Remote Control of Greenhouse Vegetable Production with Artificial Intelligence—Greenhouse Climate, Irrigation, and Crop Production

Abstract

1. Introduction

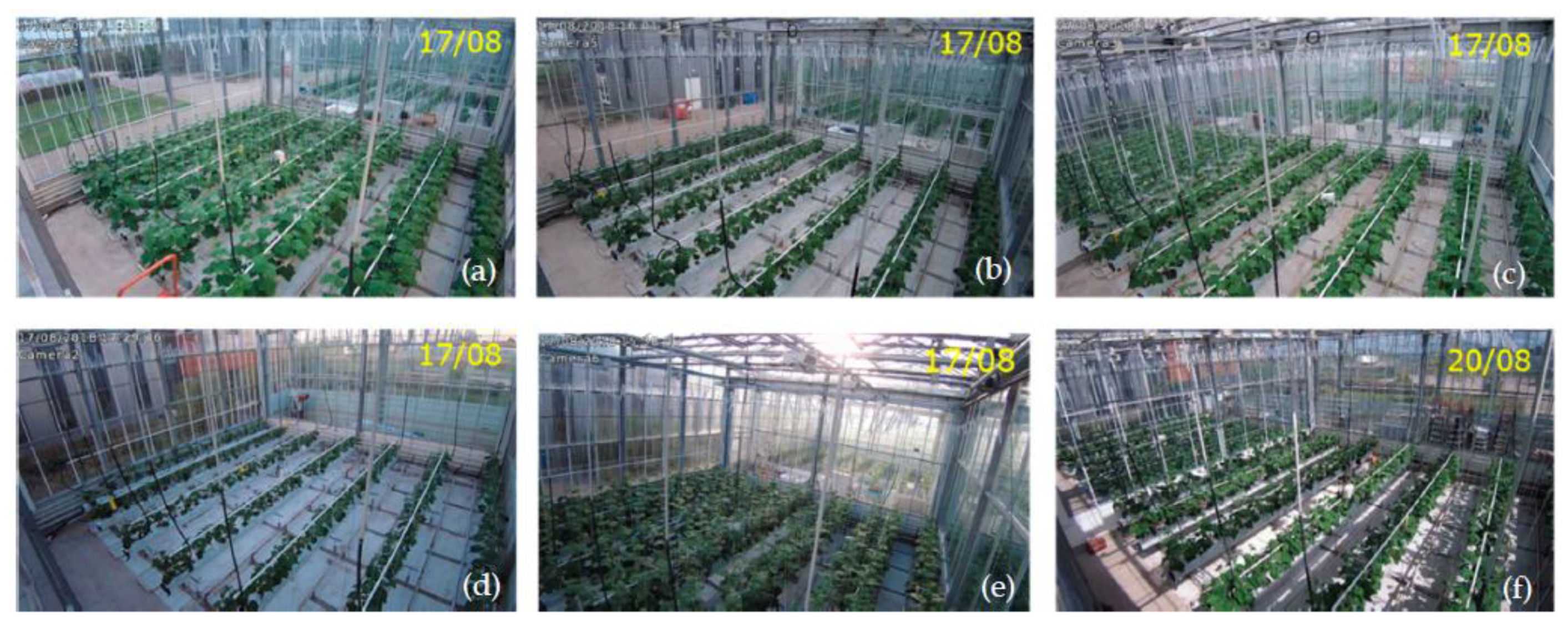

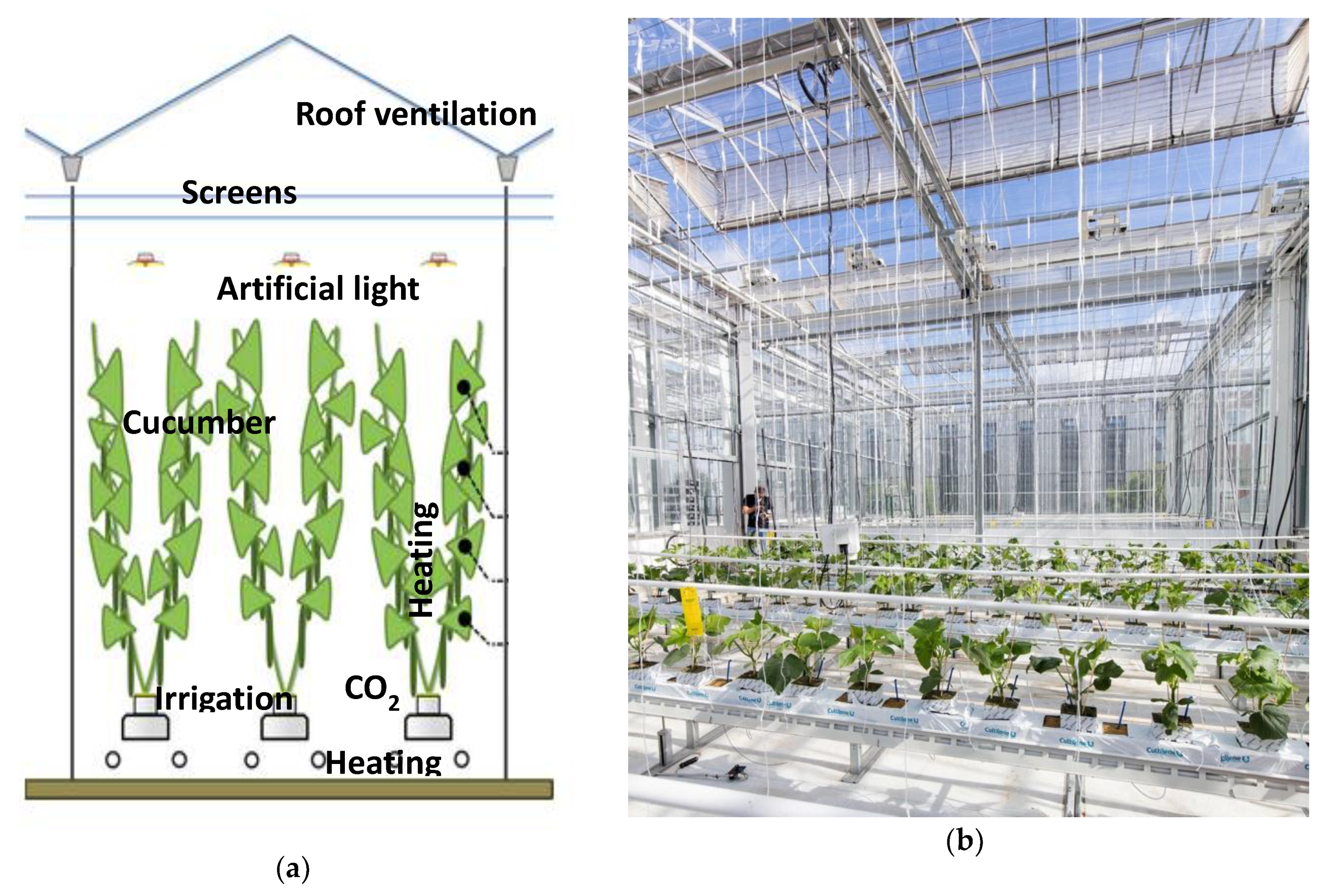

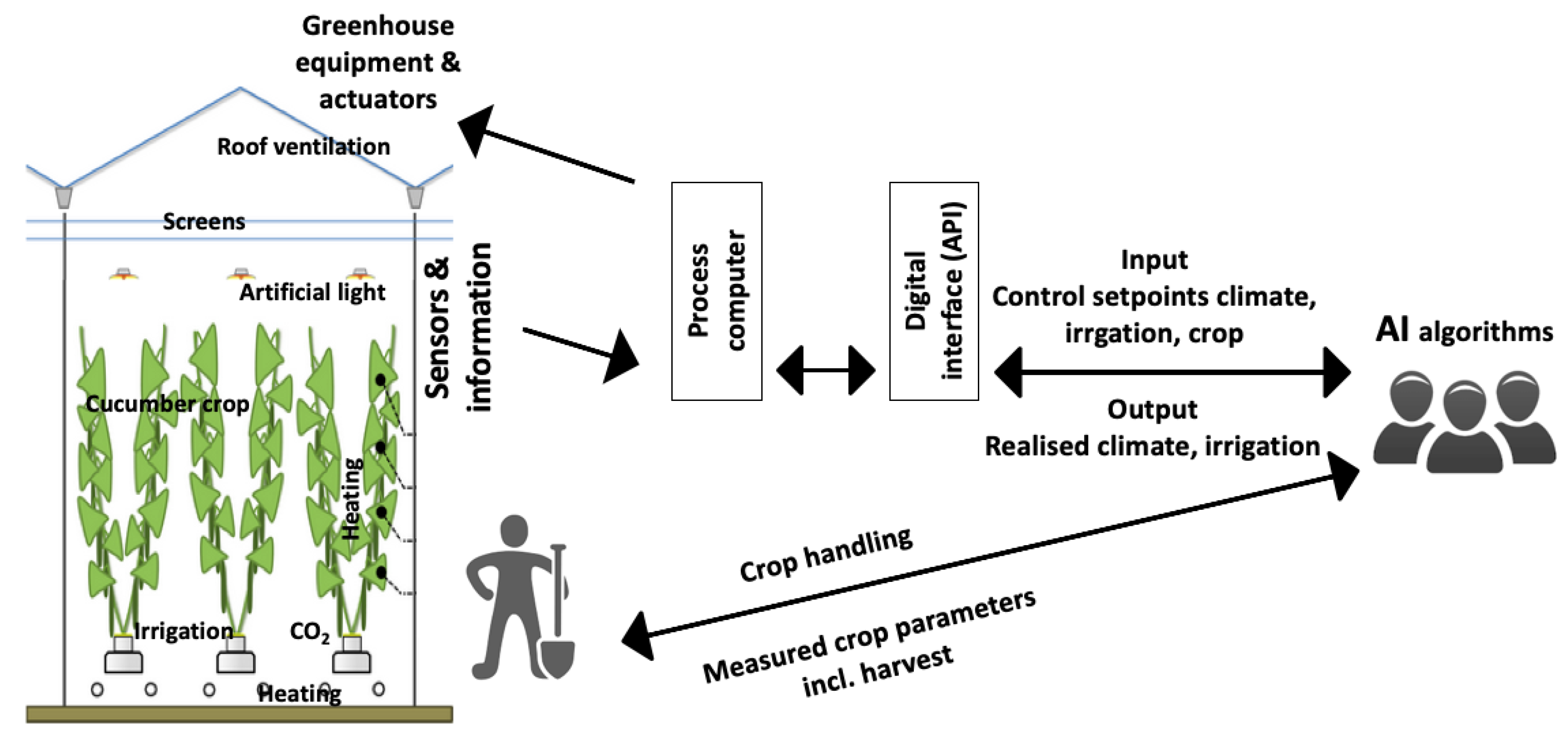

2. Materials and Methods

2.1. Greenhouse Compartments and Actuators

2.2. Sensors and Remote Control

2.3. Crop and Crop Parameters

2.4. AI Algorithms

2.5. Performance Criteria

2.6. Analysis and Interpretation of Results

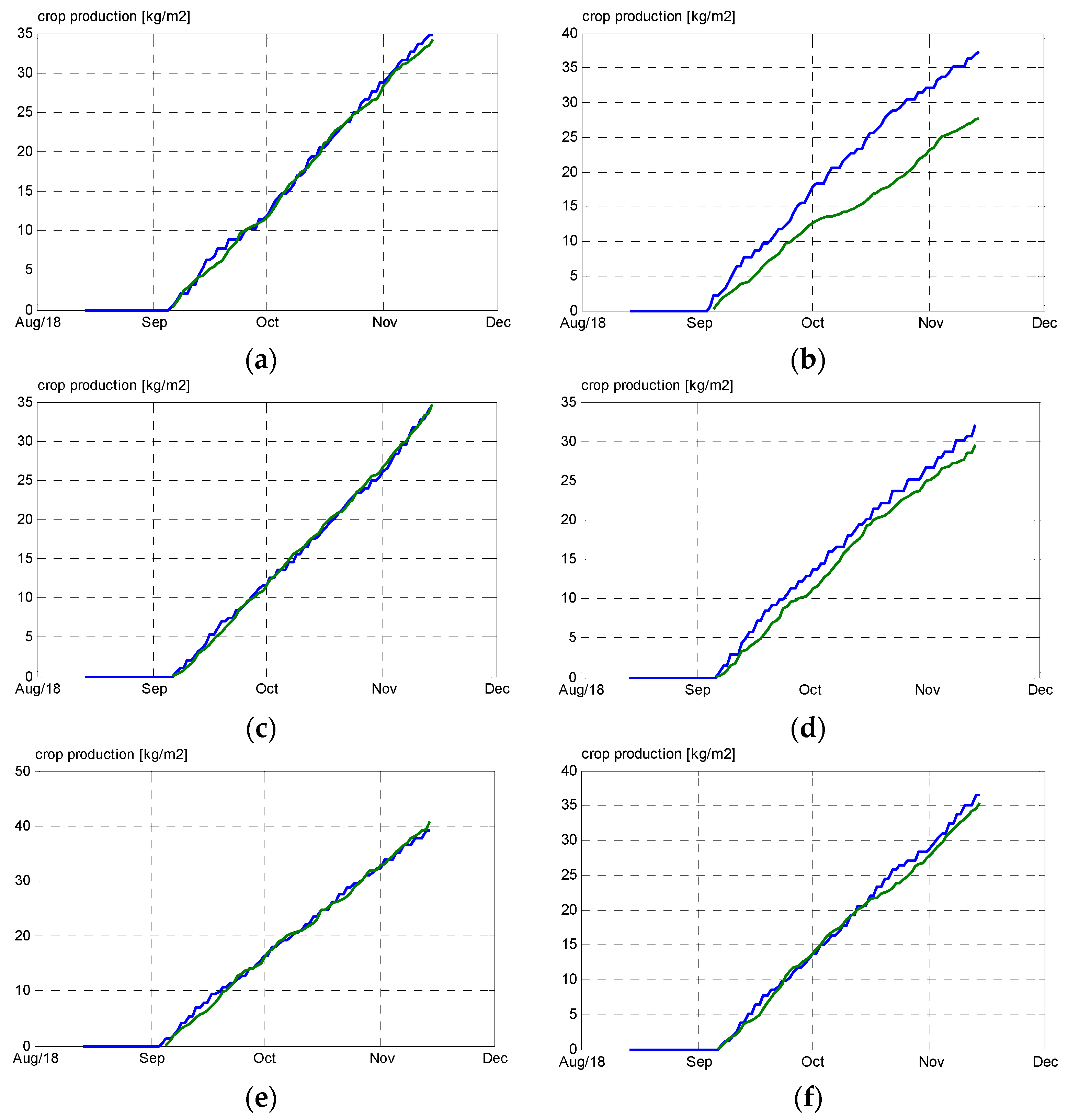

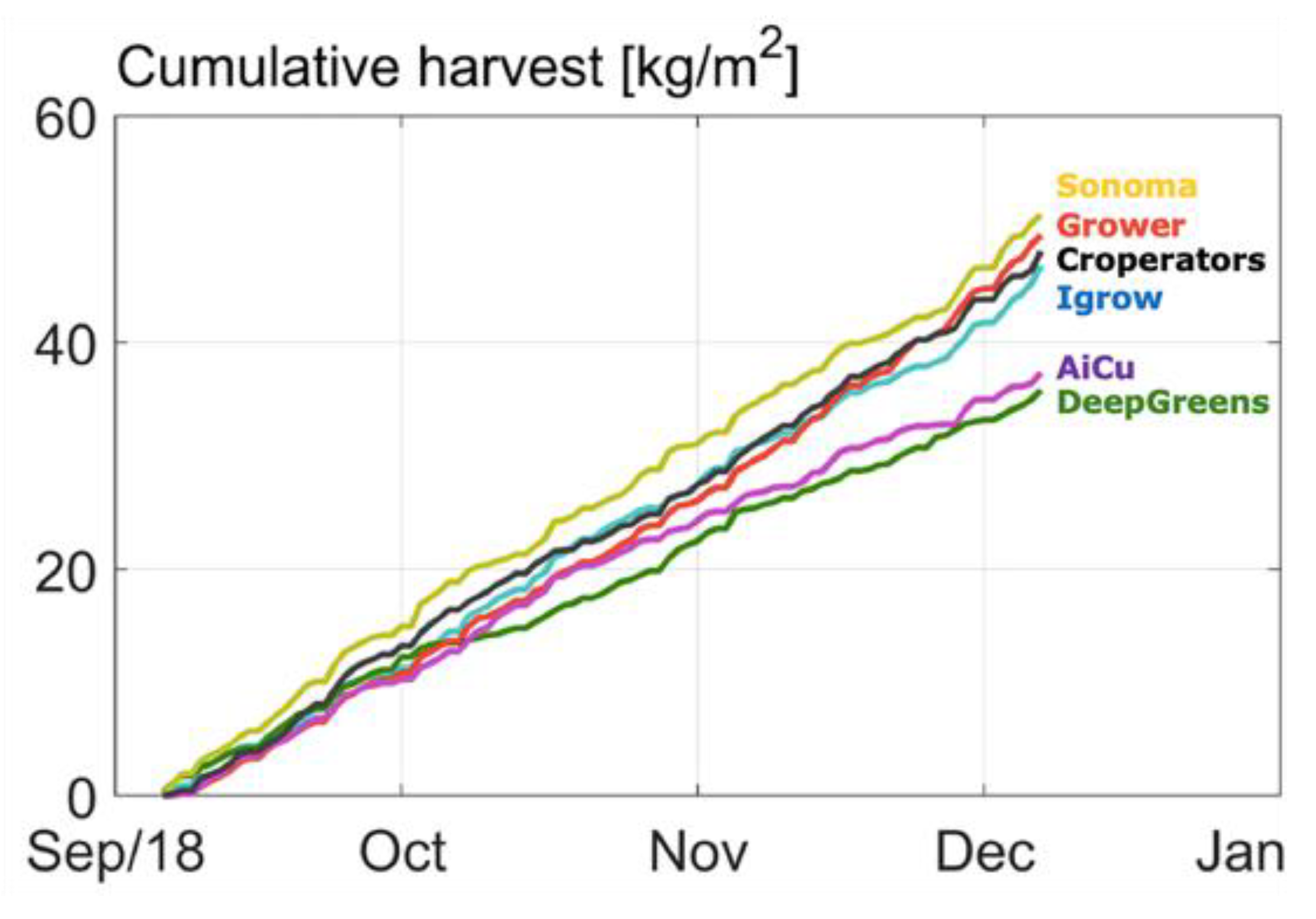

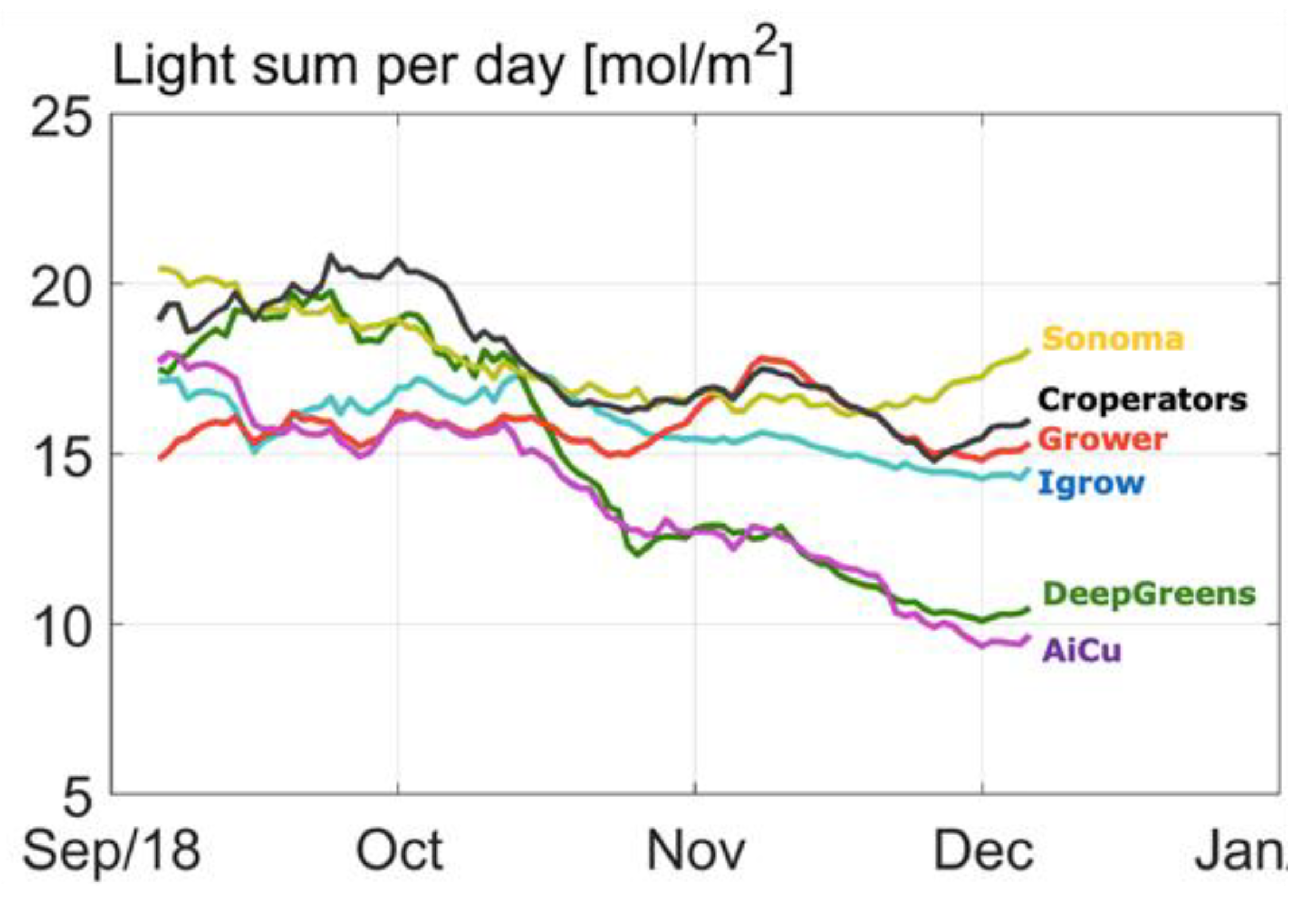

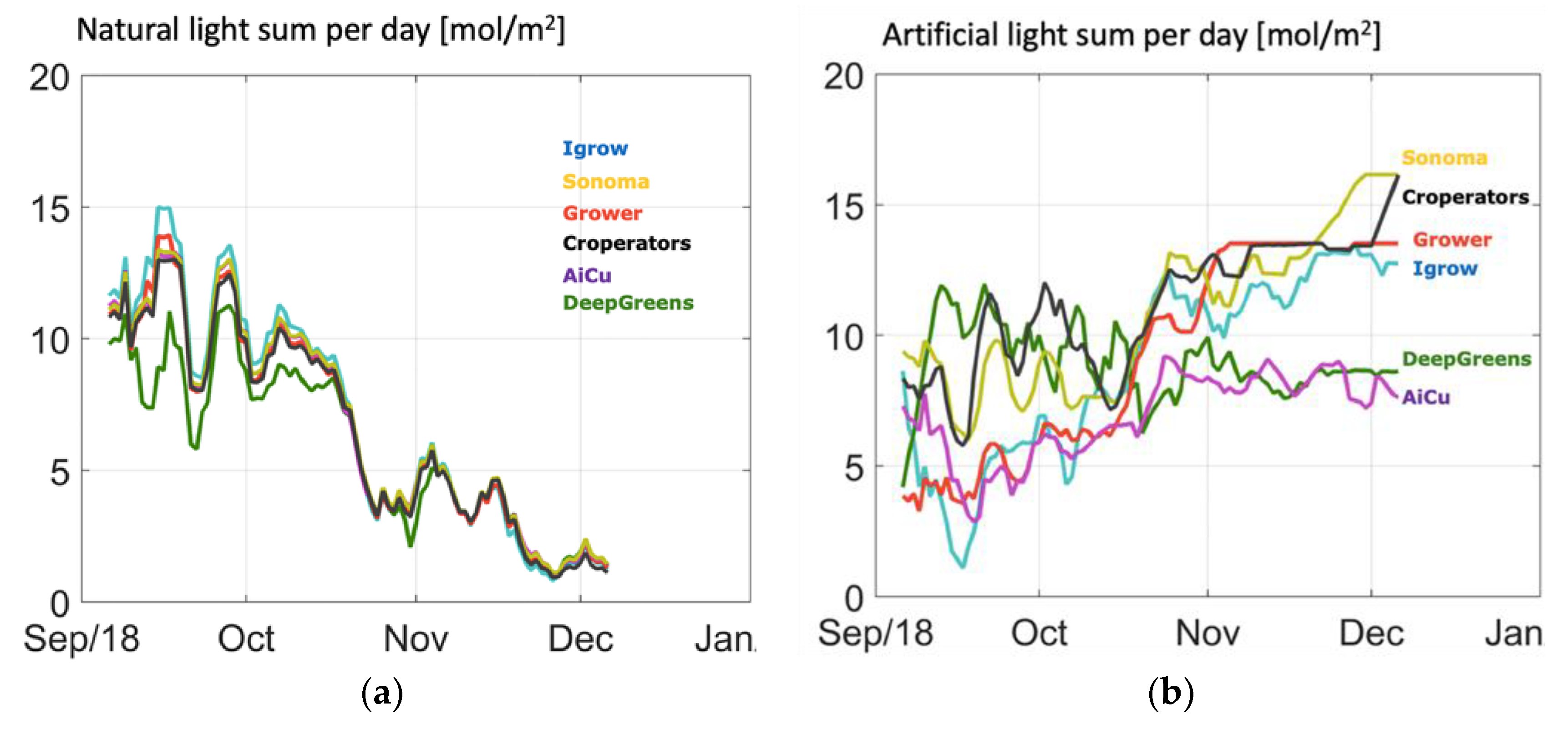

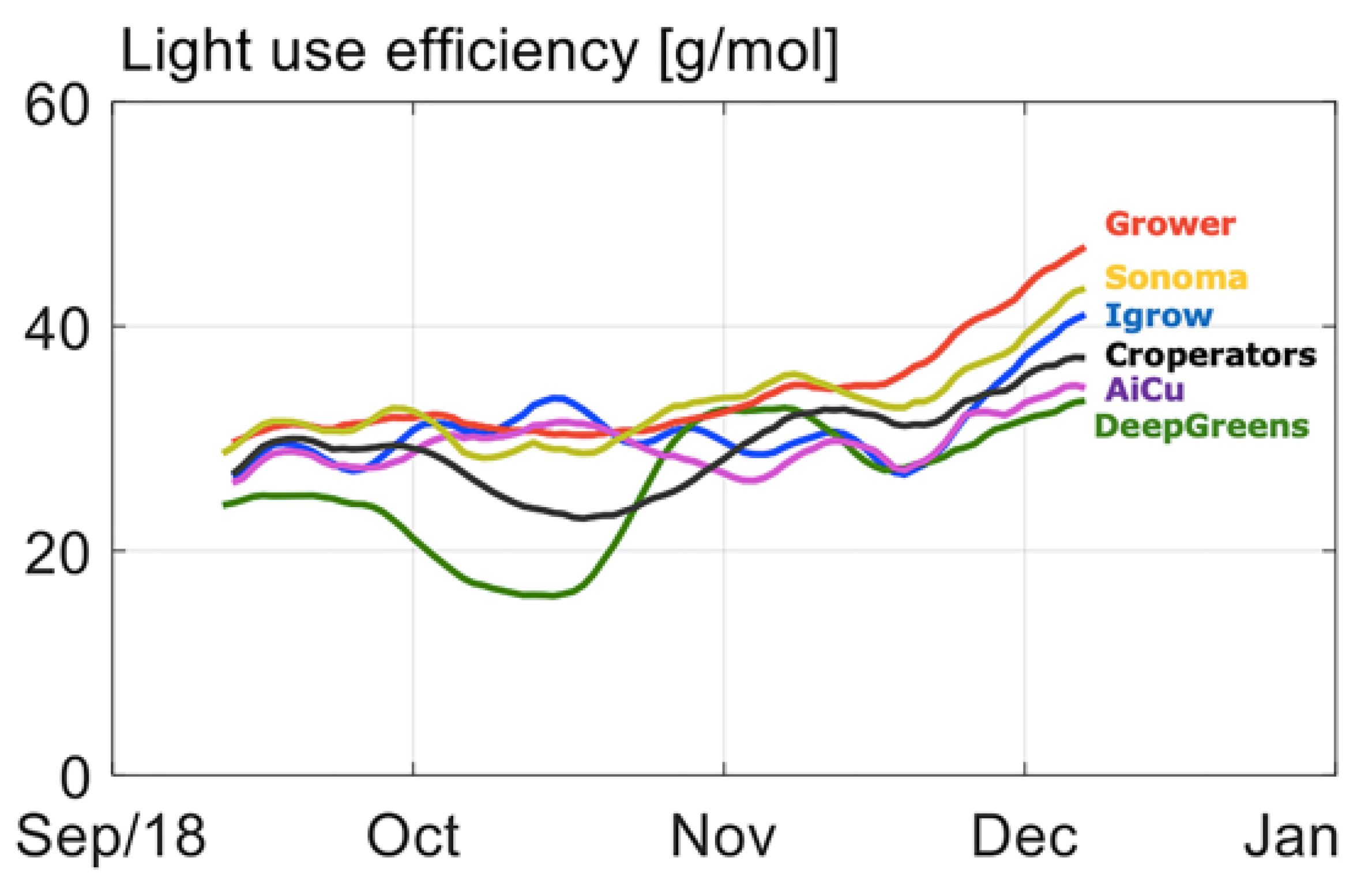

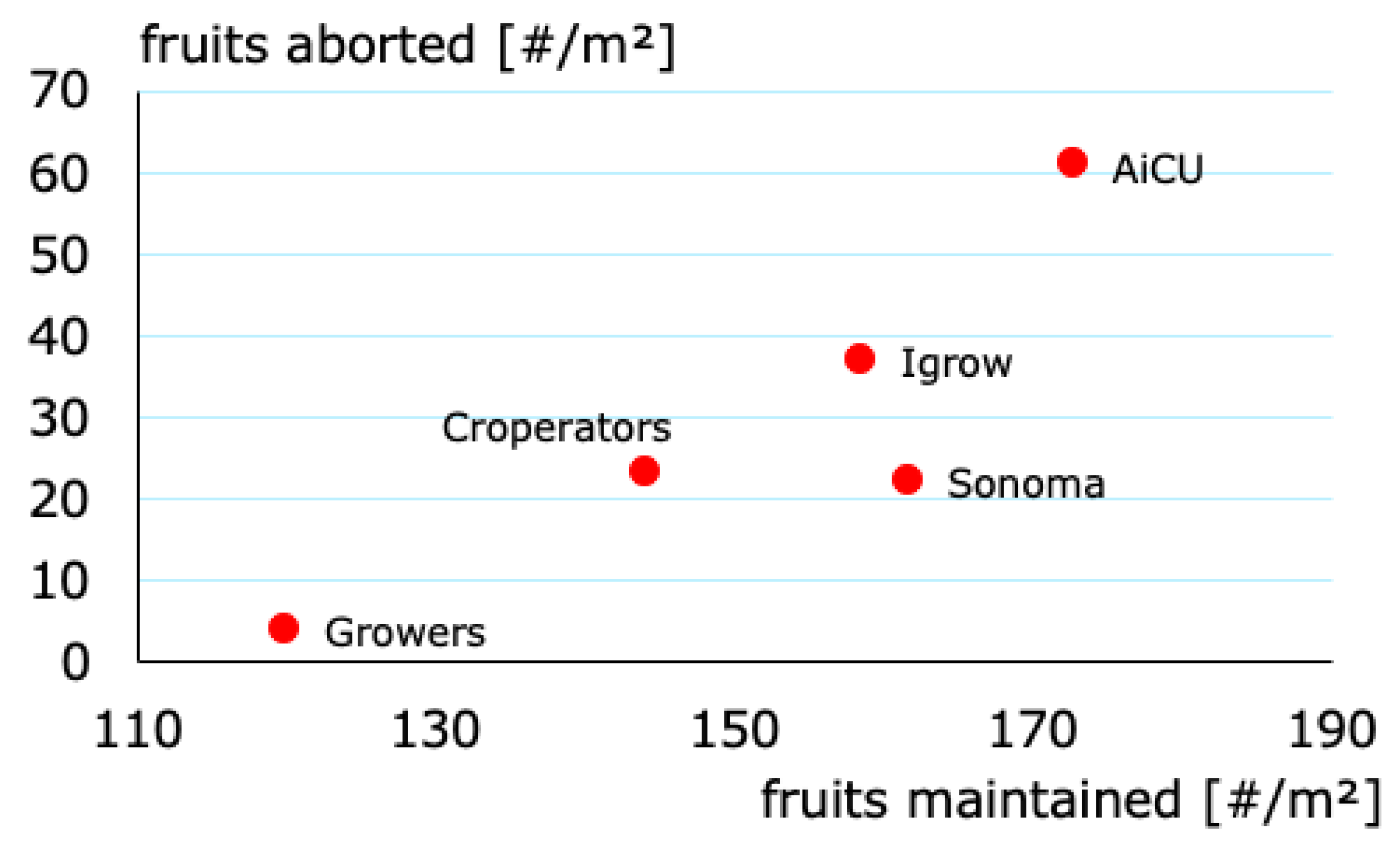

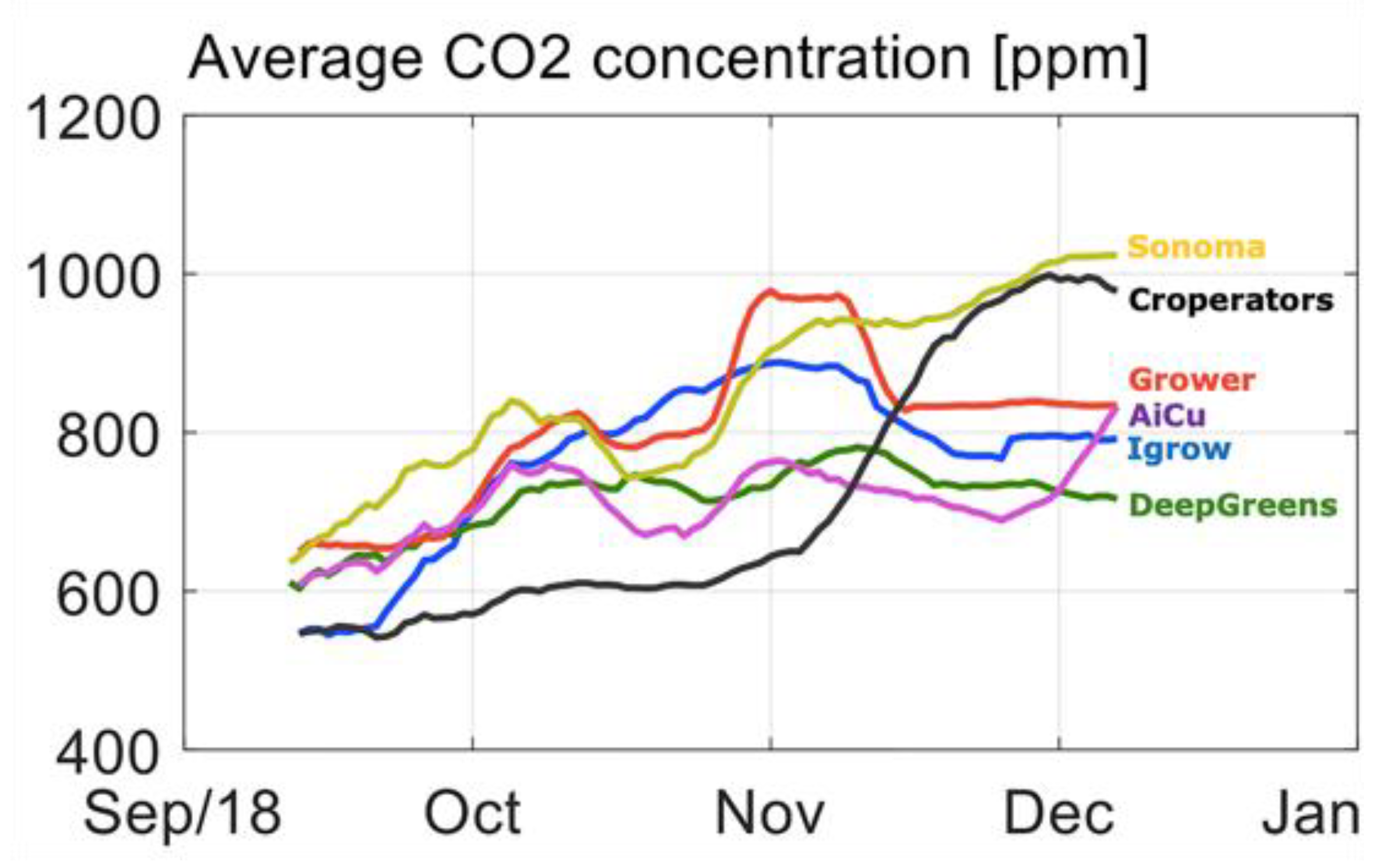

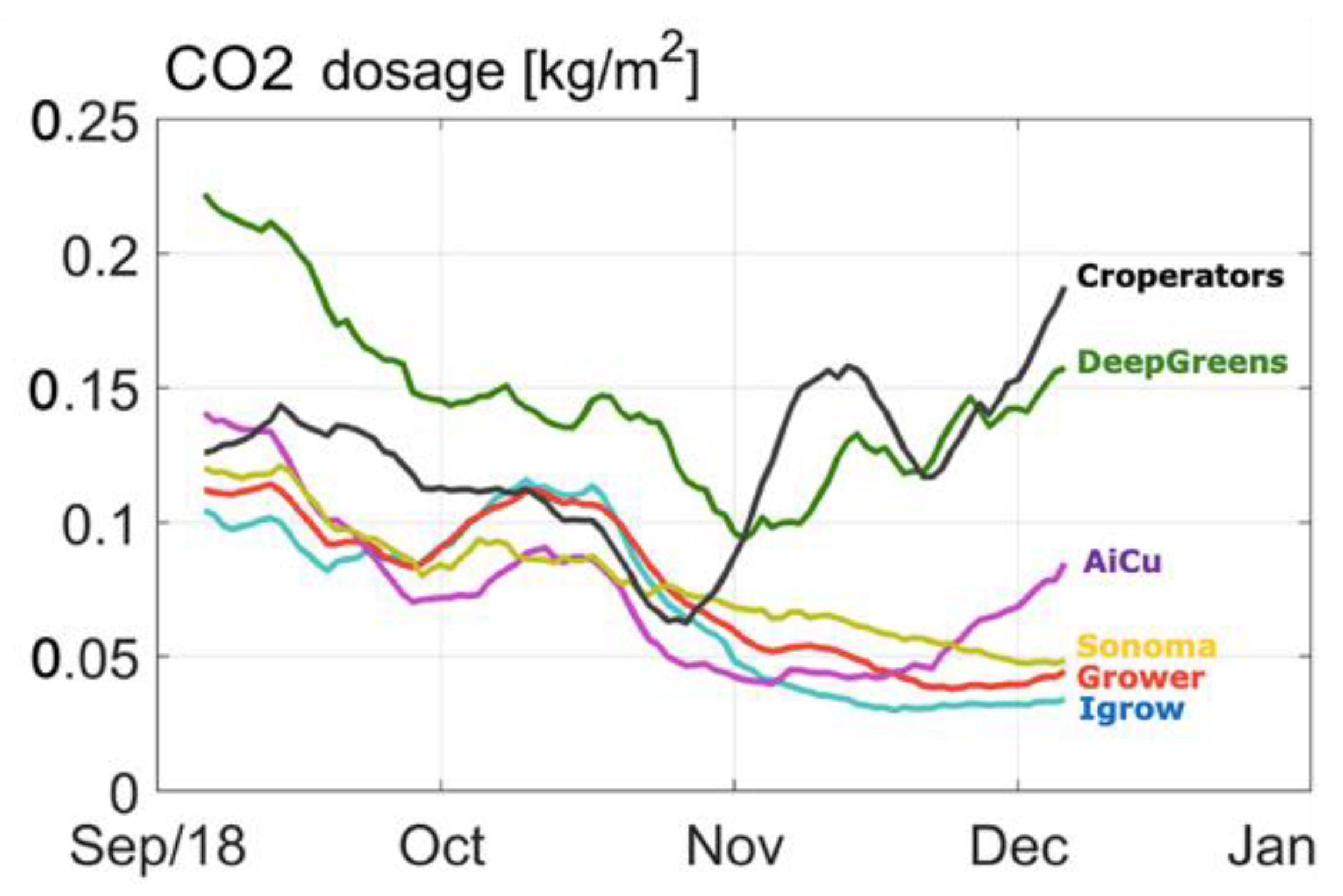

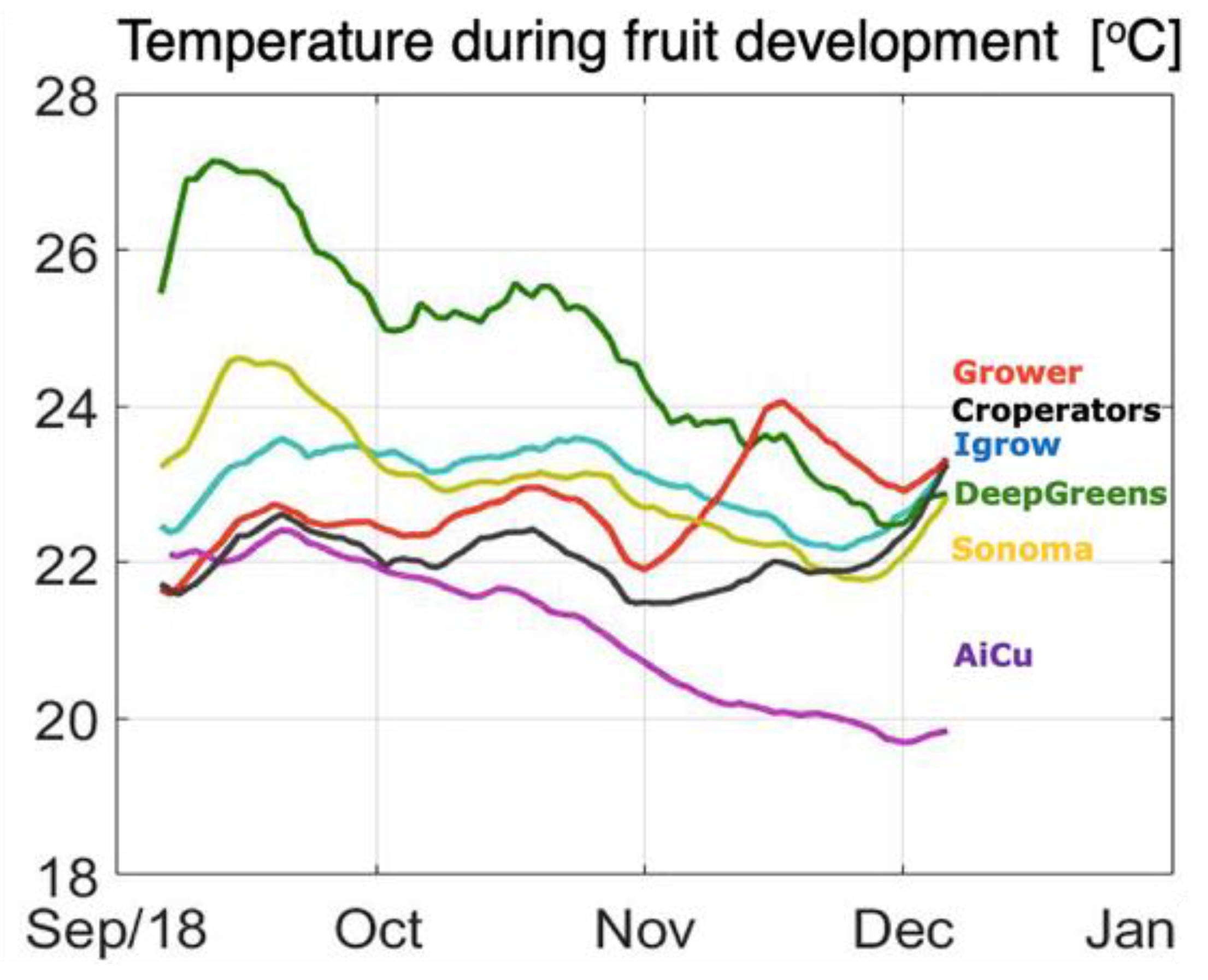

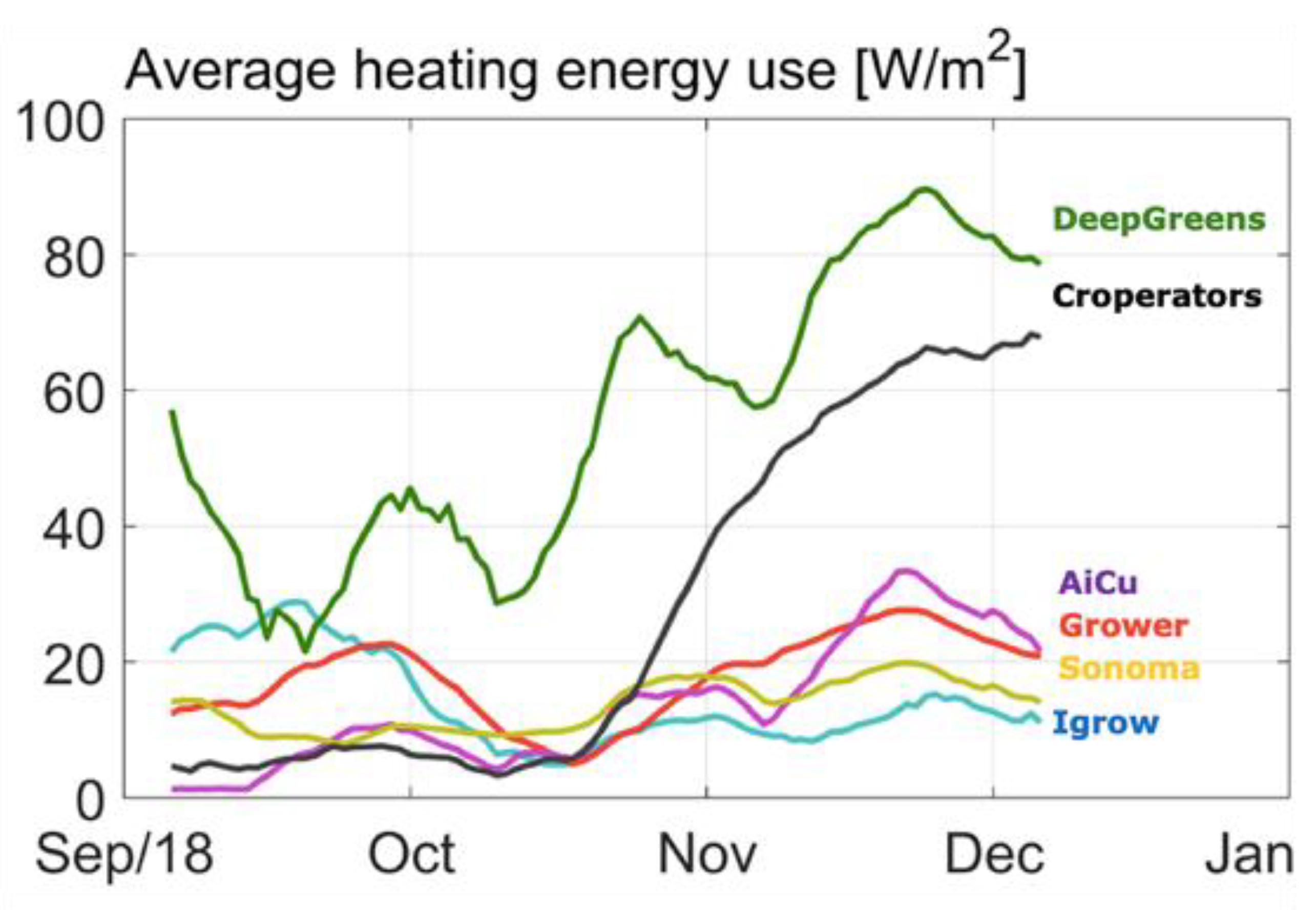

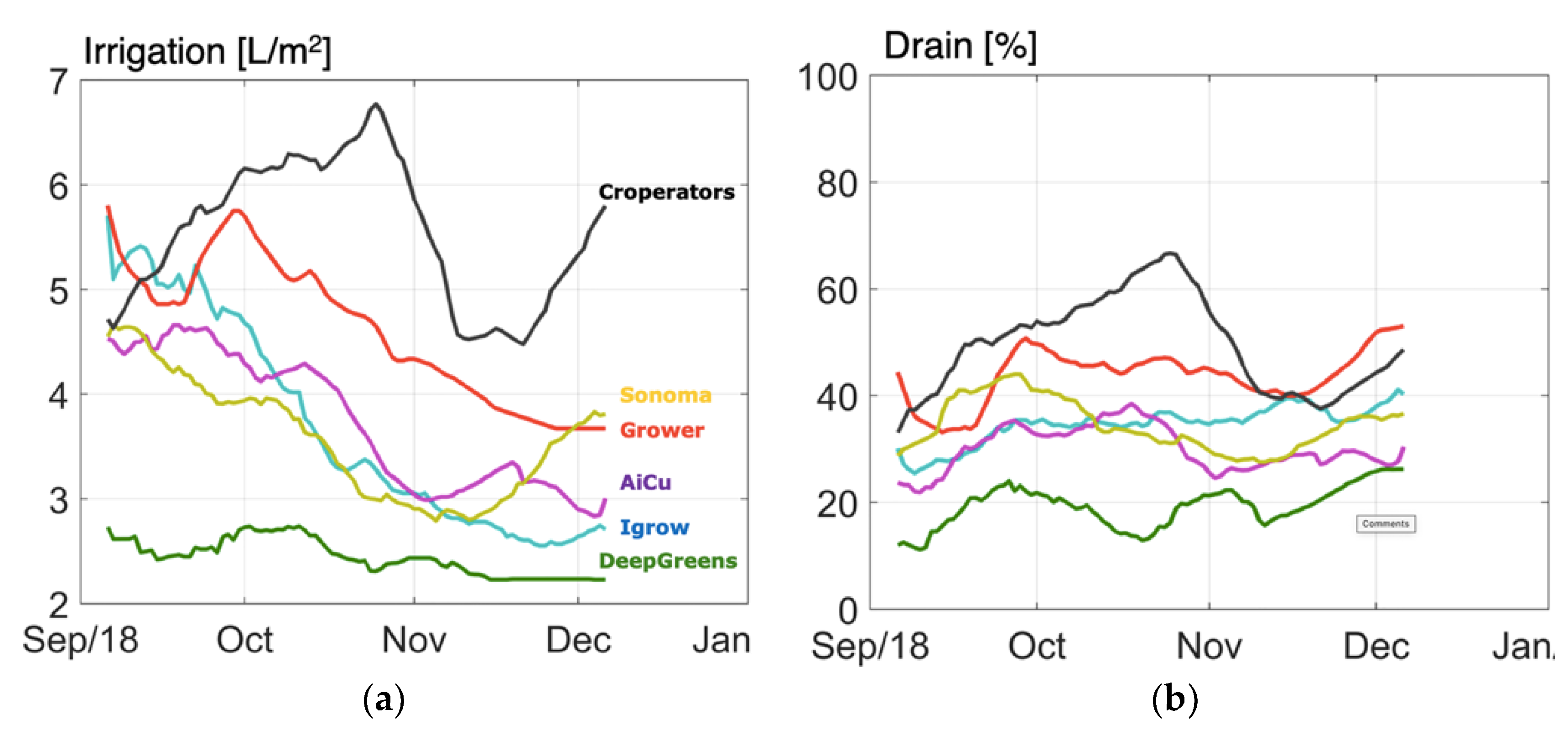

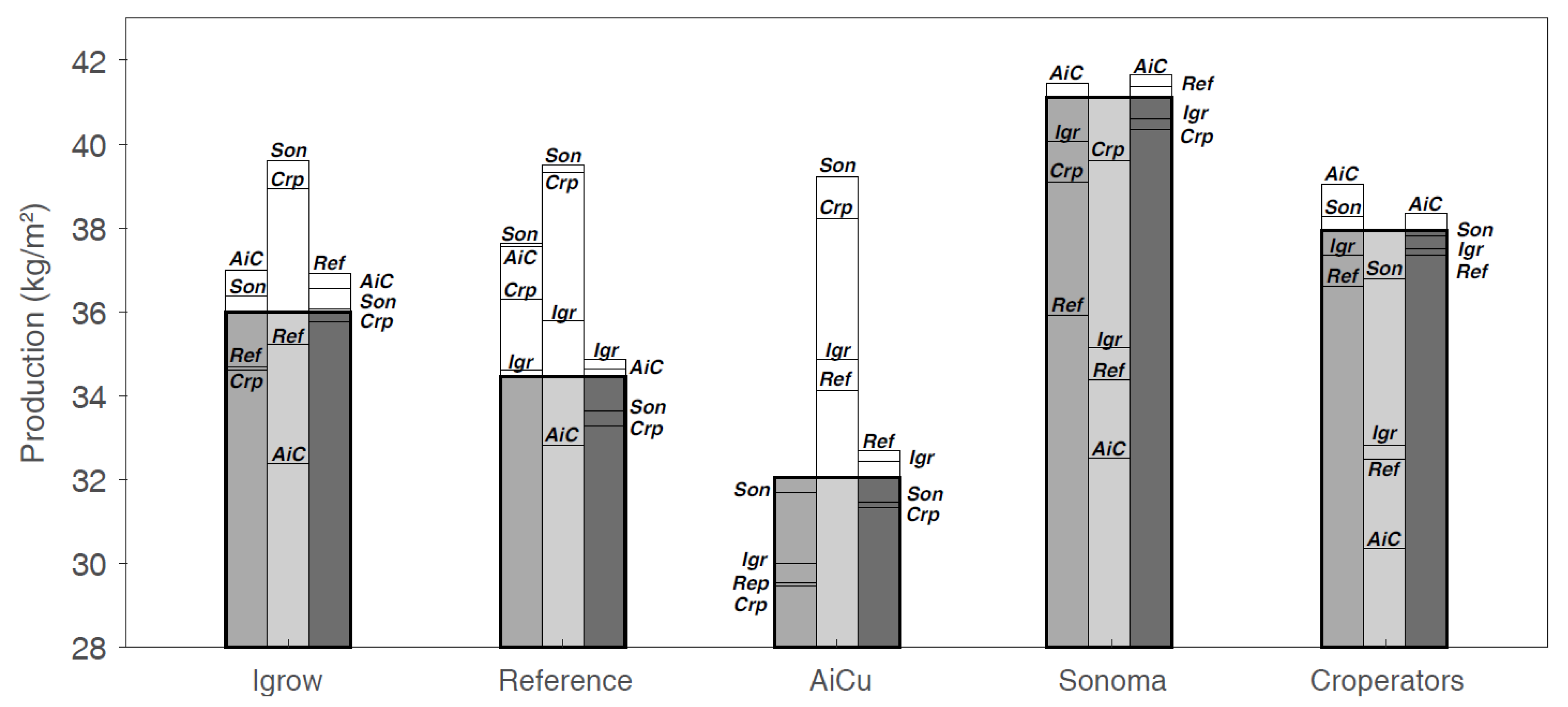

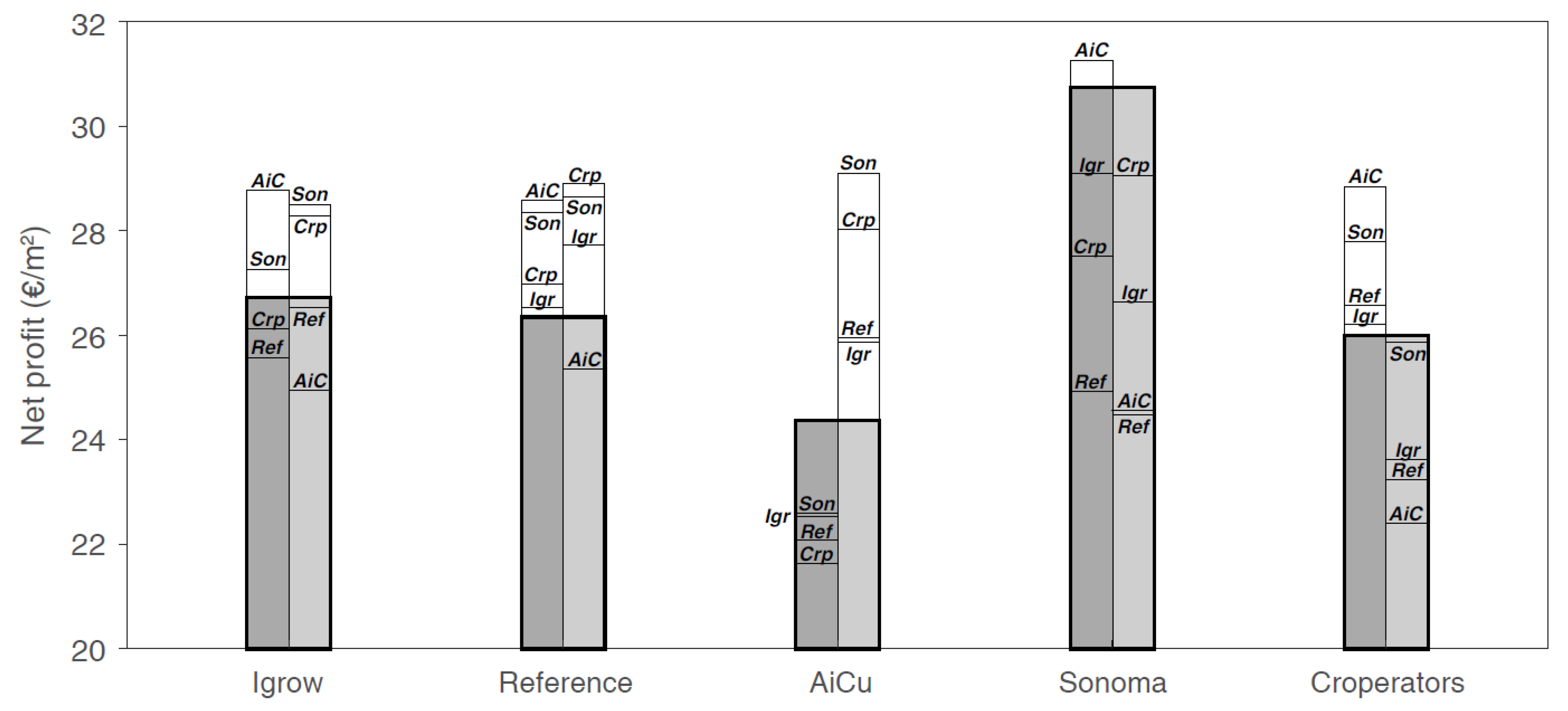

3. Results

4. Discussion

4.1. Crop Growing Strategy

4.2. Control Strategy

4.3. Sensors

