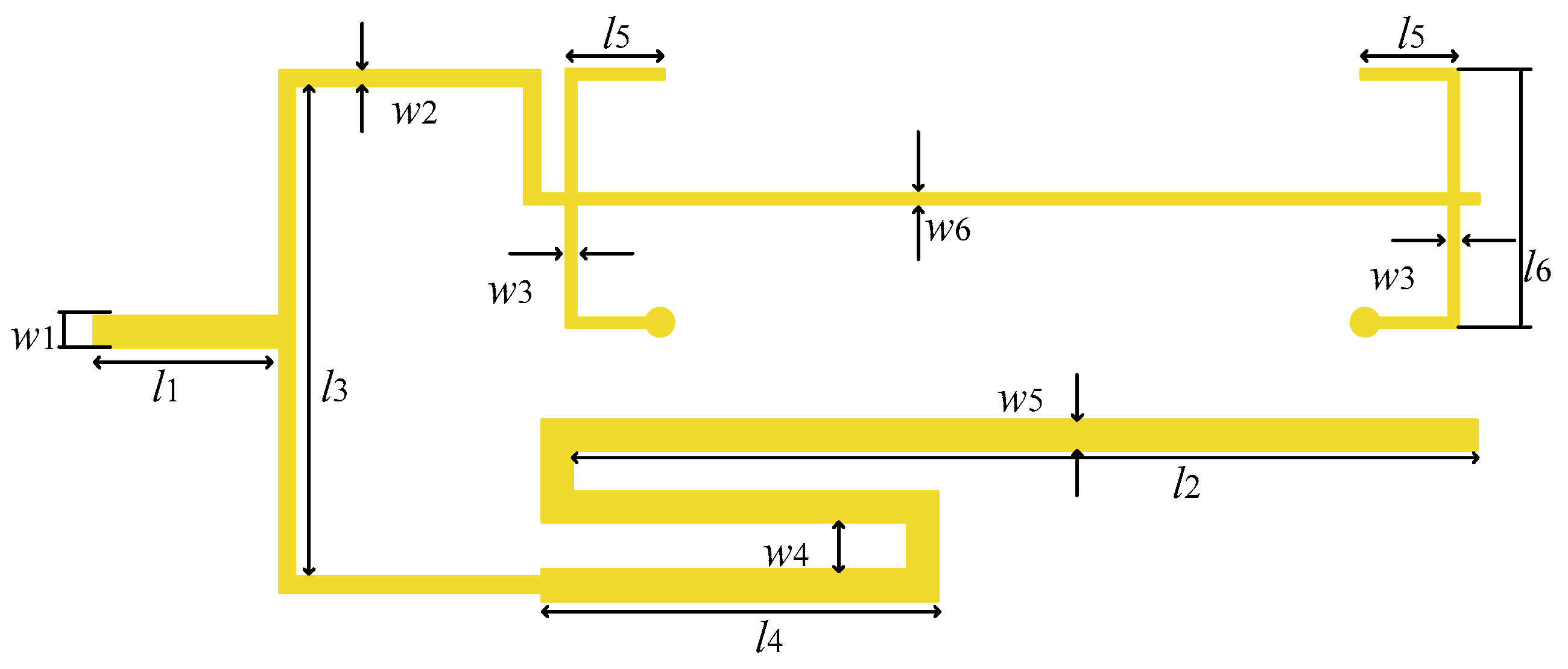

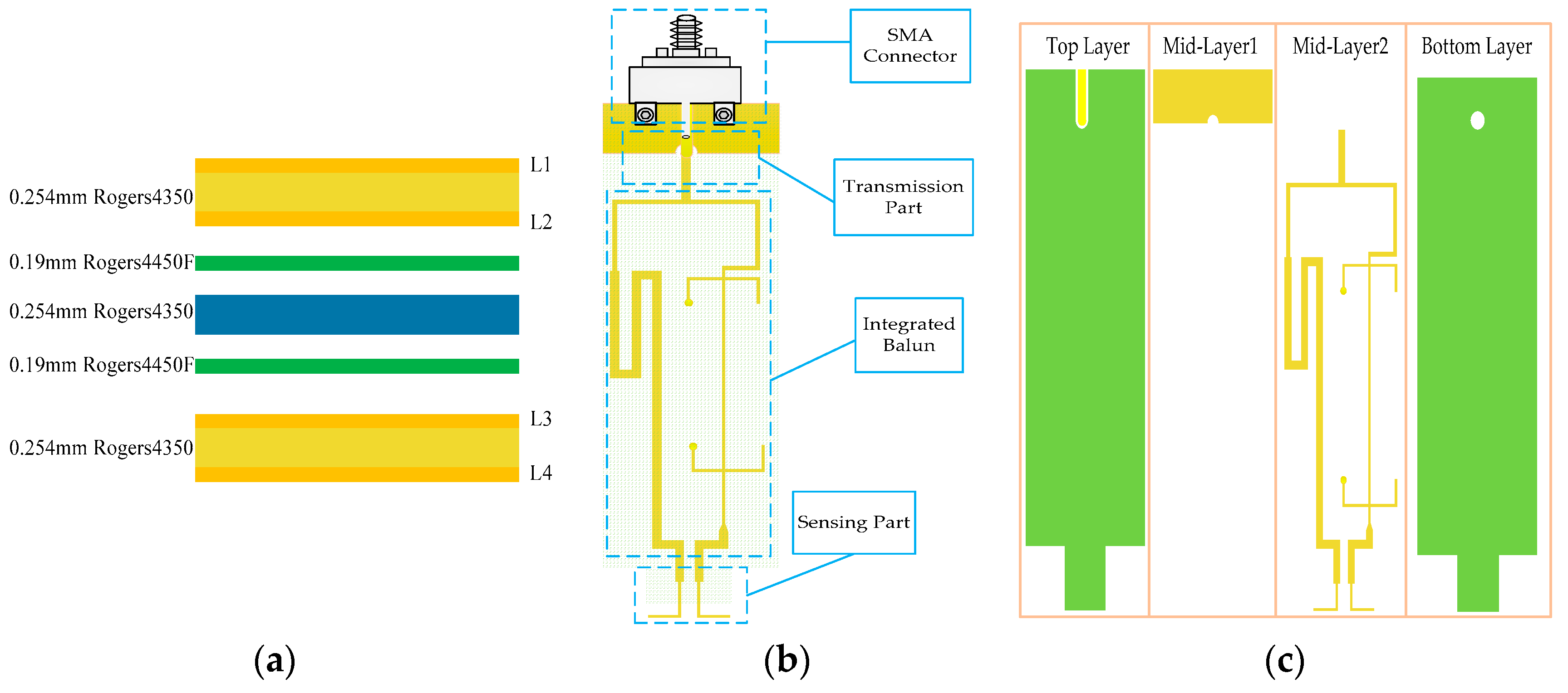

2.2.2. Structure of the Sensor

3. Results and Discussions

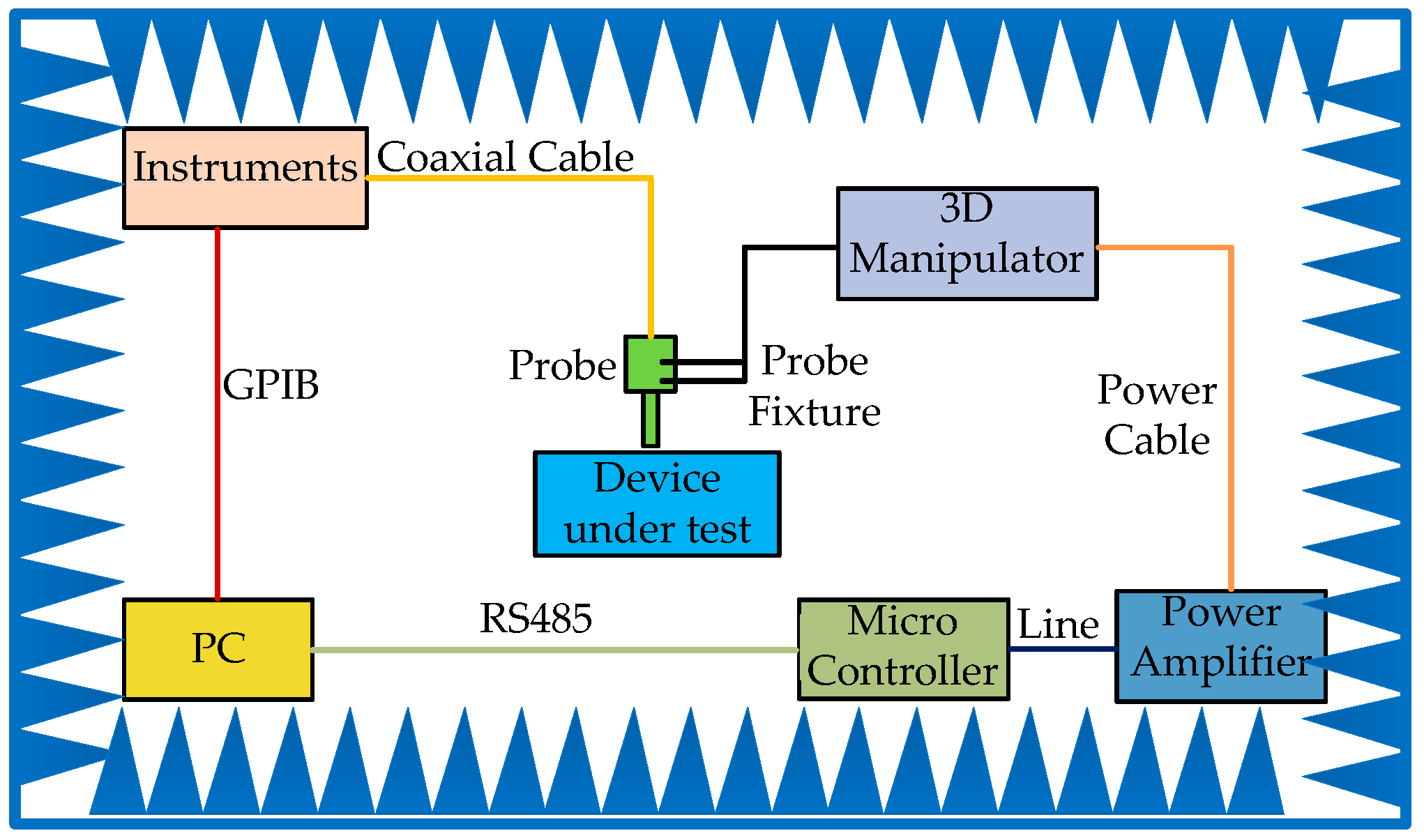

3.1. Measurement System

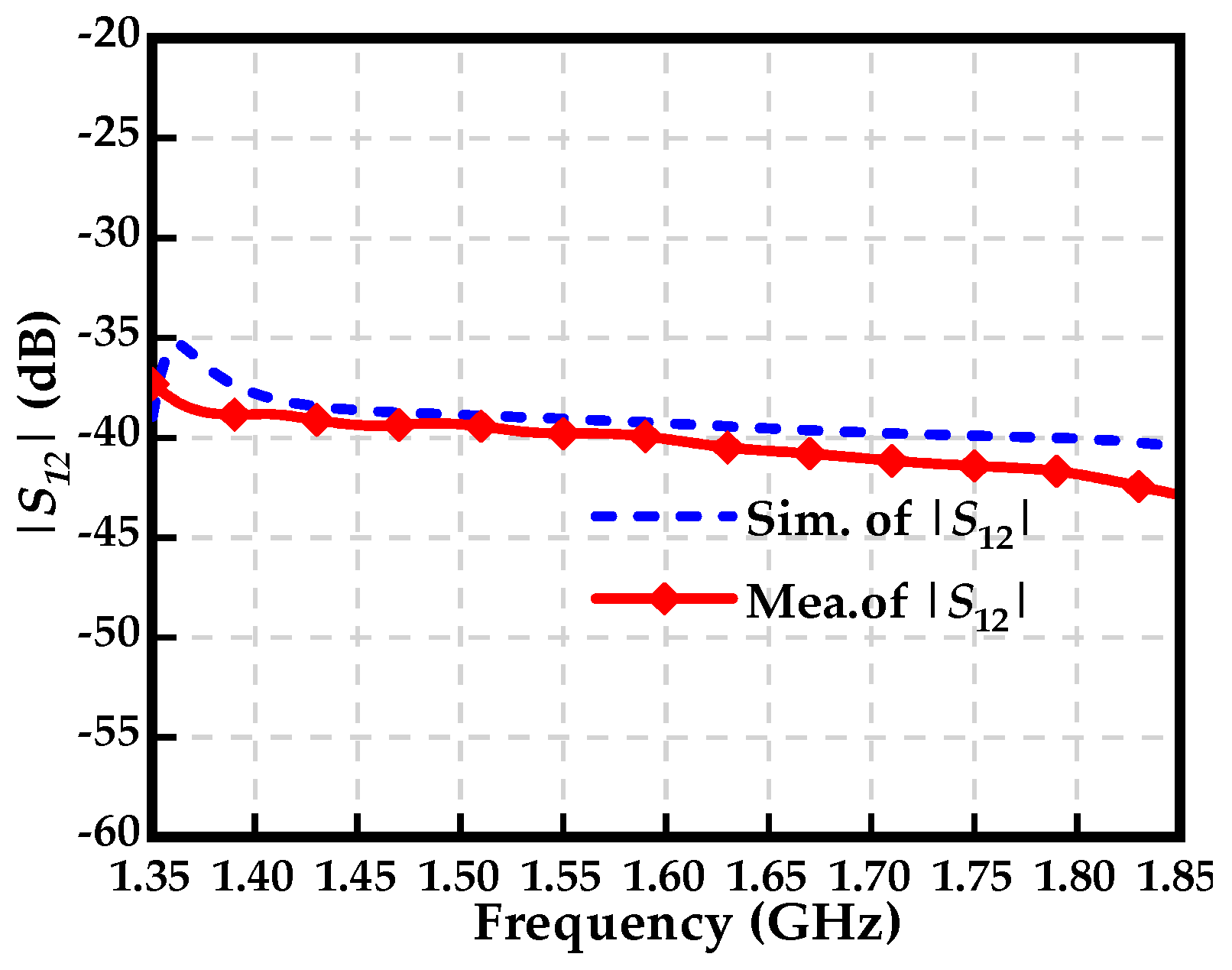

3.2. Characterization of the Sensor

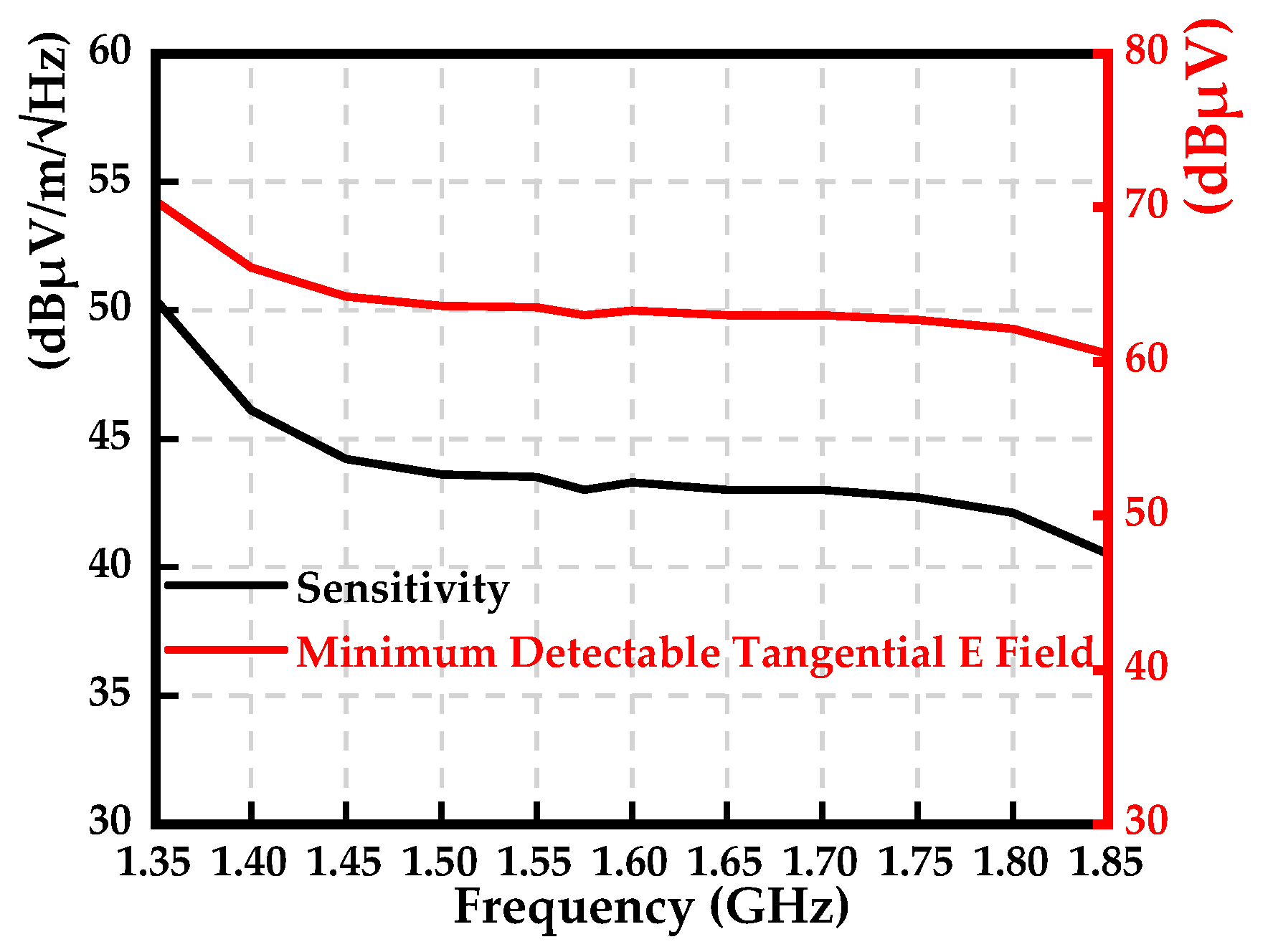

3.3. Sensitivity of the Sensor

3.4. Selectivity of the Sensor

3.5. Rejection to Magnetic Field (H-Field Rejection)

3.6. Comparisons

4. Applications and Validations

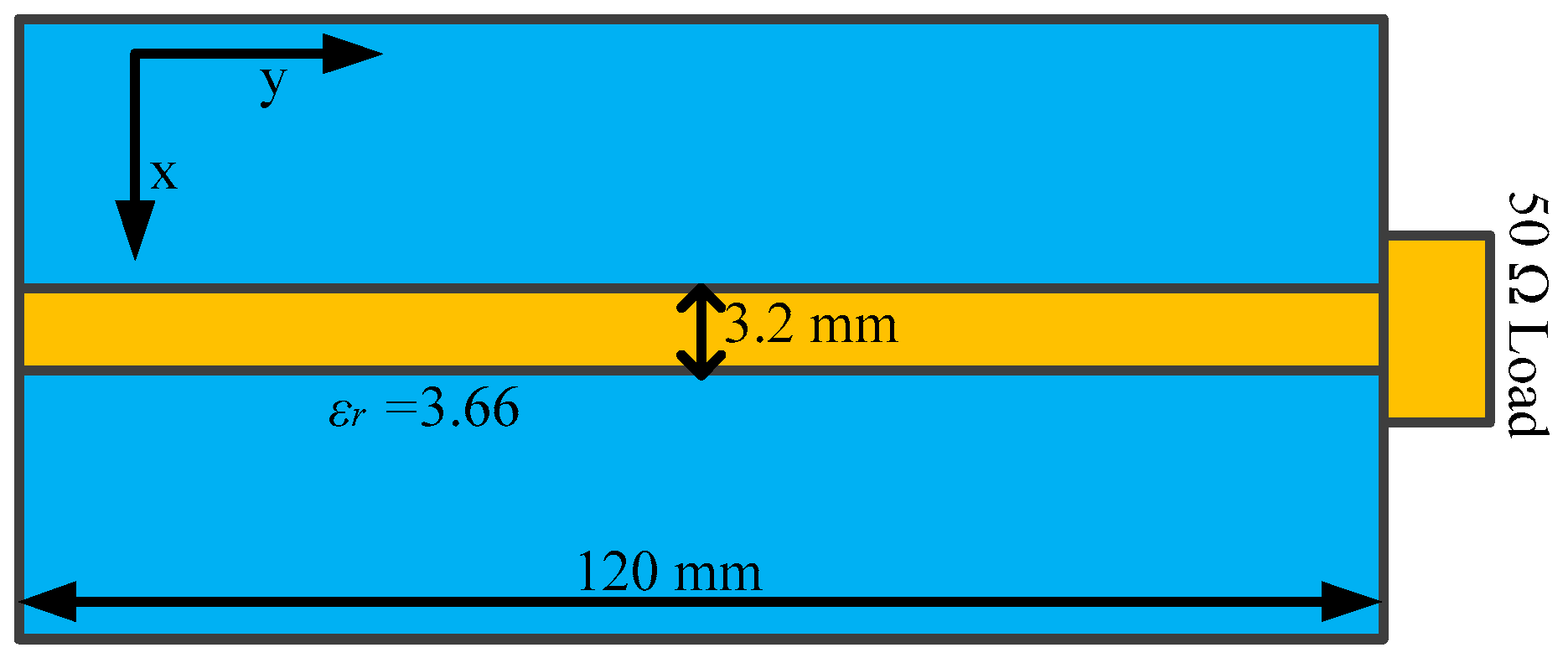

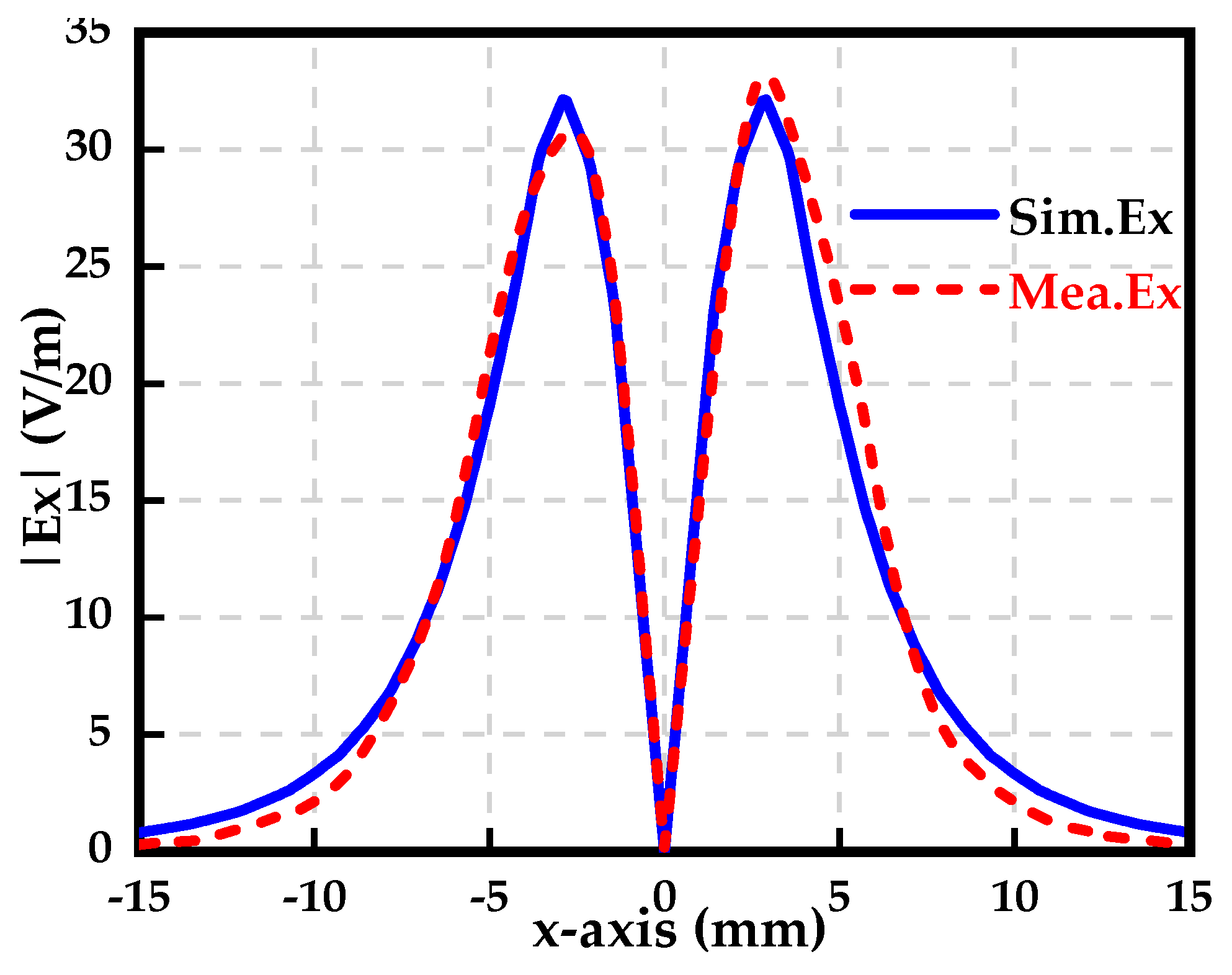

