Modeling Flaw Pulse-Echo Signals in Cylindrical Components Using an Ultrasonic Line-Focused Transducer with Consideration of Wave Mode Conversion

Abstract

1. Introduction

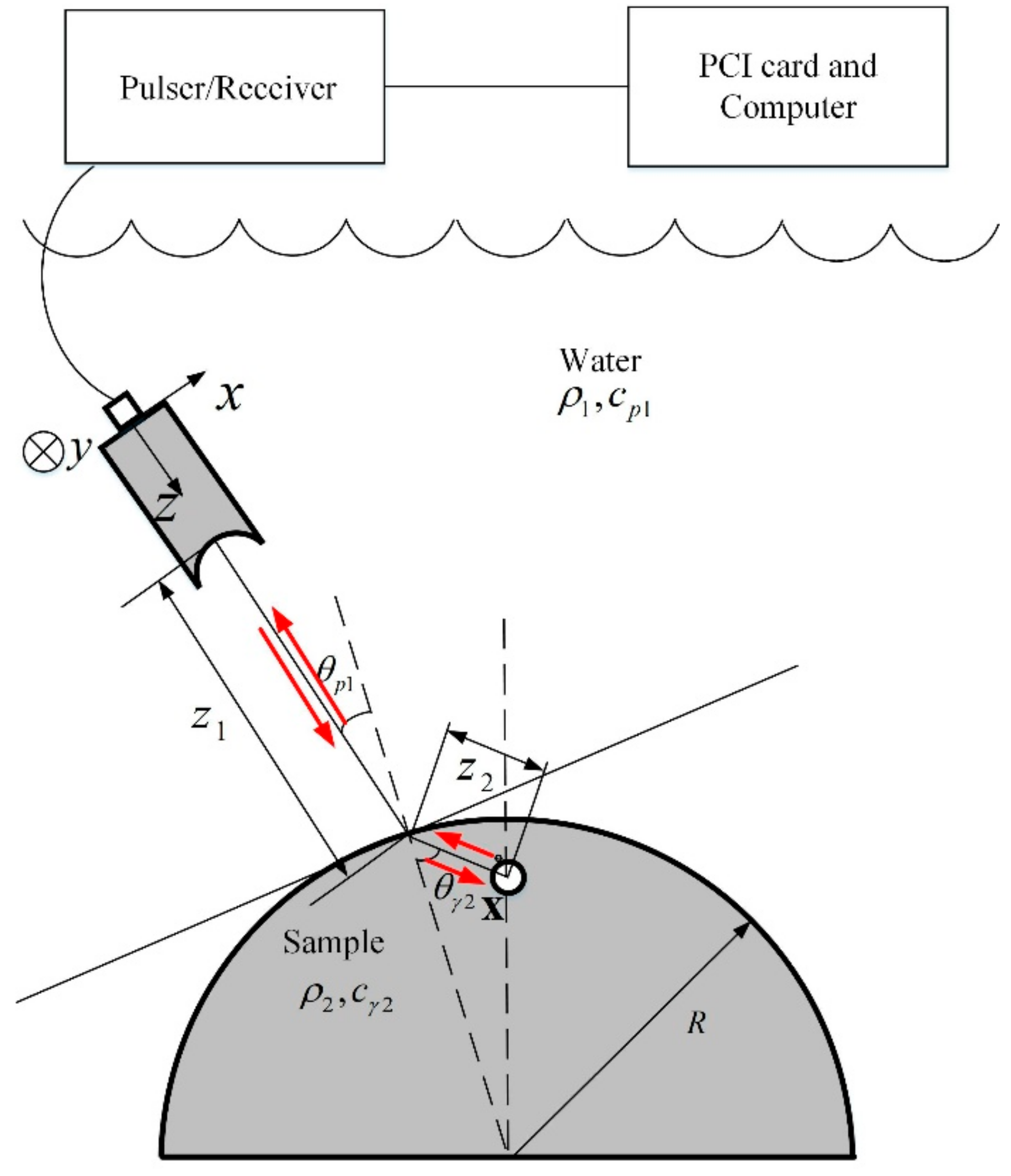

2. Theory

2.1. An UMM for Predicting Responses from an SDH

