Laser-Induced Deposition of Carbon Nanotubes in Fiber Optic Tips of MMI Devices

Abstract

1. Introduction

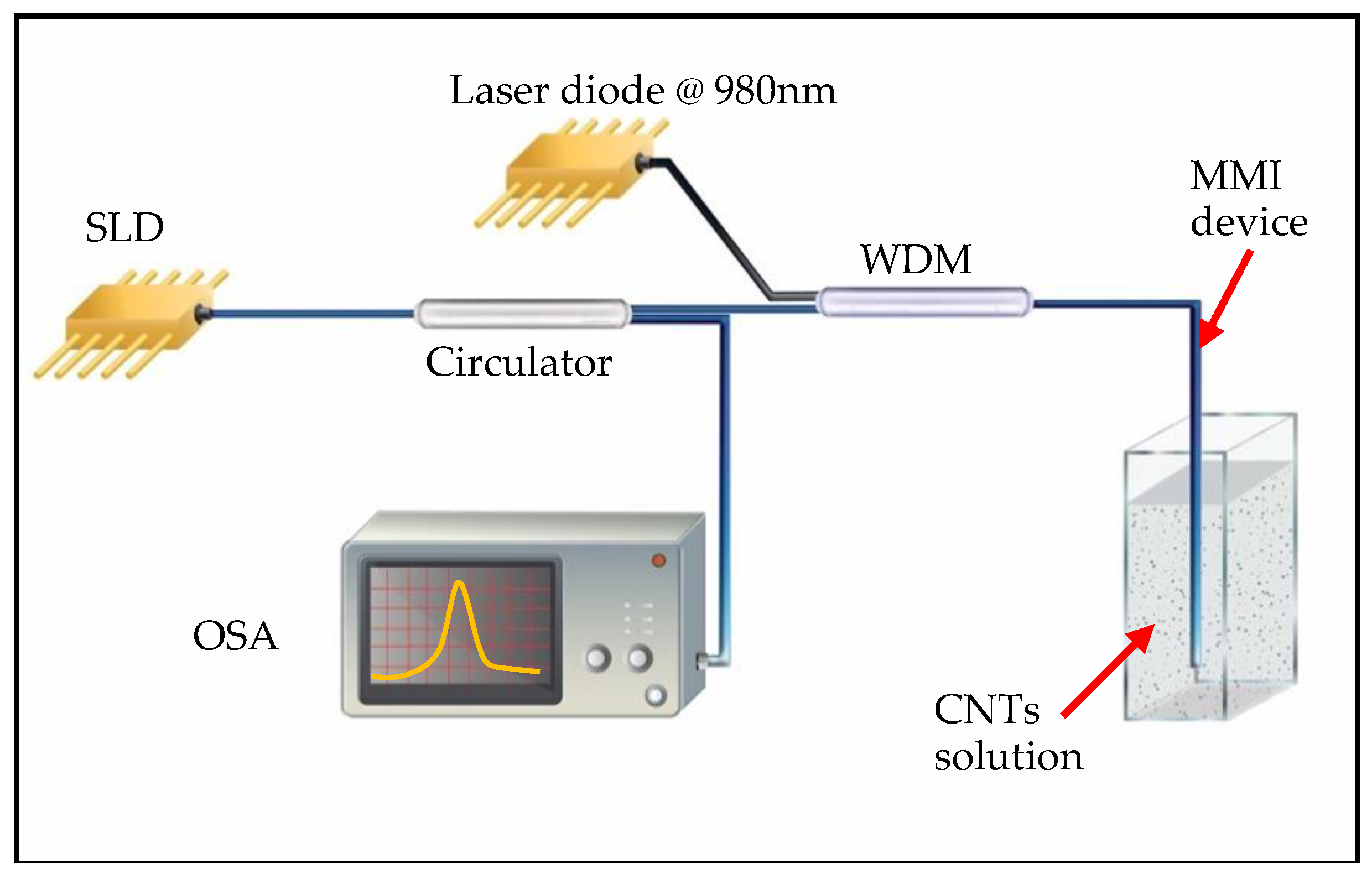

2. Materials and Methods

3. Results

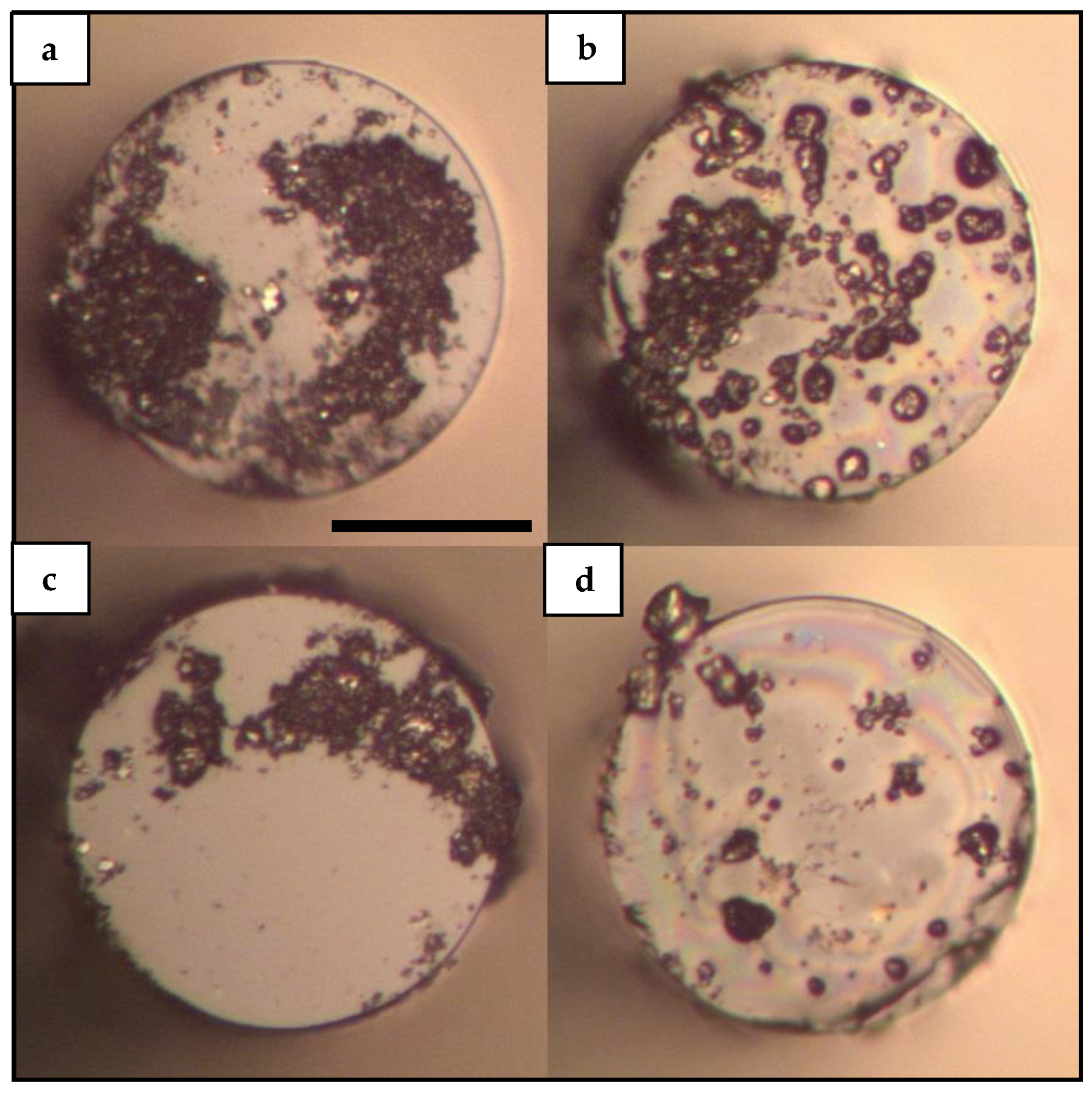

3.1. Laser-Induced Deposition of CNTs in Water Samples

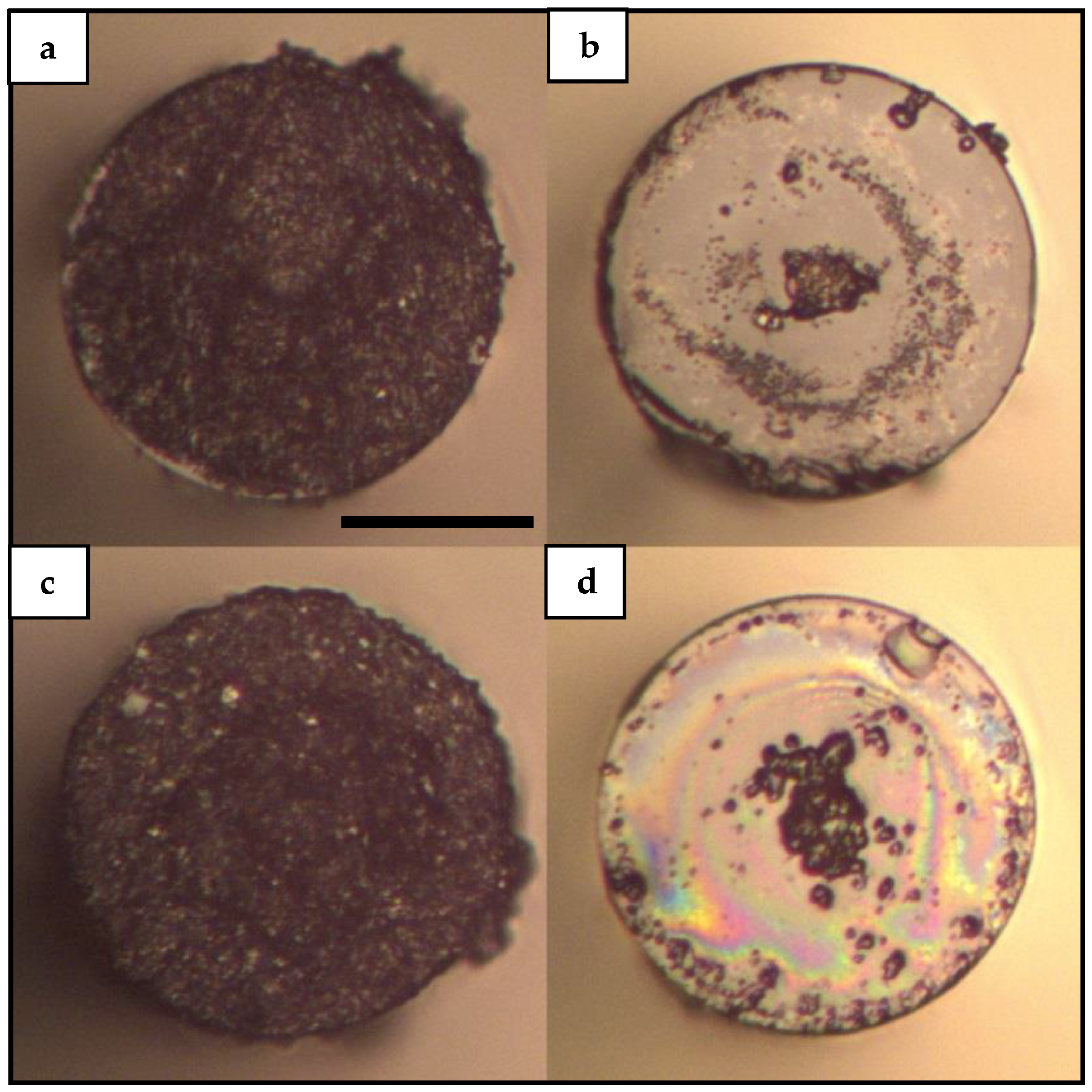

3.2. Laser-Induced Deposition of CNTs in Methanol Samples

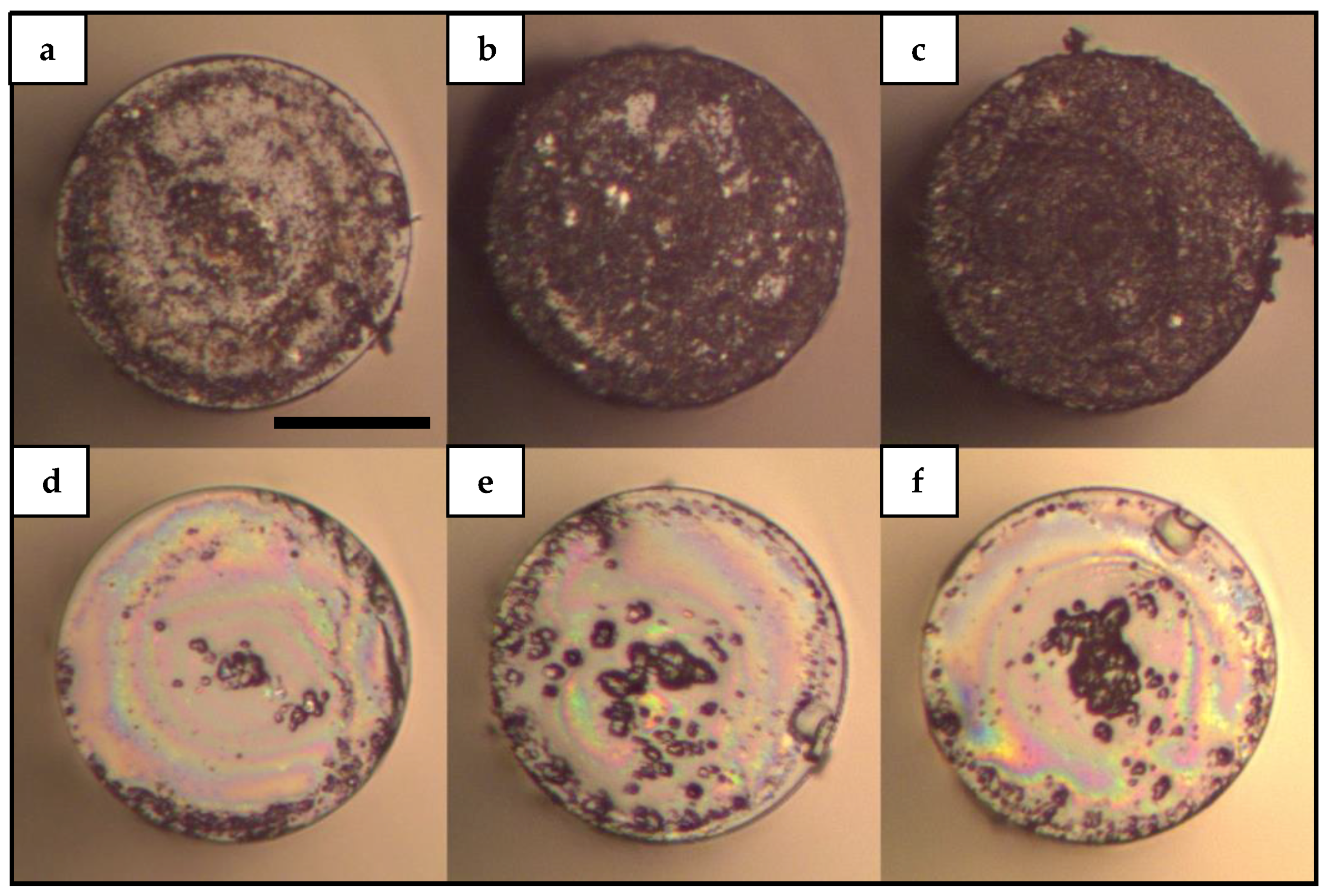

3.3. Deposition Features Dependence on Laser Power

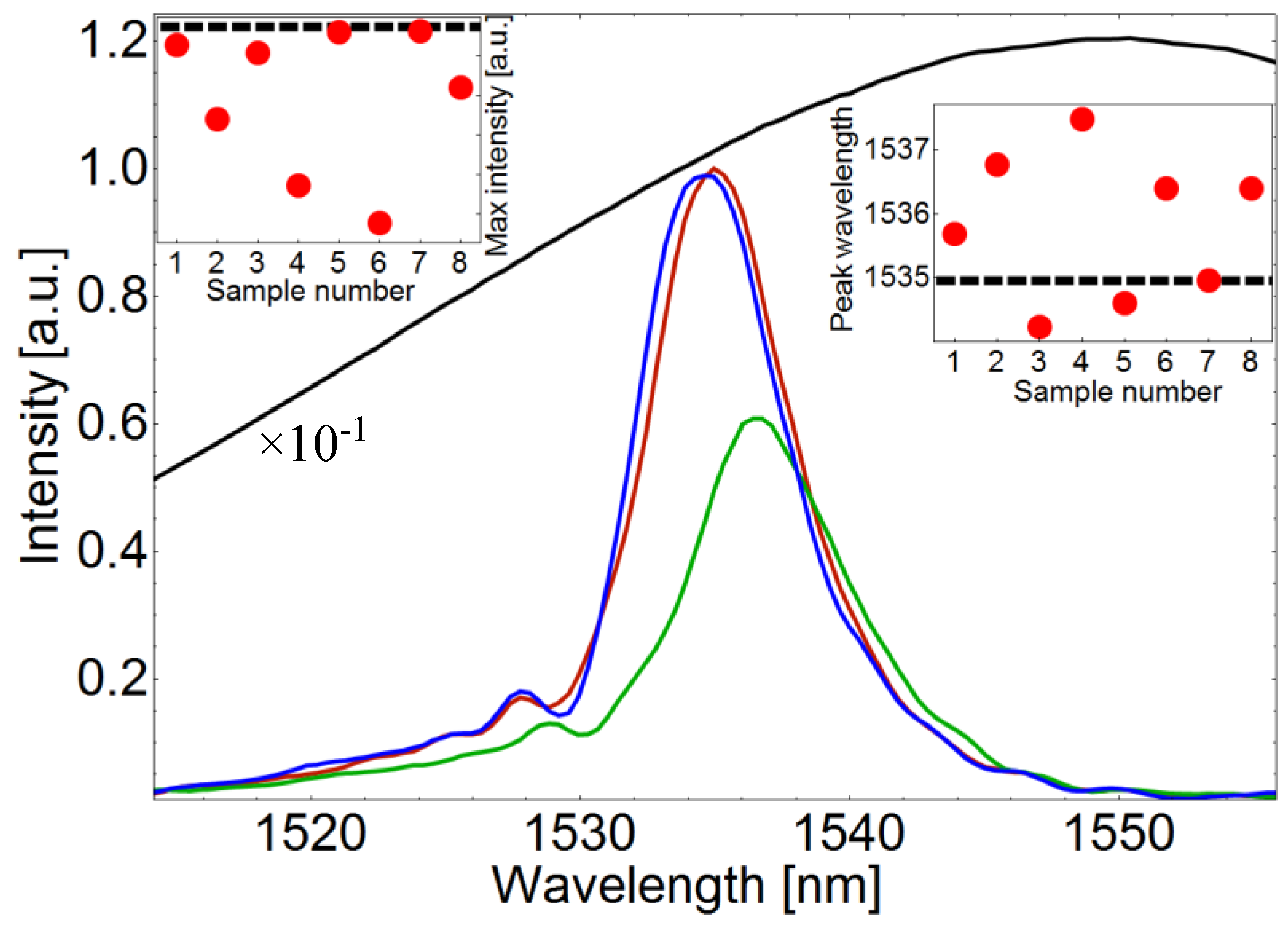

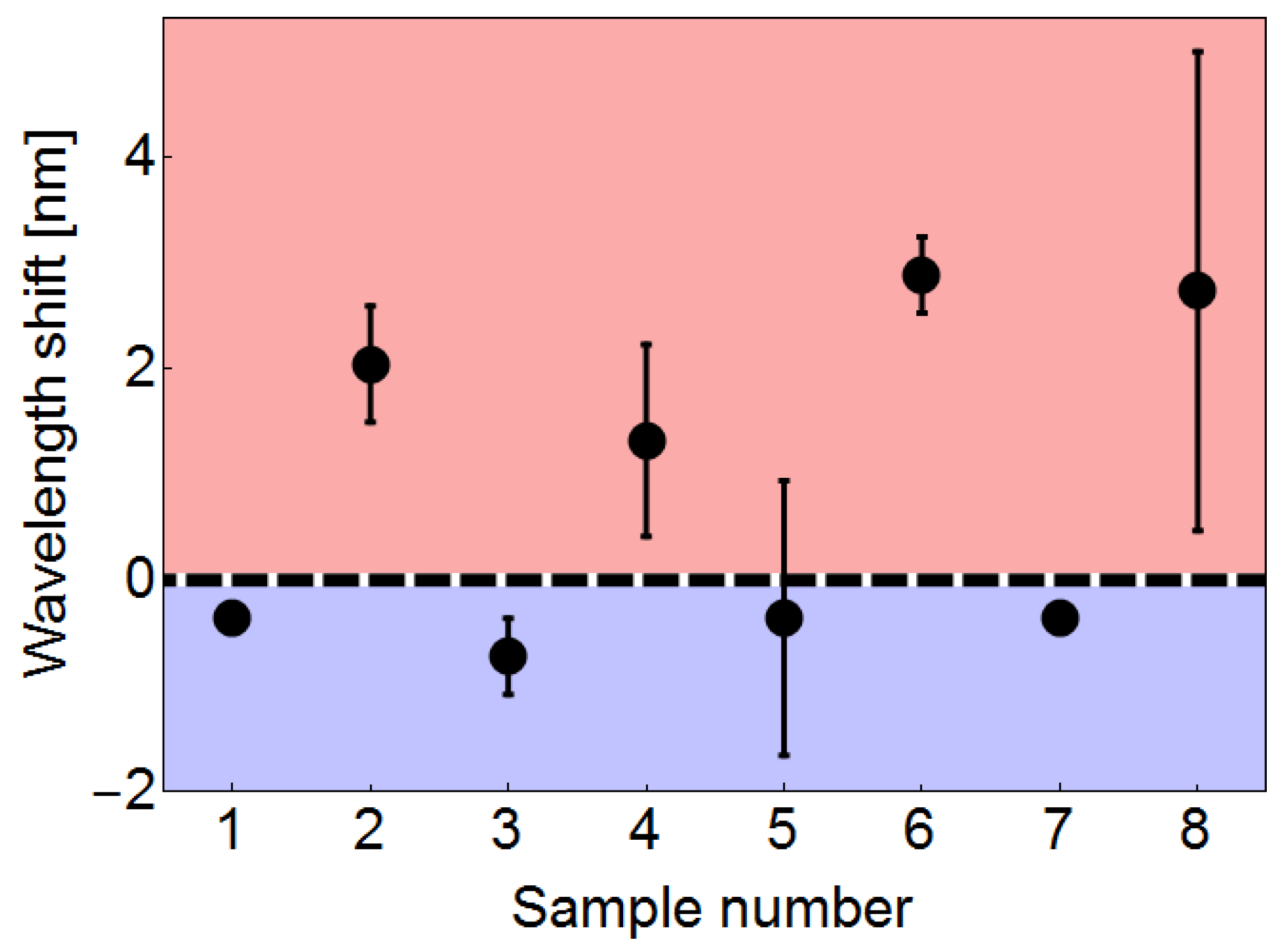

3.4. Spectral Characterization of the CNTs Deposited MMI Fiber Probe

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gao, M.; Dai, L.; Wallace, G.G. Biosensors based on aligned carbon nanotubes coated with inherently conducting polymers. Electroanal. Int. J. Devoted Fundam. Pract. Asp. Electroanal. 2003, 15, 1089–1094. [Google Scholar] [CrossRef]

