Procedure for Calibrating the Z-axis of a Confocal Microscope: Application for the Evaluation of Structured Surfaces

Abstract

1. Introduction

2. Measurement Method

- (a)

- Obtaining the surface evaluated by a confocal microscope. The file provided by the equipment contains the sampled and coordinates and the digitized coordinates .

- (b)

- Cropping the surface evaluated. As the evaluated area is not square, this is cropped so an area of l × l will be obtained. The length l will be equal to the nesting index L (Section 2 item e)

- (c)

- S Filter. The area evaluated is filtered using a low-pass filter with a nesting index S1. The primary area with coordinates is obtained. The nesting index is an extension of the cut-off wavelength concept employed in the profile roughness measurements (2D). The S1 filter nesting index determines the maximum sampling distance and eliminates small-scale lateral components of the surface, for example measurement noise or small features. The value of the nesting index S1 is determined according to the recommendations of the ISO 25178-3:2012 [51], and a Gaussian filter according to ISO 16610-61:2015 [52] is used.

- (d)

- Form removal. Since it is very laborious to place the measurand entirely perpendicular with respect to the confocal microscope optical axis, and also due to the form errors characteristic of the measurand, its nominal form needs to be removed by adjusting the surface to a basic geometrical feature (e.g., a plane or sphere). When the deviation of the adjusted component is very small, it can be corrected by subtracting the adjusted component from the measured coordinates. However, in other situations the adjusted component has to be rotated so that its normal coincides with the instrument optical axis. After removing the shape, the S–F surface with coordinates is obtained. When the element to be adjusted is a plane, it can be represented mathematically as:The coefficients can be calculated using the least squares or minimum zone method. The plane that best fits the coordinates is:where are the residuals of the adjustment. If the least square problem is solved, a method that solves homogeneous equations must be used [53]. Using the same method, it is possible to remove the form error of the evaluated surface by adjusting it to other basic geometrical features (e.g., spheres, cylinders, cones, or quadrics).

- (e)

- L Filter. The S–F Surface is filtered using a high-pass filter with a nesting index L to give the S–L surface with coordinates . The nesting index L determines the size of the primary surface and eliminate large-scale lateral components of the surface. The value of the nesting index L is determined according to ISO 25178-3:2012 [51]. A Gaussian filter is used according to the ISO 16610-61:2015 standard [52].

- (f)

- Obtaining the areal parameters, according to the ISO 25178-2:2012 standard [24]. For the determination of the height parameters Sa, Sq, Ssk, Sku, an analytical calculation method (Simpson’s rule) is used, instead of using the discrete calculation formulas [54] (Equations (6)–(9)), so that it is possible to improve the accuracy of the calculations.

3. Validation of the Algorithms

4. Roughness Parameters Calculation Model: Assurance of Traceability

4.1. Mathematical Model

- (a)

- Measurement repeatability: For its analysis, an experiment was conducted in which a roughness standard was measured 15 times, in this case, a type C1 spacing standard, grooves with a sine wave profile, with a measurement area of 0.8 × 0.8 mm. The surface was first filtered employing a low pass filter with an 8 µm nesting index, then later with a high pass filter with a nesting index of 800 µm. The lighting and the tilt of the measuring table were kept constant during the measurements. The values of the parameters Sa, Sq, Ssk, Sku, Sz, Sp, and Sv were determined in each of the measurements and the standard deviation of the 15 measurements obtained. These experimental values are shown in Table 2.Bearing in mind that measurements with confocal equipment takes a long time (20–35 min for a measurement area of 0.8 × 0.8 mm), the technique used in the virtual CMM was adopted [49], so the real behavior of the equipment was simulated. Using this technique, an uncertainty contribution was added to the captured coordinates: . The variability due to was estimated by observing the values provided by the equipment. The study assumed that the variability associated with the confocal microscope z-coordinates used was characterized by a normal of mean zero and standard deviation σ, that is , that this variability was the same for all the coordinates, and that there was no correlation between evaluated coordinates.Figure 2 shows the flowchart of how to determine the dispersion to be used in the z-coordinates. A Monte Carlo simulation model was implemented, which used the algorithms developed in Section 2, and simulated this model with a number of replications N = 1000. In each trial, the standard deviation value was varied, until variability values similar to those in Table 2 were obtained, for each of the roughness parameters. After the different trials, it was verified that the standard deviation that best adapted to the results was 0.1 µm.

