Sensor Fault Detection and Signal Restoration in Intelligent Vehicles

Abstract

:1. Introduction

- By conducting studies on fault diagnosis and restoration based on the major motion sensors that are installed in most vehicles, the possibility that this study can be used in several vehicles has increased.

- A vehicle kinematic model based on the central axis of the vehicle, which is used to detect faults and restore fault signals using a structure in which the failure of each sensor does not affect each other, is proposed.

- In the logic for fault detection, finally, a simple diagnostic logic structure is presented; this structure helps discriminate between normal and fault and distinguishes a specific fault using a conditional expression of only two variables.

2. Fault Detection and Recovery

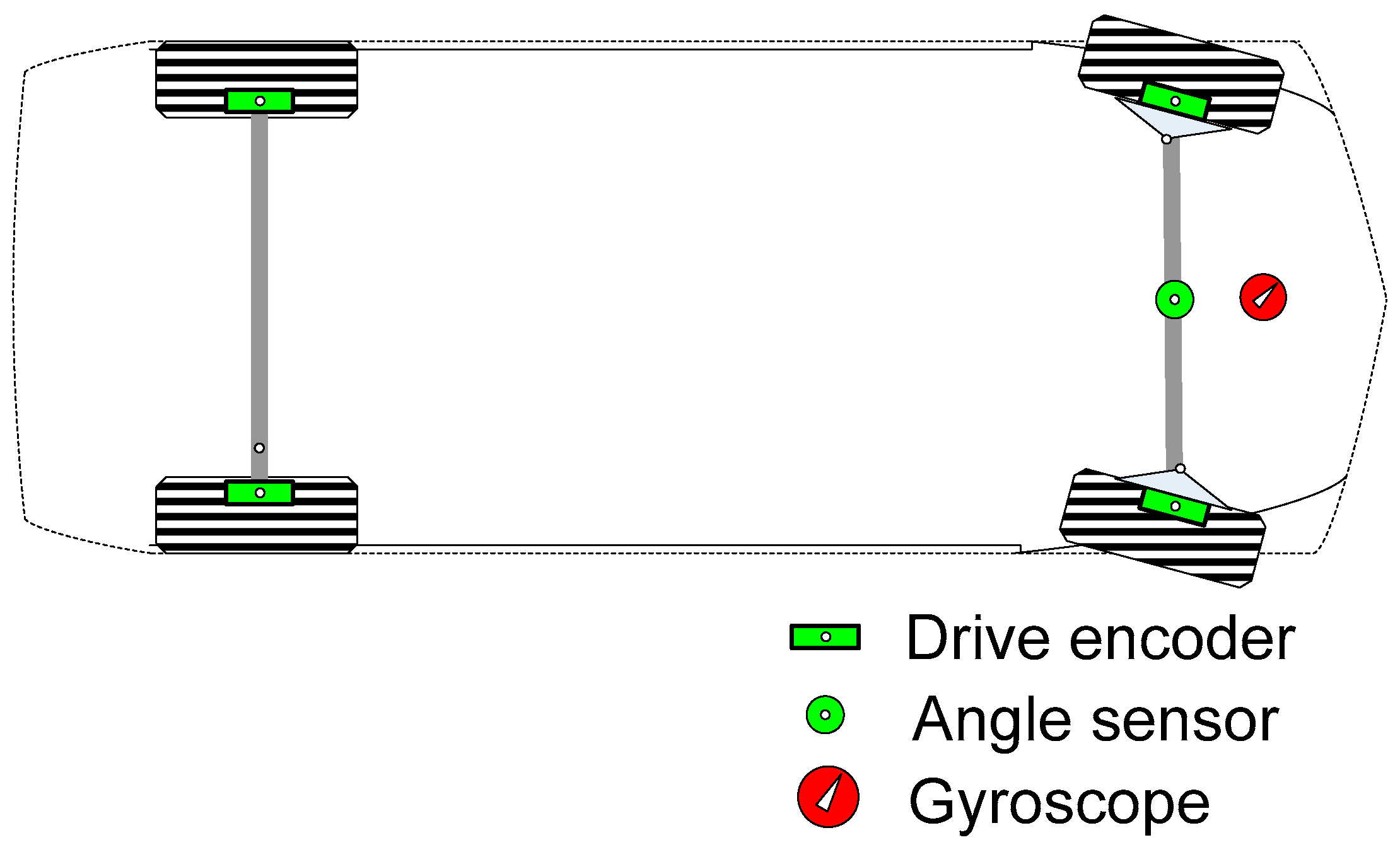

2.1. Configuration of the Autonomous Vehicle

2.2. Influence of Sensor Fault

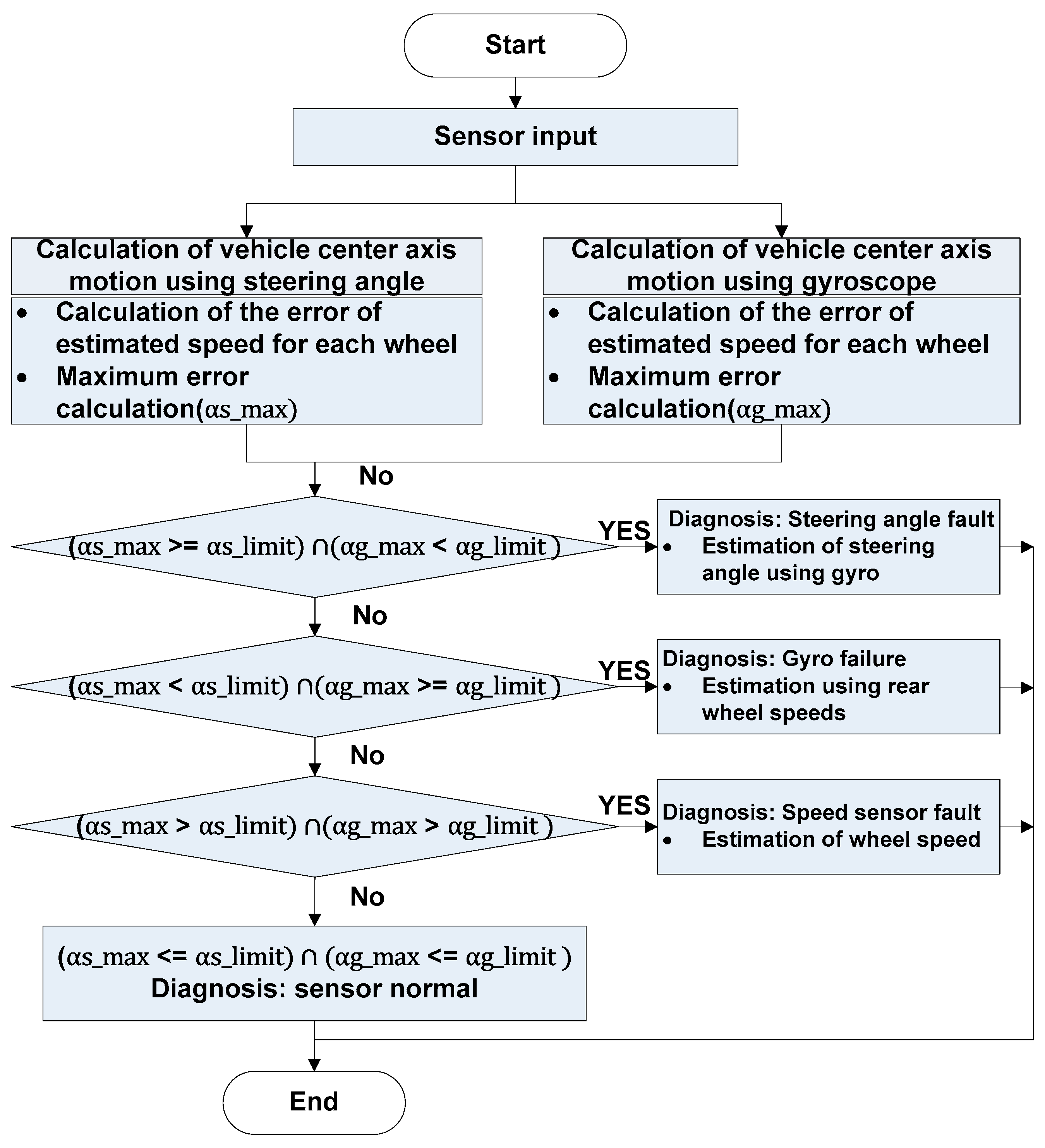

2.3. Architecture of Fault Detection

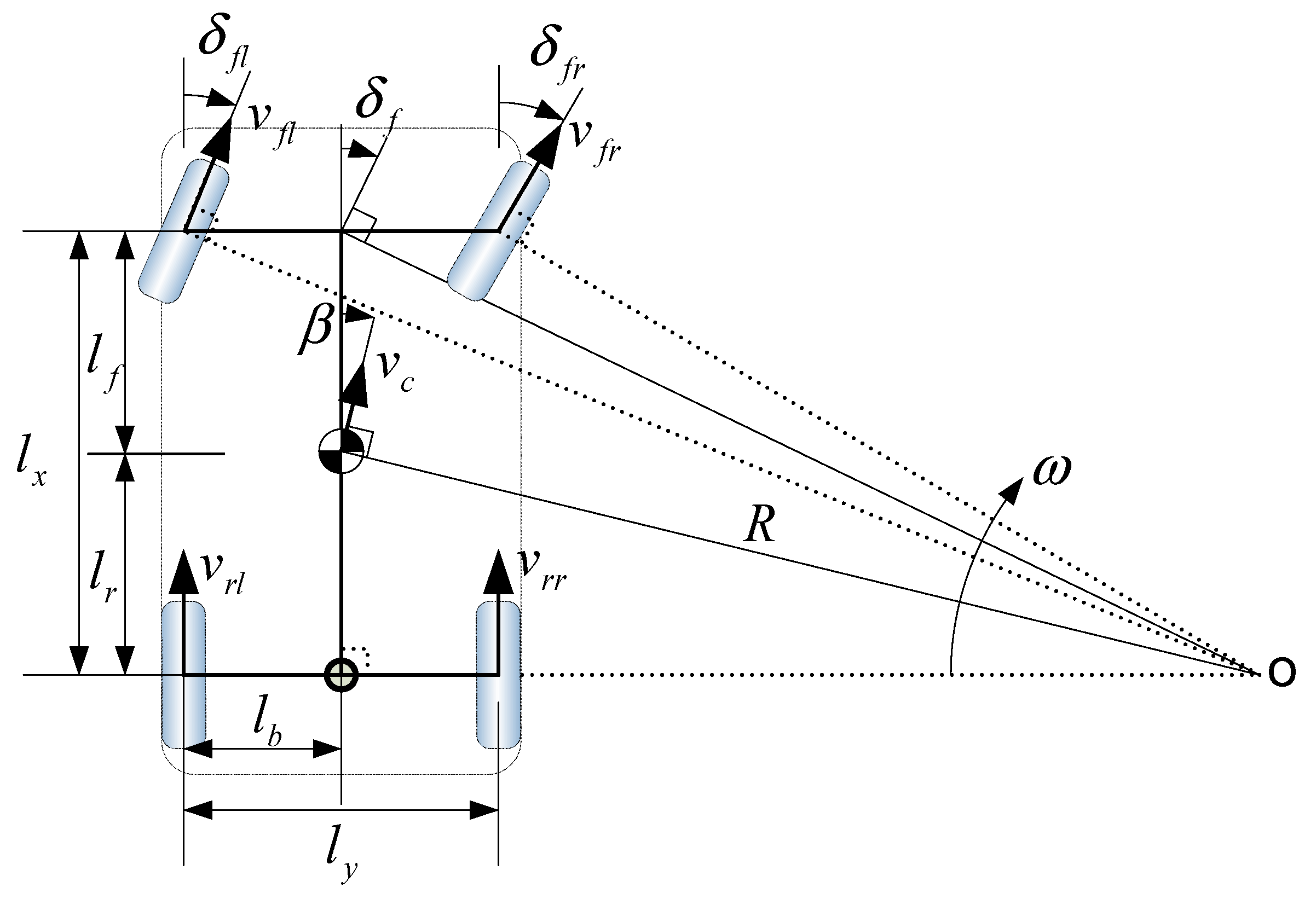

2.4. Vehicle Geometry for Kinematic Estimation

2.5. Virtual Redundancy of Sensors and Errors

2.5.1. Central Axis Speed Estimation Based on Steering Angle

2.5.2. Central Axis Speed Estimation Using the Gyroscope

2.6. Fault Detection, Identification, and Signal Recovery

2.6.1. Fault-Free Sensor Judgment Condition

