Nondestructive Analysis of Debonds in a Composite Structure under Variable Temperature Conditions

Abstract

1. Introduction

2. Experimental Analysis

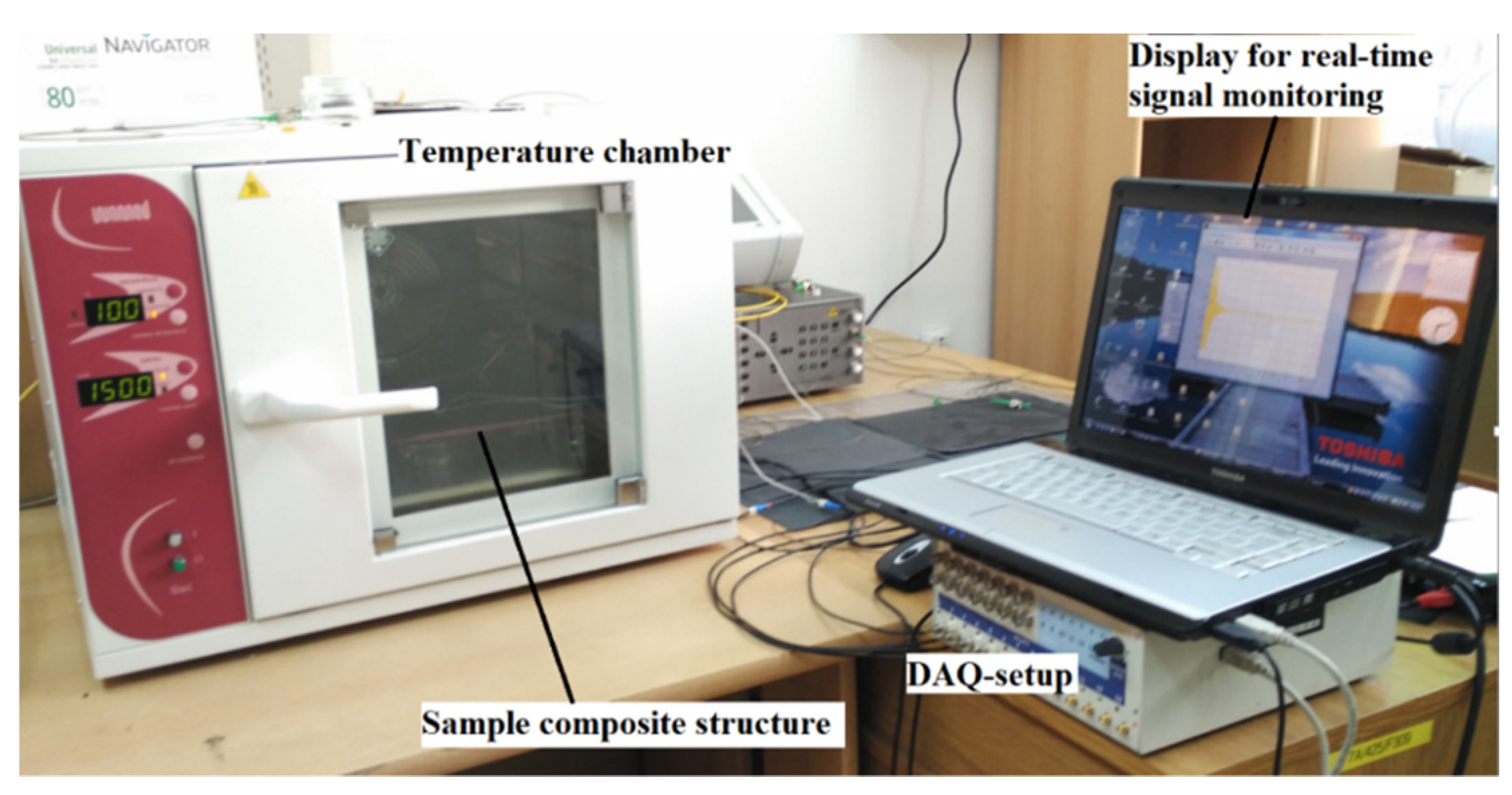

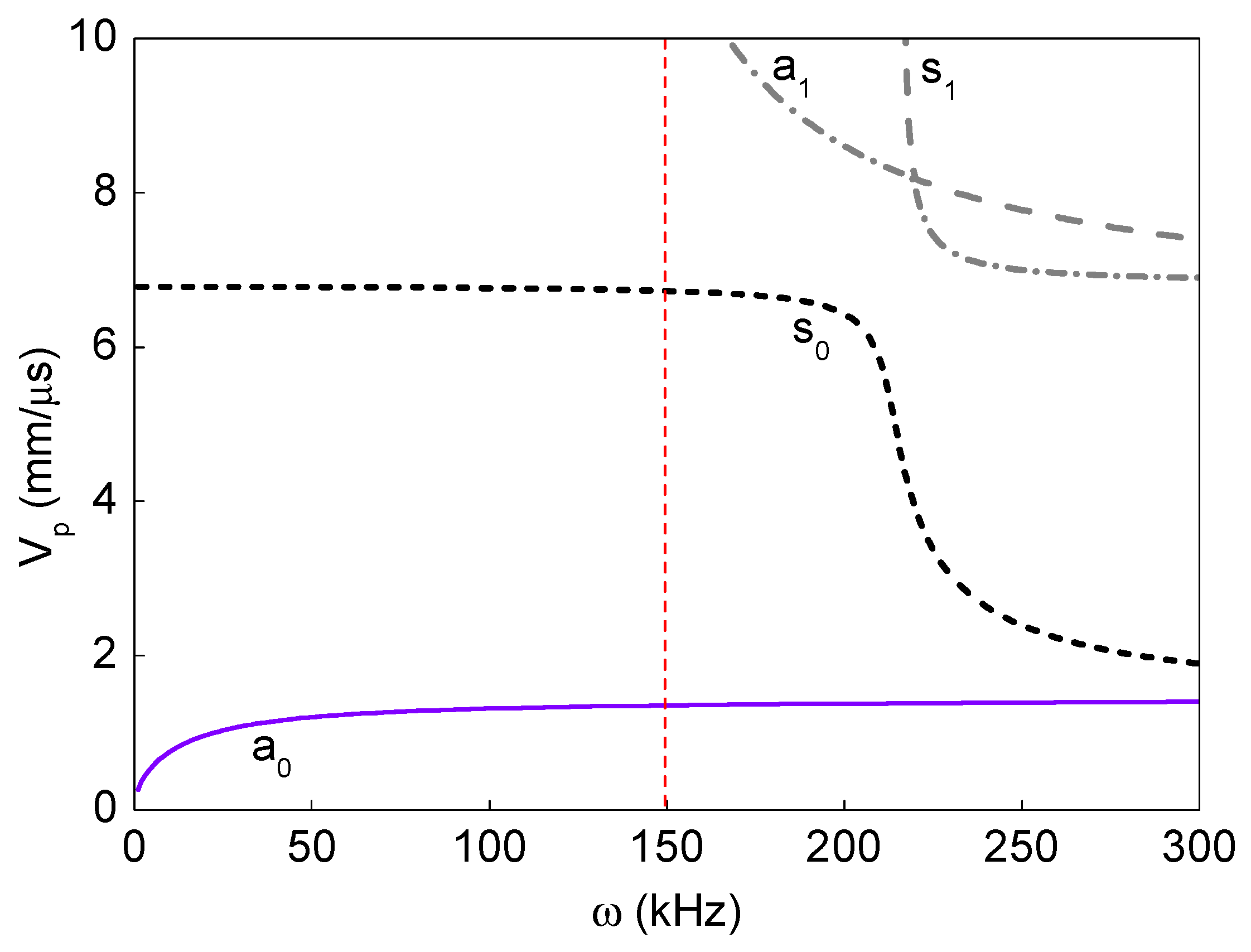

2.1. Experimental Analysis Using Guided Wave Propagation

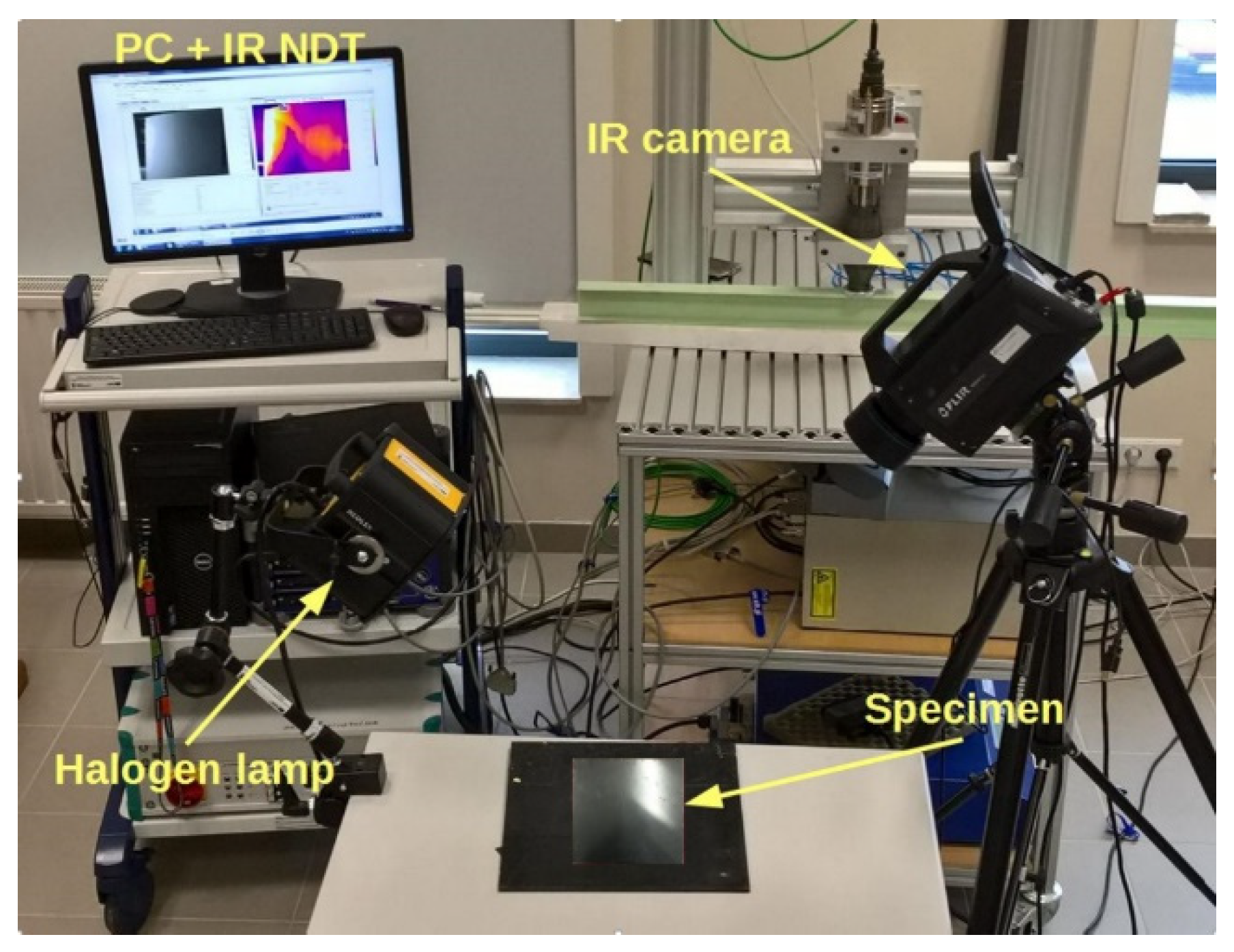

2.2. Experimental Analysis Using Active IRT Test

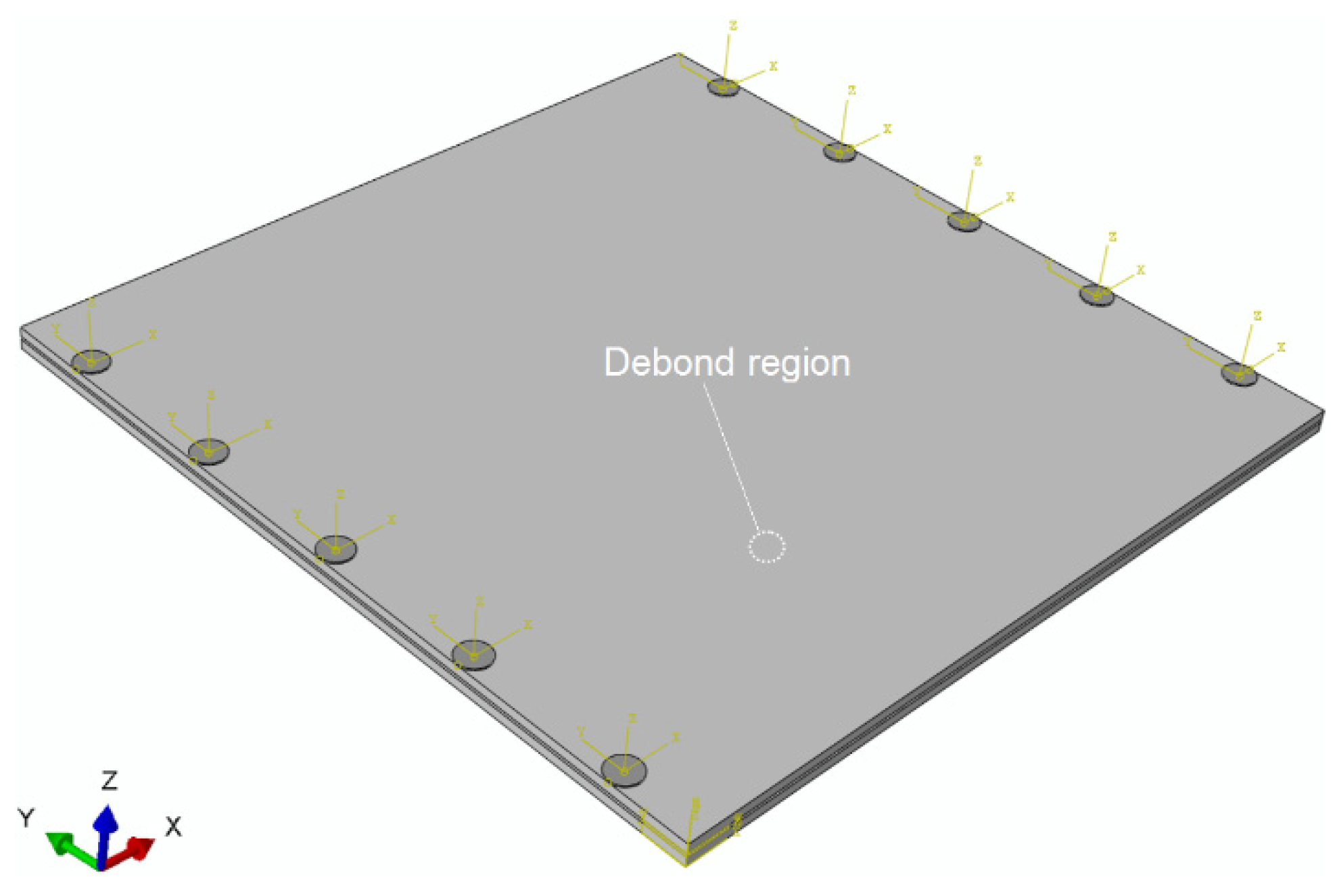

3. Finite Element Analysis

4. Results and Discussion

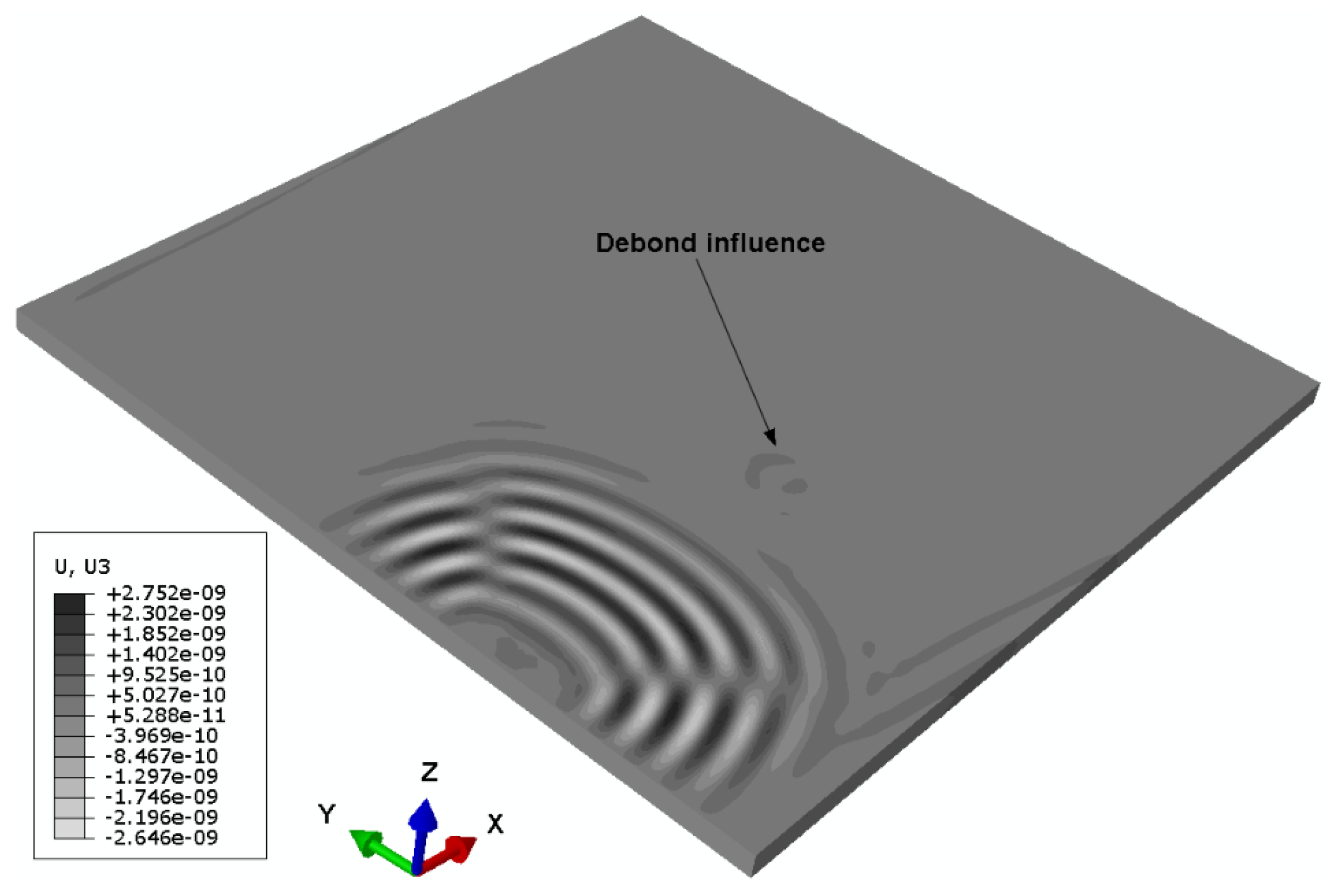

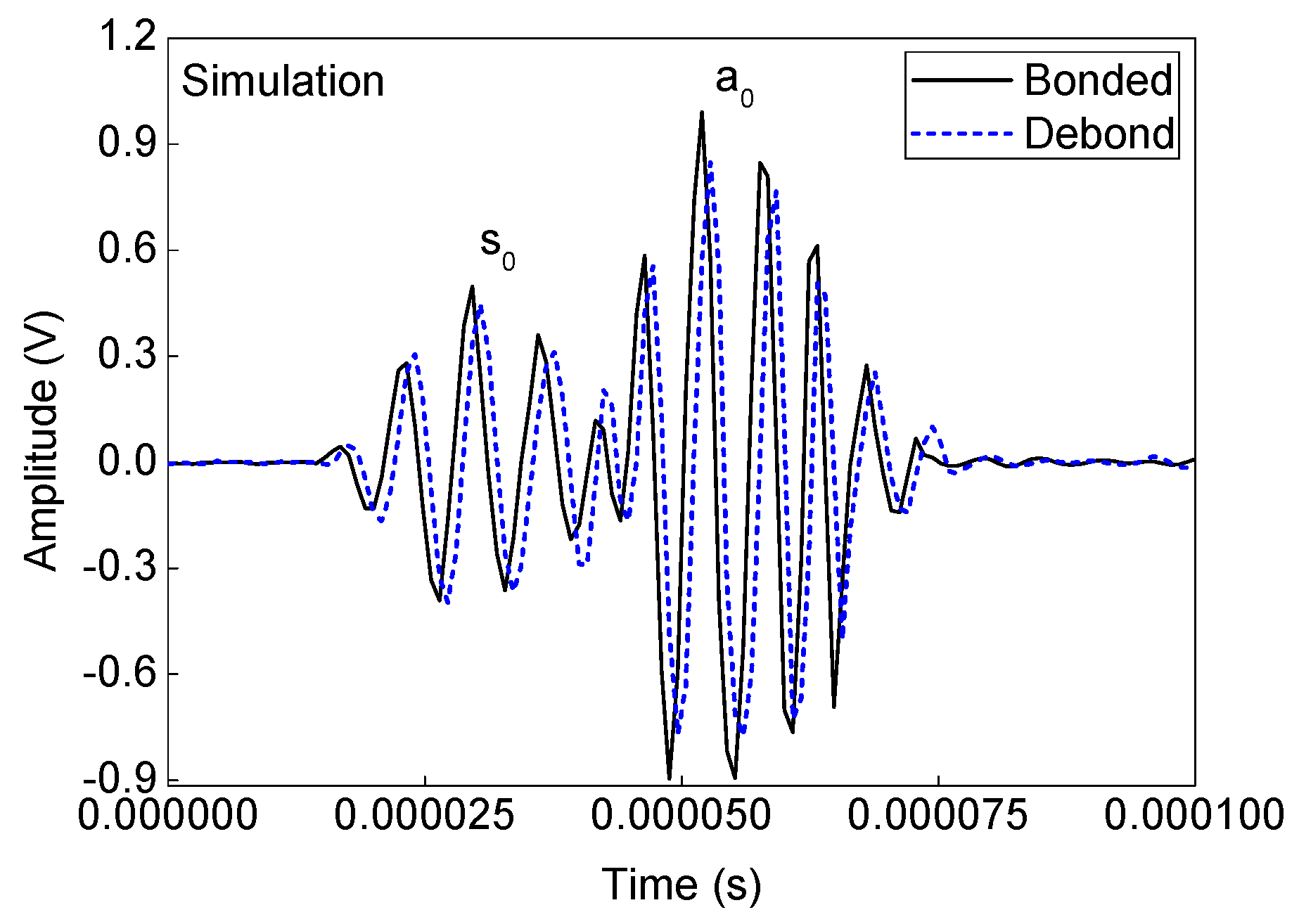

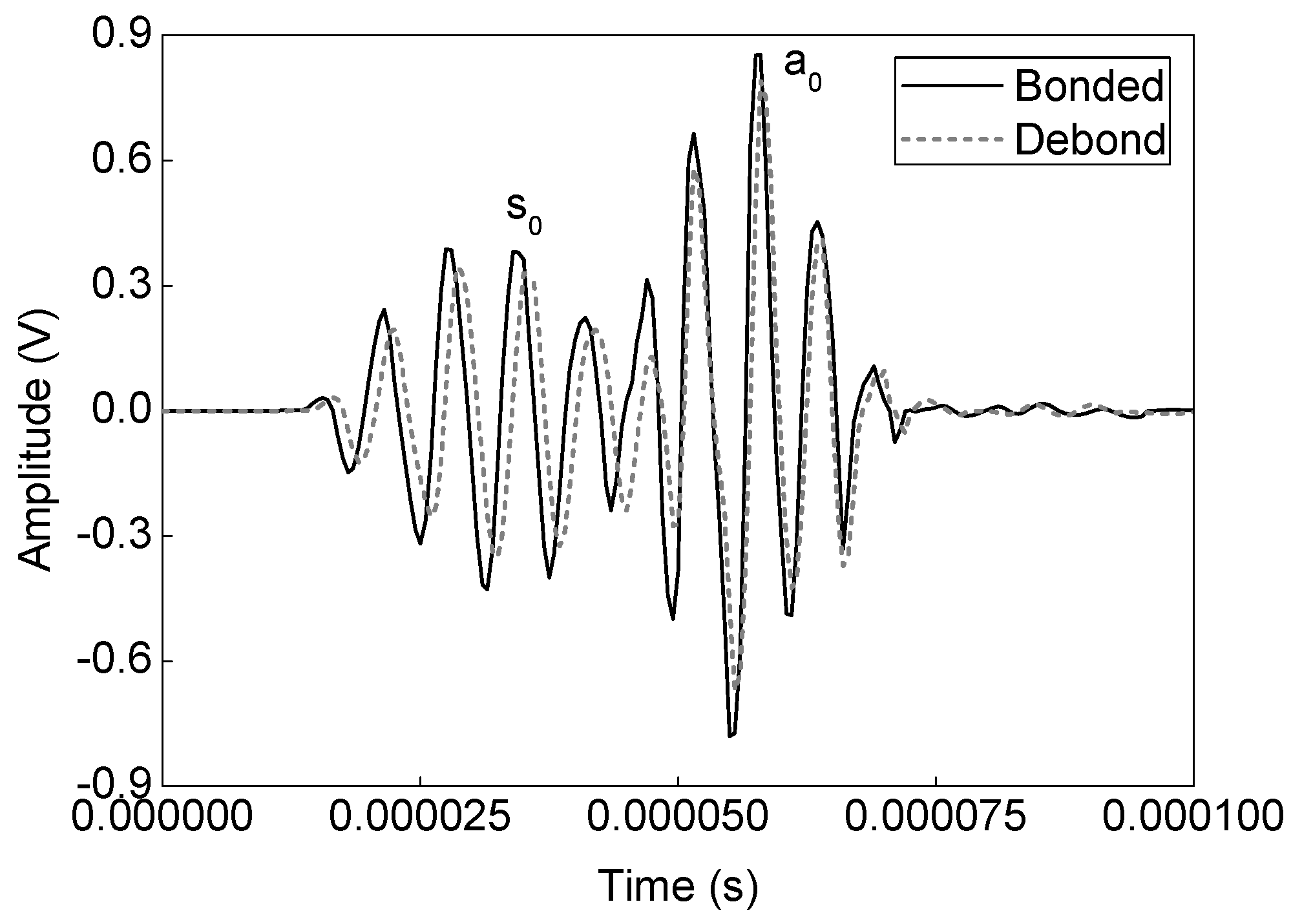

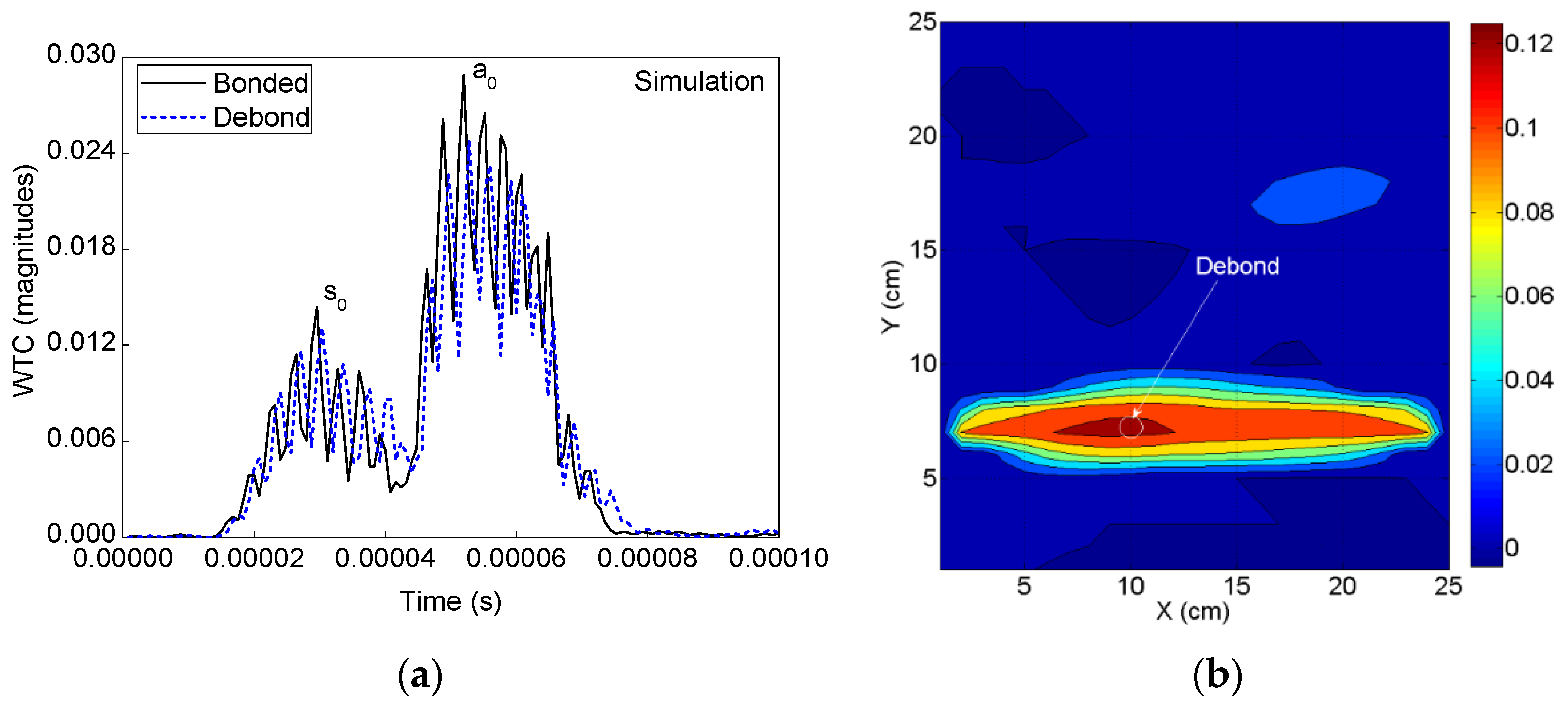

4.1. Numerical and Experimental Analysis of Debond Effects

4.2. SHM Strategy for Debond Detection

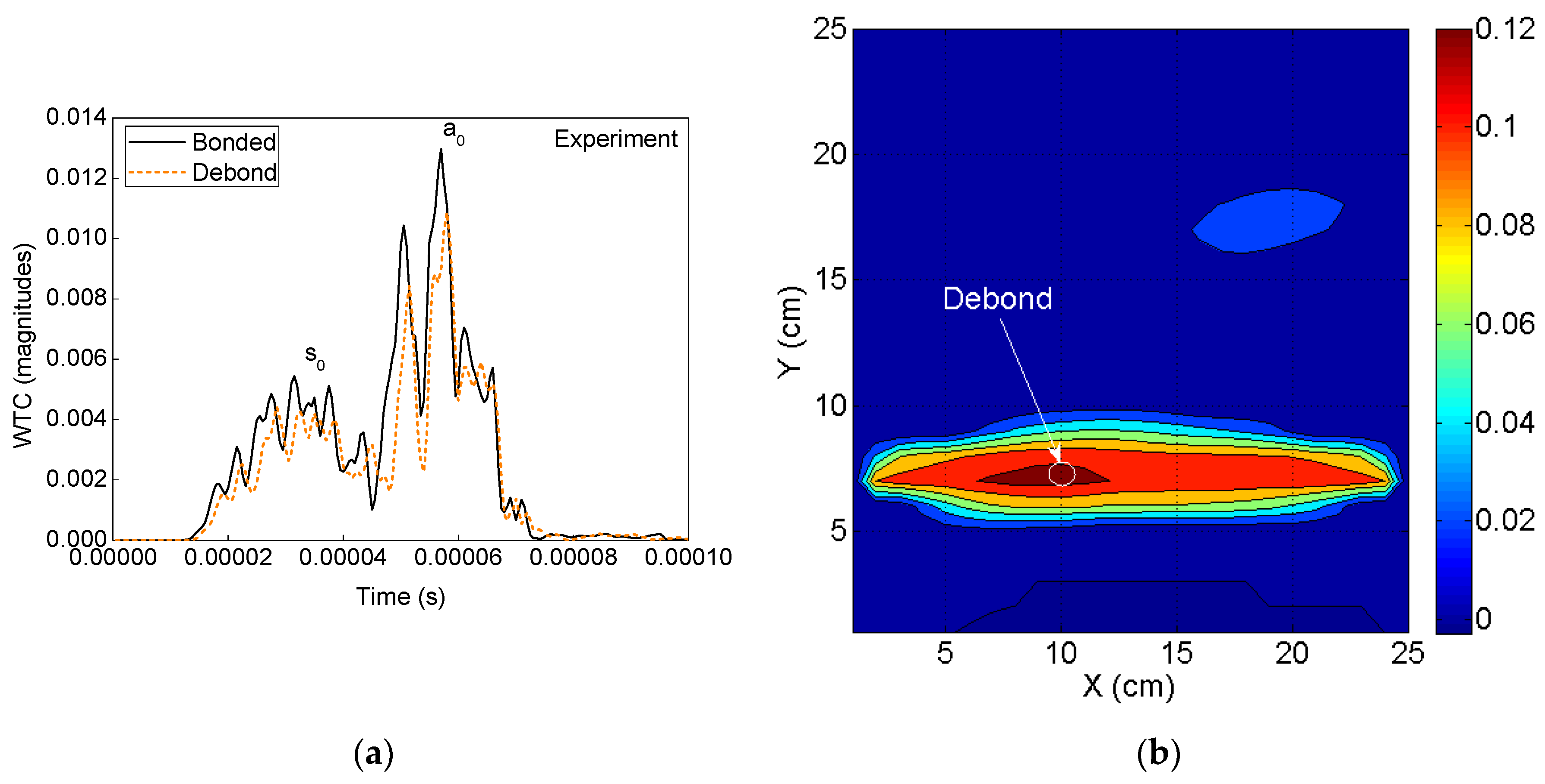

4.2.1. Detection of Debonds Using Experimental Signals