- Hirsch, A. Functionalization of single-walled carbon nanotubes. Angew. Chem. Int. Ed. 2002, 41, 1853–1859. [Google Scholar] [CrossRef]

- Hrapovic, S.; Liu, Y.; Male, K.B.; Luong, J.H. Electrochemical biosensing platforms using platinum nanoparticles and carbon nanotubes. Anal. Chem. 2004, 76, 1083–1088. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Lu, F.; Wang, J. Disposable carbon nanotube modified screen-printed biosensor for amperometric detection of organophosphorus pesticides and nerve agents. Electroanal. Int. J. Devoted Fundam. Pract. Asp. Electroanal. 2004, 16, 145–149. [Google Scholar] [CrossRef]

- Wang, J.; Musameh, M. Carbon nanotube/teflon composite electrochemical sensors and biosensors. Anal. Chem. 2003, 75, 2075–2079. [Google Scholar] [CrossRef] [PubMed]

- Lefebvre, J.; Austing, D.G.; Bond, J.; Finnie, P. Photoluminescence imaging of suspended single-walled carbon nanotubes. Nano Lett. 2006, 6, 1603–1608. [Google Scholar] [CrossRef]

- Wang, F.; Dukovic, G.; Brus, L.E.; Heinz, T.F. Time-resolved fluorescence of carbon nanotubes and its implication for radiative lifetimes. Phys. Rev. Lett. 2004, 92, 177401. [Google Scholar] [CrossRef]

- Tatsuura, S.; Furuki, M.; Sato, Y.; Iwasa, I.; Tian, M.; Mitsu, H. Semiconductor carbon nanotubes as ultrafast switching materials for optical telecommunications. Adv. Mater. 2003, 15, 534–537. [Google Scholar] [CrossRef]

- Rozhin, A.G.; Sakakibara, Y.; Kataura, H.; Matsuzaki, S.; Ishida, K.; Achiba, Y.; Tokumoto, M. Anisotropic saturable absorption of single wall carbon nanotubes aligned in polyvinyl alcohol. MRS Online Proc. Libr. Arch. 2004, 858. [Google Scholar] [CrossRef]