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- FAO. The State of Food Security and Nutrition in the World—Building Climate Resilience for Food Security And Nutrition; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2018; ISBN 978-92-5-130571-3. [Google Scholar]

- Stanghellini, C. Horticultural production in greenhouses: Efficient use of water. Acta Hortic. 2014, 1034, 25–32. [Google Scholar] [CrossRef]

- Rabobank. World Vegetable Map 2018. RaboResearch Food & Agribusiness. Available online: https://research.rabobank.com/far/en/sectors/regional-food-agri/world_vegetable_map_2018.html (accessed on 11 March 2019).

- Brain, D. What Is the Current State of Labor in the Greenhouse Industry? Greenhouse Grower. Available online: https://www.greenhousegrower.com/management/what-is-the-current-state-of-labor-in-the-greenhouse-industry/ (accessed on 15 November 2018).

- Bot, G.P.A. Greenhouse Climate: From Physical Processes to a Dynamic Model. Ph.D. Thesis, Wageningen Agricultural University, Wageningen, The Netherlands, 1983. [Google Scholar]

- Challa, H.; Bot, G.P.A.; Nederhof, E.M.; Van de Braak, N.J. Greenhouse climate control in the nineties. Acta Hortic. 1988, 230, 459–470. [Google Scholar] [CrossRef]