2.2. MGB Model for Wave Beam Calculation

2.3. System Function Determination

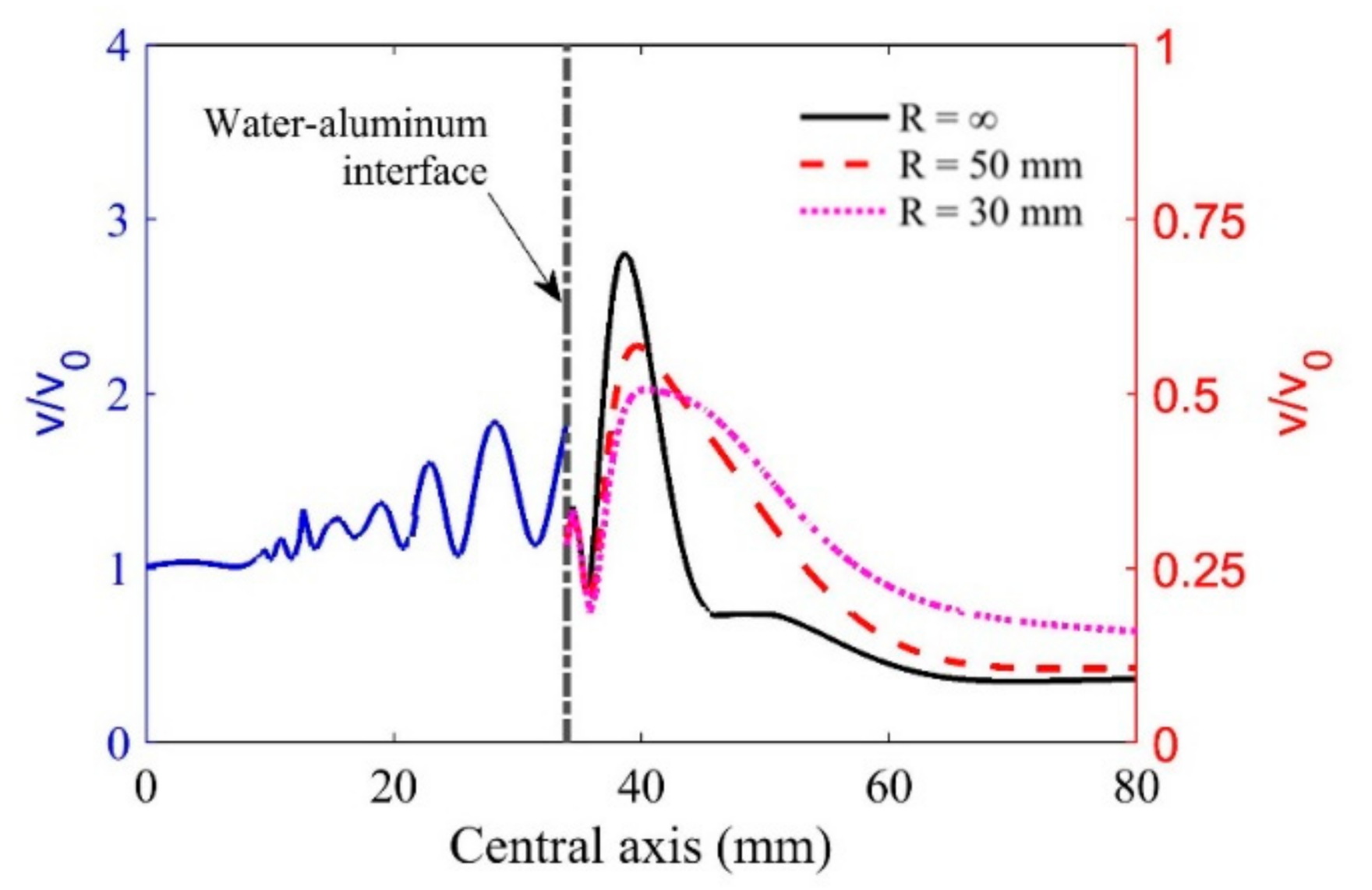

