Study on Machine Tool Positioning Uncertainty Due to Volumetric Verification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

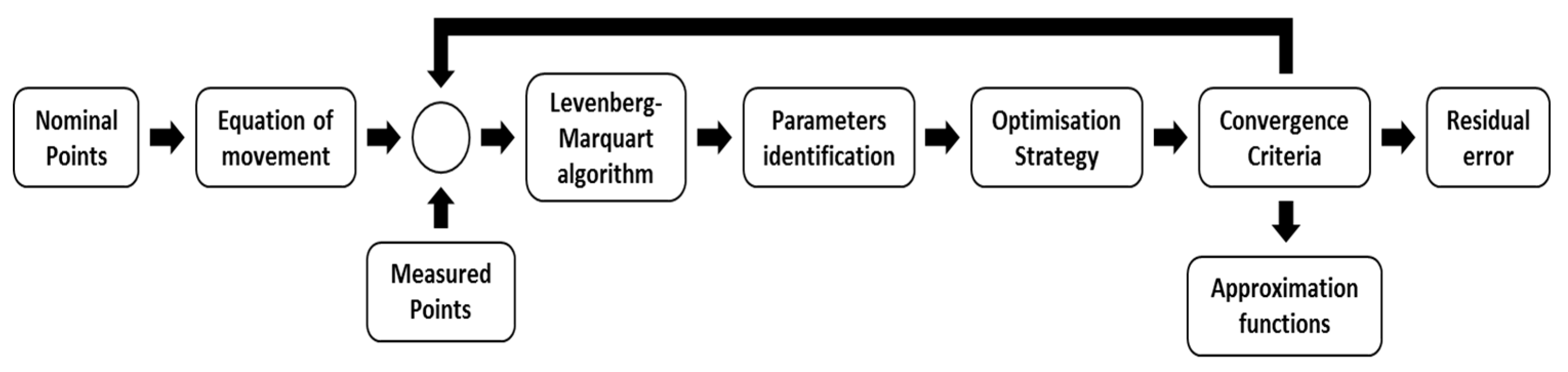

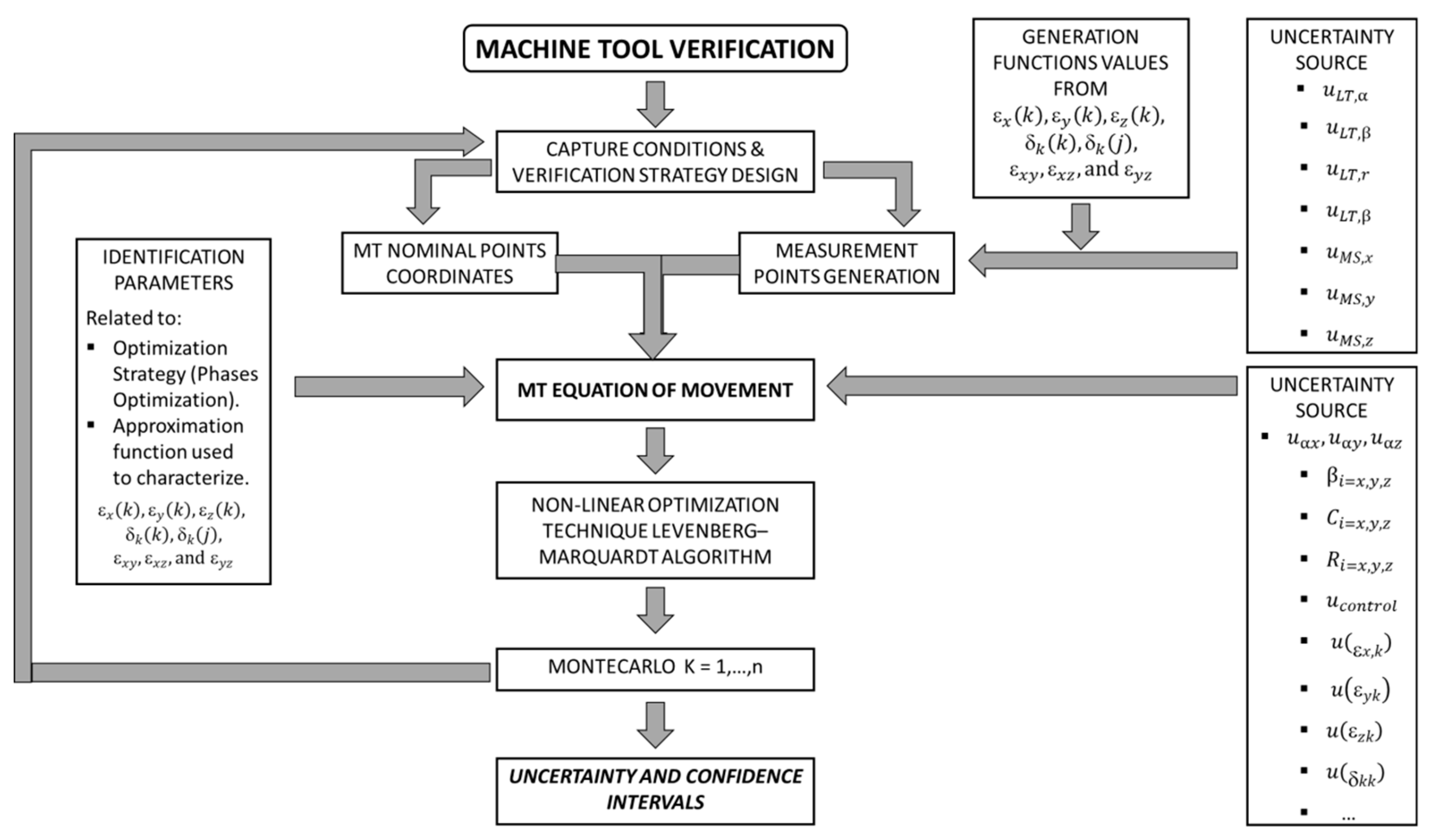

2.2. Methodology

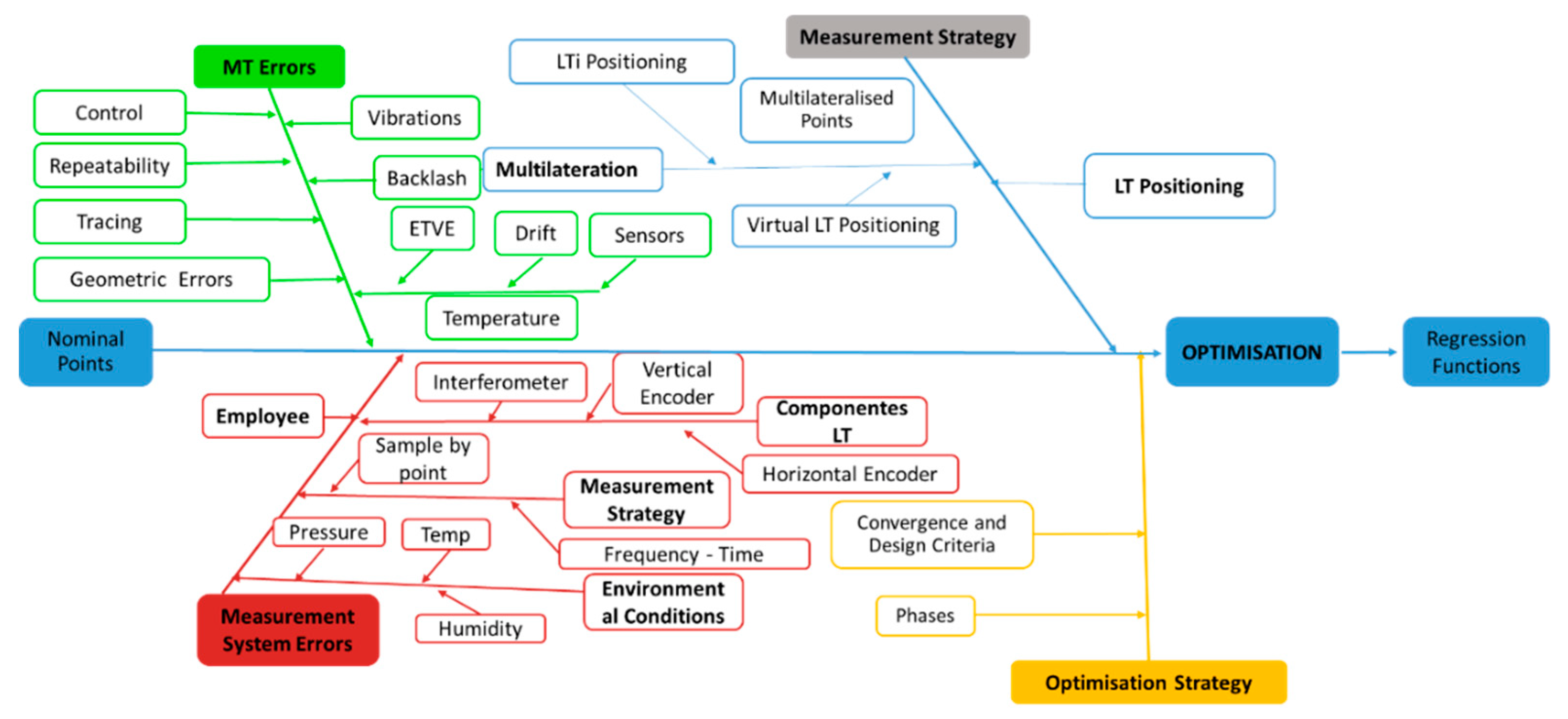

- Uncertainty related to the MT: repeatability, geometric errors, environmental conditions, control of the MT, etc.

- Uncertainty related to the employed measurement system (LT): environmental conditions, uncertainty of measurement components, and measurement design.

- Uncertainty related to the measurement strategy: LT positioning and techniques to improve measurement accuracy as multilateration.

- Uncertainty related to the optimization strategy: values of converging criteria used in the identification process, sequence of identification (optimization phases), and the approximation function used.

