Damage Detection and Evaluation for an In-Service Shield Tunnel Based on the Monitored Increment of Neutral Axis Depth Using Long-Gauge Fiber Bragg Grating Sensors

Abstract

1. Introduction

2. Damage Index for a Shield Tunnel in the Longitudinal Direction

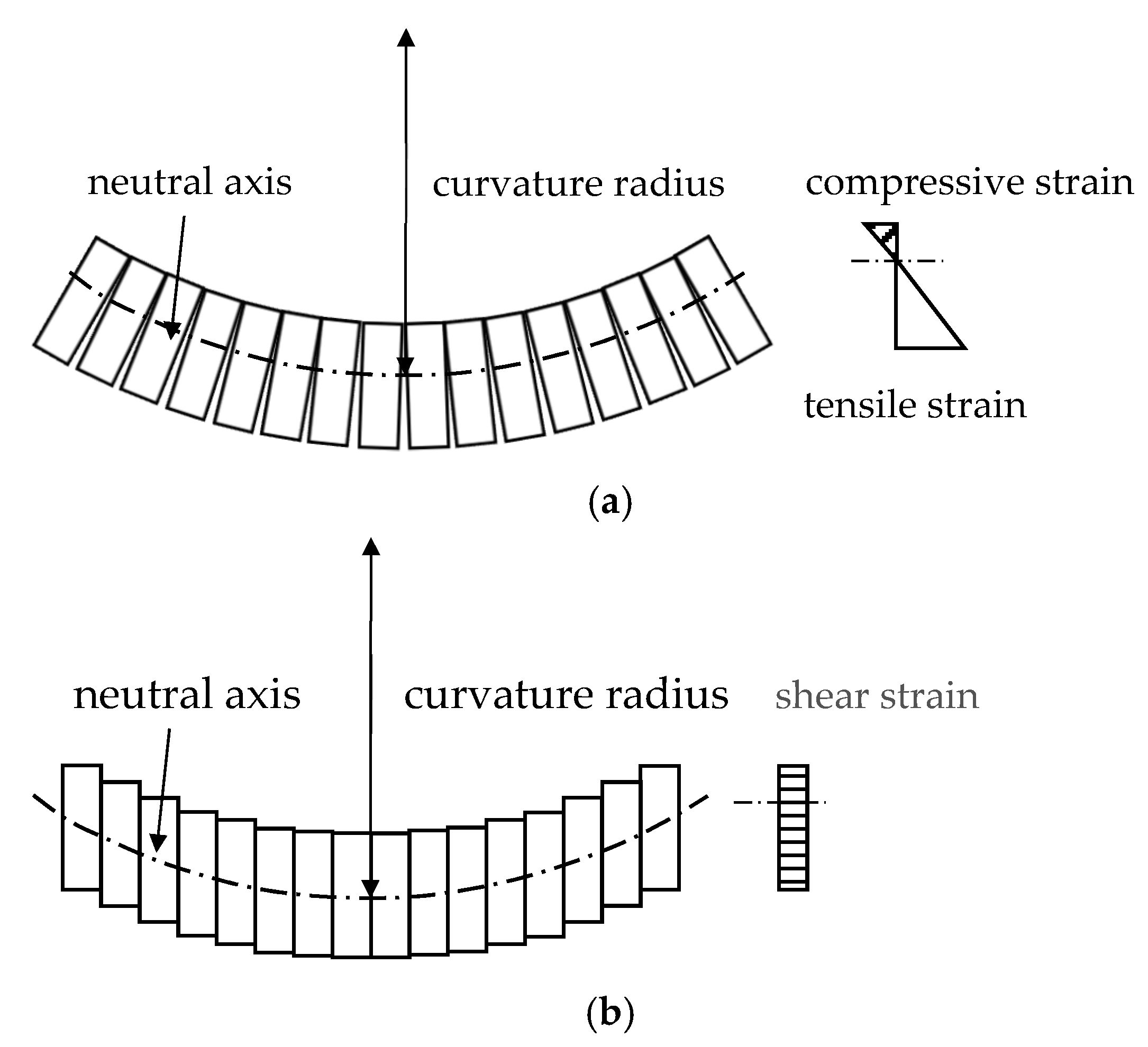

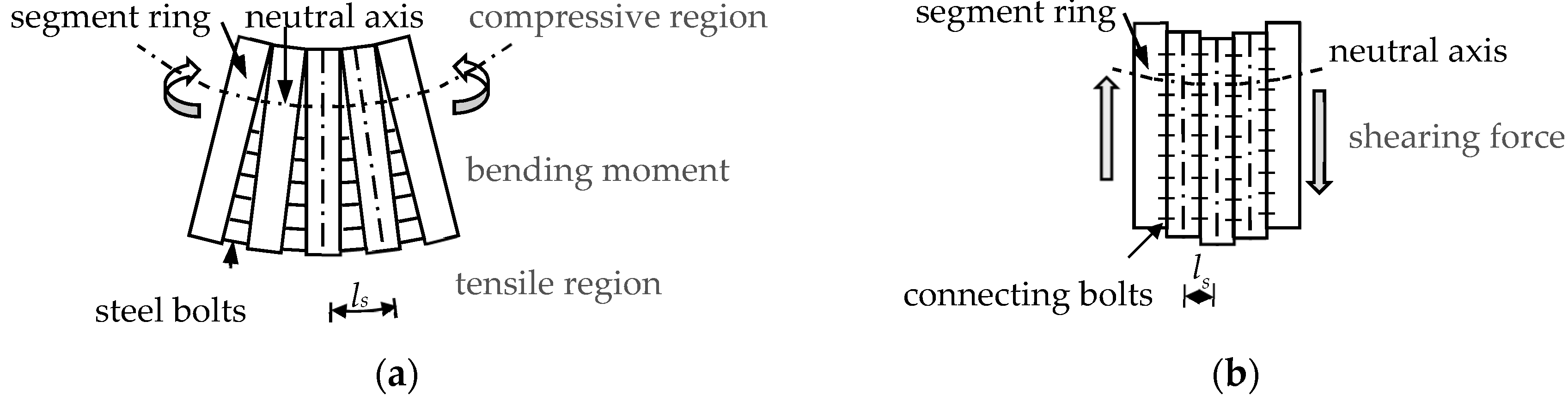

2.1. Failure Modes Based on Two Longitudinal Deformation Modes

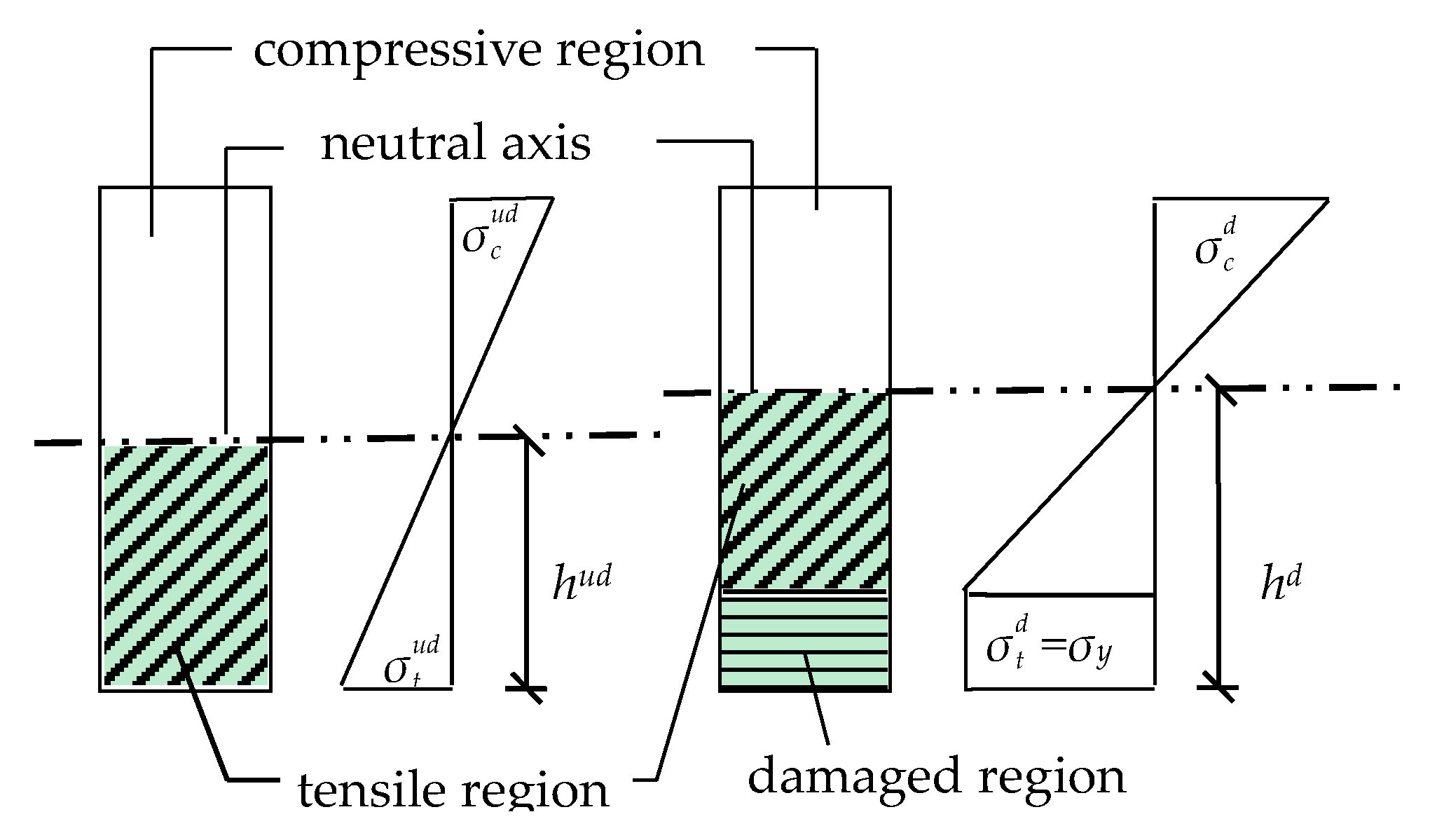

2.2. Damage Index Derivation

3. Damage Detection and Evaluation Using LFBG-Based Strain Measurements

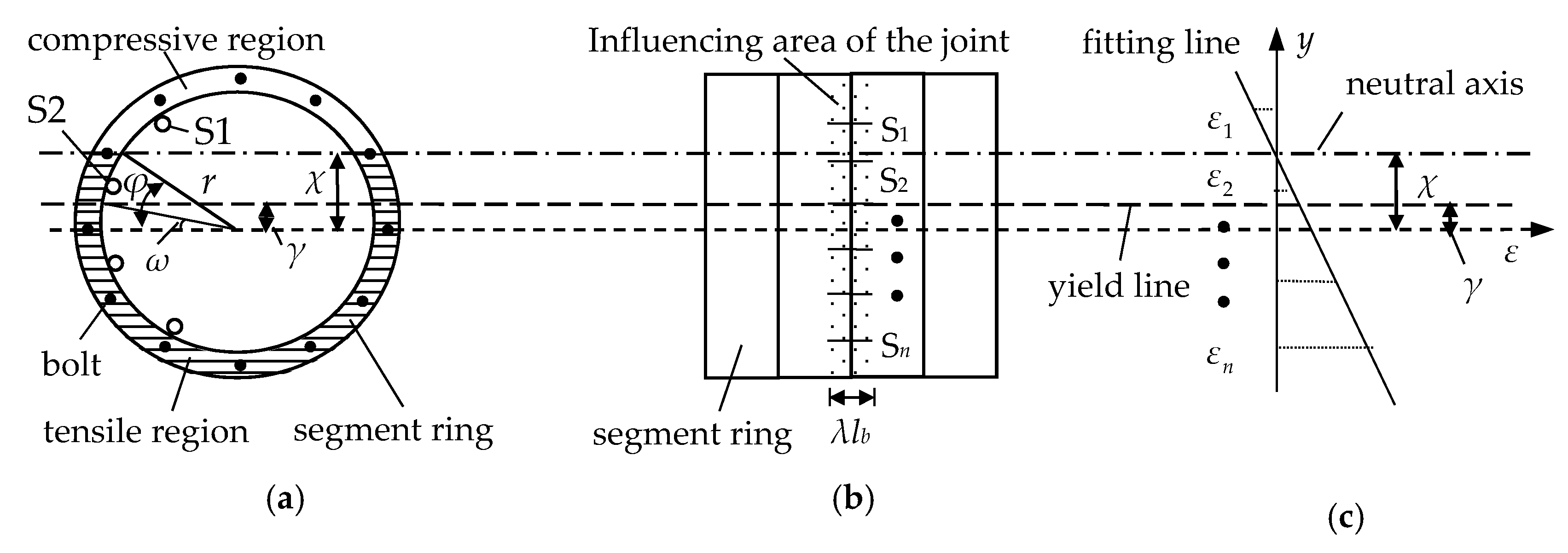

3.1. Relationship between Structural Damage Level and NAD

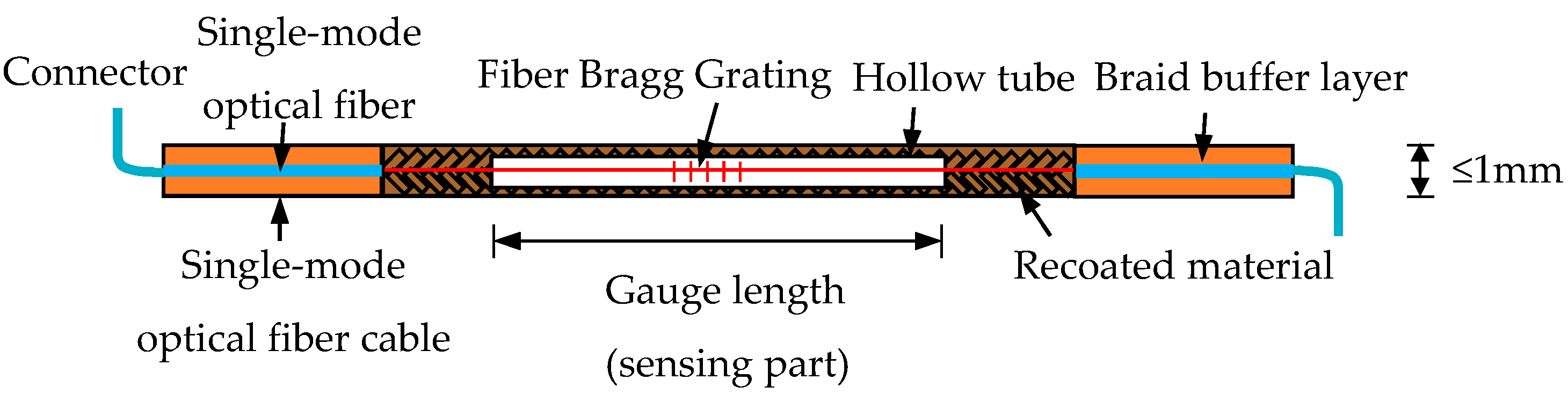

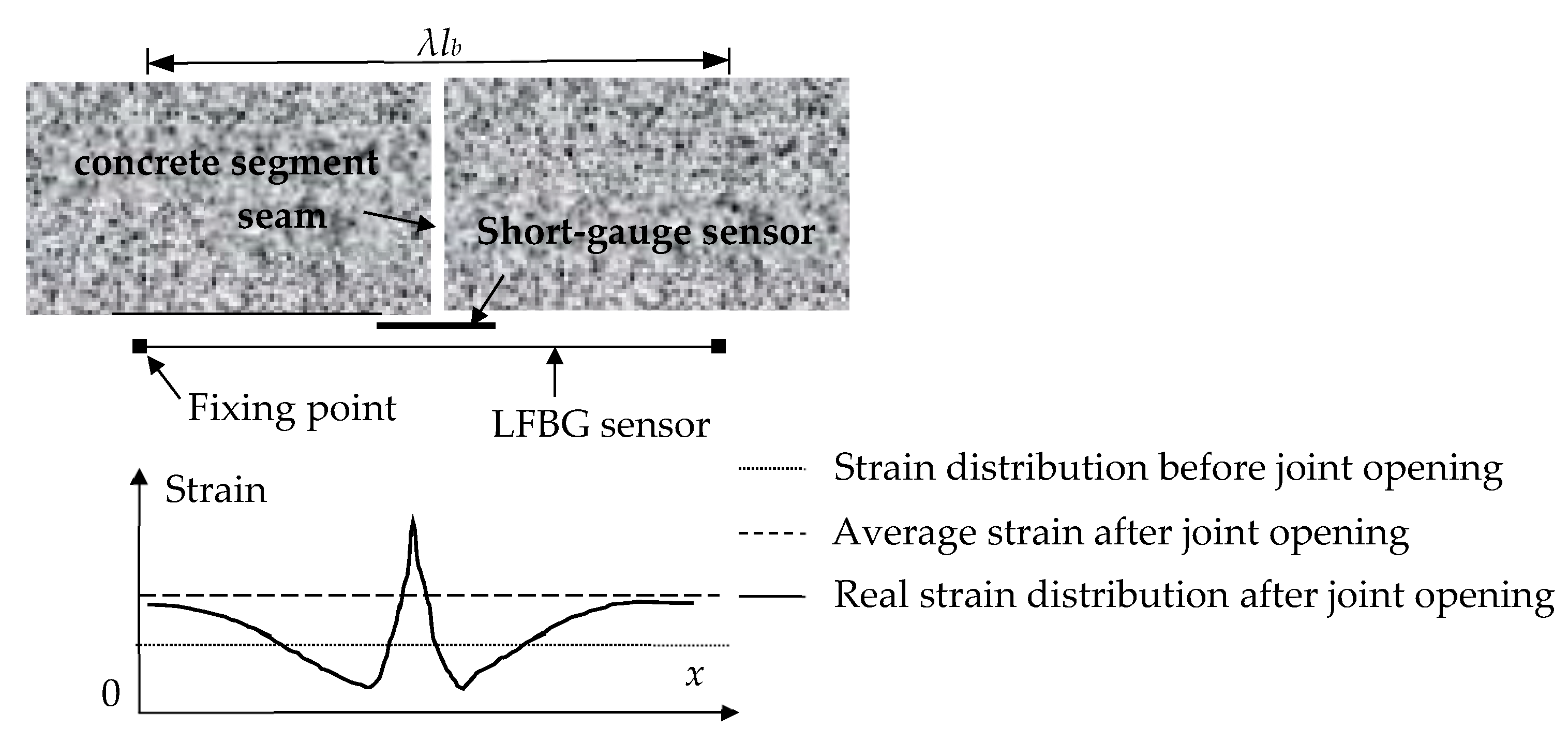

3.2. Introduction to LFBG Sensors

3.3. Damage Evaluation Using LFBG-Based Strain Measurements

4. Numerical Simulation Verification

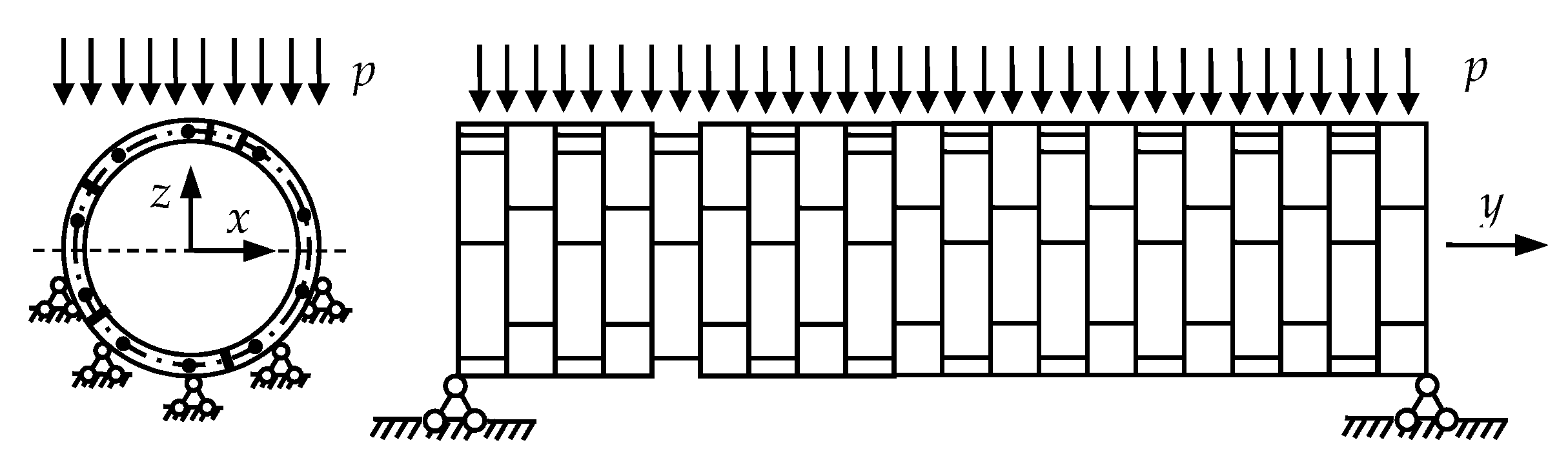

4.1. Numerical Model

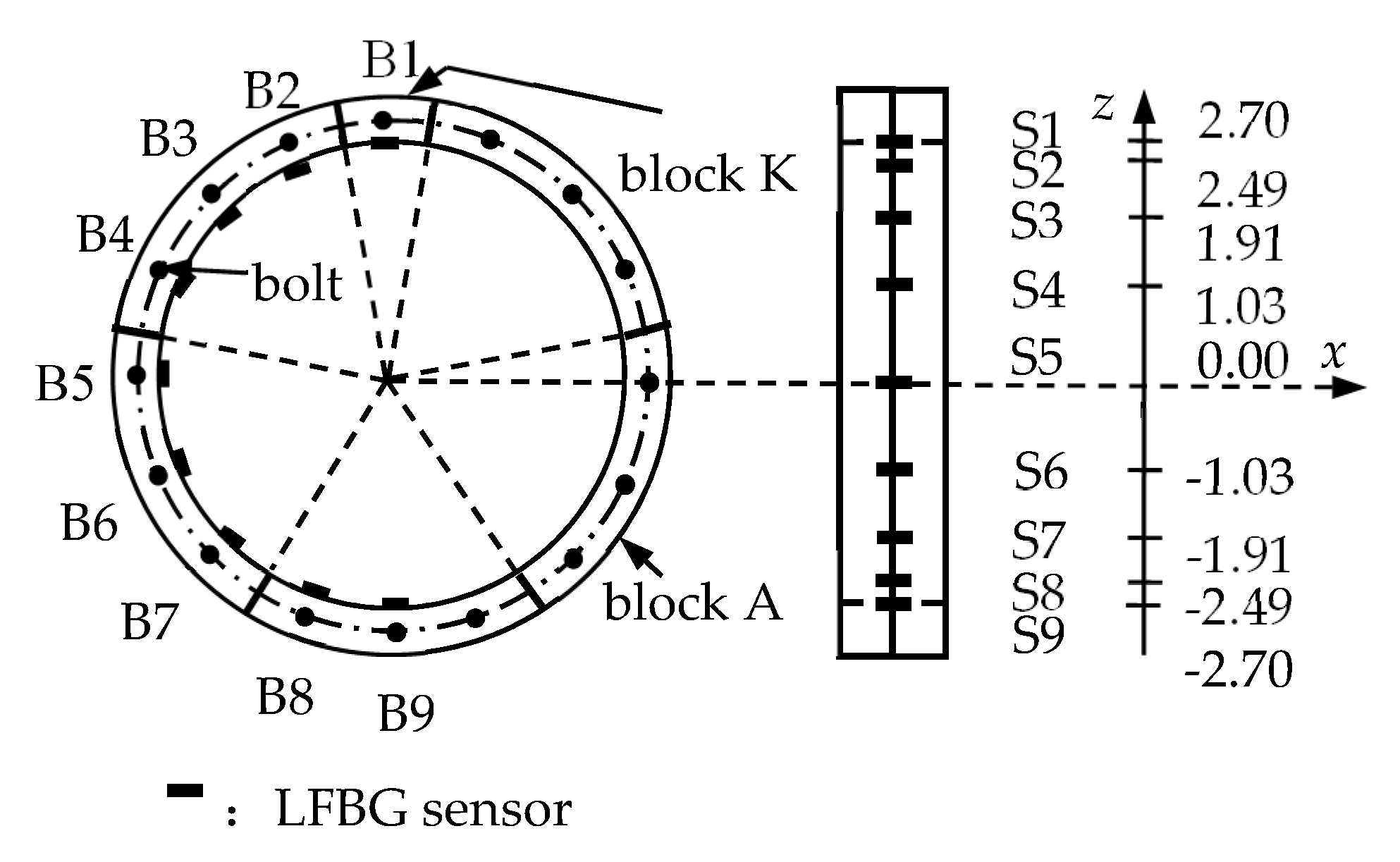

4.2. Sensor Placement and Loading Mode

4.3. Results and Analysis

4.3.1. Verification of Plane-Section Assumption and NAD Sensitivity

4.3.2. Accuracy Comparison of φud

4.3.3. Verification of the Damage Index’s Accuracy

5. Experimental Verification

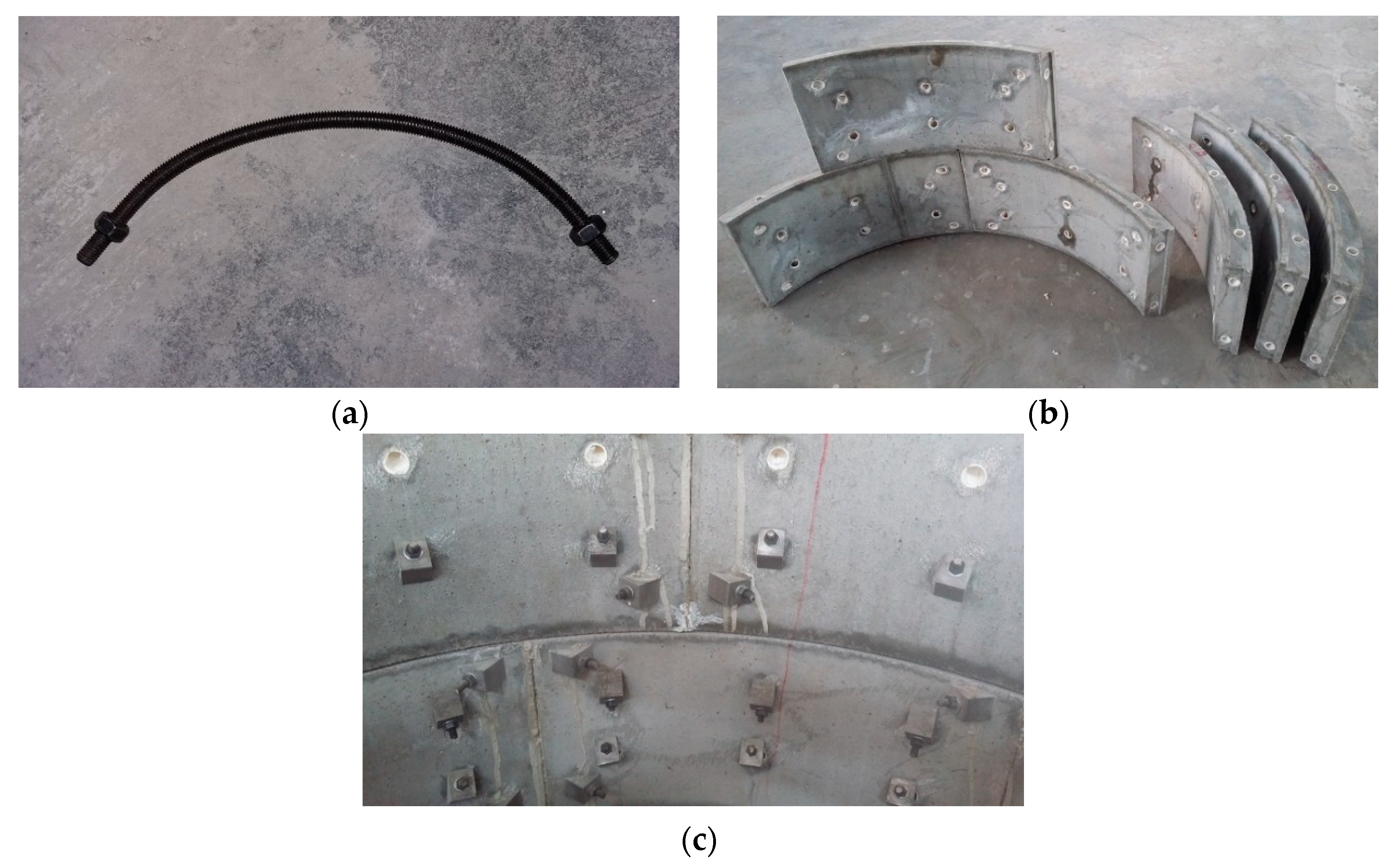

5.1. Scaled-Down Model

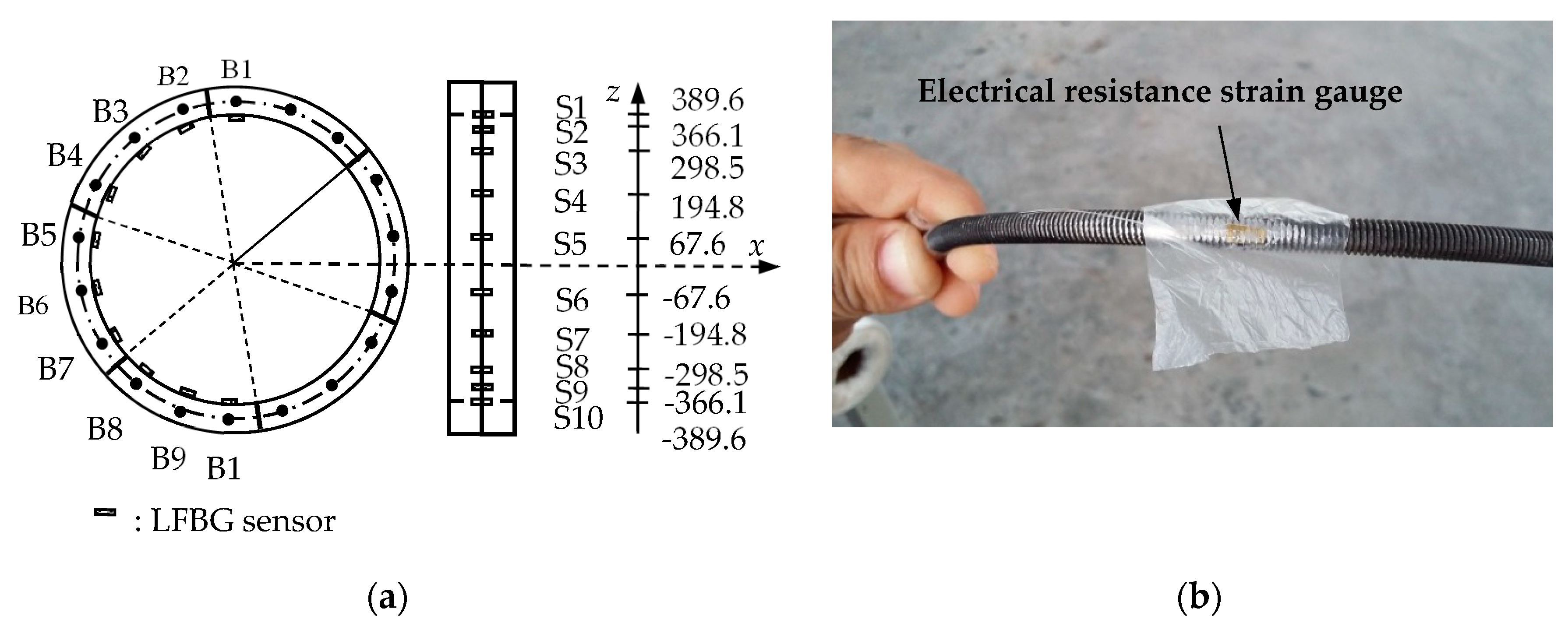

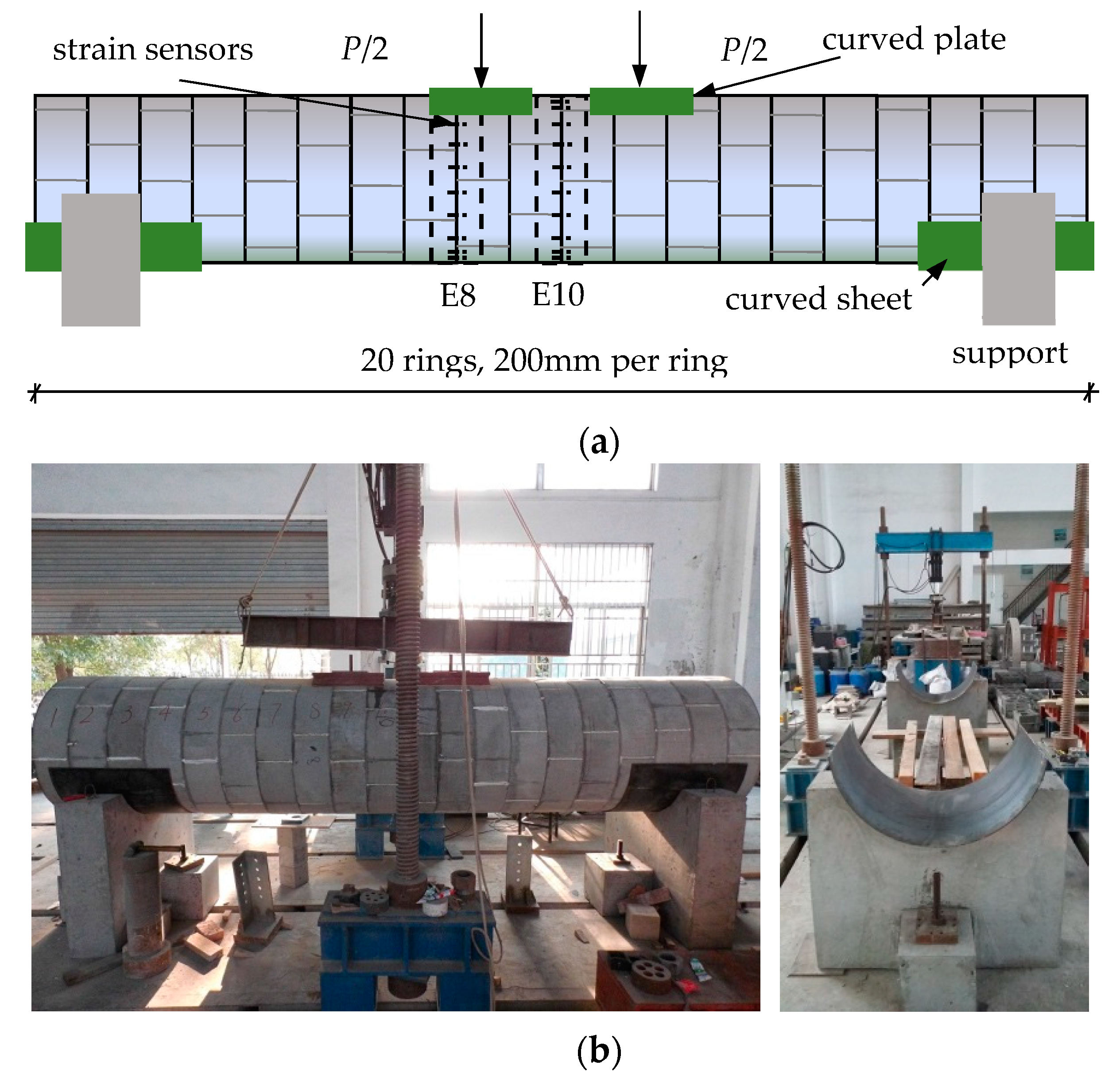

5.2. Sensor Placement and Loading Mode

5.3. Results and Analysis

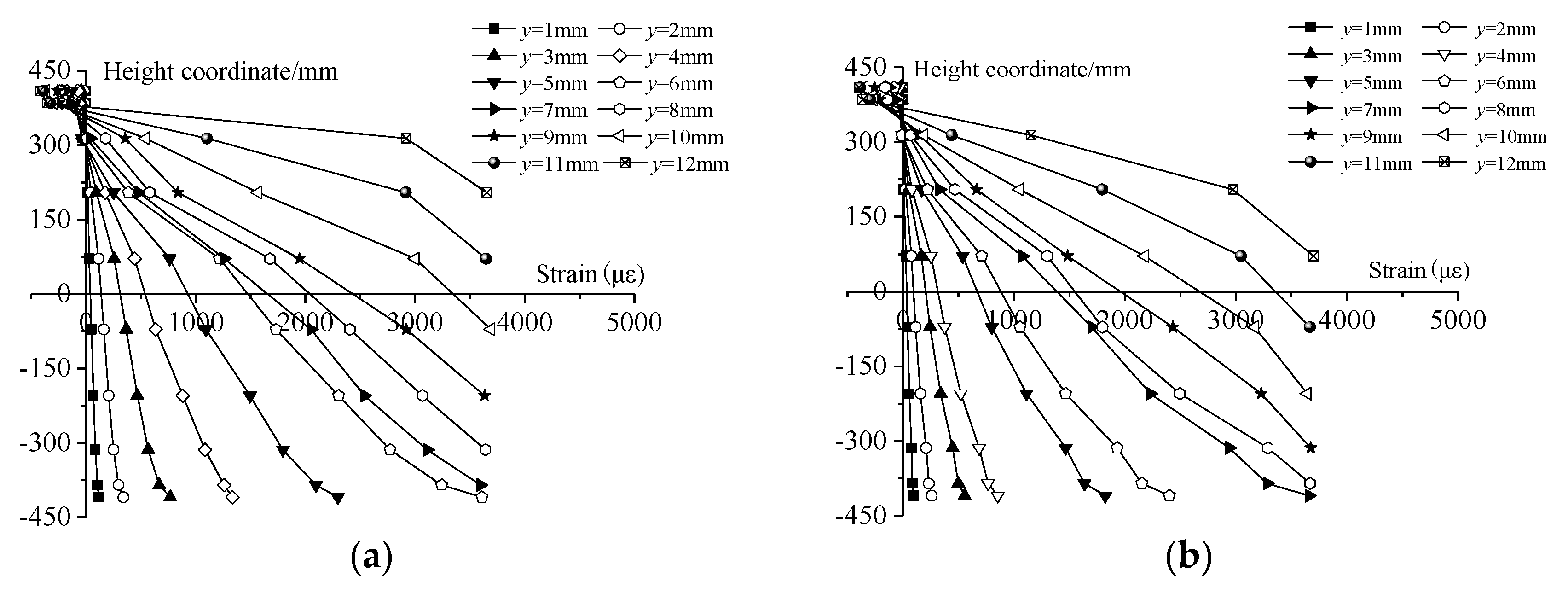

