Ultrathin Tunable Lens Based on Boundary Tension Effect

Abstract

1. Introduction

2. Liquid Surface Deformation Analysis

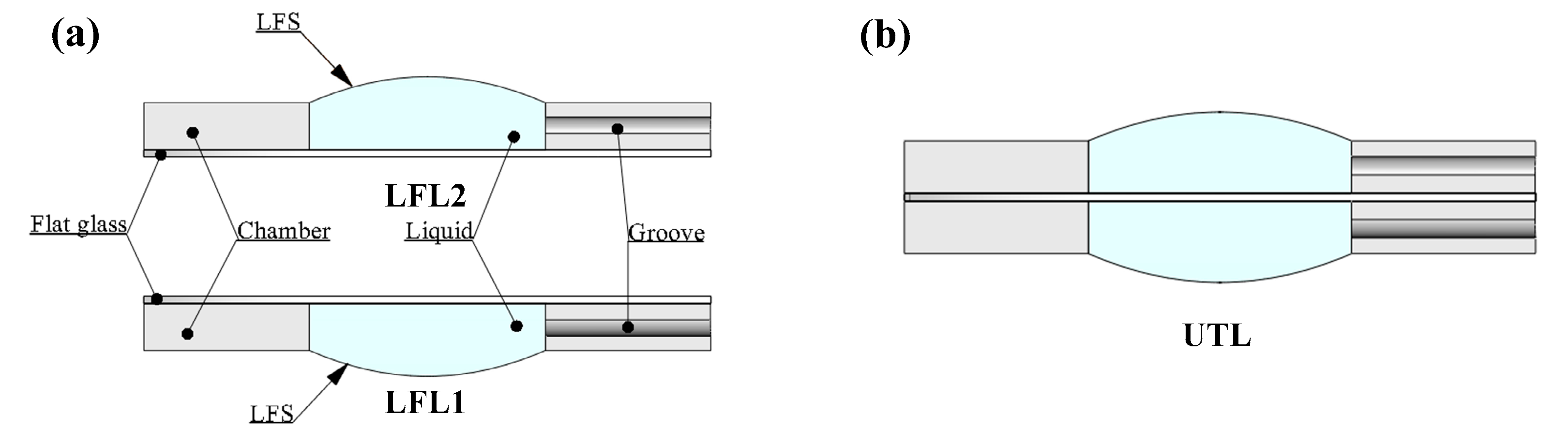

2.1. Lens Design

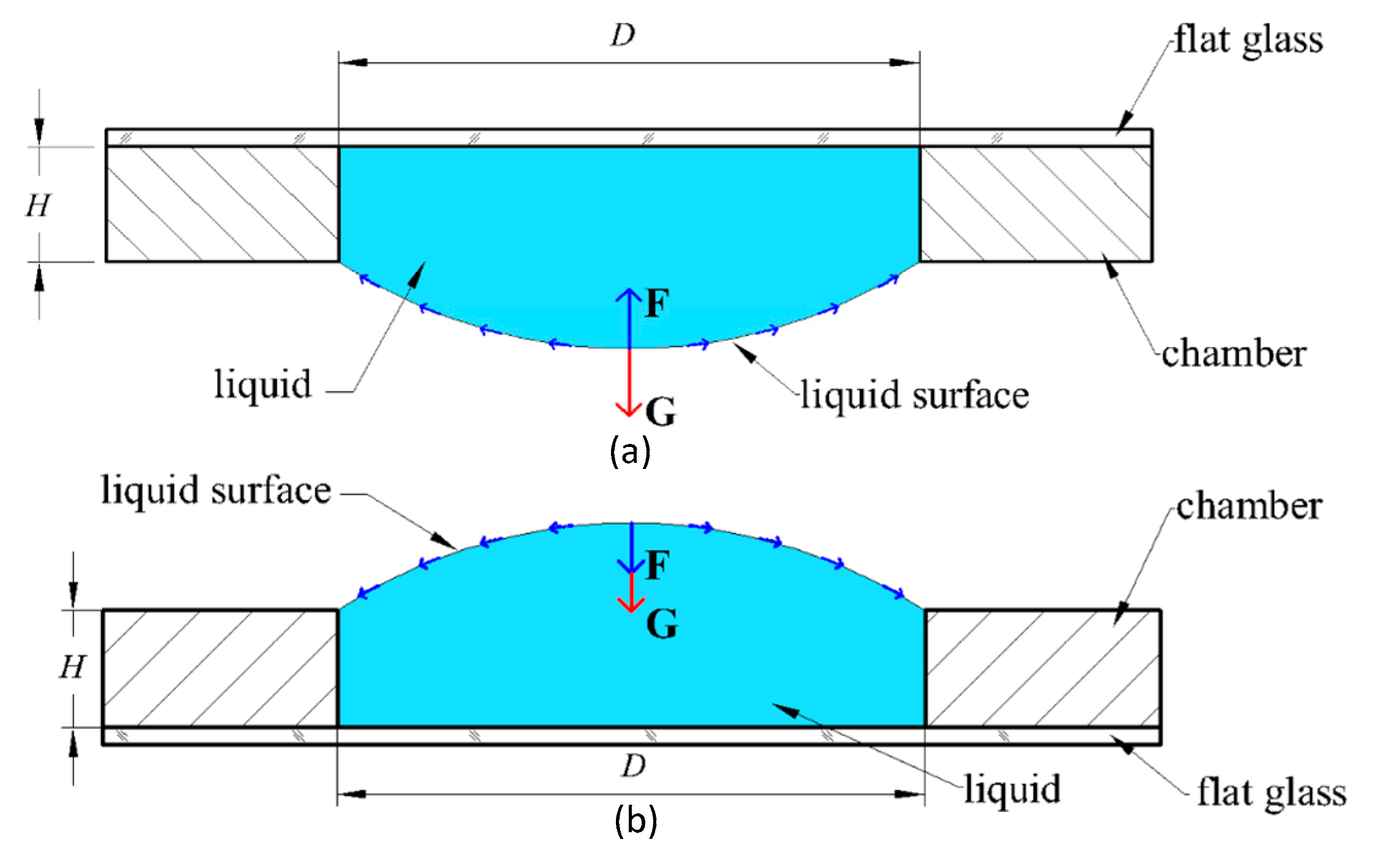