2.2.1. Uncertainty Related to the MT

2.2.2. Uncertainty Related to the Measurement System

2.2.3. Uncertainty Related to the Measurement Strategy

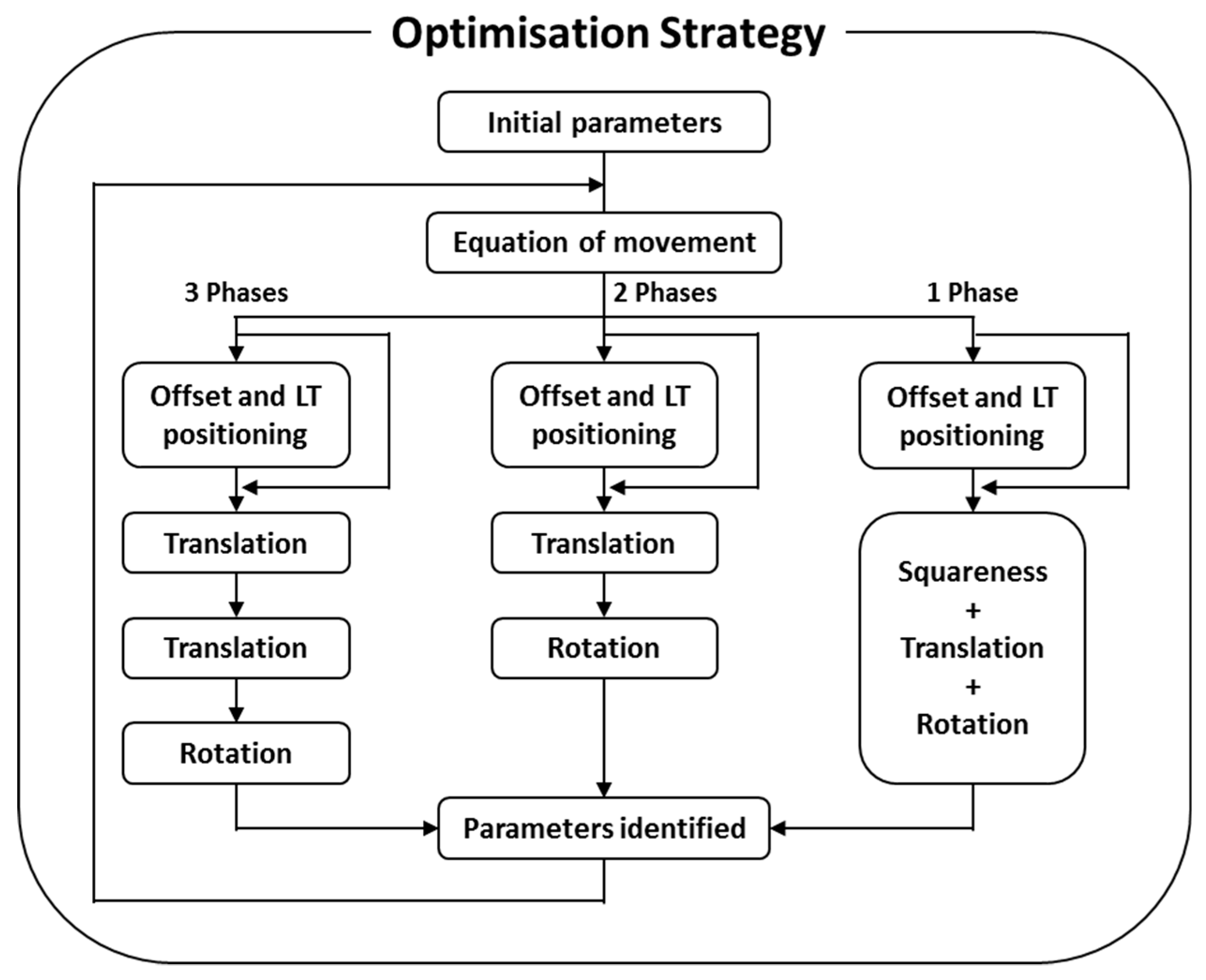

2.2.4. Uncertainty Related to the Optimization Strategy