- (b)

- Z-axis calibration coefficient (): This was obtained using a step height standard with trapezoidal grooves (Figure 3a,b). Four grooves were measured, those of nominal values 24, 7, 2, and 0.7 µm as they were the measurement range of the measurands analyzed in this work. The certified values (provided by an accredited laboratory) are shown in Table 3.A procedure to evaluate the previous step standard heights was used. This procedure is based on initially adjusting the upper surface of the step height standard to a reference plane and then rotating it. Next, the mean distance was determined between this reference plane and the lower planes of the different grooves [59]. Each groove was measured using a Leica confocal microscope, model DCM-3D, with a 50× objective. The standard was measured 10 times. Table 4 shows the mean results obtained, the difference between the measured and certified value, the correction coefficient value (the quotient of the certified value and measured value) and the correction coefficient standard uncertainty, by using the standard uncertainty and measurement repeatability of the step heights as sources of uncertainty.It was observed that for the nominal values of 2 and 0.7 µm, the differences with the certified value were in the order of nanometers. Usually, a global correction coefficient is used , with a value equal to 1 for the whole scale. The difference in values obtained with respect to the global value was included in the standard uncertainty of this coefficient. From the values of the correction coefficients (Table 4, Line 6) and their standard uncertainty (Table 6, Line 7), a global correction coefficient equal to 1 was obtained, which responded to a uniform distribution of limits 1 ± 0.03 [−].

- (c)

- Measurement noise (). An experiment was carried out measuring a flatness standard (metallic coated glass) multiple times (n = 15) with flatness , and the roughness parameter Sq was analyzed both with and without averaging the coordinates. To determine the standard uncertainty associated with the noise from each parameter, the indications of the document “Calibration of the metrological characteristics of Imaging Confocal Microscopes (ICMs) Measurement Good Practice Guide No. 128” [45] were used. The standard uncertainty associated with the noise of this parameter was calculated as:This variable had a normal distribution, with a most probable value equal to zero and standard uncertainty equal to the value provided by the previous equation. Table 5 shows the results obtained in the experiment:

- (d)

- Light intensity variation (). The determination of the contribution made by this was by measuring in reproducibility conditions with a type C1 spacing standard, with grooves and a sine wave profile. The standard was measured 10 times, with the lighting value provided by the equipment changed each time. The light intensity range should be selected so that the sensor of the microscope will not be saturated and always receives signal. Over the 10 measurements, the nominal illumination value was changed by ±15% The standard deviation of the roughness parameters was determined from the 10 measurements (Table 6). This contribution was considered because it is not possible to know with absolute certainty which is the optimum level of illumination.

- (e)

- Variation of sample inclination (). The determination of the contribution made by this was by measuring in reproducibility conditions with a type C1 spacing standard, with grooves and a sine wave profile. The standard was measured 10 times, and the inclination of the tilt table changed in each (over the 10 measurements, the table inclination changed ±1° with respect to the horizontal). The standard deviation of the roughness parameters was determined from the 10 measurements (Table 6). This contribution was considered because it is practically impossible to place the measurand perpendicular to the equipment optical axis.For the previous contributions ( and ) it was assumed these would have a normal distribution with a mean of zero and standard deviation as shown in Table 6). The standard uncertainties were calculated as type A uncertainties according to the following expression:where is the standard deviation of the analyzed parameters and represent the numbers of times the roughness was measured (typically 1).

4.2. Model for Calculating Uncertainty

- (a)

- Definition of the output quantities. Corrected roughness parameters .

- (b)

- Definition of input quantities. The Z-axis calibration coefficient () sampled z-coordinates of the surface and the , , and parameters. Sources of uncertainty that considered the variability of the parameters and coordinates measured by the confocal microscope were examined, as well as a factor for traceability for measurements on the Z-axis.

- (c)

- Assignment of the probability density functions (PDF) to the input variables. For the input variables in the previous section, the following was established:The coefficient had a uniform distribution of limits 1 ± 0.03, calculated in Section 4.1 item b.The variability associated with the z-coordinates was according to a normal distribution, whose mean was the coordinate captured by the equipment and with a standard uncertainty of 0.1µm, calculated in Section 4.1 item a.The measurement noise had a normal distribution of zero mean and standard uncertainty equal to 0.0090 µm, calculated in Section 4.2 item c.The light intensity variation had a normal distribution of zero mean and standard deviation (depending on the parameter) as shown in Table 6.The table tilt variation had a normal distribution of zero mean and standard deviation (depending on the parameter) as shown in Table 6.

- (d)

- Propagation. The Supplement 1 to the GUM (Guide to the expression of uncertainty in measurement), Section 7.2.3 [65], suggests a reduced number of trials () can be used for complex models. Based on this recommendation, the mean values and their standard uncertainty after replicating the model M trials could be taken as and respectively, and be assigned to Gaussian PDF . A total of 5000 trials were conducted to obtain the experimental results, requiring 2–3 h of calculation in a computer with an Intel(R) Core(TM)-i7-6700HQ and memory of 16 GB.

