Evaluation of a 10 nm Particle Number Portable Emissions Measurement System (PEMS)

Abstract

1. Introduction

2. Materials and Methods

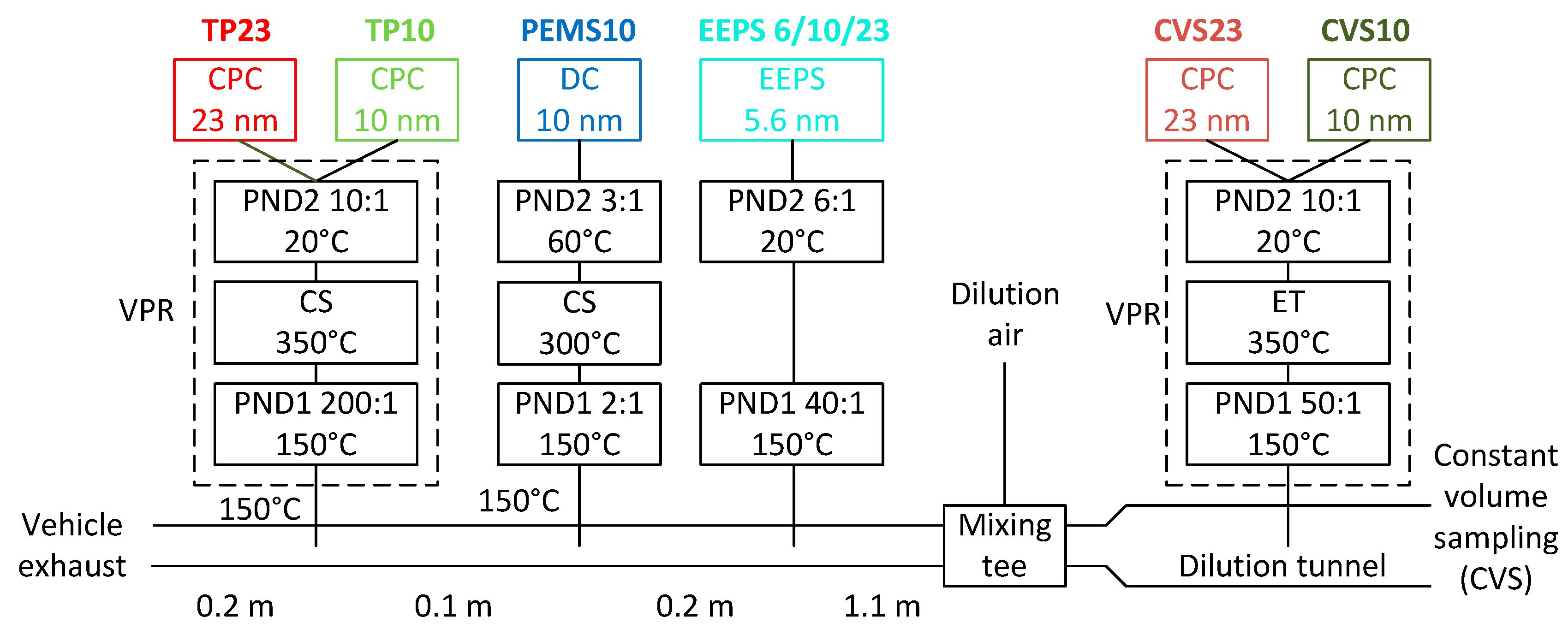

2.1. Instrumentation

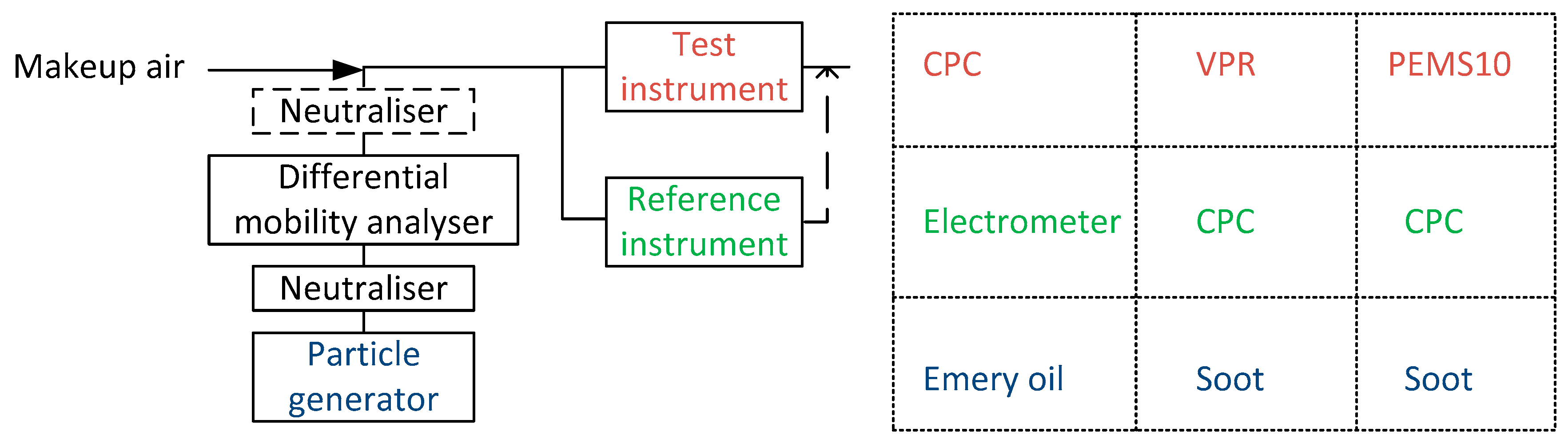

2.2. Laboratory Calibration

2.3. Test Protocol

2.4. Calculations

3. Results

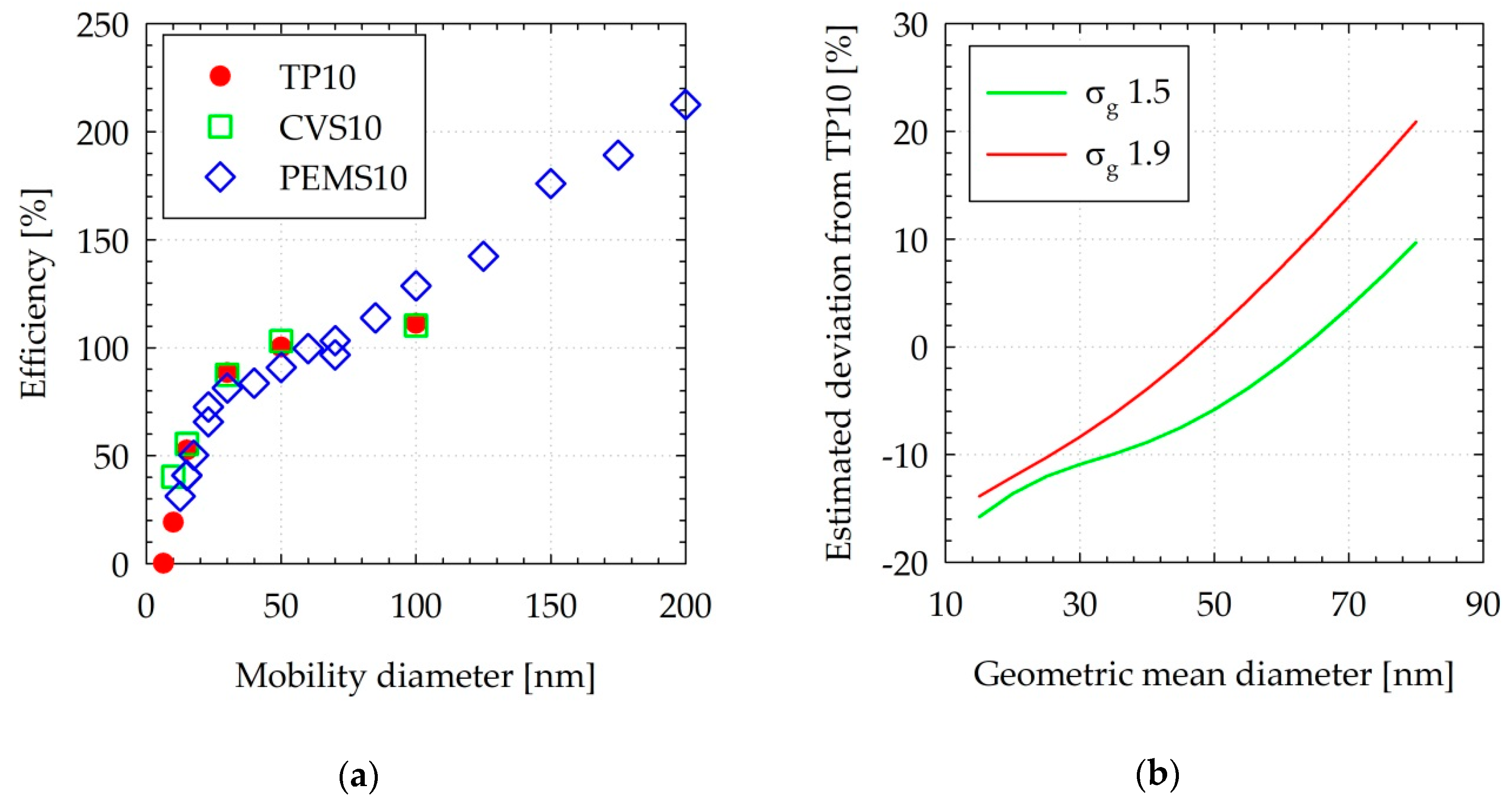

3.1. Efficiency Curves

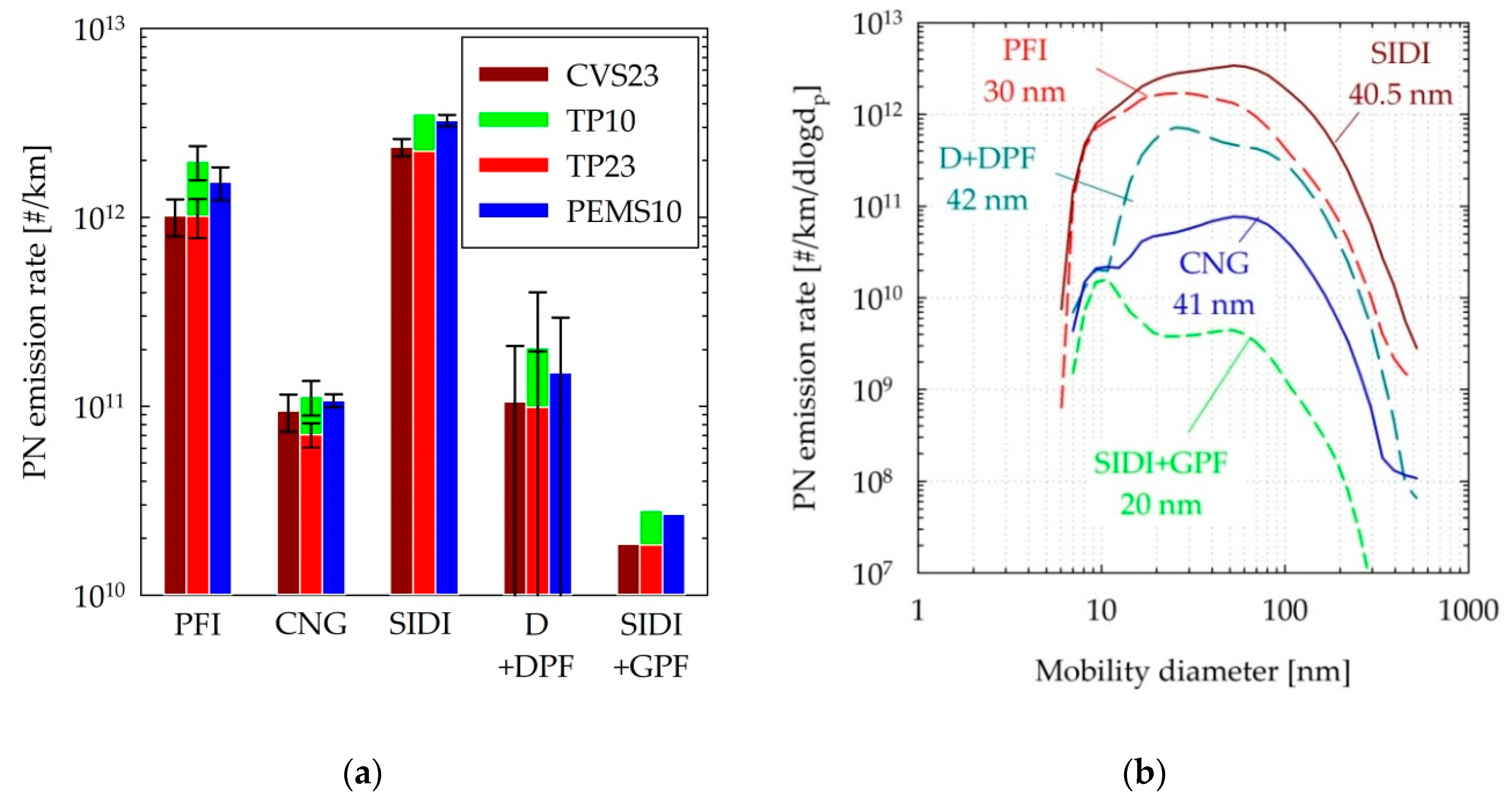

3.2. Emission Levels of the Different Technologies

4. Discussion

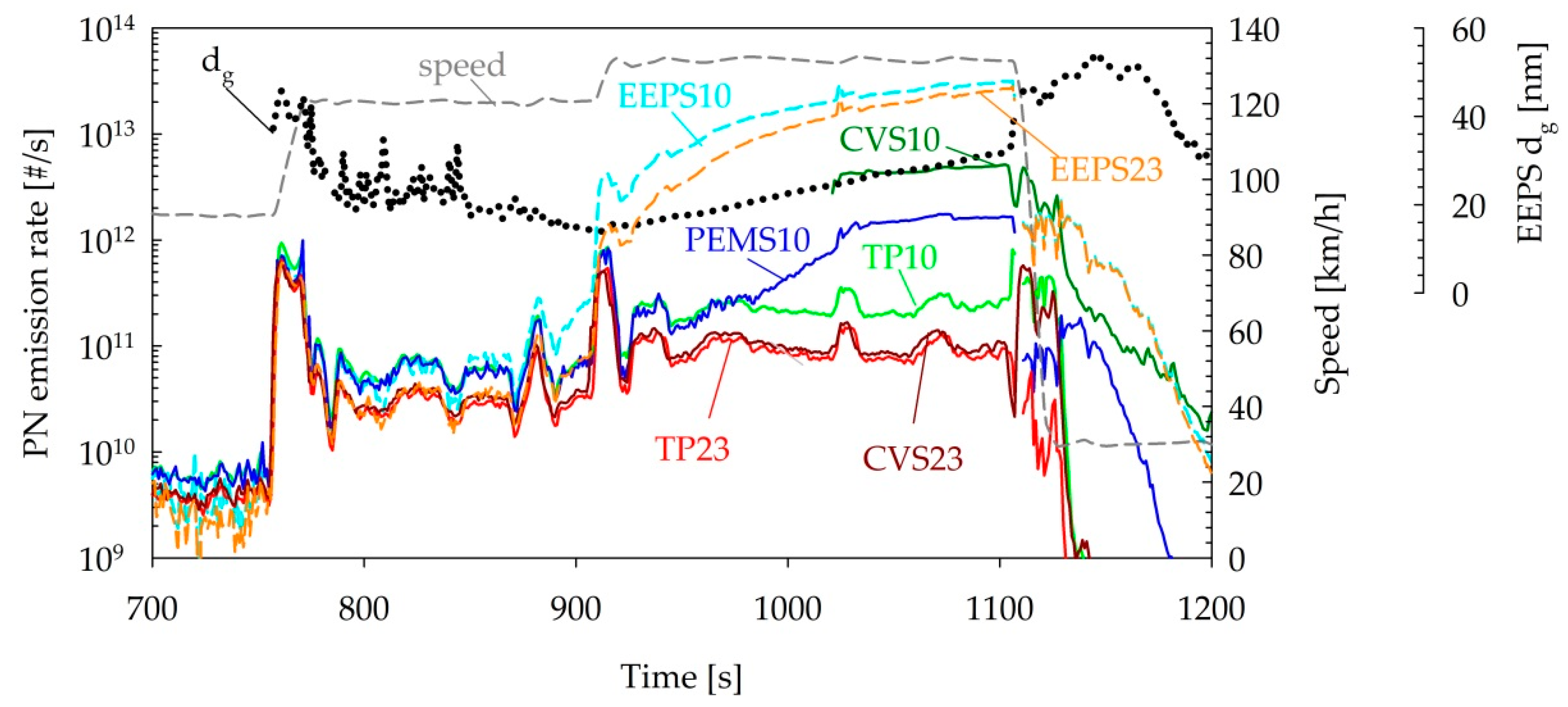

4.1. Upper Measurement Range

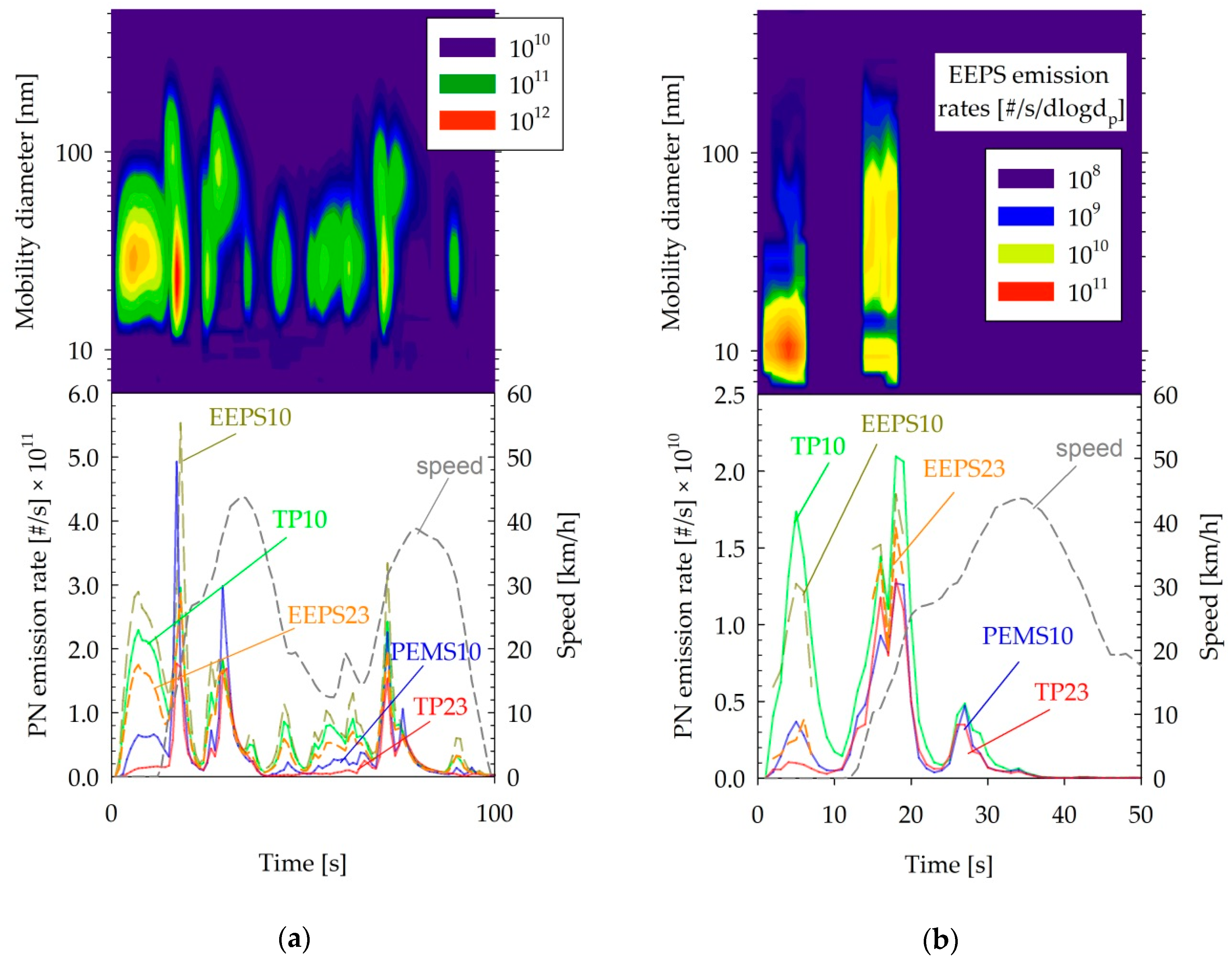

4.2. Nucleation Mode Particles

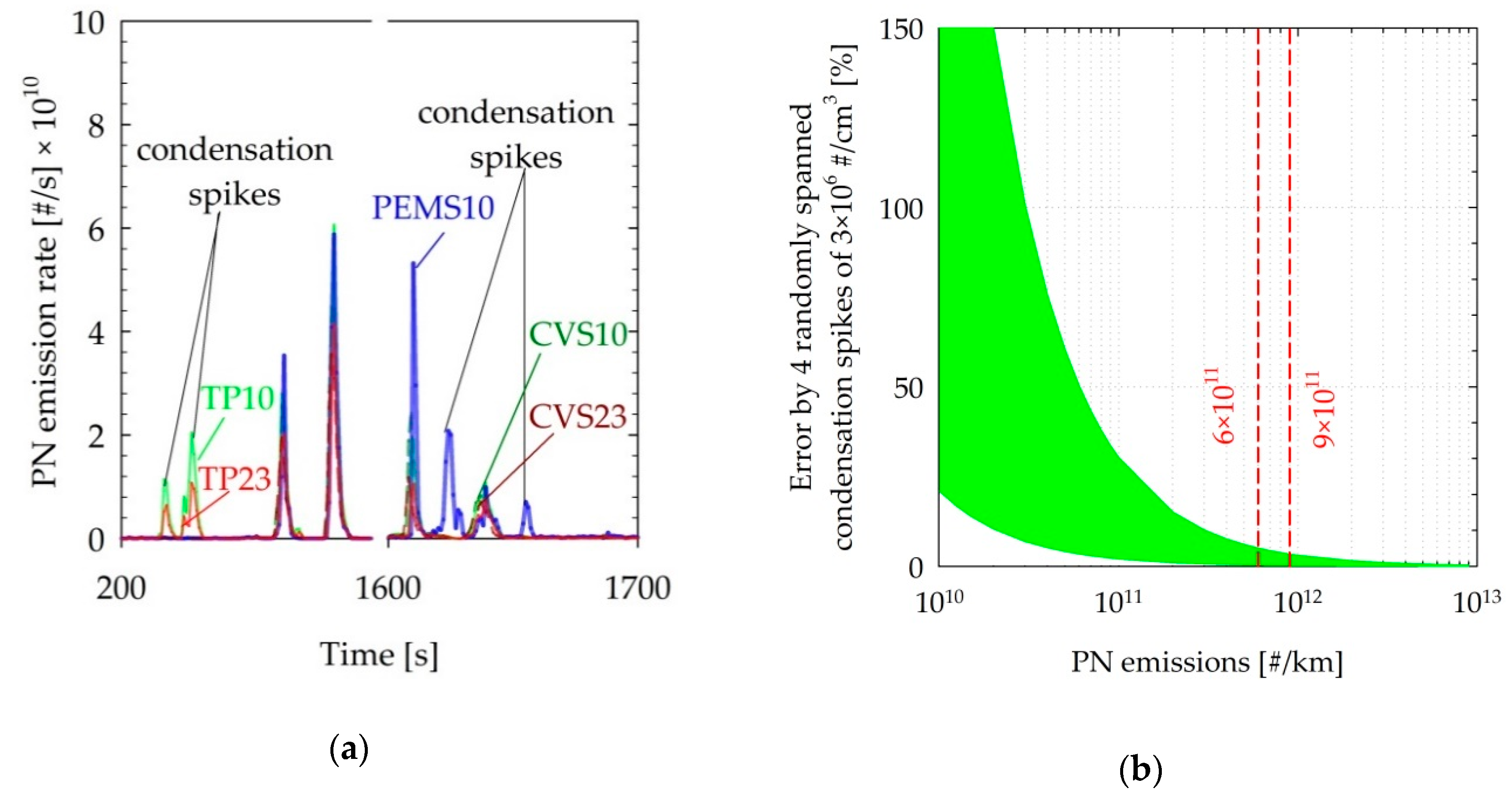

4.3. Condensation Spikes

4.4. Silicone Artefacts

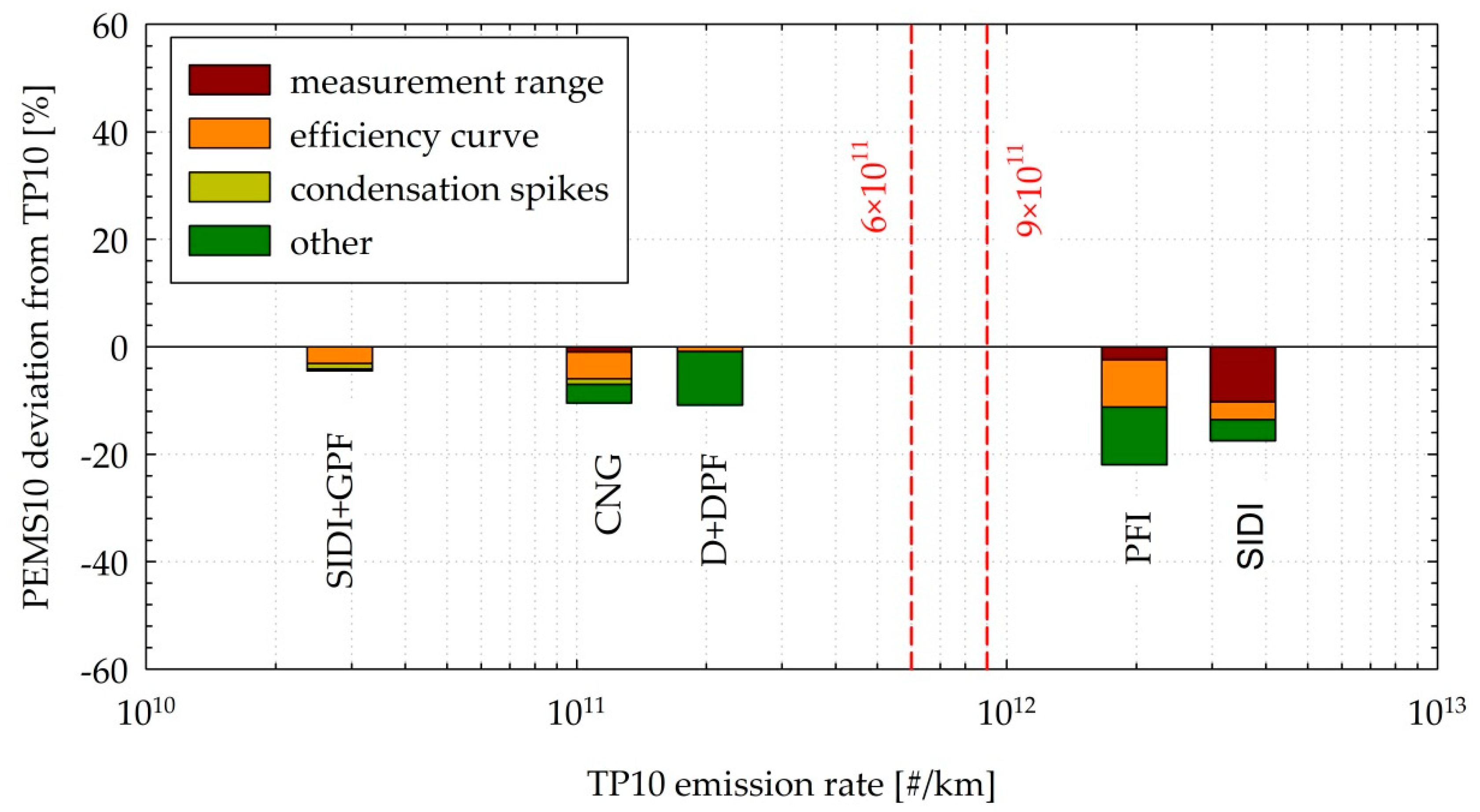