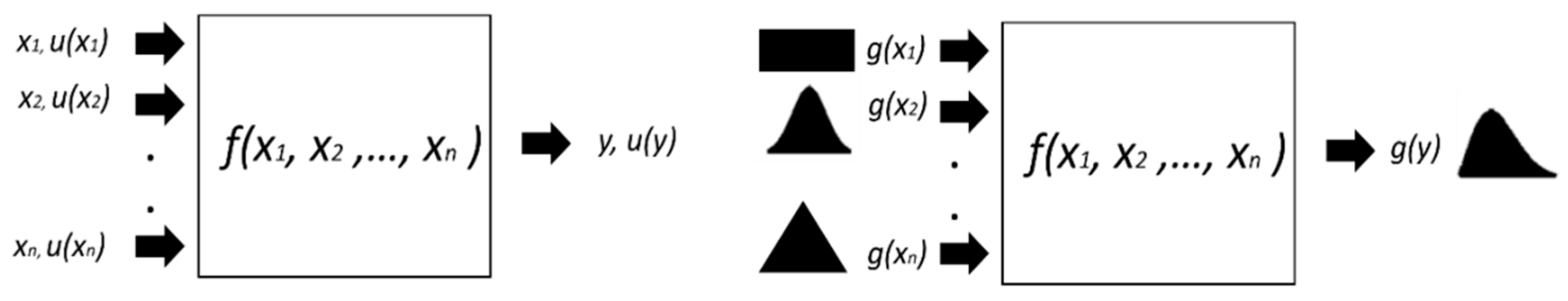

2.3. Monte Carlo Method for Uncertainty Evaluation

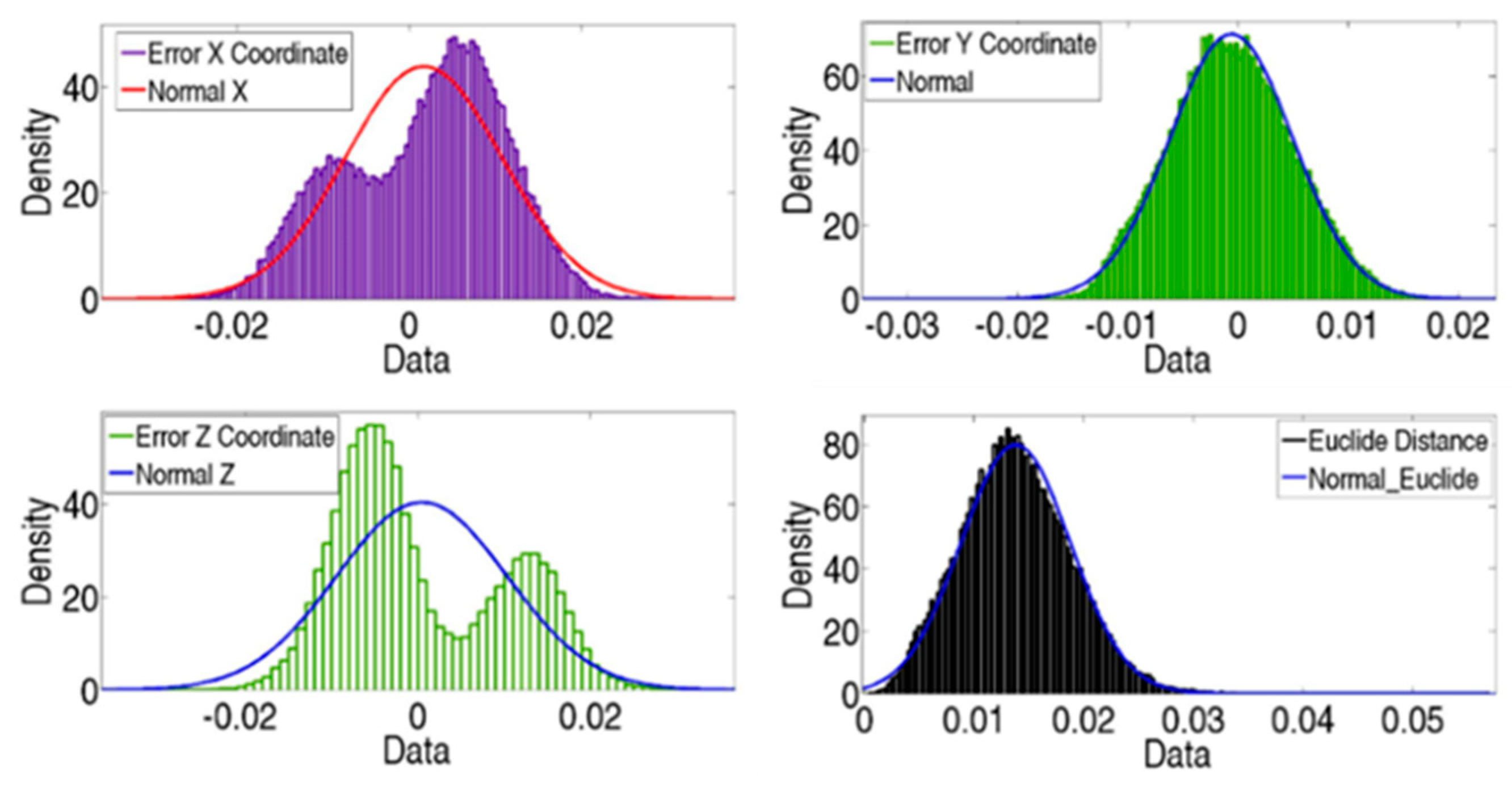

3. Simulations Results

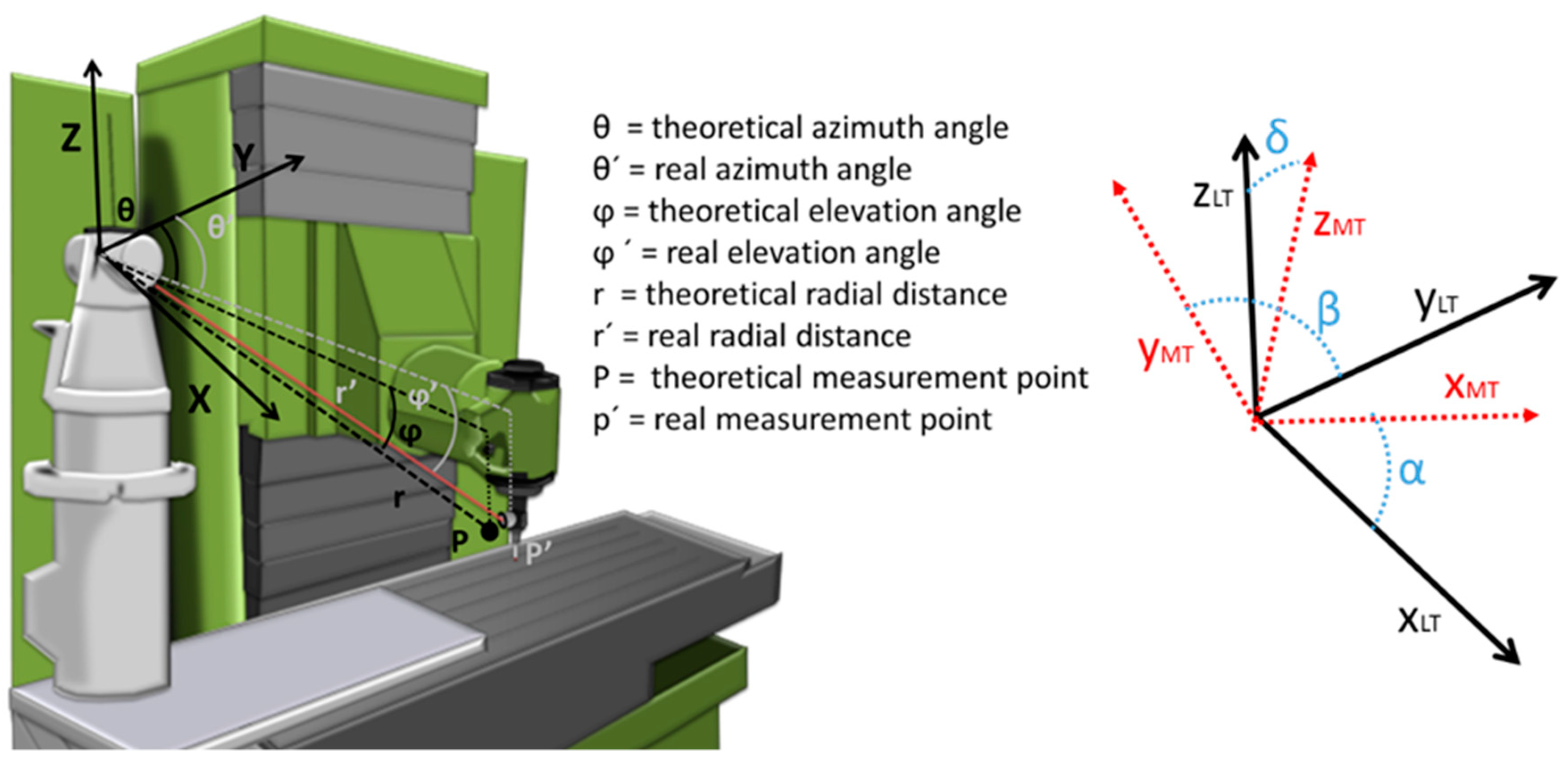

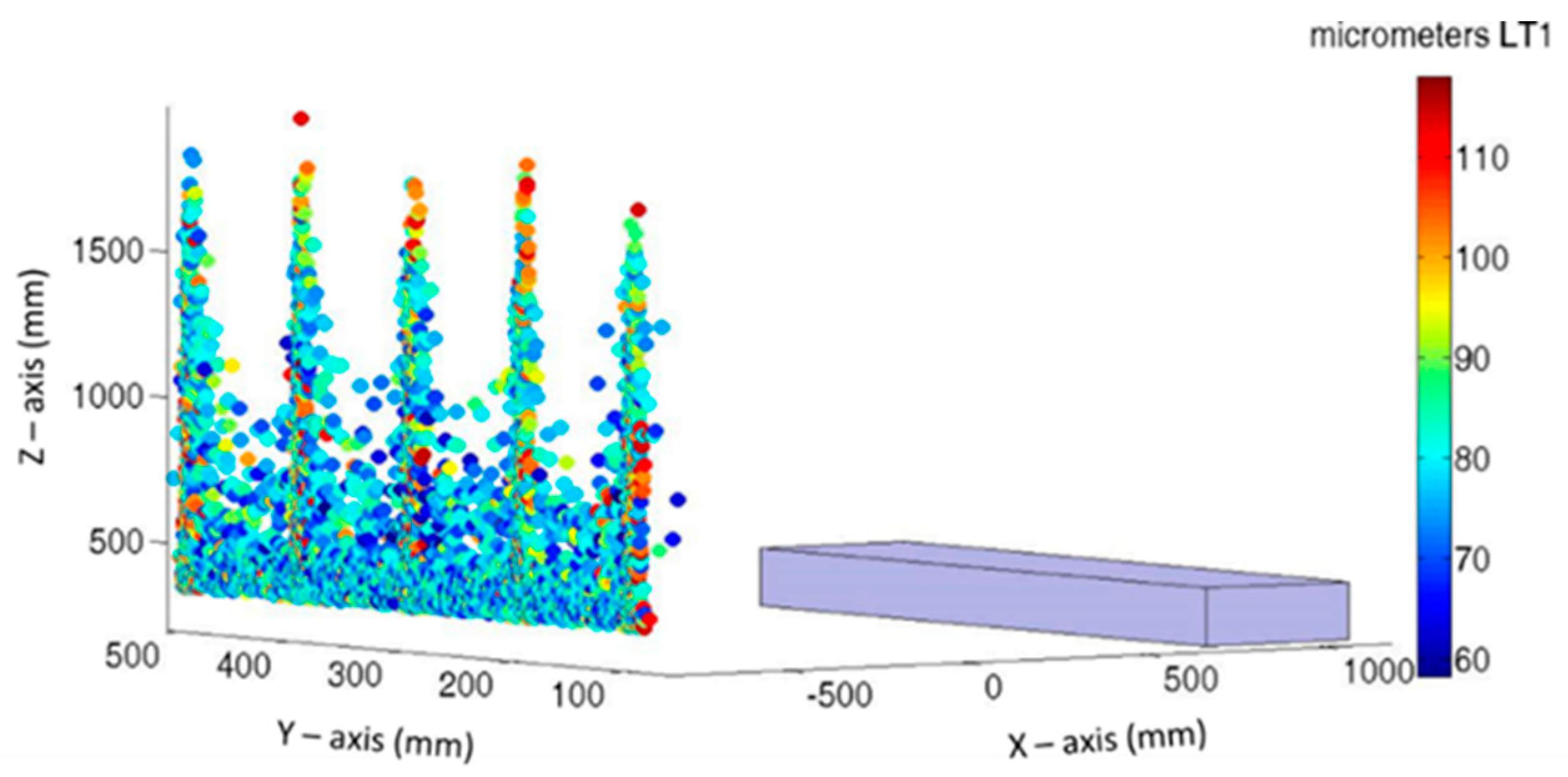