- (e)

- Results. From the M trials of the models, the most probable values and standard uncertainties of the roughness parameters were determined. To determine the interval of uncertainty, the minimum interval method was used [66,67]. Finally, when the calculation models provided multiple results, the covariance matrix was determined, as well as the matrix of correlation coefficients according to that established in Supplement 2 of the GUM [65].

5. Experimental Verification

5.1. Checking the Type C1 Spacing Standard

5.2. Structured Surface

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Evans, C.J.; Bryan, J.B. Structured, Textured or Engineered Surfaces. CIRP Ann. Manuf. Technol. 1999, 48, 541–556. [Google Scholar] [CrossRef]

- Godia, A.; Grønbæk, J.; De Chiffre, L. Characterisation and full-scale production testing of multifunctional surfaces for deep drawing applications. CIRP J. Manuf. Sci. Technol. 2017, 16, 64–71. [Google Scholar] [CrossRef]

- Sethi, S.K.; Manik, G. Recent Progress in Super Hydrophobic/Hydrophilic Self-Cleaning Surfaces for Various Industrial Applications: A Review. Polym. Plast. Technol. Eng. 2018, 57, 1932–1952. [Google Scholar] [CrossRef]

- Dongliang, C.; Jun, L.; Jianying, Z.; Guo, J.; Zhang, S.; Sherazi, T.A.; Li, S. Bioinspired superhydrophilic-hydrophobic integrated surface with conical pattern-shape for self-driven fog collection. J. Colloid Interface Sci. 2018, 530, 274–281. [Google Scholar] [CrossRef]

- Liu, C.; Li, X.W.; Lei, Y.J.; Zhang, Q.X.; Huang, X.J. Fabrication of Micro-Nano Structures on 5A02 Al Alloy Substrate Surface and Their Anti-corrosion Property. Rare Met. Mater. Eng. 2019, 47, 2875–2880. [Google Scholar]

- Lv, D.; Ou, J.; Xue, M.; Wang, F. Stability and corrosion resistance of superhydrophobic surface on oxidized aluminium in NaCl aqueous solution. Appl. Surf. Sci. 2015, 333, 163–169. [Google Scholar] [CrossRef]

- Wang, N.; Xiong, D.; Li, M.; Deng, Y.; Shi, Y.; Wang, K. Applied surface science superhydrophobic surface on steel substrate and its anti-icing property in condensing conditions. Appl. Surf. Sci. 2015, 355, 226–232. [Google Scholar] [CrossRef]

- Wenxuan, Y.; Yuan, Y.; Guoyong, L.; Bing, Z.; Rongkai, Y. The anti-icing/frosting aluminum surface with hydrangea-like micro/nano structure prepared by chemical etching. Mater. Lett. 2018, 226, 4–7. [Google Scholar] [CrossRef]

- Patzelt, G.J.; Stenzel, V.; Geils, J.; Stake, A. Anti-icing and anticontamination properties of coatings induced by surface structure. J. Coat. Technol. Res. 2016, 13, 589–596. [Google Scholar] [CrossRef]

- Wang, H.; Kexin, S.; Leizheng, S.; Liang, P.; Ji, P.; Wang, C. The effect of 3D-printed Ti6Al4V scaffolds with various macropore structures on osteointegration and osteogenesis: A biomechanical evaluation. J. Mech. Behav. Biomed. Mater. 2018, 88, 488–496. [Google Scholar] [CrossRef]

- Yuan, B.; Cheng, Q.; Zhao, R.; Zhu, X.; Yang, X.; Zhang, K.; Song, Y.; Zhang, X. Comparison of osteointegration property between PEKK and PEEK: Effects of surface structure and chemistry. Biomaterials 2018, 170, 116–126. [Google Scholar] [CrossRef] [PubMed]

- Wong, Y.S.; Hong, G.S.; Lu, W.F.; Yu, D.P.; Zhong, X.; Cheng, H.L. An automatic form error evaluation method for characterizing micro-structured surfaces. Meas. Sci. Technol. 2011, 22, 015105. [Google Scholar] [CrossRef]

- MacAulay, G.D.; Giusca, C.L. Assessment of uncertainty in structured surfaces using metrological characteristics. CIRP Ann. Manuf. Technol 2016, 65, 533–536. [Google Scholar] [CrossRef]

