A Sensor for Broken Wire Detection of Steel Wire Ropes Based on the Magnetic Concentrating Principle

Abstract

1. Introduction

2. Theoretical Background

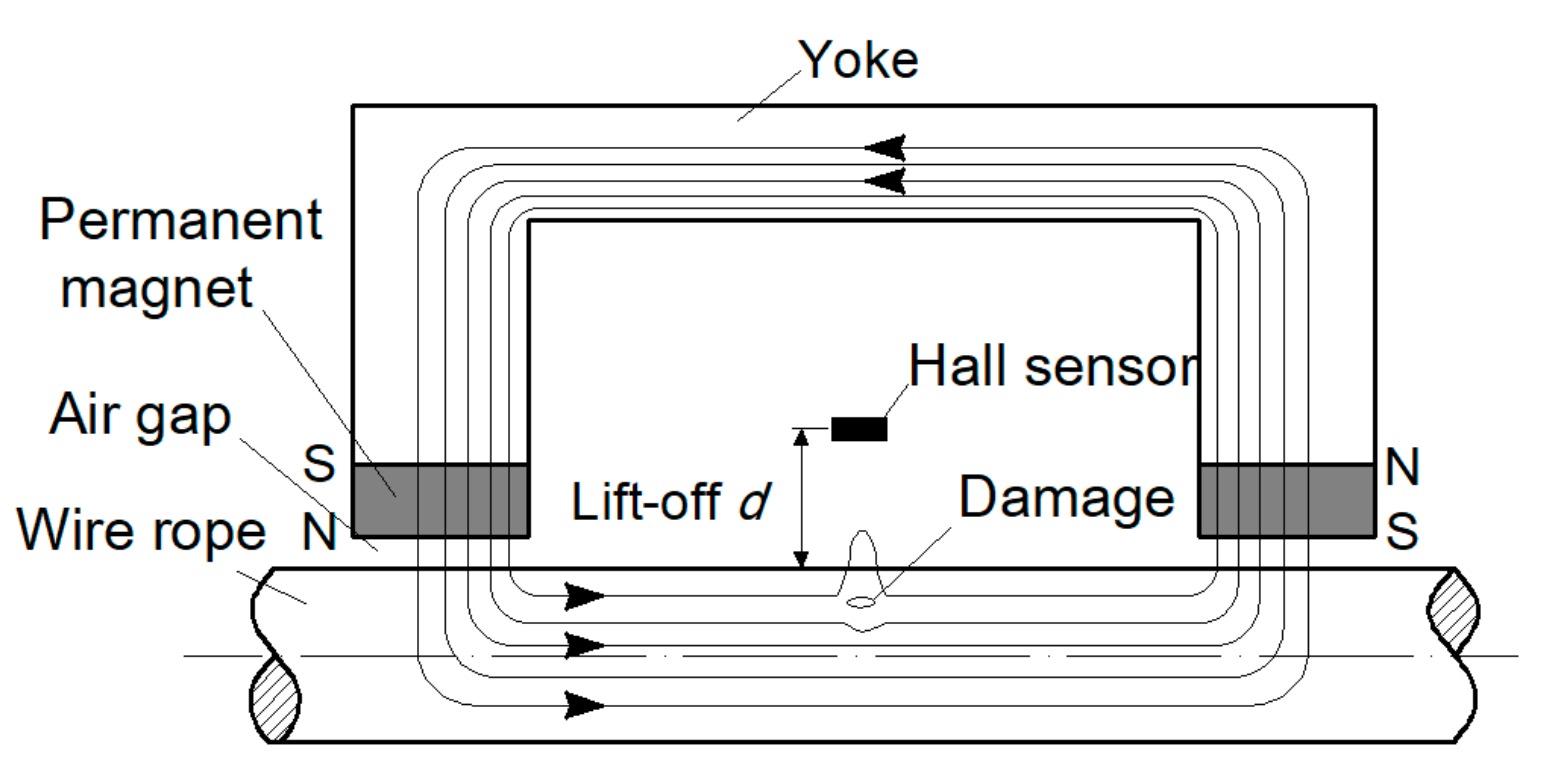