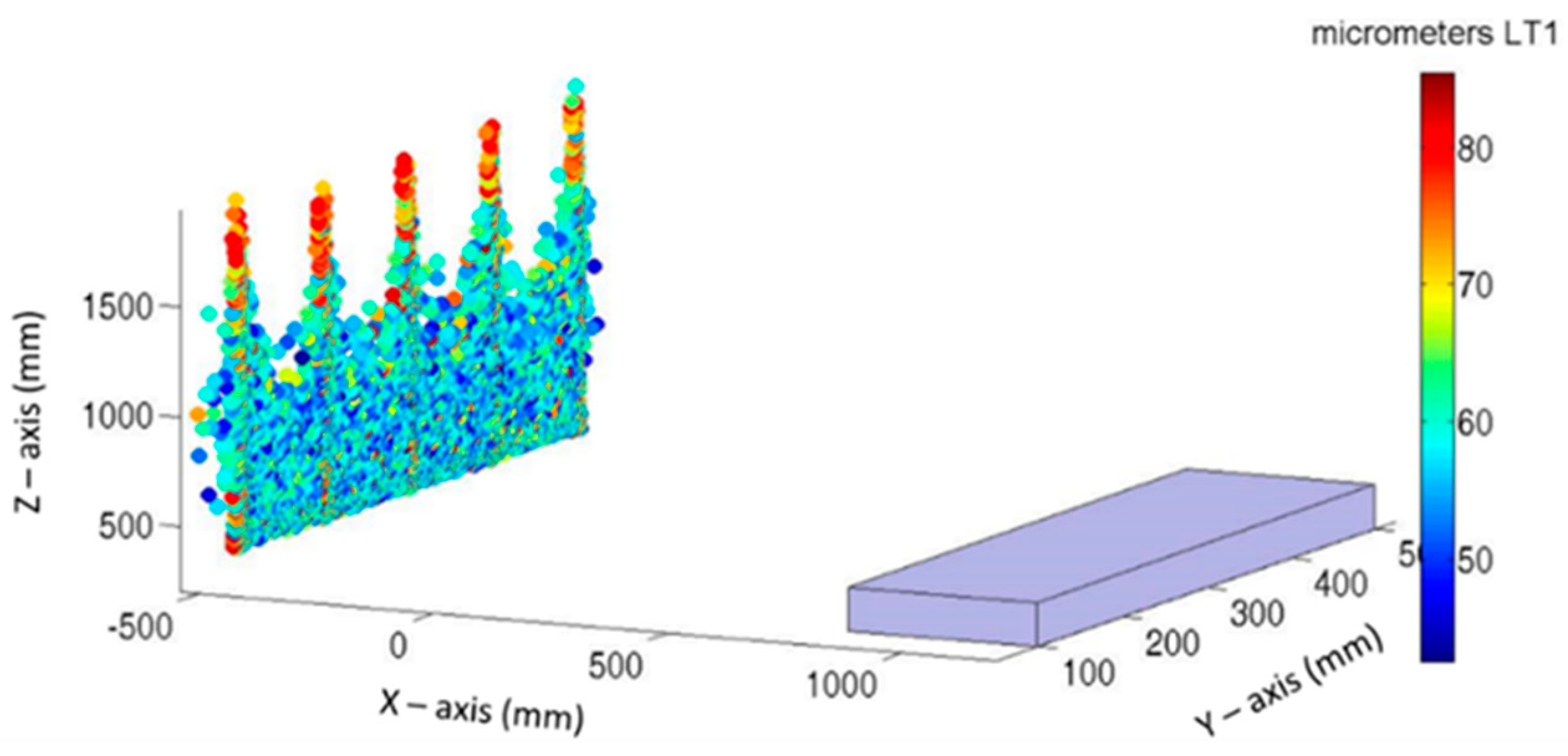

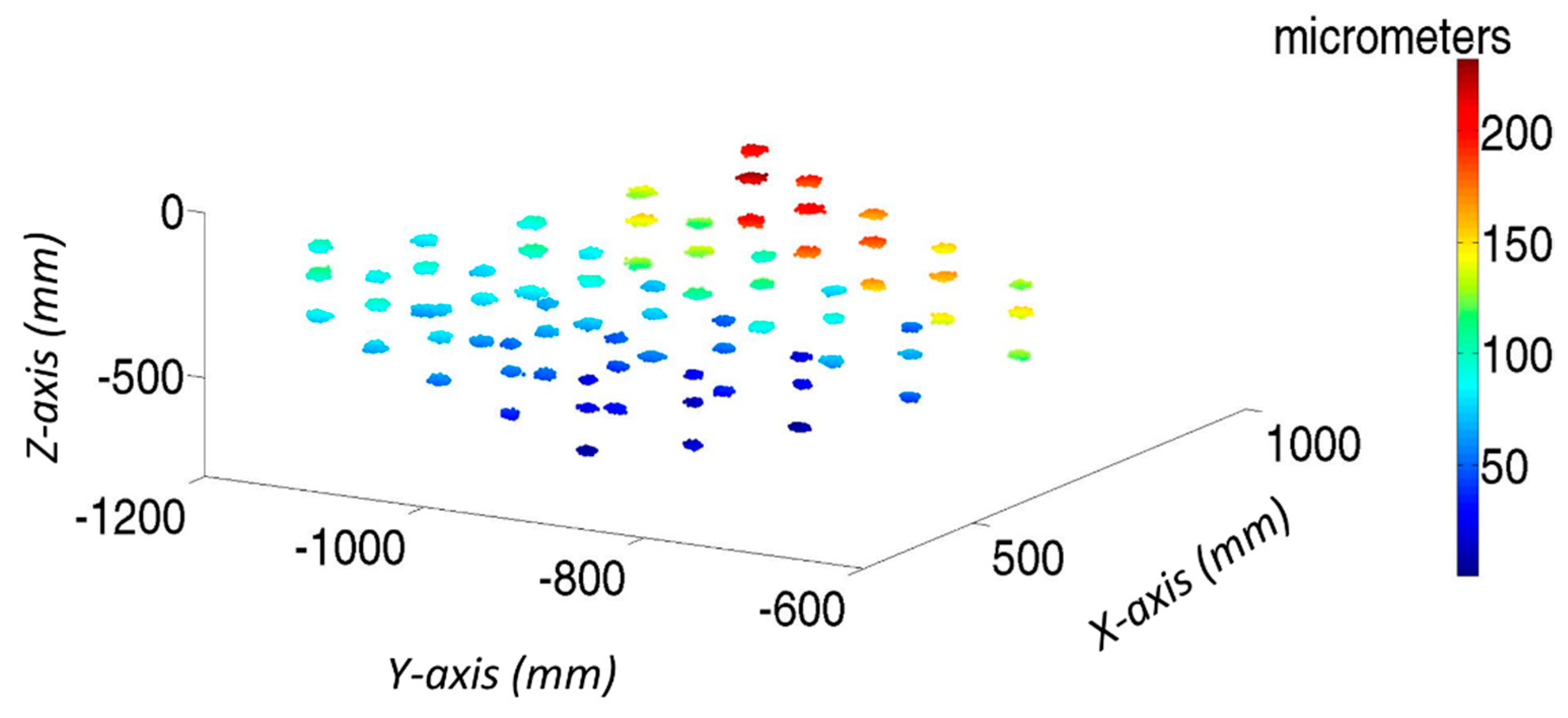

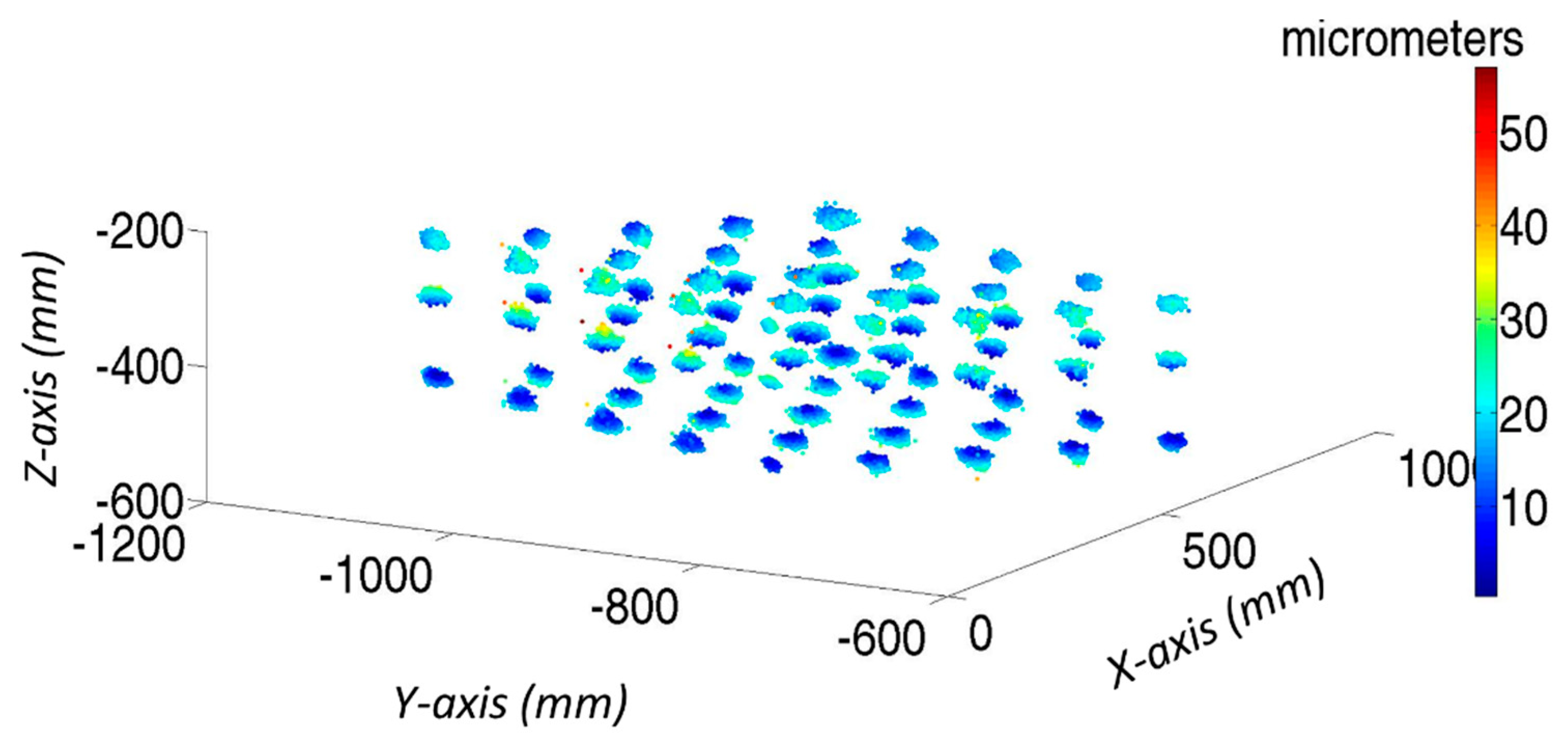

- MT workspace to verify: 800 mm ≤ X ≤ 1200 mm, 100 mm ≤ Y ≤ 500 mm, and 200 mm ≤ Z ≤ 400 mm.

