Calibration Method of Orthogonally Splitting Imaging Pose Sensor Based on KDFcmPUM

Abstract

:1. Introduction

2. Materials and Methods

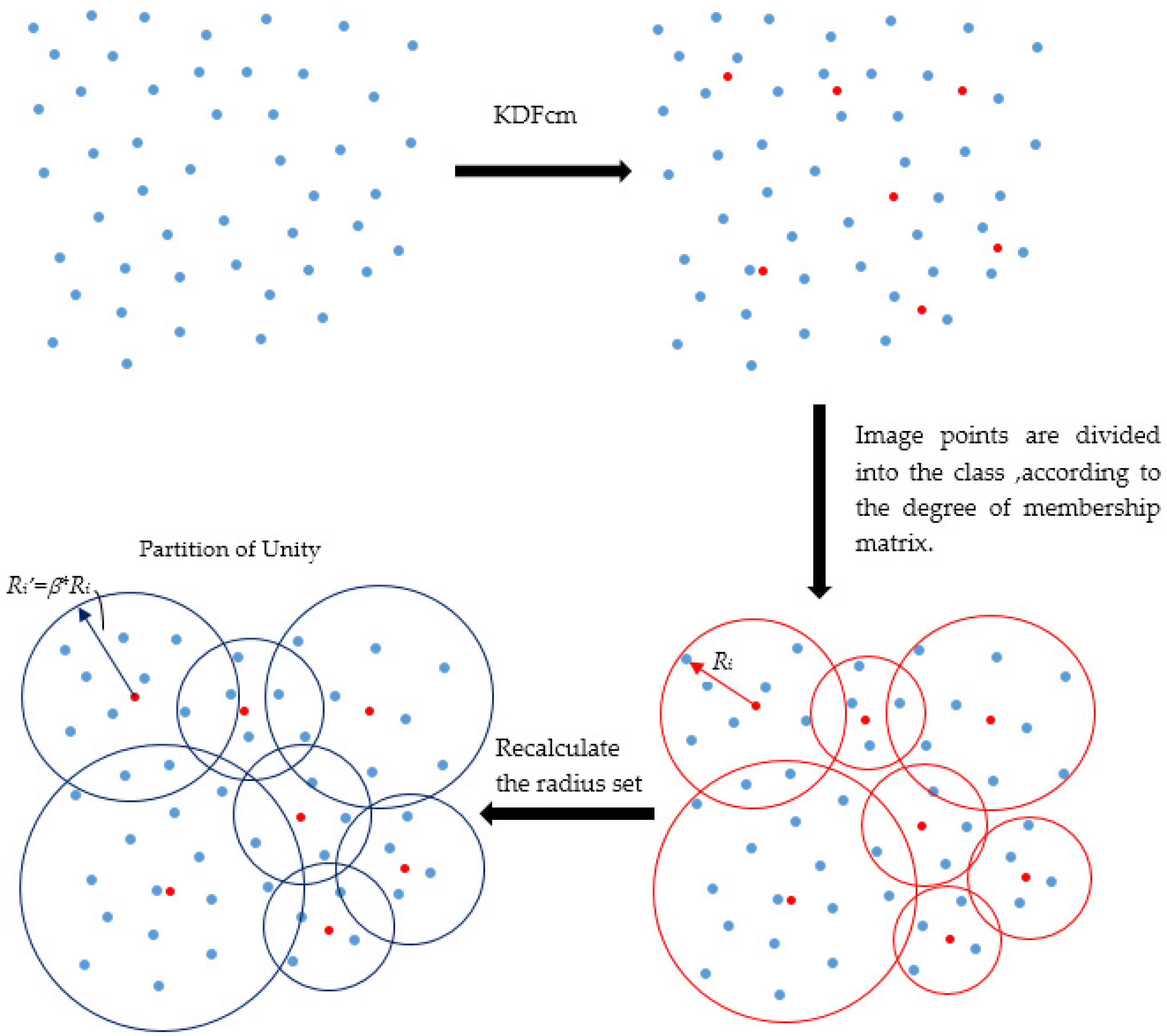

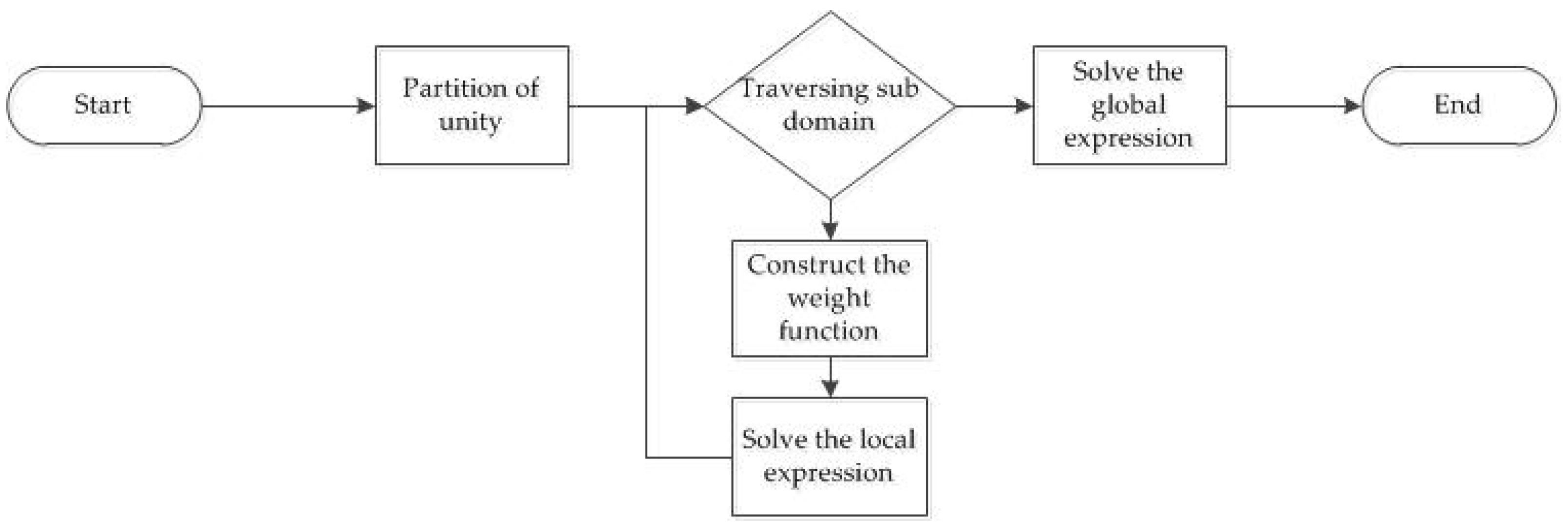

2.1. Partition of Unity Method Based on KDFcm (KDFcmPUM)

2.1.1. Fuzzy C-Means Clustering Based on Kernel Distance (KDFcm)

2.1.2. Partition of Unity

2.2. Mathematical Model

- Stage 1: Partition of unity based on KDFcm.

- Stage 2: Construction of the weight function.

- Stage 3: Solvingthe local expression with interpolation.

- Stage 4: Construction of the global expression.