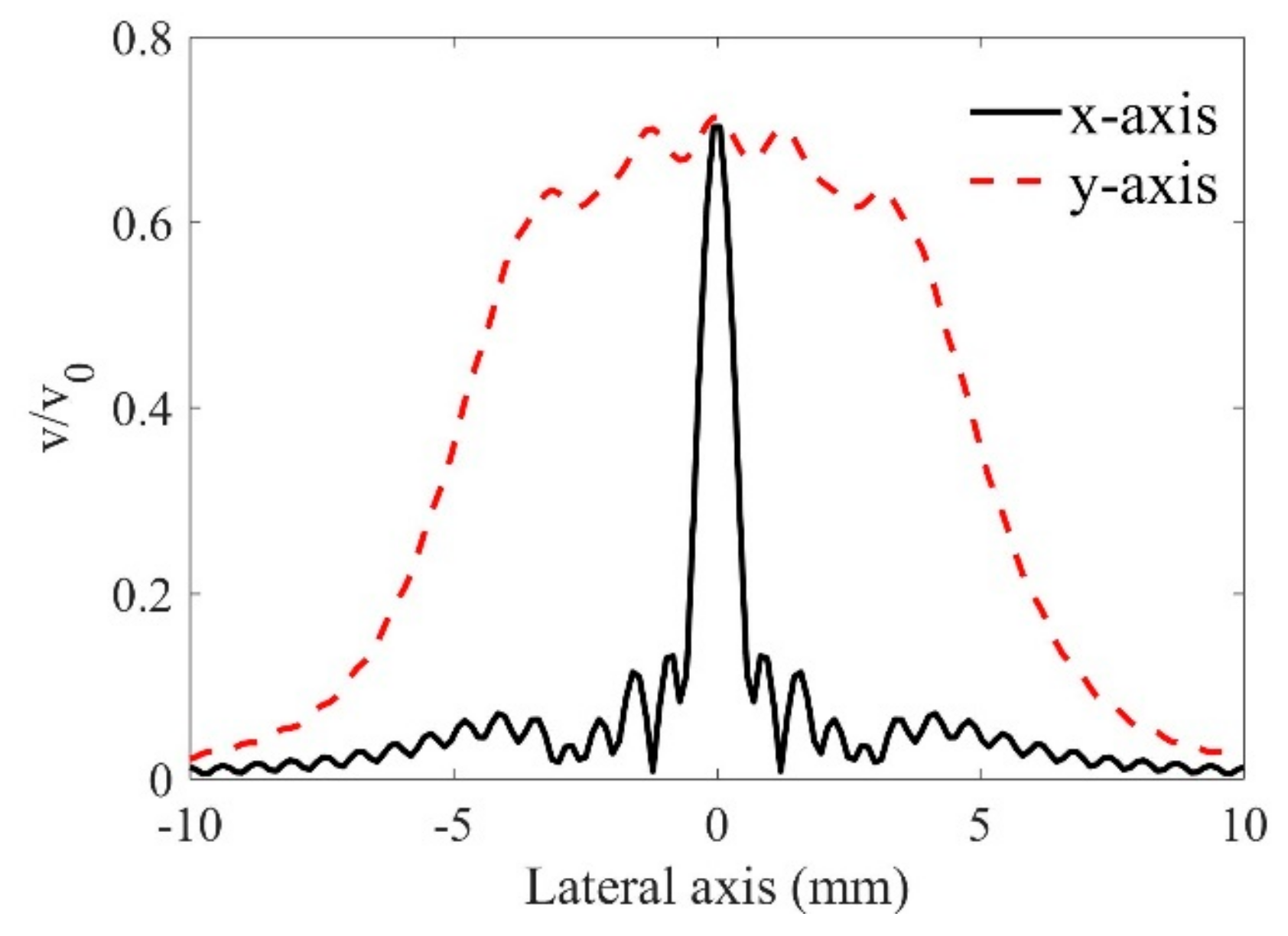

3. Numerical Results for the Propagation Wave

4. Experimental Results and Discussions

