1. Introduction

A two-dimensional (2D) galvanometer is an important optical component. Due to its compact structure, small driving load, and fast response speed, it is widely used in material processing [

1,

2,

3,

4], laser projection [

5,

6,

7], optical measurement [

8,

9], biomedical imaging [

10,

11], automatic vehicle driving [

12], optical communication [

13], and other aspects.

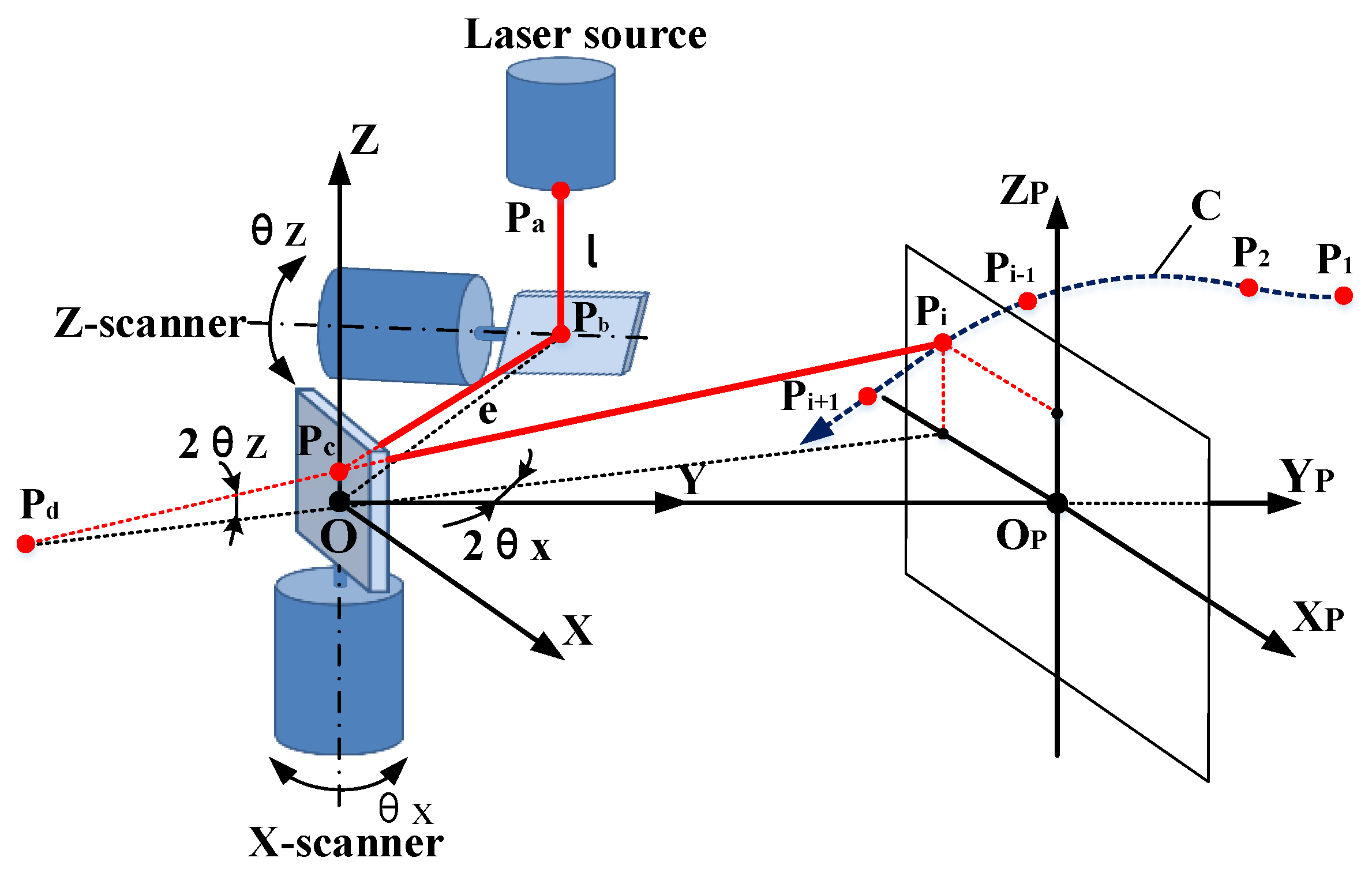

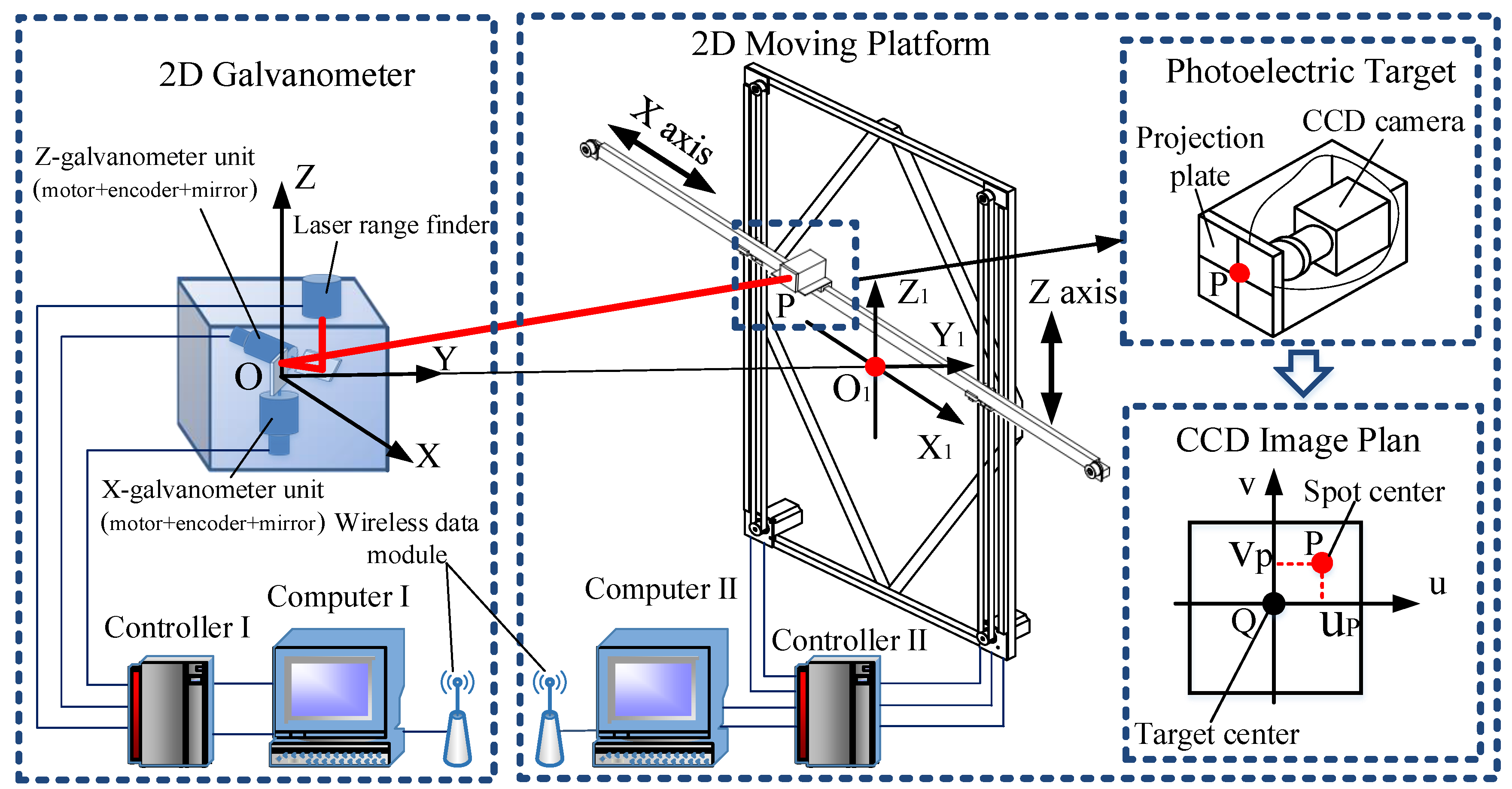

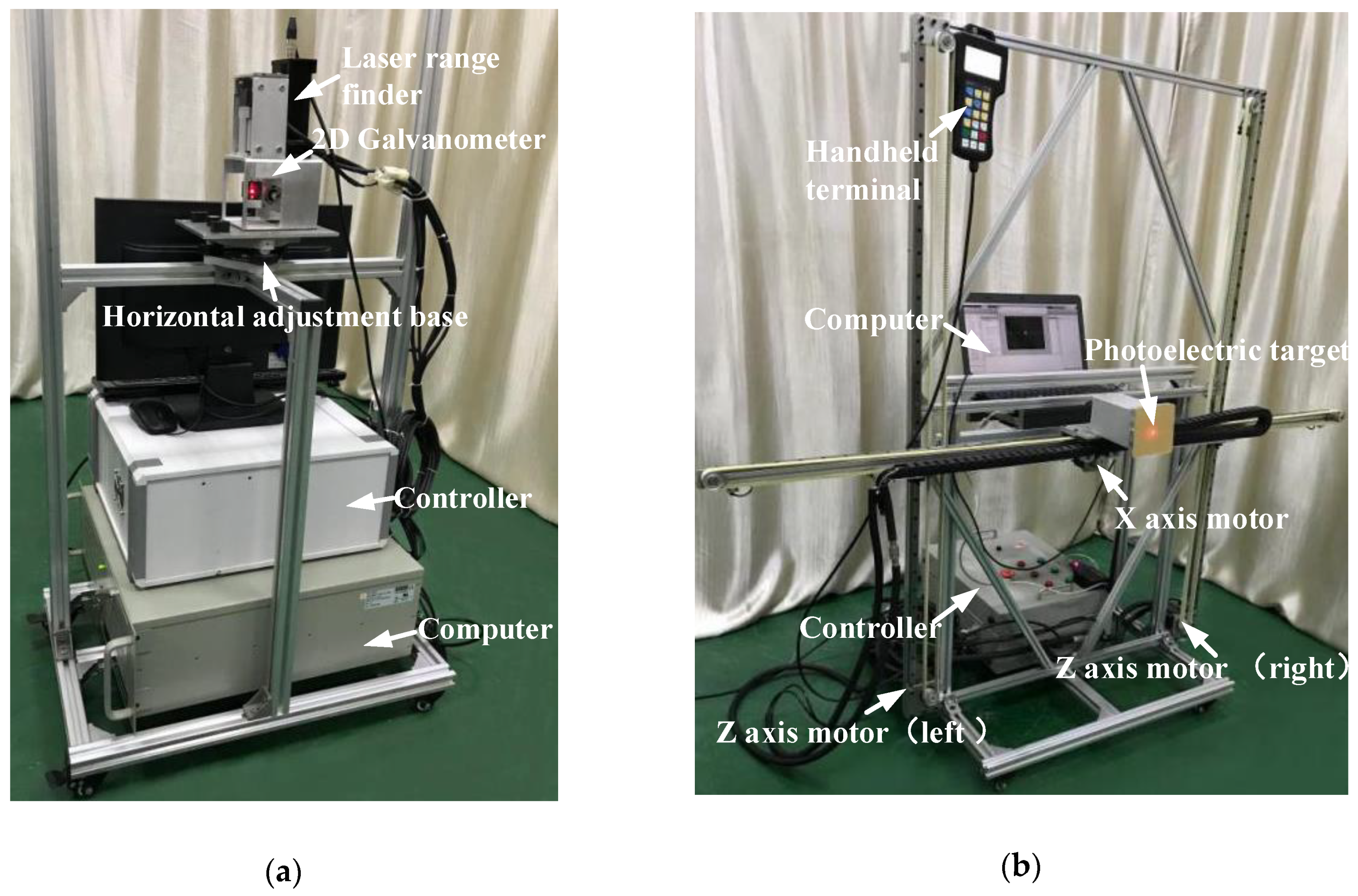

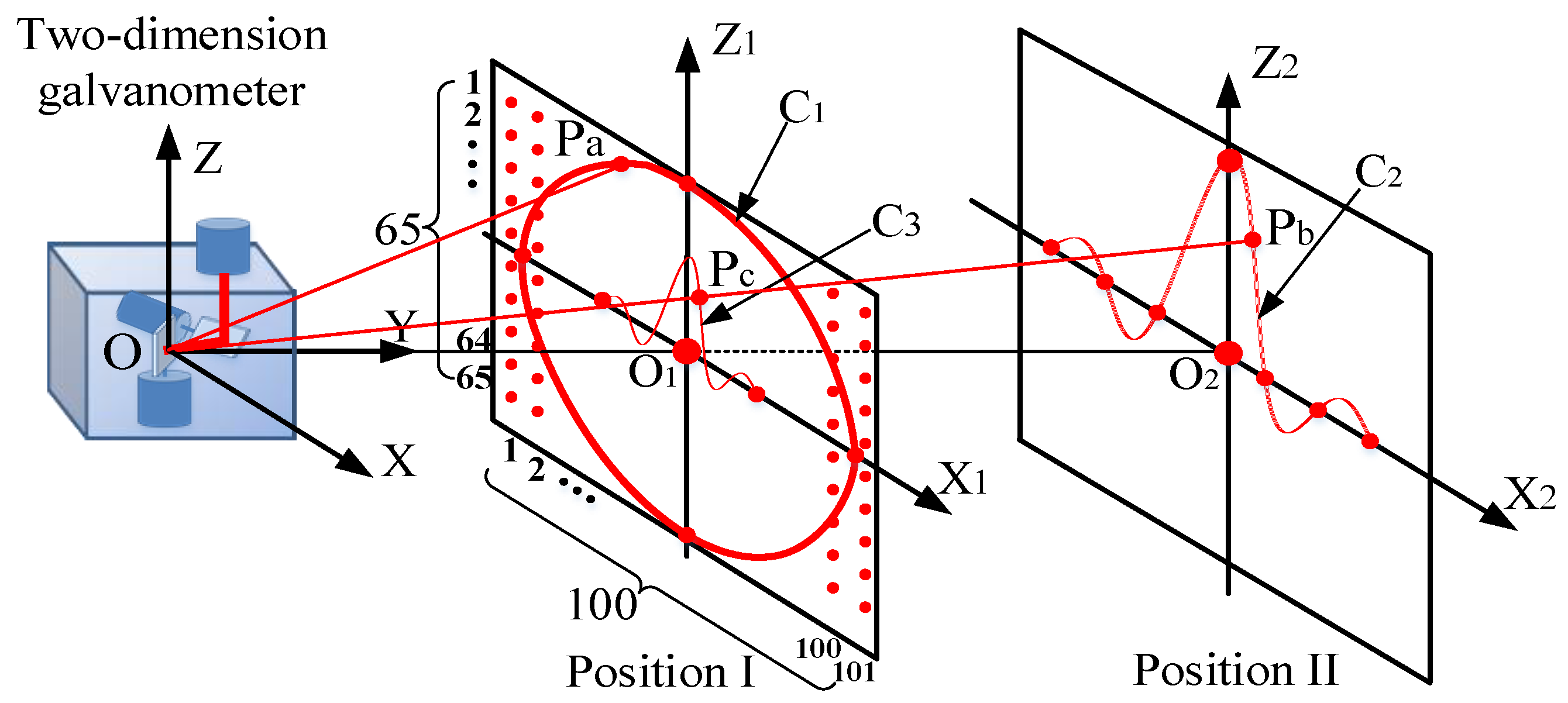

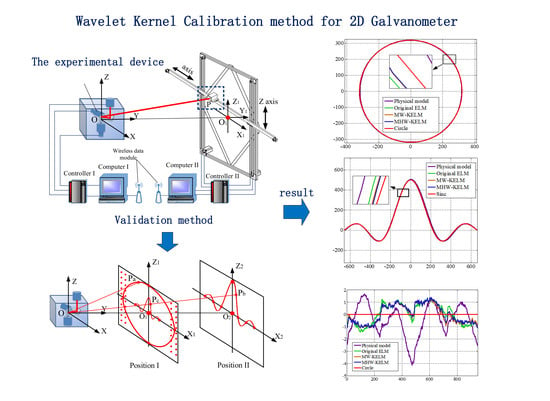

The photoelectric measurement system with a 2D galvanometer must have fast measuring speed and high measuring precision when tracking and positioning the moving target in real time. As shown in

Figure 1, the measurement system is mainly composed of a 2D galvanometer and a laser rangefinder. In the three-dimensional measurement space, the maneuvering target moves along the unknown curve C to the

position,

, and the laser beam of the range finder is refracted by the mirrors of the galvanometer. When the laser spot is following the moving object, the system detects the rotation angles of mirrors,

, and the distance,

, and then obtains the measured value,

, of

