Novel PDMS-Based Sensor System for MPWM Measurements of Picoliter Volumes in Microfluidic Devices

Abstract

1. Introduction

1.1. Microfluidic Device Materials

1.2. Techniques for Manufacturing Microfluidic Devices

1.2.1. Geometry and Quality of Microchannels Surface

1.2.2. The Microwire-Molding Technique

1.3. The Purpose Statements

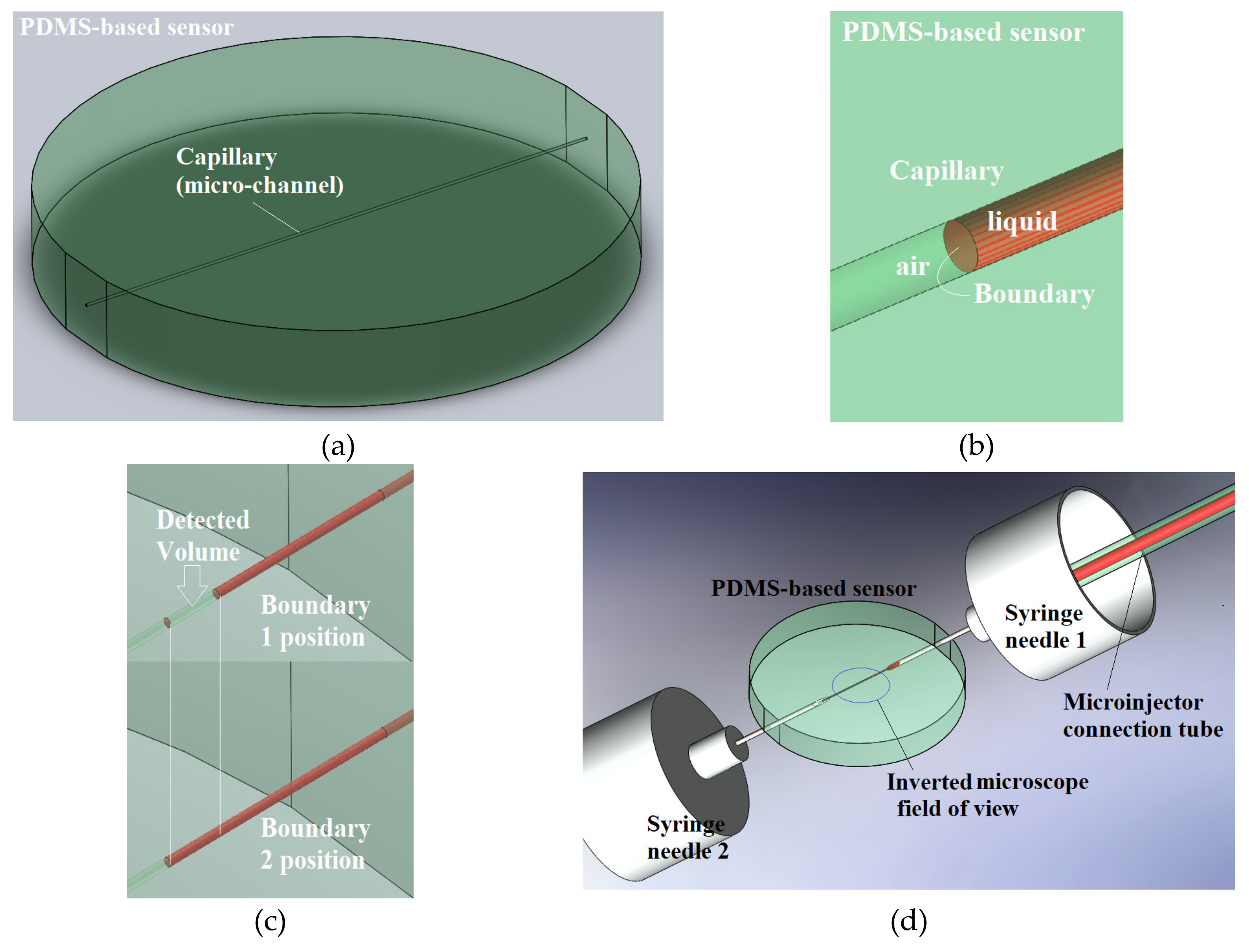

2. Materials and Methods for PDMS –Based Sensor Fabrication

2.1. Selection of Materials

2.2. Fabrication Methods of PDMS Sensor

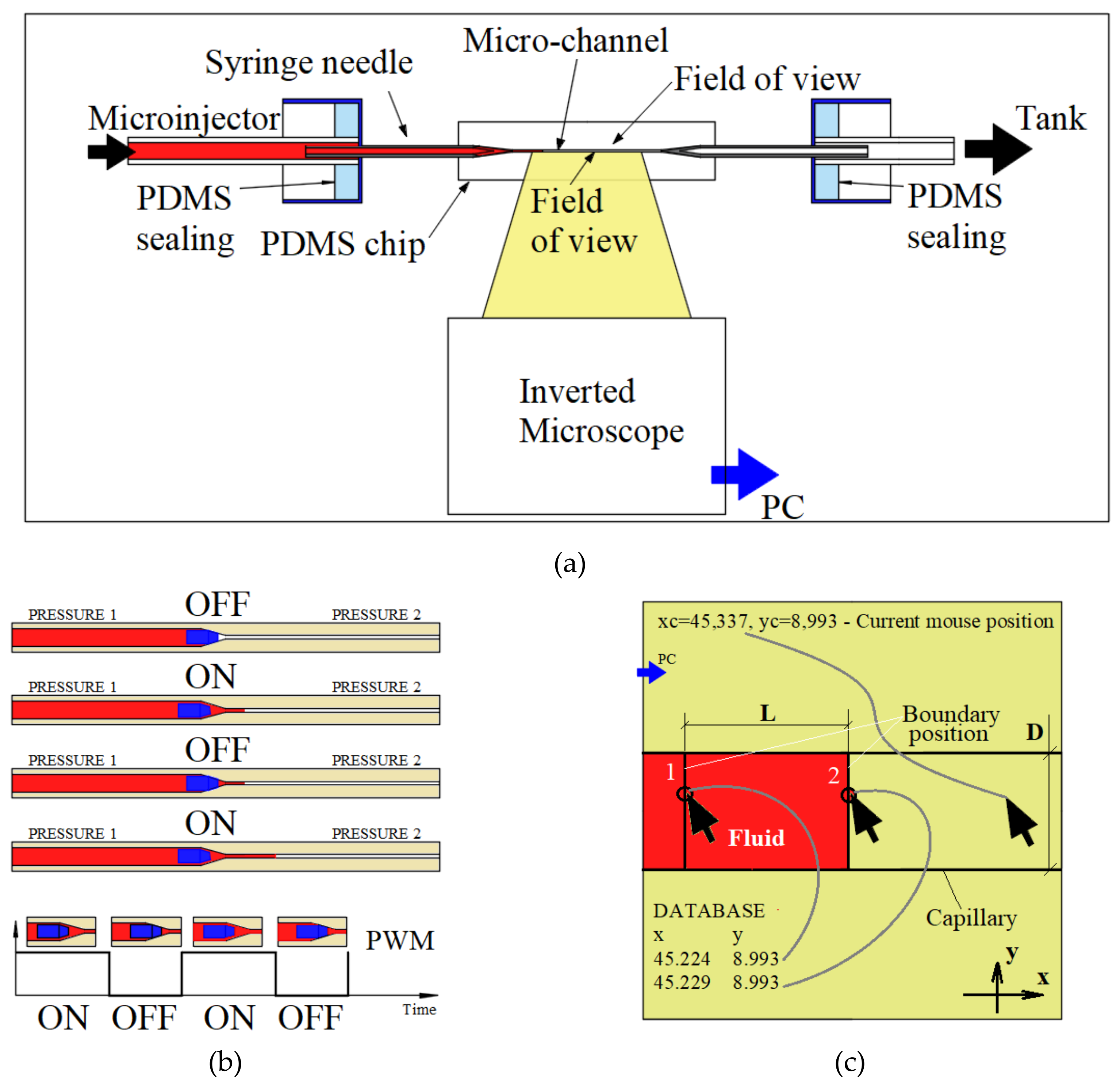

3. Volumes Detection Method