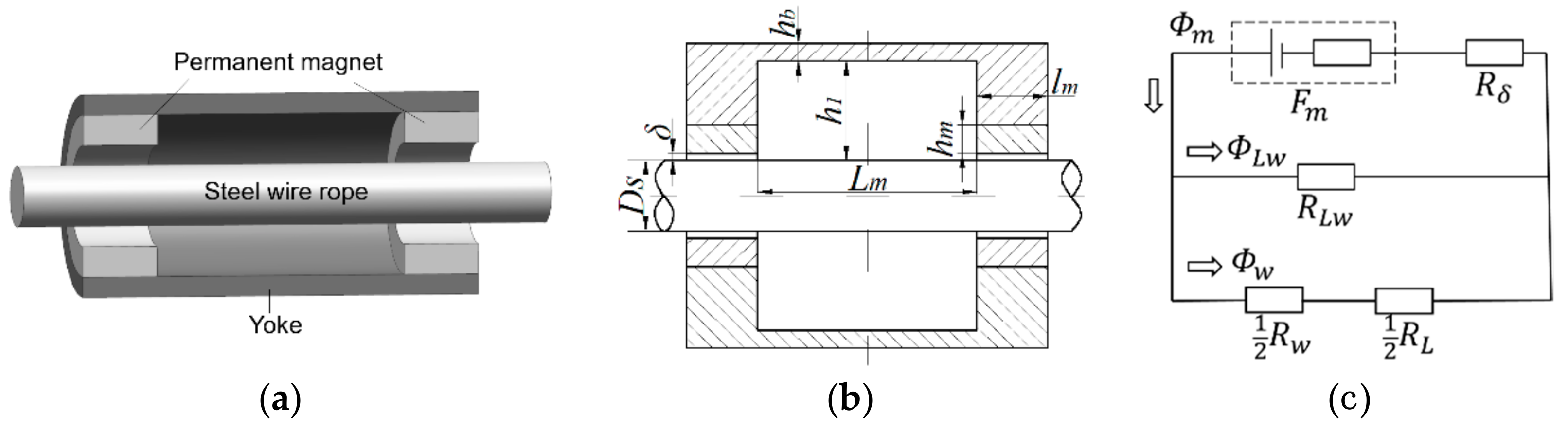

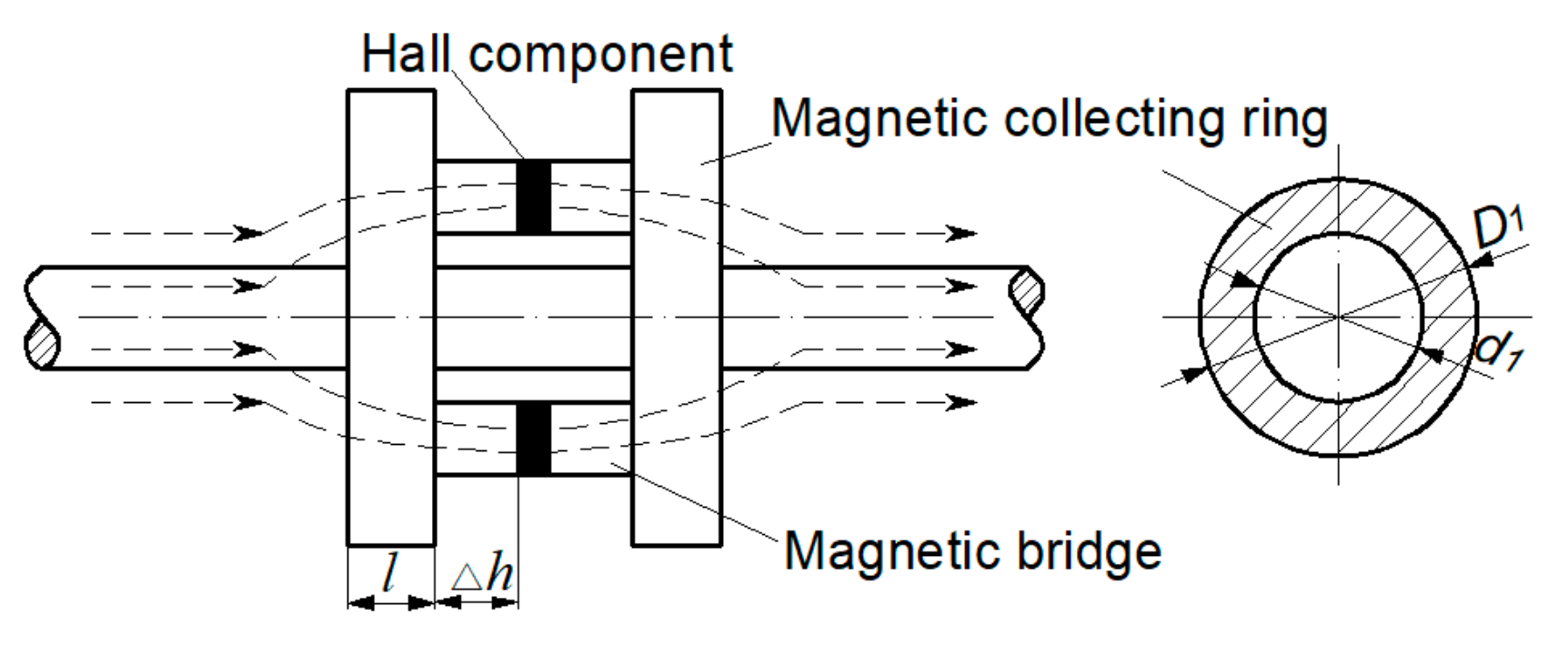

2.1. Structural Design Principle of CMPME

2.2. Principle of Magnetic Concentrating Detection

3. Finite Element Analysis of the Sensor Structure