5.3.1. Verification of Plane-Section Assumption and NAD Sensitivity

5.3.2. Verification of the Damage Index’s Accuracy

6. Conclusions

- Based on the analysis of two deformation modes (i.e., bending mode and dislocation mode), three kinds of failure modes are assumed, including the bending failure mode, the shearing failure mode due to dislocation, and the shearing failure mode of the equivalent shear stiffness reduction, which resulted from the bolts being subjected to an excessive bending moment. These three failure modes and their development were successfully detected and evaluated by the proposed damage index D.

- The damage index D can be determined only by the monitored NAD, which is obtained from the long-gauge strain distribution of the LFBG sensor array. The calculation of the damage index value is independent of the loading mode and the mechanical properties of materials.

- The damage index D characterizes the development of damage in the tunnel accurately through calculating the coefficients HFM1 and HFM3 in most cases. The maximum deviation between the HFM1 and the true decrease of the equivalent flexural stiffness is less than 1.7% in the numerical simulation result and less than 9% in the experimental result. The calculated HFM3 matches well with its true value both in the undamaged state and the early-damaged state in the numerical simulation and the experimental results. The accuracy of the index D demonstrates the great applicability of the proposed damaged detection and evaluation method in the practical monitoring and maintenance of in-service shield tunnels.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rui, Y.; Zhu, H.; Yin, M.; Li, X. Study on maintenance technology of shield tunnel in soft ground. In Proceedings of the GeoShanghai 2010 International Conference, Shanghai, China, 3–5 June 2010. [Google Scholar] [CrossRef]

- Shi, B.; Kong, X. Study of the diseases of shield tunnels and its reasons. In Proceedings of the Geo-China 2016, Jinan, China, 25–27 July 2016. [Google Scholar] [CrossRef]

- Chou, H.S.; Yang, C.Y.; Hsieh, B.J.; Chang, S.S. A study of liquefaction related damages on shield tunnels. Tunn. Undergr. Space Technol. 2001, 16, 185–193. [Google Scholar] [CrossRef]

- Wu, H.N.; Huang, R.Q.; Sun, W.J.; Shen, S.L.; Xu, Y.S.; Liu, Y.B.; Du, S.J. Leaking behavior of shield tunnels under the Huangpu River of Shanghai with induced hazards. Nat. Hazards 2014, 70, 1115–1132. [Google Scholar] [CrossRef]

- Shi, C.H.; Cao, C.; Lei, M.; Peng, L.; Ai, H. Effects of lateral unloading on the mechanical and deformation performance of shield tunnel segment joints. Tunn. Undergr. Space Technol. 2016, 51, 175–188. [Google Scholar] [CrossRef]

- Han, J.; Zhao, W.; Jia, P.; Guan, Y.; Chen, Y.; Jiang, B. Risk analysis of the opening of shield-tunnel circumferential joints induced by adjacent deep excavation. J. Perform. Constr. Facil. 2016, 32, 04017123. [Google Scholar] [CrossRef]