4.5. Overview of Differences

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Disclaimer

Abbreviations

| APC | AVL particle counter |

| CAST | Combustion aerosol standard |

| CNG | Compressed natural gas |

| CPC | Condensation particle counters |

| CS | Catalytic stripper |

| CVS | Constant volume sampling |

| D | Diesel |

| DC | Diffusion chargers |

| DMA | Differential mobility analyzer |

| DPF | Diesel particulate filter |

| EEPS | Engine exhaust particle sizer |

| ET | Evaporation tube |

| GPF | Gasoline particulate filter |

| GRPE | Group of the working party on pollution and energy |

| NEDC | New European driving cycle |

| PCRF | Particle number concentration reduction factor |

| PEMS | Portable emissions measurement system |

| PFI | Port fuel injection |

| PM | Particulate matter |

| PMP | Particle measurement programme |

| PN | Particle number |

| PND | Particle number diluter |

| RDE | Real-driving emissions |

| SIDI | Spark ignition direct injection |

| TP | Tailpipe |

| UNECE | United Nations Economic Commission for Europe |

| VPR | Volatile particle remover |

| WLTC | Worldwide harmonized light vehicles test cycle |

References

- Guerreiro, C.; González Ortiz, A.; de Leeuw, F.; Viana, M.; Colette, A.; European Environment Agency. Air Quality in Europe—2018 Report; Publications Office of the European Union: Luxembourg, 2018.

- Karagulian, F.; Belis, C.A.; Dora, C.F.C.; Prüss-Ustün, A.M.; Bonjour, S.; Adair-Rohani, H.; Amann, M. Contributions to cities’ ambient particulate matter (PM): A systematic review of local source contributions at global level. Atmos. Environ. 2015, 120, 475–483. [Google Scholar] [CrossRef]

