1. Introduction

In order to secure reliable manufacturing procedures, the effective and selective elimination of units with poor quality containing internal defects (i.e., delamination voids, cracks, or air bubble entrapment) plays a crucial role during the production of US probes for medical imaging, with the goal of reducing costs and improving the process capability. Therefore, an efficient non-destructive test method can be useful for finding and localizing such imperfections in the acoustic stack. There are many NDT methods [

1] for failure analysis of damage and for defect detection in microelectronic packages and in composite materials, including, but not limiting to: Optical microscopy [

2], infrared thermography (IRT) [

3,

4], X-ray computed tomography (XCT) [

5], and scanning acoustic microscopy (SAM) [

6,

7]. Compared to scanning electron microscopy (SEM) [

8] and transmission electron microscopy (TEM) [

9,

10], non-destructive techniques do not require time-consuming sample preparation with the further benefit of not damaging the unit under test. In fact, in most cases, i.e., for safety-relevant assemblies in aerospace [

11], rolling stock [

12], and automotive applications [

13], it is mandatory to study failures and other damages through a nondestructive technique. These techniques become very efficient and effective for the quality and safety assessment of products.

Among different non-destructive methods, analysis by means of infrared thermography is influenced by ambient factors, i.e., moisture, temperature. X-ray scans depend strongly on the thickness and density of the sample under testing. The principal disadvantage consists in the low resolution of small defects in the bulk material. X-ray-based techniques are not effective in the case of multilayered structures that are composed of high Pb contents, such as the active layer of US probes based on piezoelectric material, i.e., PZT (lead zirconate titanate) or PMN-PT (lead magnesium niobate-lead titanate). In fact, the penetration degree of X-rays inside this type of advanced materials is limited. The authors tested the effectiveness of high-resolution 3D X-ray microscopy by means of SKYSCAN 1272 (14,450 × 14,450 pixels)—BRUKER, but the phase contrast and resolution did not distinguish the virtual slices through the samples and, therefore, the defects.

Optical microscopy is useful for a fast visual inspection, but it is strongly limited to a surface investigation.

Scanning acoustic microscopy is a non-destructive technique used since the early 1980s that is able to provide imaging of the internal structure of thick-film circuits [

14] and multilayer ceramic capacitors [

15] by the inspection of defects and delamination occurring during the manufacturing process. Even though it is a complex technique, requiring specific skill and experience for operation and interpretation of the results, it still provides some advantages over other available NDT technologies, which makes it an excellent choice in some applications. The possibility to view the internal structure of every sample in a non-destructive manner and to analyze the potential effects of the failure root causes makes SAM an important tool in a wide range of production processes. Defect inspection proved that SAM has high potential in microelectronics packaging [

1,

16,

17] by detecting delamination [

18], voids [

19], and micro-cracks [

20]. High confidence levels of failure localization and the reliability assessment in MEMS sensors [

21] by means of scanning acoustic microscopy have been proved. Moreover, defect visualization in 3D packaging within the potential automatization of SAM for a fast and cost efficient failure inspection was reported in [

22,

23]. During the stages of the manufacturing process of complex and multi-layered structures, delamination can generate failures. These can be avoided by means of reliable material analysis, as determined for pins delamination of plastic-encapsulated microcircuits [

24]. Furthermore, SAM is very useful for the quality and reliability improvement of aerospace products by detecting and eliminating faulty components in the early stages of the manufacturing process [

25]. Experimental determination of the resolution and sensitivity of various transducers with frequencies up to 230 MHz has been conducted in systematic studies using well-defined calibration blocks, showing good agreement with the predicted resolution by diffraction theory [

26,

27,

28].

Nevertheless, there are a lack of studies on damage detection in multi-layered structures composed of silicone, piezoelectric material, and epoxy resins, with an overall thickness in the range 300–700 µm. The authors present the feasibility of a scanning acoustic microscopy able to detect and identify internal defects in US probe acoustic stacks for medical imaging during the manufacturing process. The SAM investigation on a multi-layer structure of a US probe is a challenge. In fact, in a multilayered structure, with a decrease of the thicknesses of around some micro-meters, it becomes increasingly difficult to separate and distinguish echo-signals coming from different layers due to the overlapping of multiple reflections. Furthermore, the highest achievable resolution of SAM is around 1 µm by using high frequency (e.g., 1 GHz) in order to increase the lateral resolution [

29,

30], but the drawback is the limitation of the penetration depth around some microns. In fact, the attenuation obeys a frequency power law [

31,

32], thus when using GHz-SAM, only the volume within a few micro-meters below the sample’s surface can be analyzed.

The aim of this study is twofold. Firstly, this study aims to detect the presence of delamination, non-homogeneous layers, and air voids at micron thicknesses in the bulk of ultrasonic transducers through SAM. Secondly, it aims to predict the quality and faulty units in the middle of the manufacturing process with the purpose of improving the production yield and decreasing the cost of the waste material. Furthermore, the study is focused not only on the inspection and timing capability for each unit under detection but also on the resolution and penetration depth that is able to assess the integrity of US probe acoustic stacks. The ad-hoc setup of the scanning acoustic microscopy and the proper preparation of 24 samples are implemented and discussed. The quantitative analyses by means of SAM are compared with the destructive analysis, i.e., scanning electron microscopy, and with the electroacoustic characterization of the complete acoustic stacks. A comparison between the SAM measurements and pulse-echo test allows for an identification of the root cause occurring during the manufacturing process of US probes for medical imaging.

The paper is organized as follows. In

Section 2, the basics of scanning acoustic microscopy are described.

Section 3 introduces the technical problem on the manufacturing process for ultrasound probes for medical imaging. The experimental setup of the SAM, the preparation of the samples under testing, and the ad-hoc measurement system for the electroacoustic characterization of the products will be discussed in

Section 4. In

Section 5, the results of the tests and the NDT detection efficiency are presented. The discussion follows in

Section 6. The conclusions close the paper in

Section 7.