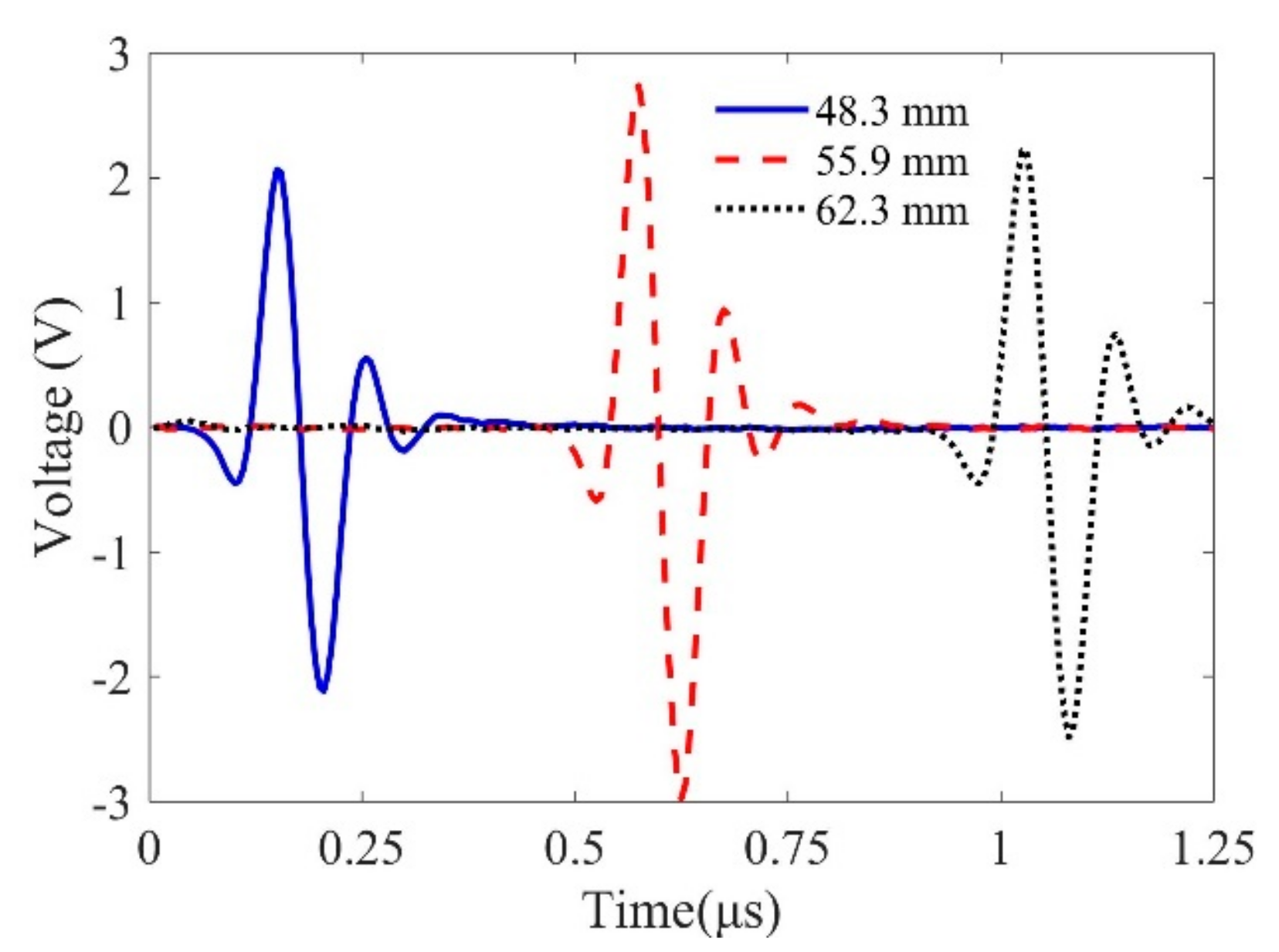

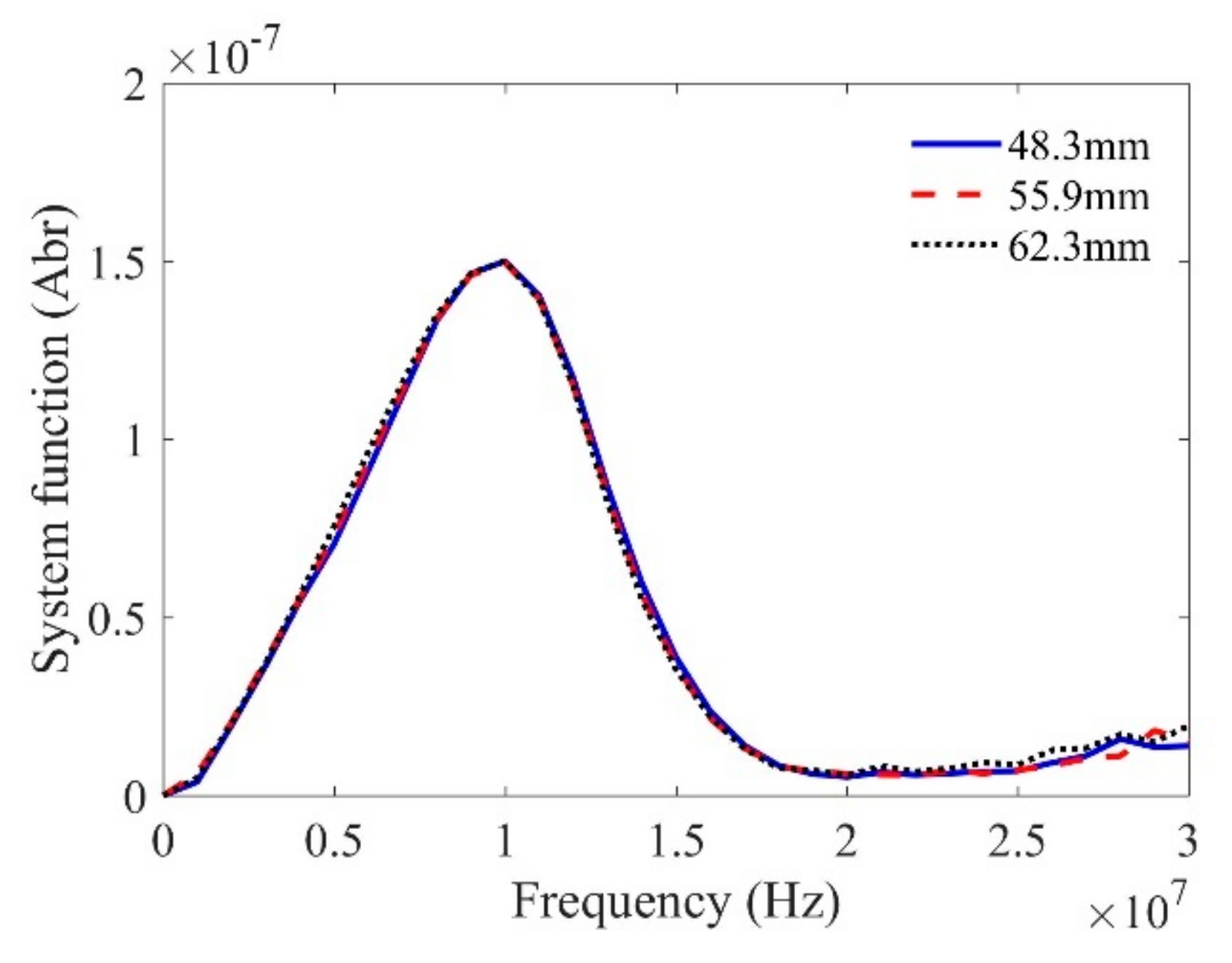

4.1. Calibrated System Function

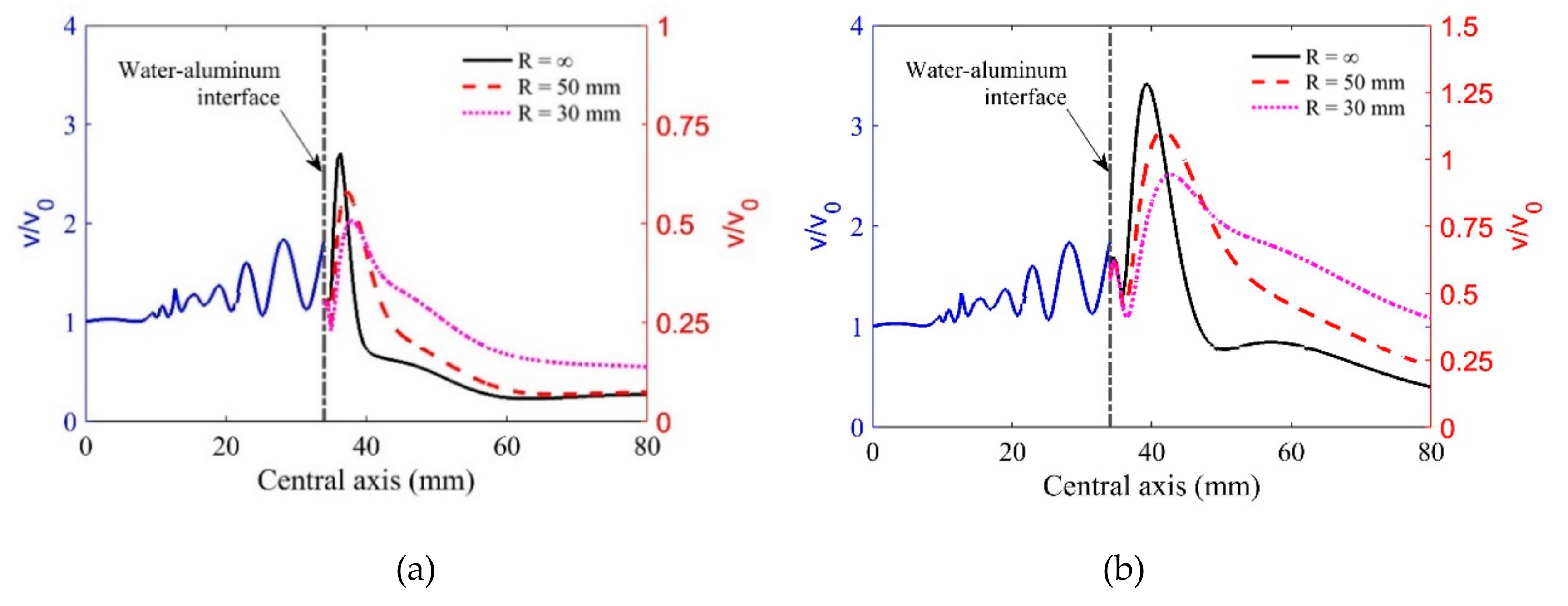