. According to the geometric relationship of the galvanometer, the position of the moving target can be calculated online. The geometric structure is analyzed with the following relations:

The galvanometer detection value,

, and the corresponding position coordinates,

, in the measurement space satisfy the following nonlinear matrix equation:

The mathematical relationship defined in Equation (4) is called the ideal physical model of the 2D galvanometer. Obviously, there is a nonlinear relationship between the coordinates and the detection value.

Due to the influence of installation error, system control error, laser ranging error, angle measurement error, and random noise, there is usually a large error between the actual position and theoretical position calculated by the ideal physical model. Obviously, in order to measure the moving target position in real time, an online calibration method is needed, which can correct the measurement error, caused by many factors, to improve the online measurement accuracy.

Currently, the calibration methods mainly include model-driven [

14,

15,

16] methods and data-driven methods. The model-driven methods are established on the basis of the ideal physical model method shown in Equation (4). If the working range of the 2D galvanometer is concentrated near the center of the optical axis, higher accuracy can be obtained by using the physical model calibration method [

17,

18]. If the working range is far away from the center of the optical axis, various errors and random noise must be considered. Alkhazur Manakov et al. [

19] presented a complicated model containing up to 26 physical parameters to predict the distortions of the 2D galvanometer. Even so, not all affecting factors are involved. Too many parameters increase the complexity of modeling and lead to the risk of local minimization [

20]. The modeling difficulty can be reduced by improving the hardware precision [

21], but this will greatly increase the cost.

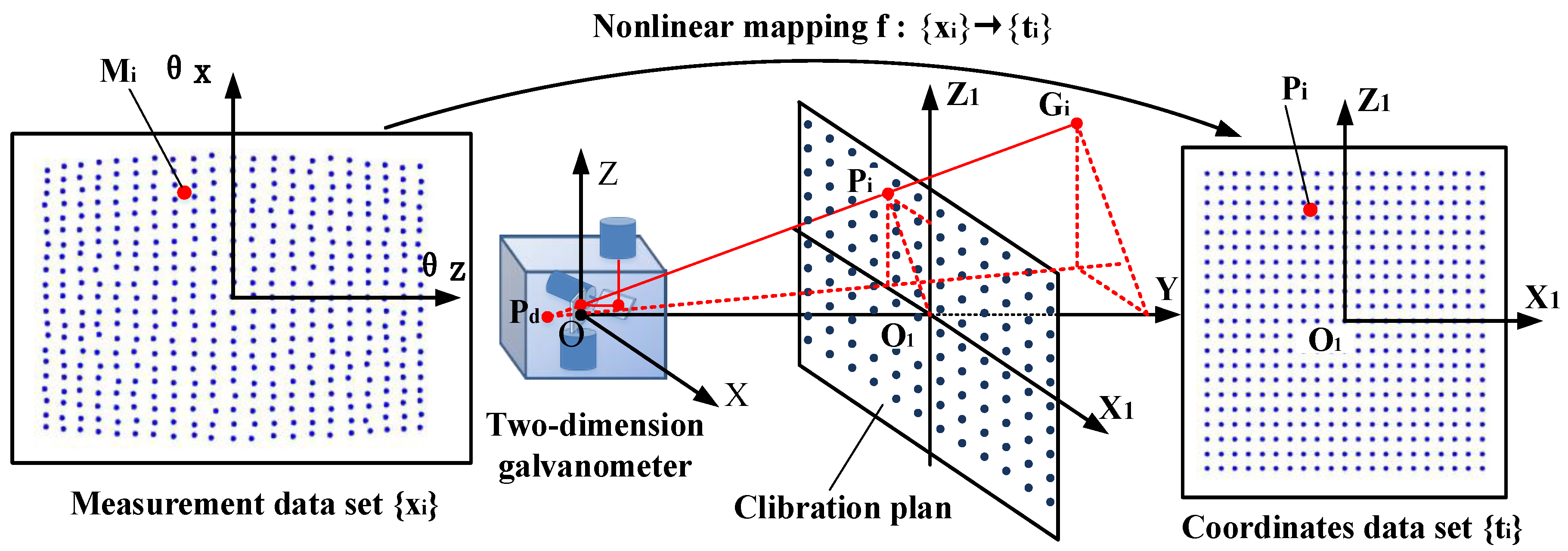

With the data-driven method, these deficiencies can be well avoided. As shown in

Figure 1 and

Figure 2, for the arbitrary moving target

in the measurement range, its corresponding measurement value is

. A fixed calibration plane,

, can be set in front of the galvanometer, the collinear point with

in

is

, and its measurement value is

. Due to

and

, the following relation can be obtained from Equation (4):

Theoretically, if the measured values of all the position points in the calibration plane are known, the coordinates of each position in the measurement space can be obtained through Equation (5).

