Fuzzy Clustering Algorithm with Non-Neighborhood Spatial Information for Surface Roughness Measurement Based on the Reflected Aliasing Images

Abstract

1. Introduction

2. Preliminary Theory

2.1. Fuzzy C-Means (FCM) Algorithm

2.2. Fuzzy Clustering with Constraints (FCM_S) and Its Variants

2.3. Fuzzy Local Information C-Means (FLICM) Clustering and Its Variants

2.4. Fuzzy Clustering Algorithm with Non-Local Spatial Constraint and Its Variants

3. Fuzzy C-Means Clustering Algorithm with Non-Neighborhood Spatial Information

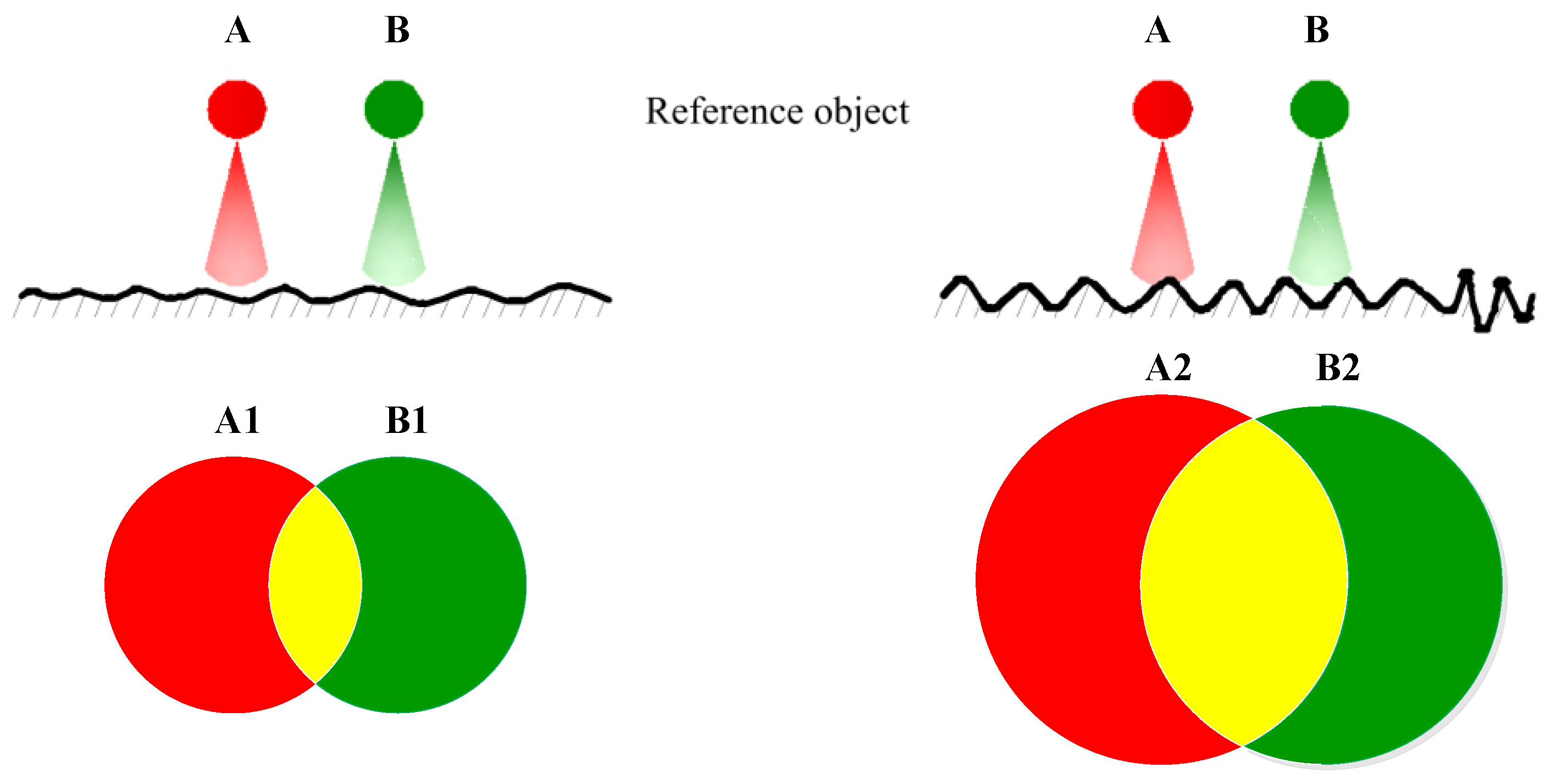

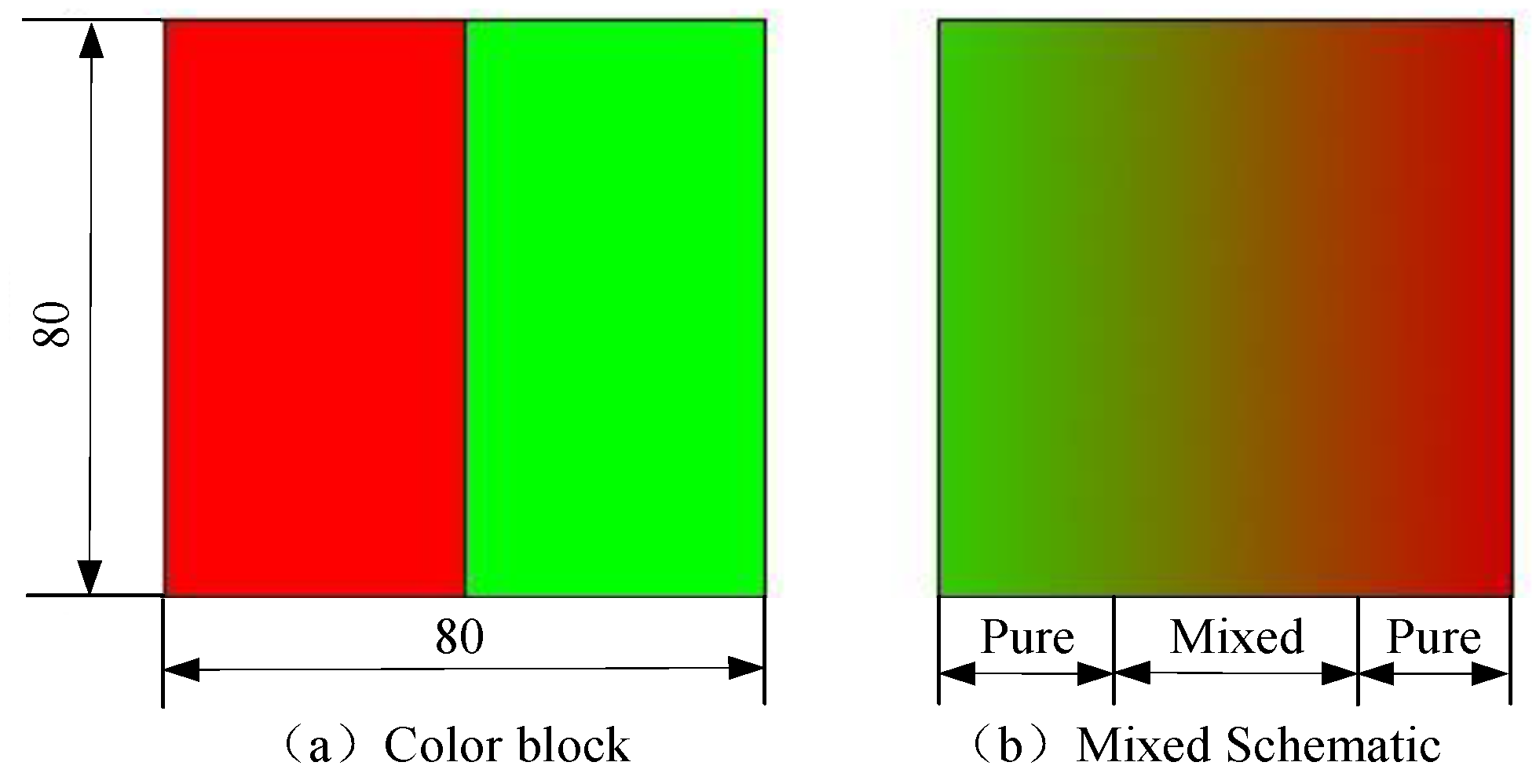

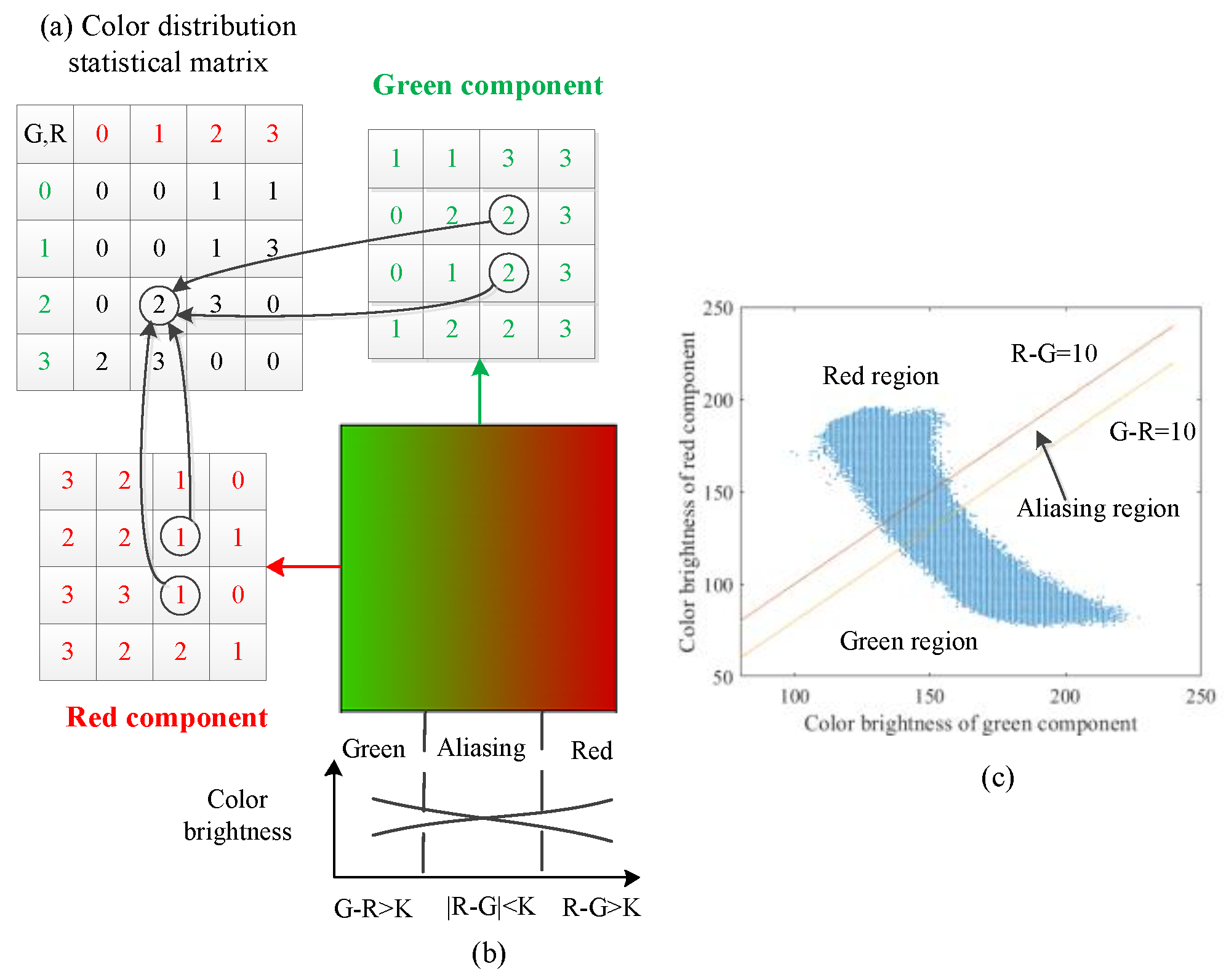

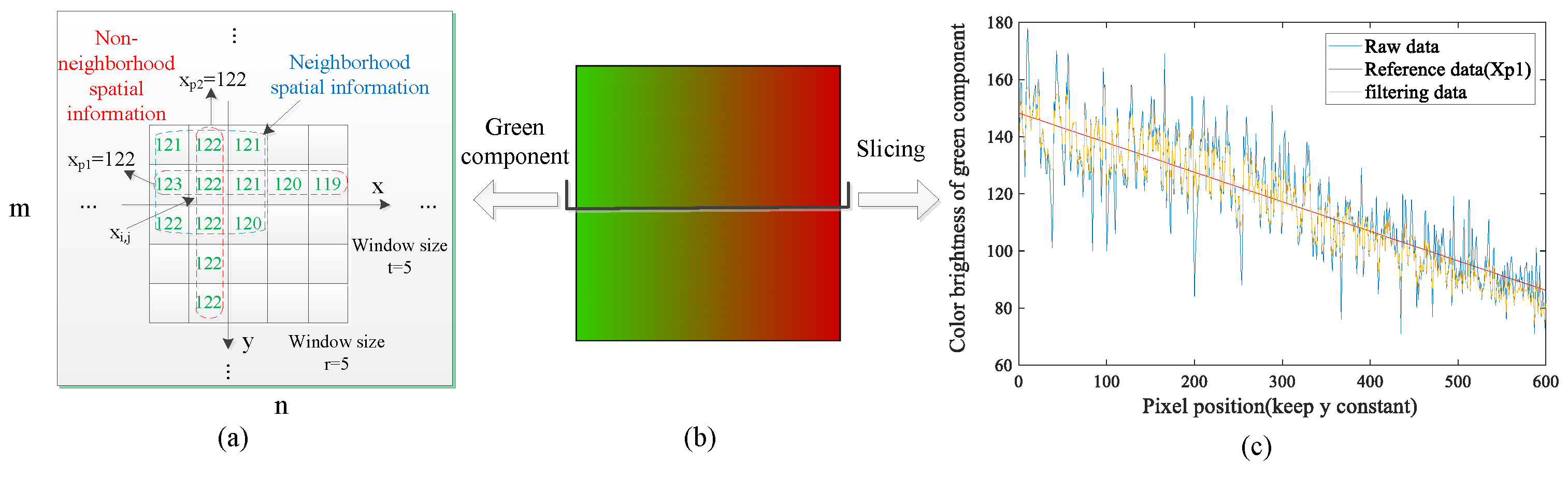

3.1. Motivation and Notation

3.2. Initializing Cluster Centers

| Algorithm 1 The process for initializing cluster centers |

| Input: aliasing image I; Output: initial cluster centers V1; Begin 1. Calculate the color difference between the red and green component of each pixel in the image; 2. Set a threshold K, and divide pixels into three regions according to the color difference; 3. Calculate the average red and green brightness values of all the pixels in each region to obtain the initial cluster centers V1. End |

3.3. Image Filtering Based on Non-Neighborhood Spatial Information

3.4. General Framework of FCM_NNS Iteration

3.5. Index Designing Based on the Clustering Results

| Algorithm 2 The process of FCM_NNS |

| Input: The original image I; Output: Cluster center V(t+1), membership degree U(t+1); Begin 1. Input the image I, then set the number of clusters , the fuzzification parameter , the stopping condition and the maximum iteration number , the spatial parameter , the between-cluster parameter , and the size of non-neighborhood search window r and t; 2. Initialize the cluster centers using Algorithm 1; 3. Obtain the non-neighborhood spatial information of each pixel using Equations (10)–(22); 4. Set the iterative index ; 5. While () 6. Compute the membership functions using Equation (26); 7. Compute the cluster centers using Equation (27); 8. If , then stop and output the membership degree U(t+1) and cluster center V(t+1); Otherwise, set and go to the 6th step. 9. End while End |

| Algorithm 3 The process of roughness measurement method based on FCM_NNS |

| Input: The original image I; Output: Roughness related feature indexes C and F; Begin 1. Input the image I; 2. Obtain the cluster center V(t+1), and the membership degree U(t+1) using Algorithm 2; 3. Obtain segmented image Is from membership degree U(t+1) using Equation (28). 4. Compute the C index by counting the number of pixels in the aliasing region class of segmented image Is. 5. Compute the F index using Equation (29) End |