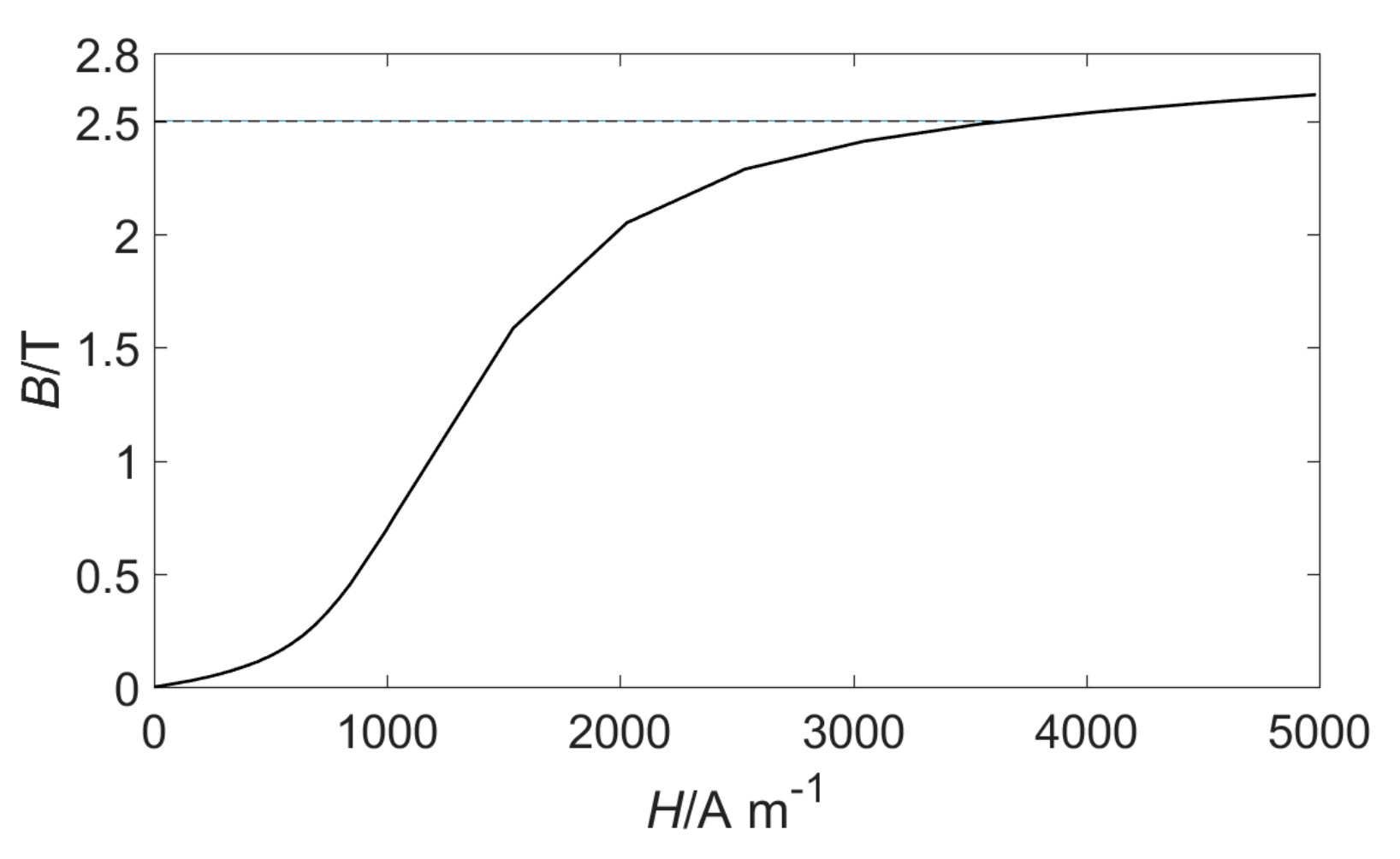

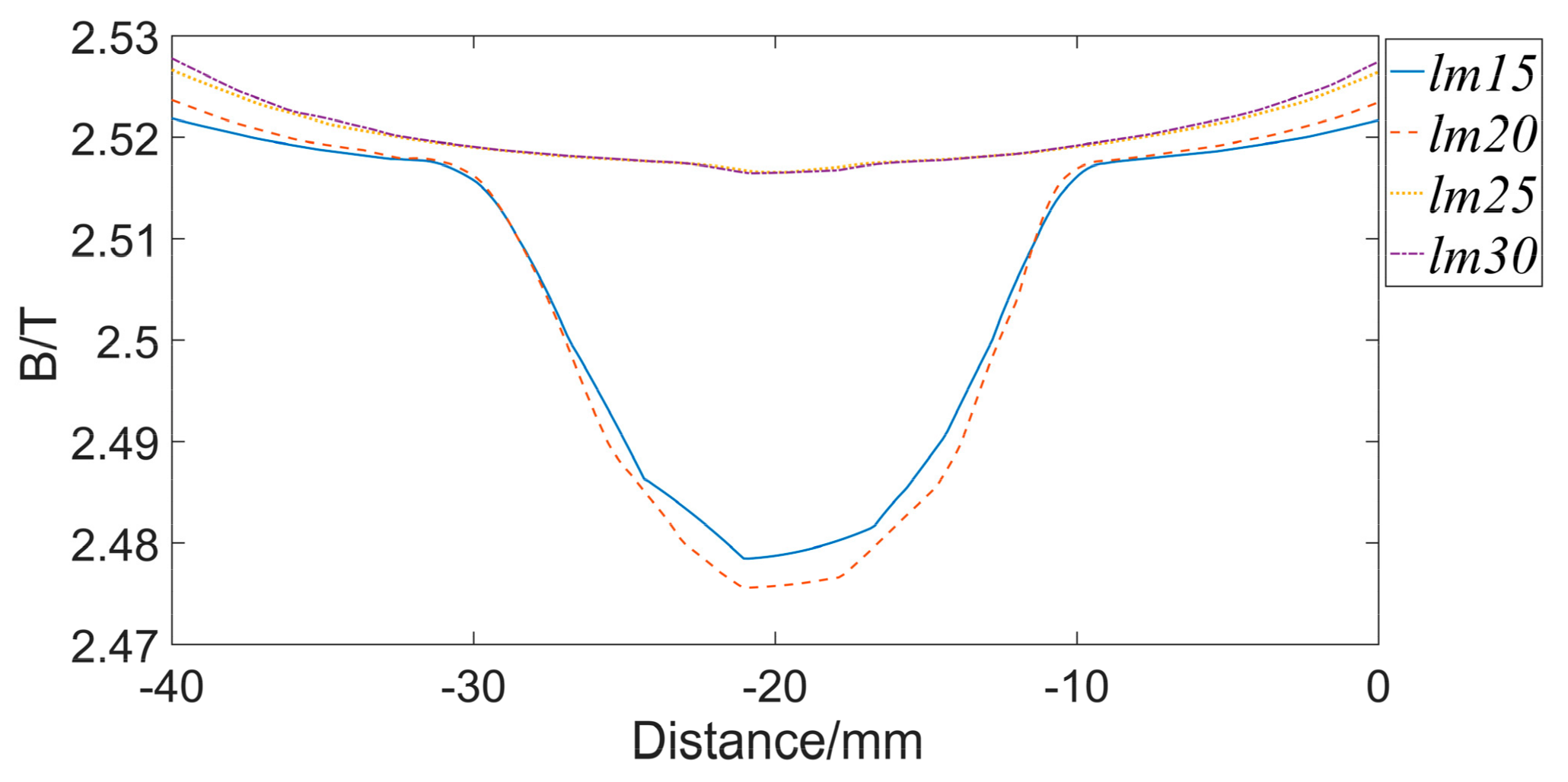

3.1. Simulation of Main Parameters of CMPME

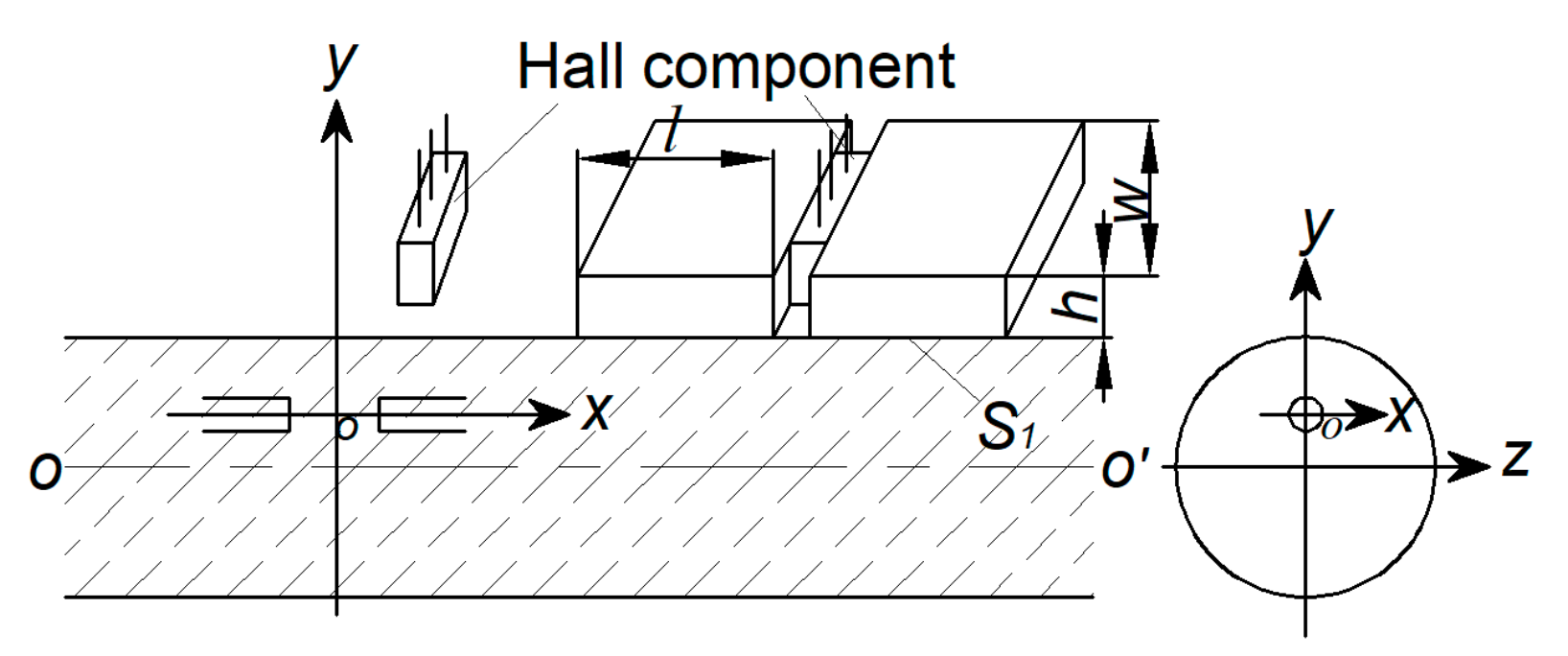

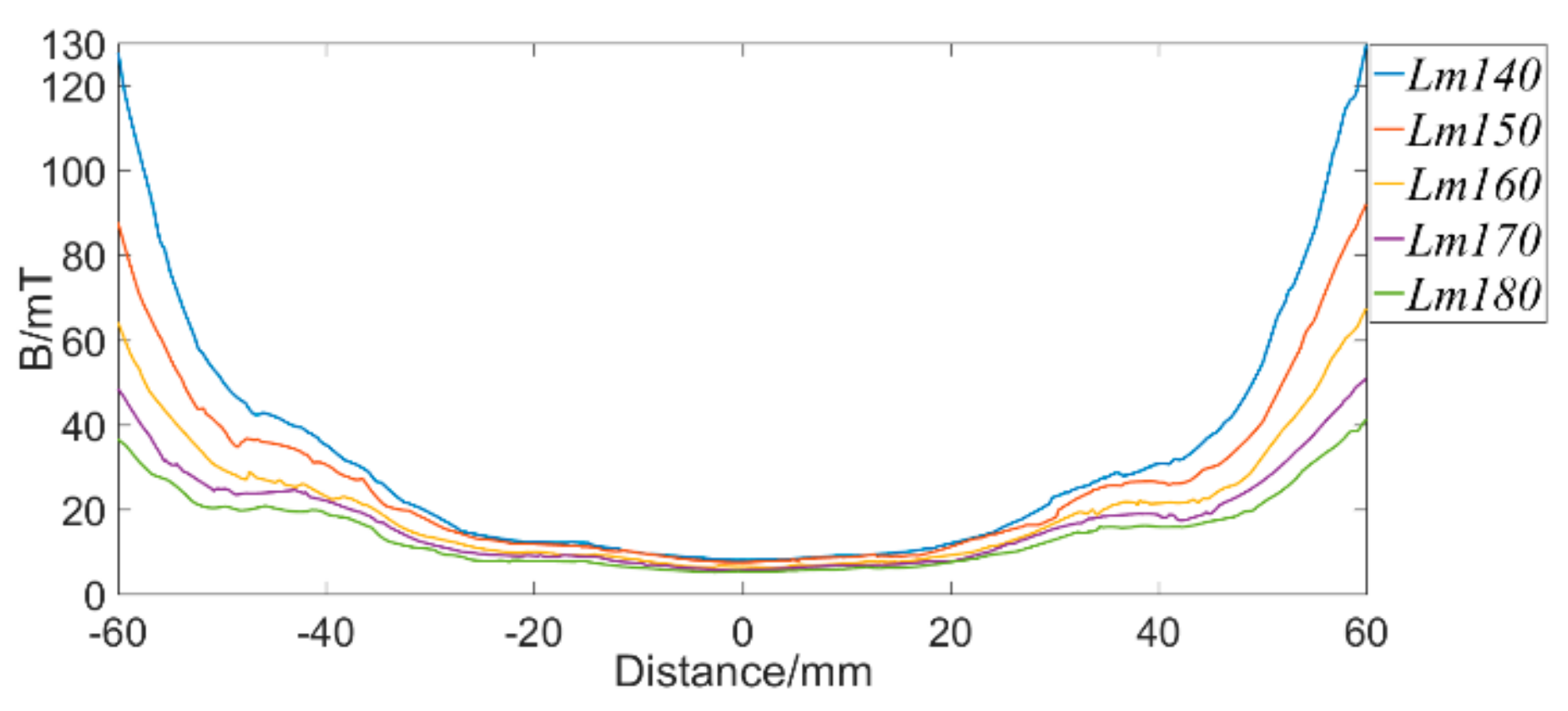