2.6.2. Fault Detection and Signal Restoration for Steering Angle Information

2.6.3. Gyroscope Fault Detection and Signal Restoration

2.6.4. Fault Detection of the Speed Sensor and Signal Restoration

3. Results and Discussion

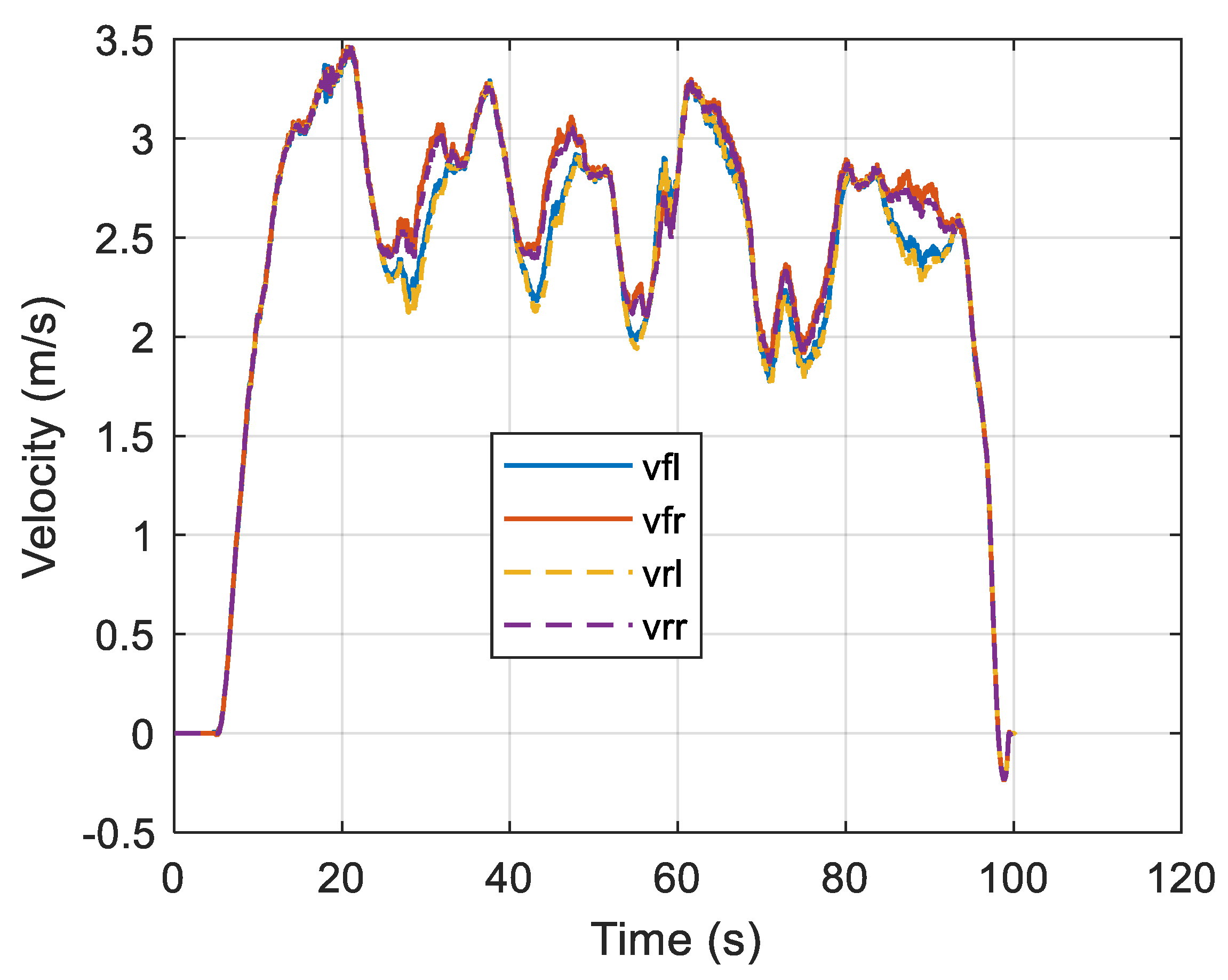

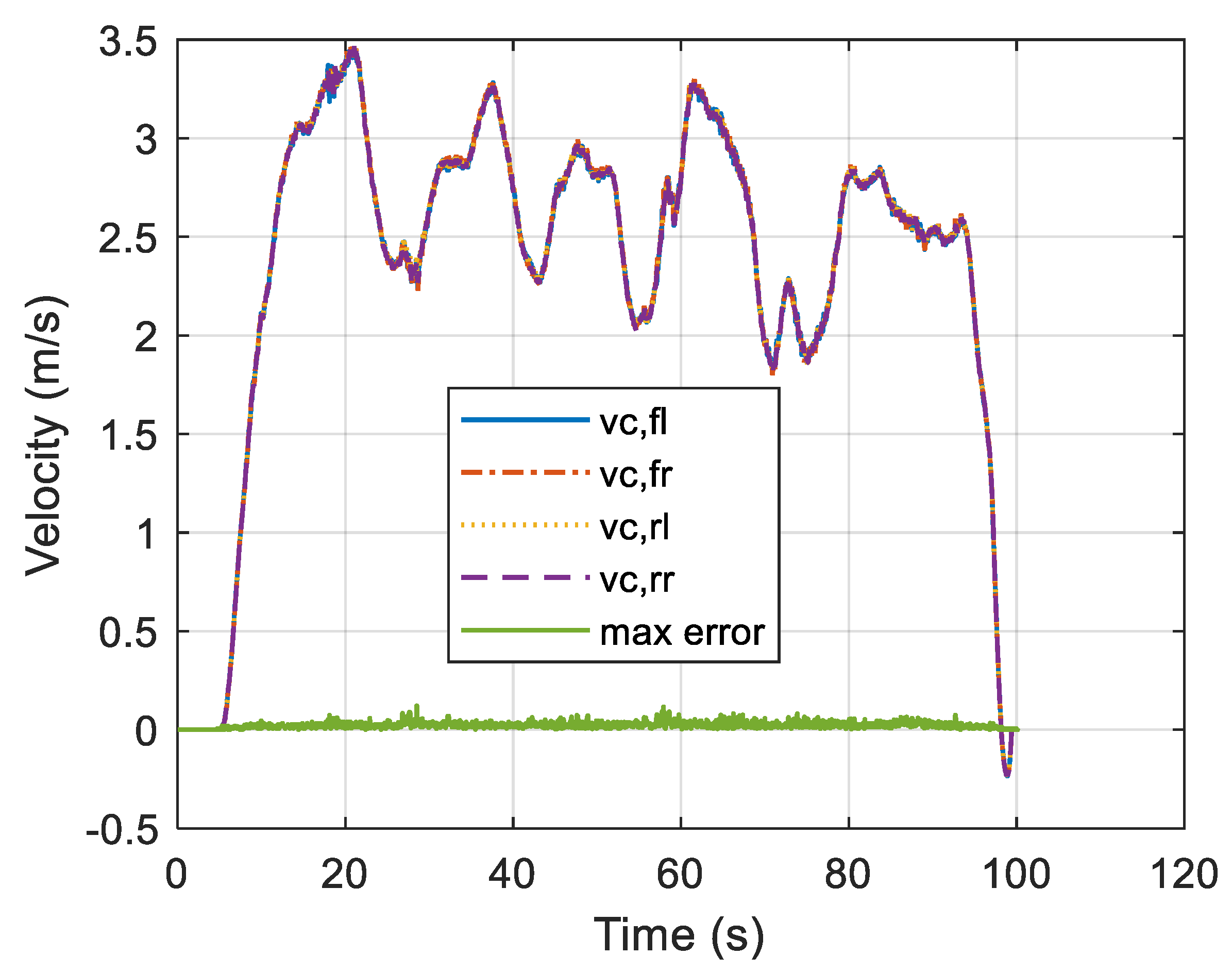

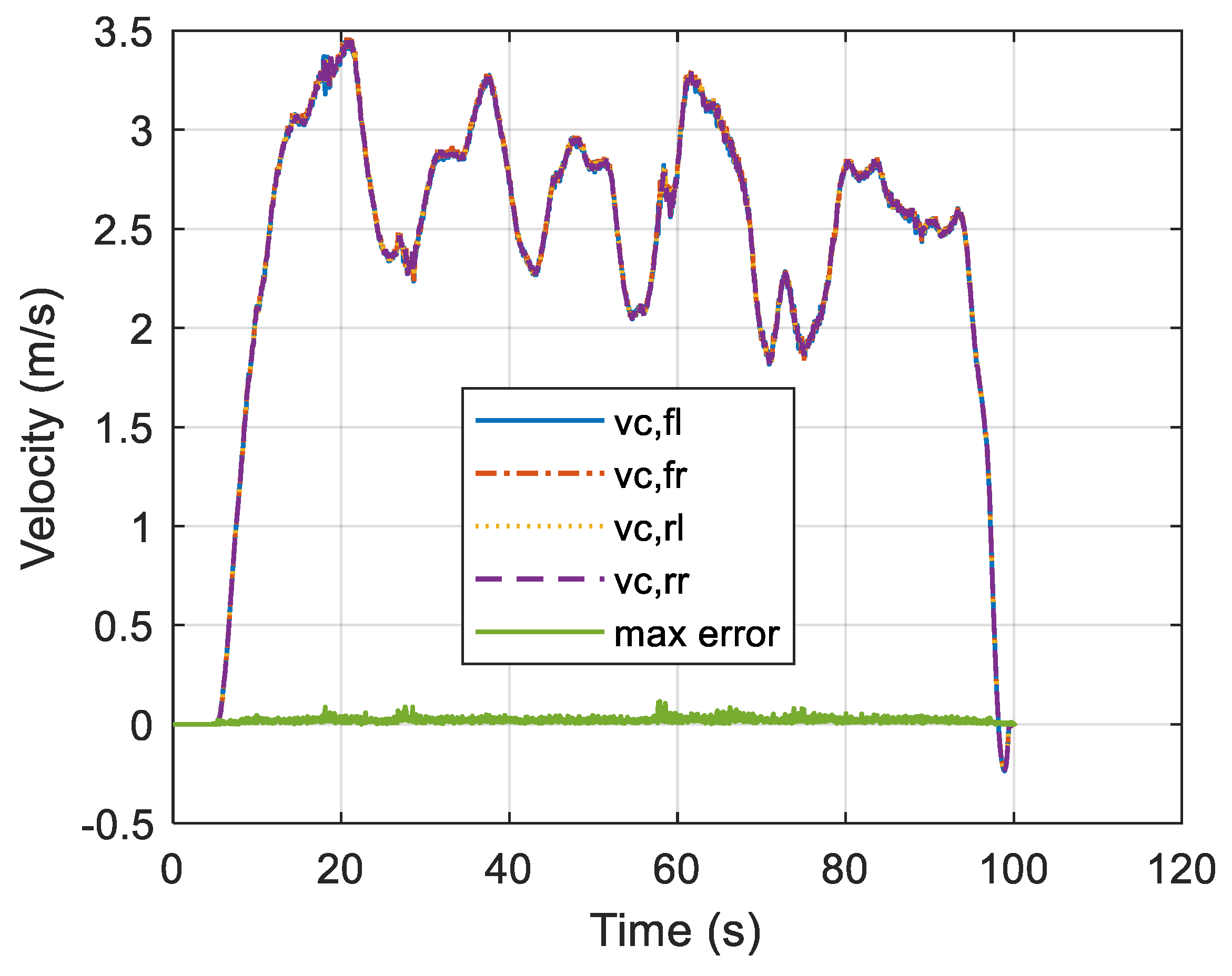

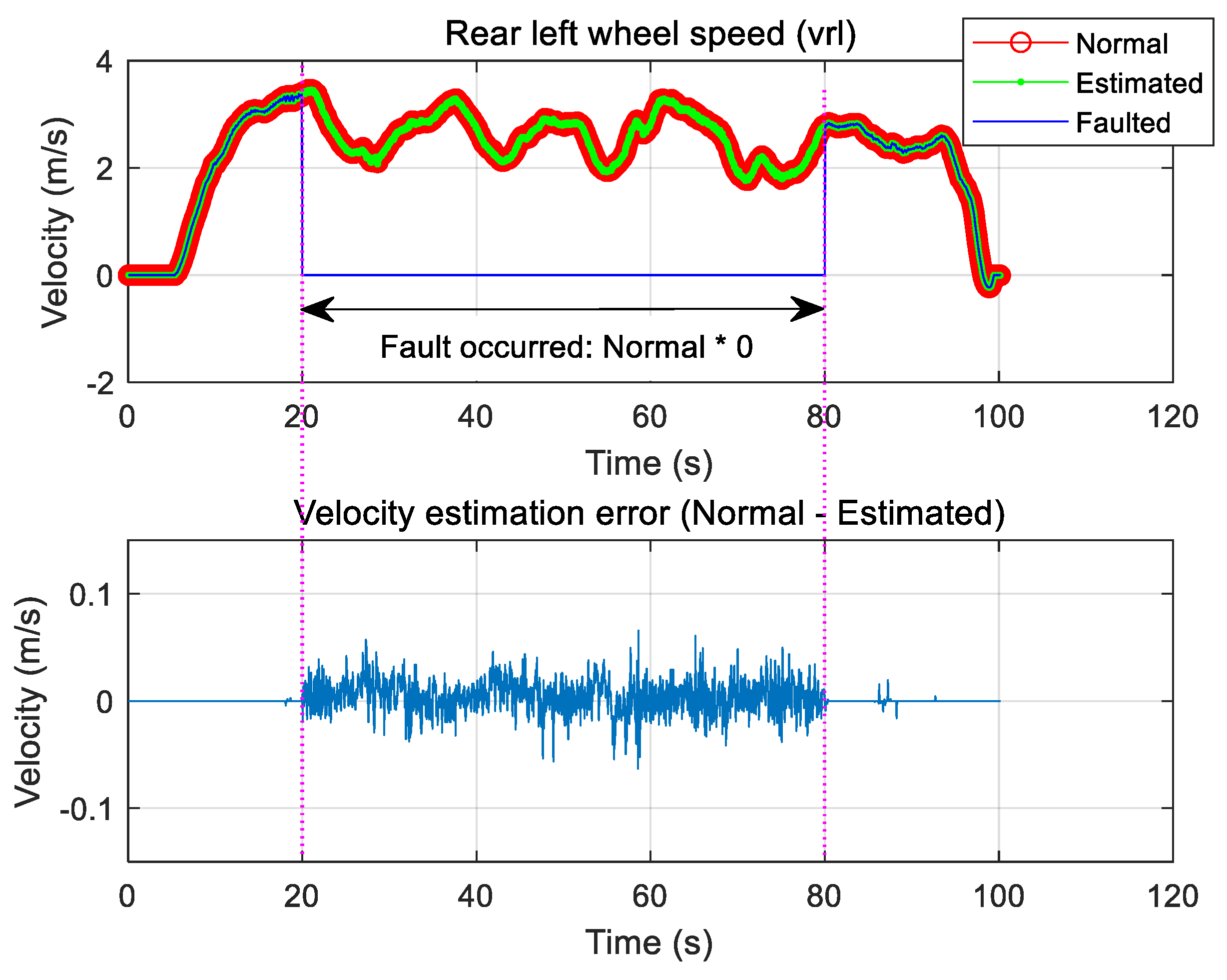

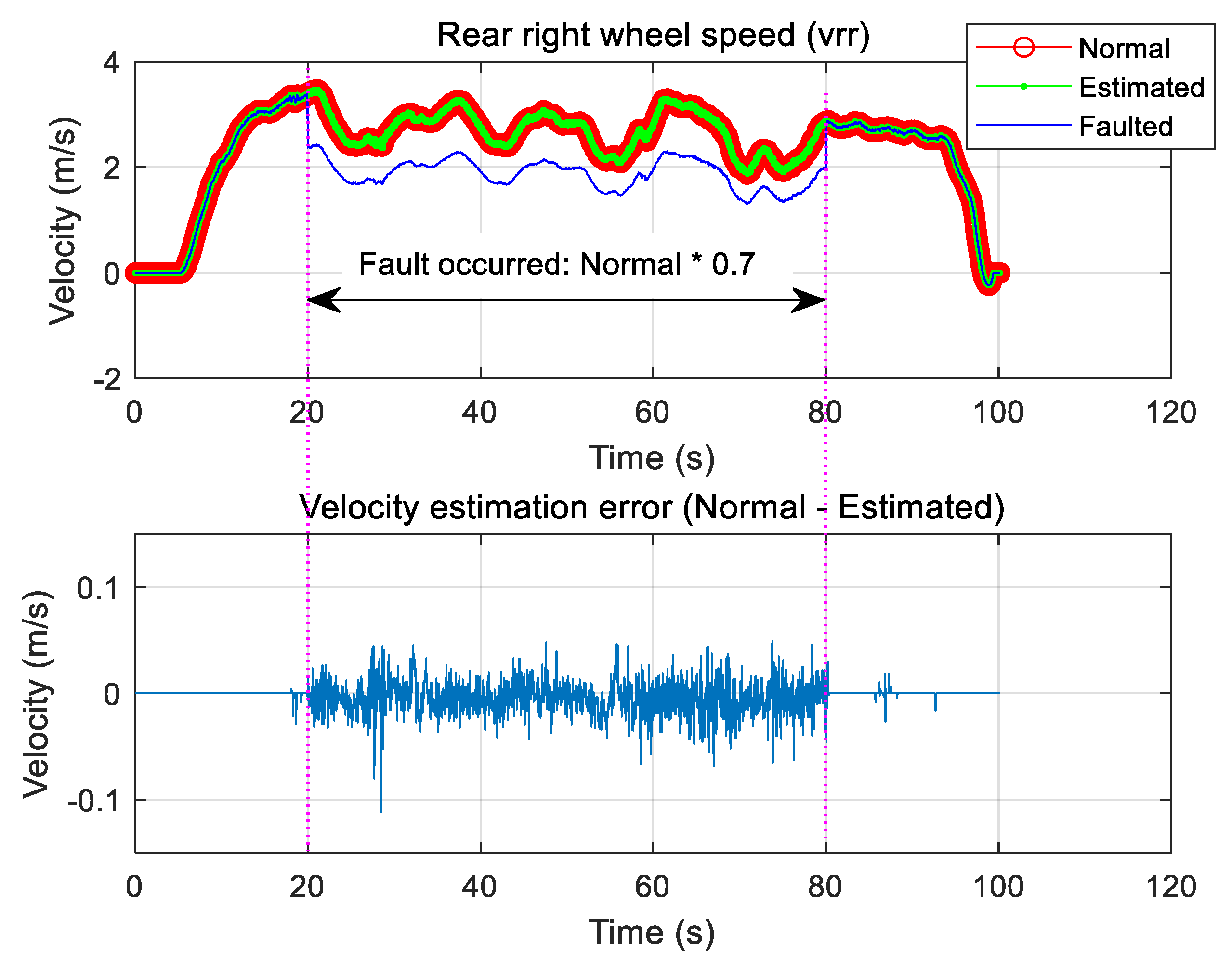

3.1. Speed Sensor Fault Test

3.2. Steering Angle Sensor Fault

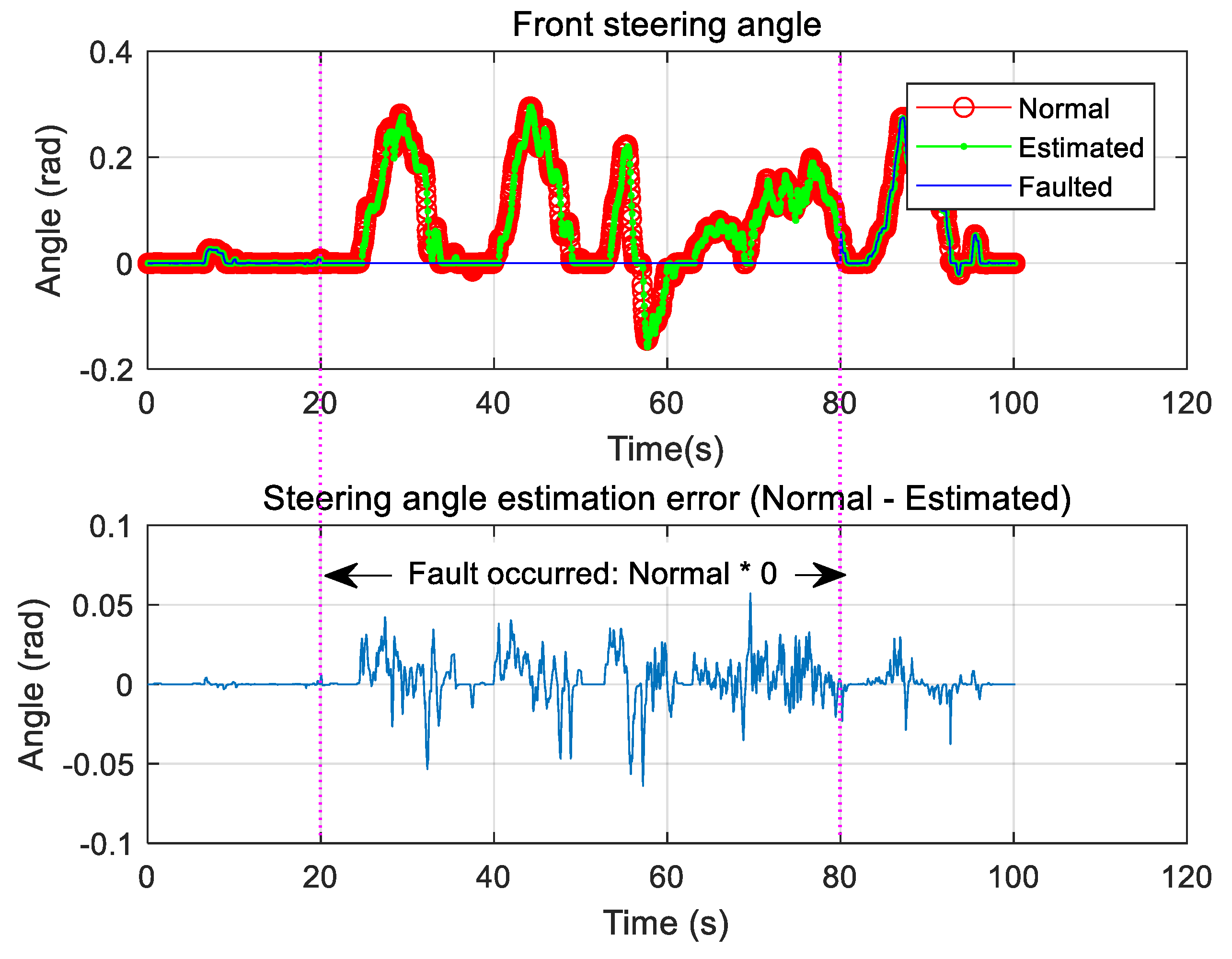

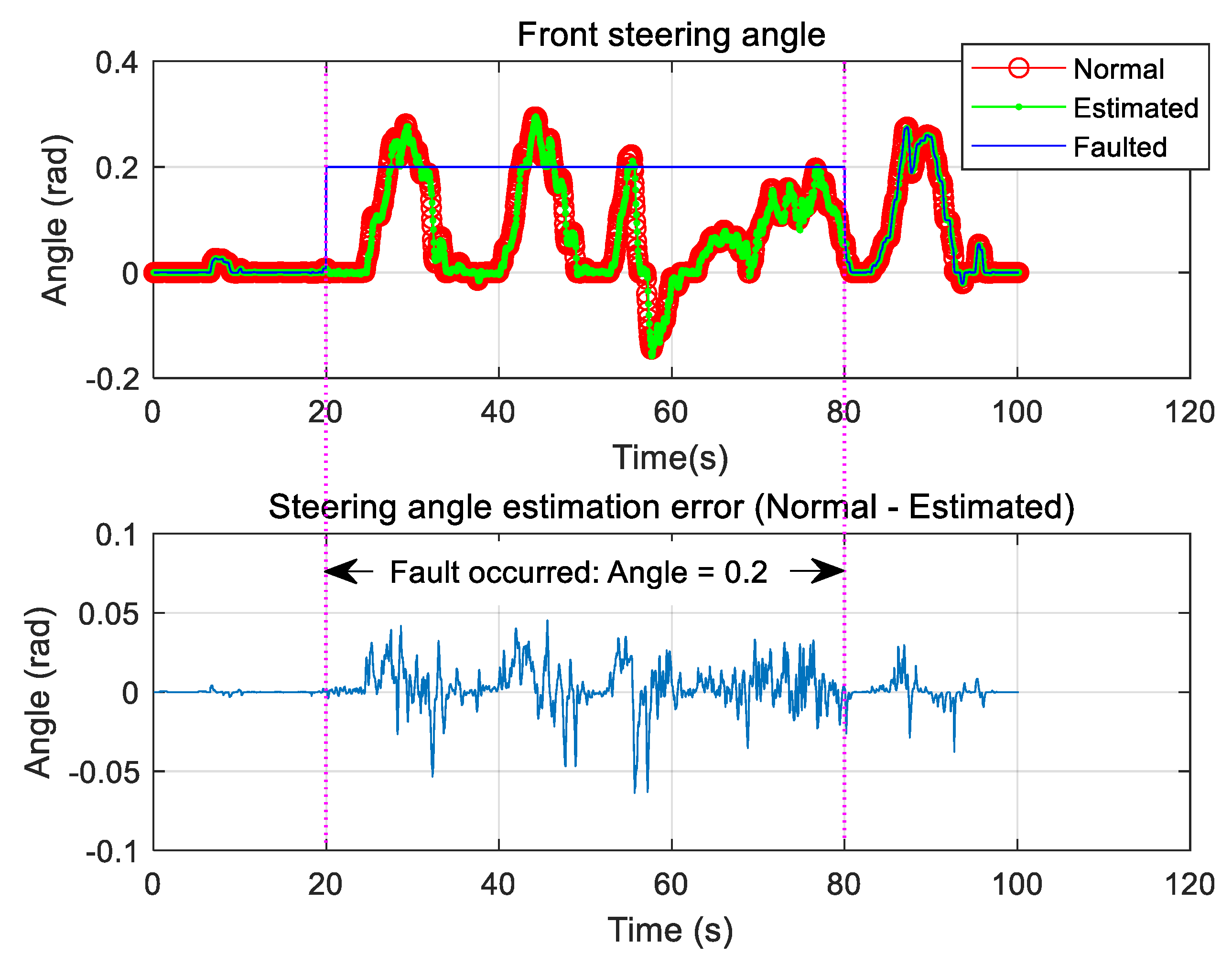

3.3. Gyroscope Fault

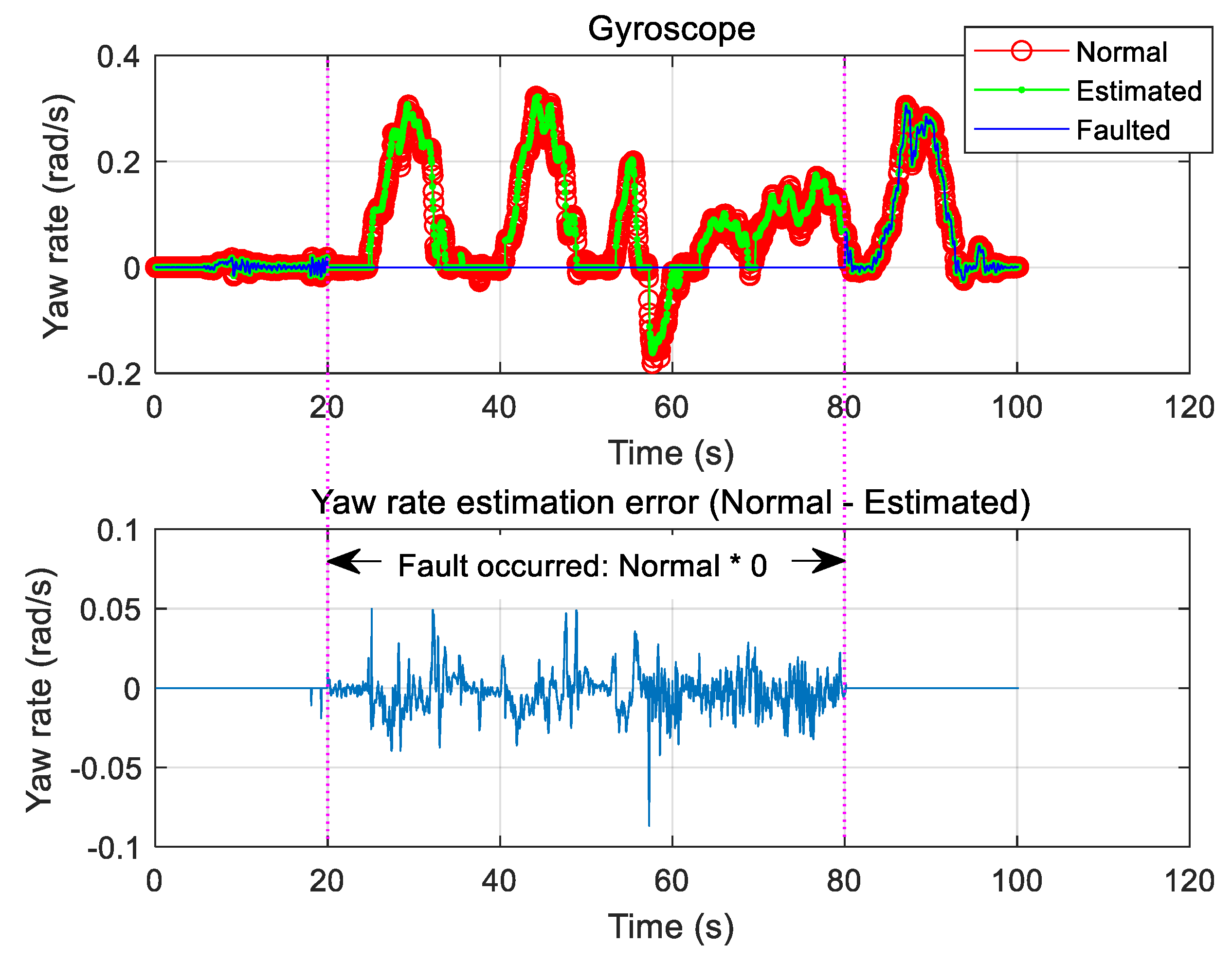

