Experimental Research on Data Synchronous Acquisition Method of Subsidence Monitoring in Submarine Gas Hydrate Mining Area

Abstract

:1. Introduction

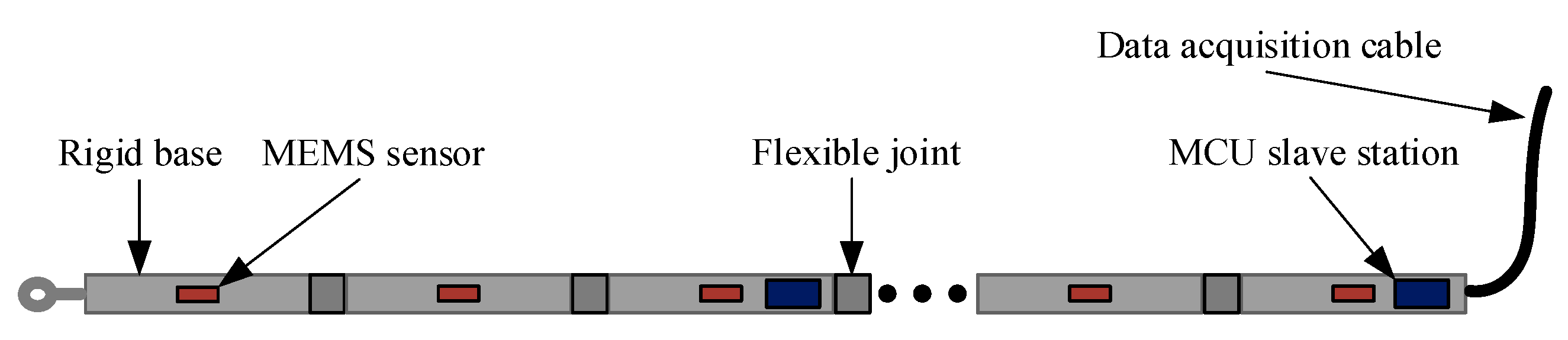

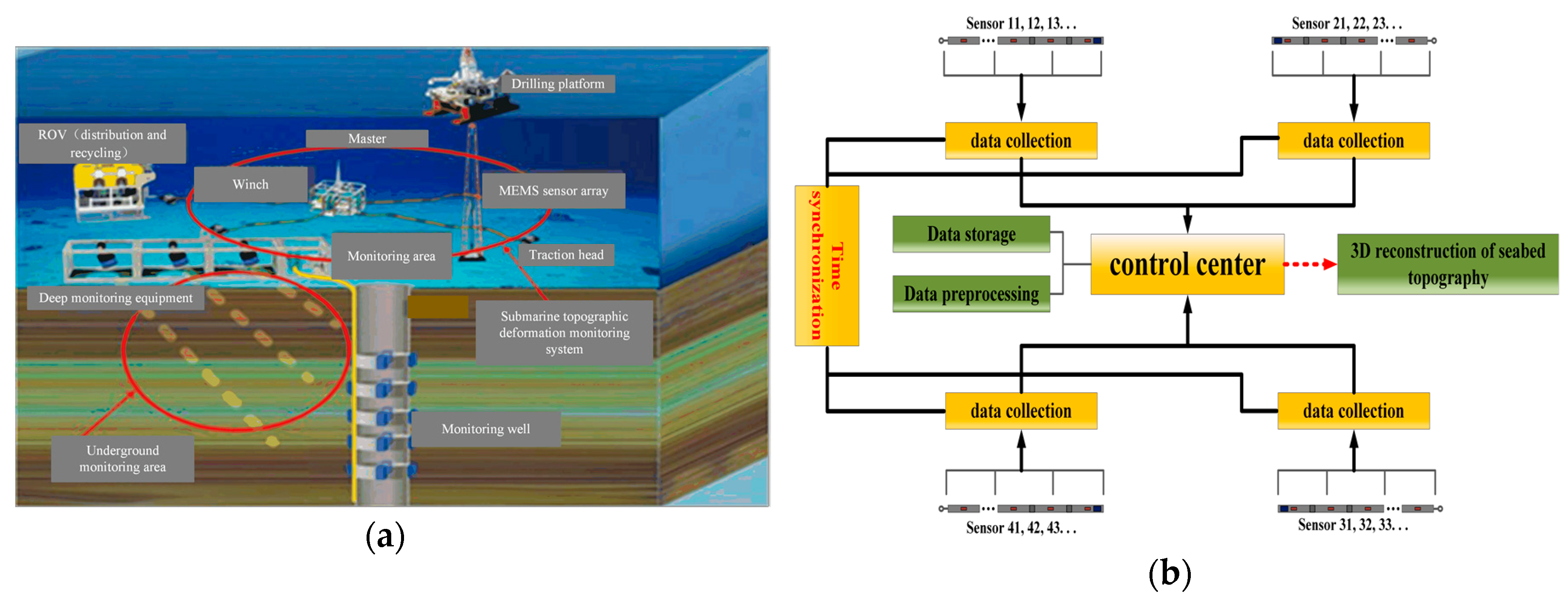

2. Design of Subsidence Monitoring System Based on MEMS Sensor for Gas Hydrate Mining Area

3. Two-Stage Data Acquisition System Based on IIC (Inter-Integrated Circuit) Bus and CAN (Controller Area Network) Bus

3.1. The First-Stage Data Acquisition and Transmission System Based on IIC Bus

3.2. Figures, Tables, and Schemes

4. Design of Relative Time Synchronization System

4.1. The First-Stage Data Acquisition and Transmission System Based on IIC Bus

4.2. The Second-Stage Data Acquisition and Transmission System Based on CAN Bus

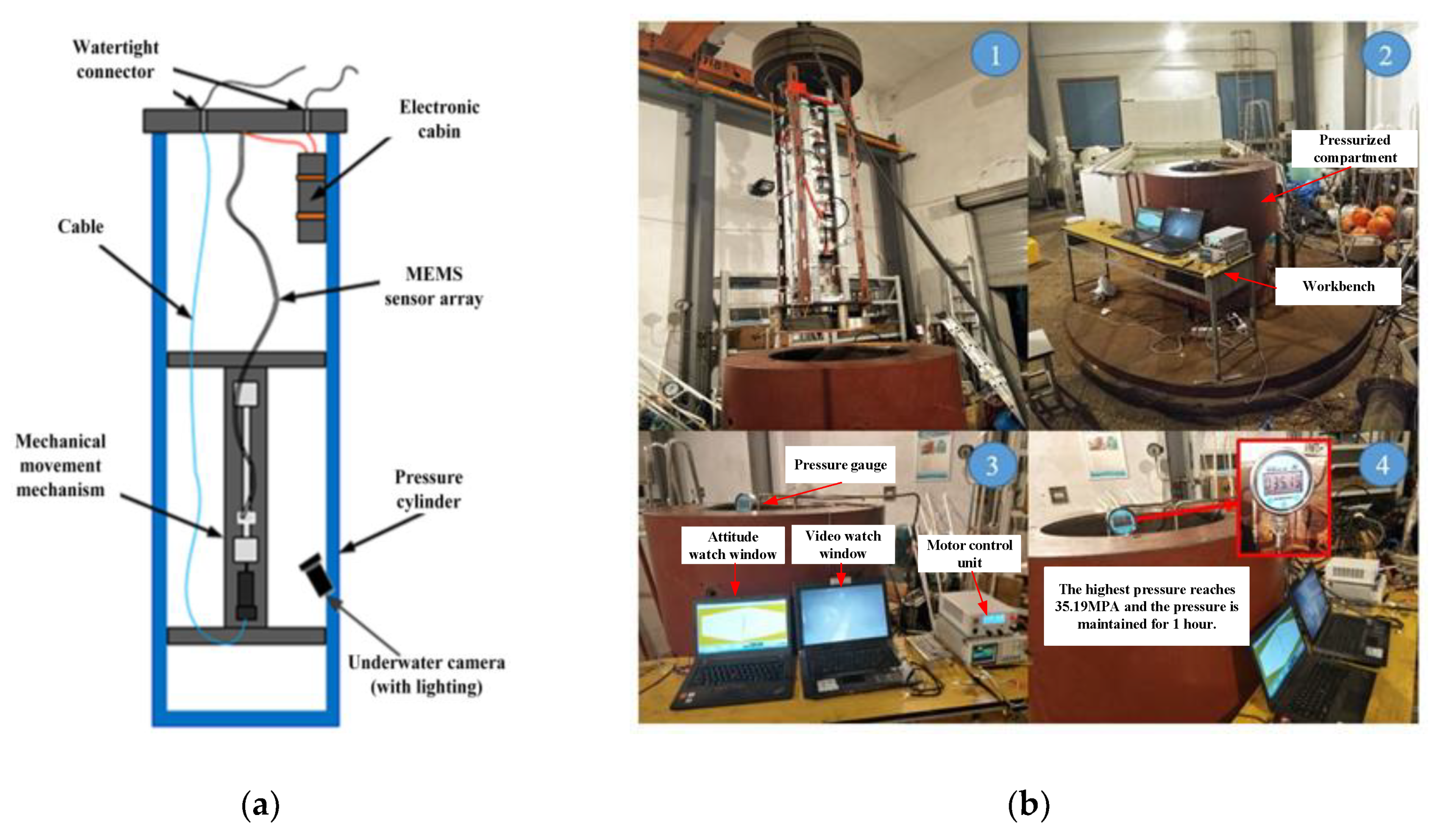

5. Tests and Results

5.1. Deformation Test of MEMS Sensor Array Under High Pressure