- Ren, M.; Ehmann, K.F.; Zhu, W.L.; Zhu, Z.; Ju, B.F. Modeling and analysis of uncertainty in on-machine form characterization of diamond-machined optical micro-structured surfaces. Meas. Sci. Technol. 2016, 27, 125017. [Google Scholar] [CrossRef]

- Bruzzone, A.A.G.; Costa, H.L. Functional Characterization of Structured Surfaces for Tribological Applications. Procedia CIRP 2013, 12, 456–461. [Google Scholar] [CrossRef]

- Lonardo, P.M.; Trumpold, H.; De Chiffre, L. Progress in 3D surface microtopography characterization. CIRP Ann. Manuf. Technol. 1996, 45, 589–598. [Google Scholar] [CrossRef]

- De Chiffre, L.; Lonardo, P.M.; Trumpold, H.; Lucca, D.A.; Goch, G.; Brown, C.A.; Raja, J.; Hansen, H.N. Quantitative Characterisation of Surface Texture. CIRP Ann. Manuf. Technol. 2000, 49, 635–652. [Google Scholar] [CrossRef]

- Lonardo, P.M.; Lucca, D.A.; De Chiffre, L. Emerging Trends in Surface Metrology. CIRP Ann. Manuf. Technol. 2002, 51, 701–723. [Google Scholar] [CrossRef]

- Todhunter, L.D.; Leach, R.; Lawes, S.; Blateyron, F. Industrial survey of ISO surface texture parameters. CIRP Ann. Manuf. Technol 2017, 19, 84–92. [Google Scholar] [CrossRef]

- ISO. ISO 4287:1997—Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; International Standards Organization: Geneva, Switzerland, 1997. [Google Scholar]

- ISO. ISO 12085:1996—Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Motif Parameters; International Standards Organization: Geneva, Switzerland, 1996. [Google Scholar]

- ISO. ISO 13565-2:1996—Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 2: Height Characterization Using the Linear Material Ratio Curve; International Standards Organization: Geneva, Switzerland, 1996. [Google Scholar]

- ISO. ISO 13565-3:1998 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 3: Height Characterization Using the Material Probability Curve; International Standards Organization: Geneva, Switzerland, 1998. [Google Scholar]

- ISO. ISO 25178-2:2012—Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; International Standards Organization: Geneva, Switzerland, 2012. [Google Scholar]

- De Chiffre, L. Industrial Survey on ISO Surface Texture Parameters. CIRP Ann. Manuf. Technol. 1999, 48, 74–77. [Google Scholar]

- Leach, R.K. Characterisation of Areal Surface Texture; Springer: Berlin, Germany, 2013; 353p, ISBN 978-3-642-36457-0. [Google Scholar]

- Blunt, L.; Jiang, X. Advanced Techniques for Assessment Surface Topography: Development of a Basis for 3D Surface Texture Standards “SURFSTAND”; Butterworth-Heinemann: London, UK, 2003; pp. 1–340. ISBN 978-1-903996-11-9. [Google Scholar]

- SoftGauges for Surface Topography. Available online: http://www.npl.co.uk/softgauges (accessed on 15 January 2019).

- Whitehouse, D.J. Handbook of Surface Metrology; CRC Press: Boca Raton, FL, USA, 1994; 350p, ISBN 9780750300391. [Google Scholar]

- Leach, R.K. Optical Measurement of Surface Topography; Springer: Berlin, Germany, 2011. [Google Scholar]

- Bruzzone, A.A.G.; Costa, H.L.; Lonardo, P.M.; Lucca, D.A. Advances in Engineered Surfaces for Functional Performance. CIRP Ann. Manuf. Technol. 2008, 57, 750–769. [Google Scholar] [CrossRef]

- Caja García, J.; Sanz Lobera, A.; Maresca, P.; Fernandez Pareja, T.; Wang, C. Some Considerations about the Use of Contact and Confocal Microscopy Methods in Surface Texture Measurement. Materials 2018, 11, 1484. [Google Scholar] [CrossRef] [PubMed]

- De Groot, P.; Fitzgerald, D. Measurement, certification and use of step-height calibration specimens in optical metrology. Proc. SPIE 2017, 10329, 1032919. [Google Scholar] [CrossRef]

- Mullan, F.; Bartlett, D.; Austin, R.S. Measurement uncertainty associated with chromatic confocal profilometry for 3D surface texture characterization of natural human enamel. Dent. Mater. 2017, 33, e273–e281. [Google Scholar] [CrossRef] [PubMed]