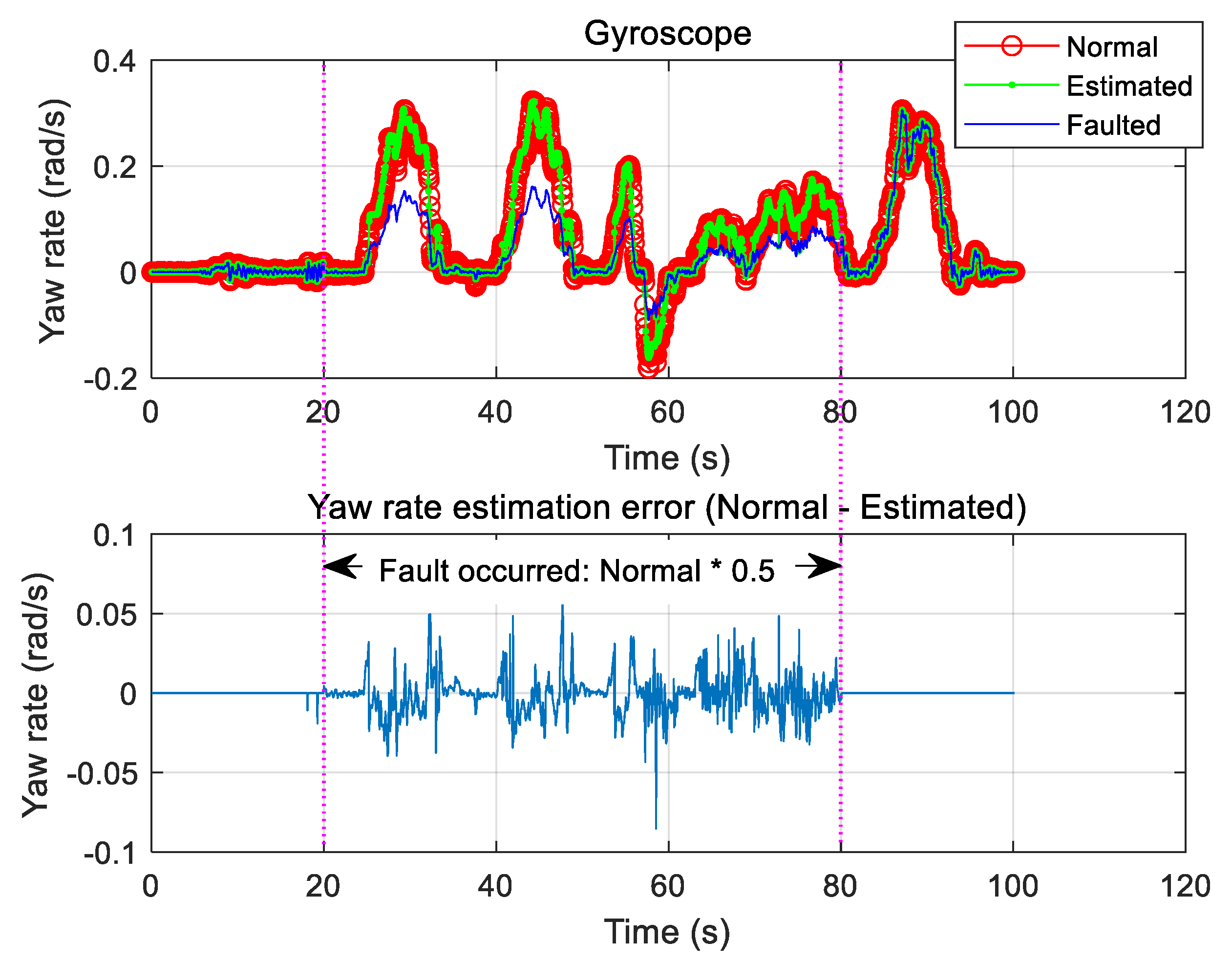

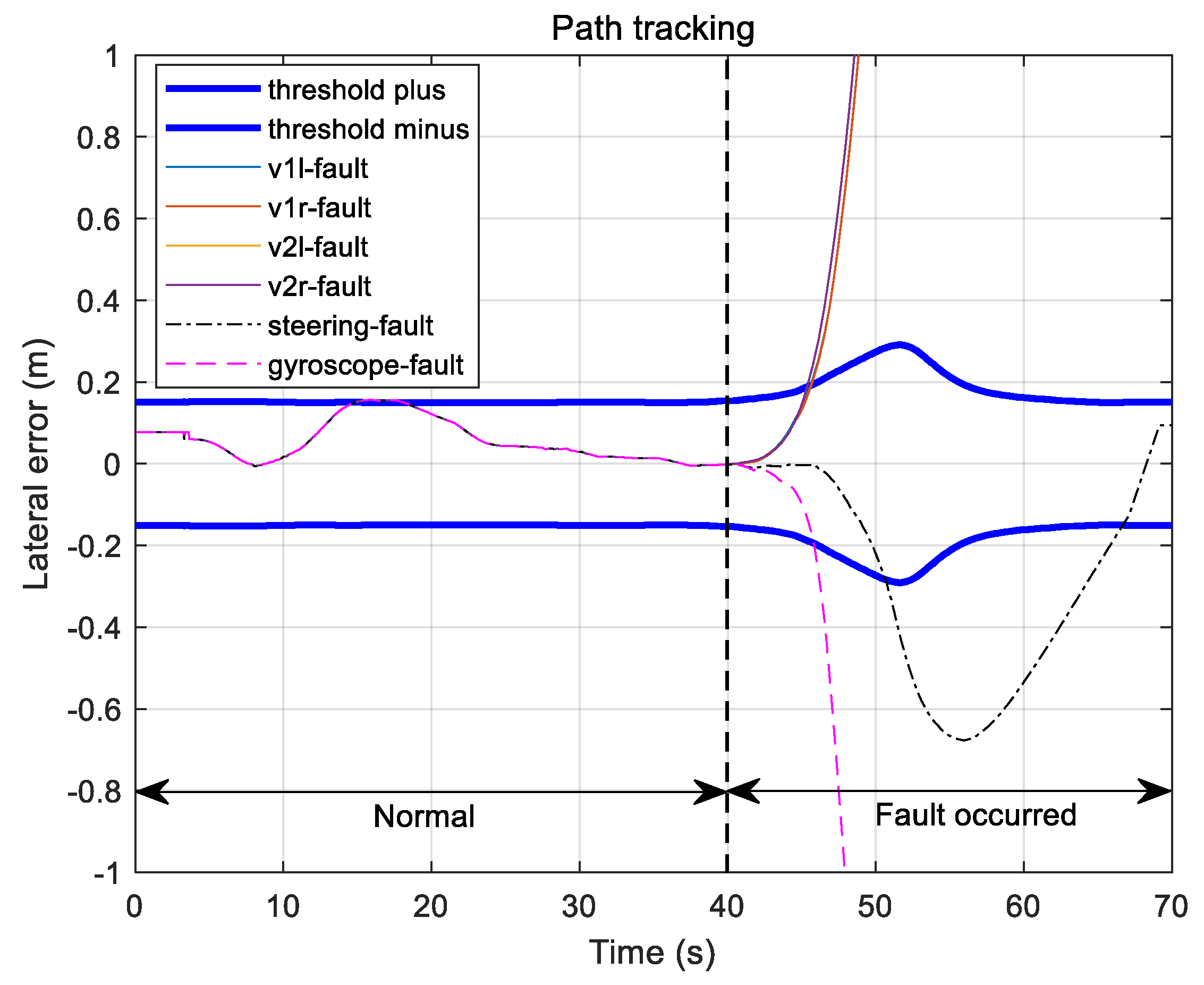

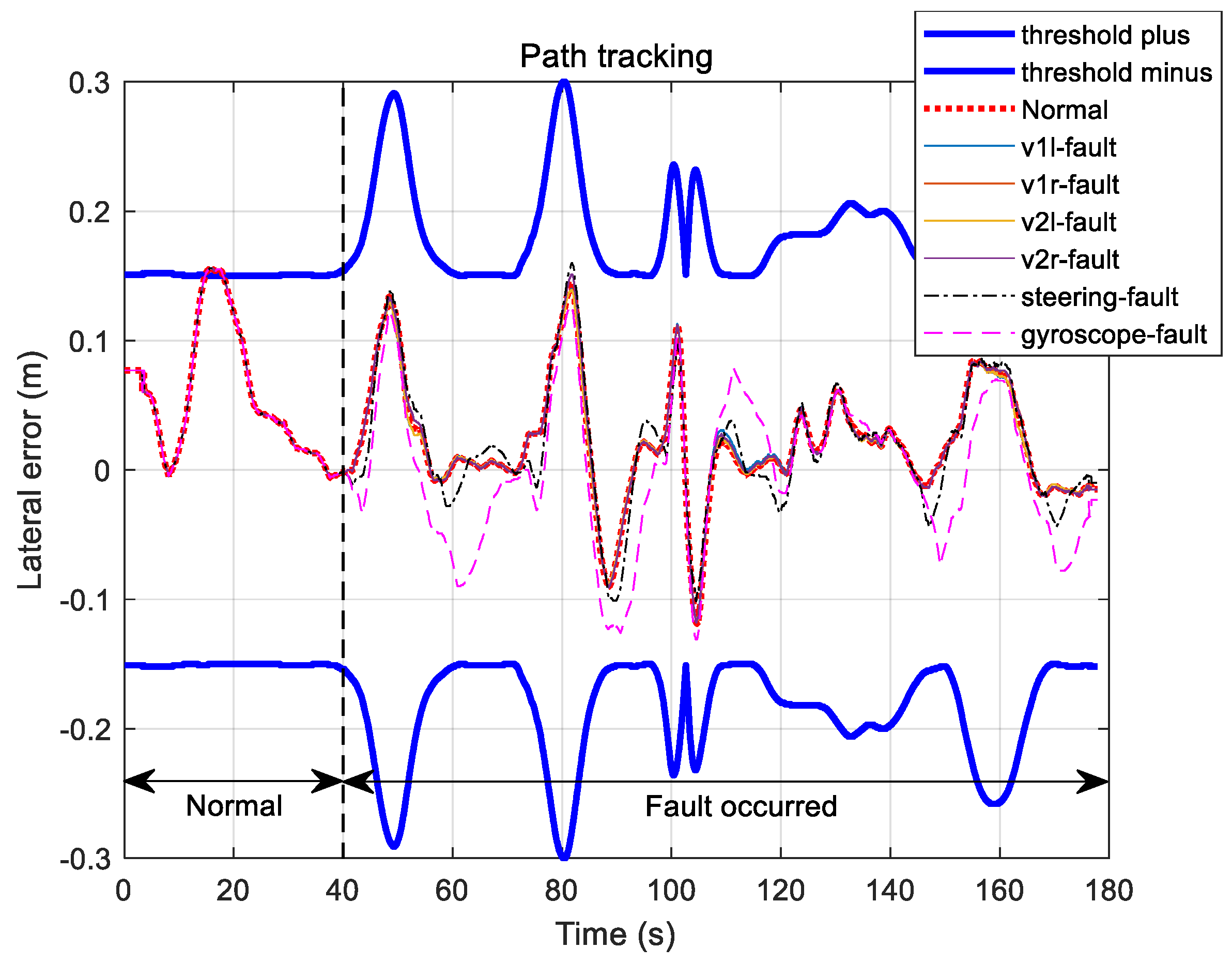

3.4. Influence of Defects in Automatic Running

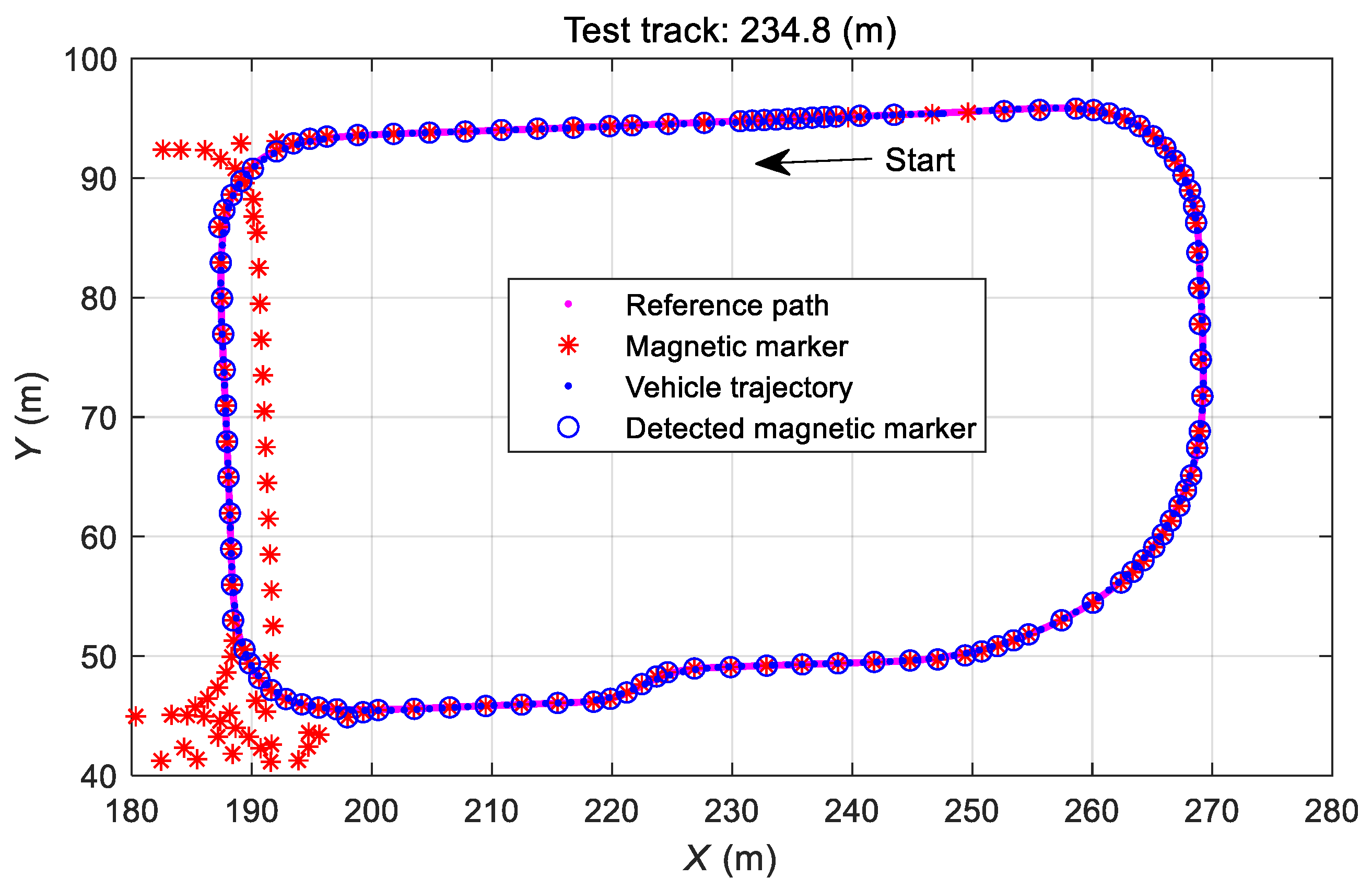

3.4.1. Fault-Free Driving

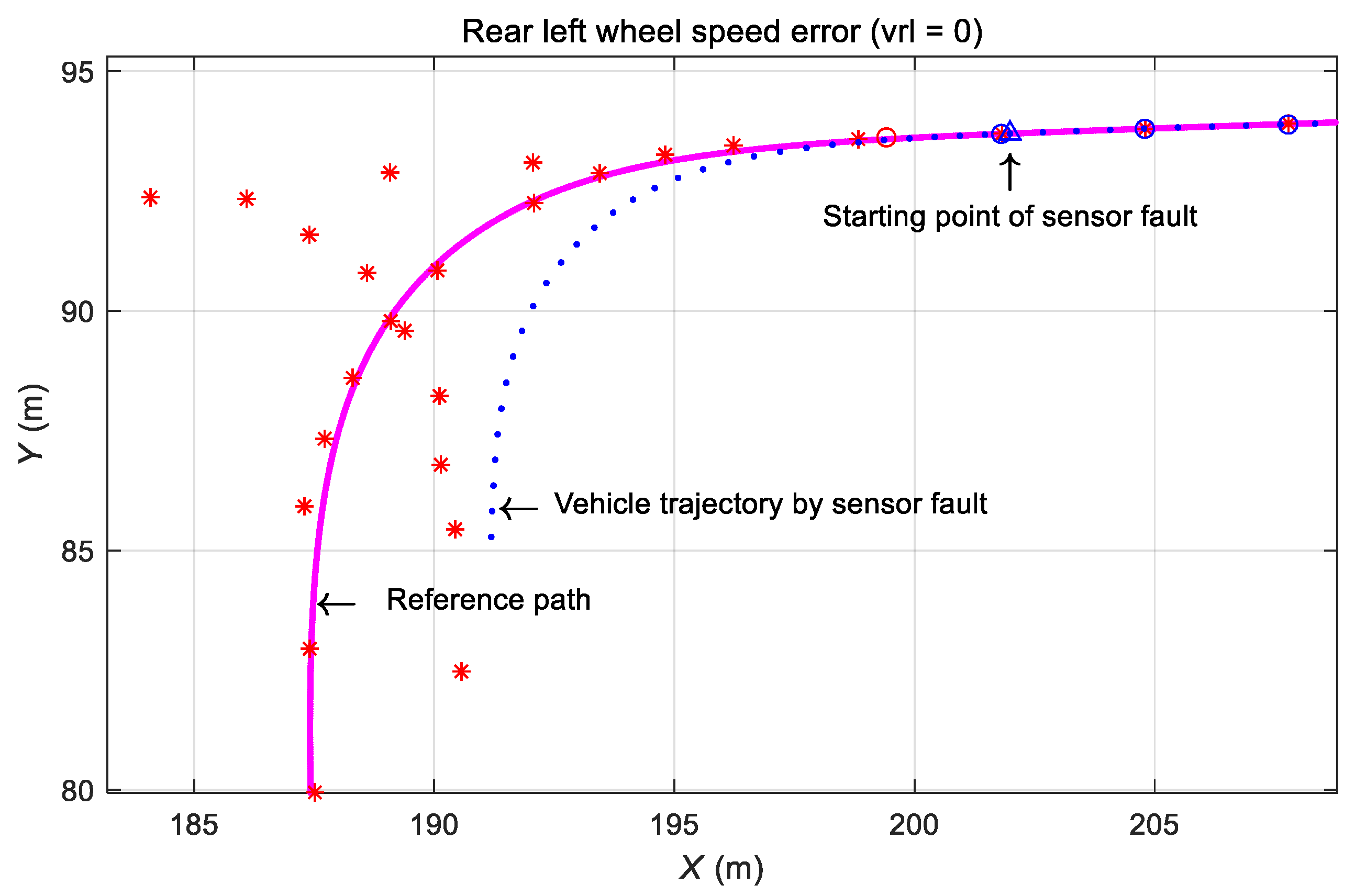

3.4.2. Effect of Rear Left-Wheel Speed Sensor Defect during Automatic Driving

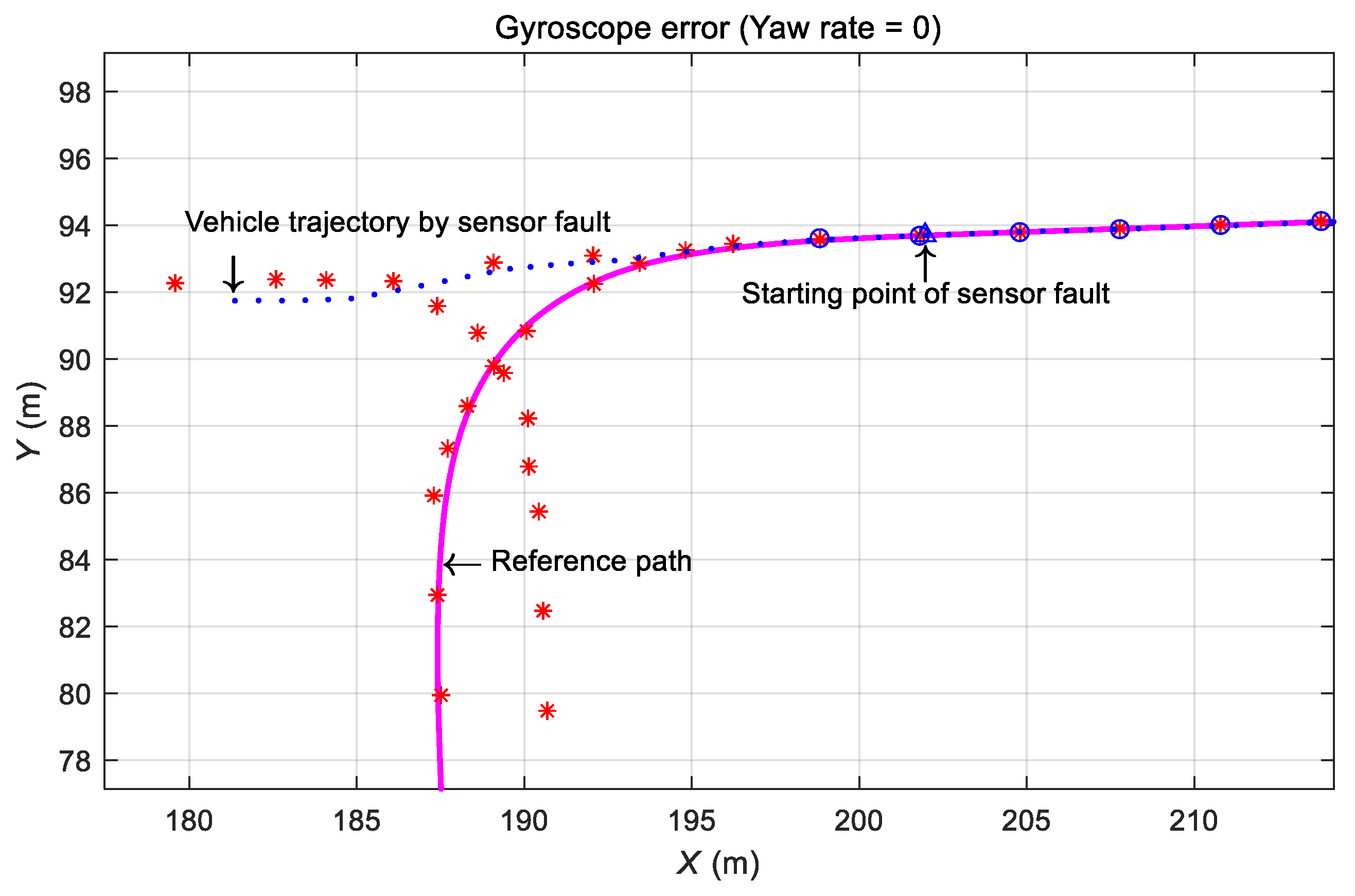

3.4.3. Effect of Gyroscope Defect during Automatic Driving

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Karimi, H.; Chadli, M.; Shi, P. Fault detection, isolation, and tolerant control of vehicles using soft computing methods. IET Control Theory Appl. 2014, 8, 655–657. [Google Scholar] [CrossRef]