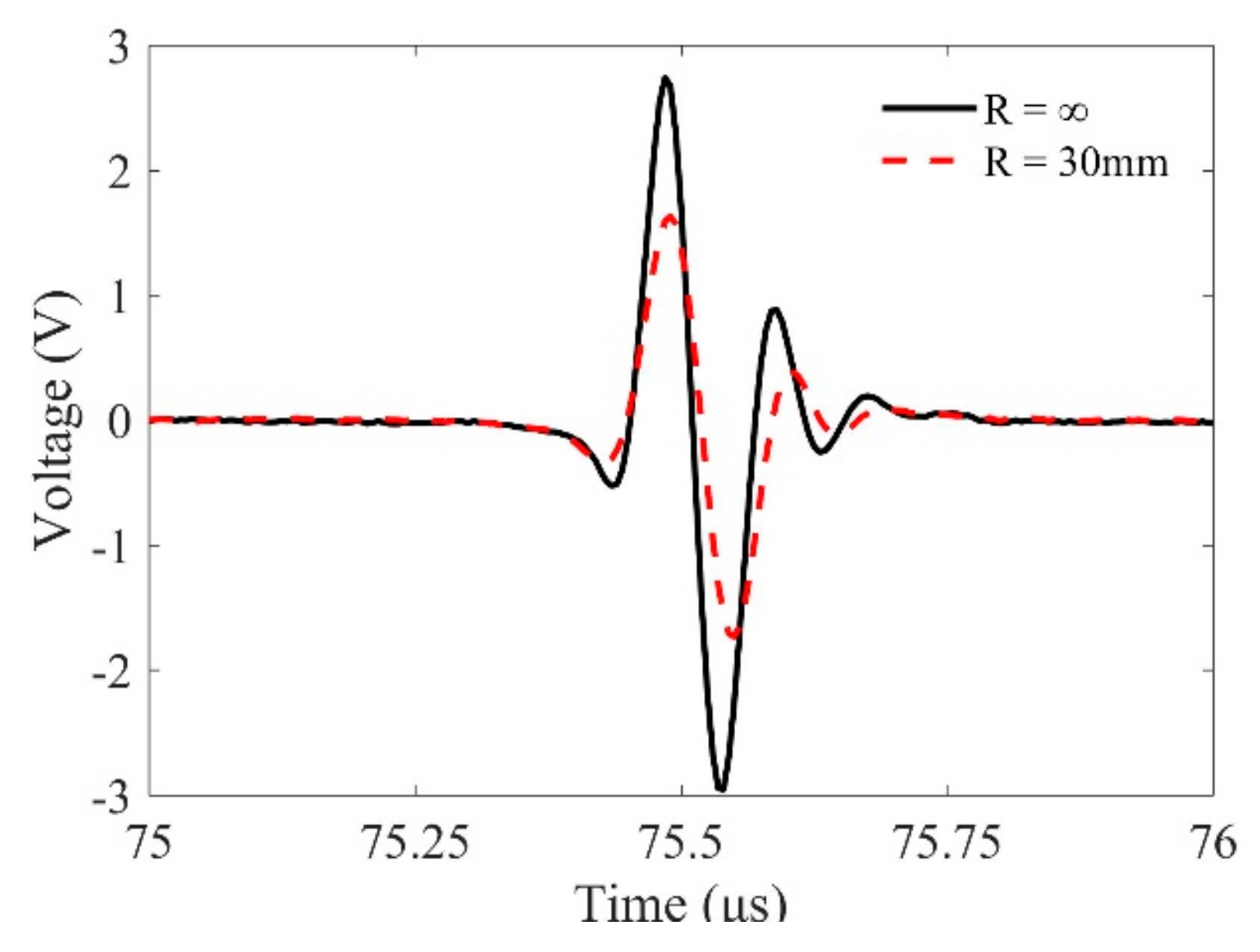

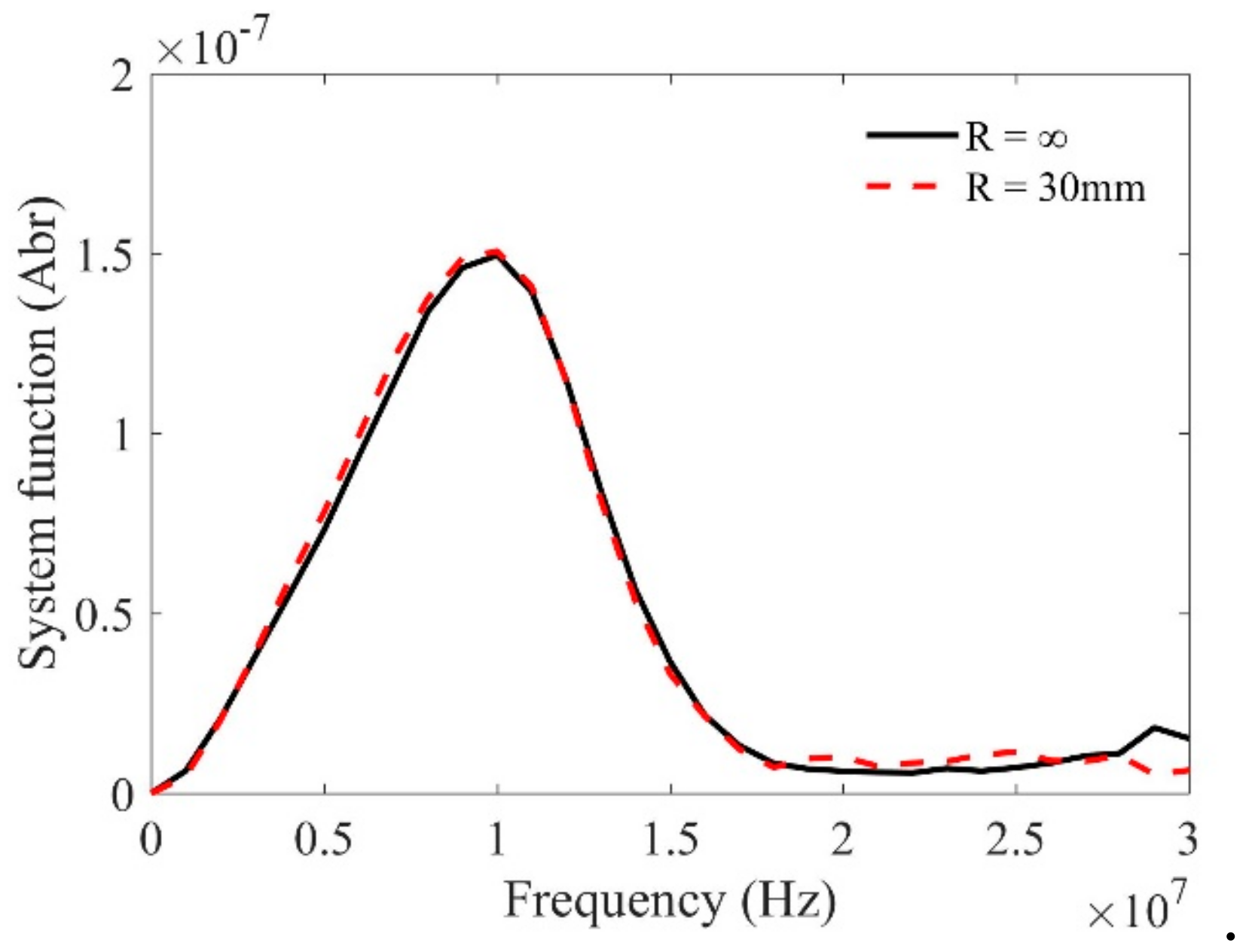

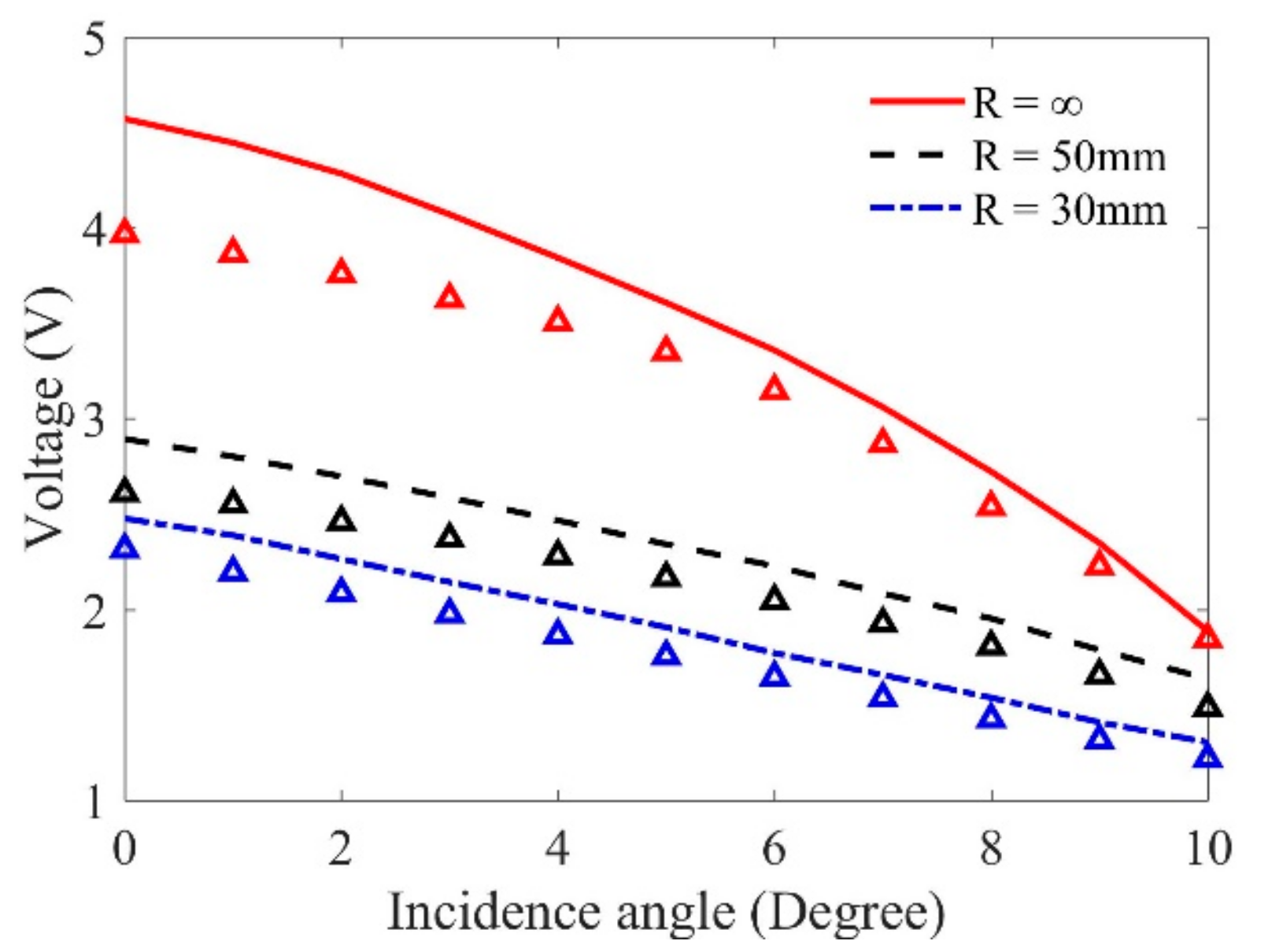