5.2. Synchronous Accuracy Test

5.3. Synchronization Error Analysis

5.3.1. Test of the Time (Ci-Bi) Required to Execute the Synchronization Code

5.3.2. Test of the Time Deviation (Bi-Bj) of the Response between the Two Slaves to the Trigger Signal of the Master

5.3.3. Synchronization Error Evaluation

5.4. Synchronization Error Analysis

Results Analysis and Conclusions

6. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Lorenson, T.D.; Collett, T.S.; Hunter, R.B. Gas geochemistry of the mount elbert gas hydrate stratigraphic test well, alaska north slope: Implications for gas hydrate exploration in the Arctic. Mar. Pet. Geol. 2011, 28, 343–360. [Google Scholar] [CrossRef]

- Zhang, Z. Combustible ice, the secret that cannot be shaken. China Electr. Power (Power Gener. Version) 2017, 7, 76–79. [Google Scholar]

- Masuda, Y.; Yamamoto, K.; Tadaaki, S.; Ebinuma, T. Japan’s methane hydrate R and D program progresses to phase 2. Nat. Gas Oil 2018. [Google Scholar]

- Mei, X. The Combustible Ice Revolution. Beijing Rev. 2017, 24, 34–35. [Google Scholar]

- Tian, S. The evolution course of Japan's combustible ice development technology. Pet. Petrochem. Today 2013. [Google Scholar]

- Lu, X.B.; Chen, X.D.; Lu, L.; Zhang, X.H. Numerical simulation on the marine landslide due to gas hydrate dissociation. Env. Earth Sci. 2017, 76, 172. [Google Scholar] [CrossRef] [Green Version]

- Mcconnell, D.R.; Zhang, Z.; Boswell, R. Review of progress in evaluating gas hydrate drilling hazards. Mar. Pet. Geol. 2012, 34, 209–223. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, Y.; Liu, X.; Wang, D.; Shan, H.; Guo, L.; Wei, W. In situ observation of storm-wave-induced seabed deformation with a submarine landslide monitoring system. Bull. Eng. Geol. Env. 2017, 77, 1091–1102. [Google Scholar] [CrossRef]