- Udink ten Cate, A.J. Modelling and (Adaptive) Control of Greenhouse Climates. Ph.D. Thesis, Wageningen Agricultural University, Wageningen, The Netherlands, 1983. [Google Scholar]

- Tantau, H.J. Climate control algorithms. Acta Hortic. 1980, 106, 49–54. [Google Scholar] [CrossRef]

- Van Straten, G.; van Willgenburg, G.; van Henten, E.; van Ooteghem, R. Optimal Control of Greenhouse Cultivation; CRC Press: Boca Raton, FL, USA, 2010; ISBN 9781420059618. [Google Scholar]

- Takakura, T.; Jordan, K.A.; Boyd, L.L. Dynamic simulation of plant growth and environment in the greenhouse. Trans. ASABE 1971, 14, 964–971. [Google Scholar] [CrossRef]

- Seginer, I. Optimizing greenhouse operation for best aerial environment. Acta Hortic. 1980, 106, 169–174. [Google Scholar] [CrossRef]

- Hashimoto, Y. Computer control of short term plant growth by monitoring leaf temperature. Acta Hortic. 1980, 106, 139–146. [Google Scholar] [CrossRef]

- López-Cruz, I.L.; Fitz-Rodríguez, E.; Salazar-Moreno, R.; Rojano-Aguilar, A.; Kacira, M. Development and analysis of dynamical mathematical models of greenhouse climate: A review. Eur. J. Hortic. Sci. 2018, 83, 269–280. [Google Scholar] [CrossRef]