2.2. Mechanical Analysis

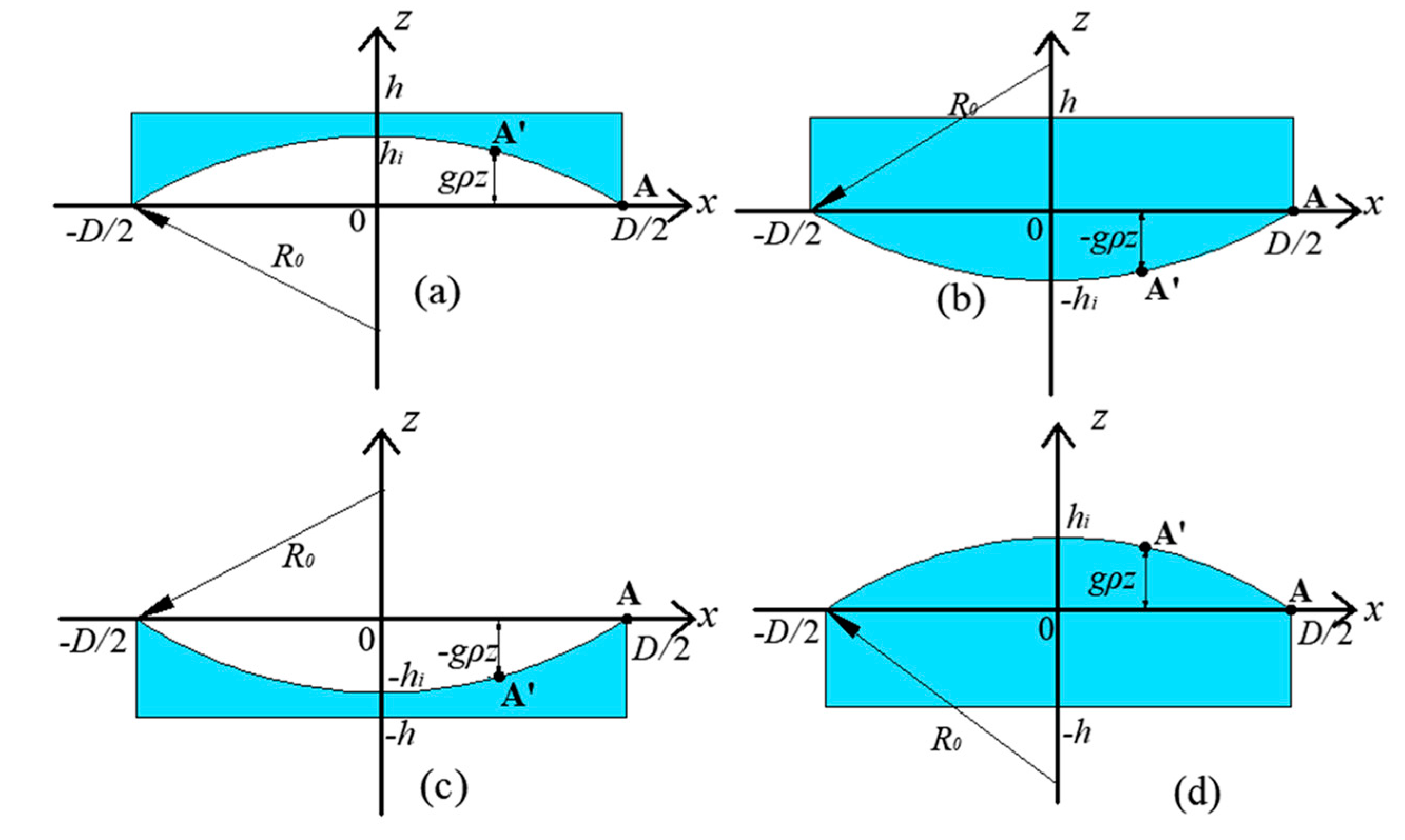

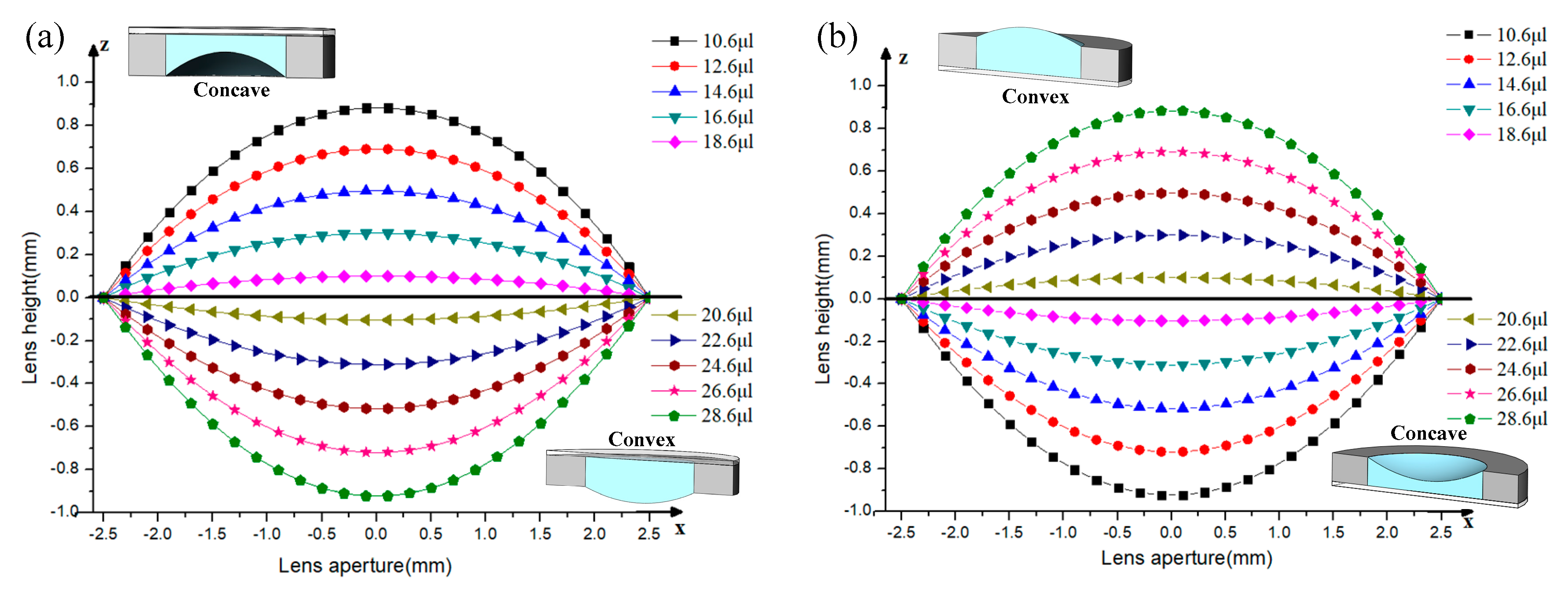

2.3. Numerical Solution of the Lfs Profile

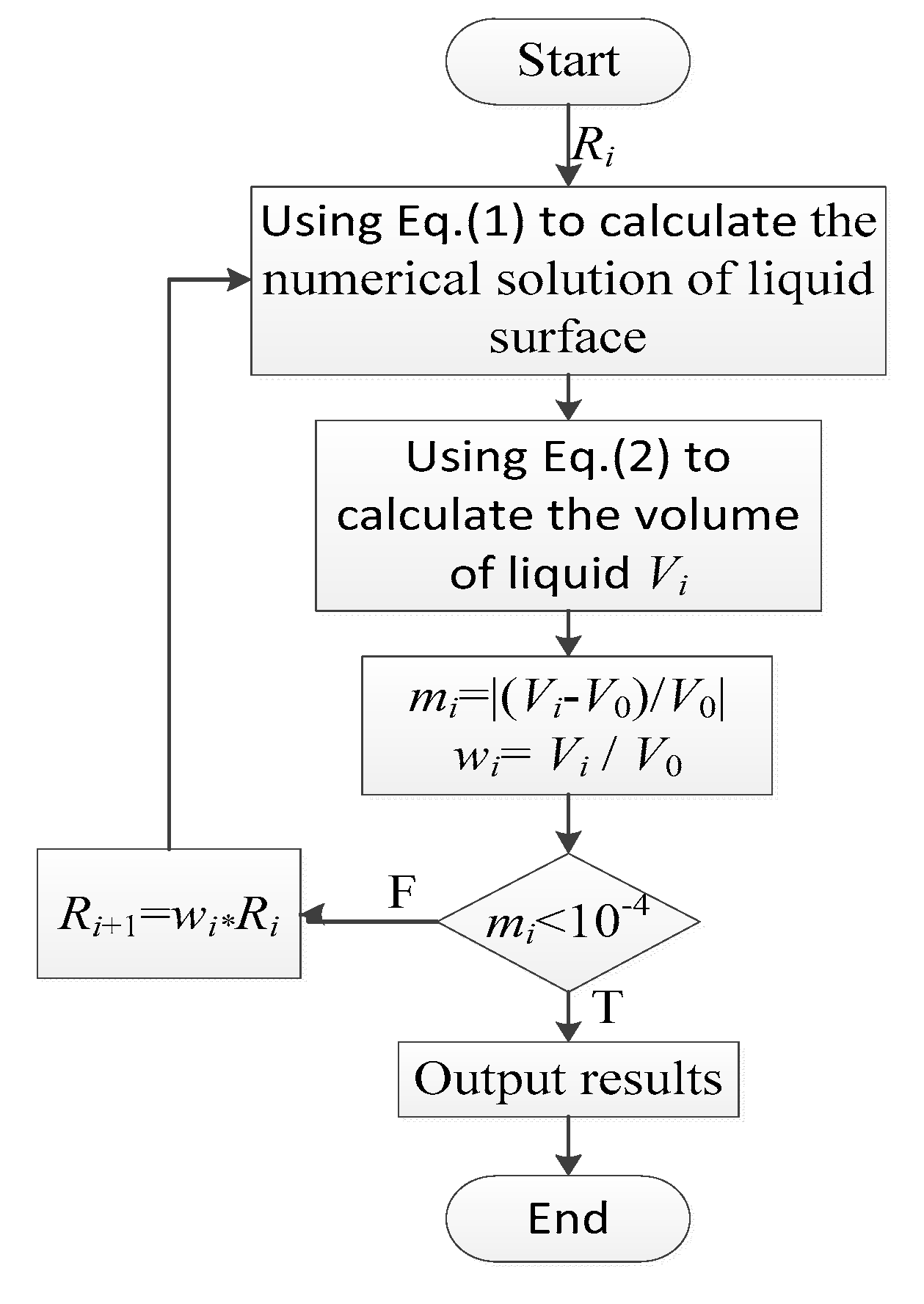

- With Equation (1), the corresponding relationship between ordinate z and abscissa x can be solved by giving a non-zero origin curvature Ri with ODE45, which is a numerical solution function of the ordinary differential equation in MATLAB.