4. Experimental Results and Discussion

4.1. Experimental Equipment and Imaging Results

4.1.1. Sample Preparation

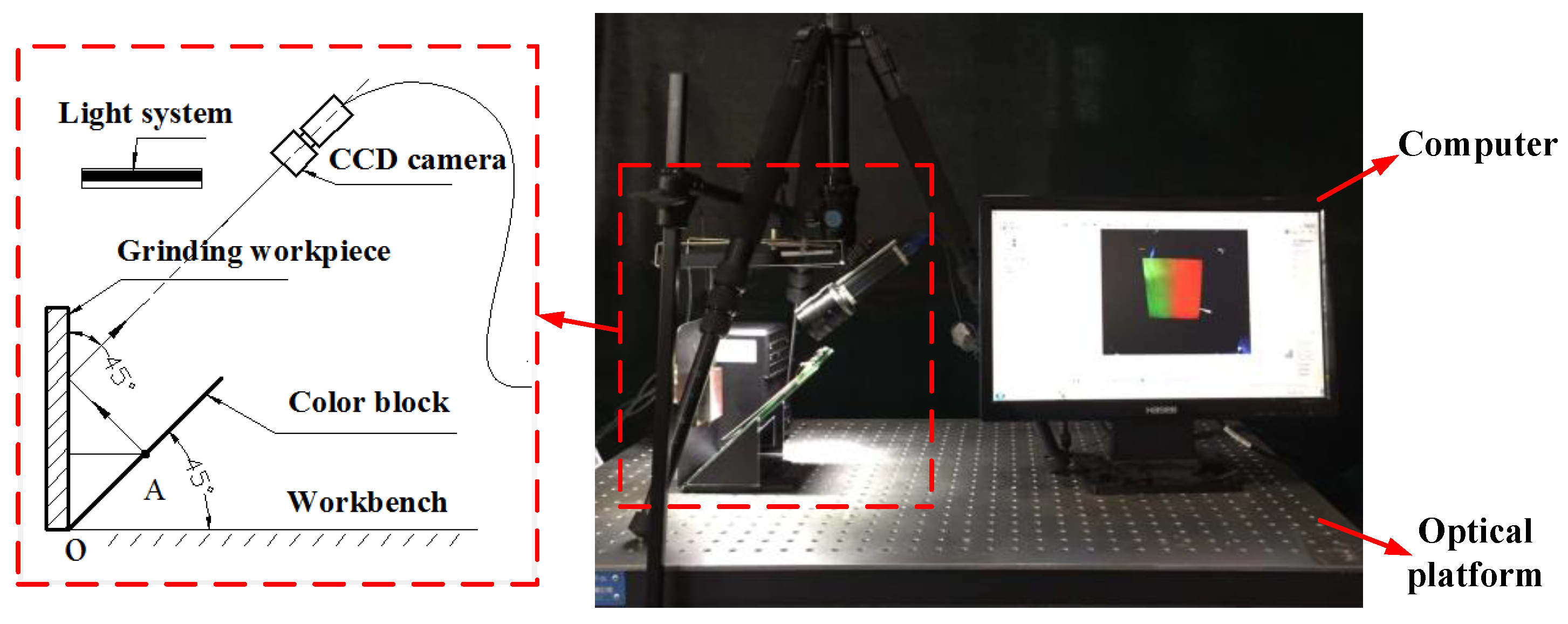

4.1.2. Experimental Equipment

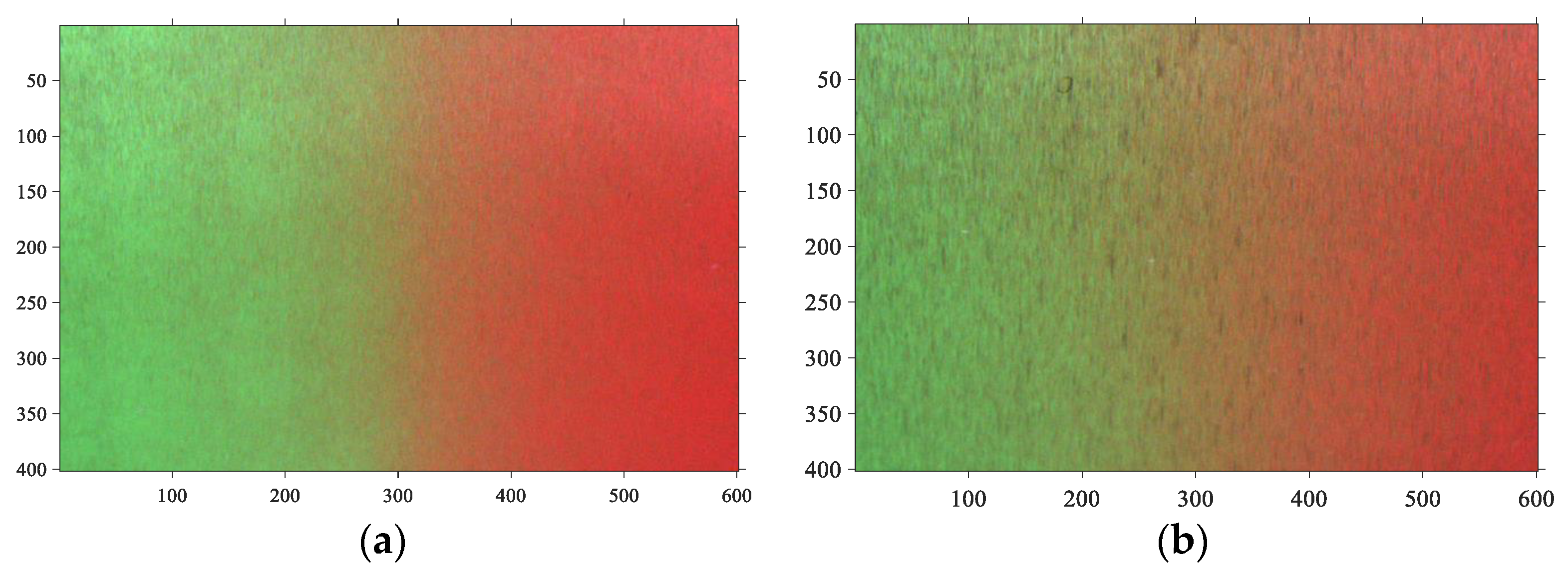

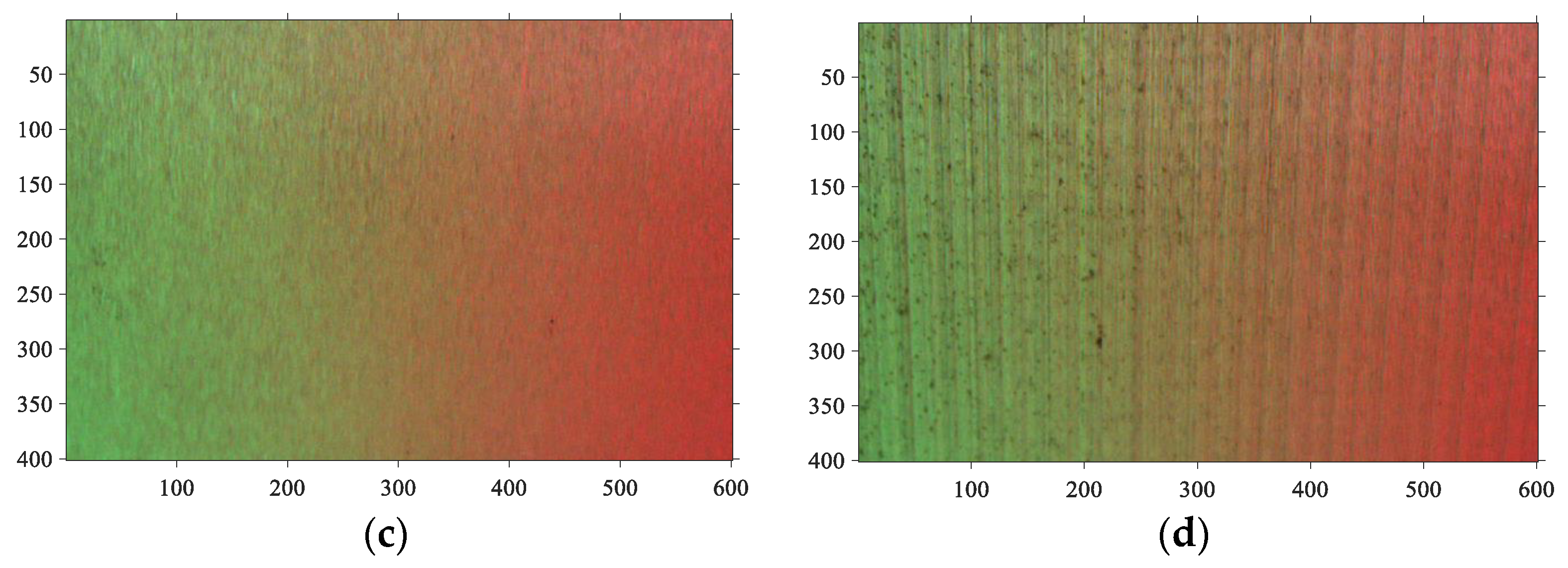

4.1.3. Imaging Results

4.2. Evaluation Indexes