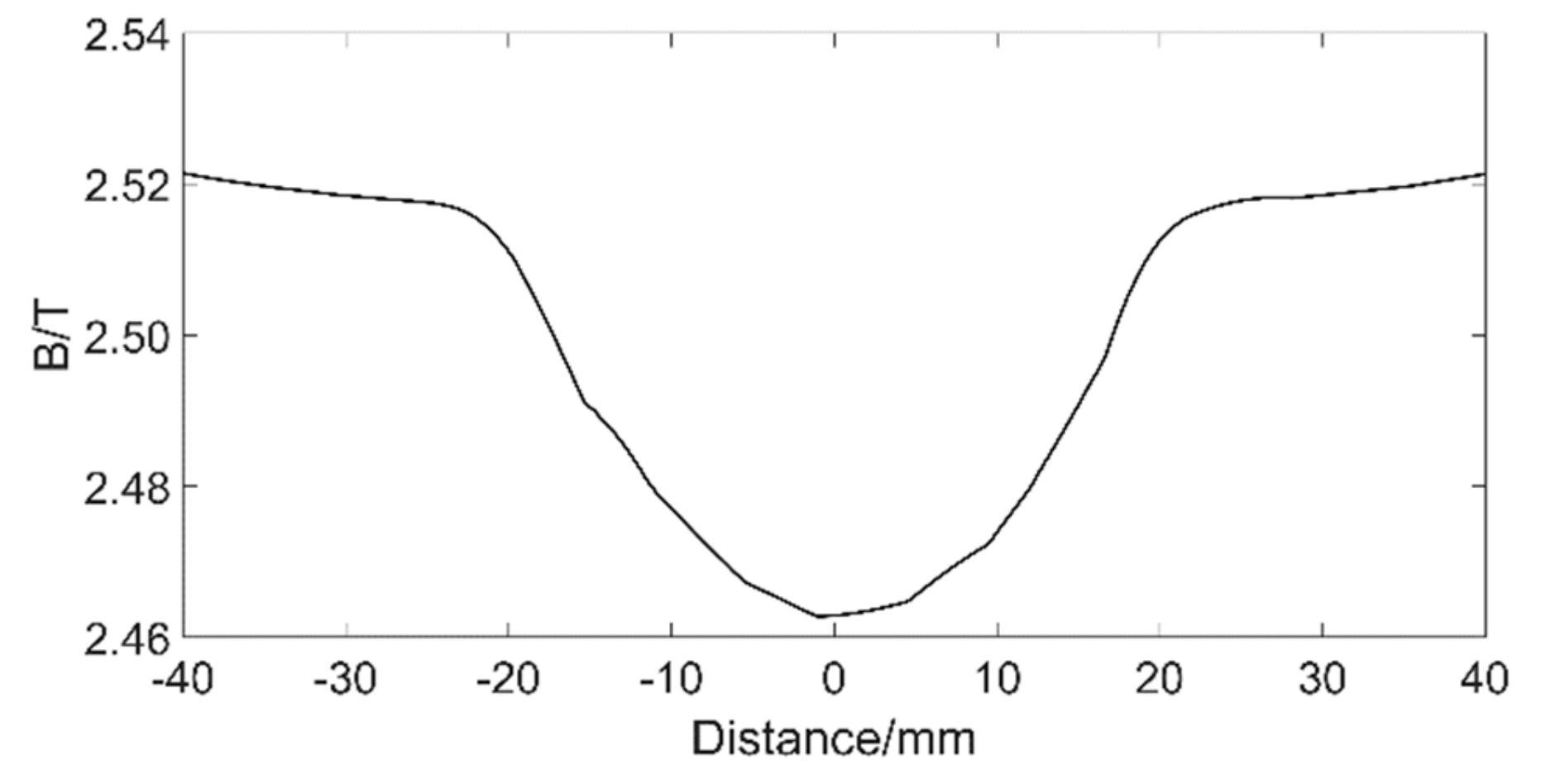

3.2. Simulation of Magnetic Concentrator

4. Experiment and Discussion

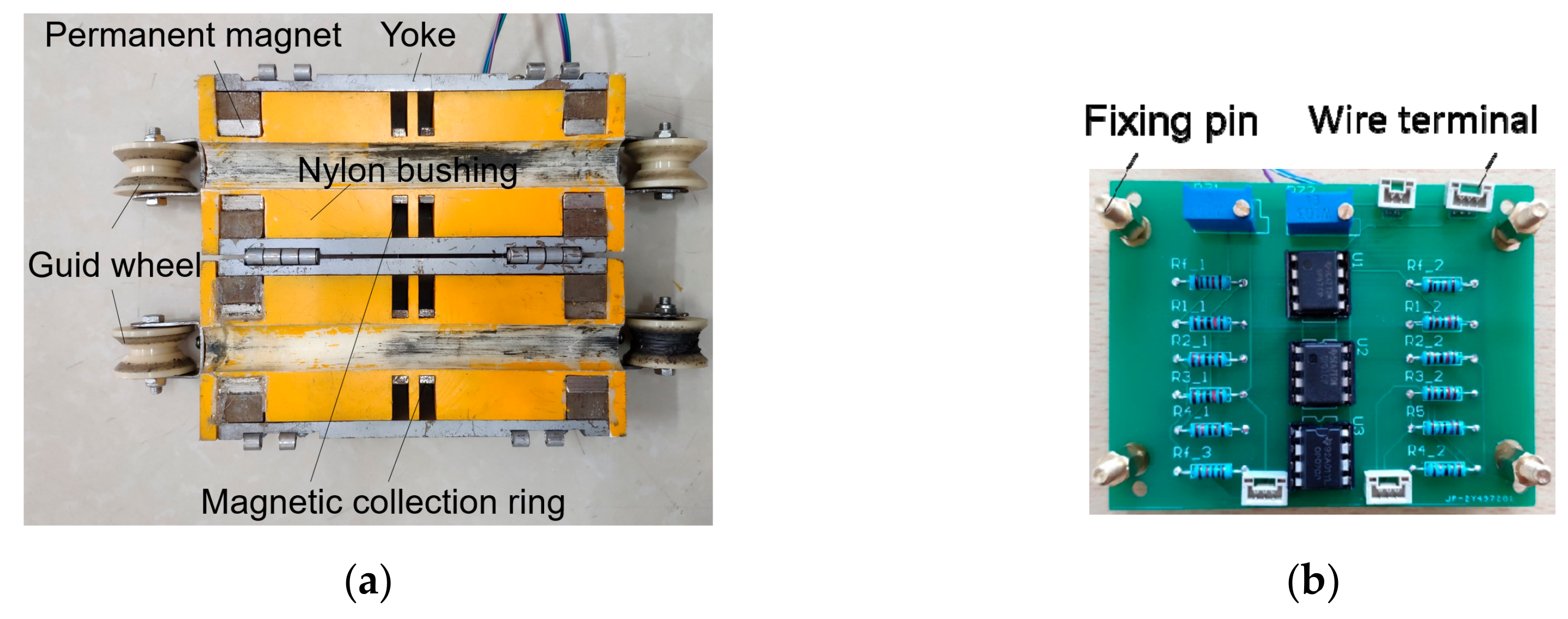

4.1. Sensor Based on Magnetic Concentration Principle