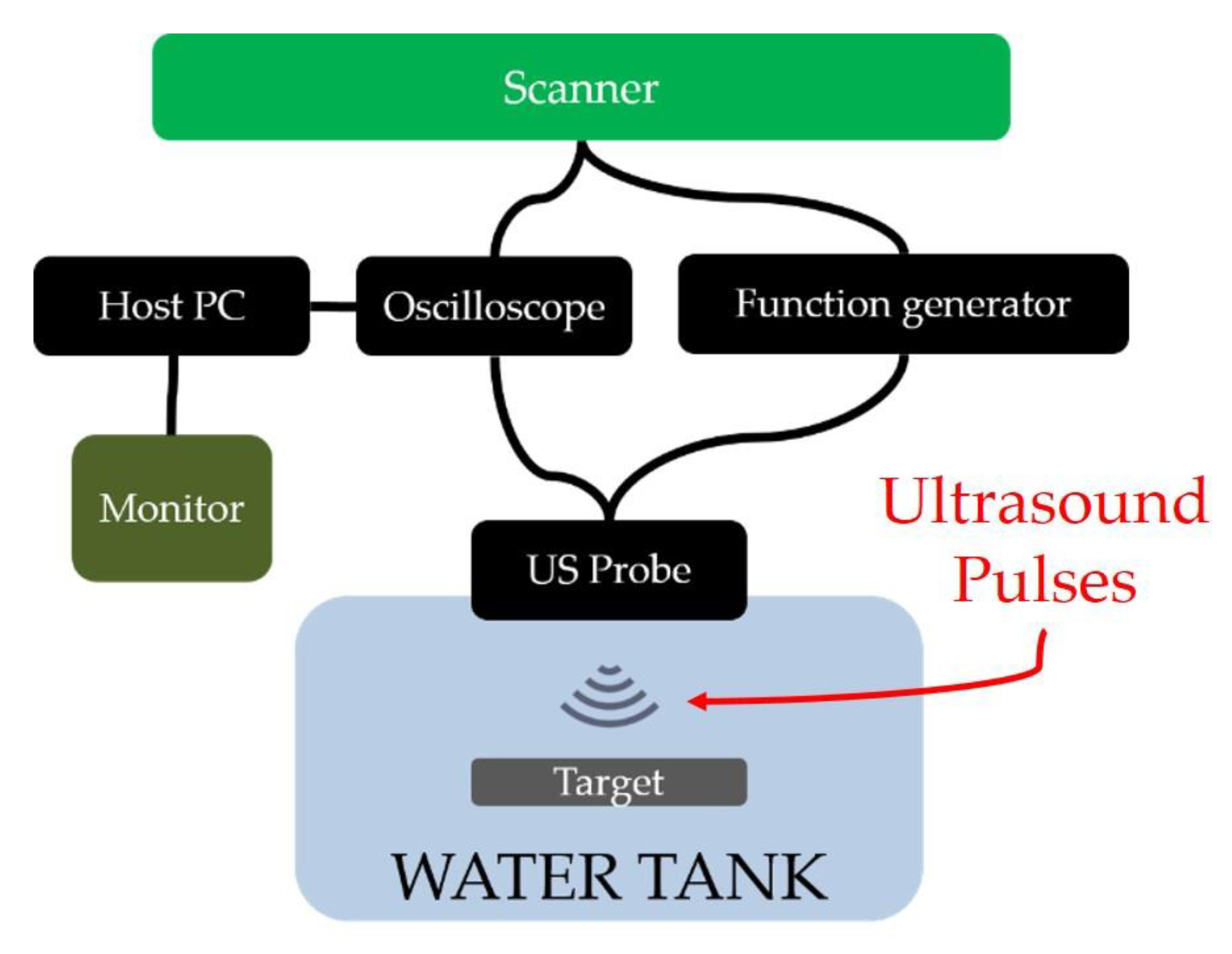

2. Principles of Scanning Acoustic Microscopy (SAM)

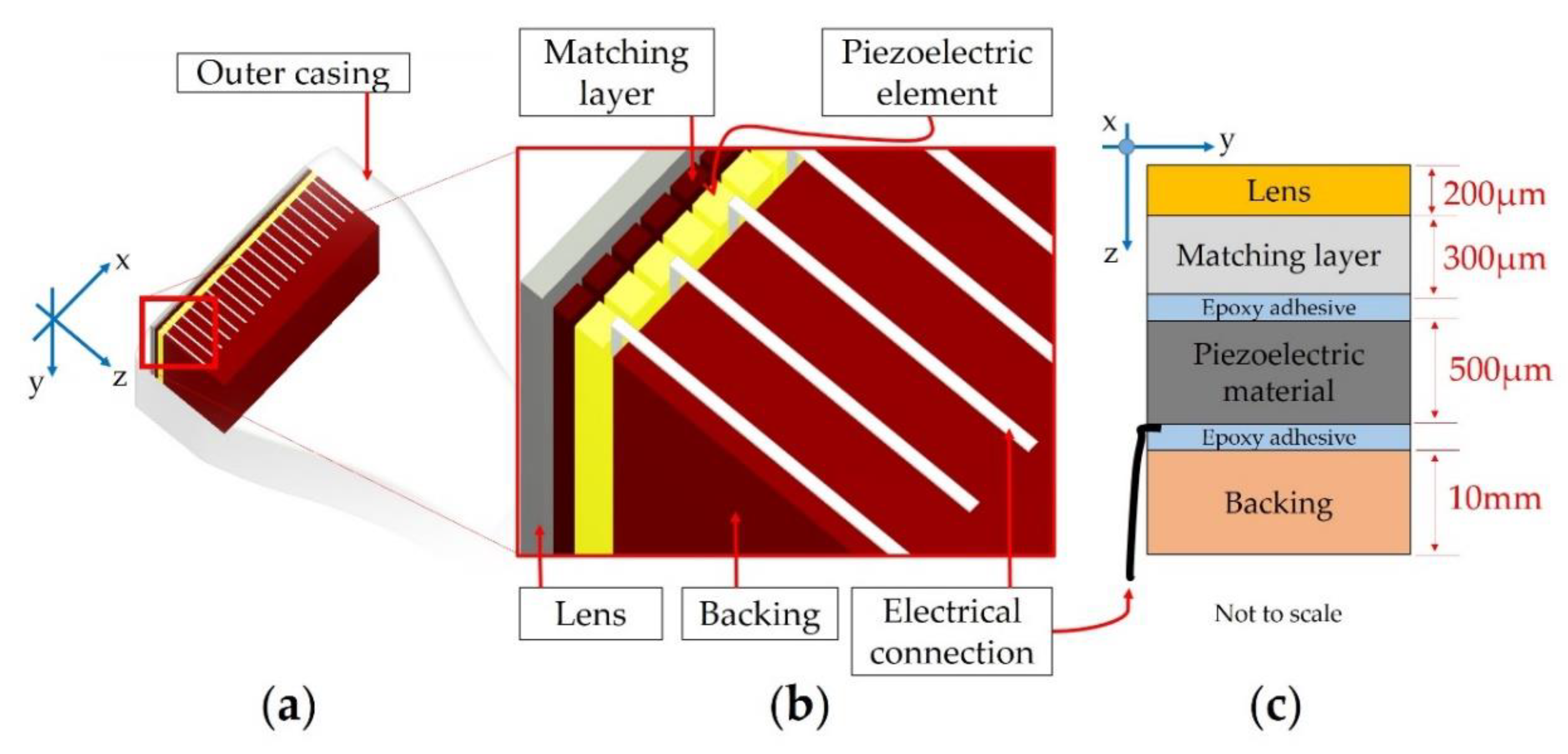

The most important part of a SAM device is the transducer. The latter sends an ultrasonic signal (TX) at a small point on the target object [

1]. The frequency of the ultrasonic signal generated by the transducer is typically in the range 15–300 MHz up to GHz (in the case of high detailed resolution but limited penetration depth). In fact, the resolution and inspection depth of SAM measurements depends not only on the acoustic frequency but also on the transducer’s focal length, material properties, and complexity of the structure of the specimen under testing, in addition to the demanded information [

29].