- Gary, C.; Jones, J.W.; Tchamitchian, M. Crop modelling in horticulture: State of the art. Sci. Hortic. 1998, 74, 3–20. [Google Scholar] [CrossRef]

- Marcelis, L.F.M.; Elings, A.; de Visser, P.H.B.; Heuvelink, E. Simulating growth and development of tomato crop. Acta Hortic. 2009, 821, 101–110. [Google Scholar] [CrossRef]

- De Zwart, H.F. Analyzing Energy-Saving Potentials in Greenhouse Cultivation Using a simulation Model. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 1996. [Google Scholar]

- Elings, A.; Heinen, M.; Werner, B.E.; de Visser, P.; van den Boogaard, H.A.G.M.; Gieling, T.H.; Marcelis, L.F.M. Feed-forward control of water and nutrient supply in greenhouse horticulture: Development of a system. Acta Hortic. 2004, 654, 195–202. [Google Scholar] [CrossRef]

- Buwalda, F.; Van Henten, E.J.; De Gelder, A.; Bontsema, J.; Hemming, J. Toward an optimal control strategy for sweet pepper cultivation—1. A dynamic crop model. Acta Hortic. 2006, 718, 367–374. [Google Scholar] [CrossRef]

- Van Henten, E.J.; Buwalda, F.; de Zwart, H.F.; de Gelder, A.; Hemming, J.; Bontsema, J. Toward an optimal control strategy for sweet pepper cultivation—2. optimization of the yield pattern and energy efficiency. Acta Hortic. 2006, 718, 391–398. [Google Scholar] [CrossRef]