- Aouaouda, S.; Chadli, M.; Boukhnifer, M. Speed sensor fault tolerant controller design for induction motor drive in EV. Neurocomputing 2016, 214, 32–43. [Google Scholar] [CrossRef]

- Oudghiri, M.; Chadli, M.; El Hajjaji, A. Robust observer-based fault tolerant control for vehicle lateral dynamics. IJVD 2008, 48, 173–189. [Google Scholar] [CrossRef]

- Realpe, M.; Vintimilla, B.; Vlacic, L. Sensor fault detection and diagnosis for autonomous vehicles. Proc. MATEC Web Conf. 2015, 30, 04003. [Google Scholar] [CrossRef]

- Abid, A.; Tahir-khan, M.; De-silva, C.W. Fault detection in mobile robots using sensor fusion. In Proceedings of the 10th ICCSE, Cambridge, UK, 22–24 July 2015; pp. 8–13. [Google Scholar]

- Agogino, A.; Alag, S.; Goebel, K. A framework for intelligent sensor validation, sensor fusion, and supervisory control of automated vehicles in IVHS, Intelligent Transportation: Serving the User through Deployment. In Proceedings of the 1995 Annual Meeting of ITS America, Washington, DC, USA, 15–17 March 1995; pp. 77–87. [Google Scholar]

- Nembhard, A.D.; Sinha, J.K.; Yunusa-Kaltungo, A. Development of a generic rotating machinery fault diagnosis approach insensitive to machine speed and support type. JSV 2015, 337, 321–341. [Google Scholar] [CrossRef]

- Napolitano, M.; An, Y.; Seanor, B.; Pispistos, S.; Martinelli, D. Application of a neural sensor validation scheme to actual Boeing B737 flight data. In Proceedings of the ’99 AIAA Guidance, Navigation and Control Conference, Portland, OR, USA, 9–11 August 1999. [Google Scholar]

- Napolitano, M.; An, Y.; Seanor, B. A fault tolerant flight control system for sensor and actuator failures using neural networks. Aircr. Des. 2000, 3, 103–128. [Google Scholar] [CrossRef]

- Napolitano, M.; Windon, D.; Casanova, J.; Innocenti, M.; Silvestri, G. Kalman filters and neural-network schemes for sensor validation in flight control systems. IEEE Trans. Control Syst. Technol. 1998, 6, 596–611. [Google Scholar] [CrossRef]