2.2.1. Construction of Weight Function

2.2.2. Local Expression

2.2.3. Global Expression

3. Results

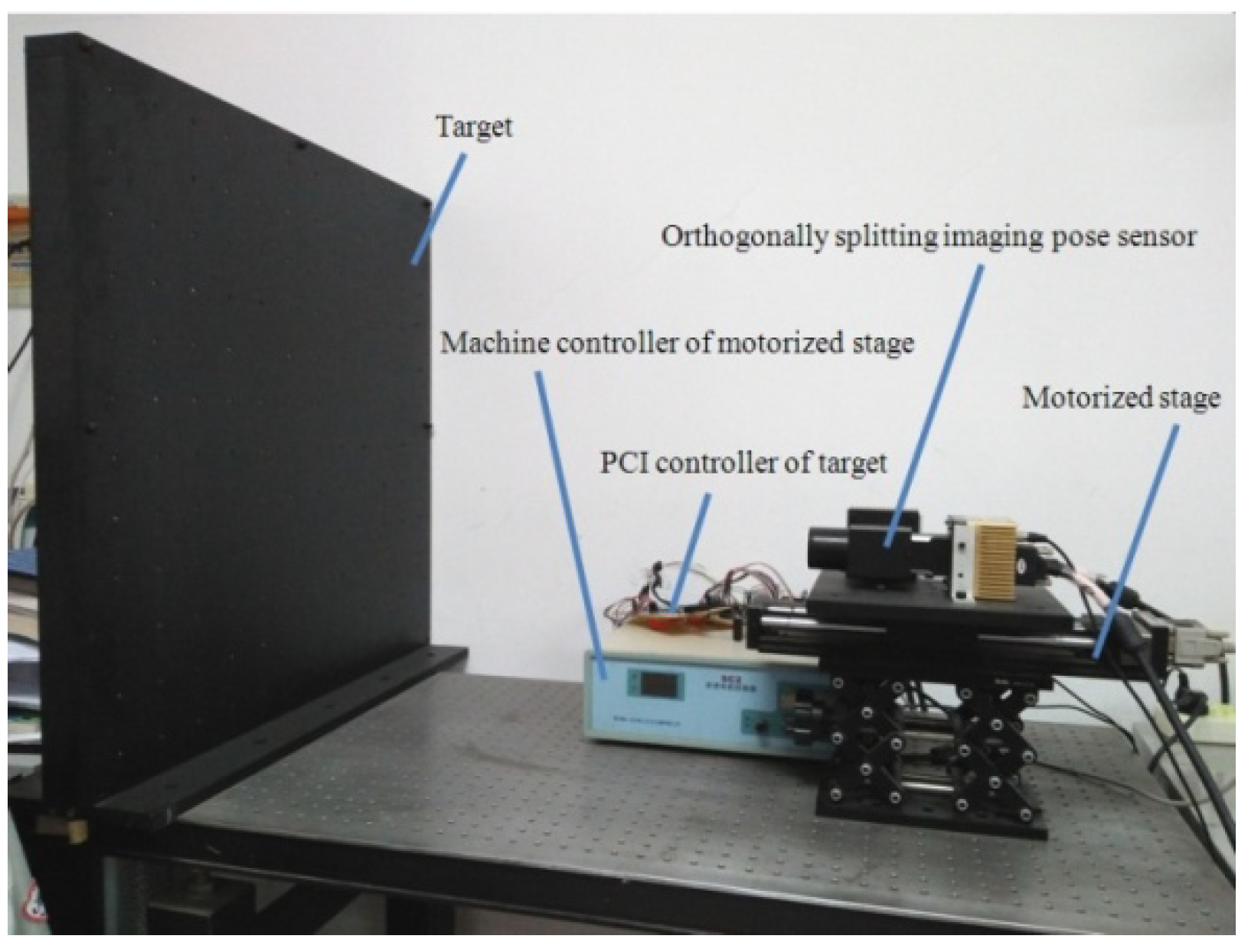

3.1. Experimental Apparatus