- Guarneros, O.; de Vicente, J.; Maya, M.; Ocaña, J.L.; Molpeceres, C.; García-Ballesteros, J.J.; Rodríguez, S.R.; Duran, H.M. Uncertainty Estimation for Performance Evaluation of a Confocal Microscope as Metrology Equipment. Mapan J. Metrol. Soc. India 2014, 29, 29–42. [Google Scholar] [CrossRef]

- Seppä, J.; Niemelä, K.; Lassila, A. Metrological characterization methods for confocal chromatic line sensors and optical topography sensors. Meas. Sci. Technol. 2018, 29, 054008. [Google Scholar] [CrossRef]

- Udupa, G.; Singaperumal, M.; Sirohi, R.S.; Kothiyal, M.P. Characterization of surface topography by confocal microscopy: I. Principles and the measurement system. Meas. Sci. Technol. 2000, 11, 305–314. [Google Scholar] [CrossRef]

- Nouira, H.; El-Hayek, N.; Yuan, X.; Anwer, N. Characterization of the main error sources of chromatic confocal probes for dimensional measurement. Meas. Sci. Technol. 2014, 25, 044011. [Google Scholar] [CrossRef]

- Giusca, C.L.; Leach, R.K.; Helary, F.; Gutauskas, T.; Nimishakavi, L. Calibration of the scales of areal surface topography-measuring instruments: Part 1. Measurement noise and residual flatness. Meas. Sci. Technol. 2012, 23, 035008. [Google Scholar] [CrossRef]

- Giusca, C.L.; Leach, R.K.; Helary, F. Calibration of the scales of areal surface topography measuring instruments: Part 2. Amplification, linearity and squareness. Meas. Sci. Technol. 2012, 23, 065005. [Google Scholar] [CrossRef]

- Jensen, K.E.; Weitz, D.A.; Spaepen, F. Note: A three-dimensional calibration device for the confocal microscope. Rev. Sci. Instrum. 2013, 84, 016108. [Google Scholar] [CrossRef] [PubMed]

- De Chiffre, L.; Carli, L.; Eriksen, R.S. Multiple height calibration artefact for 3D microscopy. CIRP Ann. Manuf. Technol. 2011, 60, 535–538. [Google Scholar] [CrossRef]

- Corbett, A.D.; Shaw, M.; Yacoot, A.; Jefferson, A.; Schermelleh, L.; Wilson, T.; Booth, M.; Salter, P.S. Microscope calibration using laser written fluorescence. Opt. Express 2018, 26, 21887–21899. [Google Scholar] [CrossRef] [PubMed]

- Korpelainen, V.; Lassila, A. Calibration of a commercial AFM: Traceability for a coordinate system. Meas. Sci. Technol. 2007, 18, 395–403. [Google Scholar] [CrossRef]

- Giusca, C.L.; Leach, R. Calibration of the metrological characteristics of Imaging Confocal Microscopes (ICMs). Available online: http://www.npl.co.uk/publications/calibration-of-the-metrological-characteristics-of-imaging-confocal-microscopes-(icms) (accessed on 26 January 2019).

- ISO. ISO 25178-602:2010—Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 602: Nominal Characteristics of Non-Contact (Confocal Chromatic Probe) Instruments; International Standards Organization: Geneva, Switzerland, 2010. [Google Scholar]

- Besseling, T.H.; Jose, J.; Van Blaaderen, A. Methods to calibrate and scale axial distances in confocal microscopy as a function of refractive index. J. Microsc. 2015, 257, 142–150. [Google Scholar] [CrossRef] [PubMed]

- Dai, G.; Koenders, L.; Fluegge, J.; Hemmleb, M. Fast and accurate: High-speed metrological large-range AFM for surface and nanometrology. Meas. Sci. Technol. 2018, 29, 054012. [Google Scholar] [CrossRef]

- Sładek, J.; Gąska, A. Evaluation of coordinate measurement uncertainty with use of virtual machine model based on Monte Carlo method. Measurement 2012, 45, 1564–1575. [Google Scholar] [CrossRef]

- NIST; PML; Semiconductor and Dimensional Metrology Division. Internet Based Surface Metrology Algorithm Testing System. Available online: https://physics.nist.gov/VSC/jsp/ (accessed on 1 December 2018).