- Huang, H.W.; Zhang, D. Deformational responses of operated shield tunnel to extreme surcharge: A case study. Struct. Infrastruct. Eng. 2016, 13, 345–360. [Google Scholar] [CrossRef]

- Liao, S.M.; Peng, F.L.; Shen, S.L. Analysis of shearing effect on tunnel induced by load transfer along longitudinal direction. Tunn. Undergr. Space Technol. 2008, 23, 421–430. [Google Scholar] [CrossRef]

- Shen, S.L.; Wu, H.N.; Cui, Y.J.; Yin, Z.Y. Long-term settlement behavior of metro tunnels in the soft deposits of Shanghai. Tunn. Undergr. Space Technol. 2014, 40, 309–323. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.L.; Yang, J. Identification of Tunnel Settlement Caused by Land Subsidence in Soft Deposit of Shanghai. J. Perform. Constr. Facil. 2017, 31, 04017092. [Google Scholar] [CrossRef]

- Miao, Y.; Yao, E.; Ruan, B.; Zhuang, H. Seismic response of shield tunnel subjected to spatially varying earthquake ground motions. Tunn. Undergr. Space Technol. 2018, 77, 216–226. [Google Scholar] [CrossRef]

- Chen, G.; Ruan, B.; Zhao, K.; Chen, W.; Zhuang, H.; Du, X.; Khoshnevisan, S.; Juang, C.H. Nonlinear response characteristics of undersea shield tunnel subjected to strong earthquake motions. J. Earthq. Eng. 2018, 4, 1–32. [Google Scholar] [CrossRef]

- Wang, Z.F.; Shen, S.L.; Cheng, W.C.; Xu, Y.S. Ground fissures in Xi’an and measures to prevent damage to the Metro tunnel system due to geohazards. Environ. Earth Sci. 2016, 75, 511–522. [Google Scholar] [CrossRef]