- Della Valle, G.; Osellame, R.; Galzerano, G.; Chiodo, N.; Cerullo, G.; Laporta, P.; Svelto, O.; Morgner, U.; Rozhin, A.; Scardaci, V. Passive mode locking by carbon nanotubes in a femtosecond laser written waveguide laser. Appl. Phys. Lett. 2006, 89, 231115. [Google Scholar] [CrossRef]

- Liu, Z.; Tabakman, S.; Welsher, K.; Dai, H. Carbon nanotubes in biology and medicine: In vitro and in vivo detection, imaging and drug delivery. Nano Res. 2009, 2, 85–120. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Zhang, X.; Yang, R.; Zhu, Z.; Chen, Y.; Tan, W. Single-walled carbon nanotubes as optical materials for biosensing. Nanoscale 2011, 3, 1949–1956. [Google Scholar] [CrossRef] [PubMed]

- Heller, D.A.; Jeng, E.S.; Yeung, T.-K.; Martinez, B.M.; Moll, A.E.; Gastala, J.B.; Strano, M.S. Optical detection of DNA conformational polymorphism on single-walled carbon nanotubes. Science 2006, 311, 508–511. [Google Scholar] [CrossRef] [PubMed]

- Niranjana, S. Characterization of Nanocarbon Thin Films; Manipal Institute of Technology: Manipal, India, 2012. [Google Scholar]

- Kawano, T.; Chiamori, H.C.; Suter, M.; Zhou, Q.; Sosnowchik, B.D.; Lin, L. An electrothermal carbon nanotube gas sensor. Nano Lett. 2007, 7, 3686–3690. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Q.; Yang, D.; Sellin, P.; Zhong, G. Multi-walled carbon nanotube-based gas sensors for NH3 detection. Diam. Relat. Mater. 2004, 13, 1327–1332. [Google Scholar] [CrossRef]

- Dharap, P.; Li, Z.; Nagarajaiah, S.; Barrera, E. Nanotube film based on single-wall carbon nanotubes for strain sensing. Nanotechnology 2004, 15, 379. [Google Scholar] [CrossRef]