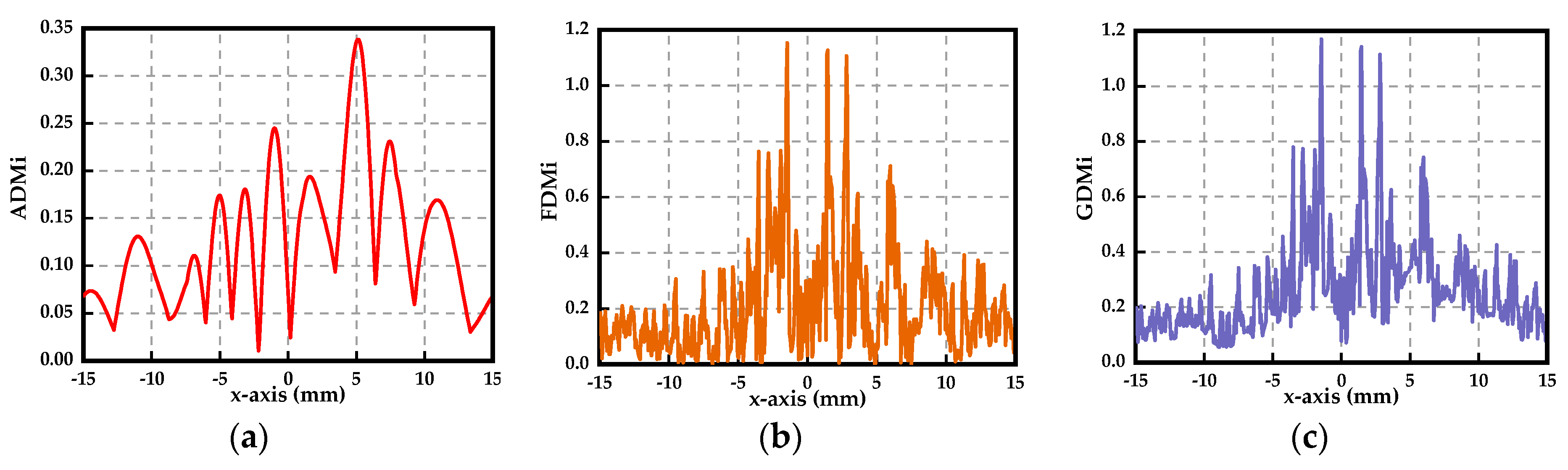

4.1. Measuring Ex-Field Distribution Over Microstrip Line

4.2. Measuring Tangential E-Field Distribution over Meander Line

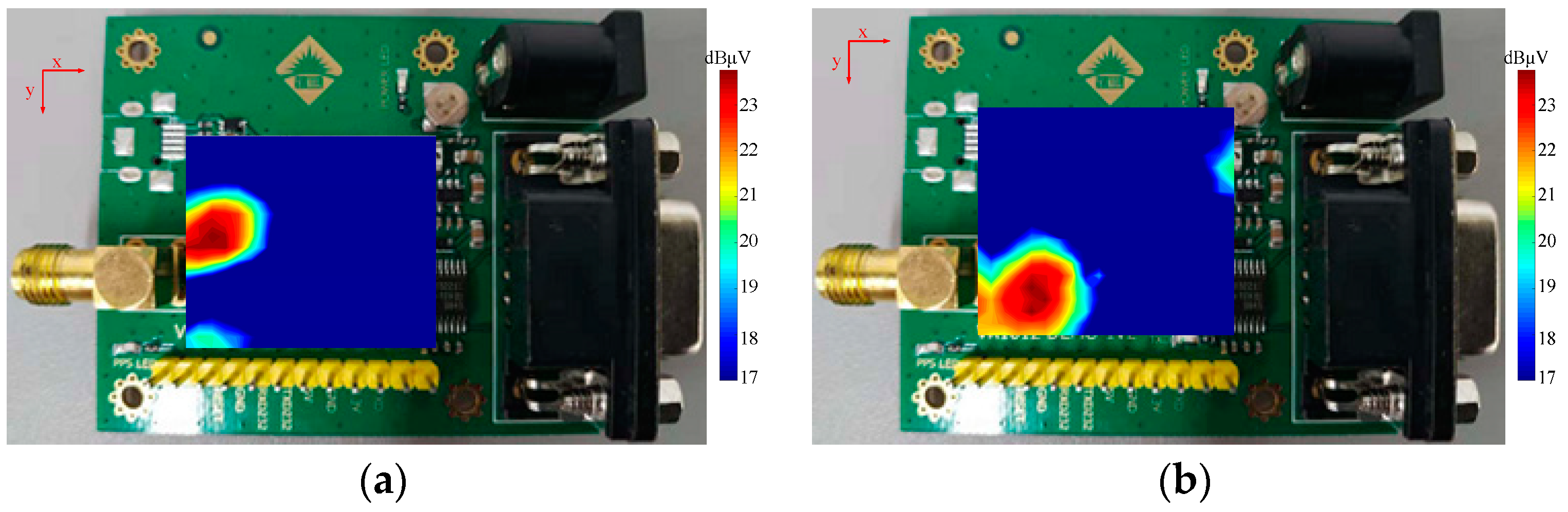

4.3. Applications in GPS Module

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Staniec, K.; Habrych, M. Telecommunication Platforms for Transmitting Sensor Data over Communication Networks—State of the Art and Challenges. Sensors 2016, 16, 1113. [Google Scholar] [CrossRef]