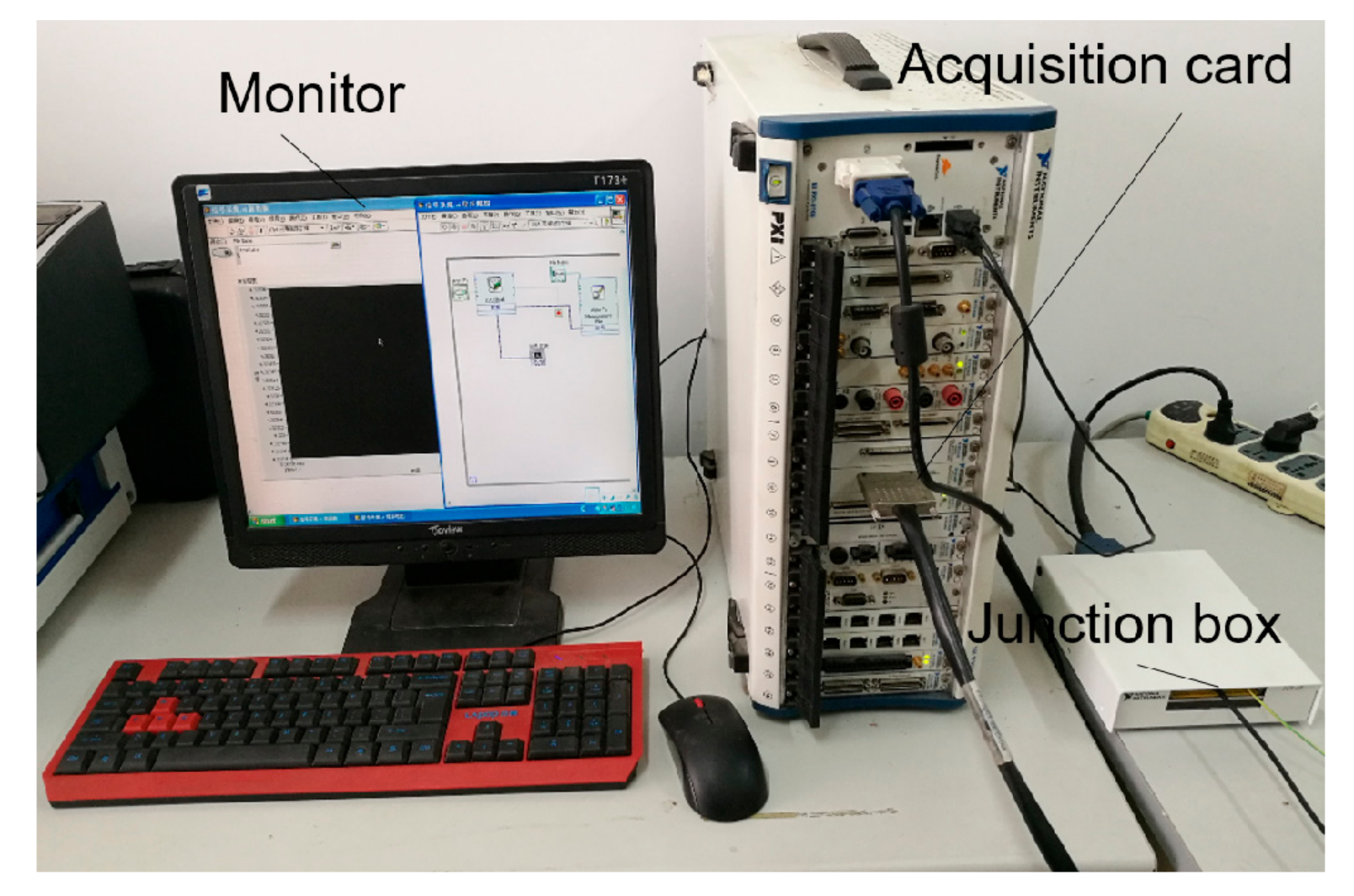

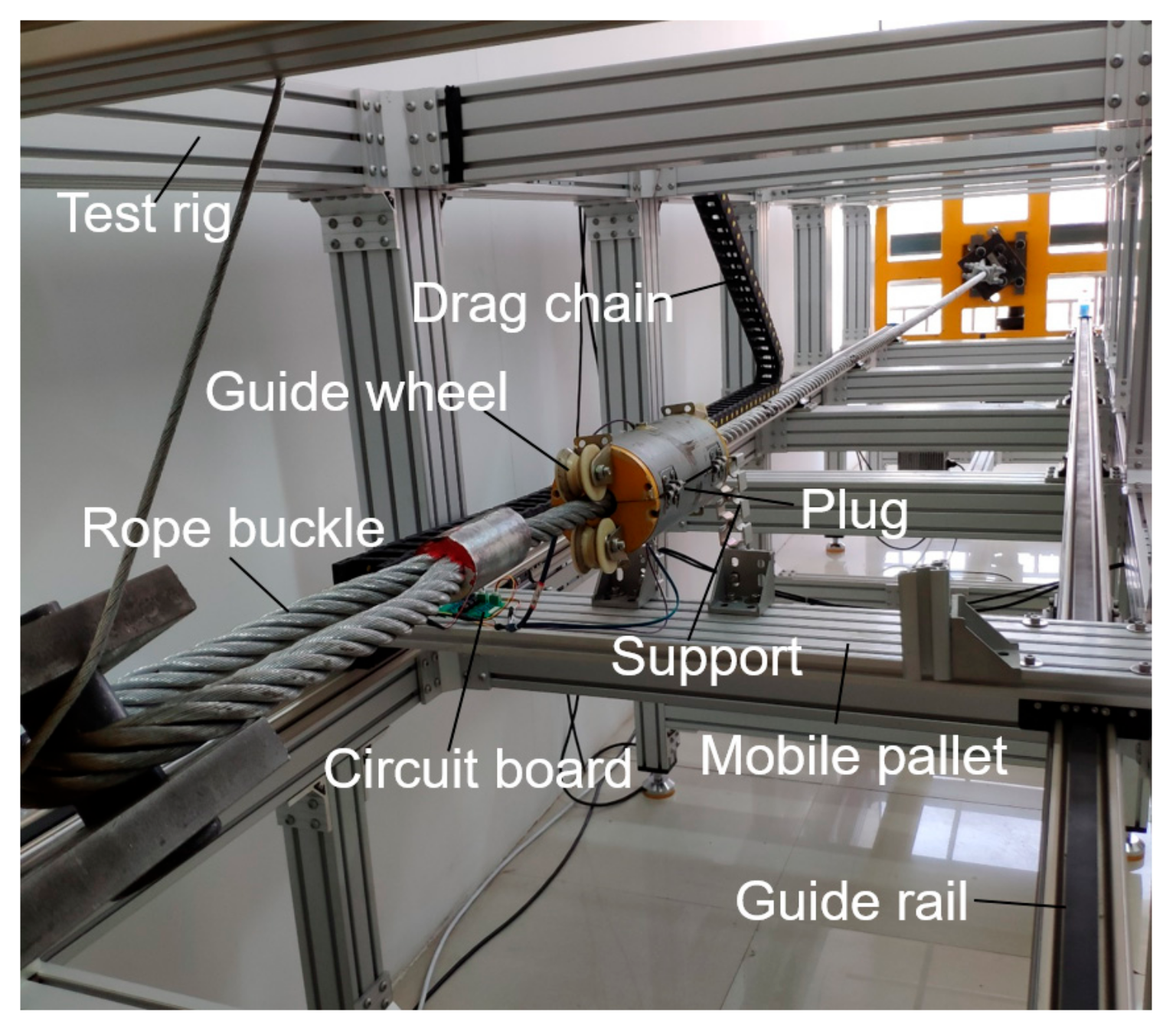

4.2. Experimental Process

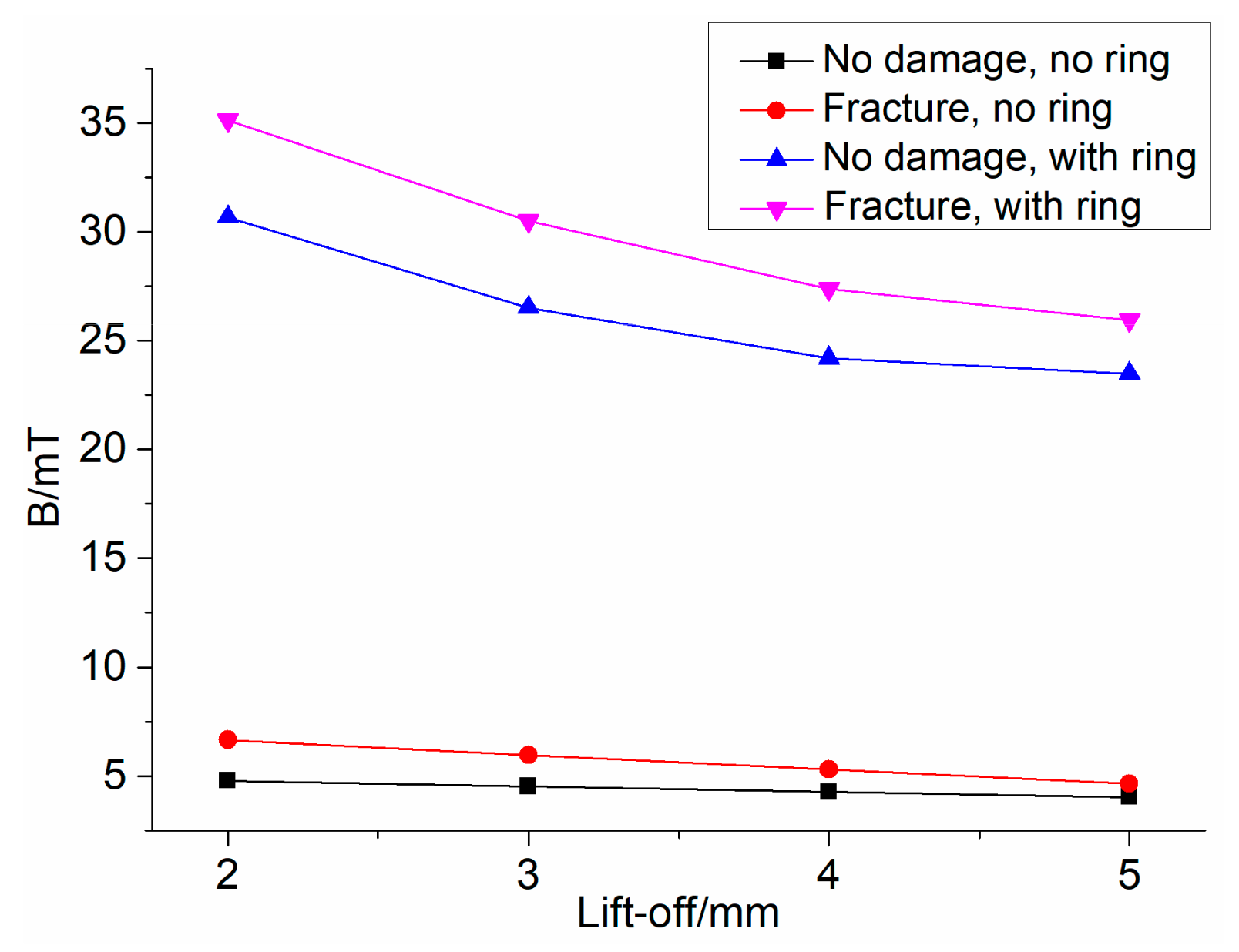

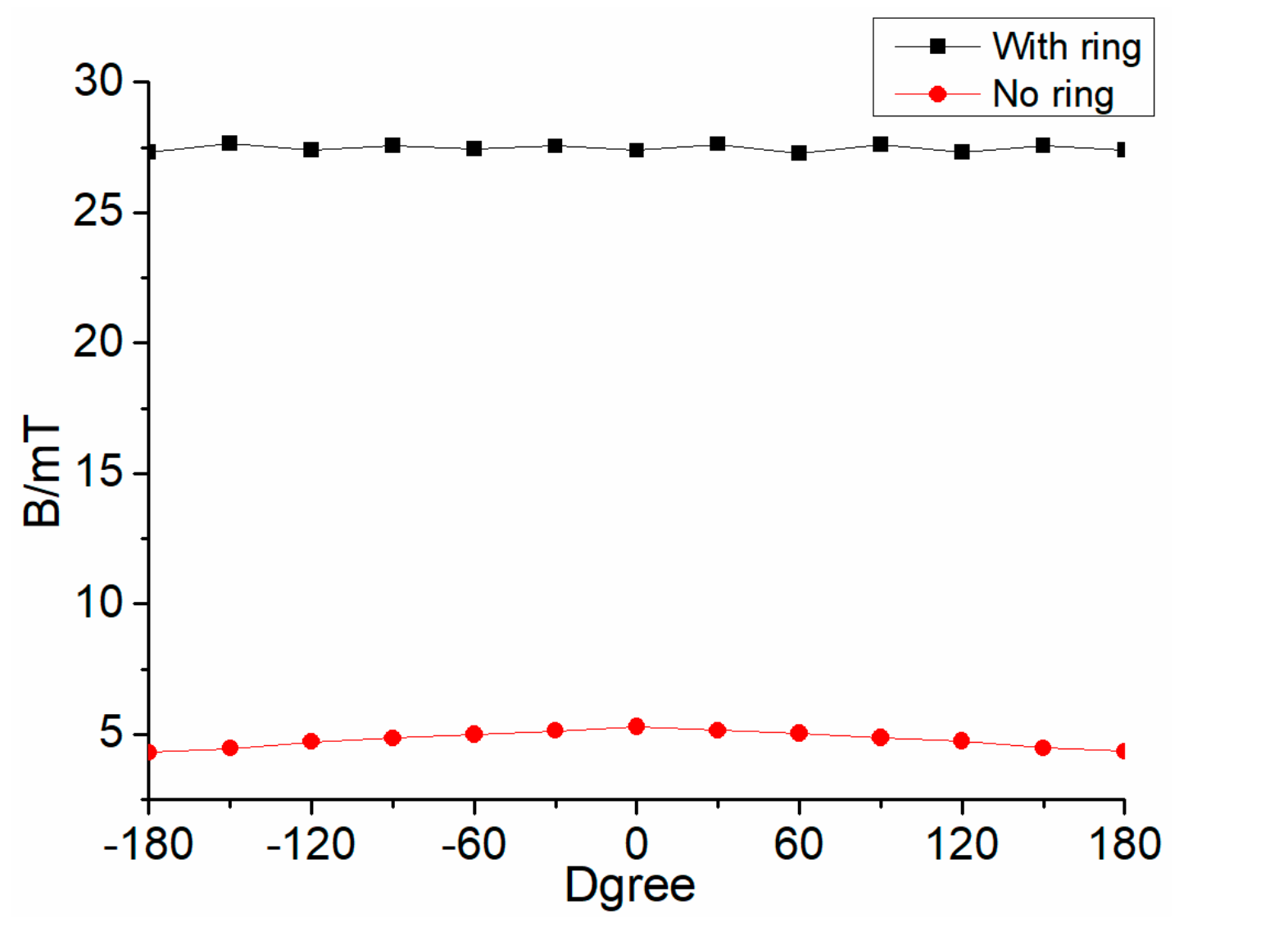

