Dual Resonator MEMS Magnetic Field Gradiometer

Abstract

:1. Introduction

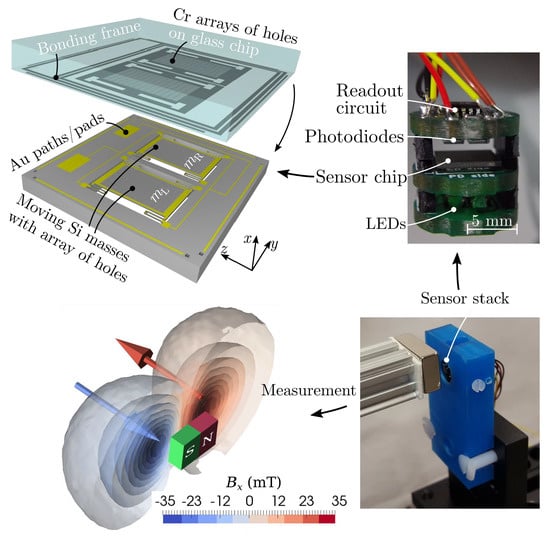

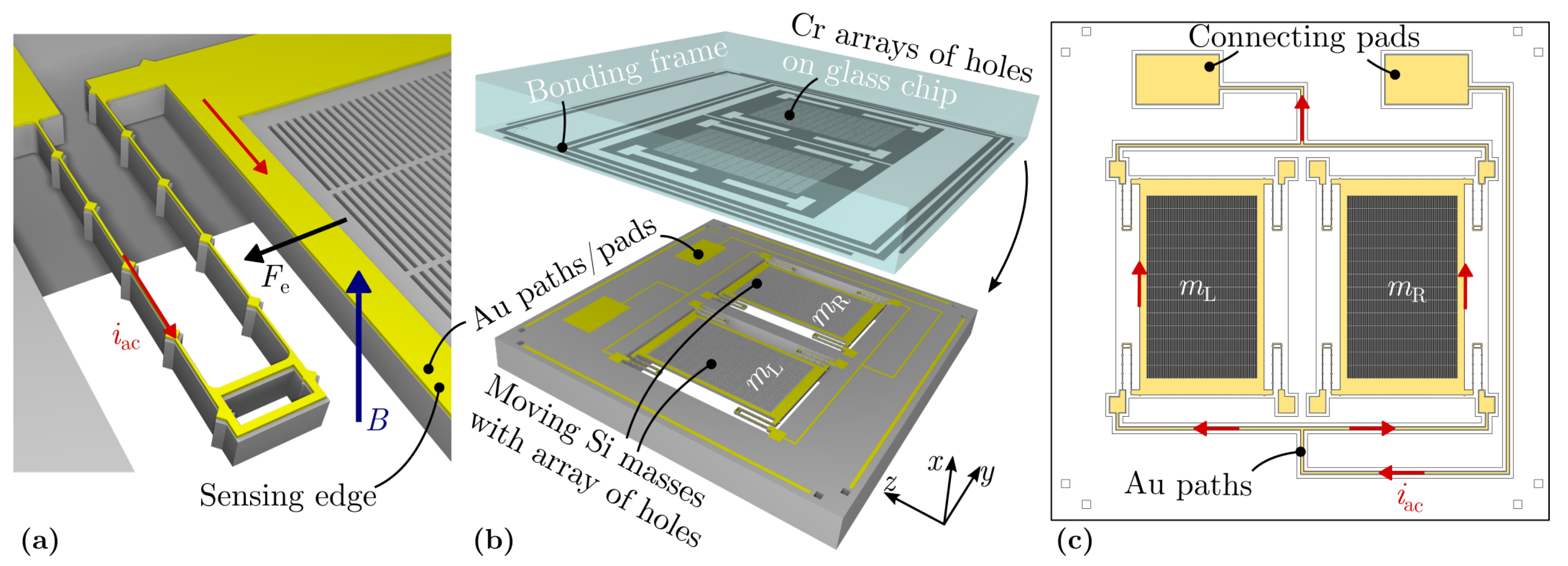

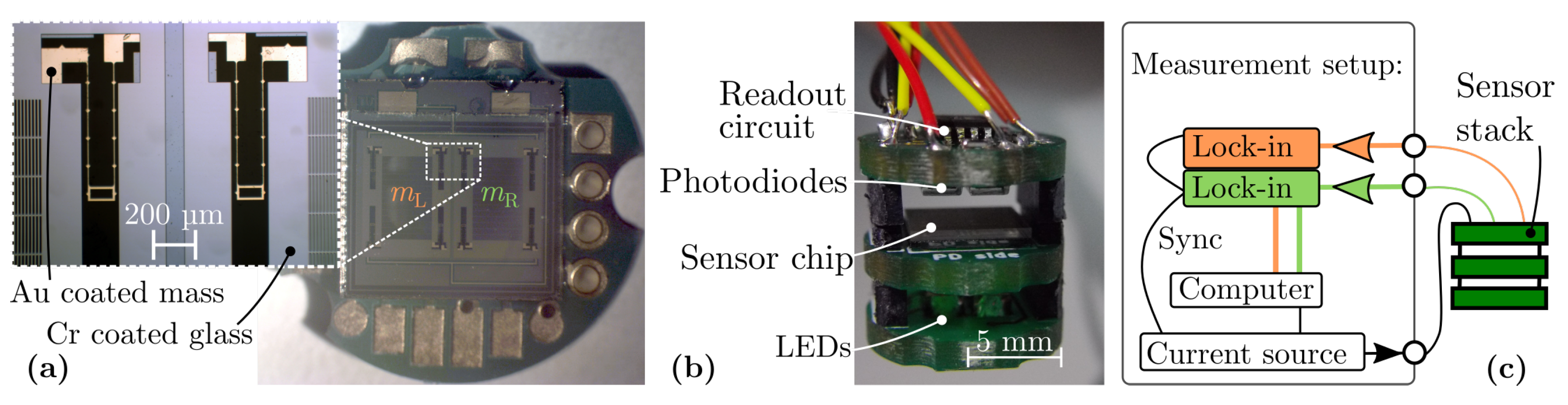

2. Sensing Principle and Fabrication

Transduction Scheme

3. Sensor Characterisation & Measurements

3.1. Frequency Response

3.2. Magnitude Response

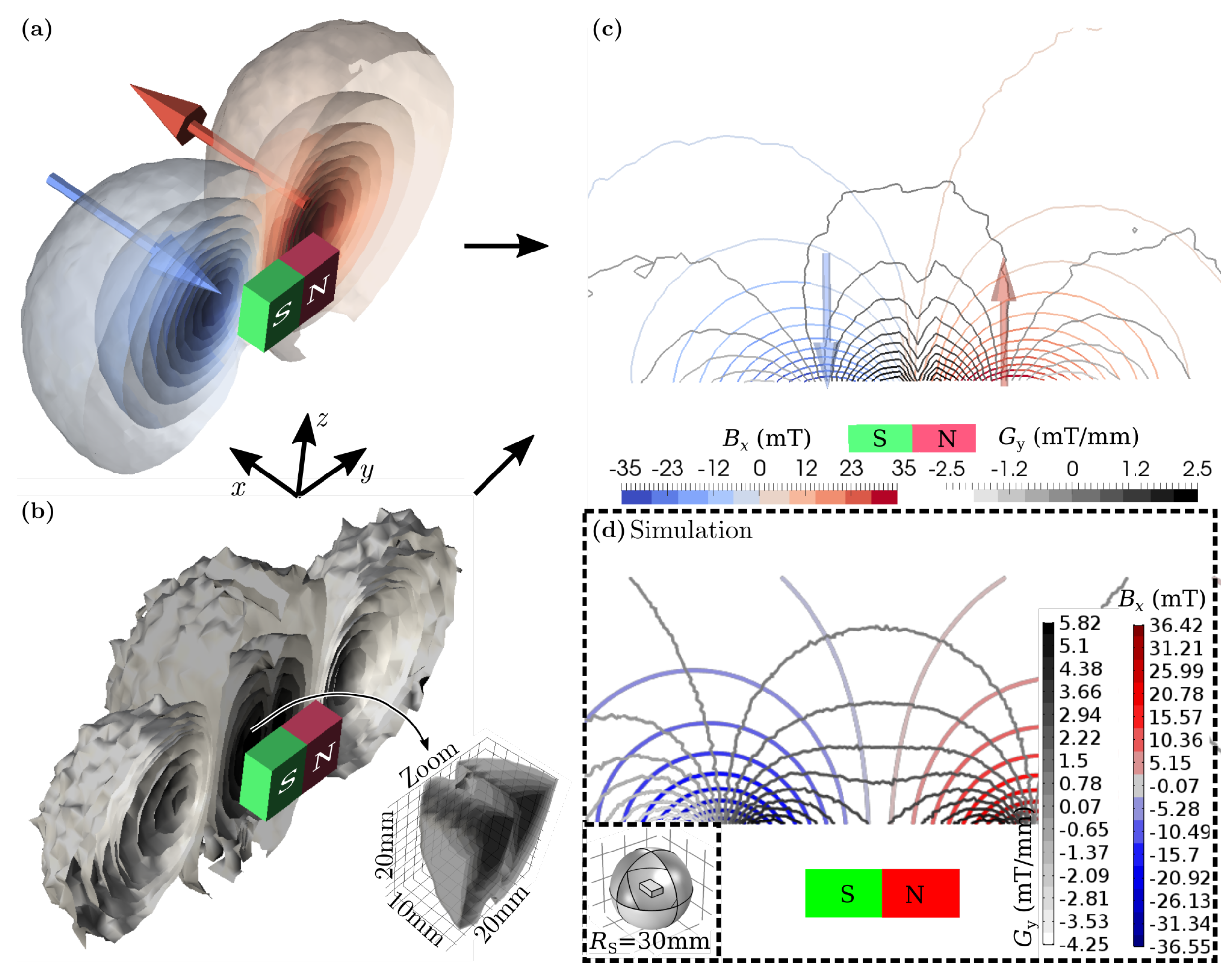

3.3. 3D Magnetic Field Characterisation of a Nd Bar Magnet

4. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Bottura, L.; Henrichsen, K.N. Field Measurements. In Proceedings of the CAS - CERN Accelerator School on Superconductivity