- Chen, J.; Xu, C.; Chen, Y.; Ji, J.; Yan, D. Study of a novel underwater cable with whole cable monitoring. Mar. Technol. Soc. J. 2016, 50, 75–82. [Google Scholar] [CrossRef]

- Xu, C.; Chen, J.; Zhu, H.; Liu, H.; Yuan, L. Experimental research on seafloor mapping and vertical deformation monitoring for gas drate zone using nine-axis MEMS sensor tapes. IEEE J. Ocean. Eng. 2018, 1–12. [Google Scholar]

- Chunying, X.; Jiawang, C.; Huangchao, Z.; Peihao, Z.; Ziqiang, R.; Hai, Z.; Yuan, L. Design and laboratory testing of a MEMS accelerometer array for subsidence monitoring. Rev. Sci. Instrum. 2018, 89, 085103. [Google Scholar]

- Yokoyama, T.; Matsuda, S.; Takeshima, J.; Sano, K.; Nakatsuka, Y. Seafloor deformation monitoring for methane hydrate production test. In Agu Fall Meeting; American Geophysical Union: Washington, DC, USA, 2014. [Google Scholar]

- Saito, H.; Yokoyama, T. Development of seafloor displacement monitoring system using a 3-component servo-accelerometer. In Proceedings of the OCEANS 2008 - MTS/IEEE Kobe Techno-Ocean, Kobe, Japan, 8–11 April 2008. [Google Scholar]

- Ning, F.; Jiang, G.; Xiang, W.; Dou, B.; Ling, Z. Seafloor gas hydrates monitoring system arranged from within borehole. In Geological Engineering: Proceedings of the 1st International Conference (ICGE 2007); American Society of Mechanical Engineers: New York, NY, USA, 2009. [Google Scholar]

- Bennett, V.G. Development of a MEMS-Based In-Place Inclinometer -Accelerometer Array for Monitoring and Evaluation of Geotechnical Systems. Ph.D. Thesis, Rensselaer Polytechnic Institute, Troy, NY, USA, 2010. [Google Scholar]

- Flores-Arias, J.M.; Ortiz-Lopez, M.; Quiles-Latorre, F.J.; Pallares, V. Complete hardware and software bench for the CAN bus. In Proceedings of the 2016 IEEE International Conference on Consumer Electronics (ICCE), Las Vegas, NV, USA, 7–11 January 2016. [Google Scholar]

- Kinugasa, N. Spike Noise Eliminating Circuit, Digital System Using The Same, and IIC Bus. U.S. Patent US7868662B2, 11 January 2011. [Google Scholar]

- Chen, T.; Jiang, H.; Xue, L.; Wang, X.; Liu, W.; Yi, W. Tri-Message: A light-weight time synchronization protocol for high latency and resource-constrained networks. In Proceedings of the 2009 IEEE International Conference on Communications, Dresden, Germany, 14–18 June 2009. [Google Scholar]

- Mcnutt, M.; Massion, G.; Raybould, K.; Bellingham, J.; Paull, C. MARS: A cabled observatory testbed in monterey bay. In Proceedings of the EGS‐AGU‐EUG Joint Assembly, Nice, France, 6–11 April 2003; pp. 1–9. [Google Scholar]

- Han, J.; Jeong, D.K. Practical considerations in the design and implementation of time synchronization systems using IEEE 1588. IEEE Commun. Mag. 2009, 47, 164–170. [Google Scholar]

- Han, J.; Jeong, D.-K. A practical implementation of IEEE 1588-2008 transparent clock for distributed measurement and control systems. IEEE Trans. Instrum. Meas. 2010, 59, 433–439. [Google Scholar]