- The verification mesh contained 75 verification points with intervals of 100 mm in all axes.

- Available space to locate LT: −2000 mm ≤ D ≤ −500 mm, 350 mm ≤ H ≤ 2000 mm, −2000 mm ≤ L ≤ 2000 mm.

- LT measurement range characteristic: 0.5 m ≤ r ≤ 15 m, −45° ≤ θ ≤ 45°; −235° ≤ φ ≤ 235°.

- LT could not be located inside the MT workspace or body for verification.

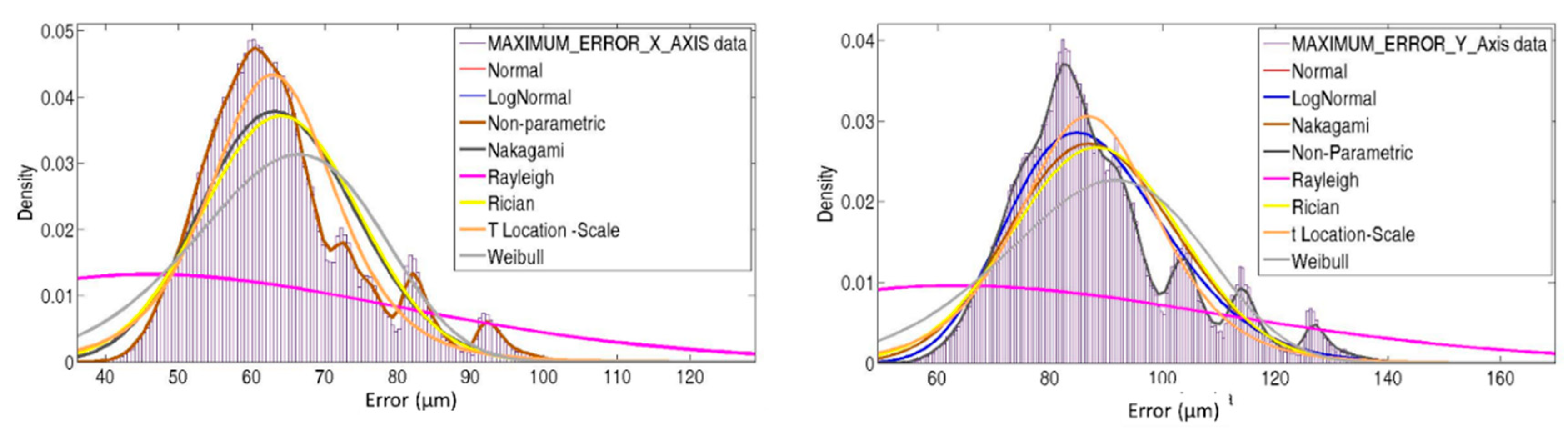

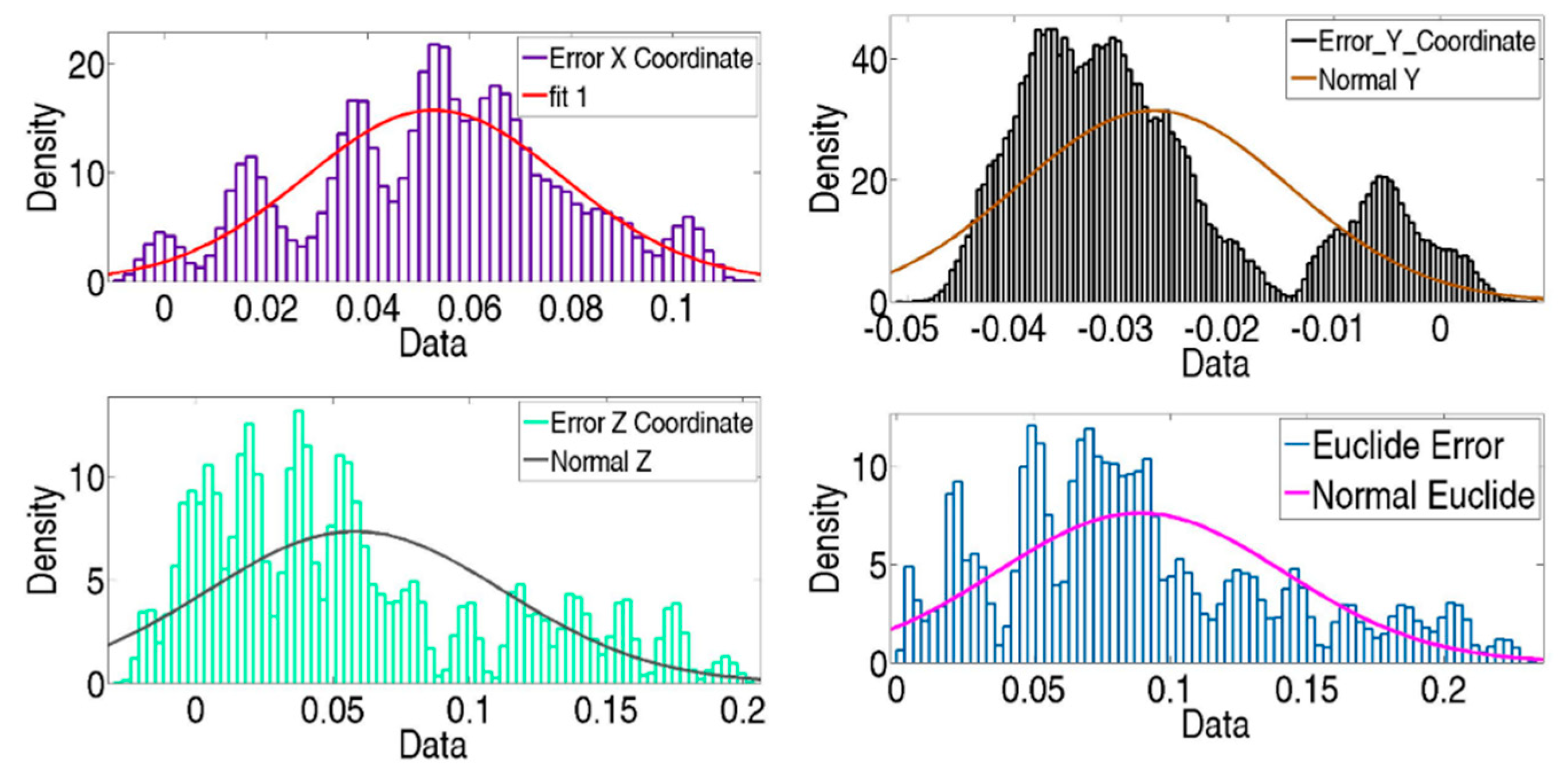

- The number of Monte Carlo tests was 100.000 in the X-axis and Y-axis directions.