- Liu, N.; Huang, Q.; Ma, Y.; Bulut, R.; Peng, J.; Fan, W.; Men, Y. Experimental study of a segmented metro tunnel in a ground fissure area. Soil Dyn. Earthq. Eng. 2017, 100, 410–416. [Google Scholar] [CrossRef]

- Russell, H.A.; Gilmore, J. Inspection Policy and Procedures for Rail Transit Tunnels and Underground Structures; Transit Cooperative Research Program Synthesis 23; National Academy Press: Washington, DC, USA, 1997. [Google Scholar]

- Molins, C.; Arnau, O. Experimental and analytical study of the structural response of segmental tunnel linings based on an in situ loading test: Part 1: Test configuration and execution. Tunn. Undergr. Space Technol. 2011, 26, 764–777. [Google Scholar] [CrossRef]

- Arnau, O.; Molins, C. Experimental and analytical study of the structural response of segmental tunnel linings based on an in situ loading test. Part 2: Numerical simulation. Tunn. Undergr. Space Technol. 2011, 26, 778–788. [Google Scholar] [CrossRef]

- Balageas, D.; Fritzen, C.P.; Güemes, A. Structural Health Monitoring; ISTE: London, UK; Newport Beach, CA, USA, 2006. [Google Scholar]

- Zhou, B.; Xie, X.Y.; Yang, Y.B.; Jiang, J.C. A novel vibration-based structure health monitoring approach for the shallow buried tunnel. Comput. Model. Eng. Sci. 2012, 86, 321–348. [Google Scholar] [CrossRef]

- Zhou, B.; Xie, X.Y.; Li, Y.S. A structural health assessment method for shield tunnels based on torsional wave speed. Sci. China Technol. Sci. 2014, 57, 1109–1120. [Google Scholar] [CrossRef]