- Ramírez-Arias, A.; Rodríguez, F.; Guzmán, J.L.; Berengue, M. Multiobjective hierarchical control architecture for greenhouse crop growth. Automatica 2012, 48, 490–498. [Google Scholar] [CrossRef]

- Martin-Clouaire, R.; Boulard, T.; Cros, M.J.; Jeannequin, B. Using empirical knowledge for the determination of climatic setpoints: An artificial intelligence approach. In The Computerized Greenhouse: Automated Control Application in Plant Production; Hashimoto, Y., Bot, G.P.A., Day, W., Tantau, H.J., Nonami, H., Eds.; Academic Press: Cambridge, MA, USA, 1993; pp. 197–224. [Google Scholar] [CrossRef]

- Kurata, K. Greenhouse control by machine learning. Acta Hortic. 1988, 230, 195–200. [Google Scholar] [CrossRef]

- Hernandez, C.; del Sagrado, J.; Rodríguez, F.; Moreno, J.C.; Sánchez, J.A. Modelling of energy demand of a high-tech greenhouse in warm climate based on bayesian networks. Math. Probl. Eng. 2015, 2015, 201646. [Google Scholar] [CrossRef]

- Wang, D.; Wang, M.; Qiao, X. Support vector machines regression and modelling of greenhouse environment. Comput. Electron. Agric. 2009, 66, 46–52. [Google Scholar] [CrossRef]