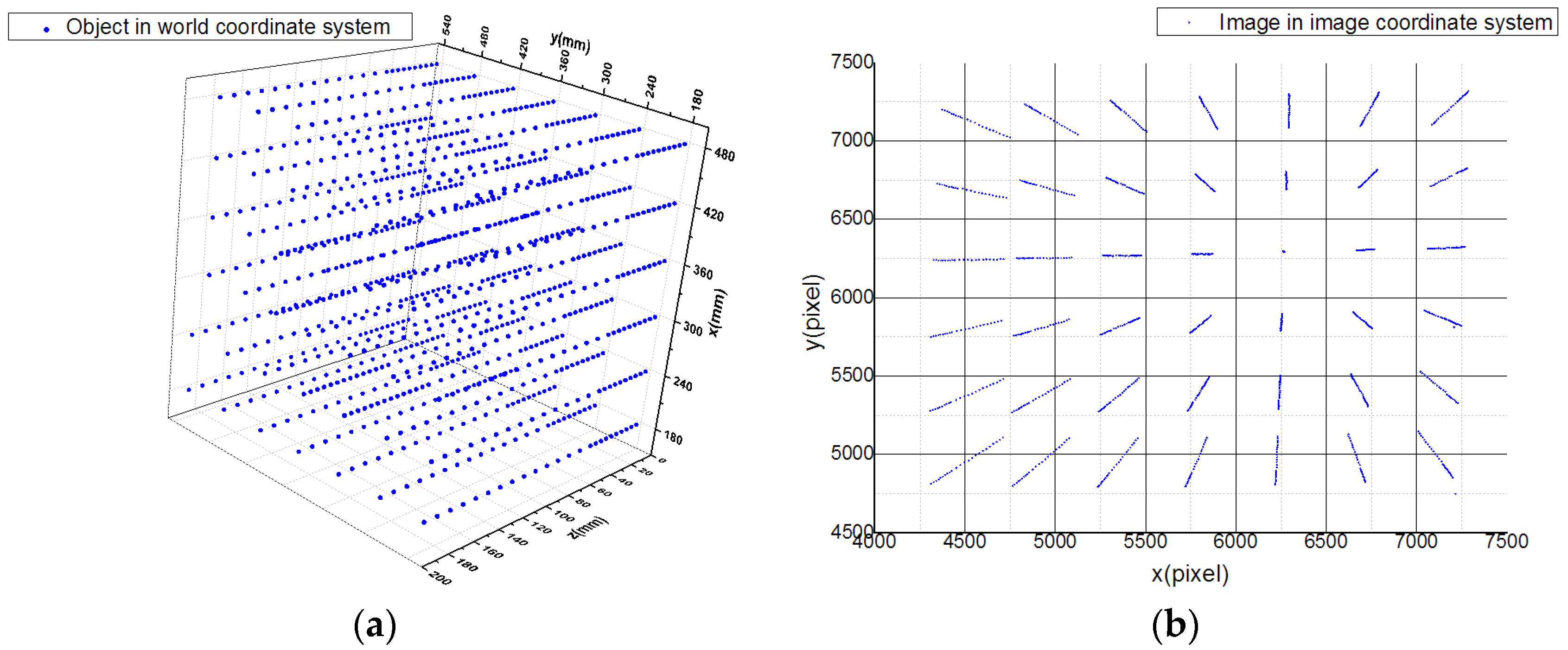

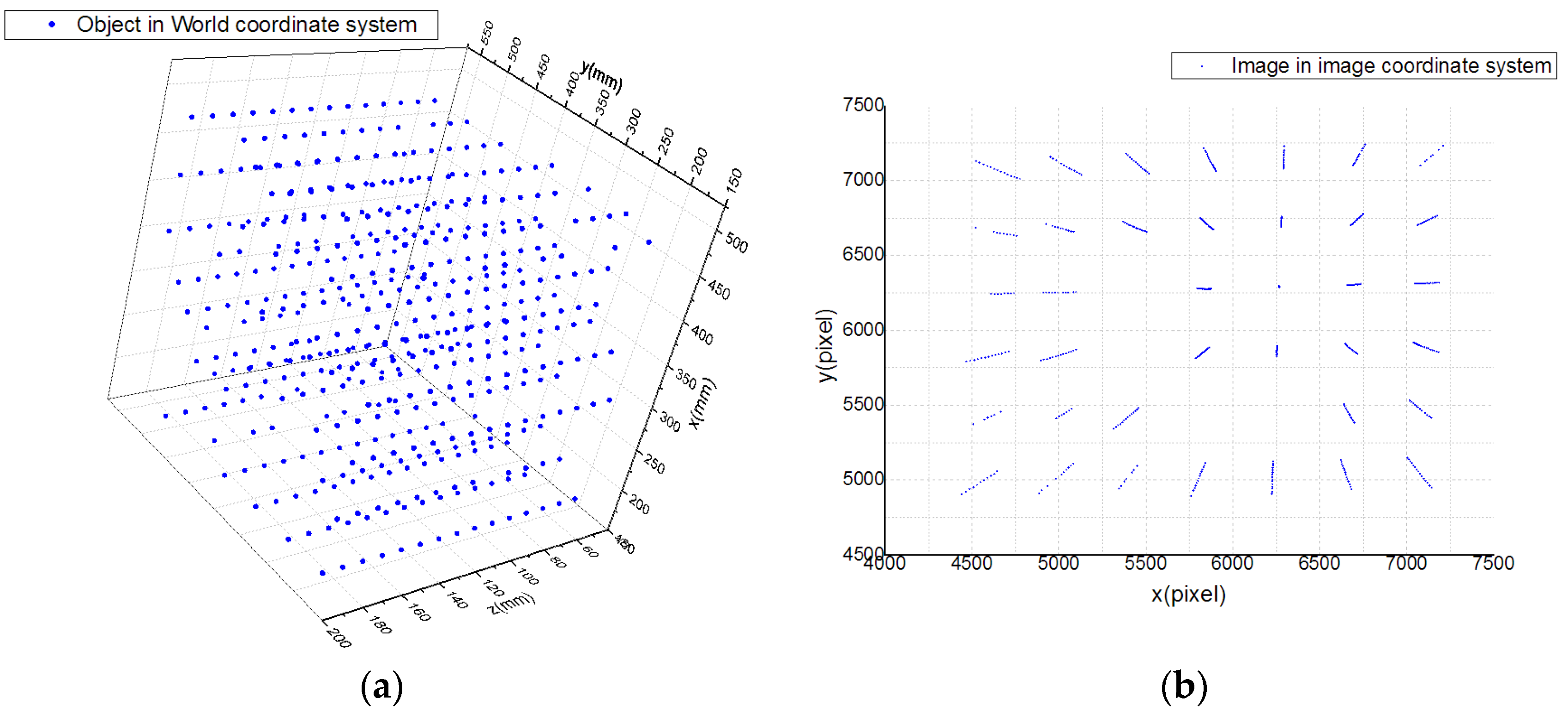

3.2. Experiment Data

3.2.1. Calibration Data Set

3.2.2. Test Data Set