and Cryogenics for Accelerators and Detectors, Erice, Italy, 8–17 May 2002; p. 35. [Google Scholar] [CrossRef]

- Ripka, P.; Janosek, M. Advances in Magnetic Field Sensors. IEEE Sens. J. 2010, 10, 1108–1116. [Google Scholar] [CrossRef]

- Ruskova, I.B.; Takov, T.; Tsankov, R.; Simonne, N. Temperature influence on Hall effect sensors characteristics. In Proceedings of the 2012 20th Telecommunications Forum (TELFOR), Belgrade, Serbia, 20–22 November 2012; pp. 967–970. [Google Scholar] [CrossRef]

- Suess, D.; Bachleitner-Hofmann, A.; Satz, A.; Weitensfelder, H.; Vogler, C.; Bruckner, F.; Abert, C.; Prügl, K.; Zimmer, J.; et al. Topologically protected vortex structures for low-noise magnetic sensors with high linear range. Nat. Electron. 2018, 1, 362–370. [Google Scholar] [CrossRef]

- Sonmezoglu, S.; Flader, I.B.; Chen, Y.; Shin, D.D.; Kenny, T.W.; Horsley, D.A. Dual-resonator MEMS magnetic sensor with differential amplitude modulation. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 814–817. [Google Scholar] [CrossRef]

- Dennis, J.; Ahmad, D.F.; Haris Bin Md Khir, M.; Hisham Bin Hamid, N. Optical characterization of lorentz force based CMOS-MEMS magnetic field sensor. Sensors 2015, 15, 18256–18269. [Google Scholar] [CrossRef] [PubMed]