3.1. The Principle of Volume Detection Using PDMS-Based Sensor

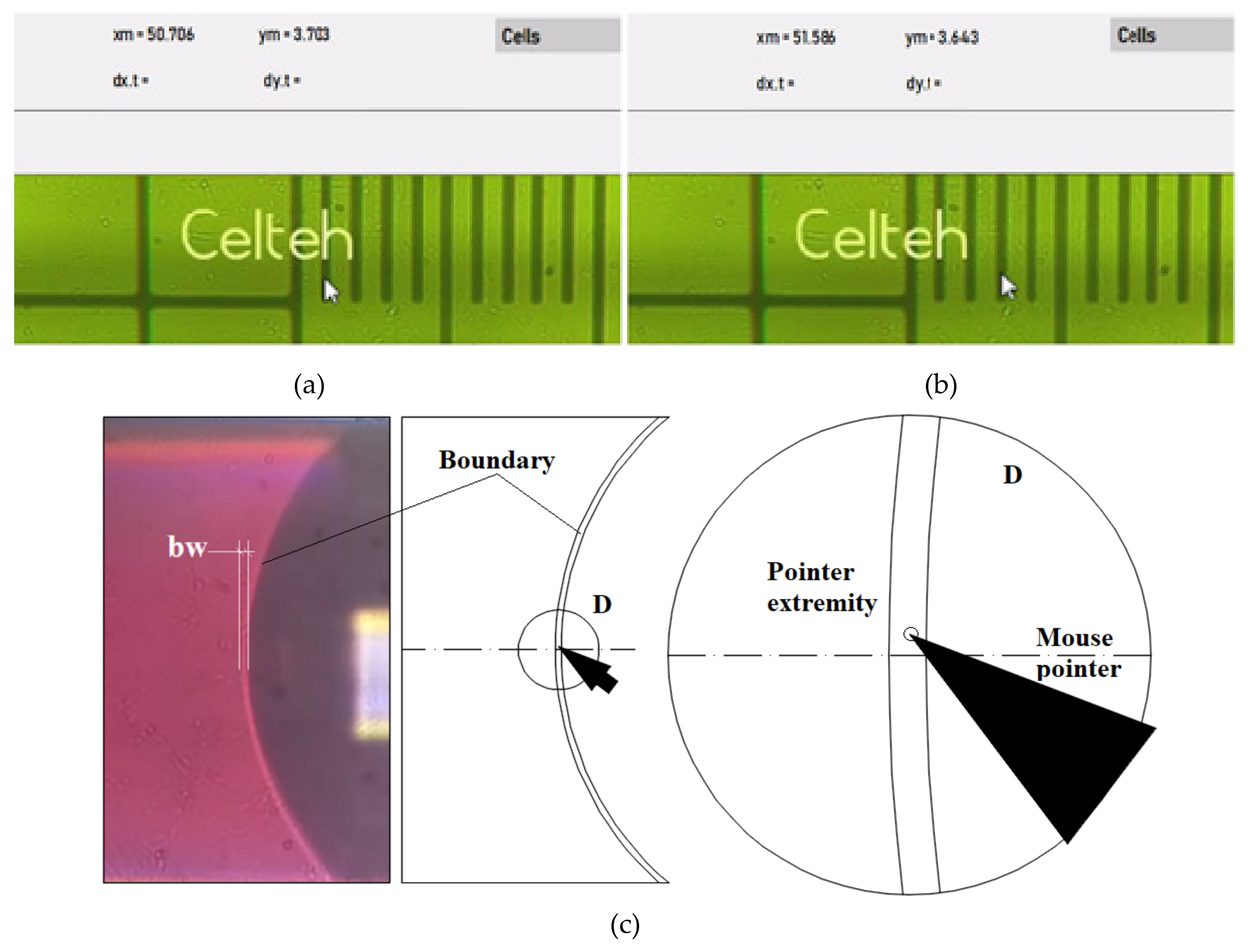

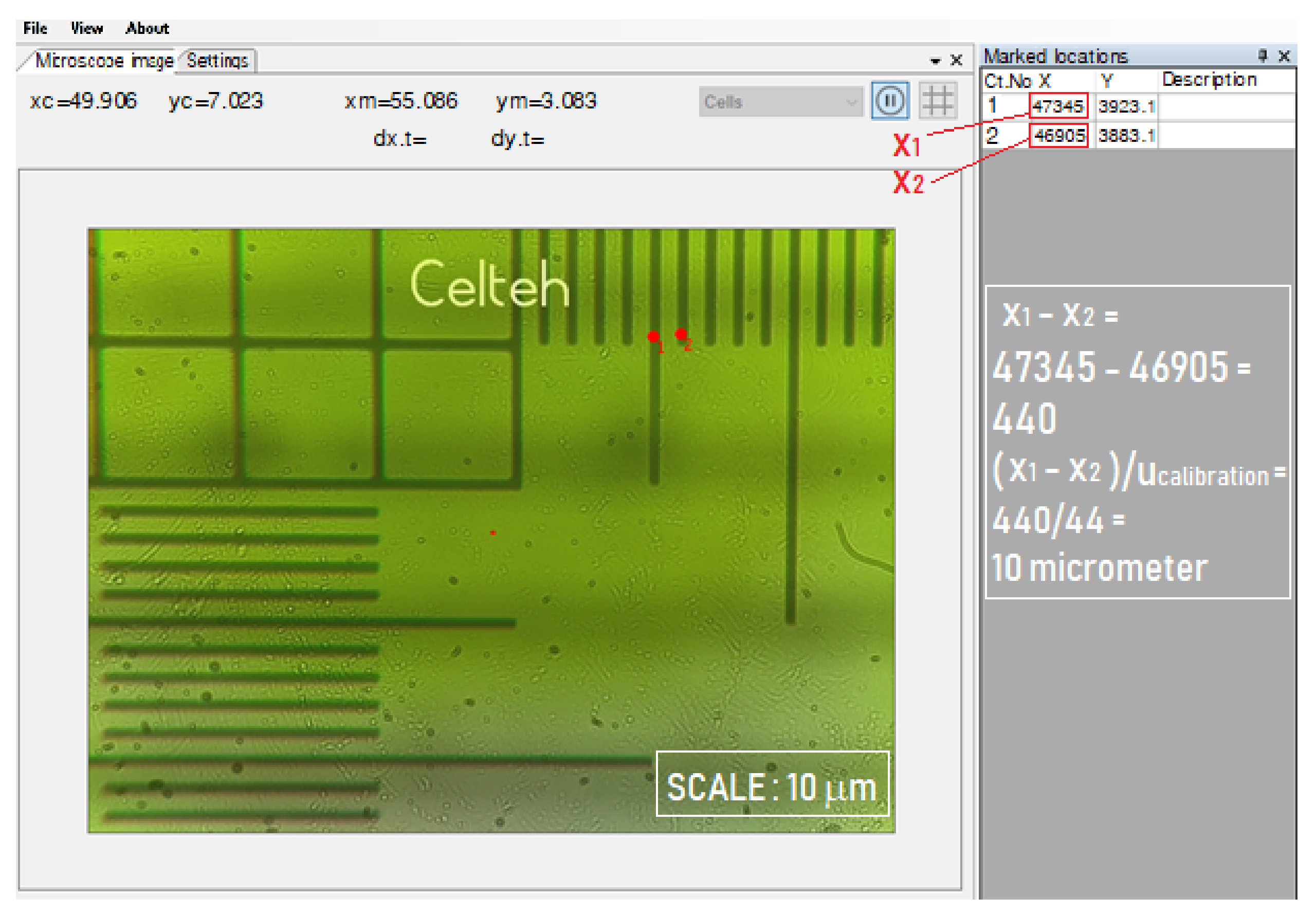

3.2. Method of Experimental Measurements of Picoliter Volumes

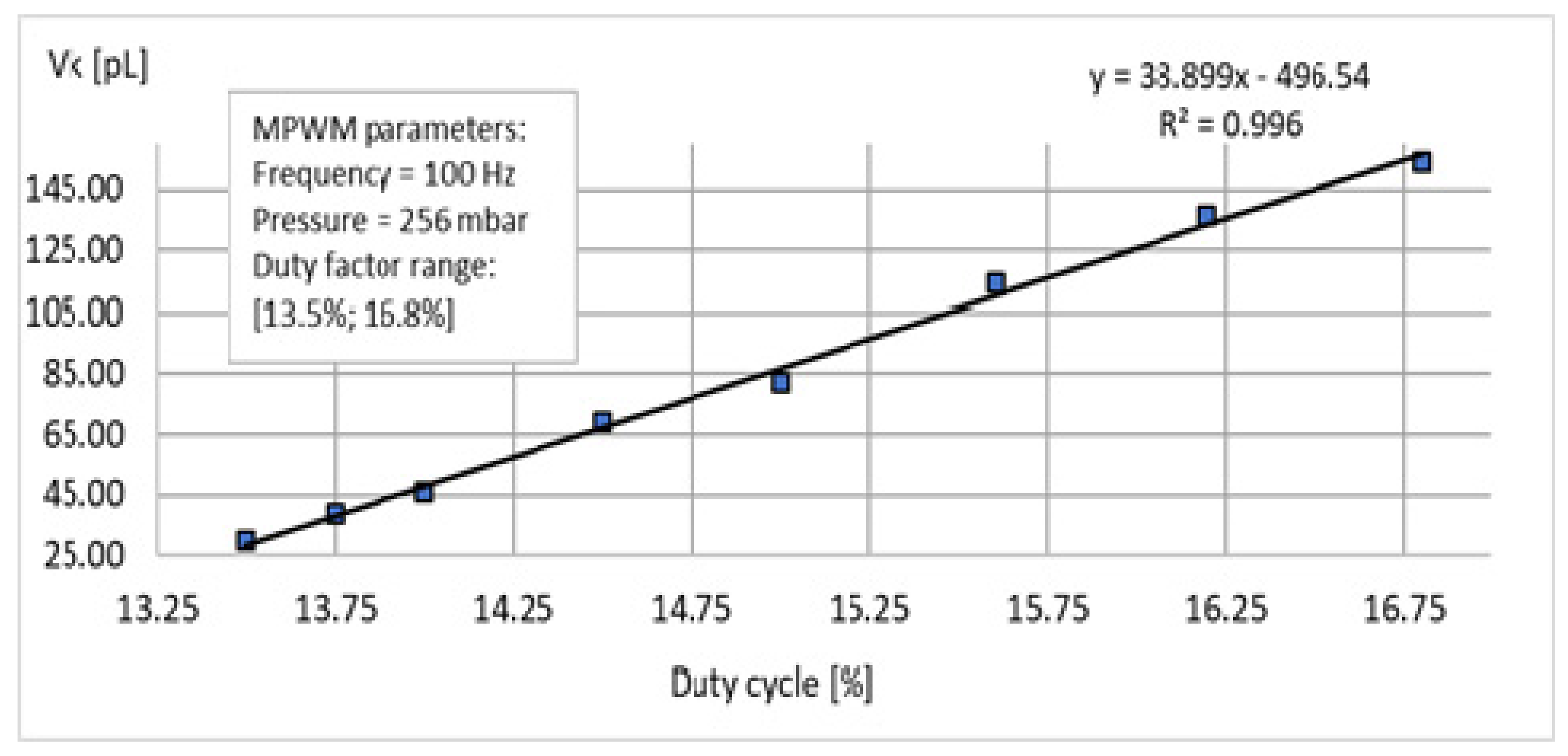

4. Calibration of MPWM for Picolitre Volumes

5. Experimental Results

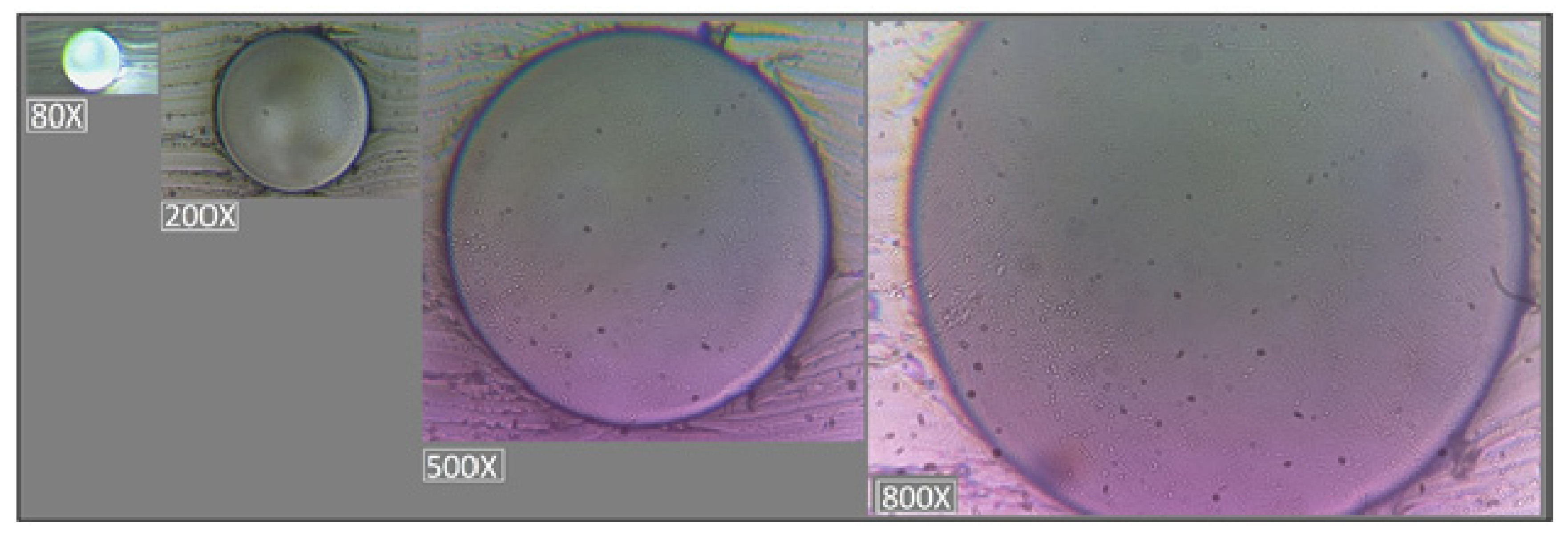

5.1. Microscopic Analyses of Microchannels

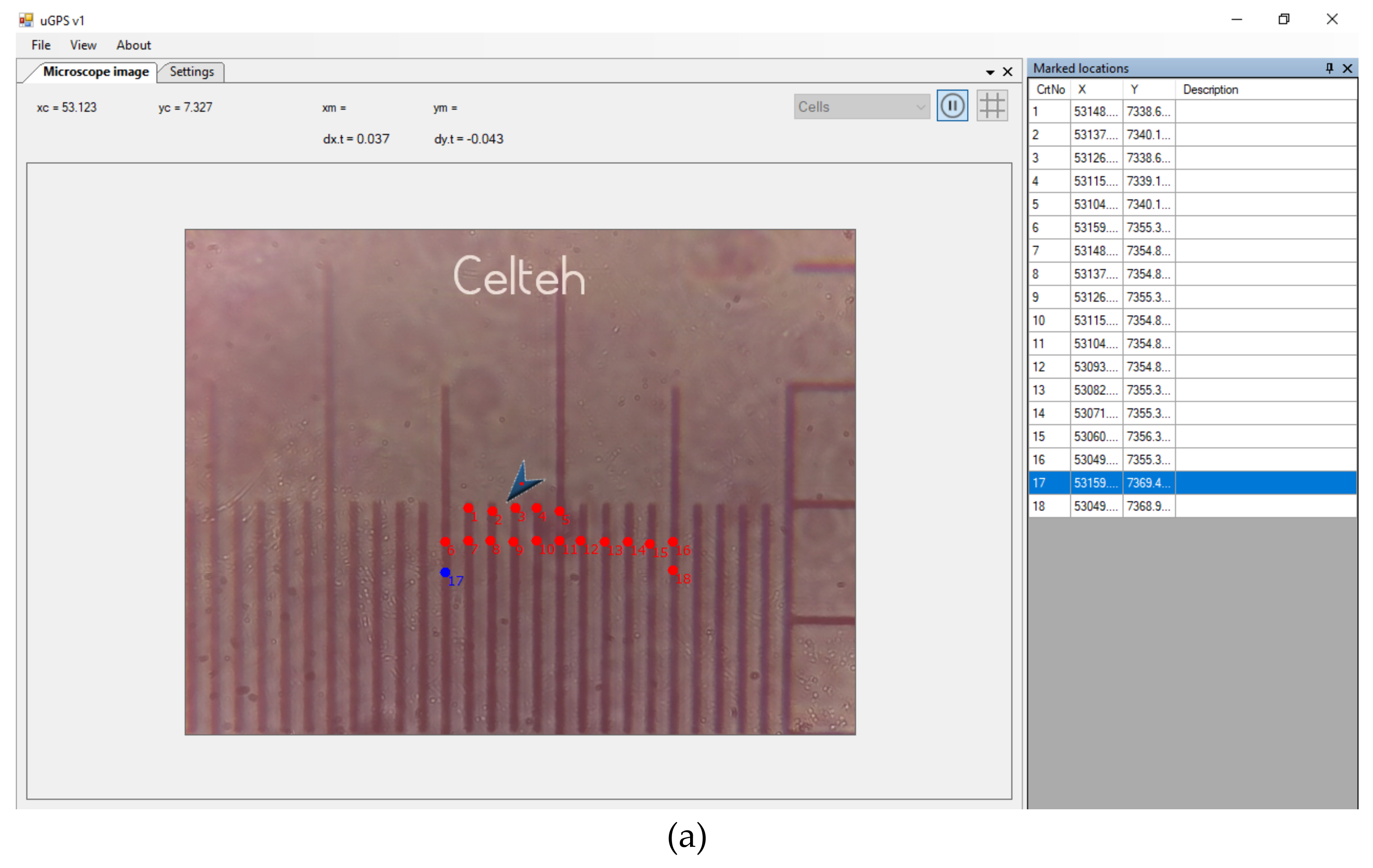

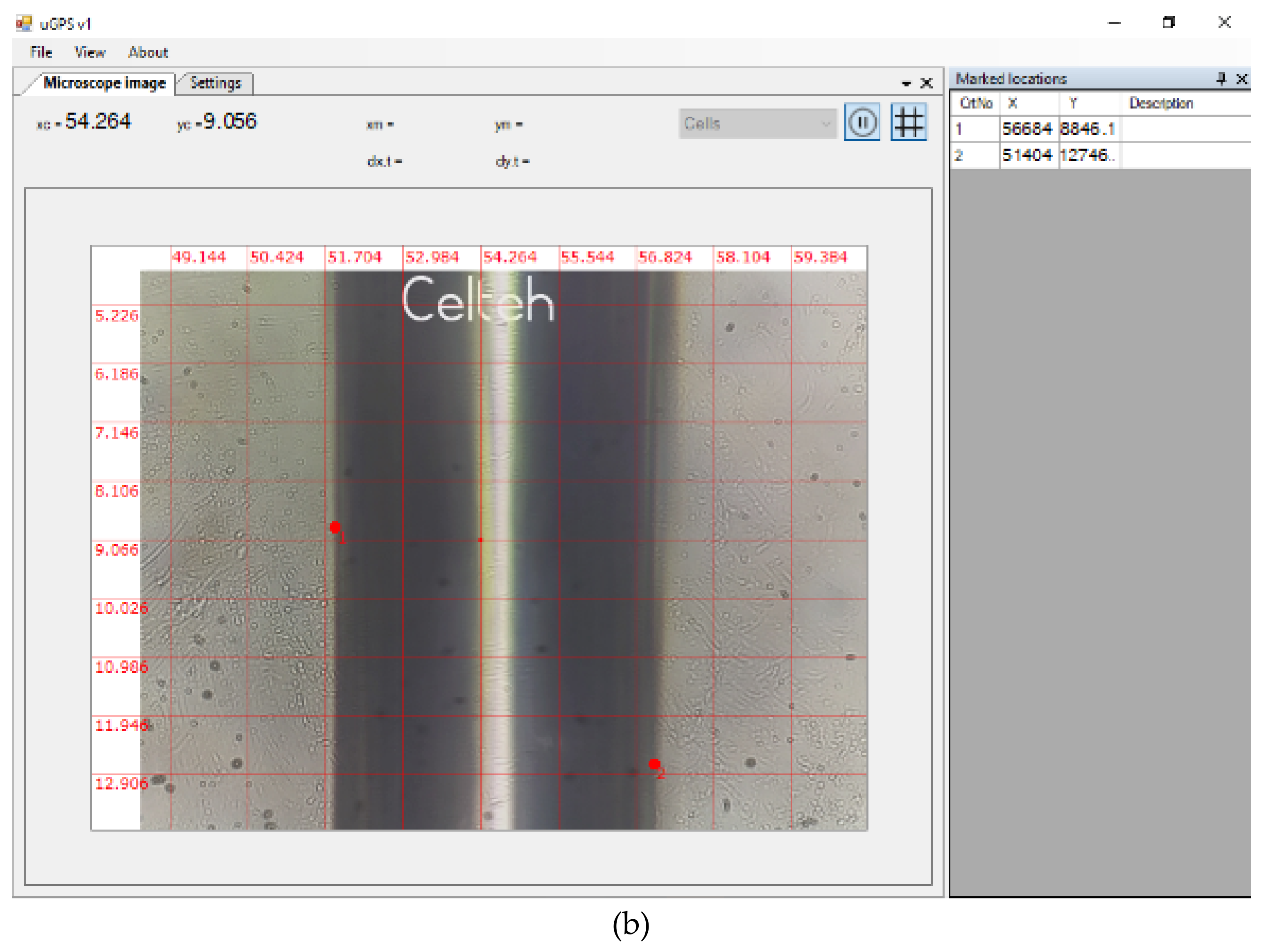

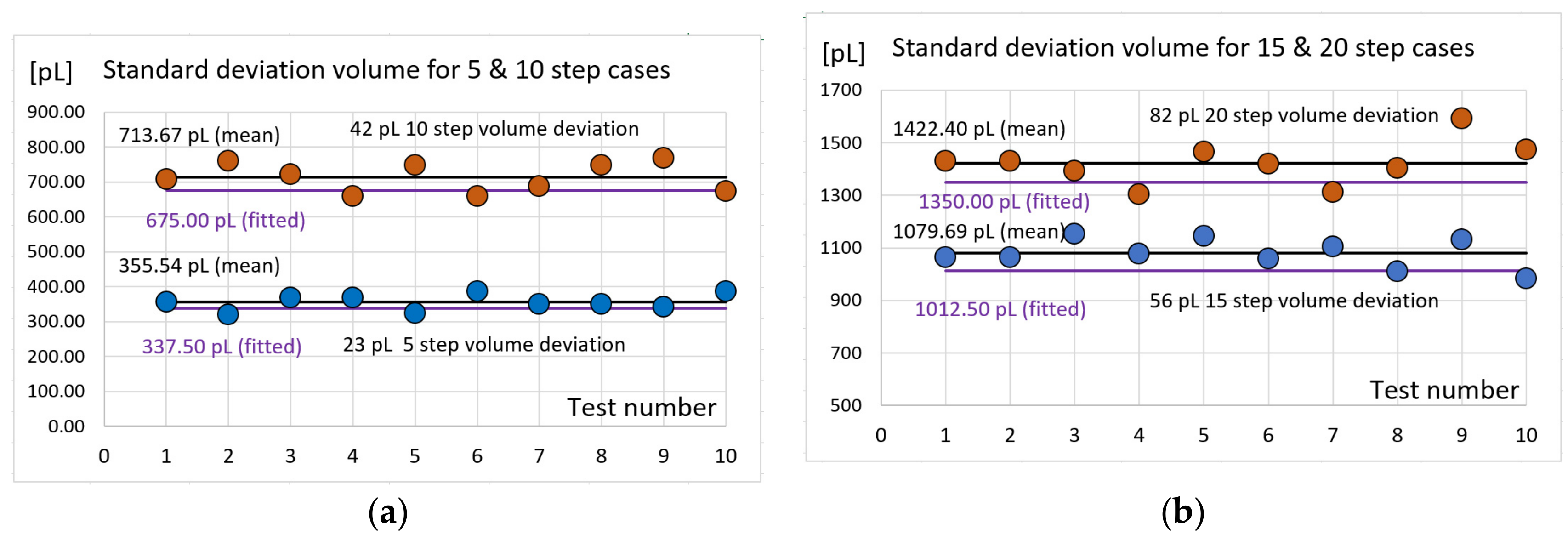