- With the aid of the trapezoidal numerical integration formula (TRAPZ) in MATLAB, the integral volume of the area surrounded by the LFS can be conducted for the numerical solution of the LFS profile, which is obtained in the first step. The volume of liquid Vi can then be calculated by Equation (2).

- The volume of liquid Vi obtained by the second step is compared with the given volume of liquid V0, and their difference is calculated as mi = |(Vi − V0)/V0|. Meanwhile, the volume ratio can be calculated as wi = Vi/V0.

- If mi < 10−4, then the calculated volume of liquid Vi is consistent with the given volume of liquid V0 and the output relationship between ordinate z and abscissa x.

- If mi > 10−4, then the calculated volume of liquid Vi is inconsistent with the given volume of liquid V0. The origin curvature is therefore corrected as Ri+1 = wi × Ri. Ri+1 is substituted into the first step, and Steps (1)–(4) are repeated until the relationship between ordinate z and abscissa x of the LFS profile satisfies the requirements.

3. Optical Simulation of the Ultrathin Tunable Lens (UTL)

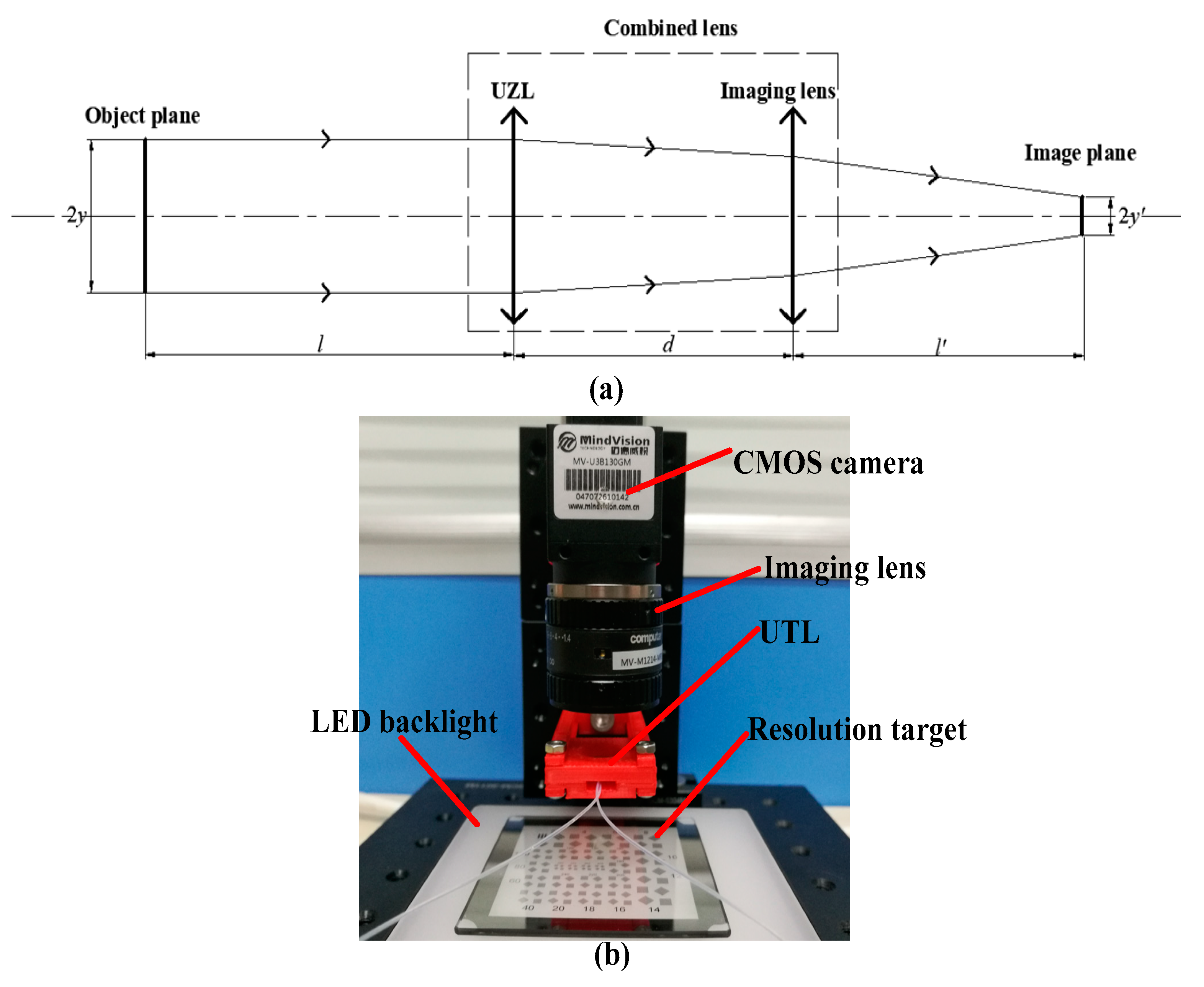

4. Experiment and Result Discussion

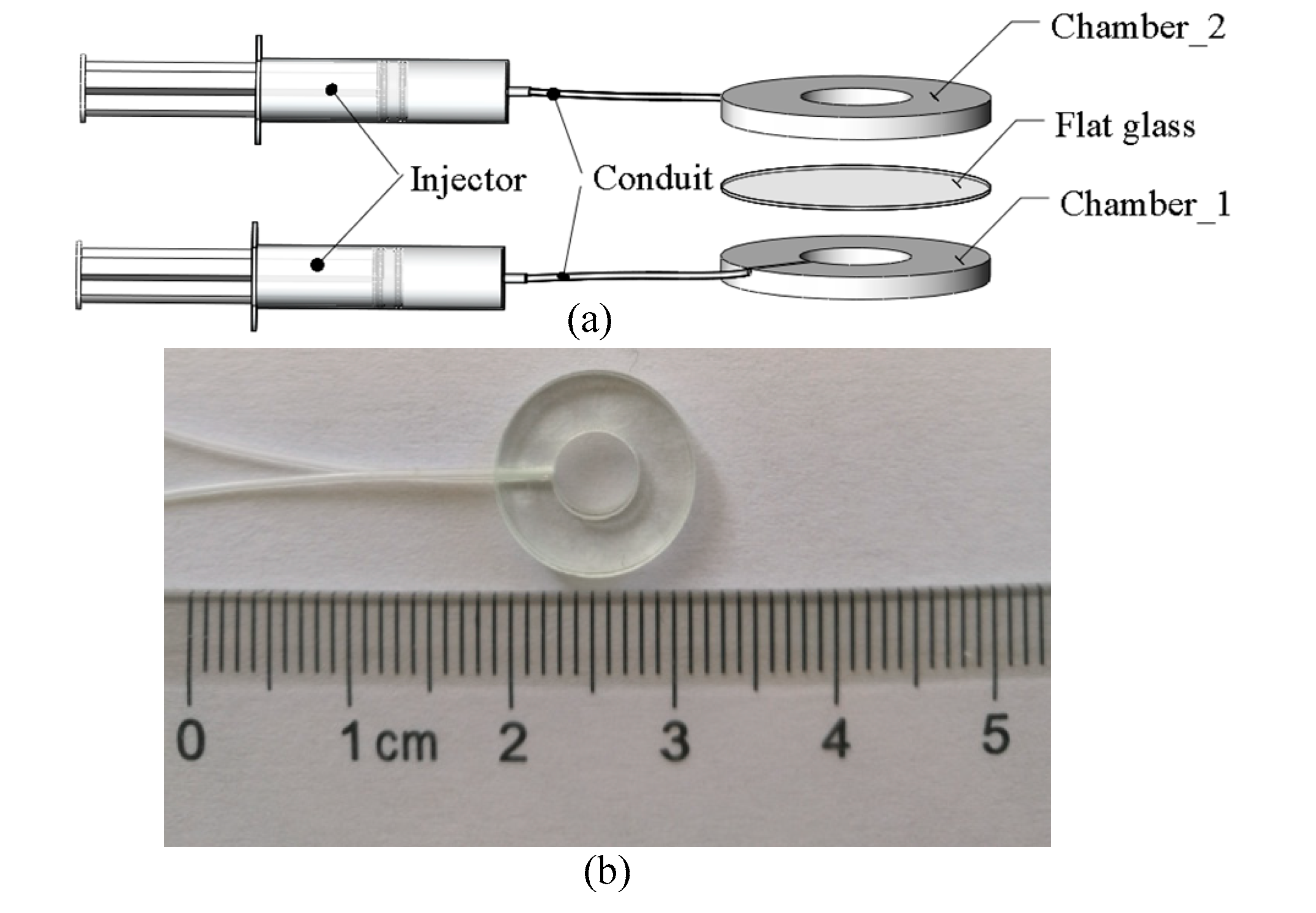

- The image height of the resolution target y′0 is obtained when no liquid is injected into the UTL, as shown in Figure 10a.

- To form a flat lens, 19.6 microbubbles are injected into LFL2.

- The zoom of the UTL is controlled by adjusting the volume of liquid injected into LFL1. Simultaneously, with the adjustment of the distance, a clear image and its height y′n of the nth zoom can be obtained by the camera. The imaging results of the UTL with different focal lengths are shown in Figure 10b–i.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Song, Y.M.; Xie, Y.; Malyarchuk, V.; Xiao, J.; Jung, I.; Choi, K.J.; Liu, Z.; Park, H.; Lu, C.; Kim, R.H.; et al. Digital cameras with designs inspired by the arthropod eye. Nature 2013, 497, 95–99. [Google Scholar] [CrossRef] [PubMed]