- Capriglione, D.; Chiariello, A.G.; Maffucci, A. Accurate Models for Evaluating the Direct Conducted and Radiated Emissions from Integrated Circuits. Appl. Sci. 2018, 8, 477. [Google Scholar] [CrossRef]

- Malyuskin, O.; Fusco, V.F. High-Resolution Microwave Near-Field Surface Imaging Using Resonance Probes. IEEE Trans. Instrum. Meas. 2016, 65, 189–200. [Google Scholar] [CrossRef]

- Tabib-Azar, M.; Müller, R.; Leclair, S.R. Nondestructive imaging of grain boundaries in polycrystalline materials using evanescent microwave probes. Eng. Appl. Artif. Intell. 2000, 13, 549–564. [Google Scholar] [CrossRef]

- Kerouedan, J.; Quéffélec, P.; Talbot, P.; Quendo, C.; Blasi, S.D.; Le Brun, A. Detection of micro-cracks on metal surfaces using near-field microwave dual-behavior resonator filters. Meas. Sci. Technol. 2008, 19, 10. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, W.; Wang, J.; Su, D.; Yan, X.; Fan, J. Noncontact Wideband Current Probes with High Sensitivity and Spatial Resolution for Noise Location on PCB. IEEE Trans. Instrum. Meas. 2018, 67, 2881–2891. [Google Scholar] [CrossRef]

- Talanov, V.V.; Scherz, A.; Moreland, R.L.; Schwartz, A.R. Noncontact dielectric constant