5.2. Results of Experimental Tests for Microfluidic Transportation

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ellson, R.N. Nanoliter and picoliter liquid handling for life science applications. In Proceedings of the Nanotech and Biotech Convergence Conference, Stanford, CA, USA, May 2003; p. 7. [Google Scholar]

- McDonald, J.C.; Duffy, D.C.; Anderson, J.R.; Chiu, D.T.; Wu, H.; Schueller, O.J.; Whitesides, G.M. Fabrication of microfluidic systems in poly(dimethylsiloxane).Pdf. Electrophoresis 2000, 21, 14. [Google Scholar] [CrossRef]

- Niu, X.; Zhang, M.; Peng, S.; Wen, W.; Sheng, P. Real-time detection, control, and sorting of microfluidic droplets. Biomicrofluidics 2007, 1, 44101. [Google Scholar] [CrossRef] [PubMed]

- Oliva, P.; Bircher, B.A.; Schoenenberger, C.A.; Braun, T. Array based real-time measurement of fluid viscosities and mass-densities to monitor biological filament formation. Lab Chip 2019, 19, 1305–1314. [Google Scholar] [CrossRef] [PubMed]

- Salafi, T.; Zeming, K.K.; Lim, J.W.; Raman, R.; Seah, A.W.R.; Tan, M.P.; Zhang, Y. Portable smartphone-based platform for real-time particle detection in microfluidics. Adv. Mater. Technol. 2019, 4, 1800359. [Google Scholar] [CrossRef]

- Shameer, K.; Badgeley, M.A.; Miotto, R.; Glicksberg, B.S.; Morgan, J.W.; Dudley, J.T. Translational bioinformatics in the era of real-time biomedical, health care and wellness data streams. Brief Bioinform 2017, 18, 105–124. [Google Scholar] [CrossRef] [PubMed]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef]

- Abgrall, P.; Gué, A.M. Lab-on-chip technologies: Making a microfluidic network and coupling it into a complete microsystem—A review. J. Micromech. Microeng. 2007, 17, R15–R49. [Google Scholar] [CrossRef]