- Rago, C.; Prasanth, R.; Mehra, R.K.; Fortenbaugh, R. Failure Detection and Identification and Fault Tolerant Control Using the IMMKF with Applications to the Eagle-Eye UAV. In Proceedings of the 37th Conference on Decision and Control, Tampa, FL, USA, 18 December 1998. [Google Scholar]

- Heredia, G.; Remuß, V.; Ollero, A.; Mahtani, R.; Musial, M. Actuator Fault Detection in Autonomous Helicopters. In Proceedings of the 5th IFAC/EURON Symposium on Intelligent Autonomous Vehicles, Lisbon, Portugal, 5–7 July 2004. [Google Scholar]

- Heredia, G.; Ollero, A.; Mahtani, R.; Béjar, M.; Remuss, V.; Musial, M. Detection of Sensor Faults in Autonomous Helicopters. In Proceedings of the IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005; pp. 2229–2234. [Google Scholar]

- Garg, V. Fault Detection in Nonlinear Systems: An Application to Automated Highway Systems. Ph.D. Thesis, University of California, Berkeley, CA, USA, July 1995. [Google Scholar]

- Agogino, A.; Chao, S.; Goebel, K.; Alag, S.; Cammon, B.; Wang, J. Intelligent Diagnosis Based on Validated and Fused Data for Reliability and Safety Enhancement of Automated Vehicles in an IVHS; PATH Research Report UCB-ITS-P RR-98-17; University of California: Berkeley, CA, USA, 1998. [Google Scholar]

- Isermann, R. Diagnosis methods for electronic controlled vehicles. Veh. Syst. Dyn. 2001, 36, 77–117. [Google Scholar] [CrossRef]

- Yi, J.; Howell, A.; Horowitz, R.; Hedrick, K.; Alvarez, L. Fault Detection and Handling for Longitudinal Control; California PATH Research Report UCB-ITS-P RR-2001-21; University of California: Berkeley, CA, USA, 2001. [Google Scholar]

- Rajamani, R.; Howell, A.S.; Chen, C.; Hedrick, J.K.; Tomizuka, M. A complete fault diagnostic system for automated vehicles operating in a platoon. IEEE Trans. Control Syst. Technol. 2001, 9, 553–564. [Google Scholar] [CrossRef]

- Howell, A. Nonlinear Observer Design and Fault Diagnostics for Automated Longitudinal Vehicle Control. Ph.D. Thesis, University of California, Berkeley, CA, USA, July 2002. [Google Scholar]

- Chen, R.H.; Ng, H.K.; Speyer, J.L.; Mingori, D.L. Testing and Evaluation of Robust Fault Detection and Identification for a Fault Tolerant Automated Highway System; UC Berkeley, California Partners for Advanced Transportation Technology: Berkeley, CA, USA, 2002; Available online: https://escholarship.org/uc/item/2bw4f9fw (accessed on 25 July 2019).

- Okatan, A.; Hajiyev, C.; Hajiyeva, U. Fault detection in sensor information fusion Kalman filter. AEU Int. J. Electron. Commun. 2009, 63, 762–768. [Google Scholar] [CrossRef]

- Rodger, J.A. Toward reducing failure risk in an integrated vehicle health maintenance system: A fuzzy multi-sensor data fusion Kalman filter approach for IVHMS. Expert Syst. Appl. 2012, 39, 9821–9836. [Google Scholar] [CrossRef]

- Arogeti, S.A.; Wang, D.; Low, C.B.; Yu, M. Fault detection isolation and estimation in a vehicle steering system. IEEE Trans. Ind. Electron. 2012, 59, 4810–4820. [Google Scholar] [CrossRef]

- Na, W.; Park, C.; Lee, S.; Yu, S.; Lee, H. Sensitivity-based fault detection and isolation algorithm for road vehicle chassis sensors. Sensors 2018, 18, 2720. [Google Scholar] [CrossRef] [PubMed]

- Emirler, M.T.; Kahraman, K.; Sentürk, M.; Güvenç, B.A.; Güvenç, L.; Efendioglu, B. Vehicle yaw rate estimation using a virtual sensor. Int. J. Veh. Technol. 2013, 2013, 582691. [Google Scholar] [CrossRef]

- Huang, W.; Su, X. Design of a fault detection and isolation system for intelligent vehicle navigation system. IJNO 2015, 2015, 279086. [Google Scholar] [CrossRef]

- Pous, N.; Gingras, D.; Gruyer, D. Intelligent vehicle embedded sensors fault detection and isolation using analytical redundancy and nonlinear transformations. J. Control Sci. Eng. 2017, 2017, 1763934. [Google Scholar] [CrossRef]

- Aldridge, H.A. Robot position sensor fault tolerance. Ph.D. Thesis, Carnegie Mellon University, Pennsylvania, PA, USA, June 1996. [Google Scholar]

- Klancar, G. Fault detection and isolation by means of principal component analysis. In Proceedings of the Cybernetics & Informatics Eurodays Workshop, Prague, Czech Republic, 26–30 September 2000; pp. 26–30. [Google Scholar]

- Isermann, R. Model-based fault-detection and diagnosis status and applications. Annu. Rev. Control. 2005, 29, 71–85. [Google Scholar] [CrossRef]

- Duan, F.; Wang, H.; Zhang, L. Study on fault-tolerant filter algorithm for integrated navigation system. In Proceedings of the 2007 International Conference on Mechatronics and Automation, Harbin, China, 5–8 August 2007; pp. 2419–2423. [Google Scholar]

- Chan, C.W.; Hua, S.; Hong, Y.Z. Application of fully decoupled parity equation in fault detection and identification of DC motors. IEEE Trans. Ind. Electron. 2006, 53, 1277–1284. [Google Scholar] [CrossRef]

- Muenchhof, M. Comparison of change detection methods for a residual of a hydraulic servo-axis. FAC Proc. Vol. 2005, 38, 317–322. [Google Scholar] [CrossRef]

- Escobet, T.; Trave-Massuyes, L. Parameter estimation methods for fault detection and isolation. Bridge Workshop Notes 2001, 40, 1–11. [Google Scholar]

- Hilbert, M.; Kuch, C.M.; Nienhaus, K. Observer based condition monitoring of the generator temperature integrated in the wind turbine controller. In EWEA 2013 Scientific Proceedings; EWEA: Vienna, Austria, 2013; pp. 189–193. [Google Scholar]

- Heredia, G.; Ollero, A. Sensor fault detection in small autonomous helicopters using observer/Kalman filter identification. In Proceedings of the 2009 IEEE International Conference on Mechatronics, Malaga, Spain, 14–17 April 2009; pp. 1–6. [Google Scholar]

- Garcia, E.A.; Frank, P.M. Deterministic nonlinear observer-based approaches to fault diagnosis: A survey. Control Eng. Pract. 1997, 5, 663–670. [Google Scholar] [CrossRef]

- Patton, R.J.; Chen, J. Observer-based fault detection and isolation: Robustness and applications. Control Eng. Pract. 1997, 5, 671–682. [Google Scholar] [CrossRef]

- Zhou, D.H.; Frank, P.M. Fault diagnostics and fault tolerant control. IEEE Trans. Aerosp. Electron. Syst. 1998, 34, 420–427. [Google Scholar] [CrossRef]

- Frank, P.M. Fault diagnosis in dynamic systems using analytical and knowledge-based redundancy. A survey and some new results. Automatica 1990, 26, 459–474. [Google Scholar] [CrossRef]

- Jayaram, S. A new fast converging Kalman filter for sensor fault detection and isolation. Sens. Rev. 2010, 30, 219–224. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, S.; Kim, Y.; Seah, C.E. A survey of fault detection, isolation, and reconfiguration methods. IEEE Trans. Control Syst. Technol. 2010, 18, 636–653. [Google Scholar] [CrossRef]

- Gertler, J. Fault detection and isolation using parity relations. Control Eng. Pract. 1997, 5, 653–661. [Google Scholar] [CrossRef]

- Isermann, R. Process fault detection based on modelling and estimation methods-a survey. Automatica 1984, 20, 387–404. [Google Scholar] [CrossRef]

- Patton, R.J.; Uppal, F.J.; Lopez-Toribio, C.J. Soft Computing Approaches to Fault Diagnosis for Dynamic Systems: A Survey. In Proceedings of the 4th IFAC Symposium on Fault Detection Supervision and Safety for Technical Processes, Budapest, Hungary, 14–16 June 2000; pp. 298–311. [Google Scholar]

- Isermann, R.; Ballé, P. Trends in the application of model based fault detection and diagnosis of technical processes. Control Eng. Pract. 1997, 5, 709–719. [Google Scholar] [CrossRef]

- Miljkovic, D. Fault Detection Methods: A Literature Survey. In Proceedings of the 34th International Convention on Information and Communication Technology Electronics and Microelectronics, Opatija, Croatia, 23–27 May 2011; pp. 750–755. [Google Scholar]

- Byun, Y.S.; Jeong, R.G.; Kang, S.W. Vehicle position estimation based on magnetic markers: Enhanced accuracy by compensation of time delays. Sensors 2015, 15, 28807–28825. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Byun, Y.-S.; Kim, B.-H.; Jeong, R.-G. Sensor Fault Detection and Signal Restoration in Intelligent Vehicles. Sensors 2019, 19, 3306. https://doi.org/10.3390/s19153306

Byun Y-S, Kim B-H, Jeong R-G. Sensor Fault Detection and Signal Restoration in Intelligent Vehicles. Sensors. 2019; 19(15):3306. https://doi.org/10.3390/s19153306

Chicago/Turabian StyleByun, Yeun-Sub, Baek-Hyun Kim, and Rag-Gyo Jeong. 2019. "Sensor Fault Detection and Signal Restoration in Intelligent Vehicles" Sensors 19, no. 15: 3306. https://doi.org/10.3390/s19153306

APA StyleByun, Y.-S., Kim, B.-H., & Jeong, R.-G. (2019). Sensor Fault Detection and Signal Restoration in Intelligent Vehicles. Sensors, 19(15), 3306. https://doi.org/10.3390/s19153306