- Kumar, P.; Morawska, L.; Birmili, W.; Paasonen, P.; Hu, M.; Kulmala, M.; Harrison, R.M.; Norford, L.; Britter, R. Ultrafine particles in cities. Environ. Int. 2014, 66, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Giechaskiel, B.; Maricq, M.; Ntziachristos, L.; Dardiotis, C.; Wang, X.; Axmann, H.; Bergmann, A.; Schindler, W. Review of motor vehicle particulate emissions sampling and measurement: From smoke and filter mass to particle number. J. Aerosol Sci. 2014, 67, 48–86. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Mamakos, A.; Andersson, J.; Dilara, P.; Martini, G.; Schindler, W.; Bergmann, A. Measurement of automotive nonvolatile particle number emissions within the European legislative framework: A review. Aerosol Sci. Technol. 2012, 46, 719–749. [Google Scholar] [CrossRef]

- Weiss, M.; Bonnel, P.; Hummel, R.; Provenza, A.; Manfredi, U. On-road emissions of light-duty vehicles in Europe. Environ. Sci. Technol. 2011, 45, 8575–8581. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Vlachos, T.; Riccobono, F.; Forni, F.; Colombo, R.; Montigny, F.; Le-Lijour, P.; Carriero, M.; Bonnel, P.; Weiss, M. Implementation of portable emissions measurement systems (PEMS) for the real-driving emissions (RDE) regulation in Europe. JoVE 2016, 118, e54753. [Google Scholar] [CrossRef]

- Riccobono, F.; Giechaskiel, B.; Mendoza Villafuerte, P. Particle Number PEMS Inter-Laboratory Comparison Exercise; Publications Office of the European Union: Luxembourg, 2016.