- Yu, H.; Chen, Y.; Gul Hassan, S.; Li, D. Prediction of the temperature in a Chinese solar greenhouse based on LS-SVM optimized by improved PSO. Comput. Electron. Agric. 2016, 122, 94–102. [Google Scholar] [CrossRef]

- Zou, W.; Yao, F.; Zhang, B.; He, C.; Guan, Z. Verification and predicting temperature and humidity in a solar greenhouse based on convex bidirectional extreme learning machine algorithm. Neurocomputing 2017, 249, 72–85. [Google Scholar] [CrossRef]

- Dariouchy, E.; Aassif, K.; Lekouch, L.; Bouirden, G. Maze Prediction of the intern parameters tomato greenhouse in a semi-arid area using a time-series model of artificial neural networks. Measurement 2009, 42, 456–463. [Google Scholar] [CrossRef]

- Ehret, D.L.; Hill, B.D.; Helmer, T.; Edwards, D.R. Neural network modelling of greenhouse tomato yield, growth and water use from automated crop monitoring data. Comput. Electron. Agric. 2011, 79, 82–89. [Google Scholar] [CrossRef]

- Ferreira, P.M.; Faria, E.A.; Ruano, A.E. Neural network models in greenhouse air temperature prediction. Neurocomputing 2002, 43, 51–75. [Google Scholar] [CrossRef]