- ISO. ISO 25178-3:2012—Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Specification Operators; International Standards Organization: Geneva, Switzerland, 2012. [Google Scholar]

- ISO. ISO 16610-61:2015—Geometrical Product Specifications (GPS)—Filtration—Part 61: Linear Areal Filters—Gaussian; International Standards Organization: Geneva, Switzerland, 2015. [Google Scholar]

- Bjõrck, A. Numerical Methods for Least Squares Problems; SIAM: Philadelphia, PA, USA, 1996; 407p, ISBN 978-0-89871-360-2. [Google Scholar]

- Muralikrishnan, B.; Raja, J. Computational Surface and Roundness Metrology; Springer: London, UK, 2009; 263p, ISBN 978-1-84996-773-0. [Google Scholar]

- Cox, M.G.; Harris, P.M. The design and use of reference data sets for testing scientific software. Anal. Chim. Acta 1998, 380, 339–351. [Google Scholar] [CrossRef]

- ISO. ISO 25178-71:2017—Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 71: Software Measurement Standards; International Standards Organization: Geneva, Switzerland, 2017. [Google Scholar]

- Leach, R.K.; Giusca, C.L.; Haitjema, H.; Evans, C.; Jiang, X. Calibration and verification of areal surface texture measuring instruments. CIRP Ann. Manuf. Technol. 2015, 64, 797–813. [Google Scholar] [CrossRef]

- HALLE Präzisions-Kalibriernormale GmbH. Available online: http://www.halle-normale.de/framesets/englisch/products/products.html (accessed on 4 December 2018).

- ISO. ISO 5436-1:2000—Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Measurement Standards—Part 1: Material Measures; International Standards Organization: Geneva, Switzerland, 2000. [Google Scholar]

- Cox, M.G.; Siebert, B.R.L. The use of a Monte Carlo method for evaluating uncertainty and expanded uncertainty. Metrologia 2006, 43, S178–S188. [Google Scholar] [CrossRef]

- Sousa, J.A.; Ribeiro, A.S. The choice of method to the evaluation of measurement uncertainty in metrology. In Proceedings of the IMEKO XIX World Congress—Fundamental and Applied Metrology, Lisbon, Portugal, 6–11 September 2009; pp. 2388–2393. [Google Scholar]

- Caja, J.; Gómez, E.; Maresca, P. Optical measuring equipments. Part I: Calibration model and uncertainty estimation. Precis. Eng. 2015, 40, 298–304. [Google Scholar] [CrossRef]

- Caja, J.; Gómez, E.; Maresca, P. Optical measuring equipments. Part II Measurement traceability and experimental study. Precis. Eng. 2015, 40, 305–308. [Google Scholar] [CrossRef]

- BIPM; IEC; IFCC; ILAC; ISO; IUPAC; IUPAP; OIML. JCGM 101:2008. Evaluation of Measurement Data—Supplement 1 to the “Guide to the Expression of Uncertainty in Measurement”—Propagation of Distributions Using a Monte Carlo Method. Available online: http://www.bipm.org/utils/common/documents/jcgm/JCGM_101_2008_E.pdf (accessed on 1 December 2018).

- BIPM; IEC; IFCC; ILAC; ISO; IUPAC; IUPAP; OIML. Evaluation of Measurement Data—Supplement 2 to the “Guide to the Expression of Uncertainty in Measurement”—Extension to Any Number of Output Quantities. JCGM 102:2008. Available online: https://www.bipm.org/utils/common/documents/jcgm/JCGM_102_2011_E.pdf (accessed on 1 December 2018).

- Fotowicz, P. An analytical method for calculating a coverage interval. Metrologia 2006, 43, 087001. [Google Scholar] [CrossRef]

- Wübbeler, G.; Krystek, M.; Elster, C. Evaluation of measurement uncertainty and its numerical calculation by a Monte Carlo method. Meas. Sci. Technol. 2008, 19, 084009. [Google Scholar] [CrossRef]

- ISO. ISO 4288:1996 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture; International Standards Organization: Geneva, Switzerland, 1997. [Google Scholar]

| Unfiltered Surface | Filtered Surface | |||||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Reference Value | Calculated Value | Q1 (× 10−6) | Percentage Difference (%) | Reference Value | Calculated Value | Q1 (× 10−6) | Percentage Difference (%) |

| Sa [µm] | 0.89928 | 0.899 | 0.5 | 0.0005 | 0.85828 | 0.858 | 0.2 | 0.0002 |

| Sq [µm] | 1.0 | 1.000 | 0.3 | 0.0003 | 0.96137 | 0.961 | 0.5 | 0.0005 |

| Ssk [−] | 0.01957 | 0.0196 | 0.5 | 0.0232 | −0.0099 | −0.0099 | 0.0 | 0.0001 |

| Sku [−] | 1.51103 | 1.5110 | 0.5 | 0.0003 | 1.56465 | 1.5647 | 0.3 | 0.0002 |

| Sz [µm] | 2.91342 | 2.913 | 0.0 | 3.5·10−6 | 3.23026 | 3.230 | 0.3 | 9.1·10−5 |