- Khorasaninejad, M.; Chen, W.T.; Devlin, R.C.; Oh, J.; Zhu, A.Y.; Capasso, F. Metalenses at visible wavelengths Diffraction-limited focusing and subwavelength resolution imaging. Science 2016, 352, 1190–1194. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.; Hua, H. Design and demonstration of a vari-focal optical see-through head-mounted display using freeform Alvarez lenses. Opt. Express. 2019, 27, 15627–15637. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Wu, P.C.; Su, V.C.; Lai, Y.C.; Hung Chu, C.; Chen, J.W.; Lu, S.H.; Chen, J.; Xu, B.; Kuan, C.H.; et al. Broadband achromatic optical metasurface devices. Nat. Commun. 2017, 8, 187. [Google Scholar] [CrossRef] [PubMed]

- Ee, H.S.; Agarwal, R. Tunable Metasurface and Flat Optical Zoom Lens on a Stretchable Substrate. Nano Lett. 2016, 16, 2818–2823. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Wang, D.; Bhowmik, D.; Liu, T.; Deng, S.; Knudson, M.P.; Ao, X.; Odom, T.W. Lattice-Resonance Metalenses for Fully Reconfigurable Imaging. ACS Nano 2019, 13, 4613–4620. [Google Scholar] [CrossRef] [PubMed]

- She, A.; Zhang, S.Y.; Shian, S.; Clarke, D.R.; Capasso, F. Adaptive metalenses with simultaneous electrical control of focal length, astigmatism, and shift. Sci. Adv. 2018, 4. [Google Scholar] [CrossRef] [PubMed]

- Arbabi, E.; Arbabi, A.; Kamali, S.M.; Horie, Y.; Faraji-Dana, M.; Faraon, A. MEMS-tunable dielectric metasurface lens. Nat. Commun. 2018, 9, 812. [Google Scholar] [CrossRef]

- Kuiper, S.; Hendriks, B.H.W. Variable-focus liquid lens for miniature cameras. Appl. Phys. Lett. 2004, 85, 1128–1130. [Google Scholar] [CrossRef]