The data-driven calibration algorithm selects a limited number of points in the calibration plane to establish the data set , obtains the corresponding measurement values of each point through experiments to establish the measurement data set , and uses a machine learning algorithm to establish a nonlinear mapping model, , between the two groups of data sets as the calibration model. For any measured value, , that does not belong to the , the mapping model is used to obtain the corresponding position in the plane.

Stefan et al. [

22] used artificial neural networks (ANN) to analyze the measurement data of the galvanometer and established the calibration model. In order to improve the learning effect of the artificial neural network, ridge regression and regularization coefficients [

23] are introduced to avoid over-fitting of the network, and higher calibration accuracy is obtained. Tobias Wissel et al. [

24] made a comparative analysis of three data-driven methods as follows: ANN, support vector regression (SVR), and Gaussian processes (GPs), and the result shows that the GPs method could obtain higher precision but slow convergence. The learning speed of ANN and SVR was faster than GPs and the accuracy of the three data-driven methods was better than that of the model-driven method. However, as ANN and SVR methods use an offline training mode to establish a calibration model, those methods often require long training time.

The extreme learning machine (ELM) is a single hidden layer neural network, which has the advantages of fewer training parameters, faster training speed, and strong generalization ability [

25,

26]. Its learning speed is many times faster than ANN, SVR, and least squares SVR algorithms [

27] and it is helpful to the solution of the online calibration problem. However, the ELM algorithm uses linear weighted mapping to train the calibration data sets. For nonlinear samples, the accuracy of ELM is reduced [

28]. In addition, the ELM algorithm randomly selects the weights and uses the trial and error method to determine the optimal number of neurons, which will affect the stability and rigor of the calibration algorithm.

For this reason, Huang, et al. [

27] proposed the kernel extreme learning machine (KELM), which utilized the kernel function to replace the linear weighted mapping in ELM. Kernel function can implicitly map the nonlinear training samples to the high-dimensional feature space and use the linear function to make nonlinear training samples more easily structured. KELM replaces the inner product in the linear algorithm with a kernel function to obtain an optimal least square solution. As a result of this, it has fast training speed and strong generalization ability. Therefore, in this paper, KELM is proposed to train the calibration data of the galvanometer with nonlinear characteristics and to solve the online calibration problem. For the given calibration data, different kernel functions have different capabilities of mapping, resulting in significant differences in the generalization. Therefore, choosing the kernel function suitable for galvanometer calibration is the key to solving the problem. The original kernel functions mainly include a polynomial kernel, Sigmoid kernel, Gaussian kernel, etc. Normally, the wavelet function has better characteristics of multi-scale subdivision and noise suppression. If the kernel function could be constructed on the basis of the mother wavelet, the algorithm would have a superior performance. Due to the complex nonlinear characteristics of the calibration data, it is difficult to determine the appropriate kernel from prior knowledge. The two wavelet kernel functions of the Morlet wavelet and Mexican Hat wavelet have been proven to be the admissible ELM kernel [

29,

30,

31]. Therefore, cross-validation will be used to verify which kernel function is best for galvanometer calibration. This article uses two groups of testing data sets to verify the training results and the results are compared and analyzed with the physical model method and the original ELM. The kernel functions with minimum error are considered to be more suitable for online calibration. On this basis, the reasons for why the wavelet KELM calibration method performs better than other methods are further analyzed from the aspects of generalization ability, noise suppression, and training time.

In this paper, a data-driven approach for the online calibration of a 2D galvanometer is presented. In

Section 2, the principle of galvanometer calibration and the experimental device is described. In

Section 3, the wavelet KELM algorithm is introduced, and the process of establishing the online calibration method is analyzed. In

Section 4, the experimental scheme and verification method are described. Finally, the conclusion is given in

Section 5 and the experimental results of existing calibration methods and wavelet KELM method are compared and analyzed.

3. Mathematical Model and Calibration Method

3.1. Kernel Extreme Learning Machine (KELM)

For the galvanometer calibration data set

with

N samples, the ELM algorithm can be used to establish the mapping model

as the calibration model. The standard single hidden layer neural network with

hidden nodes can be used to establish the mapping model

, which can be expressed as follows:

where

is the activation function,

is the weight vector to connect the

th hidden node and the input node,

is the weight vector to connect the

th hidden node and the output node, and

is the threshold of the

th hidden node. The

denotes the inner product of

and

. The above equation can be written as follows:

where

According to the proof process given by Huang et al. [

25,

26], the least-squares solution of the general linear system can be represented as:

where

H† is the Moore–Penrose generalized inverse of matrix

H.The traditional ELM algorithm is based on the empirical risk minimization criterion and there is a risk of over-fitting in the training process. Therefore, output weights

can be obtained by finding the least square solution of the following problem:

where

is the

th hidden-layer output vector,

is the difference between the

th sample and the output of the hidden layer. Based on the Karush–Kuhn–Tucker theorem, the solution of the above quadratic optimization problem is equivalent to solving the Lagrange function problem as follows:

the output weight is

the output function is

The linear weighted hidden output function

is unknown and usually does not satisfy the nonlinear sample mapping. In order to improve the fitting ability of the algorithm to nonlinear samples, the kernel function

can be used to replace

and

in Equation (16). The output function is as follows:

Where

is kernel function matrix as follows:

According to Equations (16)–(18), if the kernel function and regularization coefficient C are determined, the corresponding network output can be obtained.

3.2. Translation-Invariant Kernel Theorem

The selection of kernel function has a great influence on the accuracy of KELM. With different kernel functions, the accuracy of calibration varies greatly. If a binary function satisfies Mercer’s theorem, it is an admissible kernel function. In fact, it is difficult to prove that a binary function satisfies Mercer’s theorem. Fortunately, for the translation-invariant kernel function, the following theorem provides a necessary and sufficient condition for it become an admissible kernel function.

Theorem 1 (translation-invariant kernel theorem) [

32]

A translation-invariant kernel

is an admissible kernel, if and only if the following Fourier transform:

is non-negative.

Traditional kernel functions mainly include a linear kernel, Sigmoid kernel, polynomial kernel, Gaussian kernel, etc. The commonly used translation-invariant kernel functions are Gauss kernel functions and polynomial kernel functions. Since the linear kernel and Sigmoid kernel are not suitable for the fitting of nonlinear samples, this paper focuses on the polynomial kernel function and the Gaussian kernel function. The expression of the two kernel functions can be given as follows:

where

d is an adjustable polynomial power exponent and

is Gaussian core width.

3.3. Wavelet Kernel Function

The mapping accuracy will be affected by the noise and nonlinear characteristics of the calibration data set of the 2D galvanometer. Therefore, the performance of the kernel function is particularly important. For 2D galvanometer calibration, the kernel function is required to have both good nonlinear mapping capability and certain noise suppression capability.

In general, the wavelet function has better characteristics of multi-scale subdivision and noise suppression and, if the kernel function can be constructed by the wavelet function, it is expected to construct an ideal kernel for KELM to solve the galvanometer calibration problem. It can be proved that the Morlet wavelet kernel function and the Mexican Hat wavelet kernel function satisfy the translation-invariant kernel theorem and are admissible ELM kernel functions [

29,

30,

31]. The proof process will not be repeated in this paper. The two wavelet kernel functions can be given as follows:

where

is non-negative constant coefficient and

is non-negative wavelet parameter.

