Perturbation Analysis of a Multiple Layer Guided Love Wave Sensor in a Viscoelastic Environment

Abstract

1. Introduction

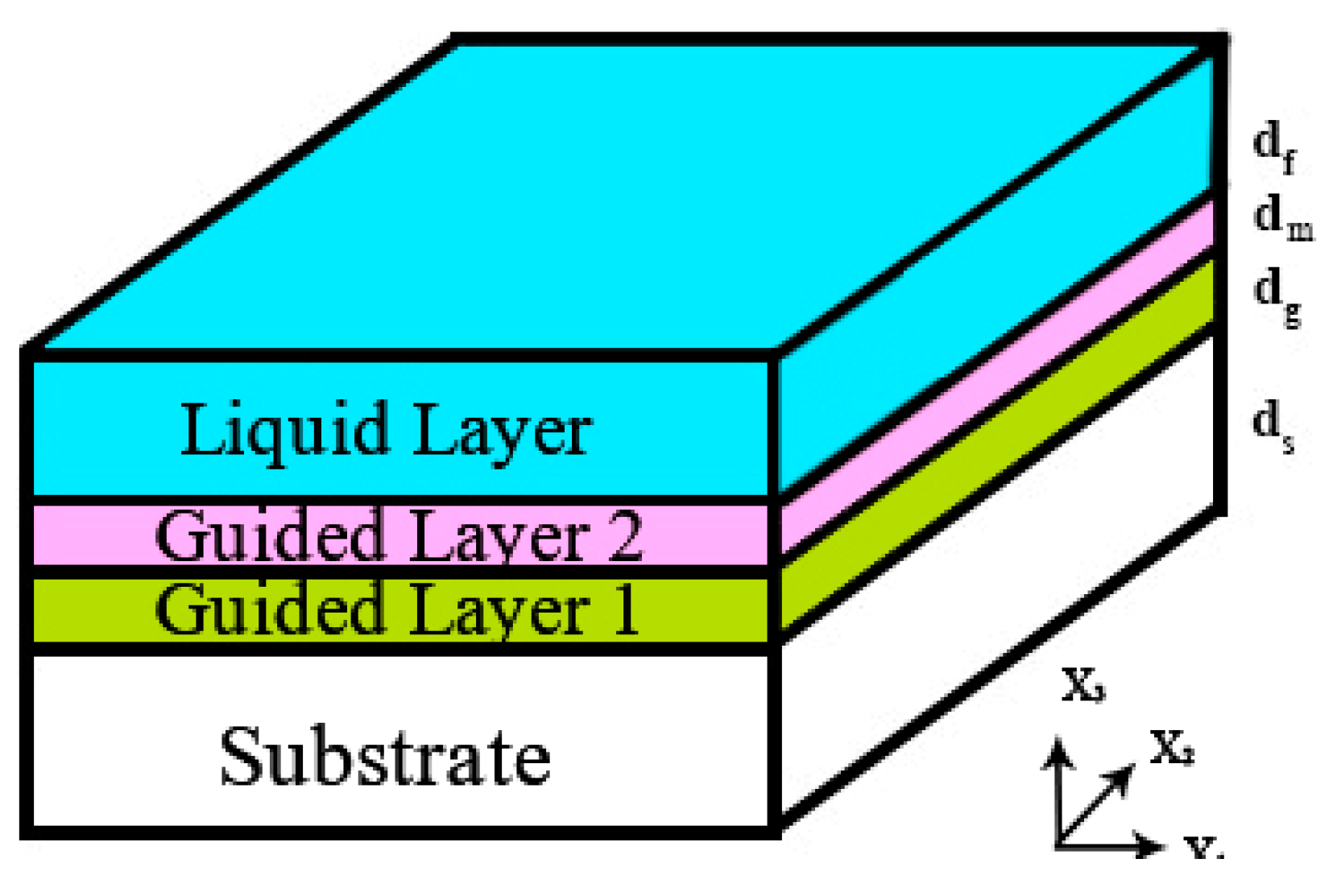

2. Analytical Modeling

3. Results and Discussion

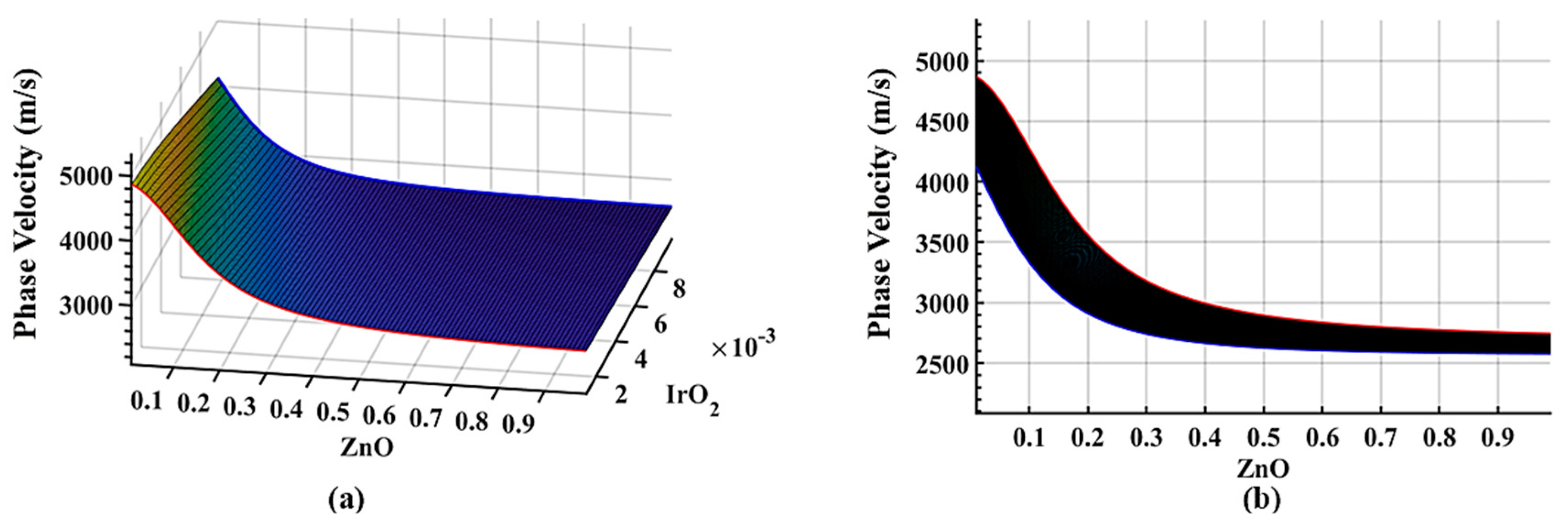

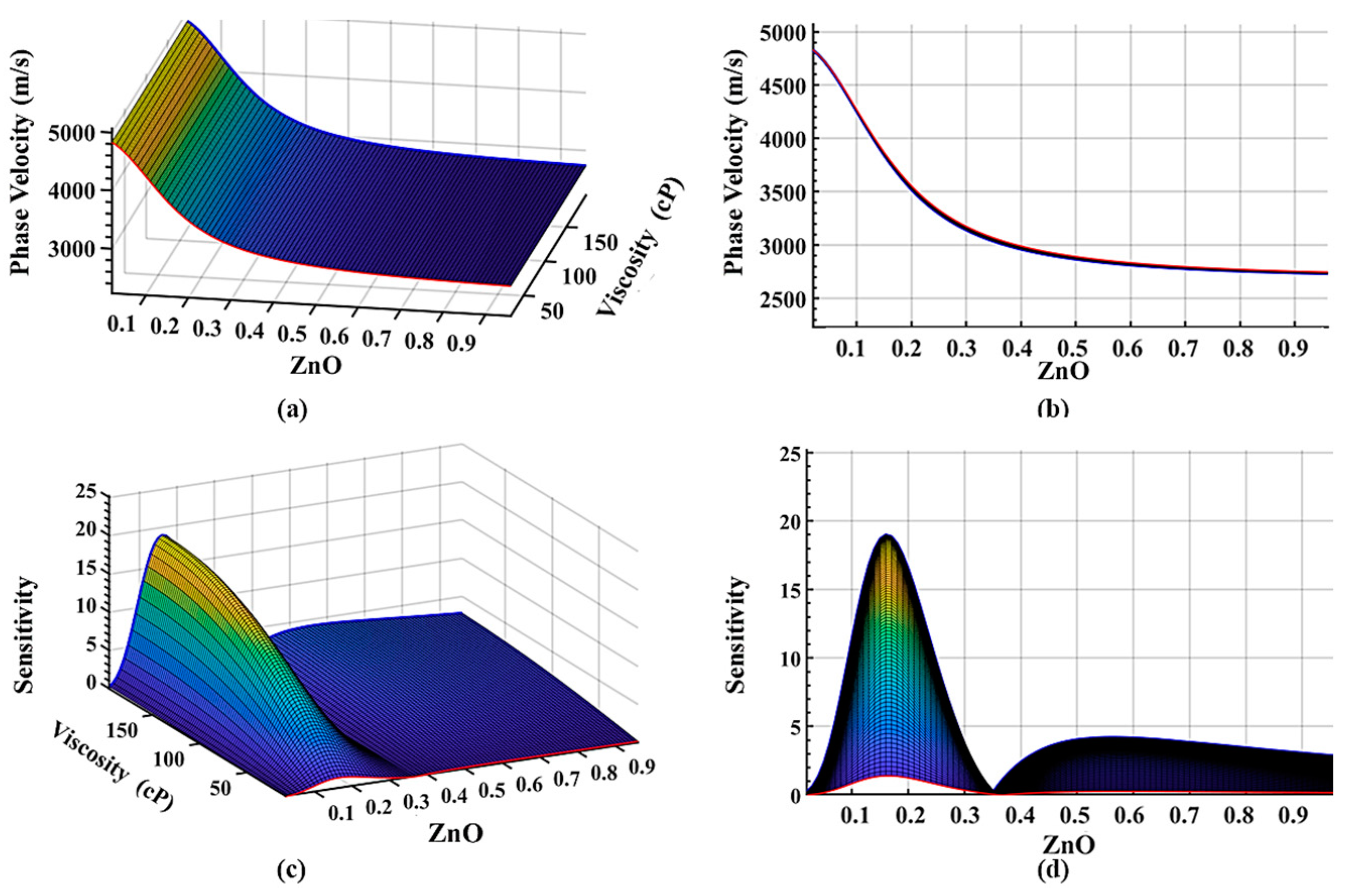

3.1. Second Guided Layer Material Effect on Phase Velocity and Sensitivity

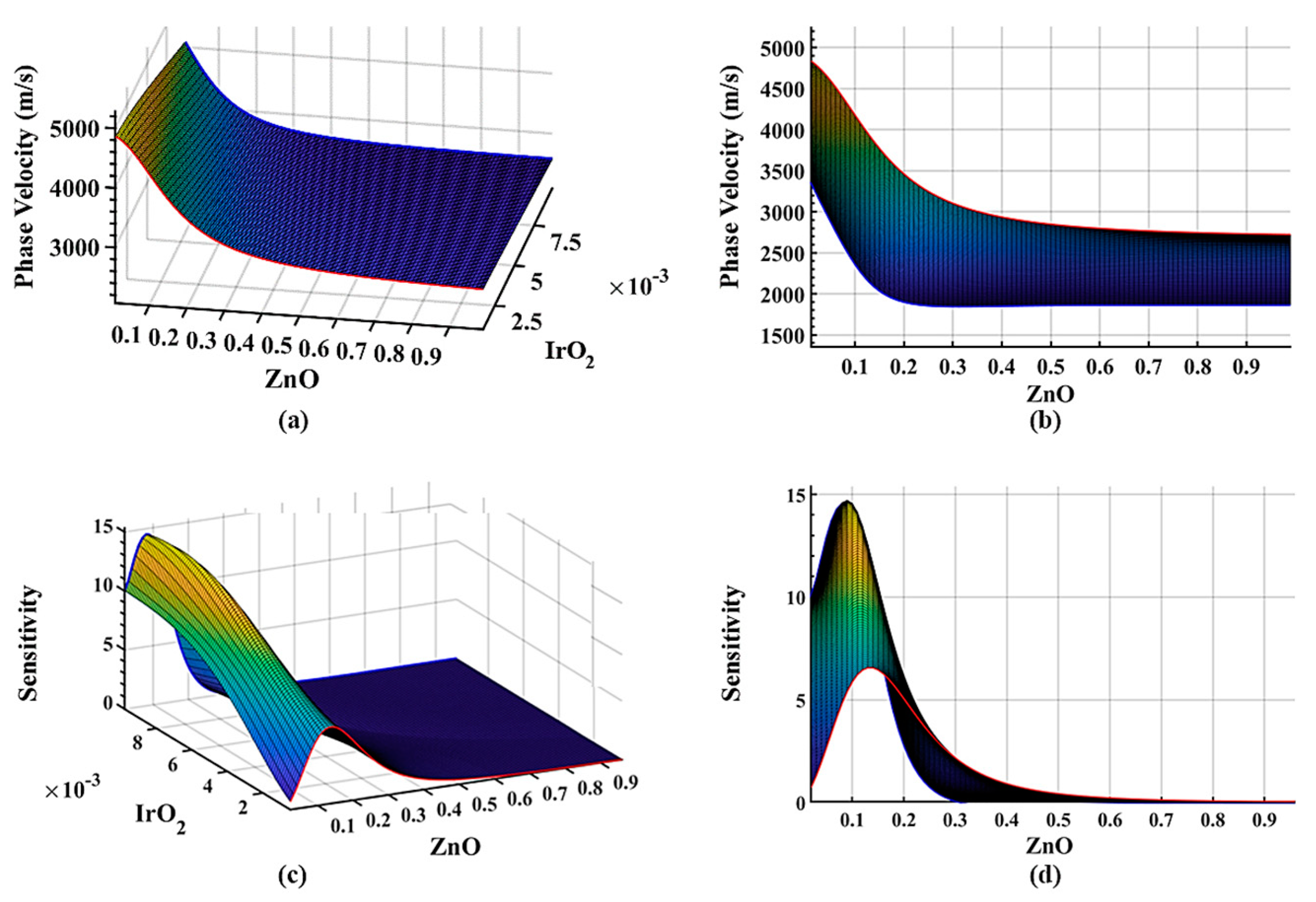