- Gaber, N.; Altayyeb, A.; Soliman, S.A.; Sabry, Y.M.; Marty, F.; Bourouina, T. On-Channel Integrated Optofluidic Pressure Sensor with Optically Boosted Sensitivity. Sensors 2019, 19, 944. [Google Scholar] [CrossRef]

- Lee, Y.H.; Peng, F.; Wu, S.T. Fast-response switchable lens for 3D and wearable displays. Opt. Express. 2016, 24, 1668–1675. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Cheng, X.; Hao, Q. An Electrically Tunable Zoom System Using Liquid Lenses. Sensors 2016, 16, 45. [Google Scholar] [CrossRef] [PubMed]

- Patra, R.; Agarwal, S.; Kondaraju, S.; Bahga, S.S. Membrane-less variable focus liquid lens with manual actuation. Opt. Commun. 2017, 389, 74–78. [Google Scholar] [CrossRef]

- Yang, A.; Ning, L.; Gao, X.; Li, M.; Li, W. Design of liquid-glass achromatic zoom lens. Opt. Rev. 2017, 24, 361–369. [Google Scholar] [CrossRef]

- Dean, J.L.; Hirsa, A.H. Performance of a microscope with an embedded oscillating pinned-contact liquid lens. Appl. Opt. 2015, 54, 8228–8234. [Google Scholar] [CrossRef]

- Li, L.; Wang, D.; Liu, C.; Wang, Q.H. Zoom microscope objective using electrowetting lenses. Opt. Express. 2016, 24, 2931–2940. [Google Scholar] [CrossRef] [PubMed]

- Llavador, A.; Scrofani, G.; Saavedra, G.; Martinez-Corral, M. Large Depth-of-Field Integral Microscopy by Use of a Liquid Lens. Sensors 2018, 18, 3383. [Google Scholar] [CrossRef]

- Xiong, K.; Yang, S.; Li, X.; Xing, D. Autofocusing optical-resolution photoacoustic endoscopy. Opt. Lett. 2018, 43, 1846–1849. [Google Scholar] [CrossRef]

- Cheng, Y.; Cao, J.; Meng, L.; Wang, Z.; Zhang, K.; Ning, Y.; Hao, Q. Reducing defocus aberration of a compound and human hybrid eye using liquid lens. Appl. Opt. 2018, 57, 1679–1688. [Google Scholar] [CrossRef]

- Watson, A.M.; Dease, K.; Terrab, S.; Roath, C.; Gopinath, J.T.; Bright, V.M. Focus-tunable low-power electrowetting lenses with thin parylene films. Appl. Opt. 2015, 54, 6224–6229. [Google Scholar] [CrossRef]

- Li, L.; Wang, D.; Liu, C.; Wang, Q.H. Ultrathin zoom telescopic objective. Opt. Express. 2016, 24, 18674–18684. [Google Scholar] [CrossRef] [PubMed]

- Xu, M.; Wang, X.; Ren, H. Tunable Focus Liquid Lens with Radial-Patterned Electrode. Micromachines 2015, 6, 1157–1165. [Google Scholar] [CrossRef]

- Hasan, N.; Banerjee, A.; Kim, H.; Mastrangelo, C.H. Tunable-focus lens for adaptive eyeglasses. Opt. Express. 2017, 25, 1221–1233. [Google Scholar] [CrossRef] [PubMed]

- Wei, K.; Huang, H.; Wang, Q.; Zhao, Y. Focus-tunable liquid lens with an aspherical membrane for improved central and peripheral resolutions at high diopters. Opt. Express. 2016, 24, 3929–3939. [Google Scholar] [CrossRef] [PubMed]

- Ding, Z.; Wang, C.; Hu, Z.; Cao, Z.; Zhou, Z.; Chen, X.; Chen, H.; Qiao, W. Surface profiling of an aspherical liquid lens with a varied thickness membrane. Opt. Express. 2017, 25, 3122–3132. [Google Scholar] [CrossRef] [PubMed]

- Reichelt, S.; Zappe, H. Design of spherically corrected achromatic variable-focus liquid lenses. Opt. Express. 2007, 15, 14146–14154. [Google Scholar] [CrossRef]

- Wang, L.; Oku, H.; Ishikawa, M. Variable-focus lens with 30 mm optical aperture based on liquid–membrane–liquid structure. Appl. Phys. Lett. 2013, 102. [Google Scholar] [CrossRef]

- Andreas, J.M.; Hauser, E.A.; Tucker, W.B. Boundary tension by pendant drops. J. Phys. Chem. 1938, 42, 1001–1019. [Google Scholar] [CrossRef]

- Milton, L. Lens Design, 4th ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 7–8. [Google Scholar]