| Sp [µm] | 1.46487 | 1.465 | 0.1 | 8.7·10−5 | 1.5812 | 1.581 | 0.3 | 0.0002 |

| Sv [µm] | 1.44855 | 1.449 | 0.1 | 8.1·10−6 | 1.64906 | 1.649 | 0.0 | 2.1·10−5 |

| Sa [µm] | Sq [µm] | Ssk [−] | Sku [−] | Sz [µm] | Sp [µm] | Sv [µm] |

|---|---|---|---|---|---|---|

| 0.006 | 0.007 | 0.018 | 0.009 | 0.071 | 0.071 | 0.050 |

| Groove 1 | Groove 2 | Groove 3 | Groove 4 | Groove 5 | Groove 6 | |

|---|---|---|---|---|---|---|

| Nominal value [µm] | 75.00 | 24 | 7 | 2 | 0.7 | 0.2 |

| Certified value [µm] | 75.43 | 24.050 | 7.510 | 2.386 | 0.728 | 0.234 |

| Expanded uncertainty (k = 2) [µm] | 0.28 | 0.089 | 0.029 | 0.014 | 0.012 | 0.011 |

| Groove 2 | Groove 3 | Groove 4 | Groove 5 | |

|---|---|---|---|---|

| Certified value [µm] | 24.05 | 7.510 | 2.386 | 0.728 |

| Measured value with CM [µm] | 24.064 | 7.546 | 2.391 | 0.728 |

| Standard deviation [µm] | 0.016 | 0.054 | 0.028 | 0.019 |

| Difference [µm] | −0.014 | −0.036 | −0.004 | 0.0001 |

| Correction coefficient [−] | 0.9994 | 0.9952 | 0.9980 | 1.0002 |

| Standard uncertainty of the correction coefficient [−] | 0.0006 | 0.0031 | 0.0049 | 0.0121 |

| Sq [µm] | |

|---|---|

| Mean without averaging the coordinates | 0.0259 |

| Mean with averaging the coordinates | 0.0244 |

| Uncertainty | 0.009 |

| Sa [µm] | Sq [µm] | Ssk [−] | Sku [−] | Sz [µm] | Sp [µm] | Sv [µm] | |

|---|---|---|---|---|---|---|---|

| 0.007 | 0.007 | 0.004 | 0.003 | 0.172 | 0.172 | 0.024 | |

| 0.024 | 0.026 | 0.189 | 0.036 | 0.332 | 0.295 | 0.142 |

| Parameter Estimation y | Standard Uncertainty u(y) | Shortest 95% Coverage Interval | ||

|---|---|---|---|---|

| Lower Limit | Upper Limit | |||

| Sacertified [µm] | 1.003 | 0.015 | 0.973 | 1.033 |

| Sameasured [µm] | 1.002 | 0.032 | 0.942 | 1.065 |

| Parameter Estimation y | Standard Uncertainty u(y) | Shortest 95% Coverage Interval | ||