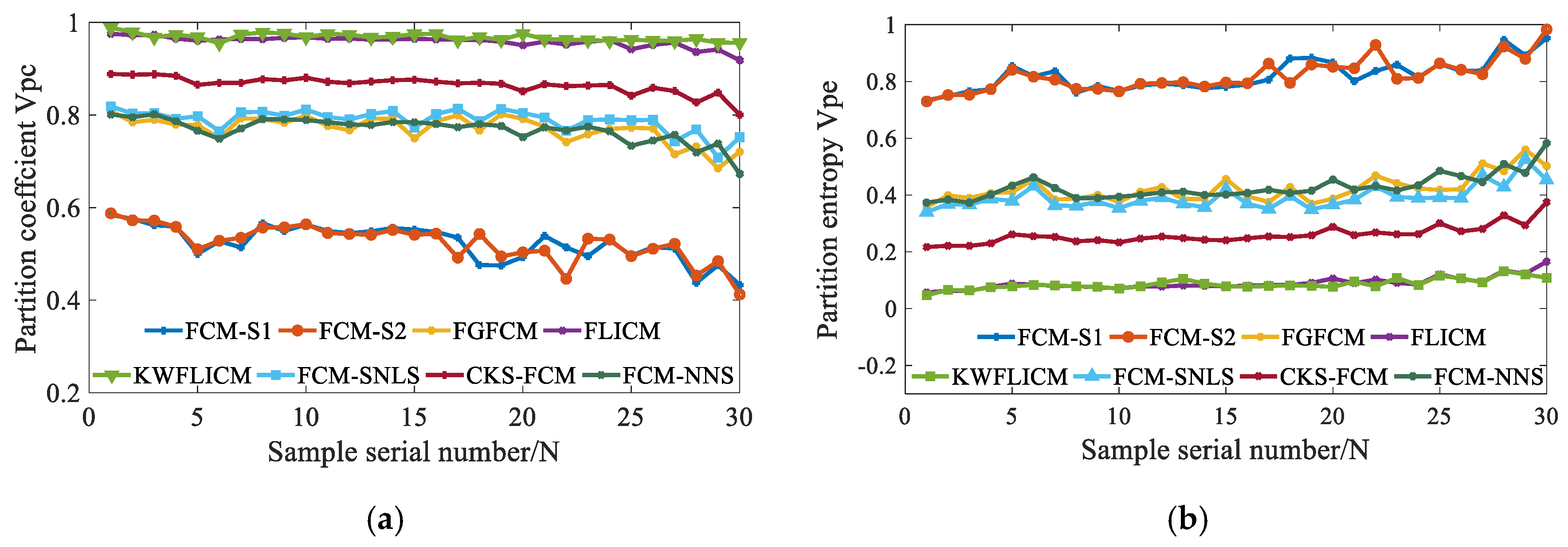

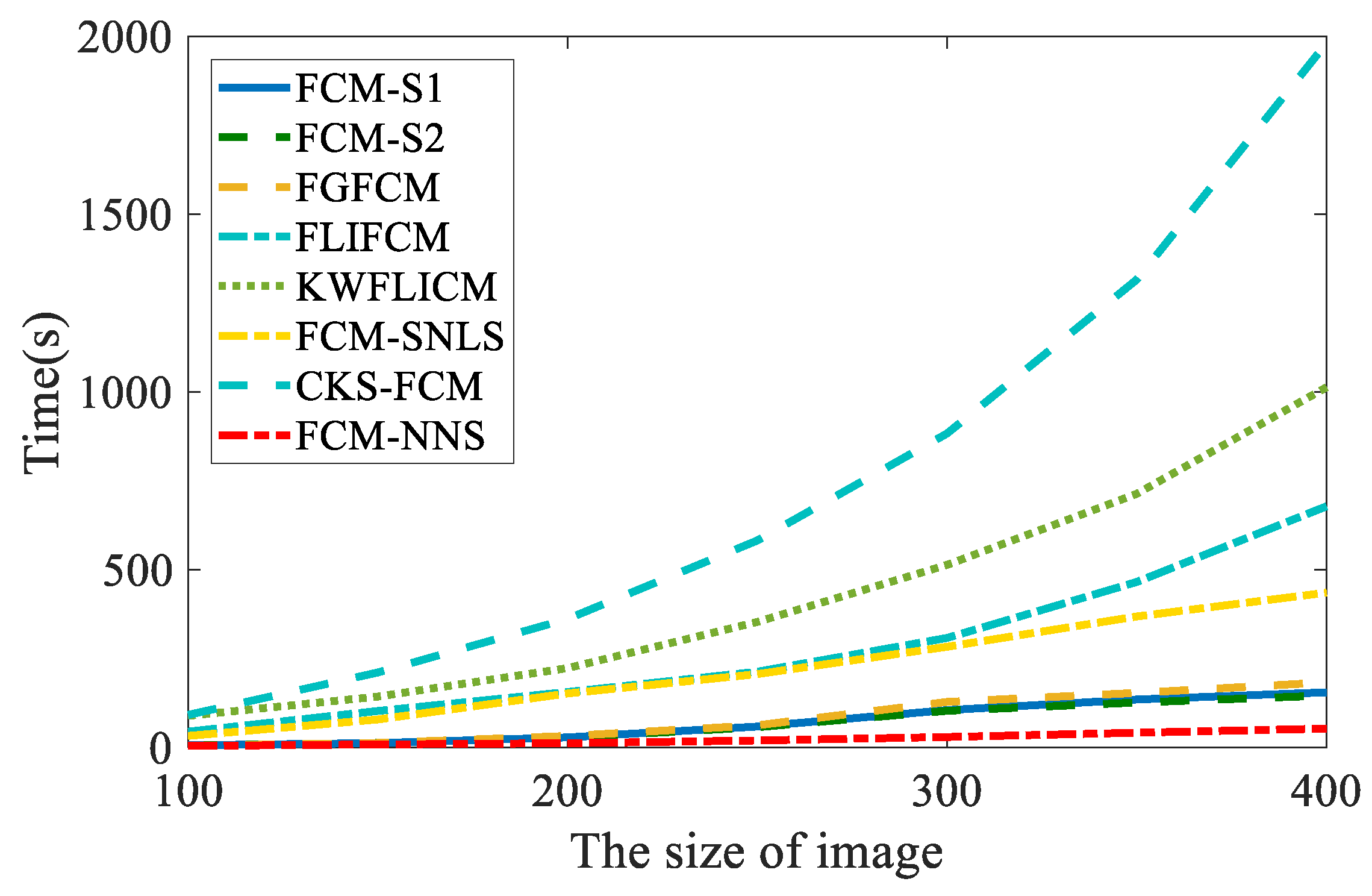

4.3. Performance Comparison of Clustering Algorithms and Parameter Analysis

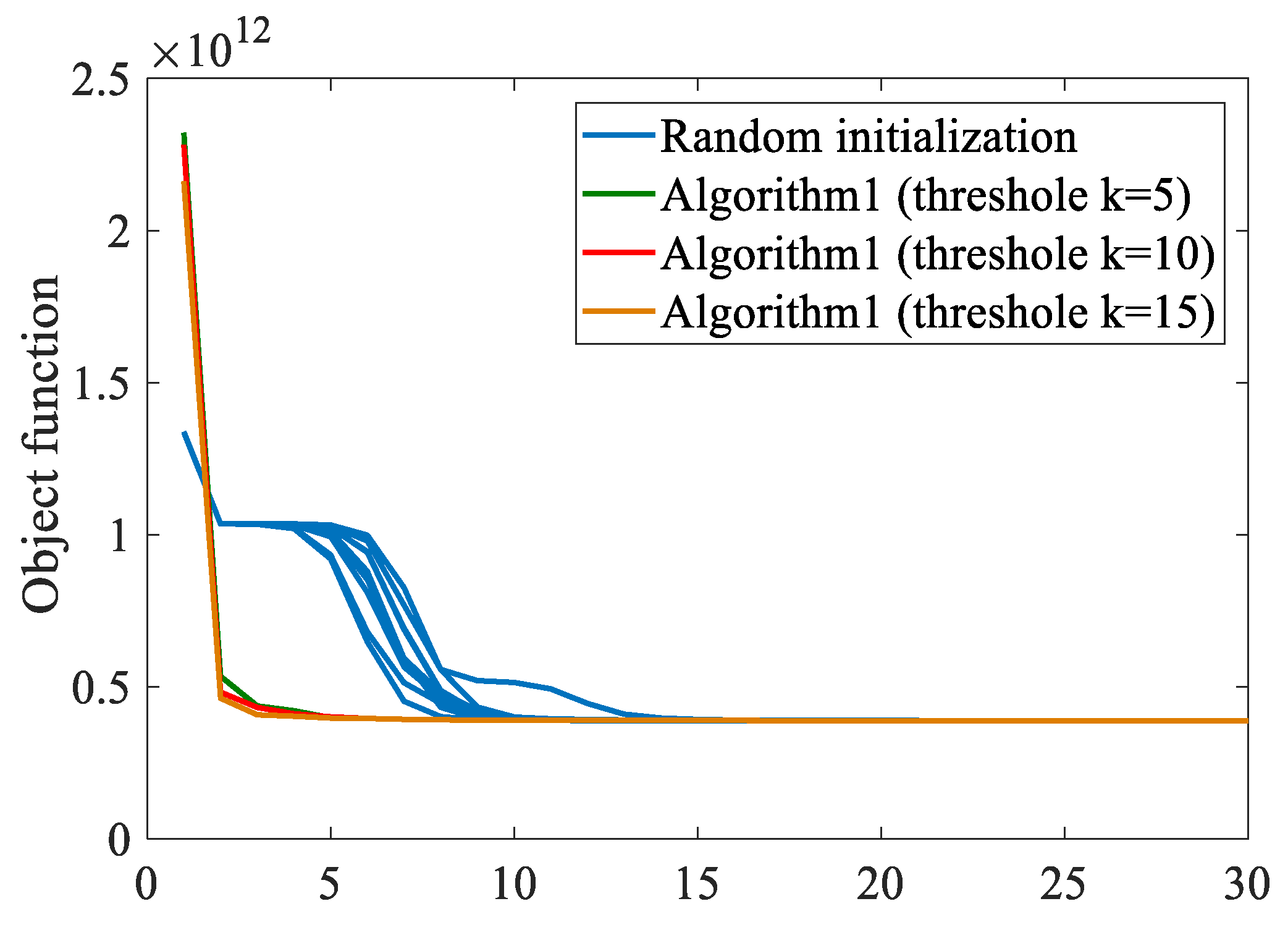

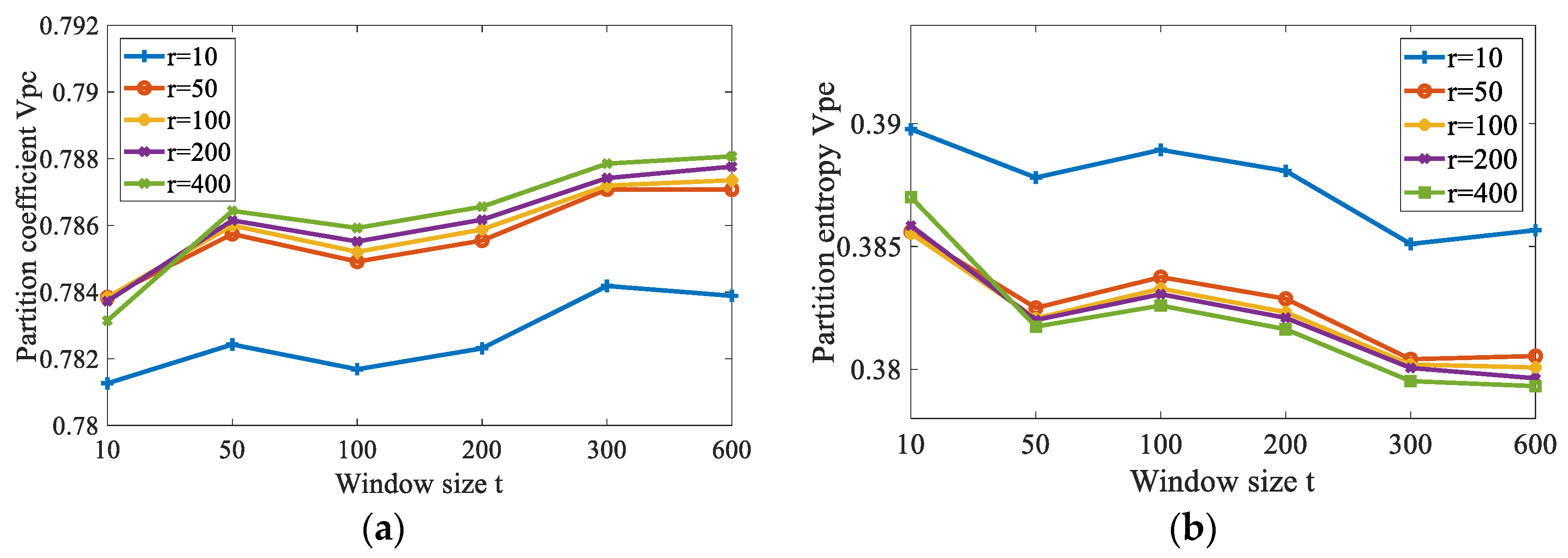

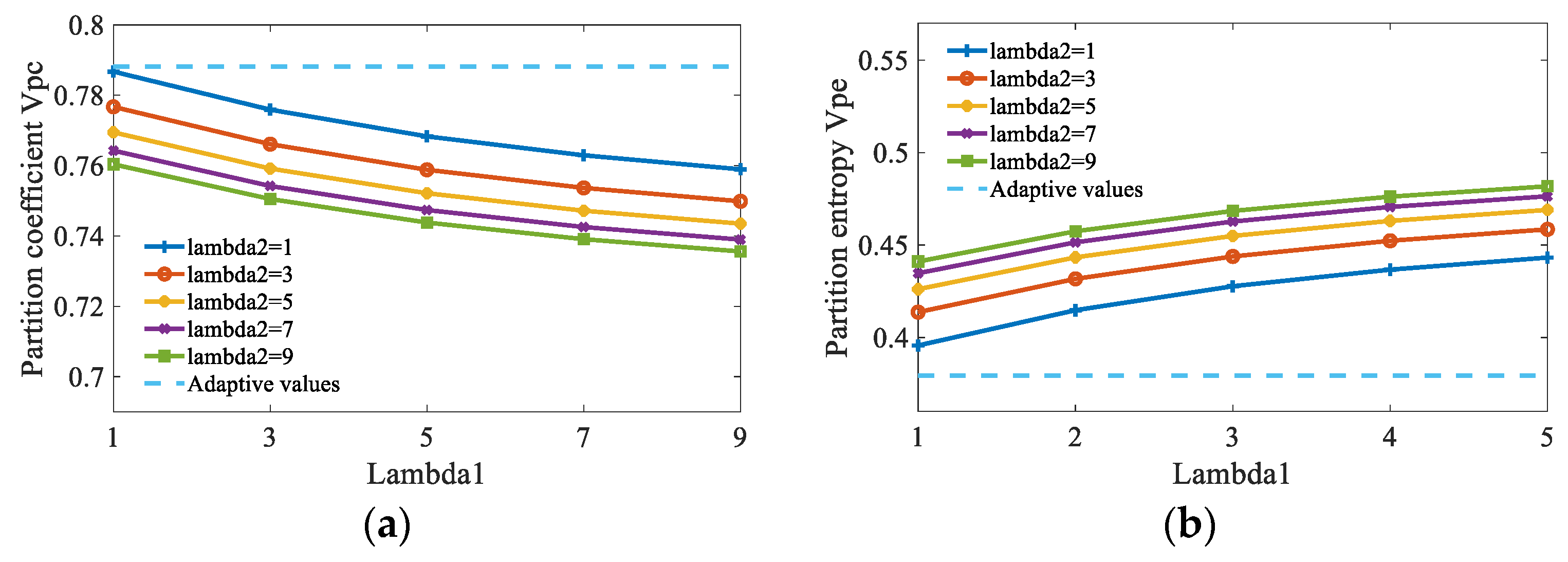

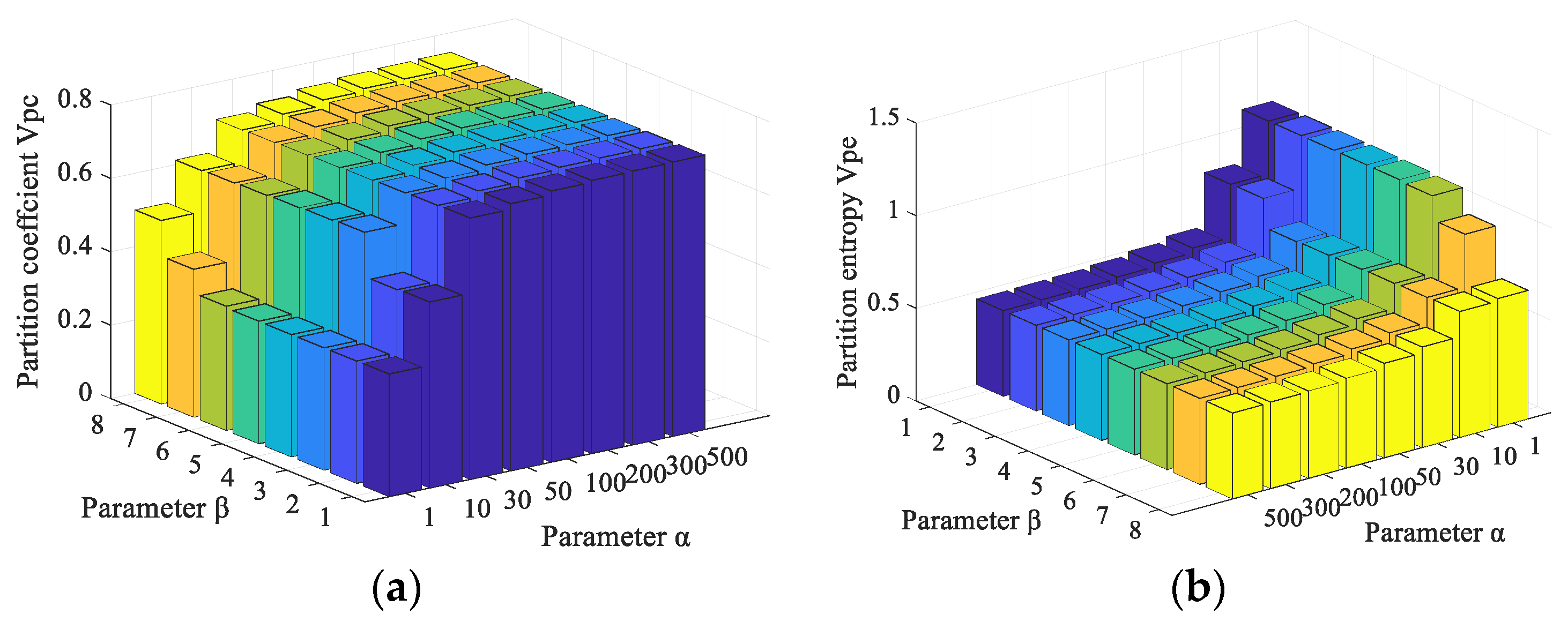