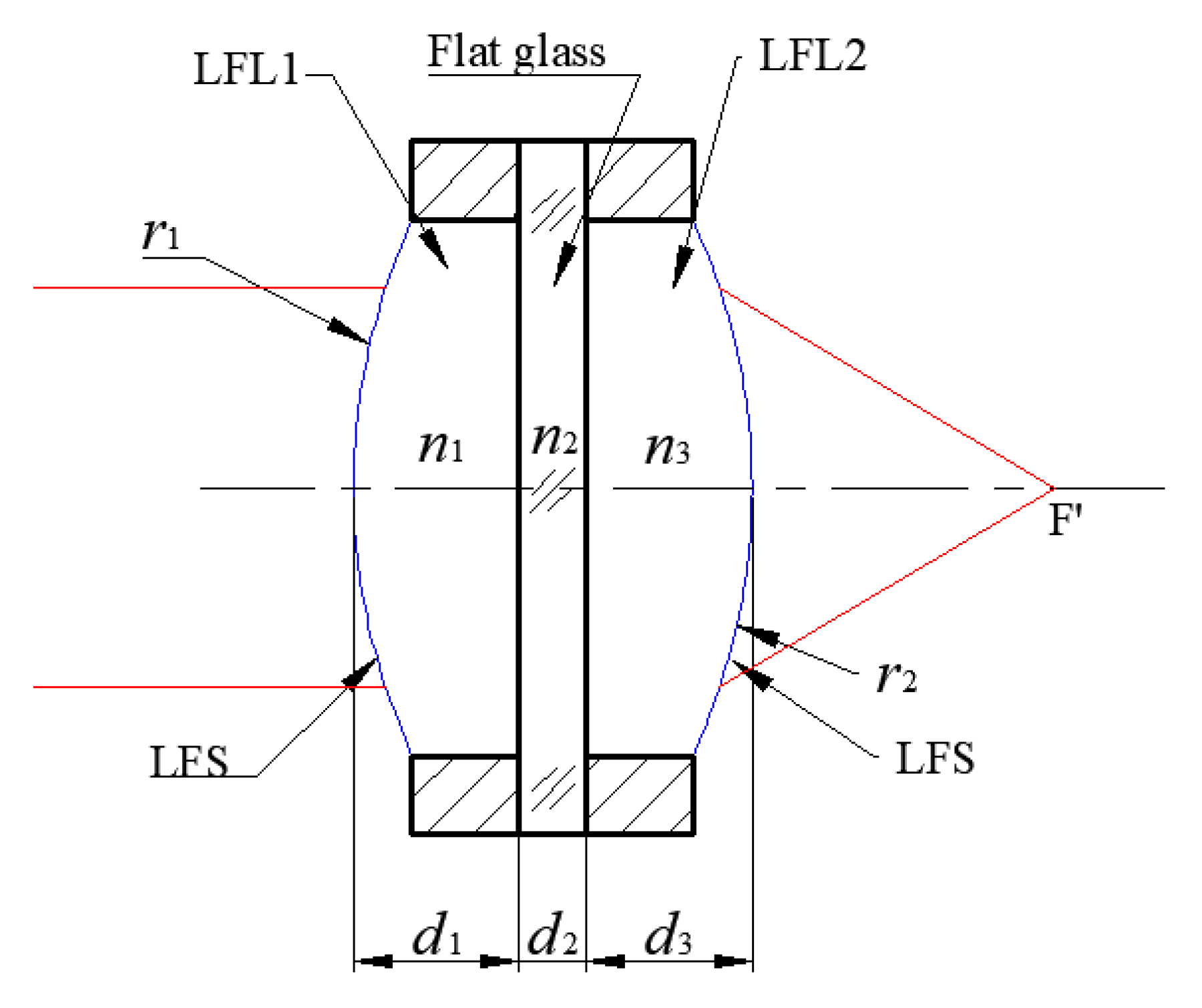

| LFL1 | Flat Glass | LFL2 | |

|---|---|---|---|

| Material | water | K9 | water |

| Index of refraction | n1 = 1.333 | n2 = 1.516 | n3 = 1.333 |

| Thickness | d1 = 1 − hi | d2 = 0.15 | d3 = 1 + hi |

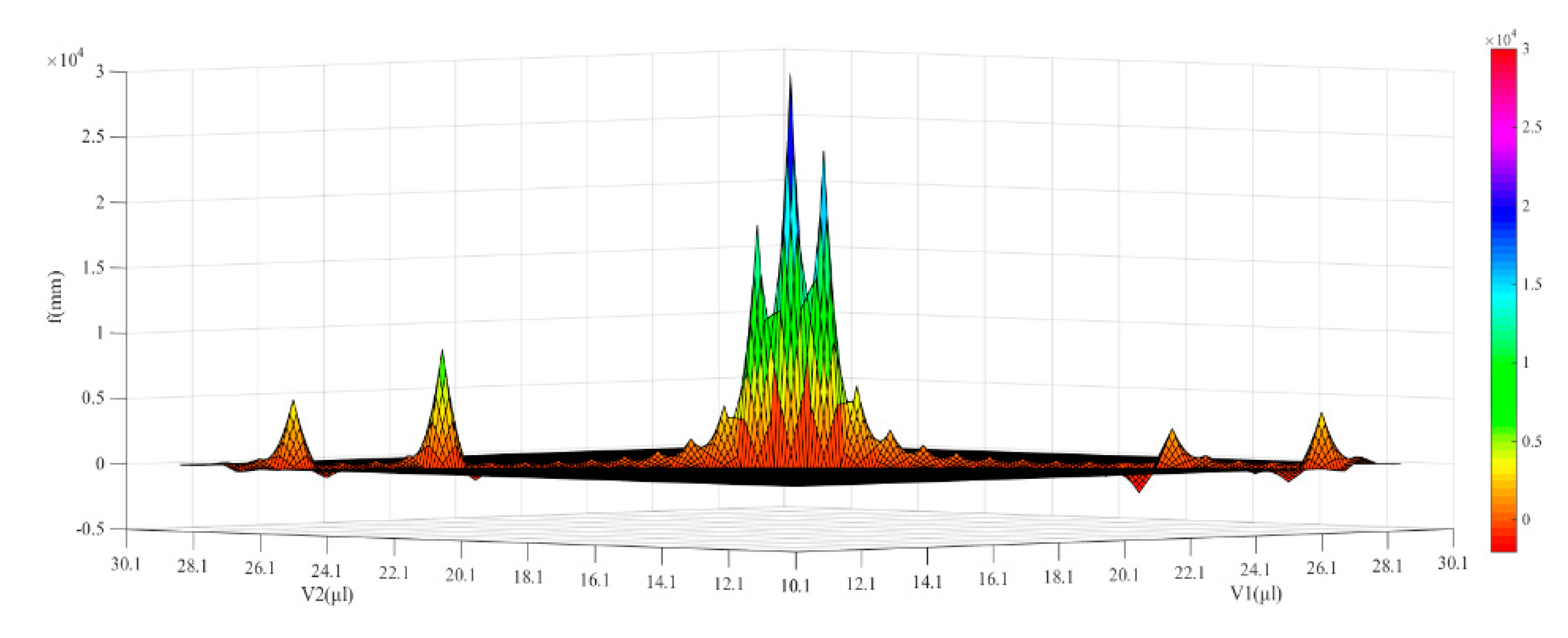

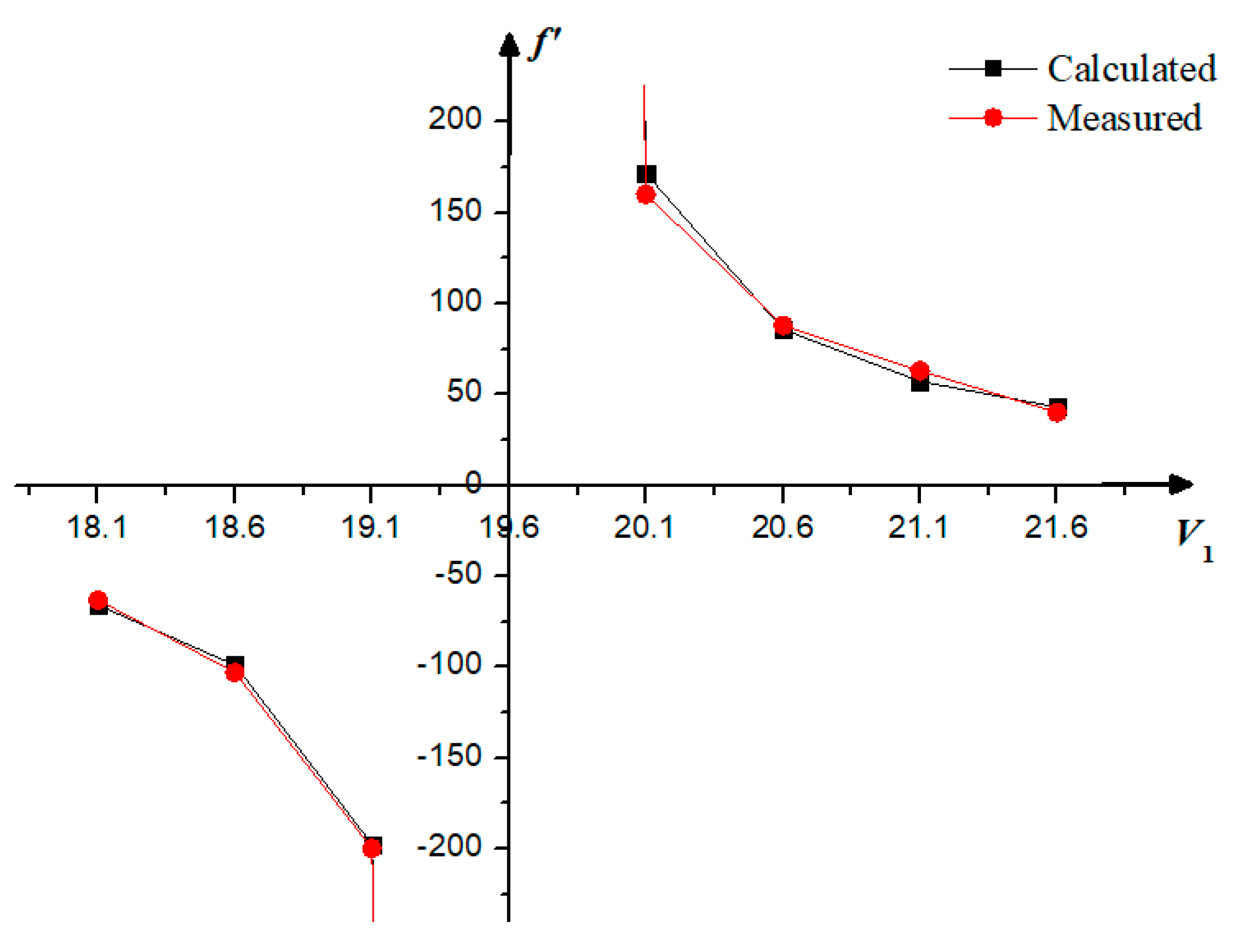

| V1 (μL) | Calculated (mm) | Measured (mm) |

|---|---|---|

| 18.1 | −66.06 | −63.2 |

| 18.6 | −98.93 | −103.07 |

| 19.1 | −197.68 | −200 |

| 19.6 | ∞ | ∞ |

| 20.1 | 171.53 | 160 |

| 20.6 | 85.83 | 88 |

| 21.1 | 57.29 | 63.07 |

| 21.6 | 43.03 | 40 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, A.; Cao, J.; Zhang, F.; Cheng, Y.; Hao, Q. Ultrathin Tunable Lens Based on Boundary Tension Effect. Sensors 2019, 19, 4018. https://doi.org/10.3390/s19184018

Yang A, Cao J, Zhang F, Cheng Y, Hao Q. Ultrathin Tunable Lens Based on Boundary Tension Effect. Sensors. 2019; 19(18):4018. https://doi.org/10.3390/s19184018

Chicago/Turabian StyleYang, Ao, Jie Cao, Fanghua Zhang, Yang Cheng, and Qun Hao. 2019. "Ultrathin Tunable Lens Based on Boundary Tension Effect" Sensors 19, no. 18: 4018. https://doi.org/10.3390/s19184018

APA StyleYang, A., Cao, J., Zhang, F., Cheng, Y., & Hao, Q. (2019). Ultrathin Tunable Lens Based on Boundary Tension Effect. Sensors, 19(18), 4018. https://doi.org/10.3390/s19184018