- Giechaskiel, B.; Schwelberger, M.; Delacroix, C.; Marchetti, M.; Feijen, M.; Prieger, K.; Andersson, S.; Karlsson, H.L. Experimental assessment of solid particle number portable emissions measurement systems (PEMS) for heavy-duty vehicles applications. J. Aerosol Sci. 2018, 123, 161–170. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Clairotte, M.; Valverde-Morales, V.; Bonnel, P.; Kregar, Z.; Franco, V.; Dilara, P. Framework for the assessment of PEMS (portable emissions measurement systems) uncertainty. Environ. Res. 2018, 166, 251–260. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Dilara, P.; Sandbach, E.; Andersson, J. Particle measurement programme (PMP) light-duty inter-laboratory exercise: Comparison of different particle number measurement systems. Meas. Sci. Technol. 2008, 19, 095401. [Google Scholar] [CrossRef]

- Andersson, J.; Giechaskiel, B.; Munoz-Bueno, R.; Sandbach, E.; Dilara, P. Particle Measurement Programme (PMP) Light-Duty Inter-Laboratory Correlation Exercise (ILCE_LD) Final Report; European Communities: Luxembourg, 2007. [Google Scholar]

- Martini, G.; Giechaskiel, B.; Dilara, P. Future European emission standards for vehicles: The importance of the UN-ECE Particle Measurement Programme. Biomarkers 2009, 14, 29–33. [Google Scholar] [CrossRef]

- Wentzel, M.; Gorzawski, H.; Naumann, K.-H.; Saathoff, H.; Weinbruch, S. Transmission electron microscopical and aerosol dynamical characterization of soot aerosols. J. Aerosol Sci. 2003, 34, 1347–1370. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Manfredi, U.; Martini, G. Engine exhaust solid sub-23 nm particles: I. literature survey. SAE Int. J. Fuels Lubr. 2014, 7, 950–964. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Drossinos, Y. Theoretical investigation of volatile removal efficiency of particle number measurement systems. SAE Int. J. Engines 2010, 3, 1140–1151. [Google Scholar] [CrossRef]

- Barone, T.L.; Storey, J.M.E.; Youngquist, A.D.; Szybist, J.P. An analysis of direct-injection spark-ignition (DISI) soot morphology. Atmos. Environ. 2012, 49, 268–274. [Google Scholar] [CrossRef]

- Liati, A.; Schreiber, D.; Dasilva, Y.A.R.; Eggenschwiler, P.D. Ultrafine particle emissions from modern gasoline and diesel vehicles: An electron microscopic perspective. Environ. Pollut. 2018, 239, 661–669. [Google Scholar] [CrossRef] [PubMed]

- Gidney, J.T.; Twigg, M.V.; Kittelson, D.B. Effect of organometallic fuel additives on nanoparticle emissions from a gasoline passenger car. Environ. Sci. Technol. 2010, 44, 2562–2569. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Joshi, A.; Ntziachristos, L.; Dilara, P. European regulatory framework and particulate matter emissions of gasoline light-duty vehicles: A review. Catalysts 2019, 9, 586. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Zardini, A.; Martini, G. Particle emission measurements from L-category vehicles. SAE Int. J. Engines 2015, 8, 2322–2337. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Zardini, A.A.; Lähde, T.; Perujo, A.; Kontses, A.; Ntziachristos, L. Particulate emissions of Euro 4 motorcycles and sampling considerations. Atmosphere 2019, 10, 421. [Google Scholar] [CrossRef]

- Giechaskiel, B. Solid particle number emission factors of Euro VI heavy-duty vehicles on the road and in the laboratory. Int. J. Environ. Res. Public Health 2018, 15, 304. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Lähde, T.; Schwelberger, M.; Kleinbach, T.; Roske, H.; Teti, E.; van den Bos, T.; Neils, P.; Delacroix, C.; Jakobsson, T.; et al. Particle number measurements directly from the tailpipe for type approval of heavy-duty engines. Appl. Sci. 2019, 9, 4418. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Lähde, T.; Drossinos, Y. Regulating particle number measurements from the tailpipe of light-duty vehicles: The next step? Environ. Res. 2019, 172, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Martini, G. PMP IWG Progress Report; Geneva, Switzerland, 8–11 January 2019. Available online: https://wiki.unece.org/display/trans/PMP+49th+Session (accessed on 13 December 2019).

- Giechaskiel, B.; Riccobono, F.; Bonnel, P. Feasibility Study on the Extension of the Real-Driving Emissions (RDE) Procedure to Particle Number (PN): Chassis Dynamometer Evaluation of Portable Emission Measurement Systems (PEMS) to Measure Particle Number (PN) Concentration: Phase II; Publications Office of the European Union: Luxembourg, 2015.