3.3. Calibration and Test

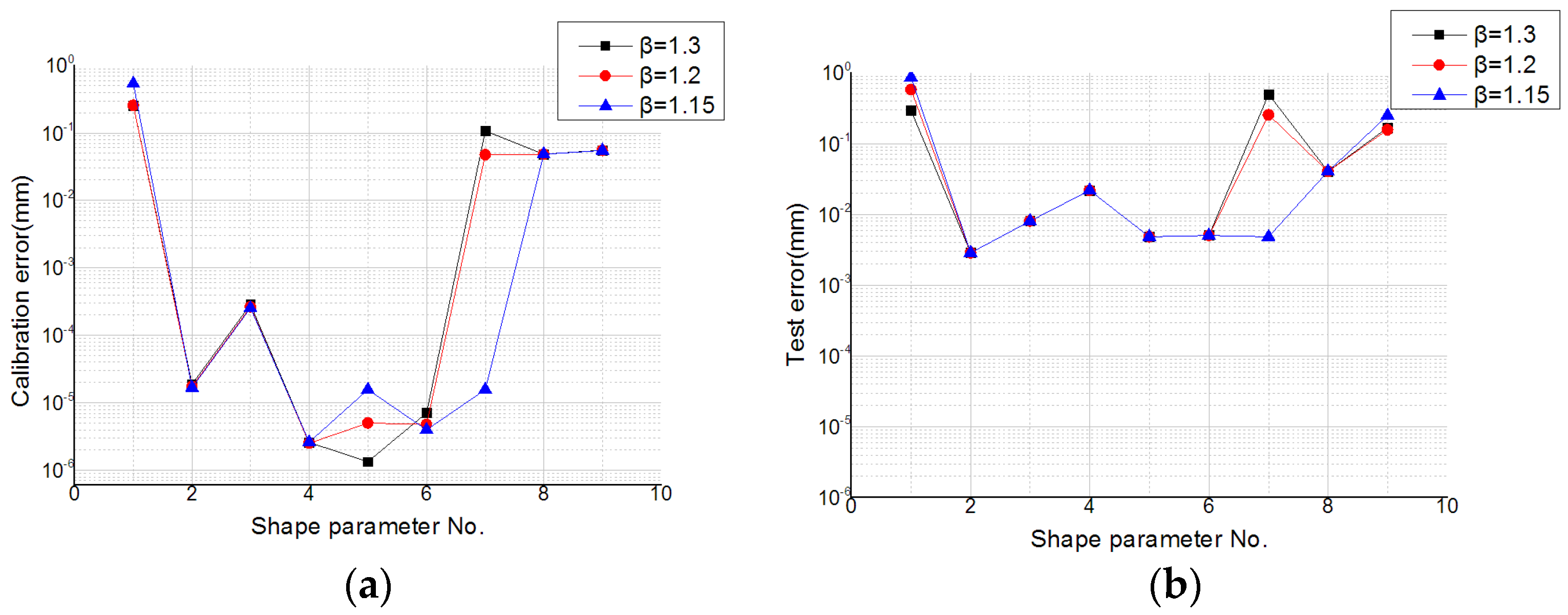

3.3.1. KDFcmPUM

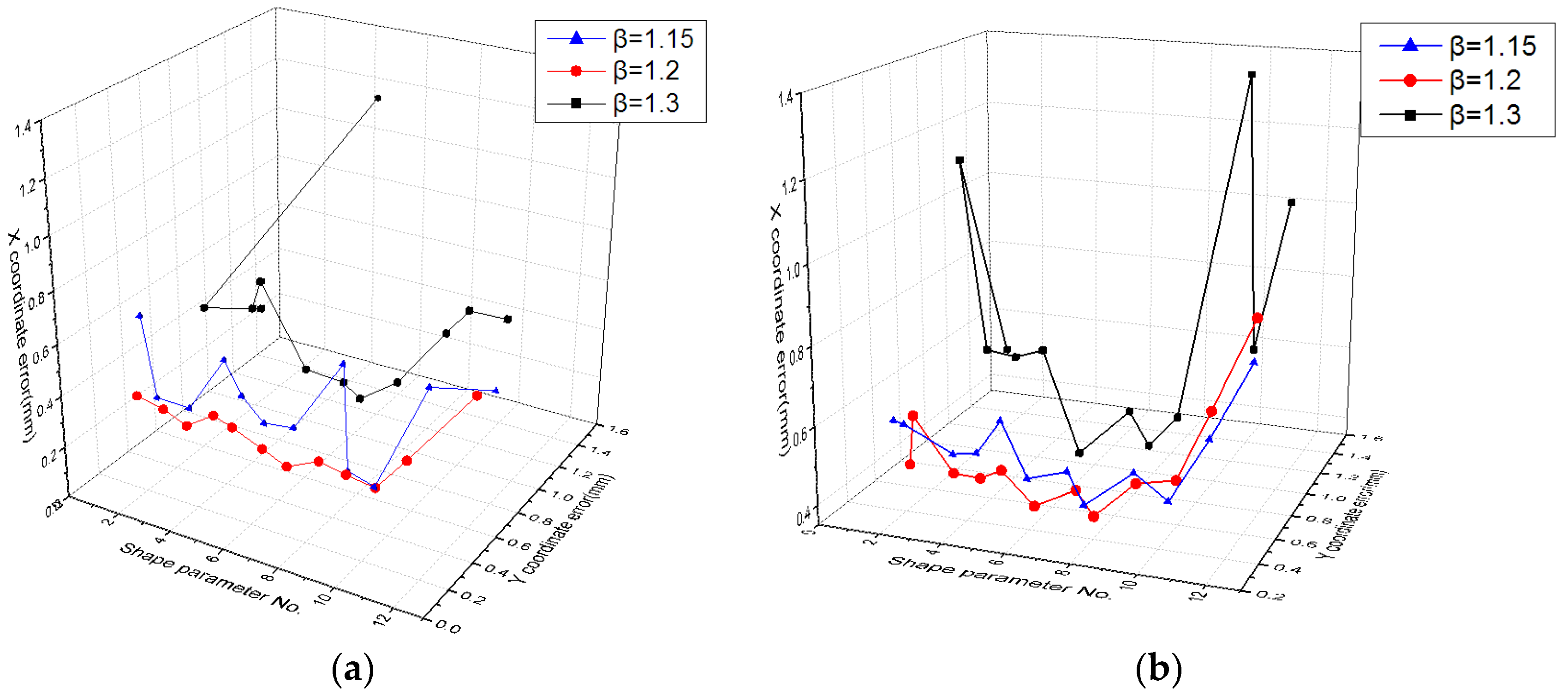

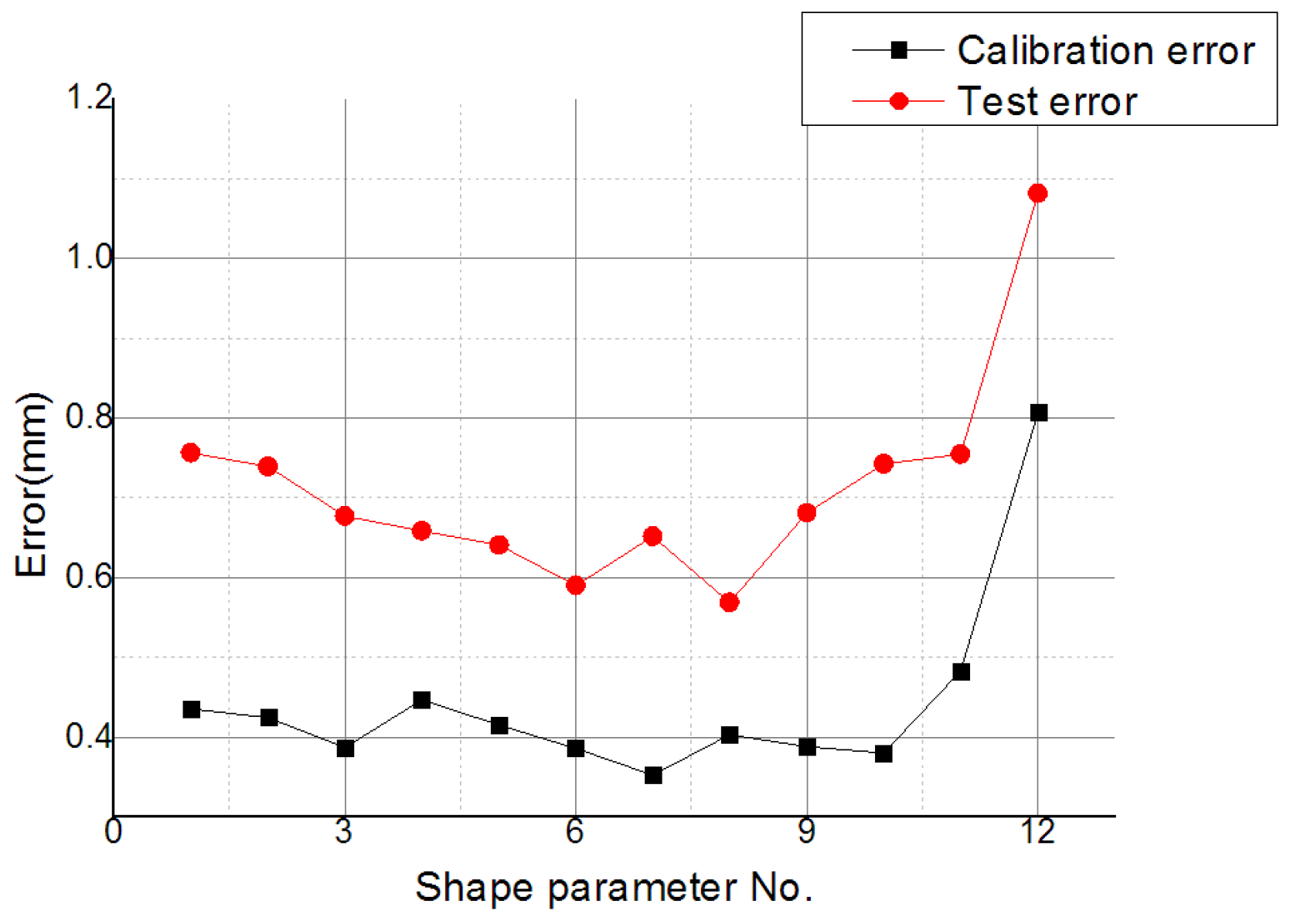