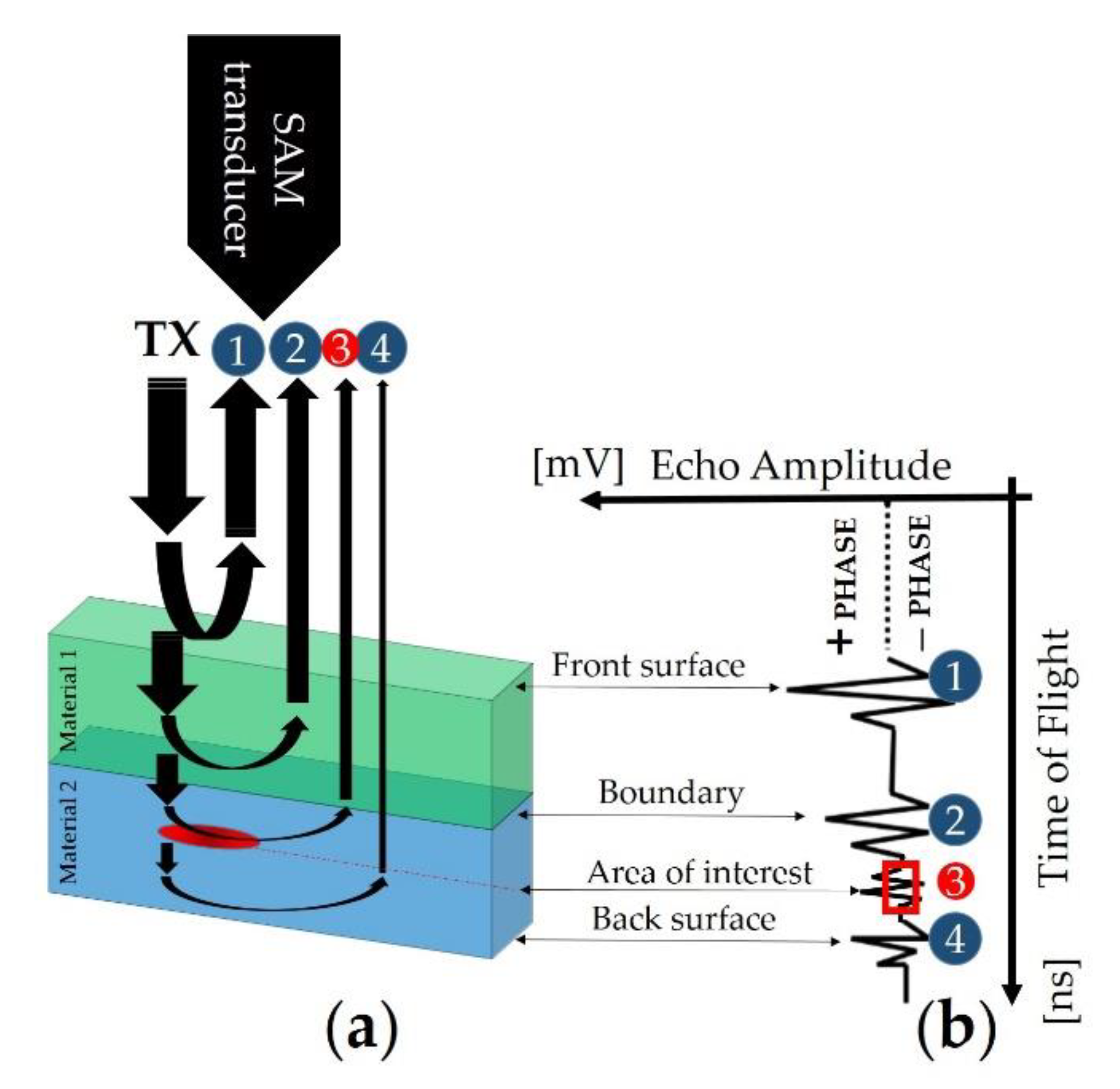

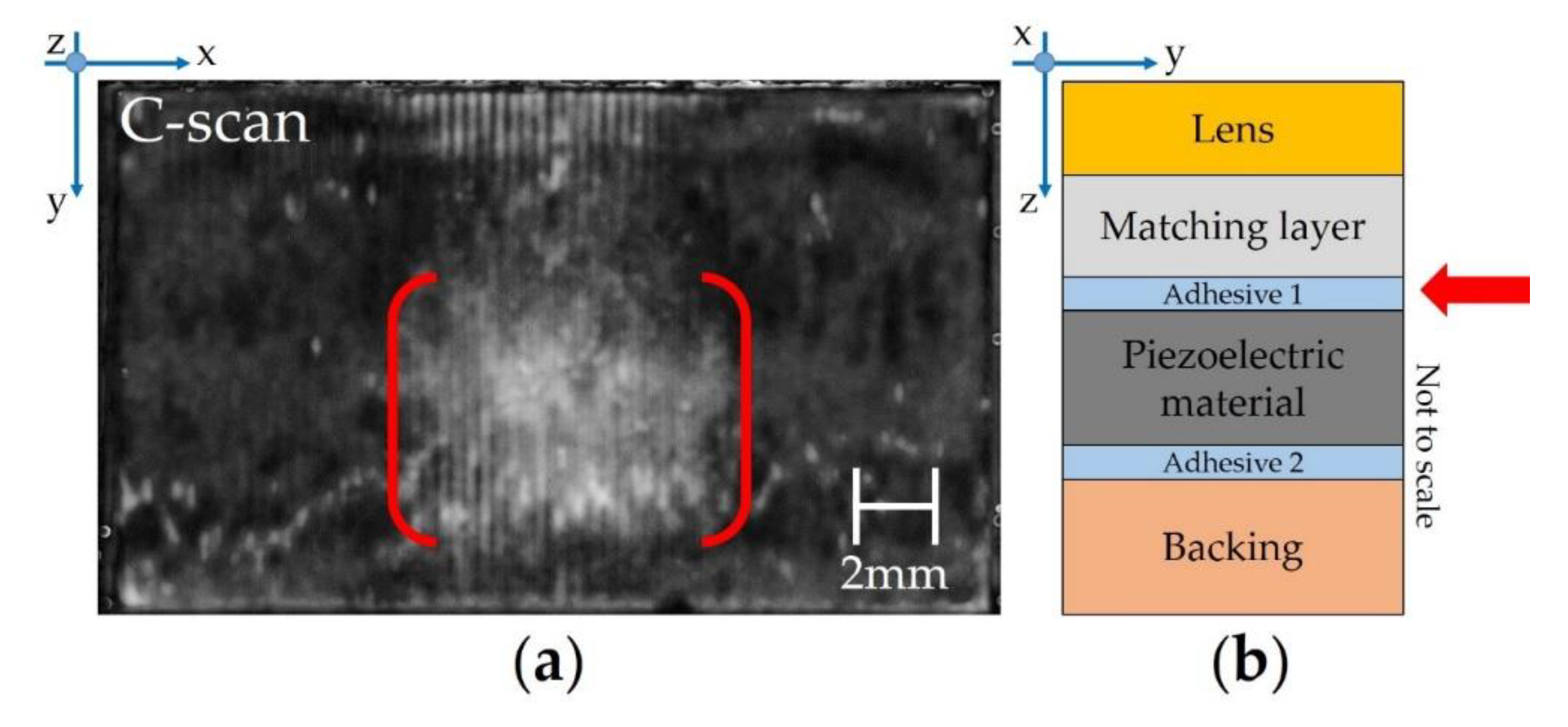

Fractions of the incident acoustic energy by TX are back-reflected when there is a change in the acoustic impedance, Z, (1) between the interfaces of internal materials (

Figure 1a) under inspection:

The index

i is the material type, and

ρ and

υ are the density and the sound velocity of the material, respectively [

33]. The exact portion of the back-reflected amplitude can by calculated by the reflection coefficient,

R, equal to (2):

The higher the impedance mismatch at the interface, the higher the intensity of the reflected signal (more brightness in the 2D image), which is measured by the echo amplitude. In the case of an interface with air (Z = 0), total reflection of the ultrasonic wave occurs; therefore, SAM is highly sensitive to any entrapped air in the sample under testing.

Besides measuring the intensity of the reflected sound wave, the time needed for the detection of the back-reflected wave is also captured and displayed in the so-called A-scan (

Figure 1b). Then, information about the depth (location),

d, of a potential defect in the material bulk can be found by:

in which time of flight (

ToF) is measurable in the A-scan and

c is the sound speed of the material. The division by 2 is explained by the back and forth trip of the sound wave from and to the SAM transducer. In the generic sample structure of

Figure 1a, the sequence of the reflected waveforms (

Figure 1b) is composed of the signal #1 that is commonly referred to as the front surface, i.e., first interface. The same behavior is connected for signal #2 due to the interface between material 1 and material 2. The waveform #3 would be considered the area of interest. The red box (data gate) indicates the depth of information, which is positioned over this signal or group of signals for evaluation. The signal #4 is referred to the back surface that indicates the bottom of the sample. Then, the echo signals are analyzed and processed by considering the location of particles, voids, air bubbles, delamination, or cracks through Equation (3).

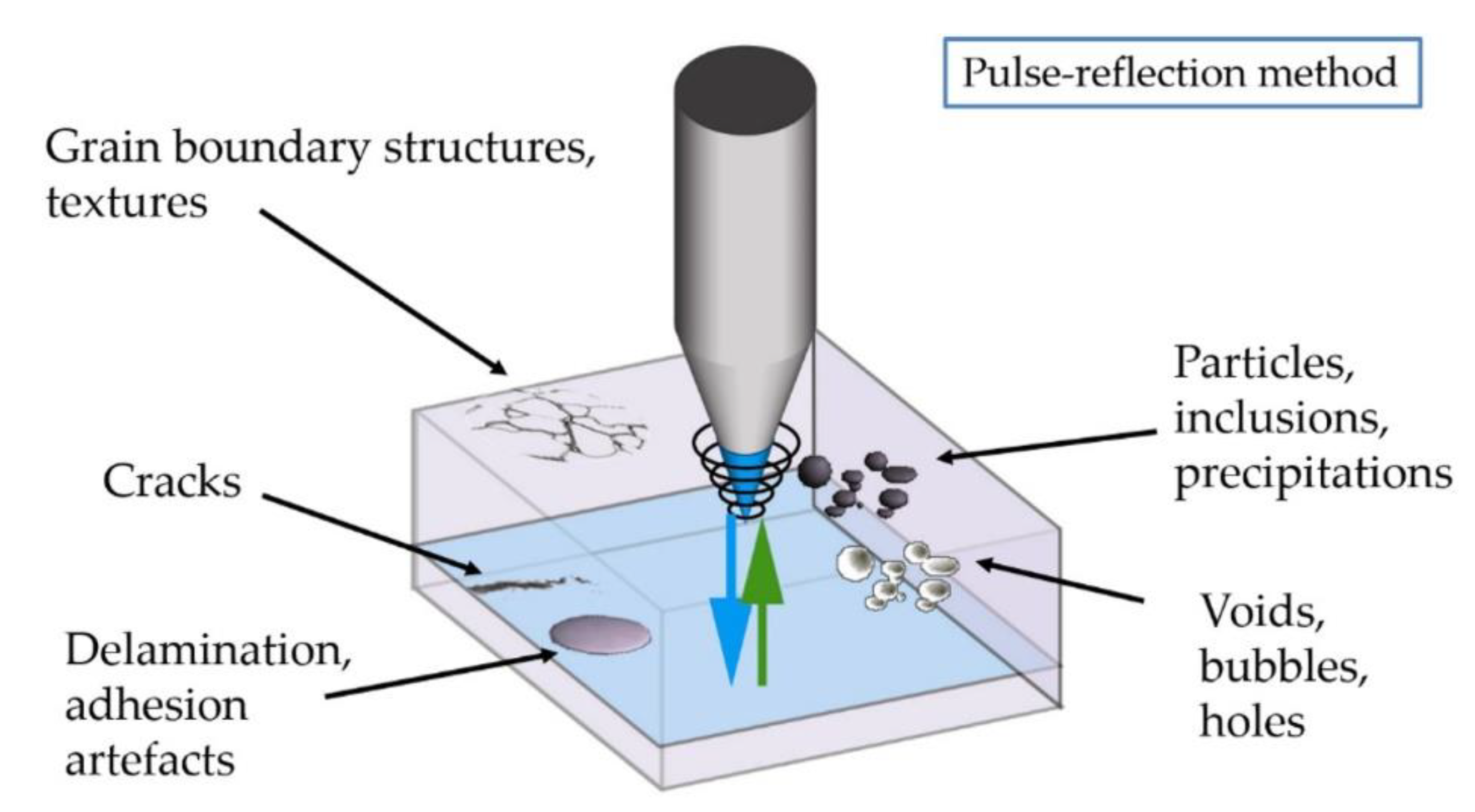

Therefore, 2D or 3D-dimensional images of the internal structure become available by means of the pulse-reflection method, in which the impedance mismatch between two materials leads to a reflection of the ultrasonic beam (

Figure 2). Phase inversion of the reflected signal can allow for discrimination of the delamination (acoustic impedance almost zero) from inclusions and particles, but not from air bubbles, which show same impedance behavior as delamination. In the case of the application of SAM to the US probe acoustic stack, phase inversion can be affected from the multiple reflections occurring due to the multilayered structure, so it is tough to attribute the phase inversion to delamination or bubbles located in deeper interfaces.