- Mukherjee, A.; Stanton, L.; Graham, A.; Roberts, P. Assessing the utility of low-cost particulate matter sensors over a 12-week period in the Cuyama valley of California. Sensors 2017, 17, 1805. [Google Scholar] [CrossRef] [PubMed]

- Kuula, J.; Mäkelä, T.; Hillamo, R.; Timonen, H. Response characterization of an inexpensive aerosol sensor. Sensors 2017, 17, 2915. [Google Scholar] [CrossRef]

- Borghi, F.; Spinazzè, A.; Rovelli, S.; Campagnolo, D.; Buono, L.D.; Cattaneo, A.; Cavallo, D. Miniaturized monitors for assessment of exposure to air pollutants: A review. Int. J. Environ. Res. Public Health 2017, 14, 909. [Google Scholar] [CrossRef]

- Borghi, F.; Spinazzè, A.; Campagnolo, D.; Rovelli, S.; Cattaneo, A.; Cavallo, D.M. Precision and accuracy of a direct-reading miniaturized monitor in PM2.5 exposure assessment. Sensors 2018, 18, 3089. [Google Scholar] [CrossRef]

- Thomas, G.; Sousan, S.; Tatum, M.; Liu, X.; Zuidema, C.; Fitzpatrick, M.; Koehler, K.; Peters, T. Low-cost, distributed environmental monitors for factory worker health. Sensors 2018, 18, 1411. [Google Scholar] [CrossRef]

- Asbach, C.; Alexander, C.; Clavaguera, S.; Dahmann, D.; Dozol, H.; Faure, B.; Fierz, M.; Fontana, L.; Iavicoli, I.; Kaminski, H.; et al. Review of measurement techniques and methods for assessing personal exposure to airborne nanomaterials in workplaces. Sci. Total. Environ. 2017, 603–604, 793–806. [Google Scholar] [CrossRef]

- Todea, A.M.; Beckmann, S.; Kaminski, H.; Bard, D.; Bau, S.; Clavaguera, S.; Dahmann, D.; Dozol, H.; Dziurowitz, N.; Elihn, K.; et al. Inter-comparison of personal monitors for nanoparticles exposure at workplaces and in the environment. Sci. Total Environ. 2017, 605–606, 929–945. [Google Scholar] [CrossRef]

- Genikomsakis, K.; Galatoulas, N.-F.; Dallas, P.; Candanedo Ibarra, L.; Margaritis, D.; Ioakimidis, C. Development and on-field testing of low-cost portable system for monitoring PM2.5 concentrations. Sensors 2018, 18, 1056. [Google Scholar] [CrossRef]

- Feulner, M.; Hagen, G.; Hottner, K.; Redel, S.; Müller, A.; Moos, R. Comparative study of different methods for soot sensing and filter monitoring in diesel exhausts. Sensors 2017, 17, 400. [Google Scholar] [CrossRef] [PubMed]

- Reynaud, A.; Leblanc, M.; Zinola, S.; Breuil, P.; Viricelle, J.-P. Responses of a resistive soot sensor to different mono-disperse soot aerosols. Sensors 2019, 19, 705. [Google Scholar] [CrossRef] [PubMed]

- Kontses, D.; Geivanidis, S.; Fragkiadoulakis, P.; Samaras, Z. Uncertainties in model-based diesel particulate filter diagnostics using a soot sensor. Sensors 2019, 19, 3141. [Google Scholar] [CrossRef] [PubMed]

- Schriefl, M.A.; Bergmann, A.; Fierz, M. Design principles for sensing particle number concentration and mean particle size with unipolar diffusion charging. IEEE Sens. J. 2019, 19, 1392–1399. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Bonnel, P.; Perujo, A.; Dilara, P. Solid particle number (SPN) portable emissions measurement systems (PEMS) in the European legislation: A review. Int. J. Environ. Res. Public Health 2019, 16, 4819. [Google Scholar] [CrossRef]

- Fierz, M.; Houle, C.; Steigmeier, P.; Burtscher, H. Design, calibration, and field performance of a miniature diffusion size classifier. Aerosol Sci. Technol. 2011, 45, 1–10. [Google Scholar] [CrossRef]

- Amanatidis, S.; Maricq, M.M.; Ntziachristos, L.; Samaras, Z. Application of the dual Pegasor Particle Sensor to real-time measurement of motor vehicle exhaust PM. J. Aerosol Sci. 2017, 103, 93–104. [Google Scholar] [CrossRef]

- Fierz, M.; Meier, D.; Steigmeier, P.; Burtscher, H. Aerosol measurement by induced currents. Aerosol Sci. Technol. 2014, 48, 350–357. [Google Scholar] [CrossRef]

- Rüggeberg, T.; Burtscher, H.; Melas, A.; Deloglou, D.; Papaioannou, E.; Konstandopoulos, A. Measuring Combustion Emissions down to 10 nm with DC-Sensors. In Proceedings of the 23rd ETH Conference on Combustion Generated Nanoparticles, Zurich, Switzerland, 17–20 June 2019. [Google Scholar]

- Bielaczyc, P.; Klimkiewicz, D.; Woodburn, J.; Szczotka, A. Exhaust emission testing methods—BOSMAL’s legislative and development emission testing laboratories. Combust. Engines 2019, 178, 88–98. [Google Scholar]

- Giechaskiel, B.; Cresnoverh, M.; Jörgl, H.; Bergmann, A. Calibration and accuracy of a particle number measurement system. Meas. Sci. Technol. 2010, 21, 045102. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Wang, X.; Horn, H.-G.; Spielvogel, J.; Gerhart, C.; Southgate, J.; Jing, L.; Kasper, M.; Drossinos, Y.; Krasenbrink, A. Calibration of condensation particle counters for legislated vehicle number emission measurements. Aerosol Sci. Technol. 2009, 43, 1164–1173. [Google Scholar] [CrossRef]

- Takegawa, N.; Sakurai, H. Laboratory evaluation of a TSI condensation particle counter (model 3771) under airborne measurement conditions. Aerosol Sci. Technol. 2011, 45, 272–283. [Google Scholar] [CrossRef]

- Amanatidis, S.; Ntziachristos, L.; Giechaskiel, B.; Katsaounis, D.; Samaras, Z.; Bergmann, A. Evaluation of an oxidation catalyst (“catalytic stripper”) in eliminating volatile material from combustion aerosol. J. Aerosol Sci. 2013, 57, 144–155. [Google Scholar] [CrossRef]

- Johnson, T.; Caldow, R.; Pöcher, A.; Mirme, A.; Kittelson, D. A New Electrical Mobility Particle Sizer Spectrometer for Engine Exhaust Particle Measurements; SAE Tech. Pap. 2004-01-1341; SAE: Warrendale, PA, USA, 2004. [Google Scholar]

- Yang, Y.; Yu, T.; Zhang, J.; Wang, J.; Wang, W.; Gui, H.; Liu, J. On the performance of an aerosol electrometer with enhanced detection limit. Sensors 2018, 18, 3889. [Google Scholar] [CrossRef] [PubMed]

- Schwelberger, M.; Mamakos, A.; Fierz, M.; Giechaskiel, B. Experimental assessment of an electrofilter and a tandem positive-negative corona charger for the measurement of charged nanoparticles formed in selective catalytic reduction systems. Appl. Sci. 2019, 9, 1051. [Google Scholar] [CrossRef]