In this paper, the calibration results of the Morlet wavelet kernel and the Mexican Hat wavelet are compared with other methods in

Section 5 to further investigate the performance of wavelet kernel functions.

3.4. Online Calibration Method

In this section, the algorithm flow of online galvanometer calibration is presented. For the 2D galvanometer device, the main parameters that affect the calibration accuracy are considered to be constant values. That is to say, the nonlinear characteristics of the galvanometer distortion are time-invariant. Therefore, the online calibration program can be divided into an offline training part and online calculation part. The time-consuming model training is scheduled to be completed in the offline stage and, after the training is finished, the parameters are saved. In the online calculation stage, the parameters are read in and the model is built rapidly, then the measured values can be put into the model to quickly calculate the calibrated results.

The calibration process is divided into part A and part B. Part A is the offline model training, and part B is for online calculation. The online calibration-based KELM algorithm is as follows:

Part A: Model training

Step (1): Obtain the training data set of galvanometer calibration and the testing data set , initialize the regularization coefficient C and other parameters in the kernel function.

Step (2): Put into the Equations (20)–(23), and compute the kernel matrix .

Step (3): Calculate the output weight matrix: .

Step (4): According to Equation (17), the output is calculated and compared with to obtain the training accuracy.

Step (5): Put and in the Equations (20)–(23) and compute the kernel matrix .

Step (6): The kernel matrix and the output weight are substituted into Equation (17) and the output is calculated and compared with to obtain the test accuracy.

Step (7): By means of cross-validation, the regularization coefficient C and kernel function parameters are modified until the optimal training accuracy is obtained, and then the optimal output weight, regularization coefficient, and kernel function parameters are saved and the network training is completed.

Part B: Online calculation

Step (1): Read the optimal output weight matrix, regularization coefficient, and other kernel function parameters.

Step (2): Read a set of measurements value online, put them in the Equations (20)–(23), and compute the kernel matrix .

Step (3): The kernel function matrix and output weight are substituted into Equation (17) to calculate the output and the calibration value of the spot center position corresponding to the measured value is obtained.

Step (4): Return to Step (2) to calculate the next laser spot coordinates.

5. Experimental Verification

The performance of four KELM methods is analyzed and compared with the physical model method and original ELM in this section. All these algorithms are run on R2014a MATLAB software, which is installed in a personal computer with 3.2 GHz CPU and 8.0 GB RAM. The training set has 6565 points, the circle testing data set has 950 points, and the Sinc testing data set has 750 points.

After the optimization training, the optimized parameters of several data-driven methods are shown in

Table 1.

5.1. Validation Results

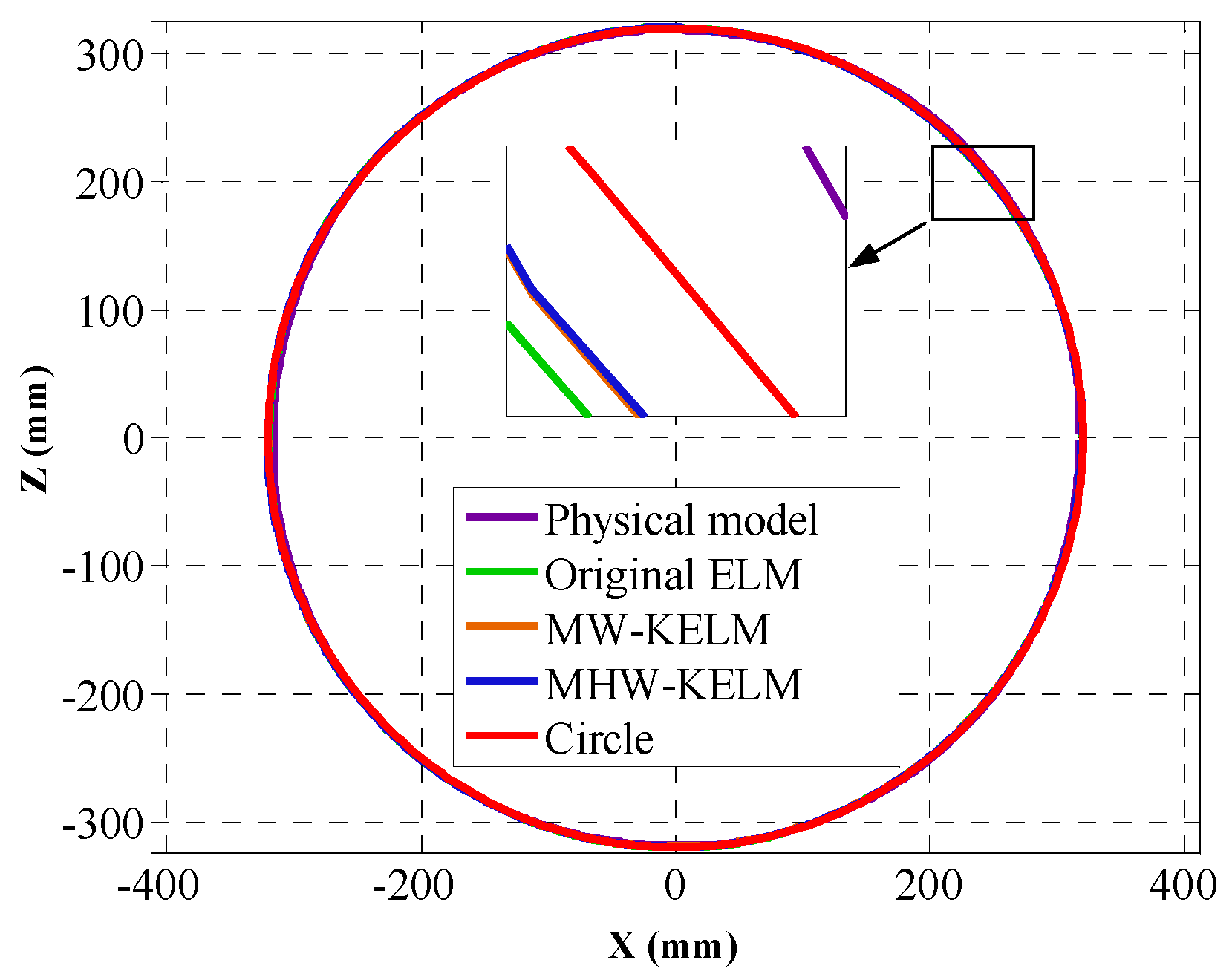

5.1.1. Results of the Circle Testing Data Set

The four kernel functions are shown in Equations (20)–(23). They are used as the kernel functions of KELM algorithm, respectively, and the calibration accuracy is verified by using the circle testing data set. The optimal training results and the training time of each algorithm are compared with the physical model method and original ELM. The position error

is calculated according to Equation (26) and the RMSE value of each method is calculated according to Equation (27). The mean absolute error (MAE) and standard deviation (S

d) of each method are calculated by Equations (28)–(29), and the fitting radius and radius error

are calculated by Equations (32)–(33). The results of the various methods are shown in

Table 2.

It can be seen from

Table 1 that the Mexican Hat wavelet KELM is observed to attain the most optimal results among all the models, with a radius of 320.03 mm and ΔR of 0.03 mm, RMSE value of 0.4130 and MAE of 0.3259, and supported by small standard deviation at 0.2536. This indicates that the accuracy of wavelet KELM is higher than that of other methods.