4.2.2. Detection of Debonds Using Simulation Signals

4.3. Active IRT Analysis Based Non-Destructive Inspection of Debonds in the ACCS

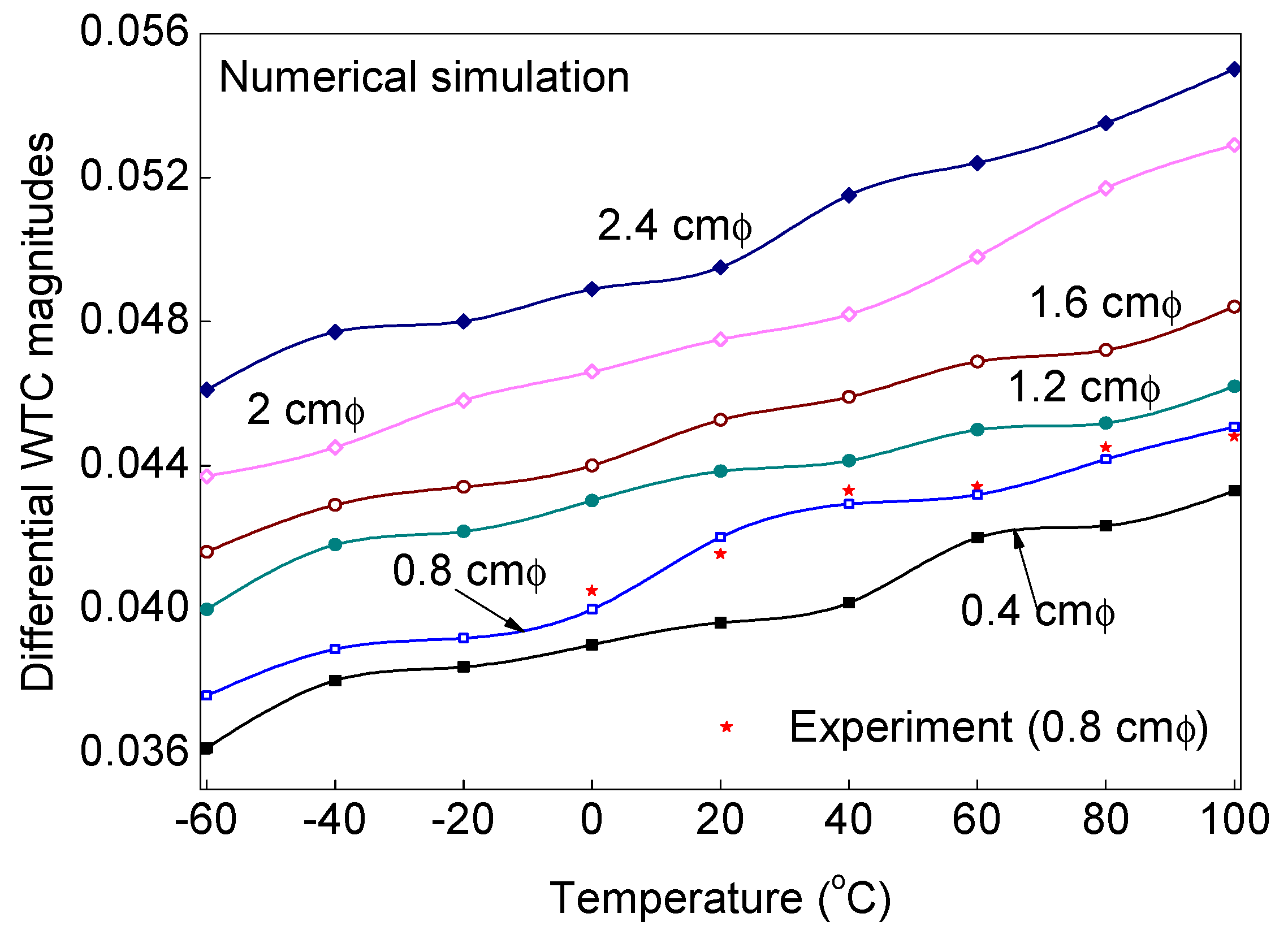

4.4. Analysis of Debond Size and Temperature Variation Influence on the Difference in WTCs

4.5. Analysis of Temperature Variation Influence on the Debond Index Magnitudes

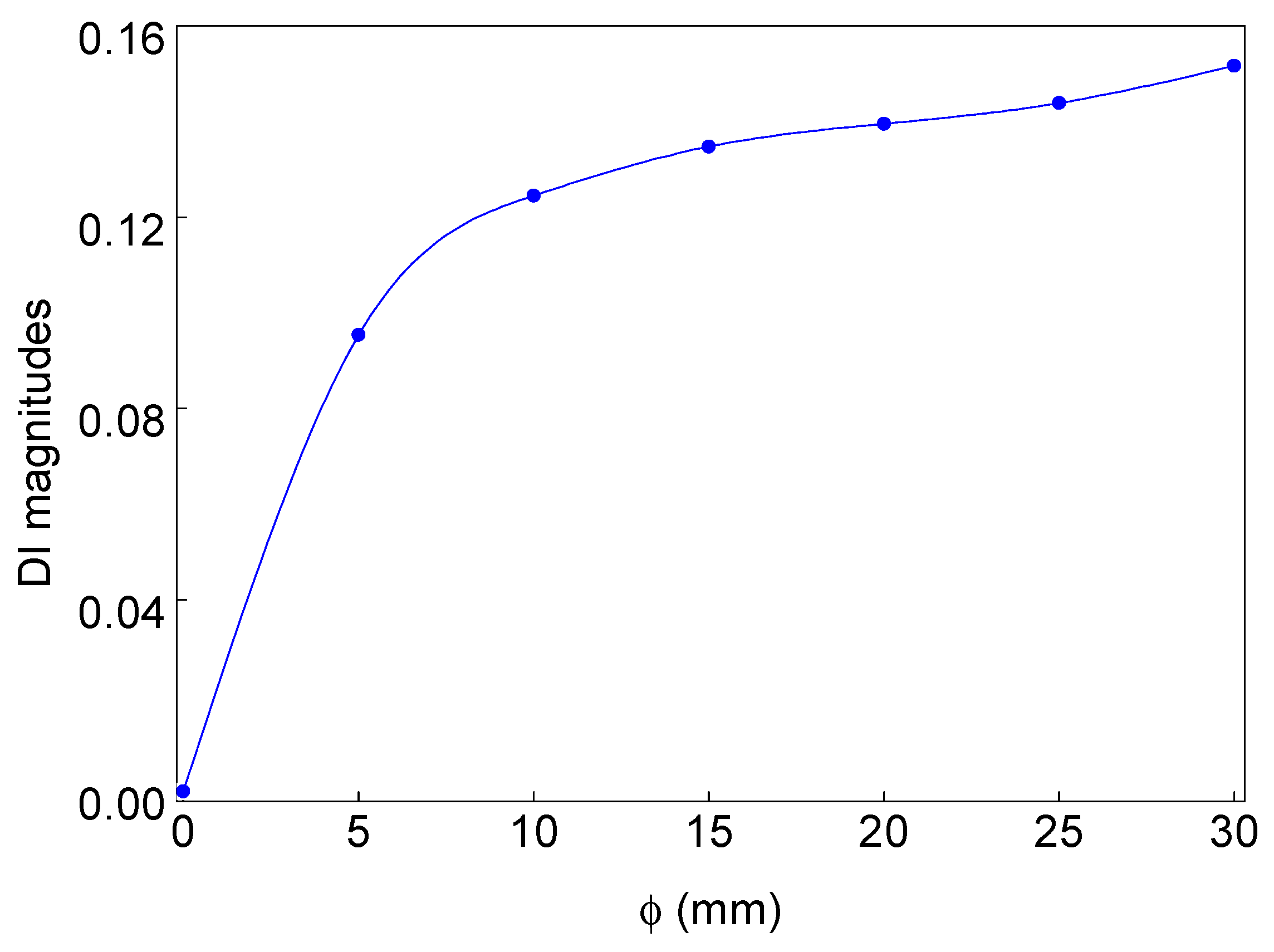

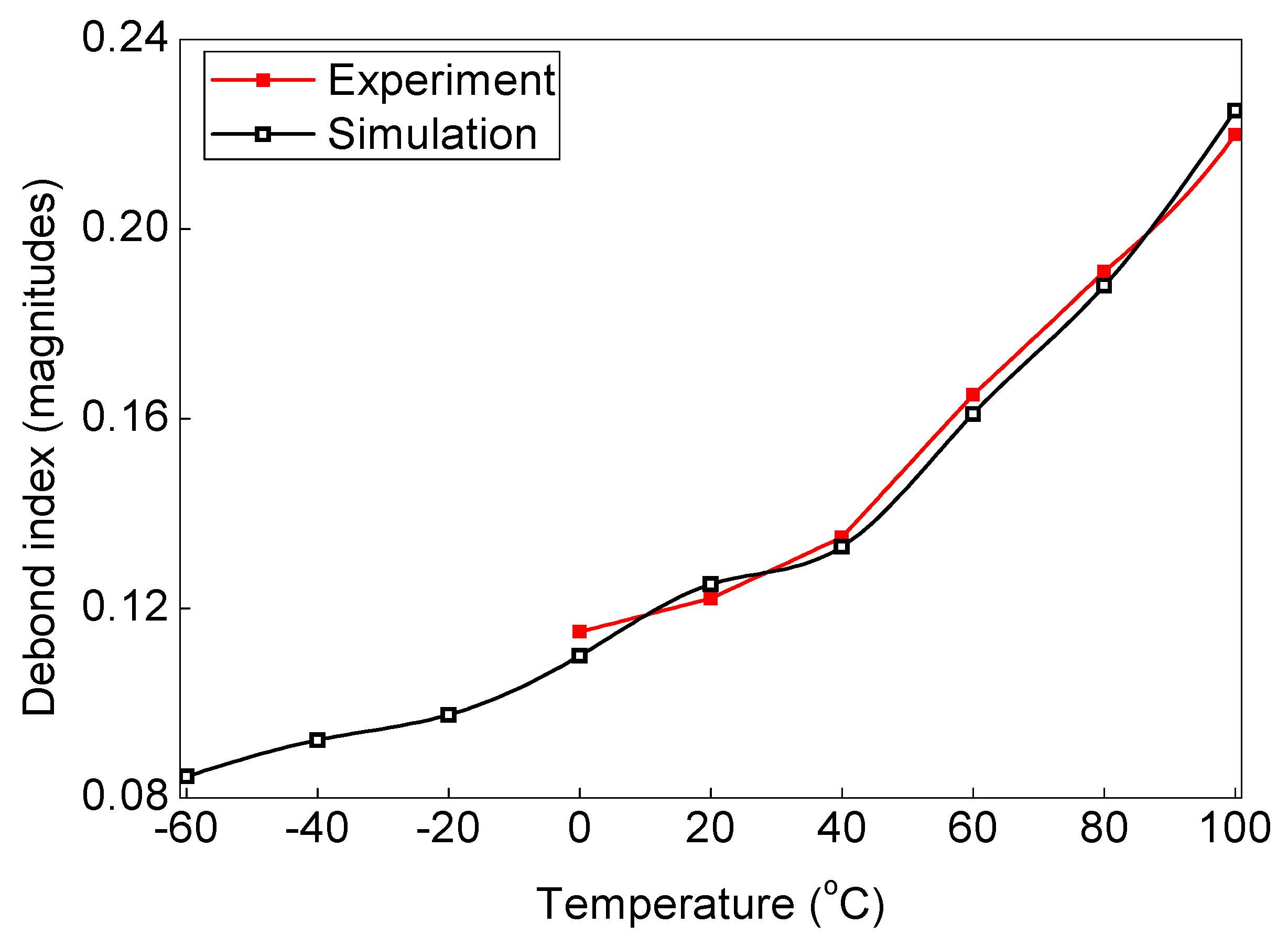

4.6. Analysis of Temperature Variation Influence on the Debond Index Magnitudes

5. Conclusions

- The existence of debond at the adhesive layer in the ACCS reduces the amplitudes of propagating wave modes.

- Increase in the debond size and the ambient temperature significantly increases the a0 mode amplitudes and leads to an increase in amplitude difference between the bonded and debond influenced signals.