- Jacobs, C.B.; Peairs, M.J.; Venton, B.J. Carbon nanotube based electrochemical sensors for biomolecules. Anal. Chim. Acta 2010, 662, 105–127. [Google Scholar] [CrossRef]

- Yamashita, S.; Inoue, Y.; Maruyama, S.; Murakami, Y.; Yaguchi, H.; Jablonski, M.; Set, S. Saturable absorbers incorporating carbon nanotubes directly synthesized onto substrates and fibers and their application to mode-locked fiber lasers. Opt. Lett. 2004, 29, 1581–1583. [Google Scholar] [CrossRef]

- Shabaneh, A.; Girei, S.; Arasu, P.; Mahdi, M.; Rashid, S.; Paiman, S.; Yaacob, M. Dynamic response of tapered optical multimode fiber coated with carbon nanotubes for ethanol sensing application. Sensors 2015, 15, 10452–10464. [Google Scholar] [CrossRef]

- Shabaneh, A.; Girei, S.; Arasu, P.; Rashid, S.; Yunusa, Z.; Mahdi, M.; Paiman, S.; Ahmad, M.; Yaacob, M. Reflectance response of optical fiber coated with carbon nanotubes for aqueous ethanol sensing. IEEE Photonics J. 2014, 6, 1–10. [Google Scholar] [CrossRef]

- Penza, M.; Cassano, G.; Aversa, P.; Antolini, F.; Cusano, A.; Cutolo, A.; Giordano, M.; Nicolais, L. Alcohol detection using carbon nanotubes acoustic and optical sensors. Appl. Phys. Lett. 2004, 85, 2379–2381. [Google Scholar] [CrossRef]

- Consales, M.; Campopiano, S.; Cutolo, A.; Penza, M.; Aversa, P.; Cassano, G.; Giordano, M.; Cusano, A. Carbon nanotubes thin films fiber optic and acoustic VOCs sensors: Performances analysis. Sens. Actuators B Chem. 2006, 118, 232–242. [Google Scholar] [CrossRef]

- Kashiwagi, K.; Yamashita, S.; Set, S.Y. Optically manipulated deposition of carbon nanotubes onto optical fiber end. Jpn. J. Appl. Phys. 2007, 46, L988. [Google Scholar] [CrossRef]

- Nicholson, J.; Windeler, R.; DiGiovanni, D. Optically driven deposition of single-walled carbon-nanotube saturable absorbers on optical fiber end-faces. Opt. Express 2007, 15, 9176–9183. [Google Scholar] [CrossRef]

- Pimentel-Domínguez, R.; Moreno-Álvarez, P.; Hautefeuille, M.; Chavarría, A.; Hernández-Cordero, J. Photothermal lesions in soft tissue induced by optical fiber microheaters. Biomed. Opt. Express 2016, 7, 1138–1148. [Google Scholar] [CrossRef]

- Pimentel-Domínguez, R.; Hernández-Cordero, J.; Zenit, R. Microbubble generation using fiber optic tips coated with nanoparticles. Opt. Express 2012, 20, 8732–8740. [Google Scholar] [CrossRef]

- Ruiz-Pérez, V.; Basurto-Pensado, M.; LiKamWa, P.; Sánchez-Mondragón, J.; May-Arrioja, D. Fiber optic pressure sensor using multimode interference. J. Phys. Conf. Ser. 2011, 274, 012025. [Google Scholar] [CrossRef]

- May-Arrioja, D.A.; Ruiz-Perez, V.I.; Bustos-Terrones, Y.; Basurto-Pensado, M.A. Fiber optic pressure sensor using a conformal polymer on multimode interference device. IEEE Sens. J. 2015, 16, 1956–1961. [Google Scholar] [CrossRef]

- Fuentes-Fuentes, M.; May-Arrioja, D.; Guzman-Sepulveda, J.; Torres-Cisneros, M.; Sánchez-Mondragón, J. Highly sensitive liquid core temperature sensor based on multimode interference effects. Sensors 2015, 15, 26929–26939. [Google Scholar] [CrossRef]

- Irace, A.; Breglio, G. All-silicon optical temperature sensor based on Multi-Mode Interference. Opt. Express 2003, 11, 2807–2812. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G. All-fiber multimode-interference-based refractometer sensor: Proposal and design. Opt. Lett. 2006, 31, 317–319. [Google Scholar] [CrossRef] [PubMed]

- Biazoli, C.R.; Silva, S.; Franco, M.A.; Frazão, O.; Cordeiro, C.M. Multimode interference tapered fiber refractive index sensors. Appl. Opt. 2012, 51, 5941–5945. [Google Scholar] [CrossRef] [PubMed]

- Antonio-Lopez, J.E.; Sanchez-Mondragon, J.; LiKamWa, P.; May-Arrioja, D.A. Fiber-optic sensor for liquid level measurement. Opt. Lett. 2011, 36, 3425–3427. [Google Scholar] [CrossRef] [PubMed]

- Antonio-Lopez, J.E.; May-Arrioja, D.A.; LiKamWa, P. Fiber-optic liquid level sensor. IEEE Photonics Technol. Lett. 2011, 23, 1826–1828. [Google Scholar] [CrossRef]

- Yao, B.C.; Wu, Y.; Yu, C.B.; He, J.R.; Rao, Y.J.; Gong, Y.; Fu, F.; Chen, Y.F.; Li, Y.R. Partially reduced graphene oxide based FRET on fiber-optic interferometer for biochemical detection. Sci. Rep. 2016, 6, 23706. Available online: https://www.nature.com/articles/srep23706#supplementary-information (accessed on 9 August 2019). [CrossRef] [PubMed]