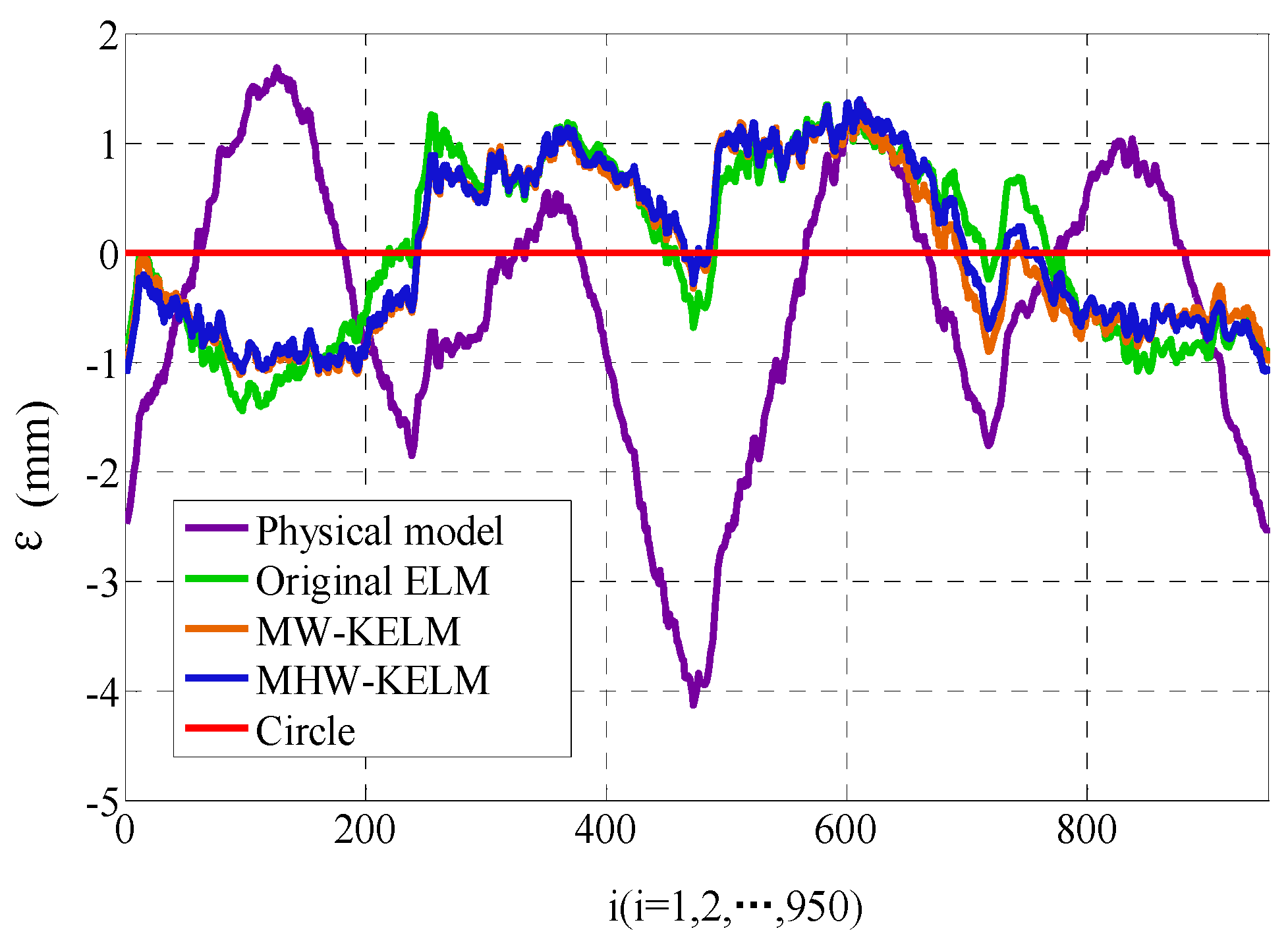

Figure 8 shows the four calibrated curves of the circle. In terms of the

values of each method, the position error is shown in

Figure 9. It can be seen from

Figure 8 and

Figure 9 that the calibrated curves are close to the theoretical circle. The calibration accuracy of the two wavelet KELM is higher than the original ELM and physical model method. In terms of the two wavelet kernel functions, the Mexican Hat wavelet KELM is slightly better than the Morlet wavelet KELM. Compared with original ELM, the calibration effect of the Mexican Hat wavelet KELM is improved. The RMSE, MAE, and S

d are reduced by 16.4%, 14.6%, and 19.2%, respectively.