- Feng, L.; Yi, X.; Zhu, D.; Xie, X.Y.; Wang, Y. Damage detection of metro tunnel structure through transmissibility function and cross correlation analysis using local excitation and measurement. Mech. Syst. Signal Process. 2015, 60–61, 59–74. [Google Scholar] [CrossRef]

- Wang, R.L.; Liu, J.H. Practice of protection and monitoring for Shanghai subway. Undergr. Eng. Tunn. 2004, 14, 27–32. (In Chinese) [Google Scholar]

- Sigurdardottir, D.H.; Glisic, B. Neutral axis as damage sensitive feature. Smart Mater. Struct. 2013, 22, 1–18. [Google Scholar] [CrossRef]

- Ni, Y.; Xia, H.W.; Ye, X.W. Neutral-axis position based damage detection of bridge deck using strain measurement: Numerical and experimental verifications. In Proceedings of the 6th European Workshop-Structural Health Monitoring, Dresden, Germany, 3–6 July 2012. [Google Scholar]

- Sigurdardottir, D.H.; Glisic, B. Detecting minute damage in beam-like structures using the neutral axis location. Smart Mater. Struct. 2014, 23, 125042. [Google Scholar] [CrossRef]

- Zhang, J.; Hong, W.; Tang, Y.S. Structural health monitoring of a steel stringer bridge with area sensing. Struct. Infrastruct. Eng. 2014, 10, 1049–1058. [Google Scholar] [CrossRef]

- Soman, R.N.; Malinowski, P.H.; Ostachowicz, W.M. Bi-axial neutral axis tracking for damage detection in wind-turbine towers. Wind Energy 2016, 19, 223–236. [Google Scholar] [CrossRef]

- Ye, X.W.; Su, Y.H.; Xi, P.S. Statistical Analysis of Stress Signals from Bridge Monitoring by FBG System. Sensors 2018, 18, 491. [Google Scholar] [CrossRef]

- Xiao, F.; Chen, G.S.; Hulsey, J.L. Monitoring Bridge Dynamic Responses Using Fiber Bragg Grating Tiltmeters. Sensors 2017, 17, 2390. [Google Scholar] [CrossRef]

- Hu, D.T.; Guo, Y.X.; Chen, X.F.; Zhang, C.R. Cable Force Health Monitoring of Tongwamen Bridge Based on Fiber Bragg Grating. Appl. Sci. 2017, 7, 384. [Google Scholar] [CrossRef]

- Zhao, X.; Li, W.; Song, G.; Zhu, Z.; Du, J. Scour monitoring system for subsea pipeline based on active thermometry: Numerical and experimental studies. Sensors 2013, 13, 1490–1509. [Google Scholar] [CrossRef]

- Kong, X.; Ho, S.C.M.; Song, G.; Cai, C.S. Scour Monitoring System Using Fiber Bragg Grating Sensors and Water-Swellable Polymers. ASCE J. Bridge Eng. 2017, 22, 04017029. [Google Scholar] [CrossRef]

- Li, W.; Ho, S.C.M.; Song, G. Corrosion detection of steel reinforced concrete using combined carbon fiber and fiber Bragg grating active thermal probe. Smart Mater. Struct. 2016, 25, 045017. [Google Scholar] [CrossRef]

- Li, W.; Xu, C.; Ho, S.C.M.; Wang, B.; Song, G. Monitoring concrete deterioration due to reinforcement corrosion by integrating acoustic emission and FBG strain measurements. Sensors 2017, 17, 657. [Google Scholar] [CrossRef]

- Mao, J.H.; Xu, F.Y.; Gao, Q.; Liu, S.L.; Jin, W.L.; Xu, Y.D. A Monitoring Method Based on FBG for Concrete Corrosion Cracking. Sensors 2016, 16, 1093. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.H.; Chen, J.Y.; Cui, L.; Jin, W.L.; Xu, C.; He, Y. Monitoring the Corrosion Process of Reinforced Concrete Using BOTDA and FBG Sensors. Sensors 2015, 15, 8866–8883. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Zhang, C.; Ni, Y.Q.; Wang, C.Y. Real-time condition assessment of railway tunnel deformation using an FBG-based monitoring system. Smart Struct. Syst. 2018, 21, 537–548. [Google Scholar] [CrossRef]

- Bursi, O.S.; Tondini, N.; Fassin, M.; Bonelli, A. Structural monitoring for the cyclic behaviour of concrete tunnel lining sections using FBG sensors. Struct. Control Health Monit. 2016, 23, 749–763. [Google Scholar] [CrossRef]

- Ye, X.W.; Ni, Y.Q.; Yin, J.H. Safety Monitoring of Railway Tunnel Construction Using FBG Sensing Technology. Adv. Struct. Eng. 2013, 16, 1401–1409. [Google Scholar] [CrossRef]

- Li, S.; Wu, Z. Development of distributed long-gage fiber optic sensing system for structural health monitoring. Struct. Health Monit. 2007, 6, 133–145. [Google Scholar] [CrossRef]

- Li, S. Structural Health Monitoring Strategy Based on Distributed Fiber Optic Sensing. Ph.D. Thesis, Ibaraki University, Ibaraki, Japan, 2007. [Google Scholar]

- Hong, W.; Wu, Z.S.; Yang, C.Q.; Wan, C.; Wu, G. Investigation on the damage identification of bridges using distributed long-gauge dynamic macrostrain response under ambient excitation. J. Intell. Mater. Syst. Struct. 2012, 23, 85–103. [Google Scholar] [CrossRef]

- Wang, T.; Tang, Y.S. Dynamic displacement monitoring of flexural structures with distributed long-gage macro-strain sensors. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Tang, Y.S.; Ren, Z.D. Dynamic Method of Neutral Axis Position Determination and Damage Identification with Distributed Long-Gauge FBG Sensors. Sensors 2017, 7, 411. [Google Scholar] [CrossRef]

- Koizumi, A.; Murakami, H.; Nishino, K. Study on the analytical model of shield tunnel in longitudinal direction. Proc. Jpn. Soc. Civ. Eng. 1988, 394, 79–88. (In Japanese) [Google Scholar]

- Shiba, Y.; Kawashima, K.; Obinata, N.; Kano, T. An evaluation method of longitudinal stiffness of shield tunnel lining for application to seismic response analyses. Proc. Jpn. Soc. Civ. Eng. 1988, 398, 319–327. (In Japanese) [Google Scholar]

- Huang, X.; Huang, H.W.; Zhang, J. Flattening of jointed shield-driven tunnel induced by longitudinal differential settlements. Tunn. Undergr. Space Technol. 2012, 31, 20–32. [Google Scholar] [CrossRef]

- Talmon, A.M.; Bezuijen, A. Calculation of longitudinal bending moment and shear force for Shanghai Yangtze river tunnel: Application of lessons from Dutch research. Tunn. Undergr. Space Technol. 2013, 35, 161–171. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.L.; Yang, J.; Zhou, A. Soil-tunnel interaction modelling for shield tunnels considering shearing dislocation in longitudinal joints. Tunn. Undergr. Space Technol. 2018, 78, 168–177. [Google Scholar] [CrossRef]

- Wu, H.N.; Shen, S.L.; Liao, S.M.; Yin, Z.Y. Longitudinal structural modelling of shield tunnels considering shearing dislocation between segmental rings. Tunn. Undergr. Space Technol. 2016, 50, 317–323. [Google Scholar] [CrossRef]

- Xu, L. Study on the Longitudinal Settlement of Shield Tunnel in Soft Soil. Ph.D. Thesis, Tongji University, Shanghai, China, 2005. (In Chinese). [Google Scholar]

- Drissi-Habti, M.; Raman, V.; Khadour, A.; Timorian, S. Fiber Optic Sensor Embedment Study for Multi-Parameter Strain Sensing. Sensor 2017, 17, 667. [Google Scholar] [CrossRef]

- Raman, V.; Drissi-Habti, M.; Limje, P.; Khadour, A. Finer SHM-Coverage of Inter-Plies and Bondings in Smart Composite by Dual Sinusoidal Placed Distributed Optical Fiber Sensors. Sensors 2019, 19, 742. [Google Scholar] [CrossRef] [PubMed]