- Suwa, W.; Inomata, N.; Toda, M.; Ono, T. Resonant magnetic sensor using magnetic gradient field formed by permalloy concentrator. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 822–825. [Google Scholar] [CrossRef]

- Kumar, V.; Ramezany, A.; Mahdavi, M.; Pourkamali, S. Amplitude modulated Lorentz force MEMS magnetometer with picotesla sensitivity. J. Micromech. Microeng. 2016, 26, 105021. [Google Scholar] [CrossRef]

- Park, B.; Li, M.; Liyanage, S.; Shafai, C. Lorentz force based resonant MEMS magnetic-field sensor with optical readout. Sens. Actuators A Phys. 2016, 241. [Google Scholar] [CrossRef]

- Laghi, G.; Marra, C.; Minotti, P.; Tocchio, A.; Langfelder, G. A 3-D Micromechanical Multi-Loop Magnetometer Driven Off-Resonance by an On-Chip Resonator. J. Microelectromech. Syst. 2016, 25, 1–15. [Google Scholar] [CrossRef]

- Herrera-May, A.; Lara-Castro, M.; López-Huerta, F.; Gkotsis, P.; Raskin, J.P.; Figueras, E. A MEMS-based magnetic field sensor with simple resonant structure and linear electrical response. Microelectron. Eng. 2015, 142, 12–21. [Google Scholar] [CrossRef]

- Sunderland, A.; Ju, L.; Blair, D.; Mcrae, W.; Veryaskin, A. Optimizing a direct string magnetic gradiometer for geophysical exploration. Rev. Sci. Instrum. 2009, 80, 104705. [Google Scholar] [CrossRef] [PubMed]

- Lucas, I.; Michelena, M.; del Real, R.; de Manuel, V.; Plaza, J.; Duch, M.; Esteve, J.; Guerrero, H. A New Single-Sensor Magnetic Field Gradiometer. Sens. Lett. 2009, 7, 563–570. [Google Scholar] [CrossRef]

- Dabsch, A.; Rosenberg, C.; Stifter, M.; Keplinger, F. MEMS cantilever based magnetic field gradient sensor. J. Micromech. Microeng. 2017, 27, 055014. [Google Scholar] [CrossRef]

- Hortschitz, W.; Steiner, H.; Sachse, M.; Stifter, M.; Kohl, F.; Schalko, J.; Jachimowicz, A.; Keplinger, F.; Sauter, T. Robust Precision Position Detection With an Optical MEMS Hybrid Device. IEEE Trans. Ind. Electron. 2012, 59, 4855–4862. [Google Scholar] [CrossRef]

- Hortschitz, W.; Steiner, H.; Stifter, M.; Kohl, F.; Kainz, A.; Raffelsberger, T.; Keplinger, F. Extremely low resonance frequency MOEMS vibration sensors with sub-pm resolution. In Proceedings of the 2014 IEEE SENSORS, Valencia, Spain, 2–5 November 2014; pp. 1889–1892. [Google Scholar] [CrossRef]

- Hortschitz, W.; Encke, J.; Kohl, F.; Sauter, T.; Steiner, H.; Stifter, M.; Keplinger, F. Receiver and amplifier optimization for hybrid MOEMS. In Proceedings of the 2012 IEEE SENSORS, Taipei, Taiwan, 28–31 October 2012; pp. 1–4. [Google Scholar] [CrossRef]

- Hortschitz, W.; Steiner, H.; Stifter, M.; Kainz, A.; Kohl, F.; Siedler, C.; Schalko, J.; Keplinger, F. Novel MOEMS Lorentz Force Transducer for Magnetic Fields. Procedia Eng. 2016, 168, 680–683. [Google Scholar] [CrossRef]

- Herrera-May, A.; Soler Balcazar, J.C.; Vazquez-Leal, H.; Martínez-Castillo, J.; Vigueras-Zúñiga, M.O.; Aguilera-Cortés, L. Recent Advances of MEMS Resonators for Lorentz Force Based Magnetic Field Sensors: Design, Applications and Challenges. Sensors 2016, 16, 1359. [Google Scholar] [CrossRef] [PubMed]