metrology of low-k interconnect films using a near-field scanned microwave probe. Appl. Phys. Lett. 2006, 88, 192906. [Google Scholar] [CrossRef]

- Isakov, D.; Stevens, C.J.; Castles, F.; Grant, P.S. A Split Ring Resonator Dielectric Probe for Near-Field Dielectric Imaging. Sci. Rep. 2017, 7, 2038. [Google Scholar] [CrossRef]

- Whiteside, H.; King, R. The loop antenna as a probe. IEEE Trans. Antennas Propag. 1964, 12, 291–297. [Google Scholar] [CrossRef]

- Mai-Khanh, N.N.; Iizuka, T.; Sasaki, A.; Yamada, M.; Morita, O.; Asada, K. A Near-Field Magnetic Sensing System with High-Spatial Resolution and Application for Security of Cryptographic LSIs. IEEE Trans. Instrum. Meas. 2015, 64, 840–848. [Google Scholar] [CrossRef]

- Sivaraman, N.; Ndagljlmana, F.; Kadi, M.; Riah, Z. Broad band PCB probes for near field measurements. In Proceedings of the 2017 International Symposium on Electromagnetic Compatibility—EMC EUROPE, Angers, France, 4–7 September 2017. [Google Scholar]

- Dahele, J.S.; Cullen, A.L. Electric Probe Measurements on Microstrip. IEEE Trans. Microw. Theory Tech. 1980, 28, 752–755. [Google Scholar] [CrossRef]