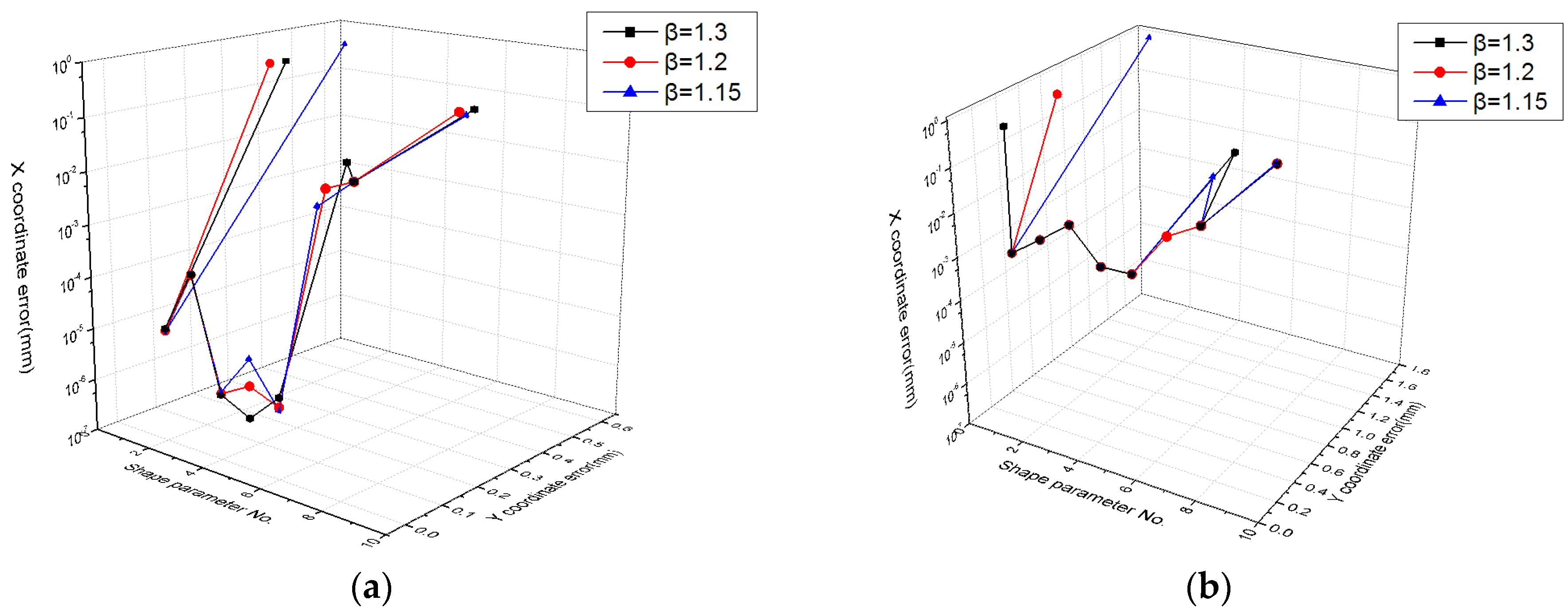

3.3.2. Parameter Experiment

3.4. Comparative Experiment

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, Q.; Sun, C.K.; Wang, P.; Li, W.Q.; Liu, X.T. Distortion correction for the orthogonally-splitting-imaging pose Sens. Opt. Laser Technol. 2015, 69, 160–171. [Google Scholar] [CrossRef]