- Zhong, R.H. Finite Element Analysis of the Lining Structure of Subsea Water Intake Tunnel. Ph.D. Thesis, Zhejiang University, Hanzhou, China, 2011. (In Chinese). [Google Scholar]

| Sensor | p (kPa) | ||||||

|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | |

| S1 | −7 | −20 | −33 | −43 | −63 | −87 | −103 |

| S2 | 3 | 10 | 17 | 57 | 97 | 707 | 900 |

| S3 | 37 | 87 | 157 | 387 | 757 | 1747 | 3230 |

| S4 | 87 | 203 | 370 | 947 | 1793 | 3217 | 7523 |

| S5 | 147 | 340 | 620 | 1497 | 2833 | 6130 | 11,333 |

| S6 | 207 | 477 | 867 | 2213 | 4057 | 9133 | 15,977 |

| S7 | 257 | 593 | 1080 | 2640 | 4857 | 10,567 | 19,997 |

| S8 | 287 | 670 | 1220 | 3033 | 5600 | 12,333 | 23,263 |

| S9 | 303 | 700 | 1270 | 3253 | 6110 | 13,107 | 24,657 |

| Sensor | p (kPa) | ||||||

|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | |

| S1 | −7 | −13 | −27 | −40 | −47 | −60 | −67 |

| S2 | 3 | 7 | 13 | 20 | 57 | 70 | 270 |

| S3 | 30 | 63 | 130 | 183 | 347 | 800 | 1400 |

| S4 | 73 | 147 | 310 | 427 | 933 | 1743 | 3210 |

| S5 | 120 | 243 | 517 | 713 | 1523 | 2803 | 5277 |

| S6 | 170 | 340 | 723 | 1000 | 2133 | 4067 | 7307 |

| S7 | 213 | 423 | 903 | 1227 | 2590 | 5013 | 9033 |

| S8 | 240 | 480 | 1017 | 1413 | 3010 | 5733 | 10,367 |

| S9 | 250 | 500 | 1063 | 1467 | 3170 | 5993 | 11,197 |

| Element | p (kPa) | |||||||

|---|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | ||

| E9 | χ (m) | 2.558 | 2.558 | 2.561 | 2.576 | 2.593 | 2.616 | 2.640 |

| γ (m) | <−2.7 | <−2.7 | <−2.7 | −2.71 | −0.20 | 1.37 | 2.02 | |

| R2 | 1.000 | 1.000 | 1.000 | 0.999 | 0.998 | 0.997 | 0.998 | |

| E6 | χ (m) | 2.558 | 2.560 | 2.561 | 2.561 | 2.571 | 2.586 | 2.607 |

| γ (m) | <−2.7 | <−2.7 | <−2.7 | <−2.7 | −2.71 | −0.21 | 1.10 | |

| R2 | 1.000 | 1.000 | 1.000 | 0.999 | 0.999 | 0.999 | 0.999 | |

| Bolt | p (kPa) | ||||||

|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | |

| B1 | −1 | −2 | −5 | −6 | −7 | −10 | −18 |

| B2 | 1 | 4 | 9 | 10 | 71 | 136 | 113 |

| B3 | 8 | 25 | 54 | 76 | 207 | 297 | 671 |

| B4 | 20 | 63 | 136 | 197 | 347 | 666 | 701 |

| B5 | 33 | 103 | 221 | 326 | 524 | 690 | 719 |

| B6 | 45 | 139 | 299 | 452 | 679 | 703 | 732 |

| B7 | 56 | 176 | 374 | 539 | 691 | 719 | 756 |

| B8 | 65 | 195 | 427 | 619 | 704 | 729 | 776 |

| B9 | 68 | 204 | 447 | 661 | 712 | 736 | 788 |

| Bolt | p (kPa) | ||||||

|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | |

| B1 | −1 | −1 | −4 | −5 | −6 | −8 | −10 |

| B2 | 1 | 2 | 6 | 5 | 10 | 39 | 102 |

| B3 | 6 | 12 | 37 | 61 | 95 | 223 | 611 |

| B4 | 16 | 31 | 94 | 164 | 234 | 513 | 642 |

| B5 | 26 | 51 | 154 | 286 | 390 | 618 | 692 |

| B6 | 35 | 69 | 208 | 401 | 514 | 671 | 711 |

| B7 | 44 | 88 | 263 | 505 | 600 | 701 | 731 |

| B8 | 50 | 101 | 301 | 591 | 639 | 713 | 754 |

| B9 | 53 | 106 | 318 | 621 | 651 | 724 | 762 |

| Equation (19) (Shiba [46]) | Equation (12) (Xu [51]) | Equation (Numerical Model) | |

|---|---|---|---|

| φud/° | 53.9 | 62.7 | 63.9 |

| p (kPa) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | ||

| Numerical model | M (104 kN·m) | 2.005 | 4.010 | 6.014 | 7.351 | 9.356 | 11.360 | 13.365 |

| θ (10−4) | 1.974 | 3.949 | 5.923 | 8.676 | 16.382 | 36.411 | 130.179 | |

| EI (108 kN·m2) | 1.523 | 1.523 | 1.523 | 1.116 | 0.857 | 0.468 | 0.154 | |

| (EI)d/(EI)ud | 1.000 | 1.000 | 1.000 | 0.617 | 0.503 | 0.323 | 0.117 | |

| Monitoring | ηud | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 |

| ηd | 0.126 | 0.126 | 0.126 | 0.078 | 0.064 | 0.041 | 0.015 | |

| HFM1 | 1.000 | 1.000 | 1.000 | 0.619 | 0.508 | 0.325 | 0.119 | |

| Error (%) | 0.0 | 0.0 | 0.0 | 0.3 | 1.0 | 0.6 | 1.7 | |

| p (kPa) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | ||

| From Numerical Model | M (104 kN·m) | 1.800 | 3.600 | 5.400 | 6.300 | 7.200 | 9.000 | 10.800 |

| θ (10−4) | 1.773 | 3.546 | 5.318 | 6.500 | 8.247 | 20.265 | 44.118 | |

| EI (108 kN·m2) | 1.523 | 1.523 | 1.523 | 1.523 | 1.172 | 0.755 | 0.408 | |

| (EI)d/(EI)ud | 1.000 | 1.000 | 1.000 | 1.000 | 0.770 | 0.496 | 0.268 | |

| From Monitoring | ηud | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 | 0.126 |

| ηd | 0.126 | 0.126 | 0.126 | 0.126 | 0.097 | 0.063 | 0.034 | |

| HFM1 | 1.000 | 1.000 | 1.000 | 1.000 | 0.770 | 0.500 | 0.270 | |

| Error (%) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.8 | 0.7 | |

| p (kPa) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | ||

| Table 4 | nd | 16 | 16 | 16 | 15 | 9 | 5 | 3 |

| From Monitoring | nd | 16 | 16 | 16 | 15 | 9 | 5 | 3 |

| p (kPa) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 30 | 60 | 90 | 105 | 120 | 150 | 180 | ||

| Table 5 | nd | 16 | 16 | 16 | 16 | 15 | 9 | 5 |

| From Monitoring | nd | 16 | 16 | 16 | 16 | 15 | 9 | 5 |

| y (mm) | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| P/kN | 0.286 | 1.499 | 3.071 | 4.57 | 6.066 | 6.784 | 7.354 | 7.999 | 8.571 | 9.144 | 9.786 | 10.071 |

| Sensor | y (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| S1 | −3 | −8 | −45 | −76 | −131 | −175 | −190 | −244 | −260 | −370 | −390 | −420 |

| S2 | −1 | −7 | −33 | −64 | −90 | −110 | −95 | −60 | −20 | 1 | 60 | 690 |

| S3 | 4 | 5 | 8 | 23 | 44 | 63 | 77 | 100 | 155 | 629 | 1602 | 3120 |

| S4 | 18 | 50 | 105 | 291 | 479 | 825 | 979 | 1182 | 1558 | 2067 | 3256 | 3555 |

| S5 | 30 | 80 | 317 | 492 | 845 | 1315 | 1559 | 1877 | 2146 | 3302 | 3649 | − * |

| S6 | 49 | 110 | 452 | 663 | 1142 | 1695 | 1752 | 2006 | 3420 | 3692 | − | − |

| S7 | 70 | 160 | 520 | 850 | 1507 | 2095 | 2339 | 3468 | 3536 | − | − | − |

| S8 | 88 | 210 | 603 | 1080 | 1901 | 3314 | 3412 | 3544 | − | − | − | − |

| S9 | 104 | 236 | 709 | 1261 | 2150 | 3473 | 3659 | − | − | − | − | − |

| S10 | 114 | 270 | 854 | 1495 | 2624 | 3578 | − | − | − | − | − | − |

| Sensor | y (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| S1 | −3 | −7 | −42 | −71 | −122 | −150 | −173 | −188 | −226 | −241 | −385 | −398 |

| S2 | −1 | −6 | −31 | −59 | −84 | −103 | −109 | −94 | −56 | −19 | 2 | 57 |

| S3 | 4 | 5 | 7 | 21 | 41 | 50 | 62 | 76 | 93 | 144 | 590 | 1555 |

| S4 | 17 | 46 | 97 | 270 | 446 | 545 | 817 | 969 | 1245 | 1504 | 2296 | 3273 |

| S5 | 28 | 74 | 294 | 457 | 784 | 964 | 1302 | 1543 | 1812 | 2071 | 3346 | 3698 |

| S6 | 45 | 105 | 419 | 615 | 1060 | 1304 | 1678 | 1814 | 1936 | 3405 | 3666 | − |

| S7 | 65 | 148 | 483 | 789 | 1398 | 1720 | 2074 | 2316 | 3347 | 3516 | − | − |

| S8 | 82 | 195 | 570 | 1005 | 1764 | 2170 | 3361 | 3478 | 3525 | − | − | − |

| S9 | 97 | 226 | 650 | 1170 | 1995 | 2441 | 3438 | 3622 | − | − | − | − |

| S10 | 106 | 252 | 793 | 1387 | 2435 | 2995 | 3542 | − | − | − | − | − |

| Element | y (mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| E10 | χ (mm) | 321.4 | 321.1 | 321.0 | 321.0 | 321.0 | 327.3 | 338.5 | 347.1 | 356.9 | 367.1 | 377.2 | 384.4 |