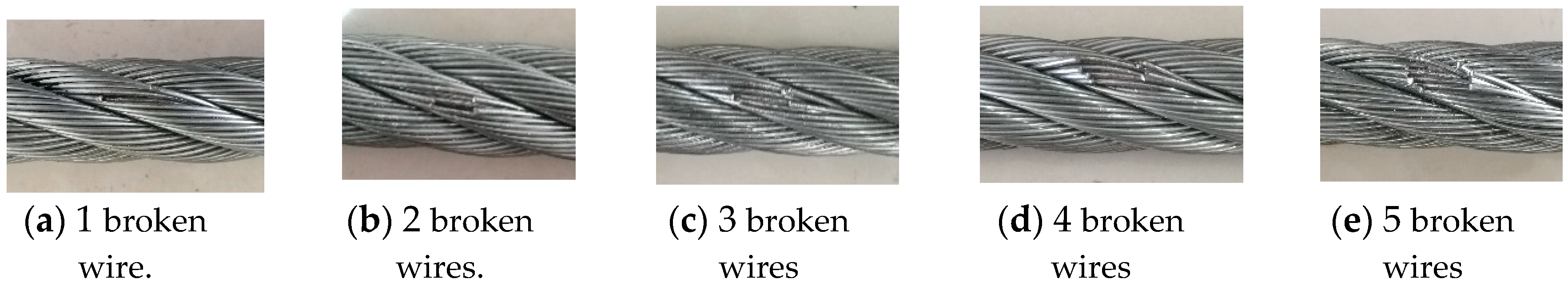

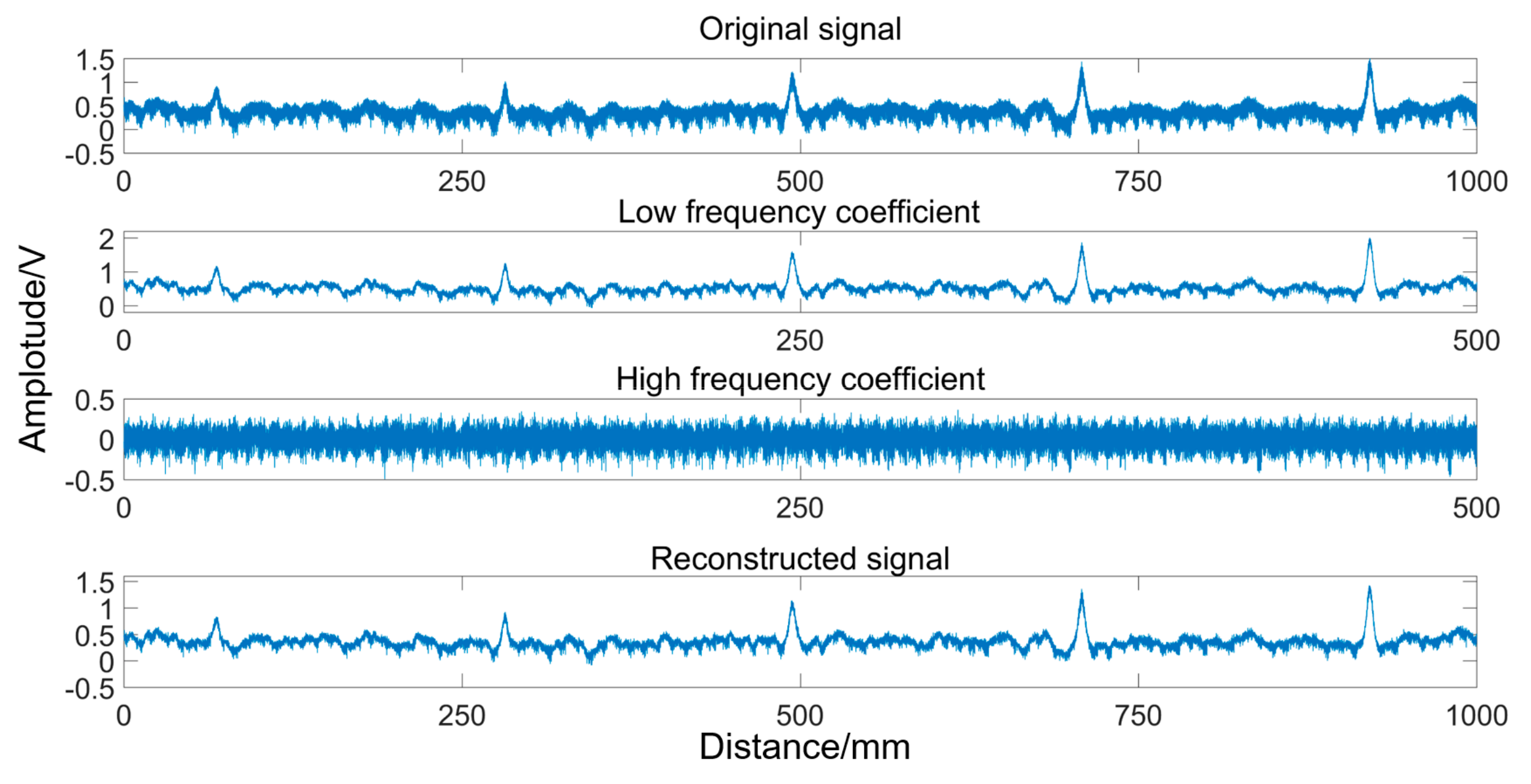

4.3. Experimental Results and Analysis

4.4. Comment and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, J.W.; Park, S. Magnetic Flux Leakage Sensing and Artificial Neural Network Pattern Recognition-Based Automated Damage Detection and Quantification for Wire Rope Non-Destructive Evaluation. Sensors 2018, 18, 109. [Google Scholar]