- The proposed SHM strategy is verified with the non-contact active IRT measurements and it has proven the debond detection potential in the ACCS.

- The proposed SHM strategy has further shown that the increase in debond size increases the debond index magnitudes of the localization maps, and the increase in ambient temperature also increases the debond index magnitudes in the localization maps.

Author Contributions

Funding

Conflicts of Interest

References

- Safri, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2017, 133, 112–121. [Google Scholar] [CrossRef]

- Kinvi-Dossou, G.; Boumbimba, R.M.; Bonfoh, N.; Koutsawa, Y.; Eccli, D.; Gerard, P. A numerical homogenization of E-glass/acrylic woven composite laminates: Application to low velocity impact. Compos. Struct. 2018, 200, 540–554. [Google Scholar] [CrossRef]

- Dey, T.; Ramachandra, L.S. Computation of worst geometric imperfection profiles of composite cylindrical shell panels by minimizing the non-linear buckling load. Appl. Math. Modell. 2019, 74, 483–495. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Kreikemeier, J.; Wille, T. An analytical scaling approach for low-velocity impact on composite structures. Compos. Struct. 2018, 187, 71–84. [Google Scholar] [CrossRef]

- Qiu, L.; Deng, X.; Yuan, S.; Huang, Y.; Ren, Y. Impact monitoring for aircraft smart composite skins based on a lightweight sensor network and characteristic digital sequences. Sensors 2018, 18, 2218. [Google Scholar] [CrossRef] [PubMed]

- Gay, D.; Hoa, S.V.; Tsai, S.N. Composite Materials: Design and Application; CRC Press: New York, NY, USA, 2003. [Google Scholar]