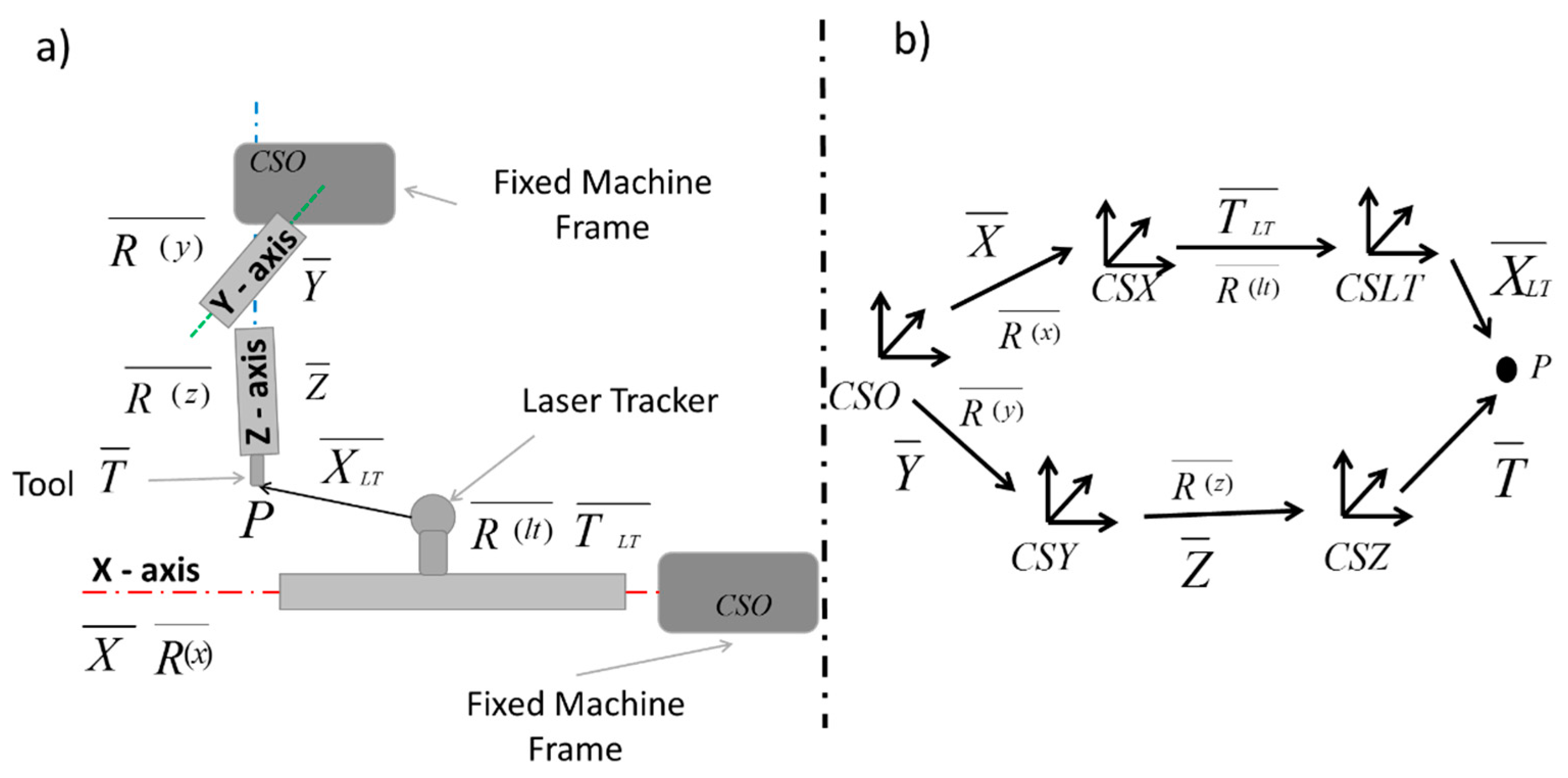

- Equation of movement of the MT and its kinematic model (Equation (2)).

- Verification mesh of points (in this case, the same used to determine the LT position).

- Laser tracker position: d = –563.52 mm, l = 194.37 mm, h = 677.78 mm, α = 0.0339°, β = 0.0343°, and δ = 59.4652°, obtained in LT position from previous tests.

- Generation functions that characterize geometrics of the MT were obtained from real verification.

- Optimization strategy. To identify the geometric errors of the MT, a one phase optimization procedure is used as is shown in Figure 6. From information of a single LT, the influence of squareness, translation, and rotation error are considered together.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

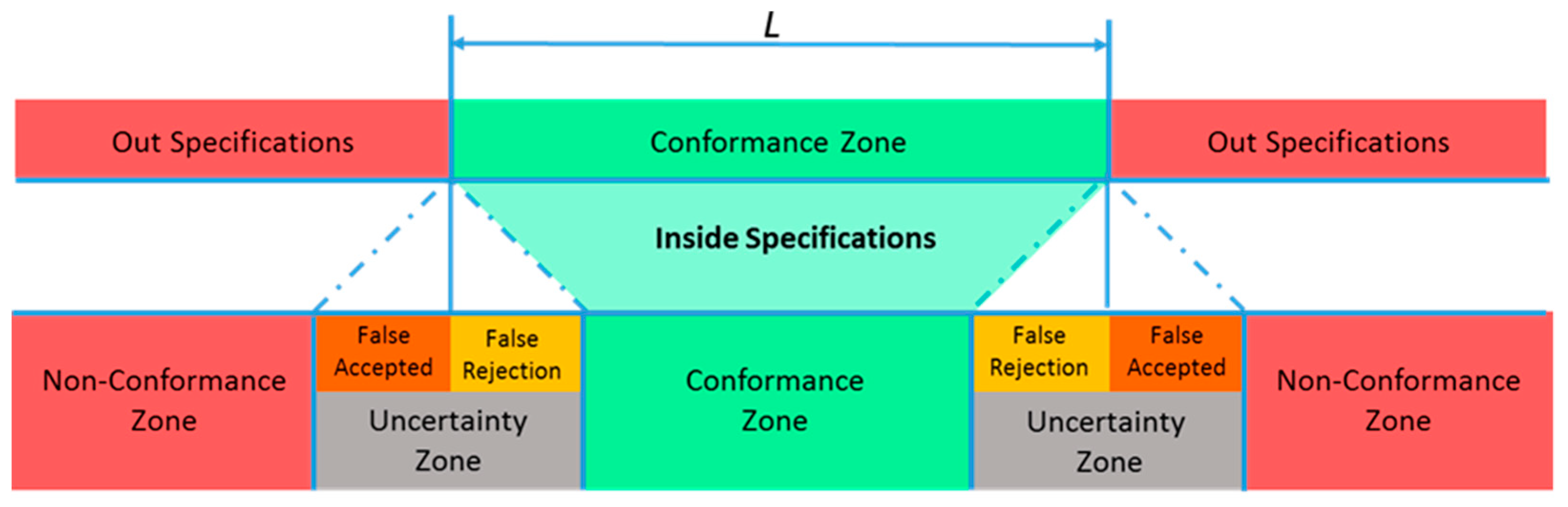

- Forbes, A.B. Measurement uncertainty and optimized conformance assessment. Measurement 2006, 39, 808–814. [Google Scholar] [CrossRef]