3.2. Fluid Layer Material Effect on Phase Velocity and Sensitivity

3.3. Viscosity Sensitivity of the Four Layer Structure

3.4. Verification of The Mass Sensitivity on Multilayer Structure

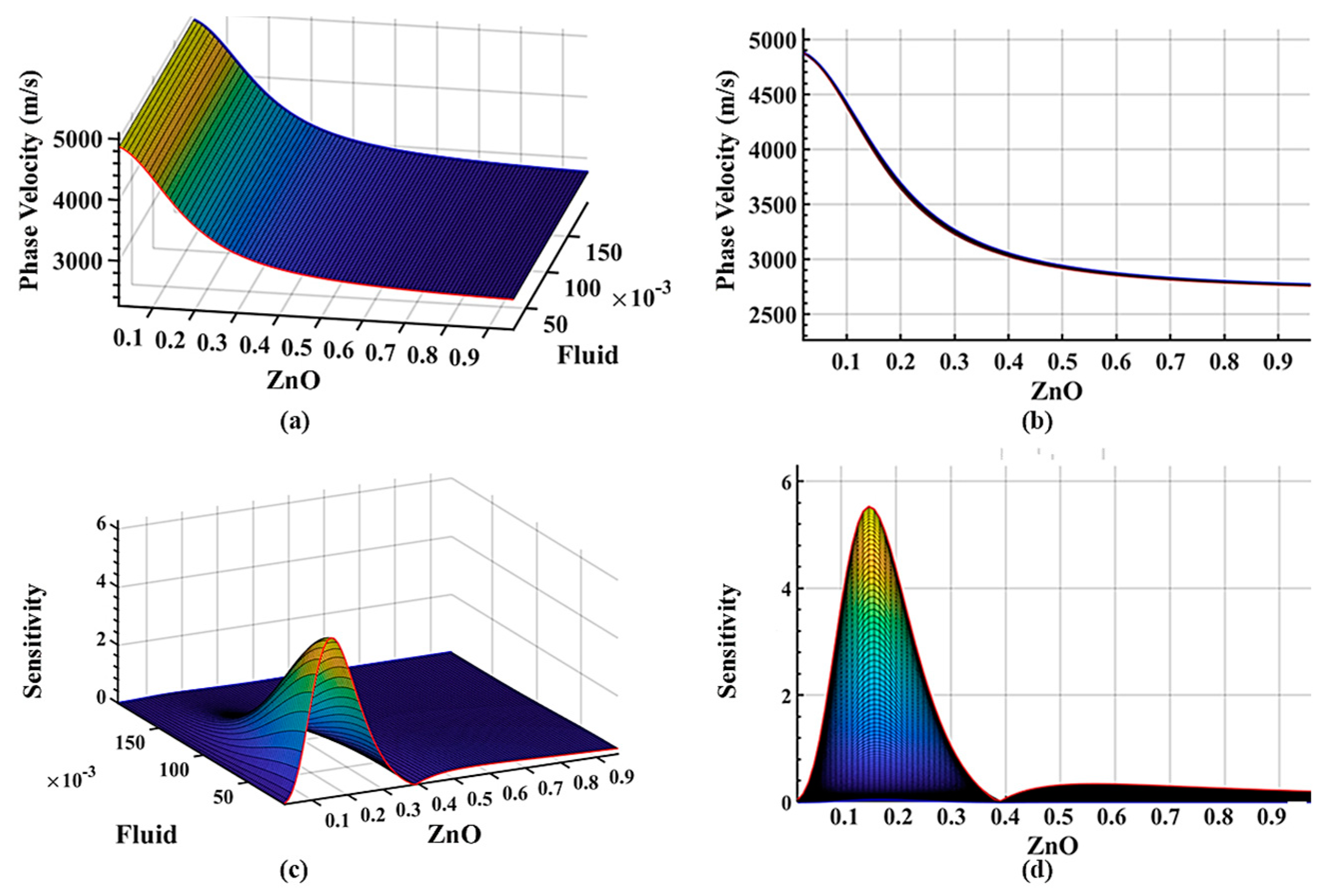

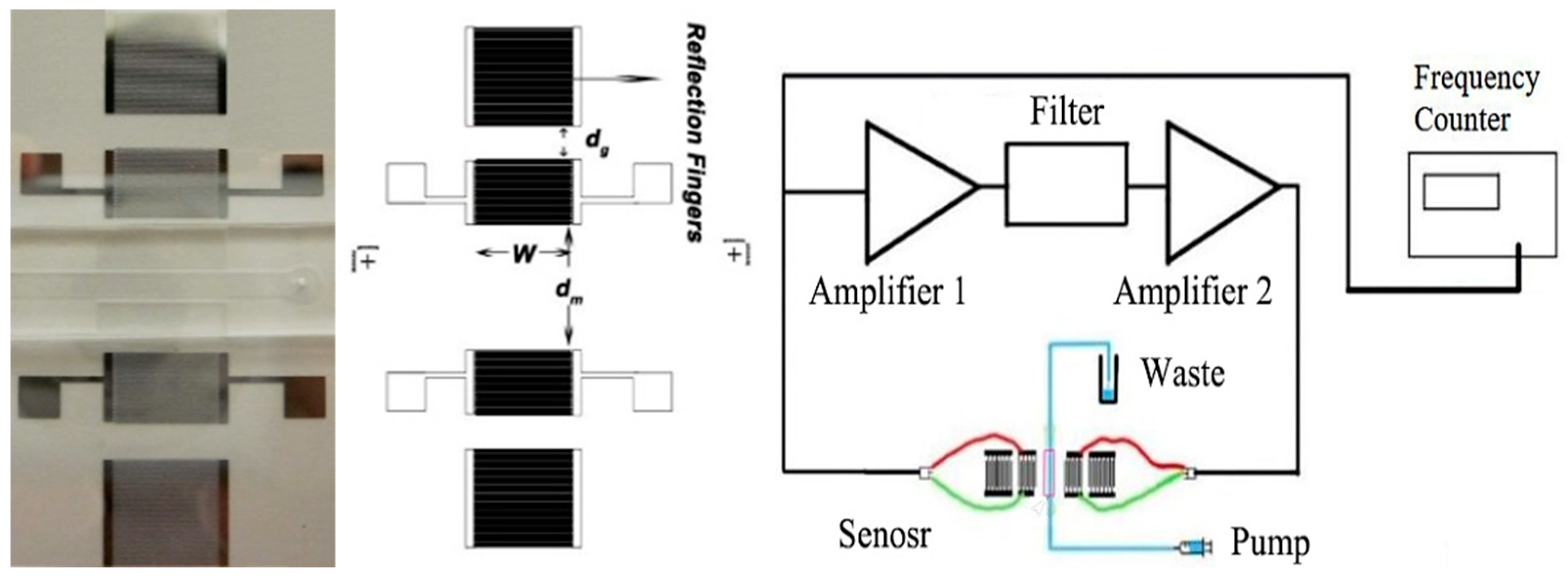

3.4.1. Surface Acoustic Device Design

3.4.2. Materials

3.4.3. Experiment Protocol of Measurement

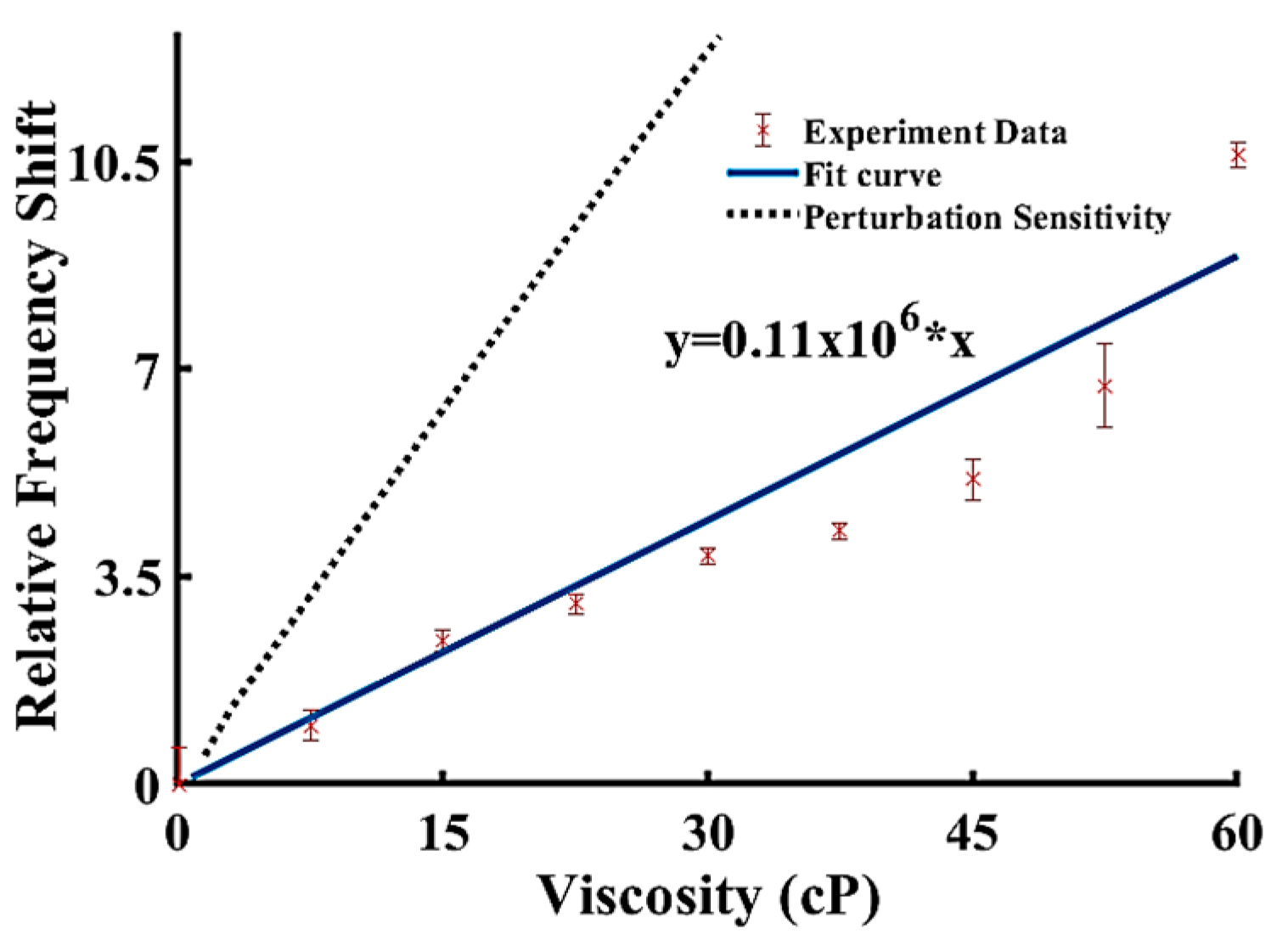

3.4.4. Comparison of Results