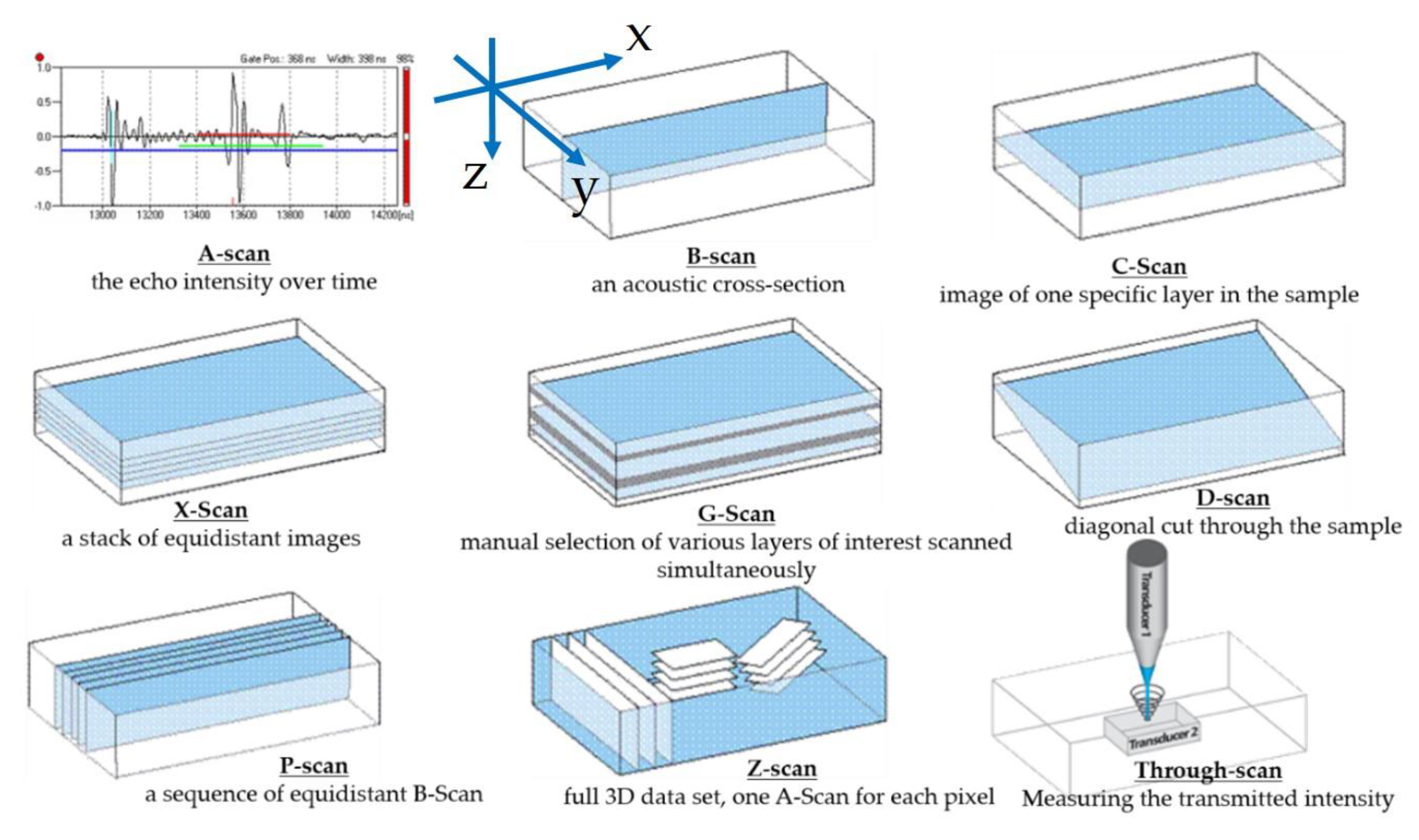

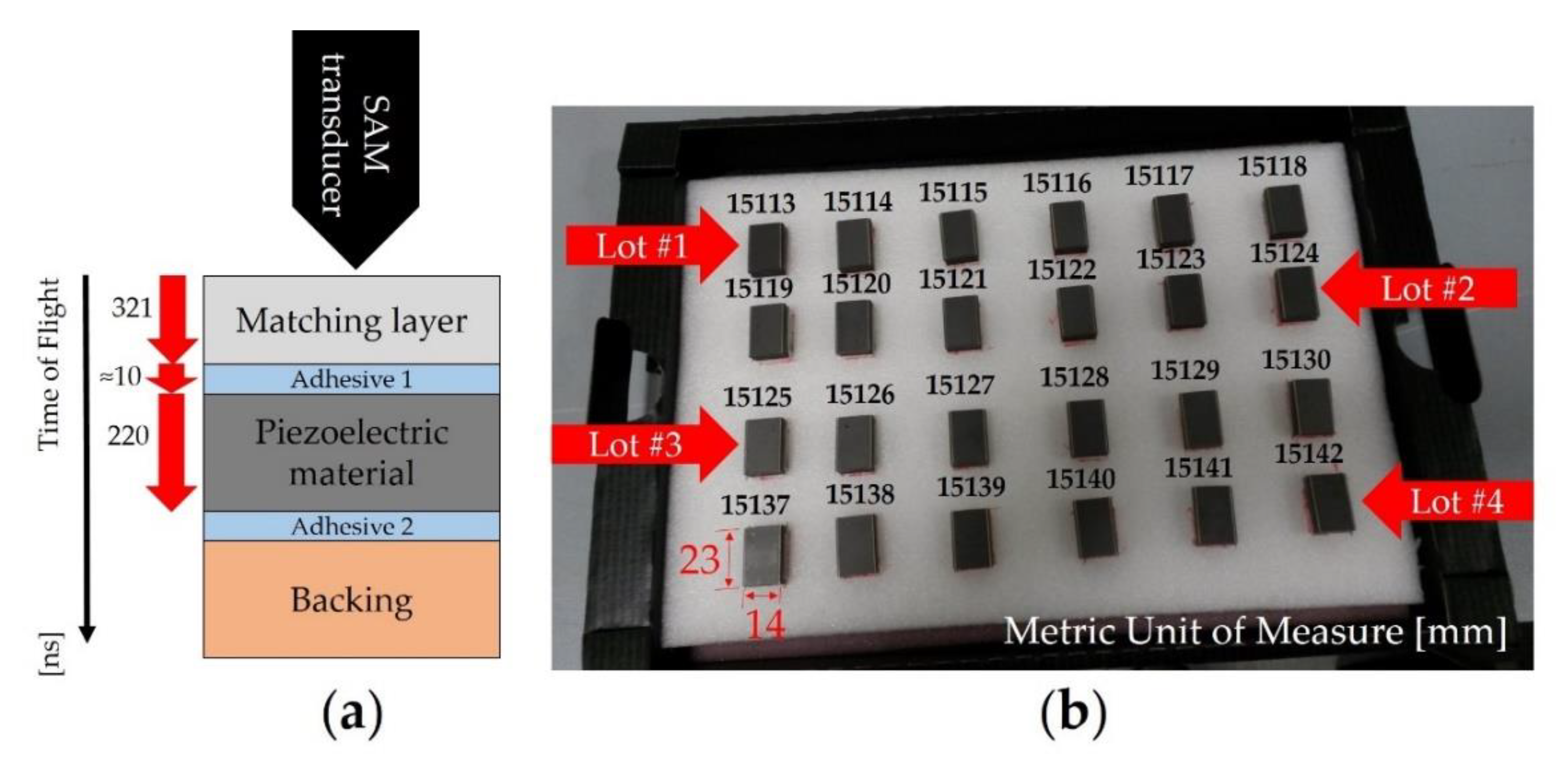

Different types of analysis modes are available in high definition SAM (

Figure 3). The main three modes are A-scans, B-scans, and C-scans. Each one provides different information about the integrity of the sample’s structure. The A-scan is the amplitude of the echo signal over

ToF. The transducer is mounted on the

z-axis of the SAM. It can be focused to a specific target layer located in a hard-to-access area by changing the z-position with respect to the sample under testing that is mechanically fixed. The B-scan provides a vertical cross section of the sample with visualization of the depth information. It is a very good feature when it comes to damage detection in the cross section. A C-scan is a commonly used scanning mode, which gives 2D images (slices) of a target layer at a specific depth in the samples; multiple equidistant layers are feasible through the X-scan mode.

3. Manufacturing Process of US Probes: The Technical Problem

The growing demand for geometrical precision and the guarantee of high process capability by limiting material damage is a continuous task that engineers must chase. The manufacturing process of miniature ultrasound probes for medical imaging requires homogeneous layers with specific thicknesses (from some microns up to 500 µm) by the bonding between materials with different thermal expansion coefficients and densities. Epoxy adhesive is usually adopted to bond the layers in US probes to each other: The thickness of the bonding line must be as small as possible, ideally less than 1 µm (generally less than 4 µm depending on the acoustic stack structure and its operating frequency), and free from air bubbles. The bonding process variability is strongly related to the surface finishing of the materials, deposition techniques, involved operators, and ambient conditions. Furthermore, multi-element arrays are obtained by means of mechanical dicing. The latter is a critical manufacturing process step, and the fundamental requirement of strong and homogeneous adhesion between materials must be satisfied.

The generation of internal defects, e.g., micro-cracks and delamination, or the realization of non-homogeneous layers of epoxy adhesive is not tolerable. The latter can lead to poor quality or failure of the US probe. SAM seems to be an attractive non-destructive testing for the detection of failure during the manufacturing process of US probes combined with less preparation time for the inspection, reducing the costs of scrapped material.

5. Experimental Results

We decided to scan lot by lot by means of X-scan analysis (multiple C-scan generating a stack of equidistant 2D-images) by simulating the potential introduction of this NDT method in the middle of the manufacturing process, in order to detect potential defects in the acoustic stacks and to quantify the cycle time of the SAM inspection for six samples. The complete cycle time for scanning a test batch was about 30 min based on the desired image resolution. Finally, the acquired data were processed. The latter were analyzed, and then the acquired data for inspection were processed.