| γ (mm) | <389.6 | <389.6 | <389.6 | <389.6 | <389.6 | 389.0 | −354.5 | −251.7 | −125.5 | 7.2 | 132.0 | 238.1 | |

| R2 | 0.981 | 0.980 | 0.980 | 0.980 | 0.980 | 0.979 | 0.977 | 0.970 | 0.965 | 0.960 | 0.910 | 0.829 | |

| E8 | χ (mm) | 321.2 | 321.2 | 321.0 | 321.0 | 321.0 | 320.9 | 326.2 | 338.7 | 348.7 | 355.8 | 366.4 | 376.5 |

| γ (mm) | <389.6 | <389.6 | <389.6 | <389.6 | <389.6 | <389.6 | −389.6 | −352.2 | −264.1 | −131.1 | 15.3 | 133.4 | |

| R2 | 0.981 | 0.980 | 0.981 | 0.980 | 0.980 | 0.980 | 0.978 | 0.976 | 0.968 | 0.967 | 0.941 | 0.916 | |

| Bolt | y (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| B1 | −11 | −37 | −84 | −116 | −153 | −175 | −186 | −279 | −322 | −474 | −541 | −597 |

| B2 | −8 | −27 | −61 | −76 | −183 | −129 | −100 | −70 | −52 | −31 | −11 | 30 |

| B3 | 5 | 17 | 38 | 55 | 84 | 97 | 170 | 302 | 328 | 436 | 711 | 1273 |

| B4 | 12 | 39 | 88 | 153 | 277 | 381 | 598 | 801 | 1179 | 1260 | 2131 | 3537 |

| B5 | 35 | 118 | 267 | 394 | 705 | 1061 | 1274 | 1401 | 1680 | 2856 | 3781 | 4643 |

| B6 | 49 | 165 | 373 | 649 | 1030 | 1715 | 1984 | 2208 | 2711 | 3792 | 4603 | − * |

| B7 | 76 | 252 | 570 | 895 | 1416 | 2280 | 2744 | 3094 | 4172 | 4495 | − | − |

| B8 | 85 | 283 | 641 | 1137 | 1846 | 2745 | 3201 | 4048 | 4673 | − | − | − |

| B9 | 96 | 321 | 715 | 1255 | 2071 | 3210 | 3861 | 4546 | − | − | − | − |

| B10 | 100 | 333 | 757 | 1315 | 2163 | 3615 | 4325 | − | − | − | − | − |

| Bolt | y (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| B1 | −2 | −8 | −18 | −28 | −61 | −79 | −130 | −136 | −283 | −364 | −476 | −502 |

| B2 | 0 | −4 | −10 | −15 | −32 | −41 | −71 | −90 | −232 | −274 | −376 | −395 |

| B3 | 0 | −1 | −2 | −3 | −7 | −10 | 51 | 98 | 167 | 195 | 440 | 1099 |

| B4 | 7 | 24 | 52 | 79 | 168 | 222 | 336 | 542 | 737 | 1096 | 1947 | 2355 |

| B5 | 27 | 77 | 165 | 253 | 539 | 710 | 1097 | 1466 | 1649 | 2268 | 3114 | 3721 |

| B6 | 41 | 114 | 245 | 375 | 801 | 1055 | 1735 | 2018 | 2701 | 3195 | 4025 | 4549 |

| B7 | 57 | 158 | 340 | 521 | 1113 | 1465 | 2274 | 2795 | 3587 | 3794 | 4524 | − |

| B8 | 76 | 209 | 448 | 687 | 1466 | 1930 | 3000 | 3675 | 4083 | 4524 | − | − |

| B9 | 85 | 233 | 499 | 766 | 1635 | 2152 | 3347 | 4097 | 4564 | − | − | − |

| B10 | 95 | 259 | 557 | 854 | 1823 | 2400 | 3623 | 4565 | − | − | − | − |

| y (mm) | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| M (kN·m) | 0.400 | 2.099 | 4.300 | 6.398 | 8.493 | 9.497 | 10.296 | 11.198 |

| κ (10−3 m−1) | 0.043 | 0.226 | 0.463 | 0.689 | 0.915 | 1.205 | 1.443 | 1.807 |

| EI (103 kN·m2) | 9.291 | 9.289 | 9.288 | 9.286 | 9.282 | 7.881 | 7.135 | 6.197 |

| (EI)d/(EI)ud | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.848 | 0.768 | 0.667 |

| y (mm) | ||||||||

| 9 | 10 | 11 | 12 | |||||

| M (kN·m) | 12.000 | 12.801 | 13.701 | 14.100 | ||||

| κ (10−3 m−1) | 2.340 | 3.295 | 4.966 | 8.930 | ||||

| EI (103 kN·m2) | 5.128 | 3.885 | 2.759 | 1.579 | ||||

| (EI)d/(EI)ud | 0.552 | 0.418 | 0.297 | 0.170 | ||||

| y (mm) | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| ηud | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 |

| ηd | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.125 | 0.114 | 0.099 |

| HFM1 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.867 | 0.788 | 0.687 |

| y (mm) | ||||||||

| 9 | 10 | 11 | 12 | |||||

| ηud | 0.144 | 0.144 | 0.144 | 0.144 | ||||

| ηd | 0.082 | 0.063 | 0.046 | 0.027 | ||||

| HFM1 | 0.572 | 0.438 | 0.316 | 0.184 | ||||

| y (mm) | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Error (%) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 2.2 | 2.6 | 3.0 |

| y (mm) | ||||||||

| 9 | 10 | 11 | 12 | |||||

| Error (%) | 3.6 | 4.8 | 6.4 | 8.2 | ||||

| y (mm) | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| M (kN·m) | 0.372 | 1.949 | 3.992 | 5.944 | 7.886 | 8.819 | 9.560 | 10.399 |

| κ (10−3 m−1) | 0.040 | 0.210 | 0.430 | 0.640 | 0.849 | 0.950 | 1.212 | 1.482 |

| EI (103 kN·m2) | 9.290 | 9.288 | 9.291 | 9.287 | 9.285 | 9.283 | 7.887 | 7.017 |

| (EI)d/(EI)ud | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.849 | 0.755 |

| y (mm) | ||||||||

| 9 | 10 | 11 | 12 | |||||

| M (kN·m) | 10.898 | 11.598 | 12.499 | 12.800 | ||||

| κ (10−3 m−1) | 1.885 | 2.586 | 4.125 | 6.972 | ||||

| EI (103 kN·m2) | 5.910 | 4.597 | 3.084 | 1.878 | ||||

| (EI)d/(EI)ud | 0.636 | 0.495 | 0.332 | 0.202 | ||||

| y (mm) | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| ηud | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 |

| ηd | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.144 | 0.125 | 0.112 |

| HFM1 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.871 | 0.777 |

| y (mm) | ||||||||

| 9 | 10 | 11 | 12 | |||||

| ηud | 0.144 | 0.144 | 0.144 | 0.144 | ||||

| ηd | 0.095 | 0.075 | 0.051 | 0.032 | ||||

| HFM1 | 0.660 | 0.519 | 0.353 | 0.220 | ||||

| y (mm) | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Error (%) | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 2.6 | 2.9 |

| y (mm) | ||||||||

| 9 | 10 | 11 | 12 | |||||

| Error (%) | 3.8 | 4.8 | 6.3 | 8.9 | ||||

| y (mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| Table 4 | nd | 18 | 18 | 18 | 18 | 18 | 17 | 15 | 13 | 11 | 9 | 7 | 5 |

| From Monitoring | nd | 18 | 18 | 18 | 18 | 18 | 18 | 15 | 13 | 11 | 9 | 7 | 5 |

| y (mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| Table 4 | nd | 18 | 18 | 18 | 18 | 18 | 18 | 17 | 15 | 13 | 11 | 9 | 7 |

| From Monitoring | nd | 18 | 18 | 18 | 18 | 18 | 18 | 17 | 15 | 13 | 11 | 9 | 7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, S.; Lv, H.; Ma, S.-L. Damage Detection and Evaluation for an In-Service Shield Tunnel Based on the Monitored Increment of Neutral Axis Depth Using Long-Gauge Fiber Bragg Grating Sensors. Sensors 2019, 19, 1840. https://doi.org/10.3390/s19081840

Shen S, Lv H, Ma S-L. Damage Detection and Evaluation for an In-Service Shield Tunnel Based on the Monitored Increment of Neutral Axis Depth Using Long-Gauge Fiber Bragg Grating Sensors. Sensors. 2019; 19(8):1840. https://doi.org/10.3390/s19081840

Chicago/Turabian StyleShen, Sheng, Huaxin Lv, and Sheng-Lan Ma. 2019. "Damage Detection and Evaluation for an In-Service Shield Tunnel Based on the Monitored Increment of Neutral Axis Depth Using Long-Gauge Fiber Bragg Grating Sensors" Sensors 19, no. 8: 1840. https://doi.org/10.3390/s19081840

APA StyleShen, S., Lv, H., & Ma, S.-L. (2019). Damage Detection and Evaluation for an In-Service Shield Tunnel Based on the Monitored Increment of Neutral Axis Depth Using Long-Gauge Fiber Bragg Grating Sensors. Sensors, 19(8), 1840. https://doi.org/10.3390/s19081840