- Zenkert, D. The Handbook of Sandwich Construction; EMAS Publishing: London, UK, 1997. [Google Scholar]

- Giurgiutiu, V. Tuned Lamb wave excitation and detection with piezoelectric wafer active sensors for structural health monitoring. J. Intell. Mater. Syst. Struct. 2005, 16, 291–305. [Google Scholar] [CrossRef]

- Salmanpour, M.S.; Sharif Khodaei, Z.; Aliabadi, M.H. Guided wave temperature correction methods in structural health monitoring. J. Intell. Mater. Syst. Struct. 2017, 28, 604–618. [Google Scholar] [CrossRef]

- Sikdar, S.; Kudela, P.; Radzieński, M.; Kundu, A.; Ostachowicz, W. Online detection of barely visible low-speed impact damage in 3D-core sandwich composite structure. Compos. Struct. 2018, 185, 646–655. [Google Scholar] [CrossRef]

- Clarke, T.; Simonetti, F.; Cawley, P. Guided wave health monitoring of complex structures by sparse array systems: Influence of temperature changes on performance. J. Sound Vib. 2010, 329, 2306–2322. [Google Scholar] [CrossRef]

- Sikdar, S.; Banerjee, S. Guided wave propagation in a honeycomb composite sandwich structure in presence of a high density core. Ultrasonics 2016, 71, 86–97. [Google Scholar] [CrossRef]

- Hay, T.R.; Wei, L.; Rose, J.L.; Hayashi, T. Rapid inspection of composite skin-honeycomb core structures with ultrasonic guided waves. J. Compos. Mater. 2003, 37, 929–939. [Google Scholar] [CrossRef]

- Xu, B.; Giurgiutiu, V. Single mode tuning effects on Lamb wave time reversal with piezoelectric wafer active sensors for structural health monitoring. J. Nondestr. Eval. 2007, 26, 123–134. [Google Scholar] [CrossRef]

- Song, F.; Huang, G.L.; Hudson, K. Guided wave propagation in honeycomb sandwich structures using a piezoelectric actuator/sensor system. Smart Mater. Struct. 2009, 18, 125007. [Google Scholar] [CrossRef]

- Bourasseau, N.; Moulin, E.; Delebarre, C.; Bonniau, P. Radome Health Monitoring with Lamb Waves: Experimental Approach. Nondestr. Test. Eval. 2000, 33, 393–400. [Google Scholar] [CrossRef]

- Ricci, F.; Monaco, E.; Maio, L.; Boffa, N.D.; Mal, A.K. Guided waves in a stiffened composite laminate with a delamination. Struct. Health Monit. 2016, 15, 351–358. [Google Scholar] [CrossRef]

- Banerjee, S.; Pol, C. Theoretical modeling of guided wave propagation in a Sandwich plate subjected to transient surface excitations. Int. J. Solids Struct. 2012, 49, 3233–3241. [Google Scholar] [CrossRef]

- Nino, G.F.; Ahmed, T.J.; Bersee, H.E.; Beukers, A. Thermal NDI of resistance welded composite structures. Compos. Part B Eng. 2009, 40, 237–248. [Google Scholar] [CrossRef]