- Guo, X.; Tang, J.; Li, J.; Wang, C.; Shen, C.; Liu, J. Determine turntable coordinate system considering its non-orthogonality. Rev. Sci. Instrum. 2019, 90, 033704. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Tang, J.; Li, J.; Shen, C.; Liu, J. Attitude measurement based on imaging ray tracking model and orthographic projection with iteration algorithm. ISA Trans. 2019. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.; Sun, C.; Wang, P. Calibration Method of Orthogonally Splitting Imaging Pose Sensor Based on General Imaging Model. Appl. Sci. 2018, 8, 1399. [Google Scholar] [CrossRef]

- Shen, C.; Zhang, Y.; Tang, J.; Cao, H.; Liu, J. Dual-optimization for a MEMS-INS/GPS System during GPS Outages Based on the Cubature Kalman Filter and Neural Networks. Mech. Syst. Signal Process. 2019, 133, 106222. [Google Scholar] [CrossRef]

- Shen, C.; Song, R.; Li, J.; Zhang, X.; Tang, J.; Shi, Y.; Liu, J.; Cao, H. Temperature drift modeling of MEMS gyroscope based on genetic-Elman neural network. Mech. Syst. Signal Process. 2016, 72, 897–905. [Google Scholar]

- Wang, J.G.; Liu, G.R. A point interpolation meshless method based on radial basis functions. Int. J. Numer. Methods Eng. 2002, 54, 1623–1648. [Google Scholar] [CrossRef]

- Cheng, R.; Sun, F.; Wang, J. Meshless analysis of two-dimensional two-sided space-fractional wave equation based on improved moving least-squares approximation. Int. J. Comput. Math. 2017, 95, 540–560. [Google Scholar] [CrossRef]

- Liu, W.K.; Jun, S.; Zhang, Y.F. Reproducing kernel particle methods. Int. J. Numer. Methods Fluid 1995, 20, 1081–1106. [Google Scholar] [CrossRef]

- Frank, R. Scattered Data Interpolation: Tests of Some Methods. Math. Comput. 1979, 48, 181–200. [Google Scholar]

- Rendall, T.C.S.; Allen, C.B. Efficient mesh motion using radial basis functions with data reduction algorithms. J. Comput. Phys. 2009, 228, 6231–6249. [Google Scholar] [CrossRef]

- Rendal, T.C.S.; Allen, C.B. Reduced Surface Point Selection Options for Efficient Mesh Deformation Using Radial Basis Functions. J. Comput. Phys. 2010, 229, 2810–2820. [Google Scholar] [CrossRef]

- Michler, A.K. Aircraft control surface deflection using RBF-based mesh deformation. Int. J. Numer. Methods Eng. 2011, 88, 986–1007. [Google Scholar] [CrossRef]

- Sheng, C.; Allen, C.B. Efficient Mesh Deformation Using Radial Basis Functions on Unstructured Meshes. AIAA J. 2013, 51, 707–720. [Google Scholar] [CrossRef]

- Kedward, L.; Allen, C.B.; Rendall, T.C.S. Efficient and exact mesh deformation using multiscale RBF interpolation. J. Comput. Phys. 2017, 345, 732–751. [Google Scholar] [CrossRef]

- Smolik, M.; Skala, V. Large scattered data interpolation with radial basis functions and space subdivision. Integr. Comput.-Aided Eng. 2017, 25, 49–62. [Google Scholar] [CrossRef]

- Pathak, H.; Singh, A.; Singh, I.V.; Yadav, S.K. A simple and efficient XFEM approach for 3-D cracks simulations. Int. J. Fract. 2013, 181, 189–208. [Google Scholar] [CrossRef]

- Morel, J.; Bac, A.; Vega, C. Terrain Model Reconstruction from Terrestrial LiDAR Data Using Radial Basis Functions. IEEE Comput. Graph. Appl. 2017, 37, 72–84. [Google Scholar] [CrossRef]

- Ho, H.S.; Lui, B.F.Y.; Wang, M.Y. Parametric structural optimization with radial basis functions and partition of unity method. Optim. Methods Softw. 2011, 26, 533–553. [Google Scholar] [CrossRef]

- Guo, G.; Wu, X.; Wang, M.Y.; Wu, J. Fast implicit surface reconstruction method based on normal constraints. In Proceedings of the 2010 IEEE International Conference on Mechatronics and Automation, Xi’an, China, 4–7 August 2010. [Google Scholar]

- Berger, M.; Levine, J.A.; Nonato, L.G.; Taubin, G.; Silva, C.T. A benchmark for surface reconstruction. ACM Trans. Graph. 2013, 32, 20. [Google Scholar] [CrossRef]

- Beatson, R.K.; Light, W.A.; Billings, S.D. Fast Solution of the Radial Basis Function Interpolation Equations: Domain Decomposition Methods. SIAM J. Sci. Comput. 2001, 22, 1717–1740. [Google Scholar] [CrossRef]

- Ohtake, Y.; Belyaev, A.; Alexa, M.; Turk, G.; Seidel, H.-P. Multi-Level Partition of Unity Implicits; ACM Siggraph 2005 Courses; ACM: New York, NY, USA, 2005; p. 173. [Google Scholar]