|---|---|---|---|---|

| Lower Limit | Upper Limit | |||

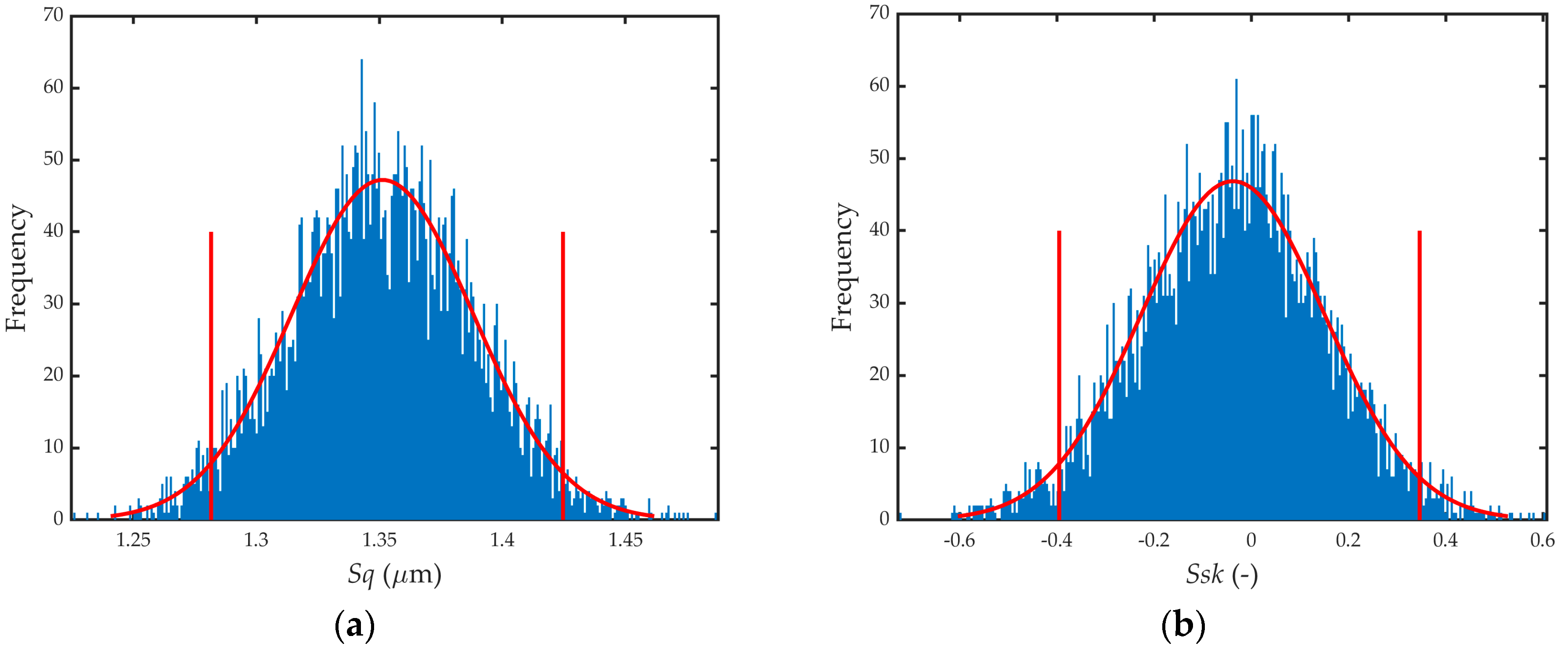

| Sa [µm] | 1.106 | 0.033 | 1.043 | 1.170 |

| Sq [µm] | 1.351 | 0.037 | 1.282 | 1.425 |

| Ssk [−] | −0.04 | 0.19 | −0.40 | 0.35 |

| Sku [−] | 2.588 | 0.058 | 2.484 | 2.699 |

| Sz [µm] | 10.43 | 0.41 | 9.64 | 11.25 |

| Sp [µm] | 4.02 | 0.35 | 3.33 | 4.67 |

| Sv [µm] | 6.41 | 0.18 | 6.07 | 6.77 |

| Sa [µm] | Sq [µm] | Ssk [−] | Sku [−] | Sz [µm] | Sp [µm] | Sv [µm] | |

|---|---|---|---|---|---|---|---|

| Sa [µm] | 1 | 0.381 | 0.012 | 0.449 | 0.257 | 0.124 | 0.348 |

| Sq [µm] | 0.381 | 1 | 0.003 | 0.480 | 0.274 | 0.140 | 0.378 |

| Ssk [−] | 0.012 | 0.003 | 1 | 0.005 | 0.020 | 0.010 | 0.004 |

| Sku [−] | 0.449 | 0.480 | 0.005 | 1 | 0.332 | 0.146 | 0.470 |

| Sz [µm] | 0.257 | 0.274 | 0.020 | 0.332 | 1 | 0.104 | 0.284 |

| Sp [µm] | 0.124 | 0.140 | 0.010 | 0.146 | 0.104 | 1 | 0.126 |

| Sv [µm] | 0.348 | 0.378 | 0.004 | 0.470 | 0.284 | 0.126 | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Caja, J.; Gómez, E.; Maresca, P. Procedure for Calibrating the Z-axis of a Confocal Microscope: Application for the Evaluation of Structured Surfaces. Sensors 2019, 19, 527. https://doi.org/10.3390/s19030527

Wang C, Caja J, Gómez E, Maresca P. Procedure for Calibrating the Z-axis of a Confocal Microscope: Application for the Evaluation of Structured Surfaces. Sensors. 2019; 19(3):527. https://doi.org/10.3390/s19030527

Chicago/Turabian StyleWang, Chen, Jesús Caja, Emilio Gómez, and Piera Maresca. 2019. "Procedure for Calibrating the Z-axis of a Confocal Microscope: Application for the Evaluation of Structured Surfaces" Sensors 19, no. 3: 527. https://doi.org/10.3390/s19030527

APA StyleWang, C., Caja, J., Gómez, E., & Maresca, P. (2019). Procedure for Calibrating the Z-axis of a Confocal Microscope: Application for the Evaluation of Structured Surfaces. Sensors, 19(3), 527. https://doi.org/10.3390/s19030527