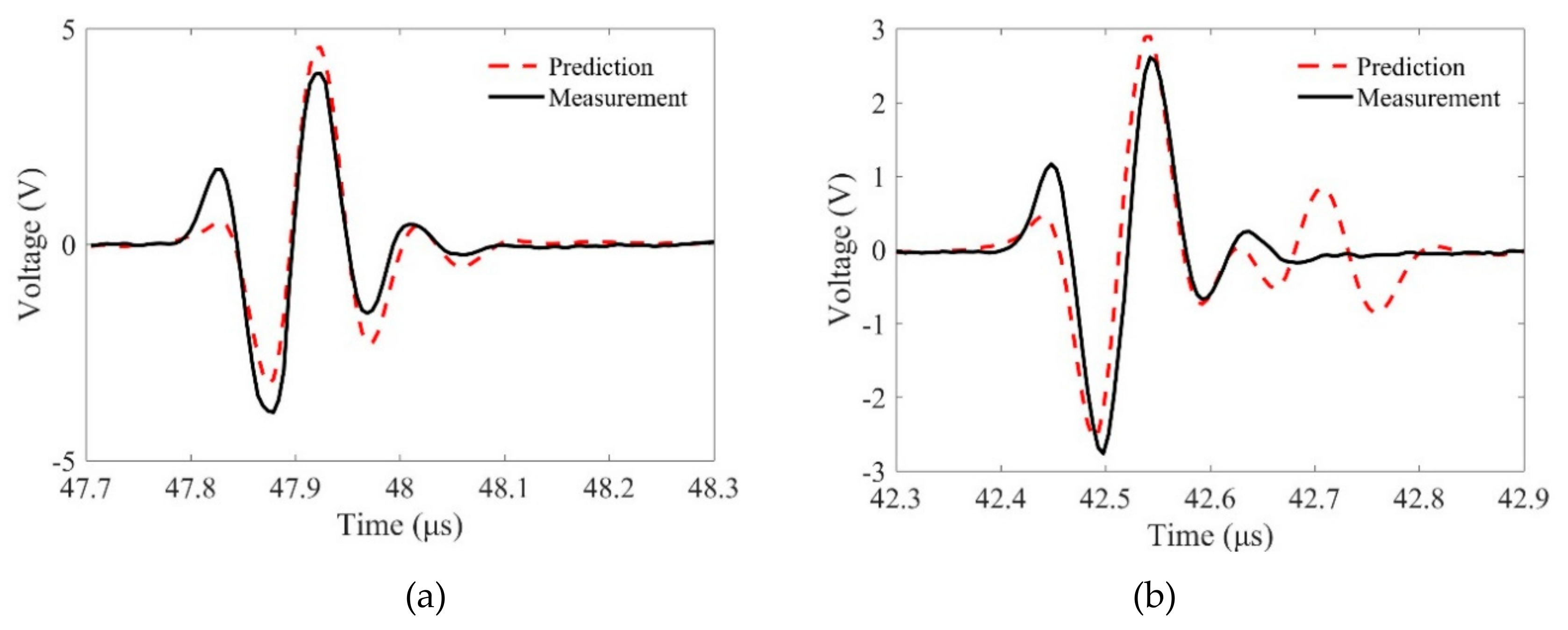

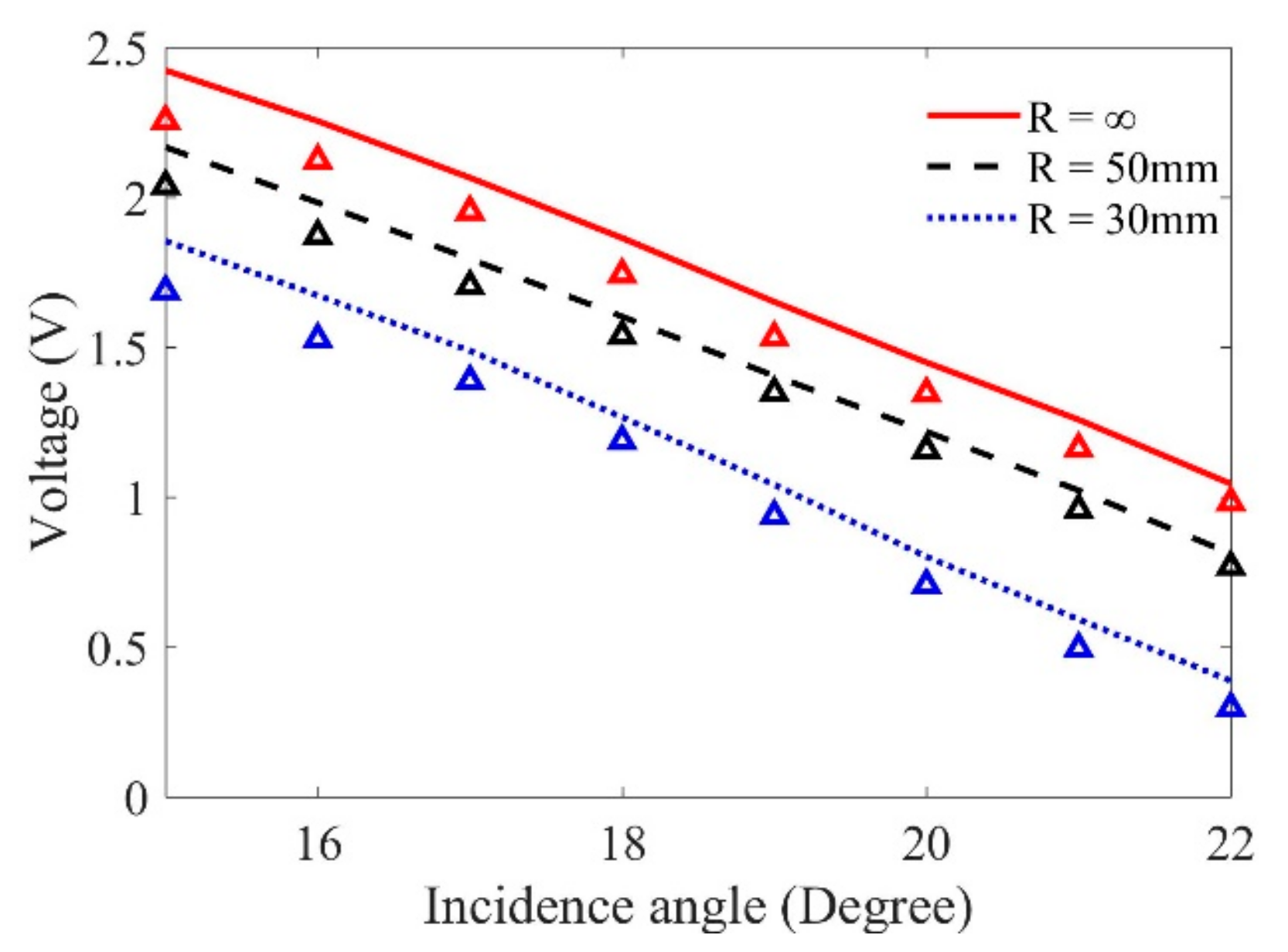

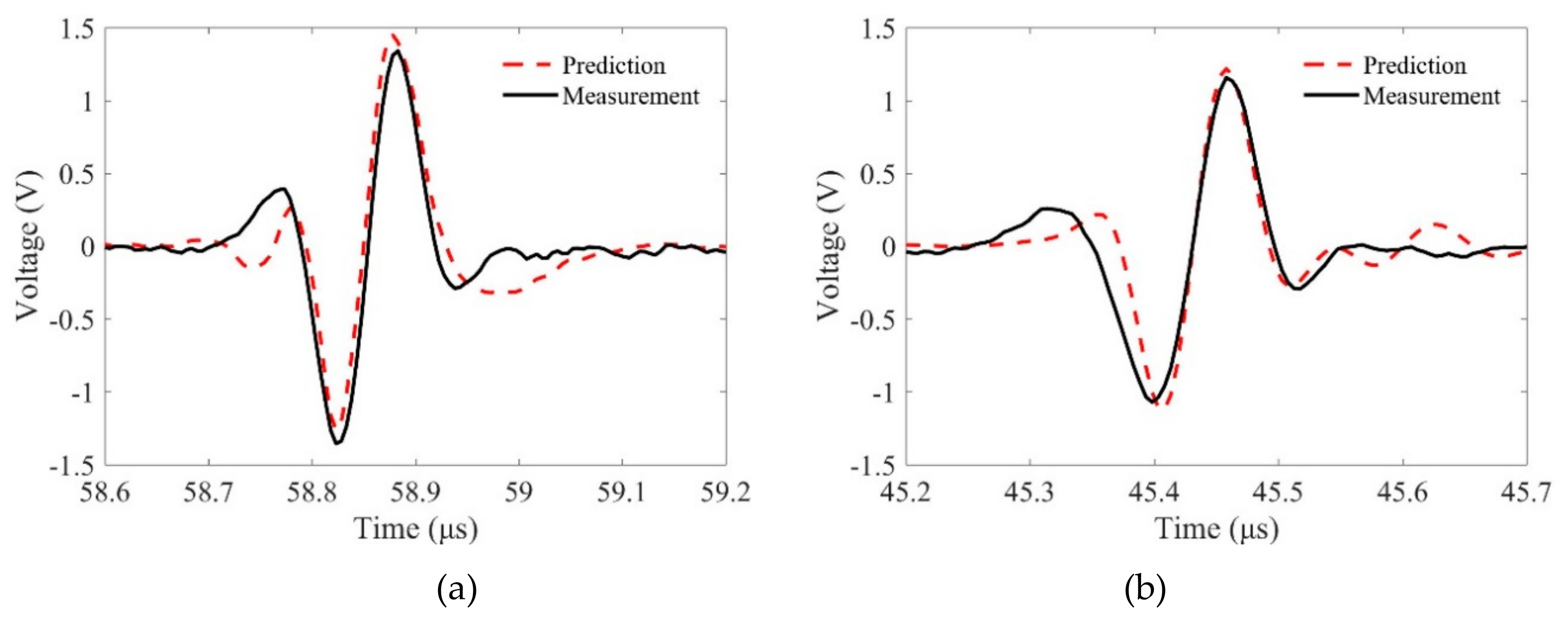