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Csete, M.; Hunt, W.D. Potential of surface acoustic wave biosensors for early sepsis diagnosis. J. Clin. Monit. Comput. 2013, 27, 427–431. [Google Scholar] [CrossRef] [PubMed]

- Scholl, G.; Schmidt, F.; Wolff, U. Surface Acoustic Wave Devices for Sensor Applications. Phys. Status Solidi Appl. Res. 2001, 185, 47–58. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Luo, J.K.; Nguyen, N.T.; Walton, A.J.; Flewitt, A.J.; Zu, X.T.; Li, Y.; McHale, G.; Matthews, A.; Iborra, E.; et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 2017, 89, 31–91. [Google Scholar] [CrossRef]

- Länge, K.; Rapp, B.E.; Rapp, M. Surface acoustic wave biosensors: A review. Anal. Bioanal. Chem. 2008, 391, 1509–1519. [Google Scholar] [CrossRef] [PubMed]

- Lozano, J.; Fernández, M.J.; Fontecha, J.L.; Aleixandre, M.; Santos, J.P.; Sayago, I.; Arroyo, T.; Cabellos, J.M.; Gutiérrez, F.J.; Horrillo, M.C. Wine classification with a zinc oxide SAW sensor array. Sens. Actuators B Chem. 2006, 120, 166–171. [Google Scholar] [CrossRef]

- Biswas, S.; Heindselmen, K.; Wohltjen, H.; Staff, C. Differentiation of vegetable oils and determination of sunflower oil oxidation using a surface acoustic wave sensing device. Food Control 2004, 15, 19–26. [Google Scholar] [CrossRef]