- Liu, L.; Cao, W.; Wu, J.; Wen, W.; Chang, D.C.; Sheng, P. Design and integration of an all-in-one biomicrofluidic chip. Biomicrofluidics 2008, 2, 34103. [Google Scholar] [CrossRef]

- Oh, K.W. Lab-on-Chip (Loc) Devices and Microfluidics for Biomedical Applications; Woodhead Publishing Limited: Sawston, UK, 2012; pp. 150–171. [Google Scholar]

- Gan, L.T.; Xia, Z.N.; Chen, H.; Yu, Y.L. A novel method for fabricating polydimethylsiloxane microfluidic chip master molds. J. Chongqing Univ. (Engl. Ed.) 2009, 8, 6. [Google Scholar]

- Halldorsson, S.; Lucumi, E.; Gomez-Sjoberg, R.; Fleming, R.M.T. Advantages and challenges of microfluidic cell culture in polydimethylsiloxane devices. Biosens Bioelectron 2015, 63, 218–231. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, C.; Cai, H.; Hu, N.; Zhou, J.; Wang, P. Cell-based biosensors and their application in biomedicine. Chem Rev 2014, 114, 6423–6461. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Li, J.; Sun, Y. Microfluidic approaches for cancer cell detection, characterization, and separation. Lab Chip 2012, 12, 1753–1767. [Google Scholar] [CrossRef] [PubMed]

- Permana, S.; Grant, E.; Walker, G.M.; Yoder, J.A. A review of automated microinjection systems for single cells in the embryogenesis stage. IEEE/ASME Trans. Mechatron. 2016, 21, 2391–2404. [Google Scholar] [CrossRef]

- Torino, S.; Corrado, B.; Iodice, M.; Coppola, G. Pdms-based microfluidic devices for cell culture. Inventions 2018, 3, 65. [Google Scholar] [CrossRef]

- Vaughan, D.A.; Sakkas, D. Sperm selection methods in the 21st century. Biol Reprod 2019. [Google Scholar] [CrossRef]

- Zhou, Y.; Basu, S.; Wohlfahrt, K.J.; Lee, S.F.; Klenerman, D.; Laue, E.D.; Seshia, A.A. A microfluidic platform for trapping, releasing and super-resolution imaging of single cells. Sens Actuators B Chem 2016, 232, 680–691. [Google Scholar] [CrossRef]

- Jokerst, J.C.; Emory, J.M.; Henry, C.S. Advances in microfluidics for environmental analysis. Analyst 2012, 137, 24–34. [Google Scholar] [CrossRef]

- Oscar, S.V.; Fernando, O.L.; Del Pilar, C.M. Total polyphenols content in white wines on a microfluidic flow injection analyzer with embedded optical fibers. Food Chem 2017, 221, 1062–1068. [Google Scholar] [CrossRef]

- Visser, C.W.; Kamperman, T.; Karbaat, L.P.; Lohse, D.; Karperien, M. In-air microfluidics enables rapid fabrication of emulsions, suspensions, and 3d modular (bio)materials. Sci. Adv. 2018, 9. [Google Scholar] [CrossRef]

- Nge, P.N.; Rogers, C.I.; Woolley, A.T. Advances in microfluidic materials, functions, integration, and applications. Chem Rev 2013, 113, 2550–2583. [Google Scholar] [CrossRef]

- Jovic, A.; Howell, B.; Takayama, S. Timing is everything: Using fluidics to understand the role of temporal dynamics in cellular systems. Microfluid. Nanofluidics 2009, 6, 717–729. [Google Scholar] [CrossRef]

- da Silva, E.N.T.; Ferreira, V.S.; Lucca, B.G. Rapid and inexpensive method for the simple fabrication of pdms-based electrochemical sensors for detection in microfluidic devices. Electrophoresis 2019, 40, 1322–1330. [Google Scholar] [CrossRef] [PubMed]

- Koo, H.J.; Velev, O.D. Design and characterization of hydrogel-based microfluidic devices with biomimetic solute transport networks. Biomicrofluidics 2017, 11, 024104. [Google Scholar] [CrossRef] [PubMed]

- Makamba, H.; Kim, J.H.; Lim, K.; Park, N.; Hahn, J.H. Surface modification of poly(dimethylsiloxane) microchannels. Electrophoresis 2003, 24, 3607–3619. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal. Chem. 2003, 75, 11. [Google Scholar] [CrossRef] [PubMed]

- Tjerkstra, R.W.; De Boer, M.; Berenschot, E.; Gardeniers, J.G.; van den Berg, A.; Elwenspoek, M.C. Etching technology for chromatography microchannels. Electrochim. Acta 1997, 42, 8. [Google Scholar] [CrossRef]

- Becker, H.; Heim, U. Hot embossing as a method for the fabrication of polymer high aspect ratio structures. Sens. Actuators 2000, 83, 6. [Google Scholar] [CrossRef]

- Fiddes, L.K.; Raz, N.; Srigunapalan, S.; Tumarkan, E.; Simmons, C.A.; Wheeler, A.R.; Kumacheva, E. A circular cross-section pdms microfluidics system for replication of cardiovascular flow conditions. Biomaterials 2010, 31, 3459–3464. [Google Scholar] [CrossRef]

- Lee, D.-K.; Kwon, J.Y.; Cho, Y.H. Fabrication of microfluidic channels with various cross-sectional shapes using anisotropic etching of si and self-alignment. Appl. Phys. A 2019, 125. [Google Scholar] [CrossRef]

- Lin, C.-H.; Lee, G.-B.; Chang, B.-W.; Chang, G.-L. A new fabrication process for ultra-thick microfluidic microstructures utilizing su-8 photoresist. J. Micromech. Microeng. 2002, 12, 590–597. [Google Scholar] [CrossRef]

- Wang, G.J.; Ho, K.H.; Hsu, S.H.; Wang, K.P. Microvessel scaffold with circular microchannels by photoresist melting. Biomed Microdevices 2007, 9, 657–663. [Google Scholar] [CrossRef] [PubMed]

- Wilson, M.E.; Kota, N.; Kim, Y.; Wang, Y.; Stolz, D.B.; LeDuc, P.R.; Ozdoganlar, O.B. Fabrication of circular microfluidic channels by combining mechanical micromilling and soft lithography. Lab Chip 2011, 11, 1550–1555. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; Li, Y.; Zhao, Q.; Yuan, D.; Yun, G.; Zhang, J.; Wen, W.; Tang, S.Y.; Li, W. Liquid metal-based amalgamation-assisted lithography for fabrication of complex channels with diverse structures and configurations. Lab Chip 2018, 18, 785–792. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, S.; Garstecki, P.; Weibel, D.B.; Whitesides, G.M. An axisymmetric flow-focusing microfluidic device. Adv. Mater. 2005, 17, 6. [Google Scholar] [CrossRef]