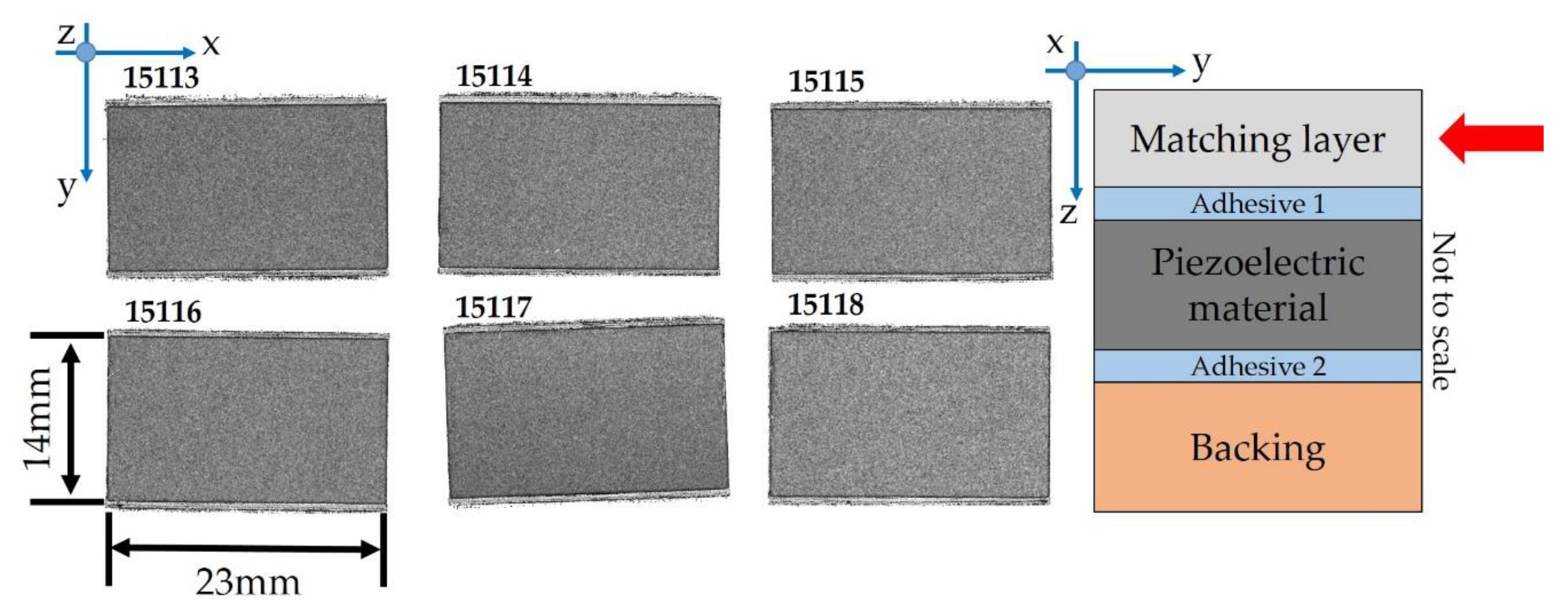

As depicted in

Figure 9, no defect in the matching layer was found.

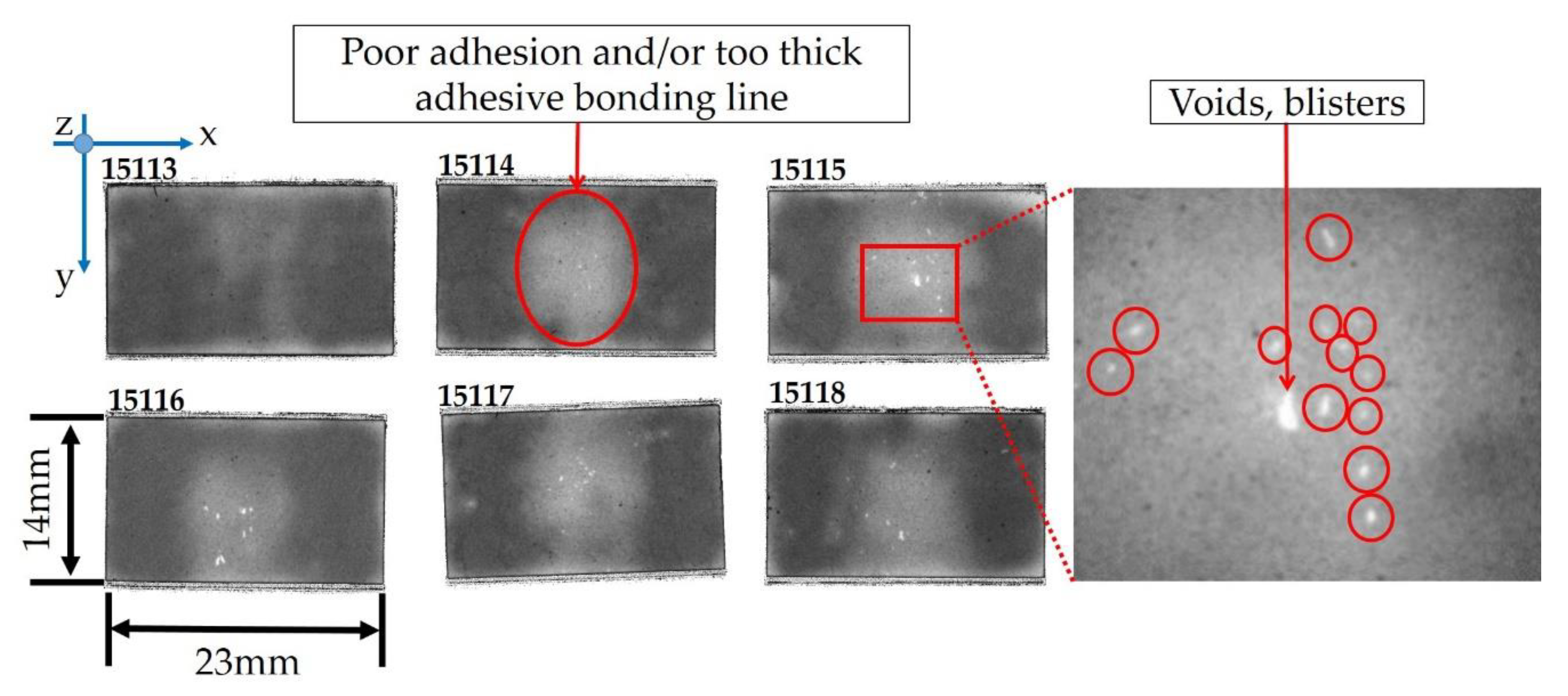

Defects were detected at the bonding line, i.e., adhesive 1, between the matching layer and the piezoelectric material (

Figure 10). By increasing the contrast and reducing the data gate, voids, and blisters (irregular shaped corresponding to the white areas), poor adhesion and/or thicker adhesive bonding line (light grey areas), good adhesion, and/or a layer of epoxy resin with a thickness less than 4 µm (dark grey areas) were shown.

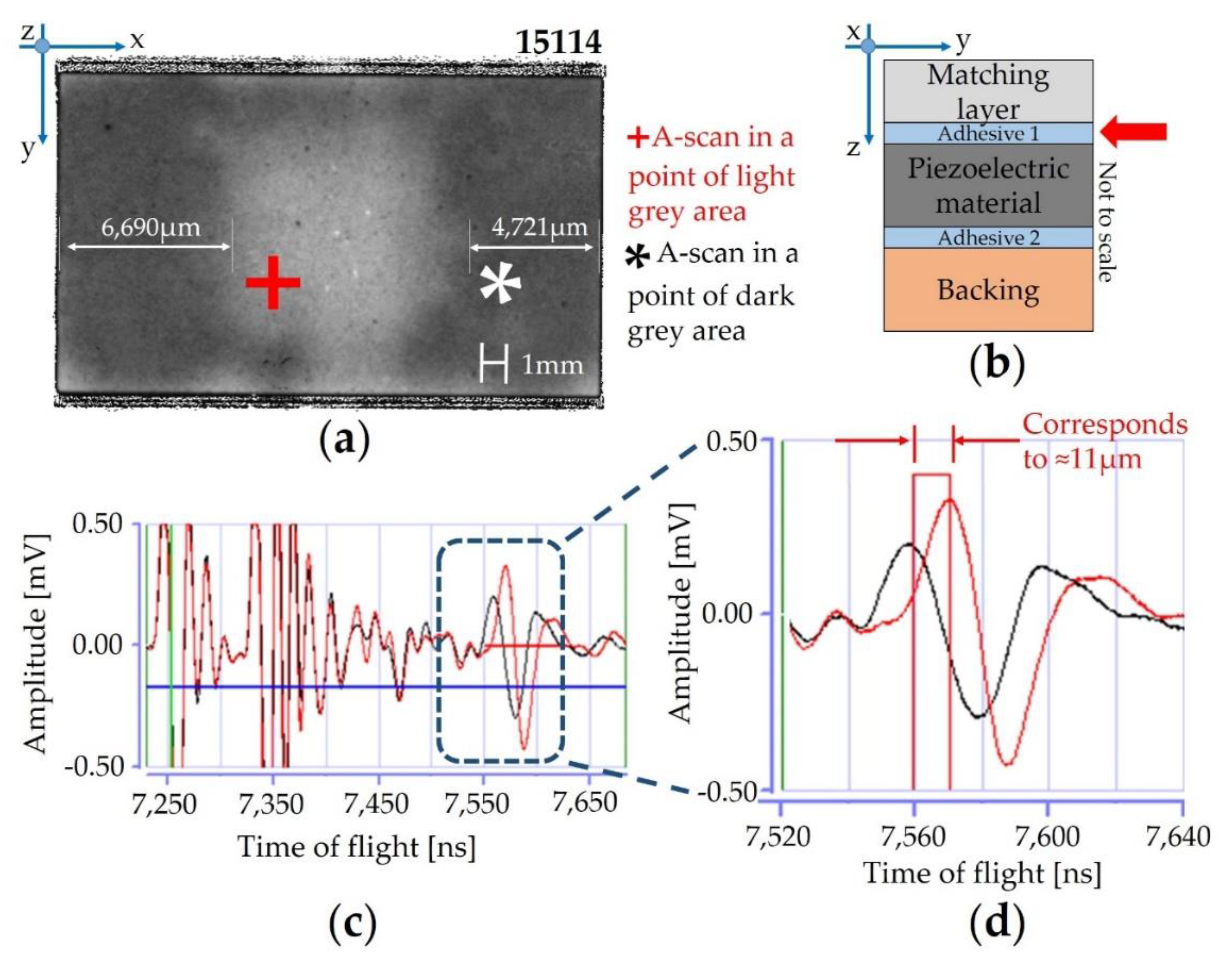

The irregular shape and proximity to each other allowed for the identification of air bubble entrapment recognized as voids (from 10 µm up to 50 µm of dimension) in the central part of the sample (e.g., 15,115), in which poor adhesion or a thicker adhesive bonding line were detected too. In order to analyze in detail the light grey area located in the middle of the acoustic stacks (

Figure 11b), we compared the A-scan signals in two different points of the adhesive 1 area (

Figure 11a).