- Baudry, D.; Louis, A.; Mazari, B. Characterization of the open-ended coaxial probe used for near-field measurements in EMC applications. Prog. Electromagn. Res. 2006, 60, 311–333. [Google Scholar] [CrossRef]

- Gao, Y.; Wolff, I. Miniature electric near-field probes for measuring 3-D fields in planar microwave circuits. IEEE Trans. Microw. Theory Tech. 1998, 46, 907–913. [Google Scholar]

- Uchida, D.; Nagai, T.; Oshima, Y.; Wakana, S. Novel high-spatial resolution probe for electric near-field measurement. In Proceedings of the 2011 IEEE Radio and Wireless Symposium, Phoenix, AZ, USA, 16–19 January 2011. [Google Scholar]

- Baudry, D.; Arcambal, C.; Louis, A.; Mazari, B.; Eudeline, P. Applications of the Near-Field Techniques in EMC Investigations. IEEE Trans. Electromagn. Compat. 2007, 49, 485–493. [Google Scholar] [CrossRef]

- Smith, G.S. The Electric-Field Probe near a Material Interface with Application to the Probing of Fields in Biological Bodies. IEEE Trans. Microw. Theory Tech. 1979, 27, 270–278. [Google Scholar] [CrossRef]

- Spang, M.; Albach, M.; Uddin, N.; Thiede, A. Miniature Dipole Antenna for Active Near-Field Sensor. In Proceedings of the 2009 German Microwave Conference (GeMIC 2009), Munich, Germany, 16–18 March 2009. [Google Scholar]

- Yan, Z.; Wang, J.; Zhang, W.; Wang, Y.; Fan, J. A miniature ultrawideband electric field probe based on coax-thru-hole via array for near-field measurement. IEEE Trans. Instrum. Meas. 2017, 66, 2762–2770. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, J.; Zhang, W.; Wang, Y.; Fan, J. A simple miniature ultrawideband magnetic field probe design for magnetic near-field measurements. IEEE Trans. Antennas Propag. 2016, 64, 5459–5465. [Google Scholar] [CrossRef]

- Chou, Y.; Lu, H. Magnetic Near-Field Probes with High-Pass and Notch Filters for Electric Field Suppression. IEEE Trans. Microw. Theory Tech. 2013, 61, 2460–2470. [Google Scholar] [CrossRef]

- Chou, Y.; Lu, H. Space Difference Magnetic Near-Field Probe with Spatial Resolution Improvement. IEEE Trans. Microw. Theory Tech. 2013, 61, 4233–4244. [Google Scholar] [CrossRef]

- Funato, H.; Suga, T.; Suhara, M. Double position-signal-difference method for electric near-field measurements. In Proceedings of the 2013 IEEE International Symposium on Electromagnetic Compatibility, Denver, CO, USA, 5–9 August 2013. [Google Scholar]

- Funato, H.; Suga, T. Magnetic near-field probe for GHz band and spatial resolution improvement technique. In Proceedings of the 2006 17th International Zurich Symposium on Electromagnetic Compatibility, Singapore, 27 February–3 March 2006. [Google Scholar]

- Tsutagaya, H.; Kazama, S. A high sensitivity electromagnetic field sensor using resonance. In Proceedings of the 2008 IEEE International Symposium on Electromagnetic Compatibility, Detroit, MI, USA, 8–12 August 2008. [Google Scholar]

- Chuang, H.; Li, G.; Song, E.; Park, H.; Jang, H.; Park, H.; Zhang, Y.; Pommerenke, D.; Wu, T.; Fan, J. A Magnetic-Field Resonant Probe with Enhanced Sensitivity for RF Interference Applications. IEEE Trans. Electromagn. Compat. 2013, 55, 991–998. [Google Scholar] [CrossRef]

- Li, G.; Itou, K.; Katou, Y.; Mukai, N.; Pommerenke, D.; Fan, J. A Resonant E-Field Probe for RFI Measurements. IEEE Trans. Electromagn. Compat. 2014, 56, 1719–1722. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Z.; Liu, W.; Yan, X.; Fan, J. Improved-Sensitivity Resonant Electric-Field Probes Based on Planar Spiral Stripline and Rectangular Plate Structure. IEEE Trans. Instrum. Meas. 2019, 68, 882–894. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Z.; Zhang, W.; Kang, T.; Zhang, M. An effective method of near to far field transformation based on dipoles model. In Proceedings of the 2015 Asia-Pacific Microwave Conference (APMC), Nanjing, China, 6–9 December 2015. [Google Scholar]

- Yu, Z.; Mix, J.A.; Sajuyigbe, S.; Slattery, K.P.; Fan, J. An Improved Dipole-Moment Model Based on Near-Field Scanning for Characterizing Near-Field Coupling and Far-Field Radiation From an IC. IEEE Trans. Electromagn. Compat. 2013, 55, 97–108. [Google Scholar] [CrossRef]

- Kanda, M. Standard probes for electromagnetic field measurements. IEEE Trans. Antennas Propag. 1993, 41, 1349–1364. [Google Scholar] [CrossRef]

- Li, G.; Pommerenke, D.; Min, J. A low frequency electric field probe for near-field measurement in EMC applications. In Proceedings of the 2017 IEEE International Symposium on Electromagnetic Compatibility & Signal/Power Integrity (EMCSI), Washington, DC, USA, 7–11 August 2017. [Google Scholar]

- Bouchelouk, L.; Riah, Z.; Baudry, D.; Kadi, M.; Louis, A.; Mazari, B. Characterization of electromagnetic fields close to microwave devices using electric dipole probes. Int. J. RF Microw. Comput.-Aided Eng. 2008, 18, 146–156. [Google Scholar] [CrossRef]