- Wu, J.; Gu, M. Microfluidic sensing- state of the art fabrication and detection techniques. J. Biomed. Opt. 2011, 16, 13. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.; Moon, B.-U.; Hidrovo, C.H. Enhancement of the thermo-mechanical properties of pdms molds for the hot embossing of pmma microfluidic devices. J. Micromech. Microeng. 2013, 23, 095024. [Google Scholar] [CrossRef]

- Qi, S.; Liu, X.; Ford, S.; Barrows, J.; Thomas, G.; Kelly, K.; McCandless, A.; Lian, K.; Goettert, J.; Soper, S.A. Microfluidic devices fabricated in poly(methyl methacrylate) using hot-embossing with integrated sampling capillary and fiber optics for fluorescence detection. Lab Chip 2002, 2, 88–95. [Google Scholar] [CrossRef]

- Attia, U.M.; Marson, S.; Alcock, J.R. Micro-injection moulding of polymer microfluidic devices. Microfluid. Nanofluidics 2009, 7, 1–28. [Google Scholar] [CrossRef]

- Ardeleanu, M.N.; Ivan, I.A.; Despa, V. Rapid prototyping technologies used for a microgripper frameworks fabrication. 2013, 44, 3. Rom. Rev. Precis. Mech. Optics Mechatron.

- Rossier, J.; Reymond, F.; Michel, P.E. Polymer microfluidic chips for electrochemical and biochemical analyses. Electrophoresis 2002, 23, 10. [Google Scholar] [CrossRef]

- Cao, H.; Tegenfeldt, J.O.; Austin, R.H.; Chou, S.Y. Gradient nanostructures for interfacing microfluidics and nanofluidics. Appl. Phys. Lett. 2002, 81, 3058–3060. [Google Scholar] [CrossRef]

- Abdelgawad, M.; Wu, C.; Chien, W.Y.; Geddie, W.R.; Jewett, M.A.; Sun, Y. A fast and simple method to fabricate circular microchannels in polydimethylsiloxane (pdms). Lab Chip 2011, 11, 545–551. [Google Scholar] [CrossRef] [PubMed]

- Mappes, T.; Achenbach, S.; Mohr, J. X-ray lithography for devices with high aspect ratio polymer submicron structures. Microelectron. Eng. 2007, 84, 1235–1239. [Google Scholar] [CrossRef]

- Lorenzini, M.; Suzzi, N. The influence of geometry on the thermal performance of microchannels in laminar flow with viscous dissipation. Heat Transf. Eng. 2016, 37, 1096–1104. [Google Scholar] [CrossRef]

- Parker, B.; Ahmadi, A.; Samanipour, R.; Kim, K. Rapid fabrication of circular channel microfluidic flow-focusing devices for hydrogel droplet generation. Micro Nano Lett. 2016, 11, 41–45. [Google Scholar] [CrossRef]

- Das, A.; Bhaumik, S.K. Fabrication of cylindrical superhydrophobic microchannels by replicating lotus leaf structures on internal walls. J. Micromech. Microeng. 2018, 28, 045011. [Google Scholar] [CrossRef]

- Lu, X.; Liu, C.; Hu, G.; Xuan, X. Particle manipulations in non-newtonian microfluidics: A review. J Colloid Interface Sci 2017, 500, 182–201. [Google Scholar] [CrossRef]

- Bliss, C.L.; McMullin, J.N.; Backhouse, C.J. Rapid fabrication of a microfluidic device with integrated optical waveguides for DNA fragment analysis. Lab Chip 2007, 7, 1280–1287. [Google Scholar] [CrossRef]

- Xiang, N.; Dai, Q.; Han, Y.; Ni, Z.H. Circular-channel particle focuser utilizing viscoelastic focusing. Microfluid. Nanofluidics 2019, 23. [Google Scholar] [CrossRef]

- Effati, E.; Pourabbas, B. New portable microchannel molding system based on micro-wire molding, droplet formation studies in circular cross-section microchannel. Mater. Today Commun. 2018, 16, 119–123. [Google Scholar] [CrossRef]

- Jia, Y.F.; Jiang, J.H.; Ma, X.D.; Li, Y.; Huang, H.M.; Cai, K.B.; Cai, S.X.; Wu, Y.P. Pdms microchannel fabrication technique based on microwire-molding. Chin. Sci. Bull. 2008, 53, 3928–3936. [Google Scholar] [CrossRef]

- Song, S.-H.; Lee, C.-K.; Kim, T.-J.; Shin, I.-c.; Jun, S.-C.; Jung, H.-I. A rapid and simple fabrication method for 3-dimensional circular microfluidic channel using metal wire removal process. Microfluid. Nanofluidics 2010, 9, 533–540. [Google Scholar] [CrossRef]

- Verma, M.K.; Majumder, A.; Ghatak, A. Embedded template-assisted fabrication of complex microchannels in pdms and design of a microfluidic adhesive. Langmuir 2006, 22, 5. [Google Scholar] [CrossRef] [PubMed]

- Ardeleanu, M.N.; Mihai, S.; Vidu, R.; Diaconu, E.M.; Popescu, I.N. Design of microfluidic device and measurements of mpwm for single cell /particle manipulation. Sci. Bull. Valahia Univ. Mater. Mech. 2019, 17, 39–43. [Google Scholar] [CrossRef]

- Dahlin, A.P.; Wetterhall, M.; Liljegren, G.; Bergstrom, S.K.; Andren, P.; Nyholm, L.; Markides, K.E.; Bergquist, J. Capillary electrophoresis coupled to mass spectrometry from a polymer modified poly(dimethylsiloxane) microchip with an integrated graphite electrospray tip. Analyst 2005, 130, 193–199. [Google Scholar] [CrossRef]

- Richter, M.; Woias, P.; Weib, D. Microchannels for applications in liquid dosing and flow-rate measurement. Sens. Actuators A 1997, 62, 4. [Google Scholar] [CrossRef]

- Ainla, A.; Gozen, I.; Orwar, O.; Jesorka, A. A microfluidic diluter based on pulse width flow modulation. Anal. Chem. 2009, 81. [Google Scholar] [CrossRef][Green Version]

- Unger, M.; Lee, S.S.; Peter, M.; Koeppl, H. Pulse width modulation of liquid flows: Towards dynamic control of cell microenvironments. In Proceedings of the 15th International Conference on Miniaturized Systems for Chemistry and Life Sciences, Seattle, Washington, USA, 2–6 October2011; p. 3. [Google Scholar]

- Ardeleanu, M.; Ionita, M.; Ivan, A.; Gurgu, V. Innovative bidimensional absolute transducer based on video detection for positioning into micro assembly processes. Appl. Mech. Mater. 2014, 658, 535–540. [Google Scholar] [CrossRef]

- Experimental Models. Available online: http://www.celteh.ro/proiecte/proiecte-2/ (accessed on 14 September 2019).