4.3.1. Parameter Analysis

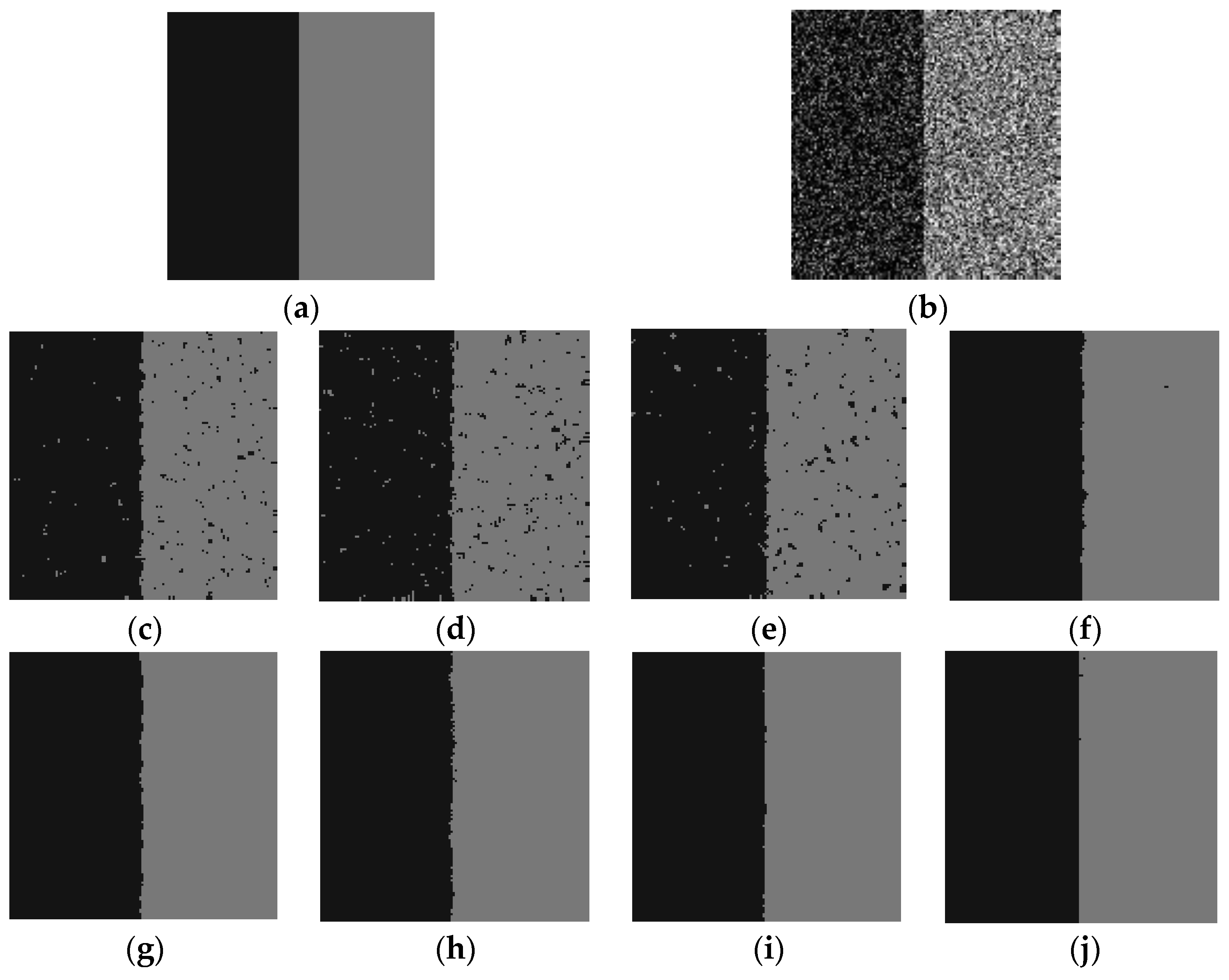

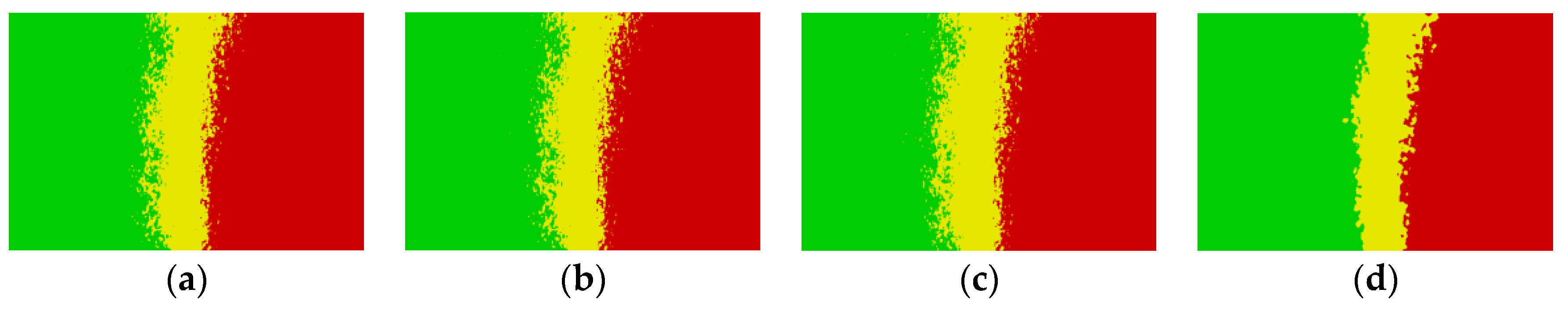

4.3.2. Results on Synthetic Images

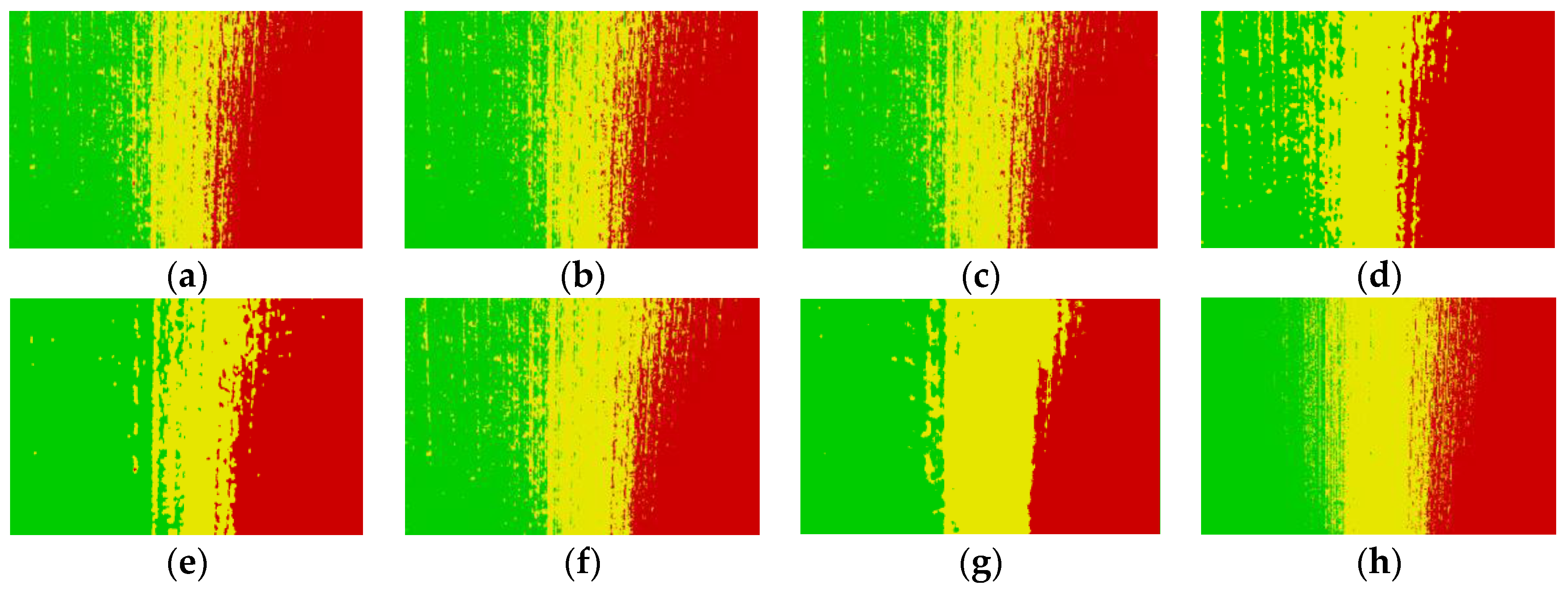

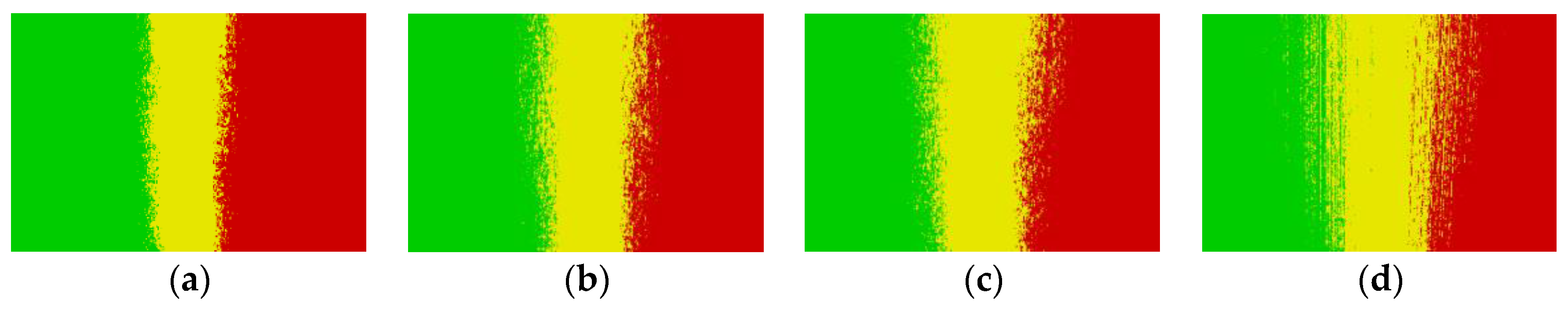

4.3.3. Results on Aliasing Images

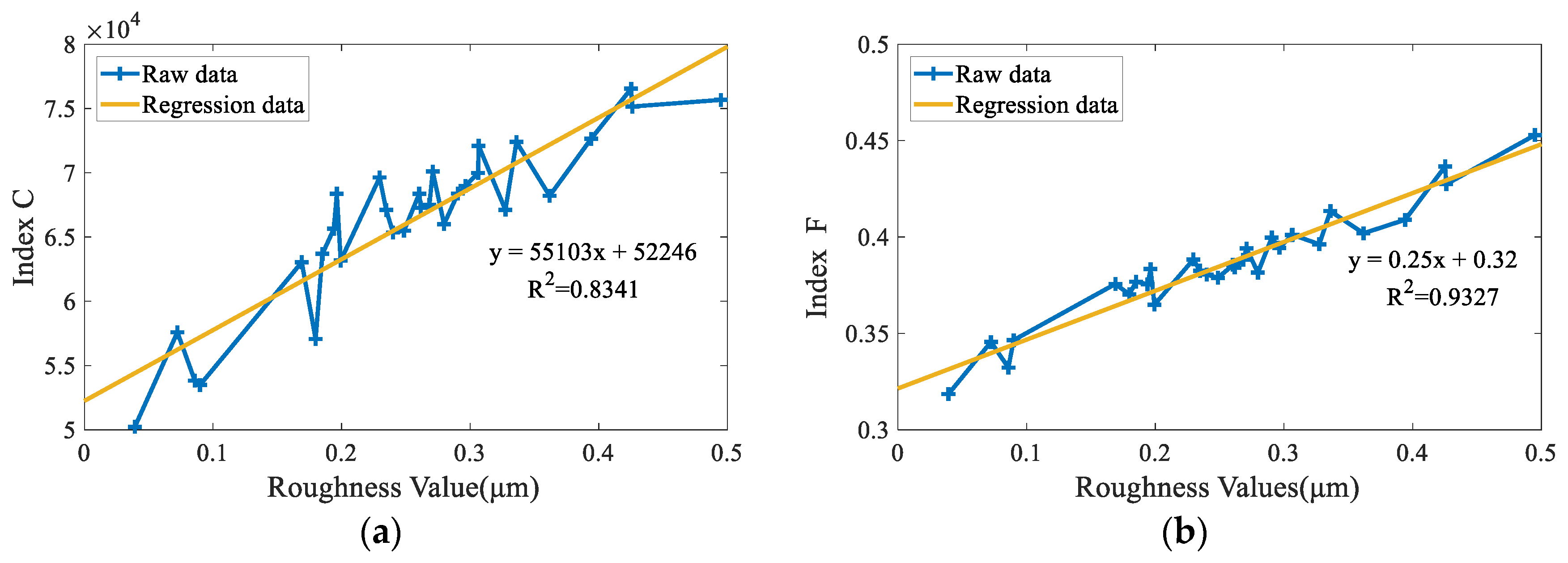

4.4. Comparison of Roughness Assessment Indexes

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| No. | First | Second | Third | Fourth | Fifth | Sixth | Average | St.dev. |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.0308 | 0.0386 | 0.0437 | 0.0330 | 0.0410 | 0.0478 | 0.0392 | 0.0064 |