- Ahn, K.G.; Cho, D.W. An analysis of the volumetric error uncertainty of a three-axis machine tool by beta distribution. Int. J. Mach. Tools Manuf. 2000, 40, 2235–2248. [Google Scholar] [CrossRef]

- Bringmann, B.; Knapp, W. Machine tool calibration: Geometric test uncertainty depends on machine tool performance. Precis. Eng. 2009, 33, 524–529. [Google Scholar] [CrossRef]

- Andolfatto, L.; Mayer, J.R.R.; Lavernhe, S. Adaptive Monte Carlo applied to uncertainty estimation in five axis machine tool link errors identification with thermal disturbance. Int. J. Mach. Tools Manuf. 2011, 51, 618–627. [Google Scholar]

- Liu, Y.; Gao, D.; Lu, Y. Volumetric calibration in multi-space in large-volume machine based on measurement uncertainty analysis. Int. J. Adv. Manuf. Technol. 2015, 76, 1493–1503. [Google Scholar] [CrossRef]

- Holub, M.; Jankovych, R.; Andrs, O.; Kolibal, Z. Capability assessment of CNC machining centres as measuring devices. Measurement 2018, 118, 52–60. [Google Scholar]

- Slocum, A.H. Precision Machine Design; Prentice Hall: Upper Saddle River, NJ, USA, 1992; ISBN 0-13-690918-3. [Google Scholar]

- Duffie, N.A.; Yang, S.M.; Bollinger, J.G. Generation of parametric kinematic error-correction functions from volumetric error measurements. CIRP Ann. 1985, 34, 435–438. [Google Scholar] [CrossRef]

- Tian, W.; Gao, W.; Zhang, D.; Huang, T. A general approach for error modelling of machine tools. Int. J. Mach. Tools Manuf. 2014, 79, 17–23. [Google Scholar] [CrossRef]

- Rahman, M.M.; Mayer, J.R.R. Five axis machine tool volumetric error prediction through an indirect estimation of intra- and inter-axis error parameters by probing facets on a scale enriched uncalibrated indigenous artefact. Precis. Eng. 2015, 40, 94–105. [Google Scholar] [CrossRef]

- Khan, A.W.; Chen, W. A methodology for systematic geometric error compensation in five-axis machine tools. Int. J. Adv. Manuf. Technol. 2011, 53, 615–628. [Google Scholar] [CrossRef]

- Aguado, S.; Santolaria, J.; Samper, D.; Aguilar, J.J. Protocol for machine tool volumetric verification using commercial laser tracker. Int. J. Adv. Manuf. Technol. 2014, 75, 1–4. [Google Scholar] [CrossRef]

- Pérez, P.; Aguado, S.; Albajez, J.A.; Santolaria, J. Influence of laser tracker noise on the uncertainty of machine tool volumetric verification using the Monte Carlo method. Measurement 2019, 133, 81–90. [Google Scholar] [CrossRef]

- ISO/TR 230-9:2005—Test Code for Machine Tools—Part 9: Estimation of Measurement Uncertainty for Machine Tool Tests According to Series ISO 230, Basic Equations; ISO: Geneva, Switzerland, 2005.

- Blaser, P.; Pavliček, F.; Mori, K.; Mayr, J.; Weikert, S.; Wegener, K. Adaptive learning control for thermal error compensation of 5-axis machine tools. J. Manuf. Syst. 2017, 44, 302–309. [Google Scholar] [CrossRef]

- Mian, N.S.; Fletcher, S.; Longstraff, A.P.; Myers, A. Efficient estimation by FEA of machine tool distortion due to environmental temperature perturbations. Precis. Eng. 2013, 37, 372–379. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, Y.; Gao, D.; Hao, Z. Thermally induced volumetric error modelling based on thermal drift and its compensation in Z-axis. Int. J. Adv. Manuf. Technol. 2013, 69, 2735–2745. [Google Scholar] [CrossRef]

- Pérez Muñoz, P.; Albajez García, J.A.; Santolaria Mazo, J. Analysis of the initial thermal stabilization and air turbulences effects on Laser Tracker measurements. J. Manuf. Syst. 2016, 41, 277–286. [Google Scholar] [CrossRef]

- Ouyang, J.; Liu, W.; Qu, X.; Yan, Y. The effect of beam incident angles on cube corner retro-reflector measuring accuracy. In Optical Design and Testing III; SPIE: Bellingham, WA, USA, 2007; Volume 6834, pp. 1–9. [Google Scholar]

- Gallagher, B.B. Optical Shop Applications for Laser Tracker Metrology Systems. Available online: www.loft.optics.arizona.edu/documents/journal_articles/2003_Ben_Gallagher.pdf (accessed on 26 June 2019).

- Ouyang, J.; Liu, W.; Qu, X.; Yan, Y. The effect of beam incident angles on cube corner retro-reflector measuring accuracy. In Proceedings of the Photonics Asia 2007, Optical Design and Testing III, Beijing, China, 11–15 November 2007; pp. 1–9. [Google Scholar]

- Muralikrishnan, B.; Sawyer, D.; Blackburn, C.; Phillips, S.; Borchardt, B.; Estler, W.T. ASME B.89.4.19 Performance evaluation tests and geometric misalignments in laser trackers. J. Res. Natl. Inst. Stand. Technol. 2009, 114, 21–35. [Google Scholar] [CrossRef] [PubMed]

- ISO 10360-10:2016—Geometrical Product Specifications (GPS)—Acceptance and Reverification Test for Coordinate Measuring Systems (CMS)—Part 10: Laser Trackers for Measuring Point-to-Point Distances; ISO: Geneva, Switzerland, 2016.

- ISO/IEC Guide 98-3:2008—Uncertainty of Measurement—Part 3: Guide to the Expression of Uncertainty in Measurement (GUM:1995); ISO: Geneva, Switzerland, 2008.

- Aguado, S.; Santolaria, J.; Samper, D.; Velazquez, J.; Aguilar, J.J. Empirical analysis of the efficient use of geometric error identification in a machine tool by tracking measurement techniques. Meas. Sci. Technol. 2016, 27, 035002. [Google Scholar] [CrossRef]

- Knapp, W. Measurement Uncertainty and Machine Tool Testing. CIRP Ann. 2002, 51, 459–462. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguado, S.; Pérez, P.; Albajez, J.A.; Santolaria, J.; Velazquez, J. Study on Machine Tool Positioning Uncertainty Due to Volumetric Verification. Sensors 2019, 19, 2847. https://doi.org/10.3390/s19132847

Aguado S, Pérez P, Albajez JA, Santolaria J, Velazquez J. Study on Machine Tool Positioning Uncertainty Due to Volumetric Verification. Sensors. 2019; 19(13):2847. https://doi.org/10.3390/s19132847

Chicago/Turabian StyleAguado, Sergio, Pablo Pérez, José Antonio Albajez, Jorge Santolaria, and Jesús Velazquez. 2019. "Study on Machine Tool Positioning Uncertainty Due to Volumetric Verification" Sensors 19, no. 13: 2847. https://doi.org/10.3390/s19132847

APA StyleAguado, S., Pérez, P., Albajez, J. A., Santolaria, J., & Velazquez, J. (2019). Study on Machine Tool Positioning Uncertainty Due to Volumetric Verification. Sensors, 19(13), 2847. https://doi.org/10.3390/s19132847