- Salem, A.; Hamada, T.; Asahina, J.K.; Ushijima, K. Detection of unexploded ordnance (UXO) using marine magnetic gradiometer data. BUTSURI-TANSA (Geophys. Explorat.) 2005, 58, 97–103. [Google Scholar] [CrossRef]

- Stifter, M.; Steiner, H.; Hortschitz, W.; Sauter, T.; Glatzl, T.; Dabsch, A.; Keplinger, F. MEMS micro-Wire Magnetic Field Detection Method at CERN. IEEE Sens. J. 2016, 16, 8744–8751. [Google Scholar] [CrossRef]

- Delmas, A.; Belguerras, L.; Weber, N.; Odille, F.; Pasquier, C.; Felblinger, J.; Vuissoz, P.A. Calibration and non-orthogonality correction of three-axis Hall sensors for the monitoring of MRI workers’ exposure to static magnetic fields. Bioelectromagnetics 2018, 39, 108–119. [Google Scholar] [CrossRef] [PubMed]

- Gabrielson, T.B. Mechanical-thermal noise in micromachined acoustic and vibration sensors. IEEE Trans. Electron Devices 1993, 40, 903–909. [Google Scholar] [CrossRef]

| Publication | Sensing | Resonant | Quality | Detection | Dimension |

|---|---|---|---|---|---|

| Technique | Frequency | Factor | Limit | ||

| kHz | nT/ | mm × mm | |||

| Kumar et al. [8] | Piezoresistive | 400 | 1.1 × | 2.76 × | 0.8 × 0.8 |

| @7.245 mA | (single mass) | ||||

| Park et al. [9] | Optical | 0.364 | 116 | 11.6 | 3.3 × 3.3 |

| @50 mA | |||||

| Sonmezoglu et al. [5] | Capacitive | 47.22 | 11760 | 50 | 2.2 × 2.2 |

| @1.1 mA | (die) | ||||

| Laghi et al. [10] | Capacitive | 19.34 | 790 | 185 | 1.6 × 0.85 |

| @100 µA | (single device) | ||||

| Herrera-May et al. [11] | Piezoresistive | 100.7 | 419.6 | 2500 | 0.472 × 0.3 |

| @10 mA | (mass only) |

| A | t | m | Q | k | c | ||

| µm | mm | Hz | N/m | µg/s | |||

| 4 | 45 | 2.5 | 38.25 | 1354 | 334 | 2.77 | 0.974 |

| V/T | µT/ | V/T | µT/ |

| 19.04 | 5.75 | 35.65 | 3.07 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kahr, M.; Stifter, M.; Steiner, H.; Hortschitz, W.; Kovács, G.; Kainz, A.; Schalko, J.; Keplinger, F. Dual Resonator MEMS Magnetic Field Gradiometer. Sensors 2019, 19, 493. https://doi.org/10.3390/s19030493

Kahr M, Stifter M, Steiner H, Hortschitz W, Kovács G, Kainz A, Schalko J, Keplinger F. Dual Resonator MEMS Magnetic Field Gradiometer. Sensors. 2019; 19(3):493. https://doi.org/10.3390/s19030493

Chicago/Turabian StyleKahr, Matthias, Michael Stifter, Harald Steiner, Wilfried Hortschitz, Gabor Kovács, Andreas Kainz, Johannes Schalko, and Franz Keplinger. 2019. "Dual Resonator MEMS Magnetic Field Gradiometer" Sensors 19, no. 3: 493. https://doi.org/10.3390/s19030493

APA StyleKahr, M., Stifter, M., Steiner, H., Hortschitz, W., Kovács, G., Kainz, A., Schalko, J., & Keplinger, F. (2019). Dual Resonator MEMS Magnetic Field Gradiometer. Sensors, 19(3), 493. https://doi.org/10.3390/s19030493