- Macri, M.; De, S. An Octree Partition of Unity Method (Octpum) with Enrichments for Multiscale Modeling of Heterogeneous Media. Comput. Struct. 2008, 866, 780–795. [Google Scholar] [CrossRef]

- Yokota, R.; Barba, L.A.; Knepley, M.G. PetRBF—A parallel O(N) algorithm for radial basis function interpolation with Gaussians. Comput. Methods Appl. Mech. Eng. 2010, 199, 1793–1804. [Google Scholar] [CrossRef]

- Li, S.; Yao, L.Q.; Yi, S.C.; Wang, W. A Meshless Radial Basis Function Based on Partition of Unity Method for Piezoelectric Structures. Math. Probl. Eng. 2016. [Google Scholar] [CrossRef]

- Wendland, H. Piecewise polynomial, positive definite and compactly supported radial functions of minimal degree. Adv. Comput. Math. 1995, 4, 389–396. [Google Scholar] [CrossRef]

- Skala, V. RBF Interpolation with CSRBF of Large Data Sets. Procedia Comput. Sci. 2017, 108, 2433–2437. [Google Scholar] [CrossRef]

- Bezdek, J.C.; Ehrlich, R.; Full, W. FCM: The fuzzy c means clustering algorithm. Comput. Geosci. 1984, 10, 191–203. [Google Scholar] [CrossRef]

- Shepard, D. A two-dimensional interpolation function for irregularly-spaced data. In Proceedings of the 1968 23rd ACM national conference, New York, NY, USA, 27–29 August 1968. [Google Scholar]

- Wu, Z. Compactly supported positive definite radial functions. Adv. Comput. Math. 1995, 4, 283. [Google Scholar] [CrossRef]

| Global RBF | Basis Function |

|---|---|

| Multi-quadric (MQ) function | |

| Gaussian function |

| No. | Calibration Data Set | Test Data Set | ||

|---|---|---|---|---|

| 1 | 0.32 | 0.30 | 0.65 | 0.39 |

| 2 | 0.33 | 0.27 | 0.46 | 0.58 |

| 3 | 0.31 | 0.24 | 0.54 | 0.42 |

| 4 | 0.32 | 0.31 | 0.51 | 0.43 |

| 5 | 0.27 | 0.32 | 0.43 | 0.48 |

| 6 | 0.29 | 0.26 | 0.45 | 0.40 |

| 7 | 0.27 | 0.23 | 0.53 | 0.42 |

| 8 | 0.30 | 0.27 | 0.41 | 0.41 |

| 9 | 0.29 | 0.25 | 0.50 | 0.47 |

| 10 | 0.30 | 0.23 | 0.58 | 0.47 |

| 11 | 0.32 | 0.37 | 0.59 | 0.65 |

| 12 | 0.64 | 0.50 | 0.71 | 0.86 |

| No. | Calibration Data Set | Test Data Set | ||

|---|---|---|---|---|

| 1 | 3.60E-01 | 3.46E-01 | 6.98E-01 | 6.81E-01 |

| 2 | 1.04E-05 | 1.39E-05 | 6.16E-05 | 2.87E-03 |

| 3 | 1.40E-04 | 2.23E-04 | 2.68E-04 | 8.29E-03 |

| 4 | 1.71E-06 | 1.85E-06 | 5.62E-04 | 2.56E-02 |

| 5 | 3.25E-06 | 3.81E-06 | 5.23E-05 | 4.85E-03 |

| 6 | 4.24E-06 | 2.28E-06 | 1.46E-04 | 5.10E-03 |

| 7 | 4.29E-02 | 2.00E-02 | 2.99E-02 | 4.19E-02 |

| 8 | 3.29E-02 | 3.54E-02 | 3.97E-02 | 9.81E-02 |

| 9 | 2.20E-01 | 3.27E-01 | 4.51E-01 | 6.17E-01 |

| RBF | Calibration Data Set (mm) | Test Data Set (mm) |

|---|---|---|

| MQ function | 0.74 | 0.55 |

| Gaussian function | 4.81 × 10−6 | 0.005 |

| Calibration Method | Test Data Set (mm) | Number of Points in Calibration Data Set | Operation Time (s) |

|---|---|---|---|

| RBF | 0.022 | 700 | 51.4 |

| KDFcmPUM | 0.005 | 1008 | 7.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, N.; Sun, C.; Wang, P. Calibration Method of Orthogonally Splitting Imaging Pose Sensor Based on KDFcmPUM. Sensors 2019, 19, 4991. https://doi.org/10.3390/s19224991

Zhao N, Sun C, Wang P. Calibration Method of Orthogonally Splitting Imaging Pose Sensor Based on KDFcmPUM. Sensors. 2019; 19(22):4991. https://doi.org/10.3390/s19224991

Chicago/Turabian StyleZhao, Na, Changku Sun, and Peng Wang. 2019. "Calibration Method of Orthogonally Splitting Imaging Pose Sensor Based on KDFcmPUM" Sensors 19, no. 22: 4991. https://doi.org/10.3390/s19224991

APA StyleZhao, N., Sun, C., & Wang, P. (2019). Calibration Method of Orthogonally Splitting Imaging Pose Sensor Based on KDFcmPUM. Sensors, 19(22), 4991. https://doi.org/10.3390/s19224991