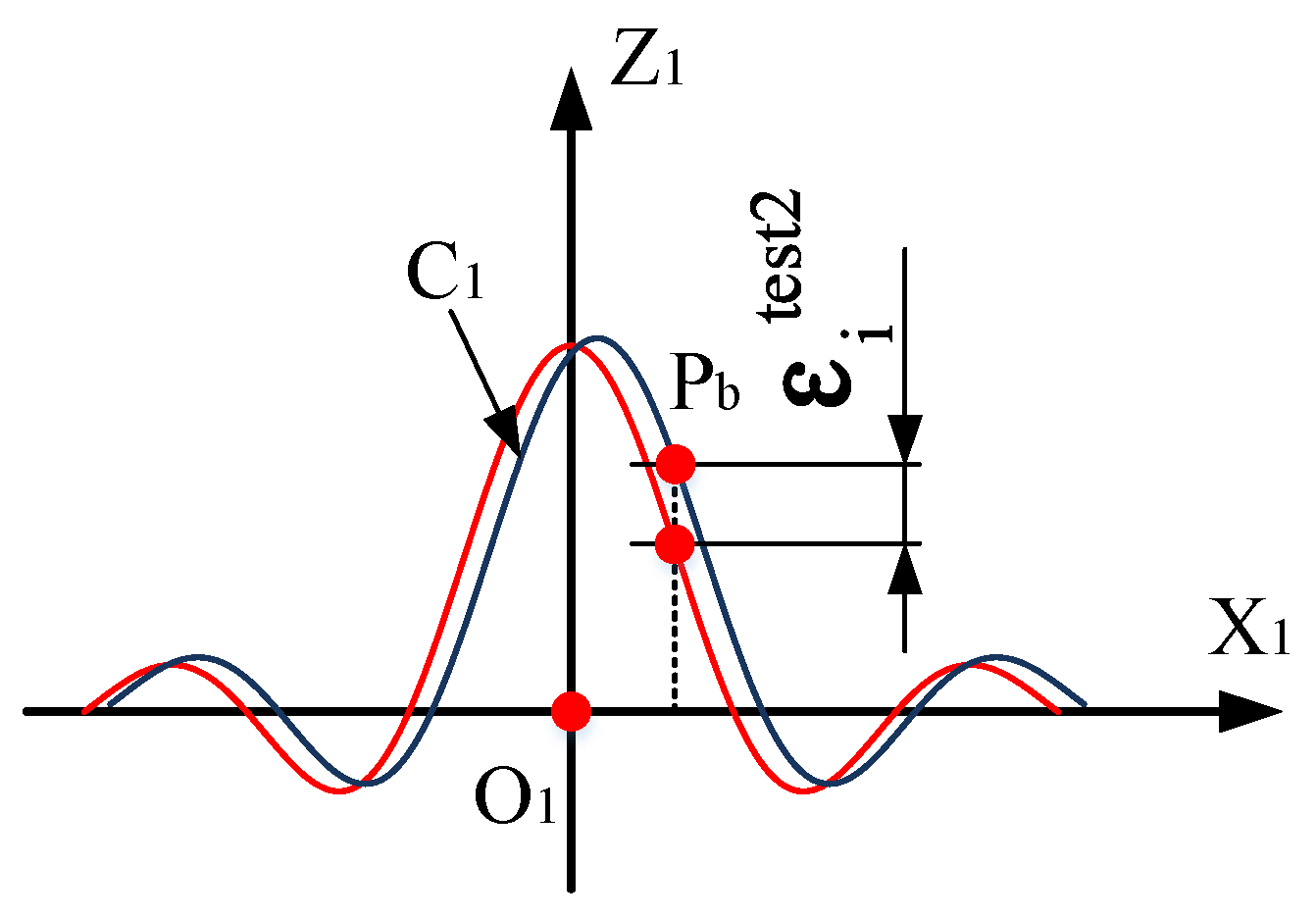

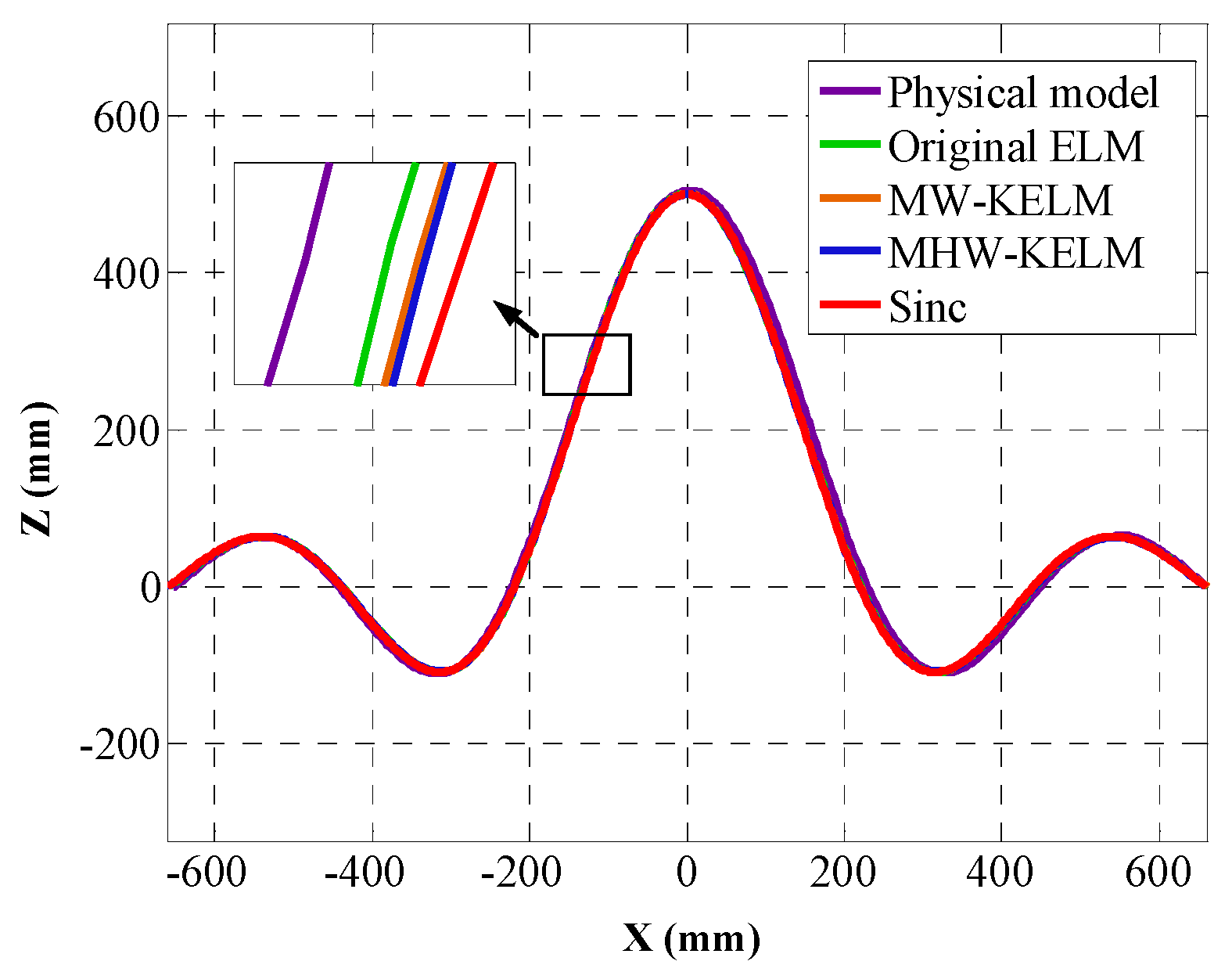

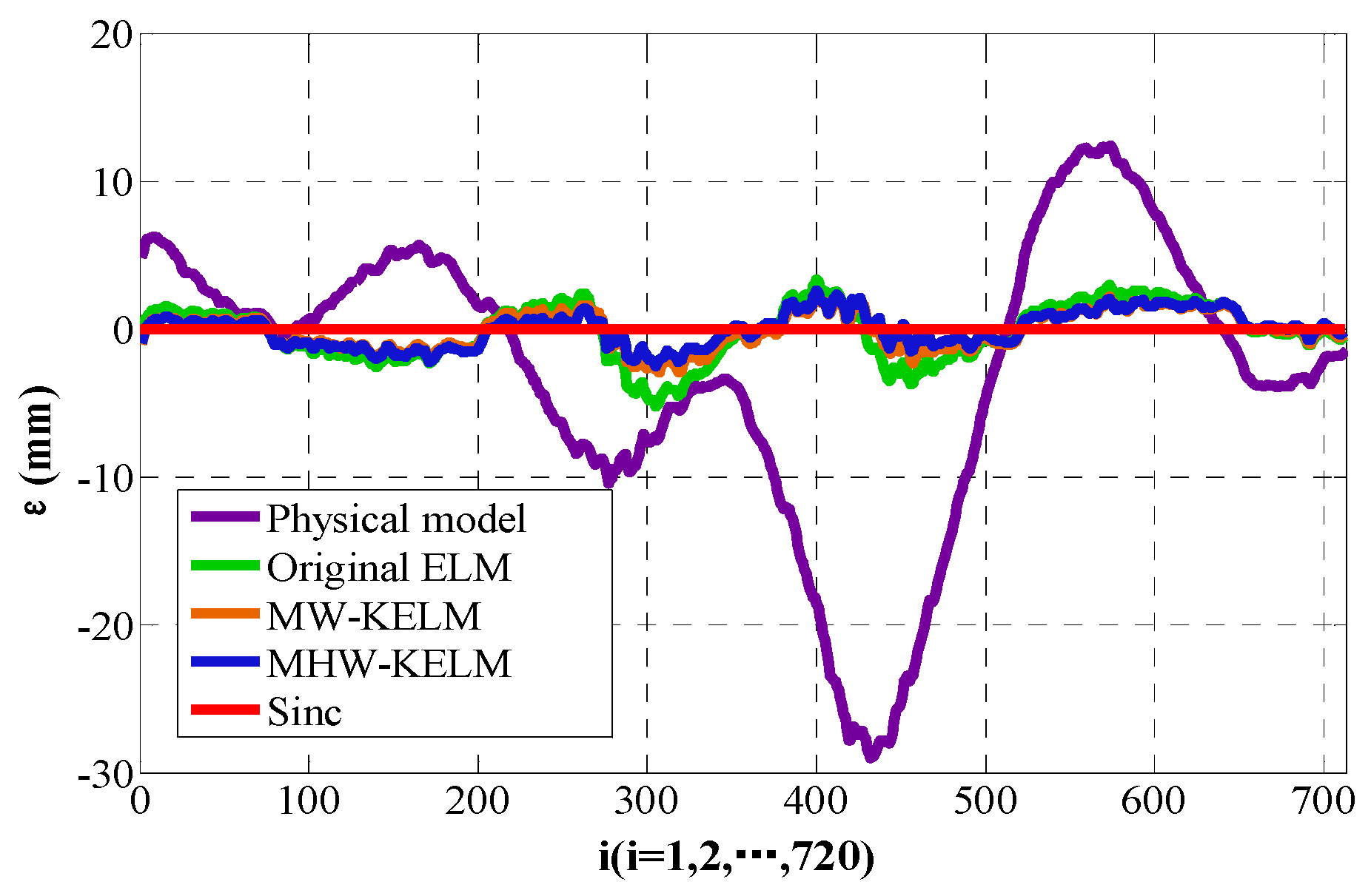

5.1.2. Results of Sinc Testing Data Set

The calibrated model is verified by using the Sinc testing set and the results of four different kernel functions are obtained. As shown in

Table 3, the results are compared with the physical model and the original ELM, respectively.

According to Equation (37), the positions of curves

are calculated and the calibrated curves, corresponding to the four KELM, are drawn in

Figure 10. The position error

is calculated according to Equation (38), the RMSE value of each method is calculated according to Equation (27), and the mean absolute error (MAE) and standard deviation (S

d) of each method are calculated by Equations (28)–(29). The calculation results are listed in

Table 3 and the position error of the four KELM are shown in

Figure 11.

As can be seen from

Table 3 and

Figure 10 and

Figure 11, the accuracy of the wavelet KELM is higher than that of other methods. It is observed to attain the best RMSE among all other models, with an RMSE value of 1.1695, MAE of 0.9777, and S

d of 0.5495. This indicates that the accuracy of the Mexican Hat wavelet KELM is slightly better than the Morlet wavelet KELM and has better results than the other methods. Compared with the original ELM, the RMSE, MAE, and Sd are reduced by 38.6%, 39.4%, and 36.6%, respectively.

5.1.3. Comparison of Calculation Speed

In terms of the calculation speed of the algorithm, the offline model training time, testing time, and online correction time are compared, respectively. Each index is tested 20 times and the average time is taken as the final value, which is listed in

Table 4. According to the procedure flow in

Section 3.3, Part B: Step (1) to Step (4), the online calculation time of calibration algorithm is calculated and the results are listed in the last column of

Table 4.

As listed in

Table 4, because of the simplicity of the algorithm and the small amount of computation, the calculation time of the physical model method is the fastest, the original ELM method is the second, and the kernel-based calibration methods are the slowest. This is due to the complexity of the kernel matrix

and output weight

, which causes the calculation time to be longer and slows down the calculation speed. As a result, the offline training and testing time of KELM are both greater than original ELM. The offline training time of the Morlet wavelet KELM is the longest, which reaches 4.76 s.

In the process of online calculation of the kernel-based method, the offline model training has been completed and the output weight has been obtained. For this reason, the computation of the online calibration algorithm is reduced. In addition, the online measurement data is one-dimensional data, which greatly reduces the amount of calculation. This is another reason why the operation time of the online calibration algorithm is greatly shortened. Among the two wavelet KELM with high calibration accuracies, the online calibration time of the Morlet wavelet KELM is less than 0.42 ms and the Mexican Hat wavelet KELM is less than 0.39 ms.

5.2. Analysis

According to the experimental process, it can be seen that the calibration data of the galvanometer contains a variety of nonlinear factors and noises, such as installation errors, system control noise, laser ranging noise, angle measurement noise, and other random noises, etc., which is typical of a nonlinear sample set. The magnitude and characteristics of these errors and noises are unknown.