In fact, two different A-scans were compared to each other with the purpose of understanding better whether the enhanced reflected intensity at the central part of the areas is caused by poor adhesion or by a thicker epoxy bonding line (

Figure 11c): The red wave corresponds to a point in the light area, whereas the black wave corresponds to a point in the dark grey area. The dashed box in

Figure 11c denotes the

ToF position of signals coming from adhesive 1, whereas the red horizontal line corresponds to the data gate that was used to record the C-scan image. The black and red waves are identical before the dashed box (in fact, no defect is recognized in the inner layer, i.e., matching layer), but there is a significant shift in the

ToF-position for the adhesive layer. The red wave form (

Figure 11d) is shifted to greater

ToF values with respect to the black wave, proving that the light grey area of adhesive layer 1 is thicker than the dark grey area. The thickness difference between the two points was measured around 11 µm (

Figure 11d) by considering Equation (3) and using 2000 m/s as the speed of sound of the epoxy resin that makes up adhesive layer 1.

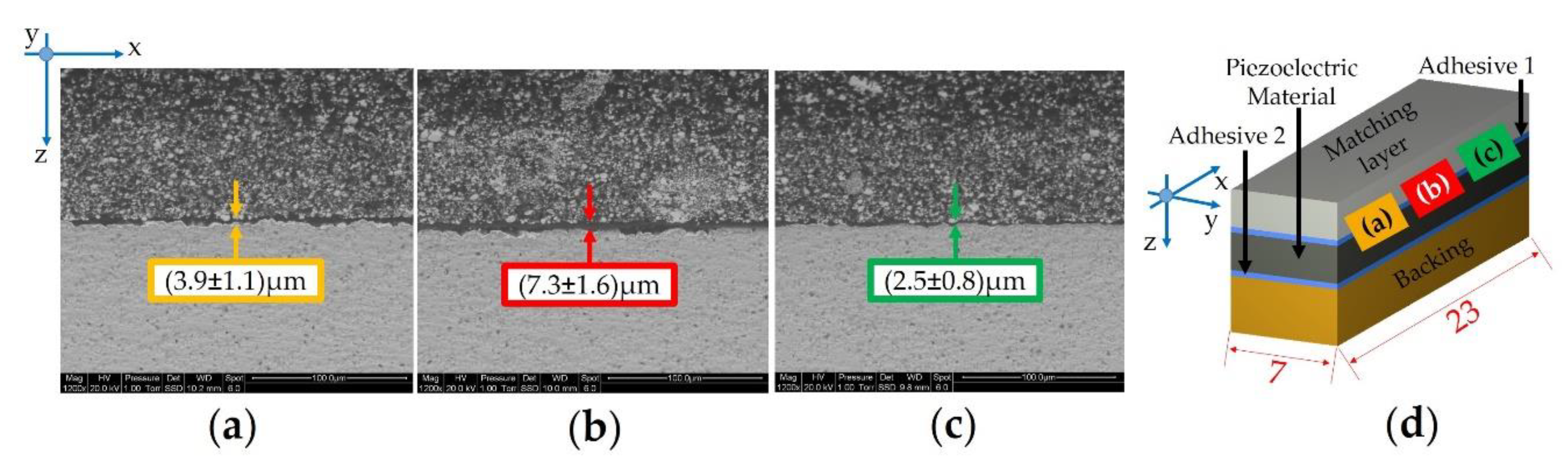

In order to prove this significant difference in the thickness of adhesive 1, a cross-section of sample 15,114 was prepared as a metallographic specimen before inspection by means of SEM (FEI Quanta 200—Hillsboro, OR, USA) (

Figure 12d). The morphological analysis revealed different thicknesses affected by a high standard deviation for the adhesive 1 layer, due to the high roughness of the PZT-based material. By the way, the difference between the thicker adhesive bonding line (

Figure 12b—central area) and the peripheral layers (

Figure 12a,c) is really significant (3–4) µm. Within the aim of understanding the entity of the non-homogeneous thickness of adhesive 1 layer, advanced signal processing techniques are essential to extract features in detail, which are not easily discernable from measurements. The data post-processing provided by A-scan analysis enhances the capabilities of the SAM method, allowing for measurement of the sample area fraction with thicknesses greater than 4 µm. In this context, the fraction of the scanned area with blisters (voids) was available. After the SAM scans on the overall lots, all the acoustic stacks were completed by executing the expected manufacturing routing to obtain the final US probe’s configuration.

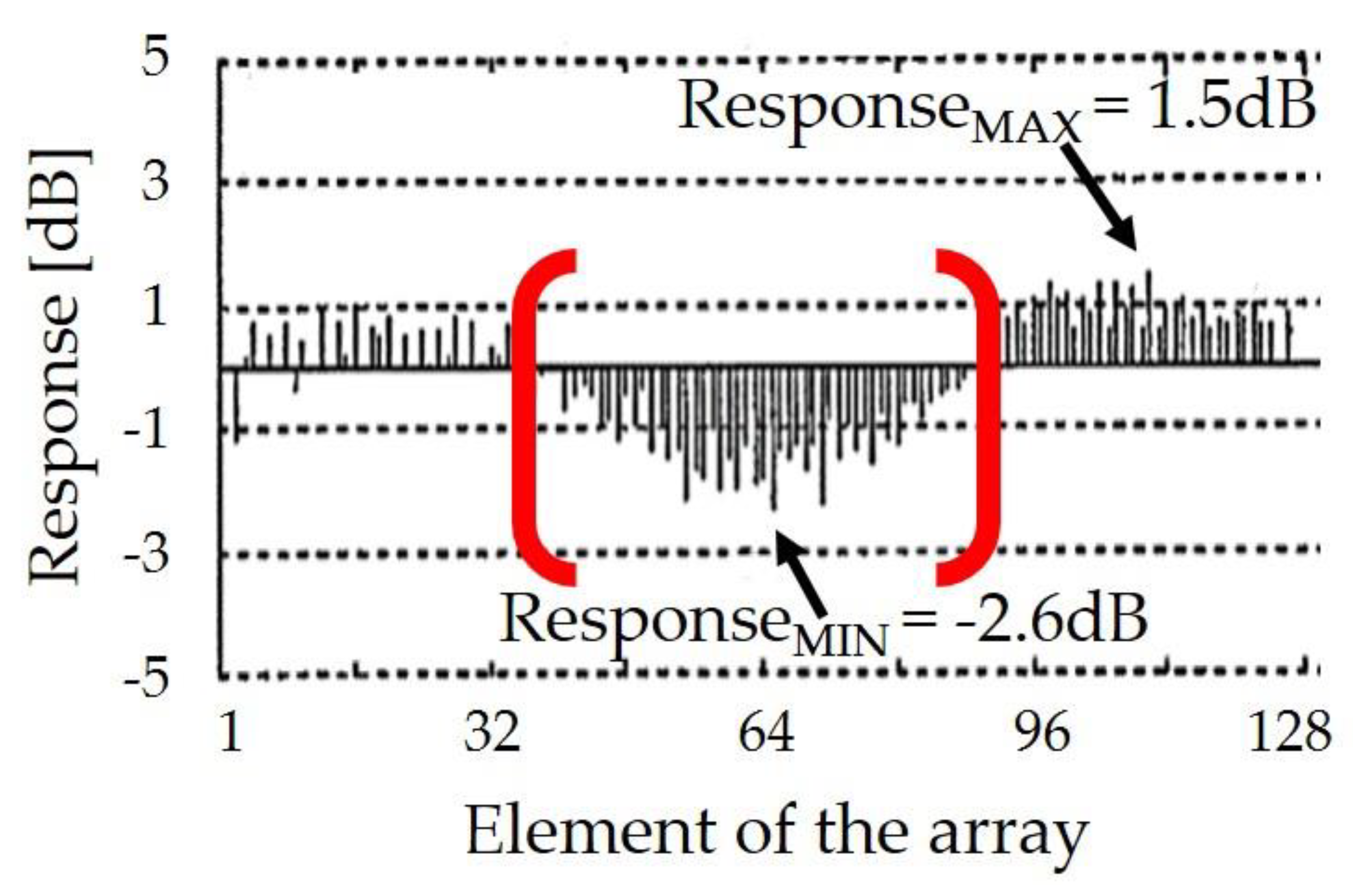

The samples were characterized by means of the measurement system (

Figure 7) and the relative Δ

Response are shown in

Table 1.