| 2 | 0.0934 | 0.0722 | 0.0727 | 0.0774 | 0.0728 | 0.0453 | 0.0723 | 0.0155 |

| 3 | 0.0542 | 0.1005 | 0.1005 | 0.0928 | 0.0878 | 0.0790 | 0.0858 | 0.0175 |

| 4 | 0.0737 | 0.0932 | 0.0884 | 0.0643 | 0.0920 | 0.1265 | 0.0897 | 0.0213 |

| 5 | 0.1472 | 0.1692 | 0.1875 | 0.1621 | 0.1786 | 0.1738 | 0.1697 | 0.0140 |

| 6 | 0.1166 | 0.2169 | 0.1994 | 0.1600 | 0.2379 | 0.1479 | 0.1798 | 0.0459 |

| 7 | 0.2480 | 0.1600 | 0.1495 | 0.1635 | 0.2088 | 0.1806 | 0.1851 | 0.0372 |

| 8 | 0.1855 | 0.1996 | 0.1922 | 0.1892 | 0.1962 | 0.201 | 0.1940 | 0.0061 |

| 9 | 0.2088 | 0.1813 | 0.1996 | 0.1828 | 0.206 | 0.199 | 0.1963 | 0.0116 |

| 10 | 0.2063 | 0.1914 | 0.1832 | 0.1746 | 0.1982 | 0.2421 | 0.1993 | 0.0237 |

| 11 | 0.2193 | 0.2193 | 0.2279 | 0.247 | 0.2228 | 0.2415 | 0.2296 | 0.0119 |

| 12 | 0.2058 | 0.2184 | 0.2557 | 0.2529 | 0.2385 | 0.2367 | 0.2347 | 0.0195 |

| 13 | 0.2268 | 0.2356 | 0.2505 | 0.2439 | 0.2512 | 0.2322 | 0.2400 | 0.0101 |

| 14 | 0.2423 | 0.2194 | 0.2535 | 0.257 | 0.276 | 0.2431 | 0.2486 | 0.0188 |

| 15 | 0.2554 | 0.282 | 0.2645 | 0.2793 | 0.2343 | 0.2471 | 0.2604 | 0.0186 |

| 16 | 0.2571 | 0.2699 | 0.231 | 0.2676 | 0.263 | 0.2811 | 0.2616 | 0.0170 |

| 17 | 0.2646 | 0.2518 | 0.2791 | 0.2896 | 0.2682 | 0.2563 | 0.2683 | 0.0141 |

| 18 | 0.2517 | 0.2763 | 0.3004 | 0.2597 | 0.268 | 0.2694 | 0.2709 | 0.0168 |

| 19 | 0.2825 | 0.3054 | 0.2578 | 0.2606 | 0.3043 | 0.2676 | 0.2797 | 0.0213 |

| 20 | 0.2301 | 0.2471 | 0.4502 | 0.3575 | 0.2709 | 0.1871 | 0.2905 | 0.0965 |

| 21 | 0.3133 | 0.2839 | 0.3198 | 0.2856 | 0.2953 | 0.2806 | 0.2964 | 0.0165 |

| 22 | 0.3185 | 0.2937 | 0.2886 | 0.3103 | 0.3163 | 0.3098 | 0.3062 | 0.0122 |

| 23 | 0.3139 | 0.3096 | 0.299 | 0.3008 | 0.3066 | 0.3098 | 0.3066 | 0.0057 |

| 24 | 0.3648 | 0.3648 | 0.3369 | 0.2765 | 0.344 | 0.2776 | 0.3274 | 0.0406 |

| 25 | 0.3632 | 0.2973 | 0.3806 | 0.3495 | 0.3149 | 0.3106 | 0.3360 | 0.0332 |

| 26 | 0.3997 | 0.3700 | 0.2951 | 0.3666 | 0.3775 | 0.3620 | 0.3618 | 0.0353 |

| 27 | 0.3813 | 0.3813 | 0.4096 | 0.4092 | 0.4003 | 0.3830 | 0.3941 | 0.0138 |

| 28 | 0.4163 | 0.4352 | 0.4036 | 0.4231 | 0.4312 | 0.4418 | 0.4252 | 0.0139 |

| 29 | 0.3605 | 0.3763 | 0.4024 | 0.5231 | 0.4470 | 0.4474 | 0.4261 | 0.0594 |

| 30 | 0.4481 | 0.5097 | 0.5264 | 0.4663 | 0.5550 | 0.4647 | 0.4950 | 0.0418 |

References

- Salazar, F.; Barrientos, A. Surface roughness measurement on a wing aircraft by speckle correlation. Sensors 2013, 13, 11772–11781. [Google Scholar] [CrossRef] [PubMed]

- Nairn, J.J.; Forster, W.A.; Leeuwen, R.M.V. Quantification of physical (roughness) and chemical (dielectric constant) leaf surface properties relevant to wettability and adhesion. Pest Manag. Sci. 2011, 67, 1562. [Google Scholar] [CrossRef] [PubMed]

- Bediaf, H.; Sabre, R.; Journaux, L.; Cointault, F. Comparison of leaf surface roughness analysis methods by sensitivity to noise analysis. Biosyst. Eng. 2015, 136, 77–86. [Google Scholar] [CrossRef]

- Wang, X.; Georganas, N.D.; Petriu, E.M. Fabric Texture Analysis Using Computer Vision Techniques. IEEE Trans. Instrum. Meas. 2010, 60, 44–56. [Google Scholar] [CrossRef]

- Duparre, A.; Ferre-Borrull, J.; Gliech, S.; Notni, G.; Steinert, J.; Bennett, J.M. Surface characterization techniques for determining the root-mean-square roughness and power spectral densities of optical components. Appl. Opt. 2002, 41, 154. [Google Scholar] [CrossRef] [PubMed]

- Werth, N.; Salazarbloise, F.; Koch, A. Influence of roughness in the phase-shifting speckle method: An experimental study with applications. Rev. Sci. Instrum. 2014, 85, 015114. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.; Liu, J.; Ao, P.; Lu, E.; Zhang, H. Visual method for measuring the roughness of a grinding piece based on color indices. Opt. Express 2016, 24, 17215–17233. [Google Scholar] [CrossRef]

- Arriandiaga, A.; Portillo, E.; Sánchez, J.; Cabanes, I.; Pombo, I. Virtual Sensors for On-line Wheel Wear and Part Roughness Measurement in the Grinding Process. Sensors 2014, 14, 8756–8778. [Google Scholar] [CrossRef]

- Aulbach, L.; Salazar Bloise, F.; Lu, M.; Koch, A. Non-Contact Surface Roughness Measurement by Implementation of a Spatial Light Modulator. Sensors 2017, 17, 596. [Google Scholar] [CrossRef]

- Liu, W.; Tu, X.; Jia, Z.; Wang, W.; Ma, X.; Bi, X. An improved surface roughness measurement method for micro-heterogeneous texture in deep hole based on gray-level co-occurrence matrix and support vector machine. Int. J. Adv. Manuf. Technol. 2013, 69, 583–593. [Google Scholar] [CrossRef]

- Jeyapoovan, T.; Murugan, M. Surface roughness classification using image processing. Measurement 2013, 46, 2065–2072. [Google Scholar] [CrossRef]

- Samtaş, G. Measurement and evaluation of surface roughness based on optic system using image processing and artificial neural network. Int. J. Adv. Manuf. Technol. 2014, 73, 353–364. [Google Scholar] [CrossRef]

- Yilbas, Z.; Hasmi, M.S. J Surface roughness measurement using an optical system. J. Mater. Process. Technol. 1999, 88, 10–22. [Google Scholar] [CrossRef]

- García Plaza, E.; Núñez López, P.J. Application of the wavelet packet transform to vibration signals for surface roughness monitoring in CNC turning operations. Mech. Syst. Signal Process. 2018, 98, 902–919. [Google Scholar] [CrossRef]

- García Plaza, E.; Núñez López, P.J. Surface roughness monitoring by singular spectrum analysis of vibration signals. Mech. Syst. Signal Process. 2017, 84, 516–530. [Google Scholar] [CrossRef]

- Kumar, R.; Kulashekar, P.; Dhanasekar, B. Application of digital image magnification for surface roughness evaluation using machine vision. Int. J. Mach. Tools Manuf. 2005, 45, 228–234. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Chen, S.; Wang, W. Novel roughness measurement for grinding surfaces using simulated data by transfer kernel learning. Appl. Soft Comput. 2018, 73, 508–519. [Google Scholar] [CrossRef]

- Dhanasekar, B.; Ramamoorthy, B. Restoration of blurred images for surface roughness evaluation using machine vision. Tribol. Int. 2010, 43, 268–276. [Google Scholar] [CrossRef]

- Gadelmawla, E.S. A vision system for surface roughness characterization using the gray level co-occurrence matrix. NDT E Int. 2004, 37, 577–588. [Google Scholar] [CrossRef]

- Priya, P.; Ramamoorthy, B. The influence of component inclination on surface finish evaluation using digital image processing. Int. J. Mach. Tools Manuf. 2007, 47, 570–579. [Google Scholar] [CrossRef]

- Liu, J.; Lu, E.; Yi, H. A new surface roughness measurement method based on a color distribution statistical matrix. Measurement 2017, 103, 165–178. [Google Scholar] [CrossRef]

- Kolaman, A.; Yadid-Pecht, O. Quaternion Structural Similarity: A New Quality Index for Color Images. IEEE Trans. Image Process. 2012, 21, 1526–1536. [Google Scholar] [CrossRef] [PubMed]

- Uno, Y.; Prasher, S.O.; Lacroix, R. Artificial neural networks to predict corn yield from Compact Airborne Spectrographic Imager data. Comput. Electron. Agr. 2005, 47, 149–1161. [Google Scholar] [CrossRef]

- Dhanasekar, B.; Mohan, N.K.; Bhaduri, B.; Ramamoorthy, B. Evaluation of surface roughness based on monochromatic speckle correlation using image processing. Precis. Eng. 2008, 32, 196–206. [Google Scholar] [CrossRef]

- Hu, Z.; Zhu, L.; Teng, J.; Ma, X.; Shi, X. Evaluation of three-dimensional surface roughness parameters based on digital image processing. Int. J. Adv. Manuf. Technol. 2009, 40, 342–348. [Google Scholar]

- Karmakar, G.C.; Dooley, L.S. A generic fuzzy rule based image segmentation algorithm. Pattern Recognit. Lett. 2002, 23, 1215–1227. [Google Scholar] [CrossRef]