- He, F.; Ma, C. Modelling greenhouse air humidity by means of artificial neural network and principal component analysis. Comput. Electron. Agric. 2010, 71, 19–23. [Google Scholar] [CrossRef]

- Linker, R.; Seginer, I. Greenhouse temperature modelling: A comparison between sigmoid neural networks and hybrid models. Math. Comput. Simul. 2004, 65, 19–29. [Google Scholar] [CrossRef]

- Seginer, I. Some artificial neural network applications to greenhouse environmental control. Comput. Electron. Agric. 1997, 18, 167–186. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Ranjbar, S.F.; Rohani, A.; Matloobi, M. Heat transfer and MLP neural network models to predict inside environment variables and energy lost in a semi-solar greenhouse. Energy Build. 2016, 110, 314–329. [Google Scholar] [CrossRef]

- Taki, M.; Mehdizadeh, S.A.; Rohani, A.; Rahnama, M.; Rahmati-Joneidabad, M. Applied machine learning in greenhouse simulation; new application and analysis. Inf. Process. Agric. 2018, 5, 253–268. [Google Scholar] [CrossRef]

- Tchamitchian, M.; Kittas, C.; Bartzanas, T.; Lykas, C. Daily temperature optimization in greenhouse by reinforcement learning. In Proceedings of the IFAC 16th Triennial World Congress, Prague, Czech Republic, 4–8 July 2005. [Google Scholar]