- Peng, P.C.; Wang, C.Y. Use of gamma rays in the inspection of steel wire ropes in suspension bridges. NDT E Int. 2015, 75, 80–86. [Google Scholar] [CrossRef]

- Weischedel, H.R.; Ramsey, R.P. Electromagnetic testing, a reliable method for the inspection of wire ropes in service. NDT Int. 1989, 22, 155–161. [Google Scholar]

- Zhang, J.; Zheng, P.; Tan, X. Recognition of broken wire rope based on remanence using EEMD and wavelet methods. Sensors 2018, 18, 1110. [Google Scholar]

- Gu, W.; Chu, J. A transducer made up of fluxgate sensors for testing wire rope defects. IEEE Trans. Instrum. Meas. 2002, 51, 120–124. [Google Scholar] [CrossRef]

- Lei, H.M.; Tian, G.Y. Broken wire detection in coated steel belts using the magnetic flux leakage method. Insight 2013, 55, 126–131. [Google Scholar] [CrossRef]

- Weischdel, H.R. The inspection of wire ropes in service: A critical review. Mater. Eval. 1985, 43, 1592–1605. [Google Scholar]

- Jomdecha, C.; Prateepasen, A. Design of modified electromagnetic main-flux for steel wire rope inspection. Ndt&E Int. 2009, 42, 77–83. [Google Scholar]

- Cao, Y.N.; Zhang, D.L.; Wang, C. A novel electromagnetic method for local defects inspection of wire rope. In Proceedings of the TENCON, IEEE Region 10 International Conference, Hong Kong, China, 14–17 November 2006. [Google Scholar]

- Zhang, J.; Tan, X. Quantitative inspection of remanence of broken wire rope based on compressed sensing. Sensors 2016, 16, 1366. [Google Scholar] [CrossRef]

- Liu, X.C.; Wang, Y.J.; Wu, B.; Gao, Z.; He, Z. Design of tunnel magnetoresistive-based circular MFL sensor array for the detection of flaws in steel wire rope. J. Sens. 2016. [Google Scholar] [CrossRef]

- Singh, W.S.; Rao, B.P.C.; Thirunavukkarasu, S. Flexible GMR sensor array for magnetic flux leakage testing of steel track ropes. J. Sens. 2012. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Y.J.; Liu, X.C.; He, C.F. A novel TMR-based MFL sensor for steel wire rope inspection using the orthogonal test method. Smart Mater. Struct. 2015, 24, 075007. [Google Scholar] [CrossRef]

- Kang, Y.; Xue, H.; Yang, K.; Yang, S. Magnetic concentrating principle for measurement of magnetic leakage flux caused by the broken wires in wire ropes. China Mech. Eng. 1993, 4, 4–6. [Google Scholar]

- Wang, H.; Tian, J.; Meng, G. A sensor model for defect detection in mine hoisting wire ropes based on magnetic focusing. Insight 2017, 59, 143–148. [Google Scholar]

- Xu, F.; Wang, X.; Wu, H. Inspection method of cable-stayed bridge using magnetic flux leakage detection: Principle, sensor design, and signal processing. J. Mech. Sci. Tech. 2012, 26, 661–669. [Google Scholar] [CrossRef]

- Tse, P.W.; Liu, X.C.; Liu, Z.H.; Wu, B.; He, C.F. An innovative design for using flexible printed coils for magnetostrictive-based longitudinal guided wave sensors in steel strand inspection. Smart Mater. Struct. 2011, 20, 055001. [Google Scholar] [CrossRef]

- Zuoying, H.; Peiwen, Q.; Liang, C. 3D FEM analysis in magnetic flux leakage method. Ndt E Int. 2006, 39, 61–66. [Google Scholar] [CrossRef]

- Al-Naemi, F.I.; Hall, J.P.; Moses, A.J. FEM modelling techniques of magnetic flux leakage-type NDT for ferromagnetic plate inspections. J. Magn. Magn. Mater. 2006, 304, e790–e793. [Google Scholar] [CrossRef]

- Hua, G.; Wang, H.; Chen, F.J.; Lu, Y.H.; Xu, Z.; Tian, J.; Zhou, B.B. Improving SNR of MFL signal in flaw detection of coal mine wire ropes. In Proceedings of the 2009 2nd International Congress on Image and Signal Processing, Tianjin, China, 17–19 October 2009. [Google Scholar]

- Wang, H.Y.; Zhao, X.U.; Gang, H. Key technique of a detection sensor for coal mine wire ropes. Min. Sci. Tech. 2009, 19, 170–175. [Google Scholar] [CrossRef]

- Chen, S.W.; Chen, Y.H. Hardware design and implementation of a wavelet de-noising procedure for medical signal preprocessing. Sensors 2015, 5, 26396–26414. [Google Scholar] [CrossRef]

- Legendre, S.; Massicotte, D.; Goyette, J.; Bose, T.K. Wavelet-transform-based method of analysis for Lamb-wave ultrasonic NDE signals. IEEE Trans. Instrum. Meas. 2000, 49, 524–530. [Google Scholar] [CrossRef]

- Rizzo, P.; di Scalea, F.L. Ultrasonic inspection of multi-wire steel strands with the aid of the wavelet transform. Smart Mater. Struct. 2005, 14, 685. [Google Scholar] [CrossRef]

| Lift-off | D1 | d1 |

|---|---|---|

| 2 mm | 38 mm | 28 mm |

| 3 mm | 40 mm | 30 mm |

| 4 mm | 42 mm | 32 mm |

| 5 mm | 44 mm | 34 mm |

| Brand | Br | Hcb | maxBH |

|---|---|---|---|

| N35 | 1170–1230 mT | 10.7–12.0 kOe | 264–288 kJ/m3 |

| 11.7–12.3 kGs | 852–955 kA/m | 33–36 MGOe |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Jing, L.; Xu, W.; Zhan, W.; Tan, J. A Sensor for Broken Wire Detection of Steel Wire Ropes Based on the Magnetic Concentrating Principle. Sensors 2019, 19, 3763. https://doi.org/10.3390/s19173763

Zhang Y, Jing L, Xu W, Zhan W, Tan J. A Sensor for Broken Wire Detection of Steel Wire Ropes Based on the Magnetic Concentrating Principle. Sensors. 2019; 19(17):3763. https://doi.org/10.3390/s19173763

Chicago/Turabian StyleZhang, Yiqing, Luyang Jing, Weixiao Xu, Weixia Zhan, and Jiwen Tan. 2019. "A Sensor for Broken Wire Detection of Steel Wire Ropes Based on the Magnetic Concentrating Principle" Sensors 19, no. 17: 3763. https://doi.org/10.3390/s19173763

APA StyleZhang, Y., Jing, L., Xu, W., Zhan, W., & Tan, J. (2019). A Sensor for Broken Wire Detection of Steel Wire Ropes Based on the Magnetic Concentrating Principle. Sensors, 19(17), 3763. https://doi.org/10.3390/s19173763