A very high Δ

Response (21.8 dB) was measured for sample 15,126, in which the potential root causes can be found in the delamination between the adhesive 1 layer and the matching layer. A comparison between the 2D images by SAM of adhesive 1 with different characteristics and the relative pulse-echo tests is provided in

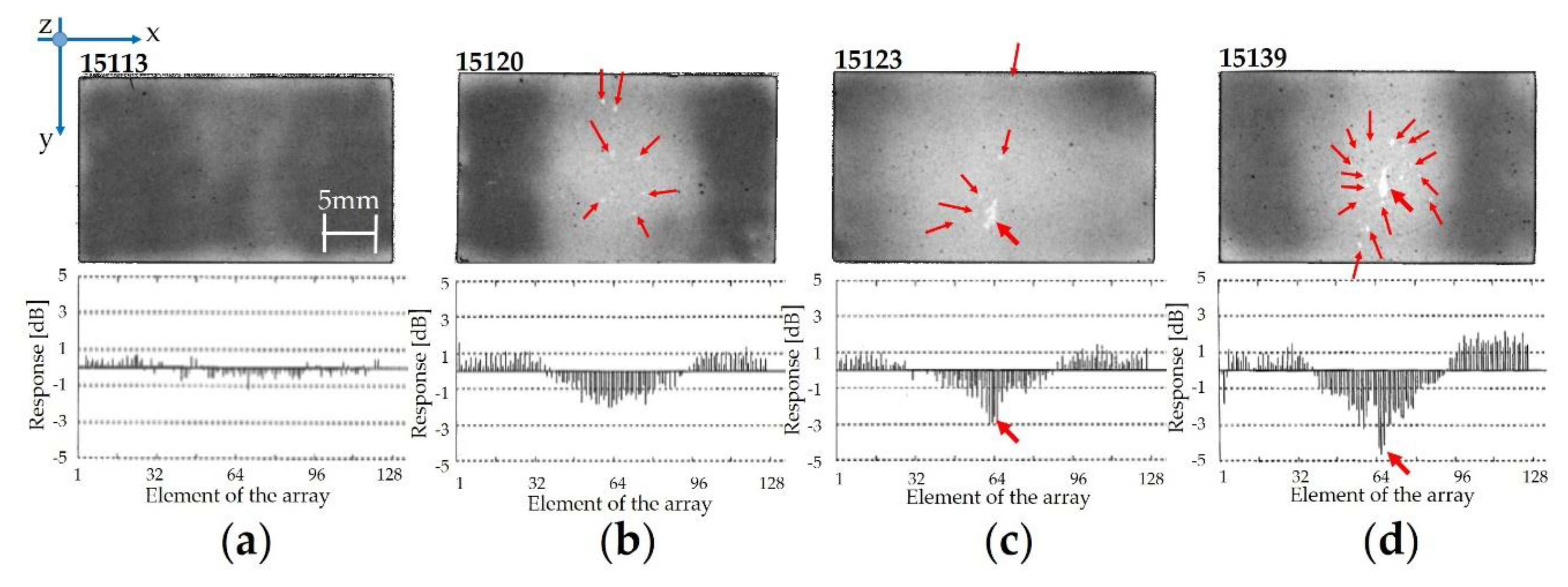

Figure 13.

In

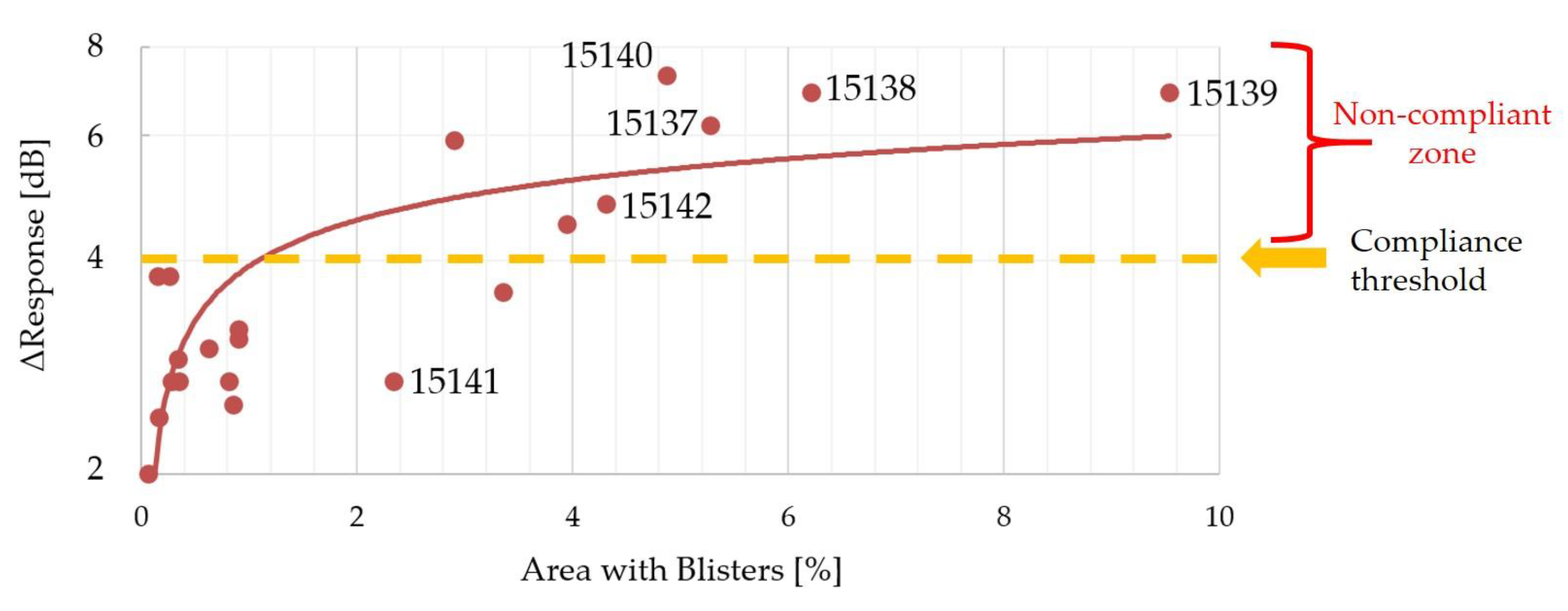

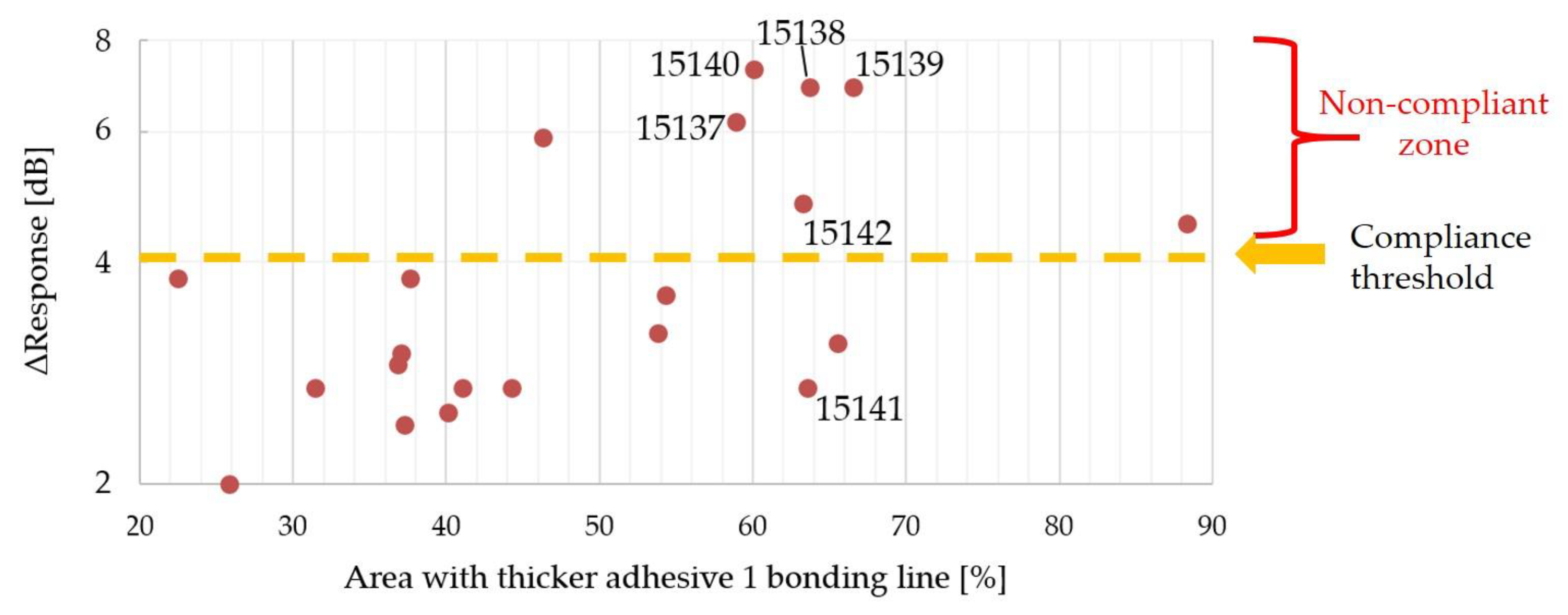

Figure 14 and in

Figure 15, the Δ

Response versus the area with blisters and the area with a thicker adhesive bonding line are shown.