- Lei, M.; Xiong, Q.Z.; Zhang, S.H.; Qian, L.I.; Hao-Liang, H.U.; He, L.I. A clock synchronization device with IRIG-B code based on the SPOC technology. Electr. Meas. Instrum. 2012. [Google Scholar]

- Huang, J.K.; Du, L.; Liu, Q.Y. Application of IRIG-B code in phasem easurement unit. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012. [Google Scholar]

- Belyea, J.; Johnson, M.C.; Nicholson, Z.M.; Ricks, J.L.; Kaufman, E.D.; Shah, P.K.; Bayless, M.; Pettersson, T.R.; Feldot, Z.; Blomberg, E. Probing protein adsorption onto mercaptoundecanoic acid stabilized gold nanoparticles and surfaces by quartz crystal microbalance and ζ-potential measurements. Langmuir Acs J. Surf. Colloids 2007, 23, 6053. [Google Scholar]

- Taranchuk, A.A.; Pidchenko, S.K.; Khoptinskiy, R.P. Dynamics of temperature-frequency processes in multifrequency crystal oscillators with digital compensations of resonator performance instability. Radioelectron. Commun. Syst. 2015, 58, 250–257. [Google Scholar] [CrossRef]

- Ni, C.; Ying, J.; Liu, S.; Zou, X. Design of LVDS high-speed I/O interface circuits. J. Huazhong Univ. Sci. Technol. 2003. [Google Scholar]

| Mean Absolute Error (mm) | Root Mean Square Error (mm) | Maximum Absolute Error (mm) | |

|---|---|---|---|

| Shape1 | 4.62 | 5.33 | 6.72 |

| Shape2 | 1.53 | 2.26 | 2.18 |

| Shape3 | 2.06 | 4.32 | 4.66 |

| Source of Error | Range of Error |

|---|---|

| The drift of the clock from slave in the interval of synchronization | 3.16 ms |

| The deviation of the slave executes the synchronization code | <8.5 us |

| The deviation of the response time of slave from the master I/O trigger signal | <375 us |

| Mean Square Error (cm) | Maximum Error (cm) | Maximum Deformation (cm) | Maximum Tilt Angle (°) | Minimum Tilt Angle (°) | |

|---|---|---|---|---|---|

| Landslide | 0.85 | 1.26 | 18.3 | 28.03 | 1.25 |

| Collapse | 1.02 | 1.32 | 23.7 | 20.95 | 1.62 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Cao, C.; Ge, Y.; Zhu, H.; Xu, C.; Sheng, Y.; Tian, L.; Zhang, H. Experimental Research on Data Synchronous Acquisition Method of Subsidence Monitoring in Submarine Gas Hydrate Mining Area. Sensors 2019, 19, 4319. https://doi.org/10.3390/s19194319

Chen J, Cao C, Ge Y, Zhu H, Xu C, Sheng Y, Tian L, Zhang H. Experimental Research on Data Synchronous Acquisition Method of Subsidence Monitoring in Submarine Gas Hydrate Mining Area. Sensors. 2019; 19(19):4319. https://doi.org/10.3390/s19194319

Chicago/Turabian StyleChen, Jiawang, Chen Cao, Yongqiang Ge, Huangchao Zhu, Chunying Xu, Yan Sheng, Lieyu Tian, and Hanquan Zhang. 2019. "Experimental Research on Data Synchronous Acquisition Method of Subsidence Monitoring in Submarine Gas Hydrate Mining Area" Sensors 19, no. 19: 4319. https://doi.org/10.3390/s19194319

APA StyleChen, J., Cao, C., Ge, Y., Zhu, H., Xu, C., Sheng, Y., Tian, L., & Zhang, H. (2019). Experimental Research on Data Synchronous Acquisition Method of Subsidence Monitoring in Submarine Gas Hydrate Mining Area. Sensors, 19(19), 4319. https://doi.org/10.3390/s19194319