- Amenabar, I.; Mendikute, A.; López-Arraiza, A.; Lizaranzu, M.; Aurrekoetxea, J. Comparison and analysis of non-destructive testing techniques suitable for delamination inspection in wind turbine blades. Compos. Part B Eng. 2011, 42, 1298–1305. [Google Scholar] [CrossRef]

- Holland, S.D. Thermographic signal reconstruction for vibrothermography. Infrared Phys. Technol. 2011, 54, 503–511. [Google Scholar] [CrossRef]

- Renshaw, J.; Chen, J.C.; Holland, S.D.; Thompson, R.B. The sources of heat generation in vibrothermography. NDT E Int. 2011, 44, 736–739. [Google Scholar] [CrossRef]

- Lahiri, B.B.; Bagavathiappan, S.; Reshmi, P.R.; Philip, J.; Jayakumar, T.; Raj, B. Quantification of defects in composites and rubber materials using active thermography. Infrared Phys. Technol. 2012, 55, 191–199. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; López, I. Feature extraction and analysis for automatic characterization of impact damage in carbon fiber composites using active thermography. NDT E Int. 2013, 54, 123–132. [Google Scholar] [CrossRef]

- Aldave, I.J.; Bosom, P.V.; González, L.V.; De Santiago, I.L.; Vollheim, B.; Krausz, L.; Georges, M. Review of thermal imaging systems in composite defect detection. Infrared Phys. Technol. 2013, 61, 167–175. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Pawar, S.S. A novel approach for one-sided thermal nondestructive testing of composites by using infrared thermography. Polym. Test. 2015, 44, 224–233. [Google Scholar] [CrossRef]

- He, Y.; Yang, R.; Zhang, H.; Zhou, D.; Wang, G. Volume or inside heating thermography using electromagnetic excitation for advanced composite materials. Int. J. Therm. Sci. 2017, 111, 41–49. [Google Scholar] [CrossRef]

- Balageas, D.L.; Roche, J.M.; Leroy, F.H. Comparative Assessment of Thermal NDT Data Processing Techniques for Carbon Fiber Reinforced Polymers. Mater. Eval. 2017, 75, 1019–1031. [Google Scholar]

- Vinson, J.R.; Sierakowski, R.L. The Behavior of Structures Composed of Composite Materials; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1993. [Google Scholar]

- Chamis, C.C. Simplified composite micromechanics equations for hygral, thermal and mechanical properties. SAMPE Quarterly 1984, 15, 14–23. [Google Scholar]

- Shepard, S.M.; Lhota, J.R.; Rubadeux, B.A.; Wang, D.; Ahmed, T. Reconstruction and enhancement of active thermographic image sequences. Opt. Eng. 2003, 42, 1337–1342. [Google Scholar] [CrossRef]

| PZT (No.) | X-Coordinate (cm) | Y-Coordinate (cm) |

|---|---|---|

| 1 | 0.5 | 2.5 |

| 2 | 24.5 | 2.5 |

| 3 | 0.5 | 7.5 |

| 4 | 24.5 | 7.5 |

| 5 | 0.5 | 12.5 |

| 6 | 24.5 | 12.5 |

| 7 | 0.5 | 17.5 |

| 8 | 24.5 | 17.5 |

| 9 | 0.5 | 22.5 |

| 10 | 24.5 | 22.5 |

| Material | E11 (GPa) | E22 (GPa) | E33 (GPa) | G12 (GPa) | G23 (GPa) | G13 (GPa) | ν12 | ν13 | ν23 | ρ (kg/m3) | Tmp (°C) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CFRC | 73.95 | 73.95 | 11.17 | 4.26 | 4.02 | 4.02 | 0.04 | 0.37 | 0.37 | 1568 | –60 |

| 73.78 | 73.78 | 11.12 | 4.11 | 3.86 | 3.86 | 0.04 | 0.37 | 0.37 | 1568 | –40 | |

| 73.53 | 73.53 | 10.7 | 3.95 | 3.71 | 3.71 | 0.04 | 0.37 | 0.37 | 1568 | –20 | |

| 73.28 | 73.28 | 10.26 | 3.78 | 3.55 | 3.55 | 0.03 | 0.37 | 0.37 | 1568 | 0 | |

| 73.02 | 73.02 | 9.8 | 3.61 | 3.38 | 3.38 | 0.03 | 0.37 | 0.37 | 1568 | 20 | |

| 72.74 | 72.74 | 9.31 | 3.42 | 3.21 | 3.21 | 0.03 | 0.37 | 0.37 | 1568 | 40 | |

| 72.44 | 72.44 | 8.79 | 3.23 | 3.02 | 3.02 | 0.03 | 0.37 | 0.37 | 1568 | 60 | |

| 72.12 | 72.12 | 8.22 | 3.017 | 2.83 | 2.83 | 0.03 | 0.37 | 0.37 | 1568 | 80 | |

| 71.77 | 71.77 | 7.62 | 2.79 | 2.61 | 2.61 | 0.03 | 0.37 | 0.37 | 1568 | 100 | |

| Adhesive | 4.82 | 4.82 | 4.82 | 1.71 | 1.71 | 1.71 | 0.4 | 0.4 | 0.4 | 1250 | –60 |

| 4.63 | 4.63 | 4.63 | 1.65 | 1.65 | 1.65 | 0.4 | 0.4 | 0.4 | 1250 | –40 | |

| 4.45 | 4.45 | 4.45 | 1.59 | 1.59 | 1.59 | 0.4 | 0.4 | 0.4 | 1250 | –20 | |

| 4.26 | 4.26 | 4.26 | 1.52 | 1.52 | 1.52 | 0.4 | 0.4 | 0.4 | 1250 | 0 | |

| 4.052 | 4.052 | 4.052 | 1.45 | 1.45 | 1.45 | 0.4 | 0.4 | 0.4 | 1250 | 20 | |

| 3.84 | 3.84 | 3.84 | 1.37 | 1.37 | 1.37 | 0.4 | 0.4 | 0.4 | 1250 | 40 | |

| 3.61 | 3.61 | 3.61 | 1.29 | 1.29 | 1.29 | 0.4 | 0.4 | 0.4 | 1250 | 60 | |

| 3.37 | 3.37 | 3.37 | 1.2 | 1.2 | 1.2 | 0.4 | 0.4 | 0.4 | 1250 | 80 | |

| 3.11 | 3.11 | 3.11 | 1.11 | 1.11 | 1.11 | 0.4 | 0.4 | 0.4 | 1250 | 100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikdar, S.; Kundu, A.; Jurek, M.; Ostachowicz, W. Nondestructive Analysis of Debonds in a Composite Structure under Variable Temperature Conditions. Sensors 2019, 19, 3454. https://doi.org/10.3390/s19163454

Sikdar S, Kundu A, Jurek M, Ostachowicz W. Nondestructive Analysis of Debonds in a Composite Structure under Variable Temperature Conditions. Sensors. 2019; 19(16):3454. https://doi.org/10.3390/s19163454

Chicago/Turabian StyleSikdar, Shirsendu, Abhishek Kundu, Michał Jurek, and Wiesław Ostachowicz. 2019. "Nondestructive Analysis of Debonds in a Composite Structure under Variable Temperature Conditions" Sensors 19, no. 16: 3454. https://doi.org/10.3390/s19163454

APA StyleSikdar, S., Kundu, A., Jurek, M., & Ostachowicz, W. (2019). Nondestructive Analysis of Debonds in a Composite Structure under Variable Temperature Conditions. Sensors, 19(16), 3454. https://doi.org/10.3390/s19163454