- Kazan, Z.; Zumeris, J.; Jacob, H.; Raskin, H.; Kratysh, G.; Vishnia, M.; Dror, N.; Barliya, T.; Mandel, M.; Lavie, G. Effective prevention of microbial biofilm formation on medical devices by low-energy surface acoustic waves. Antimicrob. Agents Chemother. 2006, 50, 4144–4152. [Google Scholar]

- Casalinuovo, I.A.; Di Pierro, D.; Bruno, E.; Di Francesco, P.; Coletta, M. Experimental use of a new surface acoustic wave sensor for the rapid identification of bacteria and yeasts. Lett. Appl. Microbiol. 2006, 42, 24–29. [Google Scholar] [CrossRef]

- Rajapaksa, A.; Qi, A.; Yeo, L.Y.; Coppel, R.; Friend, J.R. Enabling practical surface acoustic wave nebulizer drug delivery via amplitude modulation. Lab Chip 2014, 14, 1858–1865. [Google Scholar] [CrossRef]

- Ho, J.; Tan, M.K.; Go, D.B.; Yeo, L.Y.; Friend, J.R.; Chang, H.C. Paper-based microfluidic surface acoustic wave sample delivery and ionization source for rapid and sensitive ambient mass spectrometry. Anal. Chem. 2011, 83, 3260–3266. [Google Scholar] [CrossRef]

- Djoumi, L.; Vanotti, M.; Blondeau-Patissier, V. Real time cascade impactor based on Surface Acoustic Wave delay lines for PM10 and PM2.5 mass concentration measurement. Sensors 2018, 18, 255. [Google Scholar] [CrossRef]

- Smith, J.P.; Hinson-Smith, V. The new era of SAW devices. Anal. Chem. 2006, 78, 3505–3507. [Google Scholar] [CrossRef] [PubMed]

- Eppers, W.C.; Edwards, W.J. The Implementation of Surface Acoustic Wave Devices in Avionics Systems. In Proceedings of the 1980 IEEE MTT-S International Microwave Symposium Digest, Washington, DC, USA, 28–30 May 1980; p. 29. [Google Scholar]

- Wang, T.; Green, R.; Guldiken, R.; Mohapatra, S.; Mohapatra, S. Multiple-layer guided surface acoustic wave (SAW)-based pH sensing in longitudinal FiSS-tumoroid cultures. Biosens. Bioelectron. 2019, 124–125, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Green, R.; Nair, R.R.; Howell, M.; Mohapatra, S.; Guldiken, R.; Mohapatra, S.S. Surface acoustic waves (SAW)-based biosensing for quantification of cell growth in 2D and 3D Cultures. Sensors 2015, 15, 32045–32055. [Google Scholar] [CrossRef]

- Kiełczyński, P.; Szalewski, M.; Balcerzak, A. Effect of a viscous liquid loading on Love wave propagation. Int. J. Solids Struct. 2012, 49, 2314–2319. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, F.; Sun, Z.; Li, Y.T.; Zhang, G.J. A surface acoustic wave biosensor synergizing DNA-mediated: In situ silver nanoparticle growth for a highly specific and signal-amplified nucleic acid assay. Analyst 2017, 142, 3468–3476. [Google Scholar] [CrossRef]

- Yildirim, B.; Senveli, S.U.; Gajasinghe, R.W.R.L.; Tigli, O. Surface Acoustic Wave Viscosity Sensor with Integrated Microfluidics on a PCB Platform. IEEE Sens. J. 2018, 18, 2305–2312. [Google Scholar] [CrossRef]

- Go, D.B.; Atashbar, M.Z.; Ramshani, Z.; Chang, H.C. Surface acoustic wave devices for chemical sensing and microfluidics: A review and perspective. Anal. Methods 2017, 9, 4112–4134. [Google Scholar] [CrossRef]

- Onen, O.; Ahmad, A.A.; Guldiken, R.; Gallant, N.D. Surface modification on acoustic wave biosensors for enhanced specificity. Sensors 2012, 12, 12317–12328. [Google Scholar] [CrossRef]

- Onen, O.; Sisman, A.; Gallant, N.D.; Kruk, P.; Guldiken, R. A urinary Bcl-2 surface acoustic wave biosensor for early ovarian cancer detection. Sensors 2012, 12, 7423–7437. [Google Scholar] [CrossRef]

- Newton, M.I.; Roach, P.; McHale, G. ST quartz acoustic wave sensors with sectional guiding layers. Sensors 2008, 8, 4384–4391. [Google Scholar] [CrossRef] [PubMed]

- Mujahid, A.; Dickert, F.L. Surface acousticwave (SAW) for chemical sensing applications of recognition layers. Sensors 2017, 17, 2716. [Google Scholar] [CrossRef] [PubMed]

- Thompson, M.; Kipling, A.L.; Duncan-Hewitt, W.C.; Rajaković, L.V.; Avić-Vlasak, B.A. Thickness-shear-mode acoustic wave sensors in the liquid phase. A review. Analyst 1991, 116, 881–890. [Google Scholar] [CrossRef]

- Nie, G.; Liu, J.; Kong, Y.; Fang, X. SH Waves in (1 − x)Pb(Mg1/3Nb2/3)O3−xPbTiO3 Piezoelectric Layered Structures Loaded with Viscous Liquid. Acta Mech. Solida Sin. 2016, 29, 479–489. [Google Scholar] [CrossRef]

- Anisimkin, V.I.; Voronova, N.V.; Kuznetsova, I.E.; Pyataikin, I.I. Aspects of using acoustic plate modes of higher orders for acoustoelectronic sensors. Bull. Russ. Acad. Sci. Phys. 2015, 79, 1278–1282. [Google Scholar] [CrossRef]