- Mansour, M.; Le Polozec, X.; Kanaya, H. Enhanced Broadband RF Differential Rectifier Integrated with Archimedean Spiral Antenna for Wireless Energy Harvesting Applications. Sensors 2019, 19, 655. [Google Scholar] [CrossRef] [PubMed]

- Choe, W.; Jeong, J. A Broadband THz On-Chip Transition Using a Dipole Antenna with Integrated Balun. Electronics 2018, 7, 236. [Google Scholar] [CrossRef]

- Kwon, O.H.; Park, W.B.; Lee, S.; Lee, J.M.; Park, Y.M.; Hwang, K.C. 3D-Printed Super-Wideband Spidron Fractal Cube Antenna with Laminated Copper. Appl. Sci. 2017, 7, 979. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, G.; Dong, J.; Wang, J. Study on Miniaturized UHF Antennas for Partial Discharge Detection in High-Voltage Electrical Equipment. Sensors 2015, 15, 29434–29451. [Google Scholar] [CrossRef]

- Itapu, S.; Almalkawi, M.; Devabhaktuni, V. A 0.8–8 GHz Multi-Section Coupled Line Balun. Electronics 2015, 4, 274–282. [Google Scholar] [CrossRef]

- Eom, S.Y.; Jeon, S.I.; Chae, J.S.; Yook, J.G. Broadband 180 bit phase shifter using a new switched network. In Proceedings of the IEEE MTT-S International Microwave Symposium Digest, Philadelphia, PA, USA, 8–13 January 2003. [Google Scholar]

- Zhang, Z.; Guo, Y.; Ong, L.C.; Chia, M.Y.W. A new wide-band planar balun on a single-layer PCB. IEEE Microw. Wirel. Compon. Lett. 2005, 15, 416–418. [Google Scholar] [CrossRef]

- The Motion Controller of TC45 Series. Available online: http://www.top-cnc.com/index.php/products/ indextwo/11.html (accessed on 25 March 2019).

- Russo, I.; Menzel, W. 4–8 GHz near-Field Probe for Scanning of Apertures and Multimode Waveguides. IEEE Microw. Wirel. Compon. Lett. 2011, 21, 688–690. [Google Scholar] [CrossRef]

- The EMI probe products. Available online: http://www.amberpi.com/products_EMI_probes.php (accessed on 29 March 2019).

- Duffy, A.P.; Martin, A.J.M.; Orlandi, A.; Antonini, G.; Benson, T.M.; Woolfson, M.S. Feature selective validation (FSV) for validation of computational electromagnetics (CEM). Part I—The FSV method. IEEE Trans. Electromagn. Compat. 2006, 48, 449–459. [Google Scholar] [CrossRef]

- Orlandi, A.; Duffy, A.P.; Archambeault, B.; Antonini, G.; Coleby, D.E.; Connor, S. Feature selective validation (FSV) for validation of computational electromagnetics (CEM). Part II—Assessment of FSV performance. IEEE Trans. Electromagn. Compat. 2006, 48, 460–467. [Google Scholar] [CrossRef]

- The installation package of FSV_Tool_20. Available online: http://orlandi.ing.univaq.it/pub/FSV_Tool_20/ (accessed on 12 April 2019).

- Riah, Z.; Baudry, D.; Kadi, M.; Louis, A.; Mazari, B. Post-processing of electric field measurements to calibrate a near-field dipole probe. IET Sci. Meas. Technol. 2011, 5, 29–36. [Google Scholar] [CrossRef]

0.35 mm | 3.00 mm | 25.00 mm | 49.60 mm |

0.21 mm | 12.5 mm | 2.65 mm | 0.35 mm |

24.37 mm | 6.25 mm | 0.11 mm | 12.58 mm |

| Motion Distance on x, y, and z Direction | 40 mm, 30 mm 30 mm |

| Mechanical Spatial Resolution | 0.1 mm |

| Supply Voltage of the Power Amplifier | 24 V |

| Version of Micro Controller | TC45 [41] |

| Communication Protocol | MODBUS 485 Protocol |

| Sensors | Bandwidth | Sensitivity | Spatial Resolution | Balun | Complexity of Structure |

|---|---|---|---|---|---|

| This paper | GPS band | High 1 | 4 mm | Passive | Simple |

| [18] | 1 MHz–3 GHz | Low 1 | Not mentioned | Passive | Complex |

| [42] | 4–8 GHz | Low 1 | Not mentioned | Passive | Complex |

| [43] | 50 kHz–100 MHz | High 1 | 2 mm 2 | Active | Complex |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yan, Z.; Liu, W.; Su, D.; Yan, X. A Novel Tangential Electric-Field Sensor Based on Electric Dipole and Integrated Balun for the Near-Field Measurement Covering GPS Band. Sensors 2019, 19, 1970. https://doi.org/10.3390/s19091970

Wang J, Yan Z, Liu W, Su D, Yan X. A Novel Tangential Electric-Field Sensor Based on Electric Dipole and Integrated Balun for the Near-Field Measurement Covering GPS Band. Sensors. 2019; 19(9):1970. https://doi.org/10.3390/s19091970

Chicago/Turabian StyleWang, Jianwei, Zhaowen Yan, Wei Liu, Donglin Su, and Xin Yan. 2019. "A Novel Tangential Electric-Field Sensor Based on Electric Dipole and Integrated Balun for the Near-Field Measurement Covering GPS Band" Sensors 19, no. 9: 1970. https://doi.org/10.3390/s19091970

APA StyleWang, J., Yan, Z., Liu, W., Su, D., & Yan, X. (2019). A Novel Tangential Electric-Field Sensor Based on Electric Dipole and Integrated Balun for the Near-Field Measurement Covering GPS Band. Sensors, 19(9), 1970. https://doi.org/10.3390/s19091970