| (Micro)wires Type | Microwires Diameters | Solvents and Proportions | Others Materials for Supporting Substrate | Ref. | |

|---|---|---|---|---|---|

| Nylon | 50–250 μm | Chloroform | 100% | Rigid cylindrical rod of 100-500 μm Silicone oils for Channels Filling | [55] |

| Chloroform + Triethylamine | 70/30 (v/v) | ||||

| 316 L Stainless steel | 24 and 40 μm | Ethanol | 100% | PMMA ancillary supporting frame and, PTFE tubes GLASS slide as substrate | [53] |

| Hexane | |||||

| NiCr, Enameled Cu, Nylon | 150, 350, 400 μm | Chloroform and Diisopropylamine | 70/30 (v/v) | Deionized water, water and oil based colors, mineral (15 mPa.s) and silicone oils (103 mPa.s) for droplet formation | [52] |

| Stainless steel | 50, 80, 100 and 150 μm | Alcohol | 100% | Particle suspensions added with 8 wt% PVP | [51] |

| Nylon | 74, 105, 148 and 181 μm | ||||

| Soldering (H-712 type) Sn and Pb: 60/40 | 300 μm | - | - | Slide glass for bonding PDMS. For coating the inner walls of channels PDMS: solutions diluted with serial % of Sylgard 184 | [54] |

| Duty Cycle(%) | Average Volume(pL) | Fitted Value(pL) | AverageDev. of Meas. (%) |

|---|---|---|---|

| 16.80 | 154.13 | 156.96 | 1.81 |

| 16.20 | 136.42 | 133.62 | 2.10 |

| 15.60 | 114.17 | 110.28 | 3.53 |

| 15.00 | 82.35 | 86.95 | 5.28 |

| 14.50 | 69.13 | 67.50 | 2.88 |

| 14.00 | 45.85 | 48.05 | 4.57 |

| 13.75 | 38.59 | 38.32 | 2.7 |

| 13.50 | 29.68 | 28.60 | 3.96 |

| Measurement | 5 Steps | 10 Steps | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | Start, Virtual Unit | Stop, Virtual Unit | V5step (pL) | Fitted Volume (pL) | Dev. of meas. (%) | Start, Virtual Unit | Stop, Virtual Unit | V10step (pL) | Fitted Volume (pL) | Dev. of Meas. (%) |

| 1 | 87754 | 86371 | 355.48 | 337.50 | 5.33 | 87932 | 85181 | 707.11 | 675.00 | 4.76 |

| 2 | 87762 | 86520 | 319.24 | 337.50 | 5.41 | 87928 | 84966 | 761.34 | 675.00 | 12.79 |

| 3 | 87744 | 86308 | 369.11 | 337.50 | 9.37 | 87931 | 85125 | 721.25 | 675.00 | 6.85 |

| 4 | 87749 | 86313 | 369.11 | 337.50 | 9.37 | 87940 | 85372 | 660.07 | 675.00 | 2.21 |

| 5 | 87758 | 86498 | 323.87 | 337.50 | 4.04 | 87937 | 85023 | 749.01 | 675.00 | 10.96 |

| 6 | 87751 | 86245 | 387.10 | 337.50 | 14.70 | 87923 | 85356 | 659.81 | 675.00 | 2.25 |

| 7 | 87757 | 86391 | 351.12 | 337.50 | 4.03 | 87940 | 85264 | 687.83 | 675.00 | 1.90 |

| 8 | 87745 | 86379 | 351.12 | 337.50 | 4.03 | 87626 | 84715 | 748.24 | 675.00 | 10.85 |

| 9 | 87750 | 86419 | 342.12 | 337.50 | 1.37 | 87932 | 84941 | 768.80 | 675.00 | 13.90 |

| 10 | 87754 | 86248 | 387.10 | 337.50 | 14.70 | 87946 | 85327 | 673.18 | 675.00 | 0.27 |

| Measurement | 15 Steps | 20 Steps | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | Start, Virtual Unit | Stop, Virtual Unit | V15step (pL) | Fitted Volume (pL) | Dev.of Meas. (%) | Start, Virtual Unit | Stop, Virtual Unit | V20step (pL) | Fitted Volume (Pl) | Dev.of Meas. (%) |

| 1 | 88025 | 83882 | 1064.91 | 1012.50 | 5.18 | 88405 | 82843 | 1429.65 | 1350.00 | 5.90 |

| 2 | 88085 | 83941 | 1065.17 | 1012.50 | 5.20 | 88449 | 82887 | 1429.65 | 1350.00 | 5.90 |

| 3 | 88021 | 83535 | 1153.07 | 1012.50 | 13.88 | 88412 | 82991 | 1393.40 | 1350.00 | 3.22 |

| 4 | 88015 | 83818 | 1078.79 | 1012.50 | 6.55 | 88394 | 83325 | 1302.93 | 1350.00 | 3.49 |

| 5 | 88019 | 83560 | 1146.13 | 1012.50 | 13.20 | 88403 | 82700 | 1465.89 | 1350.00 | 8.58 |

| 6 | 88035 | 83918 | 1058.23 | 1012.50 | 4.52 | 88396 | 82872 | 1419.88 | 1350.00 | 5.18 |

| 7 | 88064 | 83764 | 1105.26 | 1012.50 | 9.16 | 88423 | 83318 | 1312.18 | 1350.00 | 2.80 |

| 8 | 88059 | 84130 | 1009.90 | 1012.50 | 0.26 | 88452 | 82996 | 1402.40 | 1350.00 | 3.88 |

| 9 | 88044 | 83640 | 1132 | 1012.50 | 11.80 | 88405 | 82207 | 1593.12 | 1350.00 | 18.01 |

| 10 | 88075 | 84249 | 983.43 | 1012.50 | 2.87 | 88389 | 82651 | 1474.89 | 1350.00 | 9.25 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ardeleanu, M.N.; Popescu, I.N.; Udroiu, I.N.; Diaconu, E.M.; Mihai, S.; Lungu, E.; Alhalaili, B.; Vidu, R. Novel PDMS-Based Sensor System for MPWM Measurements of Picoliter Volumes in Microfluidic Devices. Sensors 2019, 19, 4886. https://doi.org/10.3390/s19224886

Ardeleanu MN, Popescu IN, Udroiu IN, Diaconu EM, Mihai S, Lungu E, Alhalaili B, Vidu R. Novel PDMS-Based Sensor System for MPWM Measurements of Picoliter Volumes in Microfluidic Devices. Sensors. 2019; 19(22):4886. https://doi.org/10.3390/s19224886

Chicago/Turabian StyleArdeleanu, Mihăiţă Nicolae, Ileana Nicoleta Popescu, Iulian Nicolae Udroiu, Emil Mihai Diaconu, Simona Mihai, Emil Lungu, Badriyah Alhalaili, and Ruxandra Vidu. 2019. "Novel PDMS-Based Sensor System for MPWM Measurements of Picoliter Volumes in Microfluidic Devices" Sensors 19, no. 22: 4886. https://doi.org/10.3390/s19224886

APA StyleArdeleanu, M. N., Popescu, I. N., Udroiu, I. N., Diaconu, E. M., Mihai, S., Lungu, E., Alhalaili, B., & Vidu, R. (2019). Novel PDMS-Based Sensor System for MPWM Measurements of Picoliter Volumes in Microfluidic Devices. Sensors, 19(22), 4886. https://doi.org/10.3390/s19224886