- Zhang, R.; Feng, W. SH Surface Waves in a Dielectric Layered Piezoelectric Half Space Loaded with a Liquid Layer. Acta Acust. United with Acust. 2012, 98, 378–383. [Google Scholar] [CrossRef]

- Zaitsev, B.D.; Kuznetsova, I.E.; Joshi, S.G.; Borodina, I.A. Acoustic waves in piezoelectric plates bordered with viscous and conductive liquid. Ultrasonics 2001, 39, 45–50. [Google Scholar] [CrossRef]

- Voinova, M.V.; Rodahl, M.; Jonson, M.; Kasemo, B. Viscoelastic Acoustic Response of Layered Polymer Films at Fluid-Solid Interfaces: Continuum Mechanics Approach. Phys. Scr. 1999, 59, 391–396. [Google Scholar] [CrossRef]

- Rodahl, M.; Höök, F.; Fredriksson, C.; Keller, C.A.; Krozer, A.; Brzezinski, P.; Voinova, M.; Kasemo, B. Simultaneous frequency and dissipation factor QCM measurements of biomolecular adsorption and cell adhesion. Faraday Discuss. 1997, 107, 229–246. [Google Scholar] [CrossRef]

- Voinova, M.V.; Jonson, M.; Kasemo, B. Dynamics of viscous amphiphilic films supported by elastic solid substrates. J. Phys. Condens. Matter 1997, 9, 7799–7808. [Google Scholar] [CrossRef]

- McHale, G.; Newton, M.I.; Martin, F. Theoretical mass, liquid, and polymer sensitivity of acoustic wave sensors with viscoelastic guiding layers. J. Appl. Phys. 2003, 93, 675–690. [Google Scholar] [CrossRef]

- McHale, G.; Newton, M.I.; Martin, F. Theoretical mass sensitivity of Love wave and layer guided acoustic plate mode sensors. J. Appl. Phys. 2002, 91, 9701–9710. [Google Scholar] [CrossRef]

- Wang, T.; Green, R.; Guldiken, R.; Wang, J.; Mohapatra, S.; Mohapatra, S.S. Finite Element Analysis for Surface Acoustic Wave Device Characteristic Properties and Sensitivity. Sensors 2019, 19, 1749. [Google Scholar] [CrossRef] [PubMed]

- Husson, D. A perturbation theory for the acoustoelastic effect of surface waves. J. Appl. Phys. 1985, 57, 1562–1568. [Google Scholar] [CrossRef]

- Onen, O.; Guldiken, R. Investigation of guided surface acoustic wave sensors by analytical modeling and perturbation analysis. Sens. Actuators A Phys. 2014, 205, 38–46. [Google Scholar] [CrossRef]

- Caliendo, C.; Hamidullah, M. A theoretical study of love wave sensors based on ZnO-glass layered structures for application to liquid environments. Biosensors 2016, 6, 59. [Google Scholar] [CrossRef]

- Toma, K.; Miki, D.; Kishikawa, C.; Yoshimura, N.; Miyajima, K.; Arakawa, T.; Yatsuda, H.; Mitsubayashi, K. Repetitive Immunoassay with a Surface Acoustic Wave Device and a Highly Stable Protein Monolayer for On-Site Monitoring of Airborne Dust Mite Allergens. Anal. Chem. 2015, 87, 10470–10474. [Google Scholar] [CrossRef]

- Kogai, T.; Yatsuda, H.; Kondoh, J. Temperature dependence of immunoreactions using shear horizontal surface acoustic wave immunosensors. Jpn. J. Appl. Phys. 2017, 56, 7S1. [Google Scholar] [CrossRef]

- Toma, K.; Miki, D.; Yoshimura, N.; Arakawa, T.; Yatsuda, H.; Mitsubayashi, K. A gold nanoparticle-assisted sensitive SAW (surface acoustic wave) immunosensor with a regeneratable surface for monitoring of dust mite allergens. Sens. Actuators B Chem. 2017, 249, 685–690. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Lu, Y.; He, S. Properties of Love waves in a piezoelectric layered structure with a viscoelastic guiding layer. Smart Mater. Struct. 2013, 22, 125034. [Google Scholar] [CrossRef]

- Liu, J. A theoretical study on Love wave sensors in a structure with multiple viscoelastic layers on a piezoelectric substrate. Smart Mater. Struct. 2014, 23, 7. [Google Scholar] [CrossRef]

- Wang, W.; He, S. A Love wave reflective delay line with polymer guiding layer for wireless sensor application. Sensors 2008, 8, 7917–7929. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Xiong, X.; Zu, H.; Wang, J.H.C.; Wang, Q.M. Theoretical analysis of a Love wave biosensor in liquid with a viscoelastic wave guiding layer. J. Appl. Phys. 2017, 121, 054501. [Google Scholar] [CrossRef]

- Goto, M.; Yatsuda, H.; Kondoh, J. Numerical analysis of viscosity effect on shear horizontal surface acoustic wave for biosensor application. IEEJ Trans. Sens. Micromach. 2016, 136, 1–5. [Google Scholar] [CrossRef]

- Kiełczyński, P. Direct Sturm–Liouville problem for surface Love waves propagating in layered viscoelastic waveguides. Appl. Math. Model. 2018, 53, 419–432. [Google Scholar] [CrossRef]