- Blasco, X.; Martínez, M.; Herrero, J.M.; Ramos, C.; Sanchis, J. Model-based predictive control of greenhouse climate for reducing energy and water consumption. Comput. Electron. Agric. 2007, 5, 49–70. [Google Scholar] [CrossRef]

- Dai, C.; Yao, M.; Xie, Z.; Chen, C.; Liu, J. Parameter optimization for growth model of greenhouse crop using genetic algorithms. Appl. Soft Comput. 2008, 9, 13–19. [Google Scholar] [CrossRef]

- Guzmán-Cruz, R.; Castañeda-Miranda, R.; García-Escalante, J.J.; López-Cruz, I.L.; Lara-Herrera, A.; de la Rosa, J.I. Calibration of a greenhouse climate model using evolutionary algorithms. Biosyst. Eng. 2009, 104, 135–142. [Google Scholar] [CrossRef]

- He, J.; Baxter, S.L.; Xu, J.; Xu, J.; Zhou, X.; Zhang, K. The practical implementation of artificial intelligence technologies in medicine. Nat. Med. 2019, 25, 30–36. [Google Scholar] [CrossRef]

- Waldrop, M.M. Autonomous vehicles: No drivers required. Nature 2018, 518, 20–23. [Google Scholar] [CrossRef] [PubMed]

- Goldberg, K. Robots and the return to collaborative intelligence. Nat. Mach. Intell. 2019, 1, 2–4. [Google Scholar] [CrossRef]

- Samuel, A.L. Some studies in machine learning using the game of checkers. IBM J. Res. Dev. 1959, 44, 206–226. [Google Scholar] [CrossRef]

- Hassabis, D. Artificial intelligence: Chess match of the century. Nature 2017, 544, 413–414. [Google Scholar] [CrossRef]

- Silver, D.; Huang, A.; Maddison, C.; Guez, A. Mastering the game of go with deep neural networks and tree search. Nature 2016, 529, 484–489. [Google Scholar] [CrossRef]

- Liakos, K.G.; Busato, P.; Moshou, D.; Pearson, S.; Bochtis, D. Machine learning in agriculture: A review. Sensors 2018, 18, 2674. [Google Scholar] [CrossRef] [PubMed]

- Barth, R. Vision Principles for Harvest Robotics. Sowing Artificial Intelligence in Agriculture. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2018. [Google Scholar]

- Farquhar, G.D.; von Caemmerer, S.; Berry, J.A. A biochemical model of photo-synthetic CO2 assimilation in leaves of C3 species. Planta 1980, 149, 78–90. [Google Scholar] [CrossRef]

- Marcelis, L.F.M. Non-destructive measurements and growth analysis of the cucumber fruit. J. Hortic. Sci. 1992, 67, 457–464. [Google Scholar] [CrossRef]

- Li, T. Improving Radiation use Efficiency in Greenhouse Production Systems. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2015. [Google Scholar]

- Marcelis, L.F.M.; Broekhuijsen, A.G.M.; Nijs, E.M.F.M.; Raaphorst, M.G.M.; Meinen, E. Quantification of the growth response to light quantity of greenhouse grown crops. Acta Hortic. 2006, 711, 97–104. [Google Scholar] [CrossRef]

- Qian, T.; Elings, A.; Dieleman, J.A.; Gort, G.; Marcelis, L.F.M. Estimation of photosynthesis parameters for a modified Farquhar-von Caemmerer-Berry model using the simultaneous estimation method and the nonlinear mixed effects model. Environ. Exp. Bot. 2012, 82, 66–73. [Google Scholar] [CrossRef]

- Marcelis, L.F.M.; De Pascale, S. Crop management in greenhouses: Adapting the growth conditions to the plant needs or adapting the plant to the growth conditions? Acta Hortic. 2009, 807, 163–174. [Google Scholar] [CrossRef]

- Van Straten, G.; Challa, H.; Buwalda, F. Towards user accepted optimal control of greenhouse climate. Comput. Electron. Agric. 2000, 26, 221–238. [Google Scholar] [CrossRef]

- Morimoto, T.; Hashimoto, Y. AI approaches to identification and control of total plant production systems. Control Eng. Pract. 2000, 8, 555–567. [Google Scholar] [CrossRef]

- Caponetto, R.; Fortuna, L.; Nunnari, G.; Occhipinti, L.; Xibilia, M.G. Soft computing for greenhouse climate control. IEEE Trans. Fuzzy Syst. 2000, 8, 753–760. [Google Scholar] [CrossRef]

- Borovykh, A.; Bohte, S.M.; Oosterlee, C.W. Conditional time series forecasting with convolutional neural networks. Lect. Notes Comput. Sci. 2017, arXiv:1703.04691, 729–730. [Google Scholar]

- Ogunmolu, O.; Gu, X.; Jiang, S.; Gans, N.R. Nonlinear identification using deep dynamic neural networks. In Proceedings of the IEEE International Conference on Information and Automation (ICIA), Yunnan, China, 8–10 August 2015. [Google Scholar] [CrossRef]

- Vlassis, N.; Ghavamzadeh, M.; Mannor, S.; Poupart, P. Bayesian reinforcement learning. In Reinforcement Learning: Adaptation, Learning and Optimization; Springer: Berlin/Heidelberg, Germany, 2012; Volume 12. [Google Scholar] [CrossRef]

- Ghavamzadeh, M.; Mannor, S.; Pineau, J.; Tamar, A. Bayesian reinforcement learning: A survey. Found. Trends Mach. Learn. 2015, 8, 359–483. [Google Scholar] [CrossRef]

- Ross, S.; Pineau, J. Model-based Bayesian reinforcement learning in large structured domains. In Proceedings of the Twenty Four Conference on Uncertainty in Artificial Intelligence, Helsinki, Finland, 9–12 July 2008; p. 476. [Google Scholar]

- Peters, J. Policy gradient methods. Scolarpedia 2010, 5, 3698. [Google Scholar] [CrossRef]

- Goodfellow, I.J.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative adversarial nets. In Proceedings of the 27th International Conference on Neural Information Processing Systems, Montreal, Canada, 8–13 December 2014; Volume 2, pp. 2672–2680. [Google Scholar]

- Ehret, D.; Lau, A.; Bittman, S.; Lin, W.; Shelford, T. Automated monitoring of greenhouse crops. Agronomie 2001, 21, 403–414. [Google Scholar] [CrossRef]

- Nishina, H. Development of speaking plant approach technique for intelligent greenhouse. Agric. Agric. Sci. Proc. 2015, 3, 9–13. [Google Scholar] [CrossRef]

- Sug, H. Performance of machine learning algorithms and diversity in data. MATECV Web Conf. 2018, 210, 04019. [Google Scholar] [CrossRef]

| kg | kWh | kWh | L | mL | |

|---|---|---|---|---|---|

| CO2 | Electricity | Heat | Water | Pesticide | |

| per kg Cucumber | |||||

| Reference | 0.20 | 3.02 | 3.20 | 5.52 | 0.34 |

| Sonoma | 0.20 | 3.59 | 2.49 | 4.91 | 0.35 |

| iGrow | 0.20 | 3.12 | 2.94 | 5.89 | 0.39 |

| deep_greens | 0.47 | 4.39 | 13.61 | 5.87 | 0.49 |

| The Croperators | 0.29 | 3.82 | 4.87 | 5.98 | 0.35 |

| AiCU | 0.26 | 3.17 | 3.13 | 7.62 | 0.48 |

| Reference | Sonoma | iGrow | Deep_Greens | The Croperators | AiCU | |

|---|---|---|---|---|---|---|

| Young plants and substrate slabs | €3.74 | €2.74 | €3.74 | €2.29 | €2.74 | €2.47 |

| Electricity | €8.89 | €10.97 | €8.68 | €9.35 | €10.91 | €7.04 |

| Heating | €0.95 | €0.77 | €0.82 | €2.92 | €1.40 | €0.70 |

| CO2 | €0.59 | €0.62 | €0.55 | €1.00 | €0.85 | €0.59 |

| Water | €0.27 | €0.25 | €0.28 | €0.21 | €0.29 | €0.28 |

| Labour | €8.32 | €9.47 | €8.85 | €8.73 | €9.48 | €10.03 |

| Costs | €22.76 | €24.82 | €22.92 | €24.50 | €25.67 | €21.11 |

| Income | €43.94 | €49.60 | €42.95 | €31.88 | €42.82 | €36.21 |

| Net Profit | €21.18 | €24.78 | €20.03 | €7.38 | €17.15 | €15.10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hemming, S.; de Zwart, F.; Elings, A.; Righini, I.; Petropoulou, A. Remote Control of Greenhouse Vegetable Production with Artificial Intelligence—Greenhouse Climate, Irrigation, and Crop Production. Sensors 2019, 19, 1807. https://doi.org/10.3390/s19081807

Hemming S, de Zwart F, Elings A, Righini I, Petropoulou A. Remote Control of Greenhouse Vegetable Production with Artificial Intelligence—Greenhouse Climate, Irrigation, and Crop Production. Sensors. 2019; 19(8):1807. https://doi.org/10.3390/s19081807

Chicago/Turabian StyleHemming, Silke, Feije de Zwart, Anne Elings, Isabella Righini, and Anna Petropoulou. 2019. "Remote Control of Greenhouse Vegetable Production with Artificial Intelligence—Greenhouse Climate, Irrigation, and Crop Production" Sensors 19, no. 8: 1807. https://doi.org/10.3390/s19081807

APA StyleHemming, S., de Zwart, F., Elings, A., Righini, I., & Petropoulou, A. (2019). Remote Control of Greenhouse Vegetable Production with Artificial Intelligence—Greenhouse Climate, Irrigation, and Crop Production. Sensors, 19(8), 1807. https://doi.org/10.3390/s19081807