- Helsper, C.; Mölter, W.; Löffler, F.; Wadenpohl, C.; Kaufmann, S.; Wenninger, G. Investigations of a new aerosol generator for the production of carbon aggregate particles. Atmos. Environ. Part A. Gen. Top. 1993, 27, 1271–1275. [Google Scholar] [CrossRef]

- Mamakos, A.; Khalek, I.; Giannelli, R.; Spears, M. Characterization of combustion aerosol produced by a mini-CAST and treated in a catalytic stripper. Aerosol Sci. Technol. 2013, 47, 927–936. [Google Scholar] [CrossRef][Green Version]

- Moore, R.H.; Ziemba, L.D.; Dutcher, D.; Beyersdorf, A.J.; Chan, K.; Crumeyrolle, S.; Raymond, T.M.; Thornhill, K.L.; Winstead, E.L.; Anderson, B.E. Mapping the operation of the miniature combustion aerosol standard (mini-CAST) soot generator. Aerosol Sci. Technol. 2014, 48, 467–479. [Google Scholar] [CrossRef]

- Wang, X.; Grose, M.A.; Caldow, R.; Osmondson, B.L.; Swanson, J.J.; Chow, J.C.; Watson, J.G.; Kittelson, D.B.; Li, Y.; Xue, J.; et al. Improvement of engine exhaust particle sizer (EEPS) size distribution measurement—ii. engine exhaust particles. J. Aerosol Sci. 2016, 92, 83–94. [Google Scholar] [CrossRef]

- Harris, S.J.; Maricq, M.M. Signature size distributions for diesel and gasoline engine exhaust particulate matter. J. Aerosol Sci. 2001, 32, 749–764. [Google Scholar] [CrossRef]

- Ntziachristos, L.; Amanatidis, S.; Samaras, Z.; Giechaskiel, B.; Bergmann, A. Use of a catalytic stripper as an alternative to the original PMP measurement protocol. SAE Int. J. Fuels Lubr. 2013, 6, 532–541. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Wang, X.; Gilliland, D.; Drossinos, Y. The effect of particle chemical composition on the activation probability in n-butanol condensation particle counters. J. Aerosol Sci. 2011, 42, 20–37. [Google Scholar] [CrossRef]

- Mamakos, A.; Giechaskiel, B.; Drossinos, Y. Experimental and theoretical investigations of the effect of the calibration aerosol material on the counting efficiencies of TSI 3790 condensation particle counters. Aerosol Sci. Technol. 2013, 47, 11–21. [Google Scholar] [CrossRef]

- Dwyer, H.; Ayala, A.; Zhang, S.; Collins, J.; Huai, T.; Herner, J.; Chau, W. Emissions from a diesel car during regeneration of an active diesel particulate filter. J. Aerosol Sci. 2010, 41, 541–552. [Google Scholar] [CrossRef]

- Yamada, H.; Inomata, S.; Tanimoto, H. Mechanisms of increased particle and VOC emissions during DPF active regeneration and practical emissions considering regeneration. Environ. Sci. Technol. 2017, 51, 2914–2923. [Google Scholar] [CrossRef]

- Giechaskiel, B. Differences between tailpipe and dilution tunnel sub-23 nm nonvolatile (solid) particle number measurements. Aerosol Sci. Technol. 2019, 53, 1012–1022. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Riccobono, F.; Mendoza-Villafuerte, P.; Grigoratos, T. Particle Number (PN)—Portable Emissions Measurement Systems (PEMS) Heavy Duty Vehicles Evaluation Phase at the Joint Research Centre (JRC); Publications Office of the European Union: Luxembourg, 2016.

- Giechaskiel, B. Effect of sampling conditions on the sub-23 nm nonvolatile particle emissions measurements of a moped. Appl. Sci. 2019, 9, 3112. [Google Scholar] [CrossRef]

| Vehicle | Cycle | TP10 | TP23 | PEMS10 | EEPS | CVS23 | CVS10 |

|---|---|---|---|---|---|---|---|

| PFI | WLTC cold | Y | Y | Y | Y | Y | Y |

| PFI | WLTC hot | Y | Y | Y | Y | Y | Y |

| PFI | WLTC hot | Y | Y | Y | Y | Y | Y |

| PFI | Constant speeds | Y | Y | Y | Y | Y | Y |

| CNG | WLTC cold | Y | Y | Y | Y | Y | Y |

| CNG | WLTC hot | Y | Y | Y | Y | Y | Y |

| SIDI | WLTC cold | Y | Y | Y | Y | Y | N |

| SIDI | WLTC hot | Y | Y | Y | Y | Y | N |

| SIDI | Constant speeds | Y | Y | Y | Y | Y | Y |

| D + DPF | WLTC cold | Y | Y | Y | N | Y | N |

| D + DPF | DPF Regeneration 1 | Y | Y | Y | N | Y | N |

| D + DPF | WLTC cold | Y | Y | Y | Y | Y | N |

| SIDI + GPF | WLTC cold | Y | Y | Y | Y | Y | N |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giechaskiel, B.; Mamakos, A.; Woodburn, J.; Szczotka, A.; Bielaczyc, P. Evaluation of a 10 nm Particle Number Portable Emissions Measurement System (PEMS). Sensors 2019, 19, 5531. https://doi.org/10.3390/s19245531

Giechaskiel B, Mamakos A, Woodburn J, Szczotka A, Bielaczyc P. Evaluation of a 10 nm Particle Number Portable Emissions Measurement System (PEMS). Sensors. 2019; 19(24):5531. https://doi.org/10.3390/s19245531

Chicago/Turabian StyleGiechaskiel, Barouch, Athanasios Mamakos, Joseph Woodburn, Andrzej Szczotka, and Piotr Bielaczyc. 2019. "Evaluation of a 10 nm Particle Number Portable Emissions Measurement System (PEMS)" Sensors 19, no. 24: 5531. https://doi.org/10.3390/s19245531

APA StyleGiechaskiel, B., Mamakos, A., Woodburn, J., Szczotka, A., & Bielaczyc, P. (2019). Evaluation of a 10 nm Particle Number Portable Emissions Measurement System (PEMS). Sensors, 19(24), 5531. https://doi.org/10.3390/s19245531