- El Achaby, M.; Arrakhiz, F.-E.; Vaudreuil, S.; Essassi, E.M.; Qaiss, A.; Bousmina, M. Nanocomposite films of poly(vinylidene fluoride) filled with polyvinylpyrrolidone-coated multiwalled carbon nanotubes: Enhancement of β-polymorph formation and tensile properties. Polym. Eng. Sci. 2013, 53, 34–43. [Google Scholar] [CrossRef]

- Van den Mooter, G.; Wuyts, M.; Blaton, N.; Busson, R.; Grobet, P.; Augustijns, P.; Kinget, R. Physical stabilisation of amorphous ketoconazole in solid dispersions with polyvinylpyrrolidone K25. Eur. J. Pharm. Sci. 2001, 12, 261–269. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Y. Monodisperse Silica-Coated Polyvinylpyrrolidone/NaYF4 Nanocrystals with Multicolor Upconversion Fluorescence Emission. Angew. Chem. Int. Ed. 2006, 45, 7732–7735. [Google Scholar] [CrossRef]

- Simonelli, A.P.; Mehta, S.C.; Higuchi, W.I. Dissolution Rates of High Energy Polyvinylpyrrolidone (PVP)-Sulfathiazole Coprecipitates. J. Pharm. Sci. 1969, 58, 538–549. [Google Scholar] [CrossRef]

- Ntim, S.A.; Sae-Khow, O.; Witzmann, F.A.; Mitra, S. Effects of polymer wrapping and covalent functionalization on the stability of MWCNT in aqueous dispersions. J. Colloid Interface Sci. 2011, 355, 383–388. [Google Scholar] [CrossRef]

- Bernal-Martínez, J.; Seseña-Rubfiaro, A.; Godínez-Fernández, R.; Aguilar-Elguezabal, A. Electrodes made of multi-wall carbon nanotubes on PVDF-filters have low electrical resistance and are able to record electrocardiograms in humans. Microelectron. Eng. 2016, 166, 10–14. [Google Scholar] [CrossRef]

- bernal-martinez, J.; Godínez-Fernández, R.; Aguilar-Elguezabal, A. Suitability of the Composite Made of Multi Wall Carbon Nanotubes-Polyvinylpyrrolidone for Culturing Invertebrate Helix aspersa Neurons. J. Mater. Sci. Chem. Eng. 2017, 5, 41–50. [Google Scholar] [CrossRef]

- Haghighat, F.; Mokhtary, M. Preparation and Characterization of Polyvinylpyrrolidone-functionalized Multiwalled Carbon Nanotube (PVP/f-MWNT) Nanocomposites. Polym. Plast. Technol. Eng. 2017, 56, 794–803. [Google Scholar] [CrossRef]

- Socorro, A.B.; Del Villar, I.; Corres, J.M.; Arregui, F.J.; Matias, I.R. Mode transition in complex refractive index coated single-mode–multimode–single-mode structure. Opt. Express 2013, 21, 12668–12682. [Google Scholar] [CrossRef] [PubMed]

- Walbaum, T.; Fallnich, C. Multimode interference filter for tuning of a mode-locked all-fiber erbium laser. Opt. Lett. 2011, 36, 2459–2461. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Pérez, V.I.; Basurto-Pensado, M.A.; May-Arrioja, D.; Sánchez Mondragón, J.J.; LiKamWa, P. Intrinsic fiber optic pressure sensor based on multimode interference device as sensitive element. In Proceedings of the Frontiers in Optics 2010/Laser Science XXVI, Rochester, NY, USA, 24 October 2010; p. JWA36. [Google Scholar]

- Mohammed, W.S.; Mehta, A.; Johnson, E.G. Wavelength tunable fiber lens based on multimode interference. J. Lightwave Technol. 2004, 22, 469–477. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G. Multimode-fiber-based edge filter for optical wavelength measurement application and its design. Microw. Opt. Technol. Lett. 2006, 48, 900–902. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G.; Yan, W. Investigation on Single-Mode–Multimode– Single-Mode Fiber Structure. J. Lightwave Technol. 2008, 26, 512–519. [Google Scholar] [CrossRef]

- Ayala, R.; Martínez, J.M.; Pappalardo, R.R.; Sánchez Marcos, E. Theoretical Study of the Microsolvation of the Bromide Anion in Water, Methanol, and Acetonitrile: Ion−Solvent vs Solvent−Solvent Interactions. J. Phys. Chem. A 2000, 104, 2799–2807. [Google Scholar] [CrossRef]

- Saleh, B.E.; Teich, M.C. Fundamentals of Photonics; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Buongiorno, J. Convective Transport in Nanofluids. J. Heat Transf. 2005, 128, 240–250. [Google Scholar] [CrossRef]

- Yu, W.; France, D.M.; Routbort, J.L.; Choi, S.U.S. Review and Comparison of Nanofluid Thermal Conductivity and Heat Transfer Enhancements. Heat Transf. Eng. 2008, 29, 432–460. [Google Scholar] [CrossRef]

- Mahian, O.; Kolsi, L.; Amani, M.; Estellé, P.; Ahmadi, G.; Kleinstreuer, C.; Marshall, J.S.; Siavashi, M.; Taylor, R.A.; Niazmand, H.; et al. Recent advances in modeling and simulation of nanofluid flows-Part I: Fundamentals and theory. Phys. Rep. 2019, 790, 1–48. [Google Scholar] [CrossRef]

- Das, S.K.; Putra, N.; Thiesen, P.; Roetzel, W. Temperature Dependence of Thermal Conductivity Enhancement for Nanofluids. J. Heat Transf. 2003, 125, 567–574. [Google Scholar] [CrossRef]