- Akhtar, R.; Sherratt, M.J.; Cruickshank, J.K.; Derby, B. Characterizing the elastic properties of tissues. Mater. Today 2011, 14, 96–105. [Google Scholar] [CrossRef]

- Chu, S.Y.; Water, W.; Liaw, J.T. An investigation of the dependence of ZnO film on the sensitivity of Love mode sensor in ZnO/quartz structure. Ultrasonics 2003, 41, 133–139. [Google Scholar] [CrossRef]

- Herrmann, F.; Hahn, D.; Büttgenbach, S. Separation of density and viscosity influence on liquid-loaded surface acoustic wave devices. Appl. Phys. Lett. 1999, 74, 3410–3412. [Google Scholar] [CrossRef]

- Weiss, M.; Welsch, W.; Schickfus, M.V.; Hunklinger, S. Viscoelastic Behavior of Antibody Films on a Shear Horizontal Acoustic Surface Wave Sensor. Anal. Chem. 1998, 70, 2881–2887. [Google Scholar] [CrossRef]

- Greenwood, M.S.; Bamberger, J.A. Measurement of viscosity and shear wave velocity of a liquid or slurry for on-line process control. Ultrasonics 2002, 39, 623–630. [Google Scholar] [CrossRef]

- Springer US. Encyclopedia of Microfluidics and Nanofluidics; Li, D., Ed.; Springer: Boston, MA, USA, 2013; ISBN 978-3-642-27758-0. [Google Scholar]

- Fischerauer, G.; Dickert, F.L. A simple model for the effect of nonuniform mass loading on the response of gravimetric chemical sensors. Sens. Actuators B Chem. 2016, 229, 618–626. [Google Scholar] [CrossRef]

- McHale, G.; Martin, F.; Newton, M.I. Mass sensitivity of acoustic wave devices from group and phase velocity measurements. J. Appl. Phys. 2002, 92, 3368–3373. [Google Scholar] [CrossRef]

- Ricco, A.J.; Martin, S.J. Acoustic wave viscosity sensor. Appl. Phys. Lett. 1987, 50, 1474–1476. [Google Scholar] [CrossRef]

- Du, J.; Harding, G.L.; Ogilvy, J.A.; Dencher, P.R.; Lake, M. A study of Love-wave acoustic sensors. Sens. Actuators A Phys. 1996, 56, 211–219. [Google Scholar] [CrossRef]

- Josse, F.; Bender, F.; Cernosek, R.W. Guided shear horizontal surface acoustic wave sensors for chemical and biochemical detection in liquids. Anal. Chem. 2001, 73, 5937–5944. [Google Scholar] [CrossRef] [PubMed]

- Du, J.; Harding, G.L.; Collings, A.F.; Dencher, P.R. An experimental study of Love-wave acoustic sensors operating in liquids. Sens. Actuators A Phys. 1997, 60, 54–61. [Google Scholar] [CrossRef]

- Hoummady, M.; Bastien, F. Acoustic wave viscometer. Rev. Sci. Instrum. 1991, 62, 1999–2003. [Google Scholar] [CrossRef]

- Jakoby, B.; Vellekoop, M.J. Viscosity sensing using a Love-wave device. Sens. Actuators A Phys. 1998, 68, 275–281. [Google Scholar] [CrossRef]

| Material | E (GPa) | ν | G (GPa) | Vs (m/s) | |

|---|---|---|---|---|---|

| ST-cut 90°X Quartz | 2650 | 4996 | |||

| ZnO | 90 | 0.15 | 39 | 5610 | 2650 |

| SiO2 | 70 | 0.17 | 30 | 2650 | 3726 |

| IrO2 | 290 | 0.3381 | 108 | 11660 | 3043 |

| Liquid Layer | 0.52 [47] | 1350 | 35 |

| Parameters | Parameters | ||

|---|---|---|---|

| Wavelength (λ) | 300 μm | Channel height | 100 μm |

| Pairs of fingers | 30 | Channel Length | 25 mm |

| Pairs of reflecting fingers | 50 | Finger height | 100 nm |

| Finger width | 75 μm | Phase velocity | 4996 m/s |

| Aperture (w) | 9.8 mm | Wavelength of reflecting fingers | 300 μm |

| Channel width | 2 mm | Design frequency | ~16.6 MHz |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Murphy, R.; Wang, J.; Mohapatra, S.S.; Mohapatra, S.; Guldiken, R. Perturbation Analysis of a Multiple Layer Guided Love Wave Sensor in a Viscoelastic Environment. Sensors 2019, 19, 4533. https://doi.org/10.3390/s19204533

Wang T, Murphy R, Wang J, Mohapatra SS, Mohapatra S, Guldiken R. Perturbation Analysis of a Multiple Layer Guided Love Wave Sensor in a Viscoelastic Environment. Sensors. 2019; 19(20):4533. https://doi.org/10.3390/s19204533

Chicago/Turabian StyleWang, Tao, Ryan Murphy, Jing Wang, Shyam S. Mohapatra, Subhra Mohapatra, and Rasim Guldiken. 2019. "Perturbation Analysis of a Multiple Layer Guided Love Wave Sensor in a Viscoelastic Environment" Sensors 19, no. 20: 4533. https://doi.org/10.3390/s19204533

APA StyleWang, T., Murphy, R., Wang, J., Mohapatra, S. S., Mohapatra, S., & Guldiken, R. (2019). Perturbation Analysis of a Multiple Layer Guided Love Wave Sensor in a Viscoelastic Environment. Sensors, 19(20), 4533. https://doi.org/10.3390/s19204533