The results from

Section 5.1 indicate that the accuracy of KELM algorithm with different kernel functions differs greatly. Among the four kernel functions, the error of the Gaussian kernel function is the largest, even worse than original ELM. The two wavelet KELM are higher than the original ELM and other kernel functions. The Mexican Hat wavelet kernel is slightly higher than the Morlet wavelet kernel. The smaller RMSE value means that the wavelet KELM has better generalization ability than other calibration methods for the nonlinear samples of the galvanometer.

Further analysis of the reasons for this result shows that the wavelet kernel is constructed from a wavelet function, which can form a set of primary functions of space through stretching and translation. For any nonlinear function, it can be expressed as a linear combination of the primary functions and has a good fitting ability for nonlinear functions. Therefore, wavelet KELM has a better generalization ability for nonlinear samples than other kernel ELM methods and the original ELM.

As can be seen from

Table 1 and

Table 2, for the two testing data sets, the error of the physical model method has a large MAE value and S

d value, which means that the calibration result contains a large noise, while the error dispersion of ELM and wavelet KELM is greatly reduced. This means that both ELM and wavelet KELM method have a certain noise suppression ability, but the wavelet KELM has better generalization ability and noise suppression effect than other methods.

From Equation (23), it can be found that the Mexican Hat wavelet kernel is a function of the distance between vector and vector . With the increase of the distance between the two vectors, the influence of on decreases. The attenuation law is determined by the Mexican Hat wavelet kernel function and is significantly affected by . The larger the value is, the faster the weaken speed of is. It can also be seen from Equation (17) that the output of the calibration model is obtained by the superposition of the product of the Mexican Hat wavelet kernel and the weight at various positions. In this process, the Mexican Hat wavelet kernel is like a low-pass filter, which weakens the influence of noise points, so that the wavelet KELM has low MAE and Sd values and a noise suppression effect.

After the wavelet KELM is adopted, the complexity of the algorithm increases and the speed of the calibration algorithm slows down. For the online calibration algorithm, the operation time of the Mexican Hat wavelet KELM is slightly faster than that of the Morlet wavelet KELM. As can be seen from the comparison between Equations (22) and (23), the independent variable of the Mexican Hat wavelet kernel only contains quadratic terms and the Morlet wavelet kernel also contains the primary term and its cosine operation. For the higher-dimensional input vector and , the calculation of requires decomposing it into the product form of multiple one-dimensional vectors, then performing the cosine calculation, which will take a certain calculation time and makes Morlet wavelet kernel functions slower than the Mexican Hat wavelet kernel functions.

Based on the above analysis, the Mexican Hat wavelet KELM has higher accuracy than other existing methods for 2D galvanometer calibration. Although the calculation speed is slower than the original ELM, it can still reach 0.39 ms, which can meet the needs of a conventional online measurement system.