- Xu, G.; Fu, J.; Dong, B.; Quan, Y.; Song, G. A novel method to measure thermal conductivity of nanofluids. Int. J. Heat Mass Transf. 2019, 130, 978–988. [Google Scholar] [CrossRef]

- Mintsa, H.A.; Roy, G.; Nguyen, C.T.; Doucet, D. New temperature dependent thermal conductivity data for water-based nanofluids. Int. J. Therm. Sci. 2009, 48, 363–371. [Google Scholar] [CrossRef]

- Bailey, J.; Sharp, J.S. Infrared dielectric mirrors based on thin film multilayers of polystyrene and polyvinylpyrrolidone. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 732–739. [Google Scholar] [CrossRef]

- Slistan-Grijalva, A.; Herrera-Urbina, R.; Rivas-Silva, J.F.; Ávalos-Borja, M.; Castillón-Barraza, F.F.; Posada-Amarillas, A. Synthesis of silver nanoparticles in a polyvinylpyrrolidone (PVP) paste, and their optical properties in a film and in ethylene glycol. Mater. Res. Bull. 2008, 43, 90–96. [Google Scholar] [CrossRef]

- England, M.W.; Sato, T.; Urata, C.; Wang, L.; Hozumi, A. Transparent gel composite films with multiple functionalities: Long-lasting anti-fogging, underwater superoleophobicity and anti-bacterial activity. J. Colloid Interface Sci. 2017, 505, 566–576. [Google Scholar] [CrossRef]

- Chen, Y.-Y.; Wei, W.-C.J. Formation of mullite thin film via a sol-gel process with polyvinylpyrrolidone additive. J. Eur. Ceram. Soc. 2001, 21, 2535–2540. [Google Scholar] [CrossRef]

- Karpushkin, E.; Gvozdik, N.; Klimenko, M.; Filippov, S.K.; Angelov, B.; Bessonov, I.; Sergeyev, V. Structure and flow behavior of dilute dispersions of carbon nanotubes in polyacrylonitrile–dimethylsulfoxide solution. Colloid Polym. Sci. 2016, 294, 1187–1195. [Google Scholar] [CrossRef]

- Karpushkin, E.; Berkovich, A.; Sergeyev, V. Stabilization of Multi-Walled Carbon Nanotubes Aqueous Dispersion with Poly-N-vinylpyrrolidone via Polymer-Wrapping. Macromol. Symp. 2015, 348, 63–67. [Google Scholar] [CrossRef]

- Zhang, W.-B.; Xu, X.-L.; Yang, J.-H.; Huang, T.; Zhang, N.; Wang, Y.; Zhou, Z.-W. High thermal conductivity of poly(vinylidene fluoride)/carbon nanotubes nanocomposites achieved by adding polyvinylpyrrolidone. Compos. Sci. Technol. 2015, 106, 1–8. [Google Scholar] [CrossRef]

- Boguslavsky, Y.; Fadida, T.; Talyosef, Y.; Lellouche, J.-P. Controlling the wettability properties of polyester fibers using grafted functional nanomaterials. J. Mater. Chem. 2011, 21, 10304–10310. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, K.; Mao, X.; Yu, Q. A reflective fiber-optic refractive index sensor based on multimode interference in a coreless silica fiber. Opt. Commun. 2015, 340, 50–55. [Google Scholar] [CrossRef]

- Sun, Y.-P.; Fu, K.; Lin, Y.; Huang, W. Functionalized carbon nanotubes: Properties and applications. Acc. Chem. Res. 2002, 35, 1096–1104. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, K.; Burghard, M. Chemically functionalized carbon nanotubes. Small 2005, 1, 180–192. [Google Scholar] [CrossRef]

- Zhao, W.; Song, C.; Pehrsson, P.E. Water-soluble and optically pH-sensitive single-walled carbon nanotubes from surface modification. J. Am. Chem. Soc. 2002, 124, 12418–12419. [Google Scholar] [CrossRef]

| Sample Number | Description | Abbreviation |

|---|---|---|

| 1 | Deionized water + SWCNT | W-SW |

| 2 | Deionized water + SWCNT +PVP | W-SW-PVP |

| 3 | Deionized water + MWCNT | W-MW |

| 4 | Deionized water + MWCNT + PVP | W-MW-PVP |

| 5 | Methanol + SWCNT | M-SW |

| 6 | Methanol + SWCNT + PVP | M-SW-PVP |

| 7 | Methanol + MWCNT | M-MW |

| 8 | Methanol + MWCNT + PVP | M-SW-PVP |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cuando-Espitia, N.; Bernal-Martínez, J.; Torres-Cisneros, M.; May-Arrioja, D. Laser-Induced Deposition of Carbon Nanotubes in Fiber Optic Tips of MMI Devices. Sensors 2019, 19, 4512. https://doi.org/10.3390/s19204512

Cuando-Espitia N, Bernal-Martínez J, Torres-Cisneros M, May-Arrioja D. Laser-Induced Deposition of Carbon Nanotubes in Fiber Optic Tips of MMI Devices. Sensors. 2019; 19(20):4512. https://doi.org/10.3390/s19204512

Chicago/Turabian StyleCuando-Espitia, Natanael, Juan Bernal-Martínez, Miguel Torres-Cisneros, and Daniel May-Arrioja. 2019. "Laser-Induced Deposition of Carbon Nanotubes in Fiber Optic Tips of MMI Devices" Sensors 19, no. 20: 4512. https://doi.org/10.3390/s19204512

APA StyleCuando-Espitia, N., Bernal-Martínez, J., Torres-Cisneros, M., & May-Arrioja, D. (2019). Laser-Induced Deposition of Carbon Nanotubes in Fiber Optic Tips of MMI Devices. Sensors, 19(20), 4512. https://doi.org/10.3390/s19204512