The two diagrams collect the data for 21 samples, instead of 24 samples, because sample 15,113 was considered as an outlier (scrap) due to the very high Δ

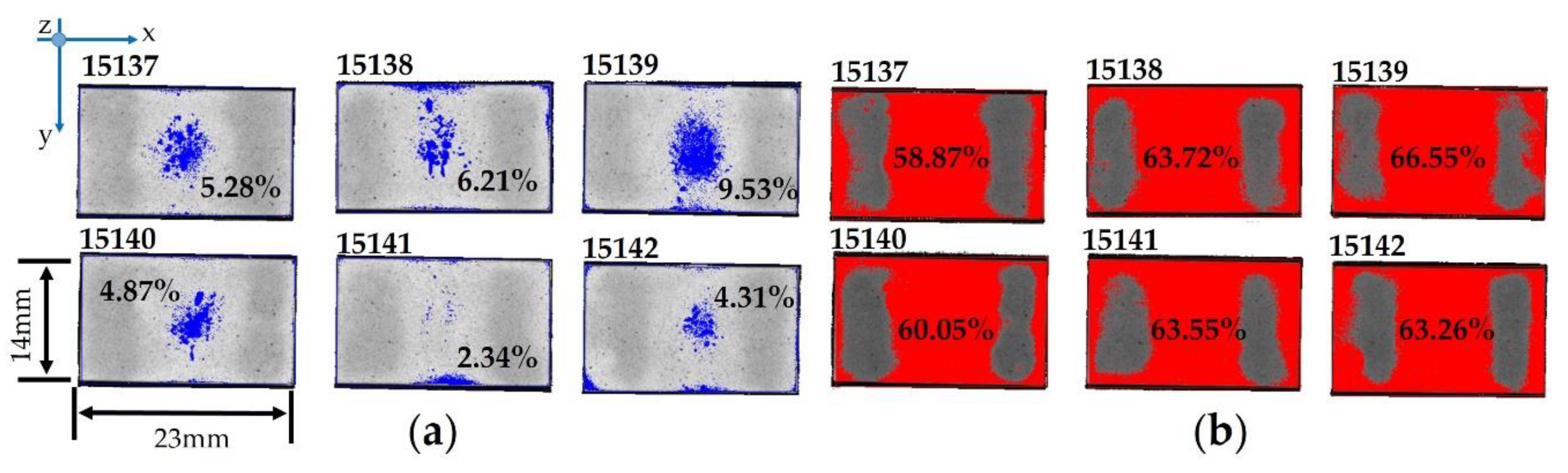

Response (21.8 dB), 15,114 was analyzed by destructive testing, i.e., SEM, and 15,130 was scrapped for other root causes due to the handling operations. In particular, lot #4 (from 15,137 to 15,142) is affected by some defects, especially in the central part of the epoxy resin layer (

Figure 16), in which blisters filled with air (blue color) are not negligible. At the same time, the difference in bonding line (red color) is considerable.

6. Discussion

The measurement of the cross section for the thicker bonding line (

Figure 12b) did not match the thickness difference of 11 µm estimated by means of SAM, likely due to the uncertain sound velocity adopted for adhesive 1. Furthermore, the

ToF measurement is affected by the thickness variation of all the layers that comprise the sound path. These reasons explain the difference between the SEM and SAM results. However, SAM scans revealed that the deposition of epoxy resin is not homogeneous, and the thickness of the epoxy resin in the central area of the layer is greater than 4 µm, which is considered the reference.

In

Figure 13, the Δ

Response for the acoustic stacks is considerable depending on the

Responses of each piezoelectric element, in which samples 15,123 and 15,139 are affected by very low values in the central part of the array.

Figure 13a corresponds to the best case thanks to the homogeneity of adhesive 1 (large dark grey area) without blisters, in which Δ

Response is very low (2.0 dB).

Figure 13b shows a not-negligible non-homogeneity for the adhesive 1 layer with a high fraction of the thicker bonding line (around 54%). Despite the presence of some blisters (red arrows), which affect the central area of the sample (3.36%), the Δ

Response (3.6 dB) complies with the quality requirements (less than 4.0 dB). On the other hand, sample 15,123 (

Figure 13c) is affected by the greatest area fraction of the thicker bonding line (88.32%) and the entrapped air bubble fraction is around 4%. This case leads to a high Δ

Response (4.5 dB). The blister fraction (9.53%) and the thicker adhesive 1 bonding line fraction (66.55%) contribute to a Δ

Response of 6.9 dB (

Figure 13d). This latter represents one of the worst cases and it is not acceptable from the quality point of view.

The crucial requirements for an in-process inspection system can be listed as proper data acquisition, accurate data processing, suitable user interface, flexibility of the operation, and effectiveness of the information on the specimen under testing. Therefore, SAM inspection in the middle of the manufacturing process can predict the poor quality and potential failure of an acoustic stack under construction. The discussion on

Figure 14 identifies that some samples with blister fractions less than 2% have a Δ

Response value that is less than the threshold (4 dB—orange dashed line), which is in compliance with the internal requirements. On other hand, the logarithmic trend (red line) grows more and more for the area with blisters greater than 2%, leading to the poor quality of the acoustic stacks (Δ

Response over 4 dB). As regards

Figure 15, better results are obtained for areas with a thicker epoxy bonding line less than 45% (all ultrasonic transducers are in compliance with the threshold of 4 dB). The Δ

Response does not show a specific trend, but by considering the area fraction with a thicker bonding line greater than 45%, the number of non-compliant acoustic stacks is seven: These scraps are not sustainable especially when the continuous improvement of the manufacturing process must be developed in a more and more intense competitive scenario by reducing the cost of the poor quality. The simultaneous presence of blisters and a great area fraction of thicker epoxy resin (

Figure 16) leads to a non-compliant manufacturing process for the adhesive 1 layer. In this analysis, it is important to underline that sample 15,141 (in compliance with the Δ

Response) is affected by the very high fraction (63.55%) of the thicker bonding line, but the low fraction (2.34%) of the blisters and their location (close to the edge) will open a large discussion and study about the cross-correlation between defects that affects the acoustic stack.

The failure analysis by means of SAM showed that the issue of US probes’ manufacturing process is primarily due to blisters between the piezoelectric material and matching layer, mostly occurring in the central area of the array. Blisters generate poor quality in the production of US phased array probes, in which the ΔResponse is greater than 4 dB. The thicker epoxy resin in the central part of the array and the non-homogeneity of the adhesive 1 are evident by SAM analysis: These two factors contribute to a non-compliant value of ΔResponse and lead to a limited process capability by considering this response.

In this context, the reduction of the area with blisters (less than 2%) and the thicker adhesive 1 bonding line (less than 45%) is essential for improving the US probes manufacturing process. Thanks to the accurate and detailed failure analysis by means of SAM, the root cause of the problem of the manufacturing process was identified and a strategy for the solution can be efficiently driven.

7. Conclusions and Future Developments

This work dealt with the detection and the visualization of defects on US probes for medical imaging by means of scanning acoustic microscopy. This non-destructive testing technique, using a transducer with a frequency of 30 MHz and focal length of 13 mm, led to the detection of blisters as defects in the micrometer range with irregular shapes and located close to each other. In particular, the phase inversion, time of flight, and amplitude of the reflected signal are important factors that allowed for discrimination of entrapped air bubbles (voids) with respect to delamination, inclusions, and particles. The SAM technique can measure the fraction of the non-homogeneous thickness of an epoxy adhesive greater than a specific reference (4 µm), located in the bulk of the acoustic stacks under test. The electroacoustic characterizations of the complete US probe structures allowed a comparison of the NDT analyses implemented in the middle of the manufacturing process by means of scanning acoustic microscopy. In fact, the areas of the bonding layer with blisters greater than 2% and a thicker epoxy bonding line greater than 45% led to a poorer quality and failure of an acoustic stack under construction. To this end, the measurements by means of SAM allowed for identification of the root cause in the manufacturing process of US probes as well as an evaluation of the quality of the bonding layer. Therefore, SAM is a robust technique that provides an efficient solution for quick identification and location of defects in multi-layered structures (up to 5 min for each piece under test), enabling efficient failure analysis to predict the integrity of US probes. Manufacturers of ultrasound probes and multilayered structures (i.e., silicon wafers) with thicknesses of some microns will find the SAM technique very useful for the continuous improvement of the process capability and product quality. A drawback can be recognized by the immersion of the device under testing in water, with the consequence that it dries the product immediately after testing to avoid the activation of galvanic corrosion or oxidations. Therefore, SAM is not recommended for non-hermetic packaging in electronics.

Many efforts will be addressed to implement corrective actions, with the priority being the elimination of blister creations during the bonding process between the matching layer and piezoelectric material. Secondly, the epoxy-based adhesive application will be studied, in order to deposit and realize a homogeneous and compliant layer by limiting the thickness up to 1 µm (best case). The lack of non-destructive in-process inspection during the manufacturing process can be overcome by means of this technique.

Future developments will investigate the factors that can affect the blister phenomenon during bonding, i.e., roughness of the piezoelectric material, adhesive type, and surface modification for better bonding under vacuum. The study will be focused on the significant factors, in order to optimize the best solution for increasing the process capability and the quality of the acoustic stacks. By considering the SAM capability (the device allows for a large field of scan of 320 × 320 mm), around 200 samples can be processed, with one providing non-destructive quality control of the ultrasonic transducers with a fast inspection throughput (less than 3 h). Based on these features, SAM becomes a special technique that is very useful for in-line inspection during the manufacturing process of US probes, and also for new product development during the design stage.