- Chatzis, S.P.; Varvarigou, T.A. A Fuzzy Clustering Approach Toward Hidden Markov Random Field Models for Enhanced Spatially Constrained Image Segmentation. IEEE Trans. Fuzzy Syst. 2008, 16, 1351–1361. [Google Scholar] [CrossRef]

- Fan, J.L.; Zhen, W.Z.; Xie, W.X. Suppressed fuzzy c-means clustering algorithm. Pattern Recognit. Lett. 2003, 24, 1607–1612. [Google Scholar] [CrossRef]

- Zadeh, L. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Qian, P.; Zhao, K.; Jiang, Y.; Su, K.H.; Deng, Z.; Wang, S.; Muzic, R.F., Jr. Knowledge-leveraged transfer fuzzy C-Means for texture image segmentation with self-adaptive cluster prototype matching. Knowl. Based Syst. 2017, 130, 33–50. [Google Scholar] [CrossRef]

- Tolias, Y.A.; Panas, S.M. Image segmentation by a fuzzy clustering algorithm using adaptive spatially constrained membership functions. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 1998, 28, 359–369. [Google Scholar] [CrossRef]

- Han, Y.F.; Shi, P.F. An improved ant colony algorithm for fuzzy clustering in image segmentation. Neurocomputing 2007, 70, 665–671. [Google Scholar] [CrossRef]

- Bezdek, J.C. Pattern Recognition with Fuzzy Objective Function Algorithms; Plenum Press: New York, NY, USA, 1981. [Google Scholar]

- Pham, D.L.; Prince, J.L. An adaptive fuzzy C-means algorithm for image segmentation in the presence of intensity inhomogeneities. Pattern Recognit. Lett. 1998, 20, 57–68. [Google Scholar] [CrossRef]

- Krinidis, S.; Chatzis, V. A robust fuzzy local information C-Means clustering algorithm. IEEE Trans. Image Process. 2010, 19, 1328. [Google Scholar] [CrossRef] [PubMed]

- Gong, M.; Liang, Y.; Shi, J.; Ma, W.; Ma, J. Fuzzy C-means clustering with local information and kernel metric for image segmentation. IEEE Trans. Image Process. 2013, 22, 573–584. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.N.; Yamany, S.M.; Mohamed, N.; Farag, A.A.; Moriarty, T. A modified fuzzy C-means algorithm for bias field estimation and segmentation of MRI data. IEEE Trans. Med. Imaging 2002, 21, 193–199. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.; Chen, S.; Zhang, D. Fast and robust fuzzy c-means clustering algorithms incorporating local information for image segmentation. Pattern Recognit. 2007, 40, 825–838. [Google Scholar] [CrossRef]

- Zhao, F.; Jiao, L.; Liu, H.; Gao, X. A novel fuzzy clustering algorithm with non local adaptive spatial constraint for image segmentation. Signal Process. 2011, 91, 988–999. [Google Scholar] [CrossRef]

- Zhao, F. Fuzzy clustering algorithms with self-tuning non-local spatial information for image segmentation. Neurocomputing 2013, 106, 115–125. [Google Scholar] [CrossRef]

- Dai, J.; Qi, H.; Xiong, Y.; Li, Y.; Zhang, G.; Hu, H.; Wei, Y. Deformable Convolutional Networks. In Proceedings of the IEEE international Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 764–773. [Google Scholar]

- Dunn, J.C. A fuzzy relative of the ISODATA Process and Its Use in Detecting Compact Well-Separated Clusters. J. Cybern. 1973, 3, 32–57. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, D. Robust image segmentation using FCM with spatial constraints based on new kernel-induced distance measure. Syst. Man Cybern. Part B Cybern. IEEE Trans. 2004, 34, 1907–1916. [Google Scholar] [CrossRef]

- Szilagyi, L.; Benyo, Z.; Szilágyi, S.M.; Adam, H.S. MR brain image segmentation using an enhanced fuzzy C-means algorithm. In Proceedings of the 25th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Cancun, Mexico, 17–21 September 2003; Volume 1, pp. 724–726. [Google Scholar]

- Gong, M.; Zhou, Z.; Ma, J. Change Detection in Synthetic Aperture Radar Images Based on Image Fusion and Fuzzy Clustering; IEEE Press: Piscataway, NJ, USA, 2012. [Google Scholar]

- Shang, R.; Tian, P.; Jiao, L.; Stolkin, R.; Feng, J.; Hou, B.; Zhang, X. A Spatial Fuzzy Clustering Algorithm With Kernel Metric Based on Immune Clone for SAR Image Segmentation. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2016, 9, 1640–1652. [Google Scholar] [CrossRef]

- Jaffar, M.A.; Naveed, N.; Ahmed, B.; Hussain, A.; Mirza, A.M. Fuzzy c-means clustering with spatial information for color image segmentation. In Proceedings of the 2009 Third International Conference on Electrical Engineering, Lahore, Pakistan, 9–11 April 2009. [Google Scholar]

- Sen, D.; Pal, S.K. Generalized Rough Sets, Entropy, and Image Ambiguity Measures; IEEE Press: Piscataway, NJ, USA, 2009. [Google Scholar]

- Sun, L.; Xu, J.; Tian, Y. Feature selection using rough entropy-based uncertainty measures in incomplete decision systems. Knowl. Based Syst. 2012, 36, 206–216. [Google Scholar] [CrossRef]

| Notation | Description | Notation | Description |

|---|---|---|---|

| Threshold in Algorithm 1 | Red/green components | ||

| Membership matrix/centers | Reference values | ||

| The jth pixel/average value of pixel | Linear regressive coefficient | ||

| The pixel in ith row, jth column and corresponding reference values | Size of non-neighborhood window | ||

| Filtered image | Similarity measure | ||

| Scale factors | Scale parameters | ||

| Distance between pixel and it reference value | The number of centers/the number of pixels | ||

| Weighting exponent | Parameters in objective function | ||

| Roughness correlated indexes | The membership degree of ith pixel belonging to the aliasing region class | ||

| Input image/segmented image | Stopping condition/maximum iteration number | ||

| Objective function/between-cluster separation term parameter | Weighting exponent |

| Method | Input Parameters | Appearance in |

|---|---|---|

| FCM_S1 [43] | IEEE SMC Part B (2004) | |

| FCM_S2 [43] | IEEE SMC Part B (2004) | |

| FGFCM [38] | PATTERN RECOGNITION (2007) | |

| FLICM [35] | IEEE Image Processing (2010) | |

| KWFLICM [36] | IEEE Image Processing (2013) | |

| FCM_SNLS [40] | SIGNAL PROCESSING (2011) | |

| CKS_FCM [46] | IEEE J-STARS (2016) |

| Noise | FCM_S1 | FCM_S2 | FGFCM | FLICM | KWFLICM | FCM_SNLS | CKS_FCM | FCM_NNS |

|---|---|---|---|---|---|---|---|---|

| Gaussian 15% | 98.29 | 97.15 | 97.60 | 99.76 | 99.80 | 99.70 | 99.73 | 99.96 |

| Gaussian 20% | 94.65 | 92.63 | 93.80 | 99.37 | 99.42 | 99.59 | 99.68 | 99.93 |

| Gaussian 30% | 85.17 | 83.56 | 84.13 | 95.67 | 96.53 | 99.32 | 99.12 | 99.87 |

| Salt & Pepper 15% | 99.10 | 99.89 | 98.60 | 99.92 | 99.93 | 99.93 | 99.94 | 99.96 |

| Salt & Pepper 20% | 97.35 | 99.72 | 95.71 | 99.88 | 99.92 | 99.81 | 99.87 | 99.95 |

| Salt & Pepper 30% | 83.52 | 93.71 | 84.12 | 99.52 | 99.63 | 98.36 | 99.32 | 99.93 |

| Ga | F1 | En | S | CD | MRA | RMD | |

|---|---|---|---|---|---|---|---|

| R2 | 0.7179 | 0.7261 | 0.7174 | 0.7786 | 0.7916 | 0.8173 | 0.7984 |

| FCM_S1 | FCM_S2 | FGFCM | FLICM | KWFLICM | FCM_SNLS | CKS_FCM | FCM_NNS | |

|---|---|---|---|---|---|---|---|---|

| R2 (Index C) | 0.2755 | 0.1556 | 0.6781 | 0.7935 | 0.7673 | 0.5800 | 0.7834 | 0.8341 |

| R2 (Index F) | 0.8752 | 0.8712 | 0.7402 | 0.8149 | 0.8342 | 0.7061 | 0.8981 | 0.9327 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Liu, J.; Chen, L.; Chen, N.; Yang, X. Fuzzy Clustering Algorithm with Non-Neighborhood Spatial Information for Surface Roughness Measurement Based on the Reflected Aliasing Images. Sensors 2019, 19, 3285. https://doi.org/10.3390/s19153285

Zhang H, Liu J, Chen L, Chen N, Yang X. Fuzzy Clustering Algorithm with Non-Neighborhood Spatial Information for Surface Roughness Measurement Based on the Reflected Aliasing Images. Sensors. 2019; 19(15):3285. https://doi.org/10.3390/s19153285

Chicago/Turabian StyleZhang, Hang, Jian Liu, Lin Chen, Ning Chen, and Xiao Yang. 2019. "Fuzzy Clustering Algorithm with Non-Neighborhood Spatial Information for Surface Roughness Measurement Based on the Reflected Aliasing Images" Sensors 19, no. 15: 3285. https://doi.org/10.3390/s19153285

APA StyleZhang, H., Liu, J., Chen, L., Chen, N., & Yang, X. (2019). Fuzzy Clustering Algorithm with Non-Neighborhood Spatial Information for Surface Roughness Measurement Based on the Reflected Aliasing Images. Sensors, 19(15), 3285. https://doi.org/10.3390/s19153285