4.2. Results Obtained Using Longitudinal Waves

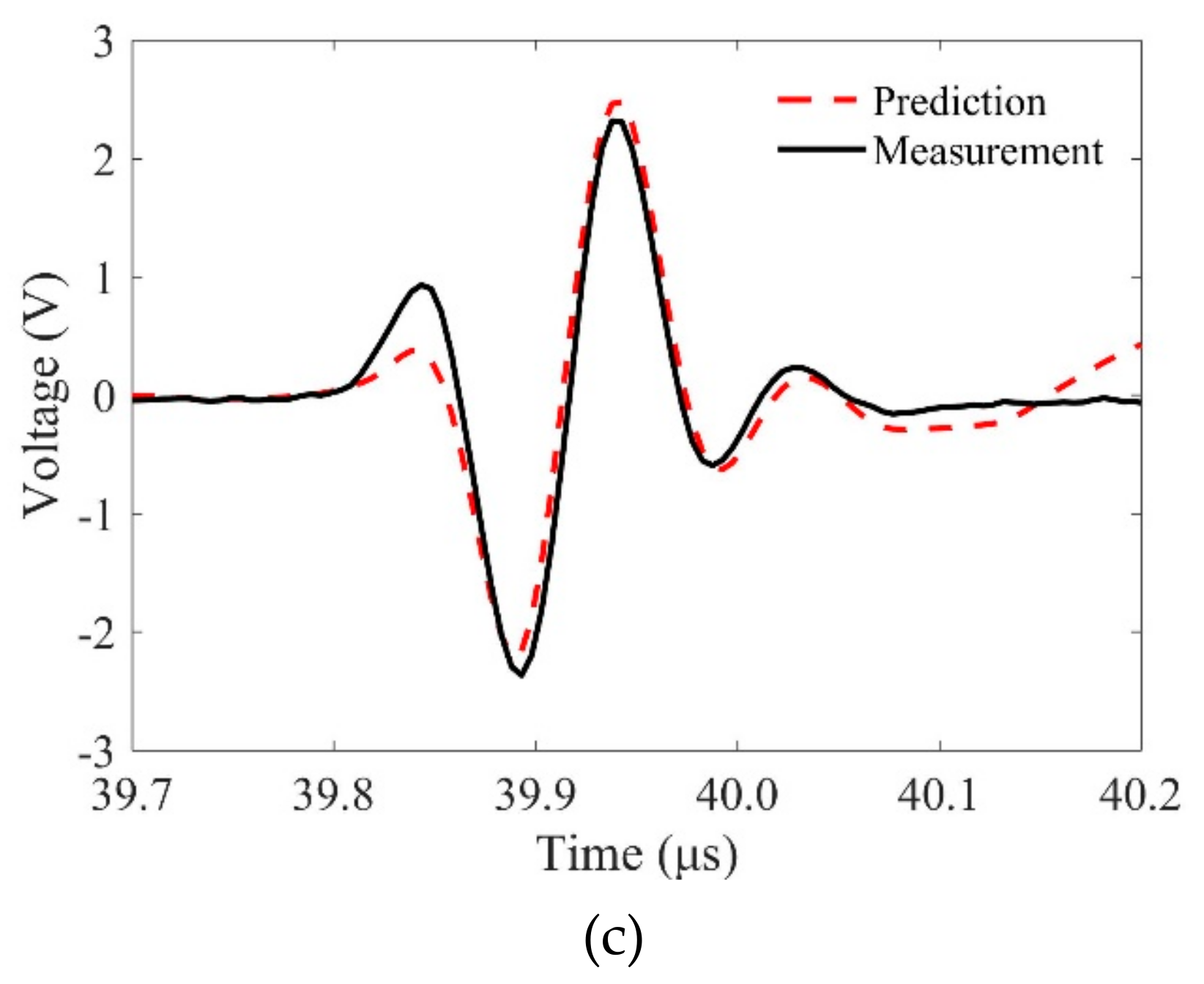

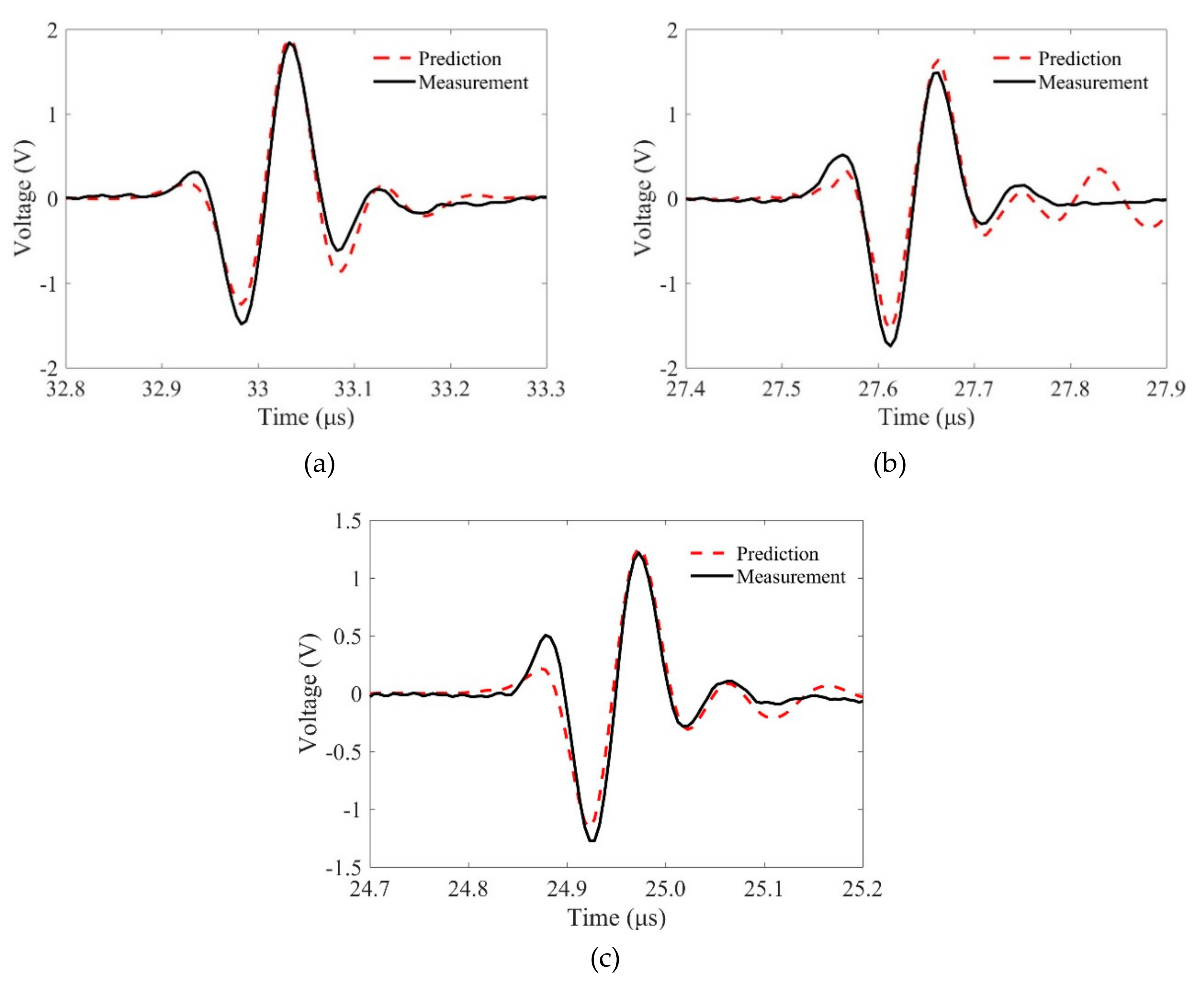

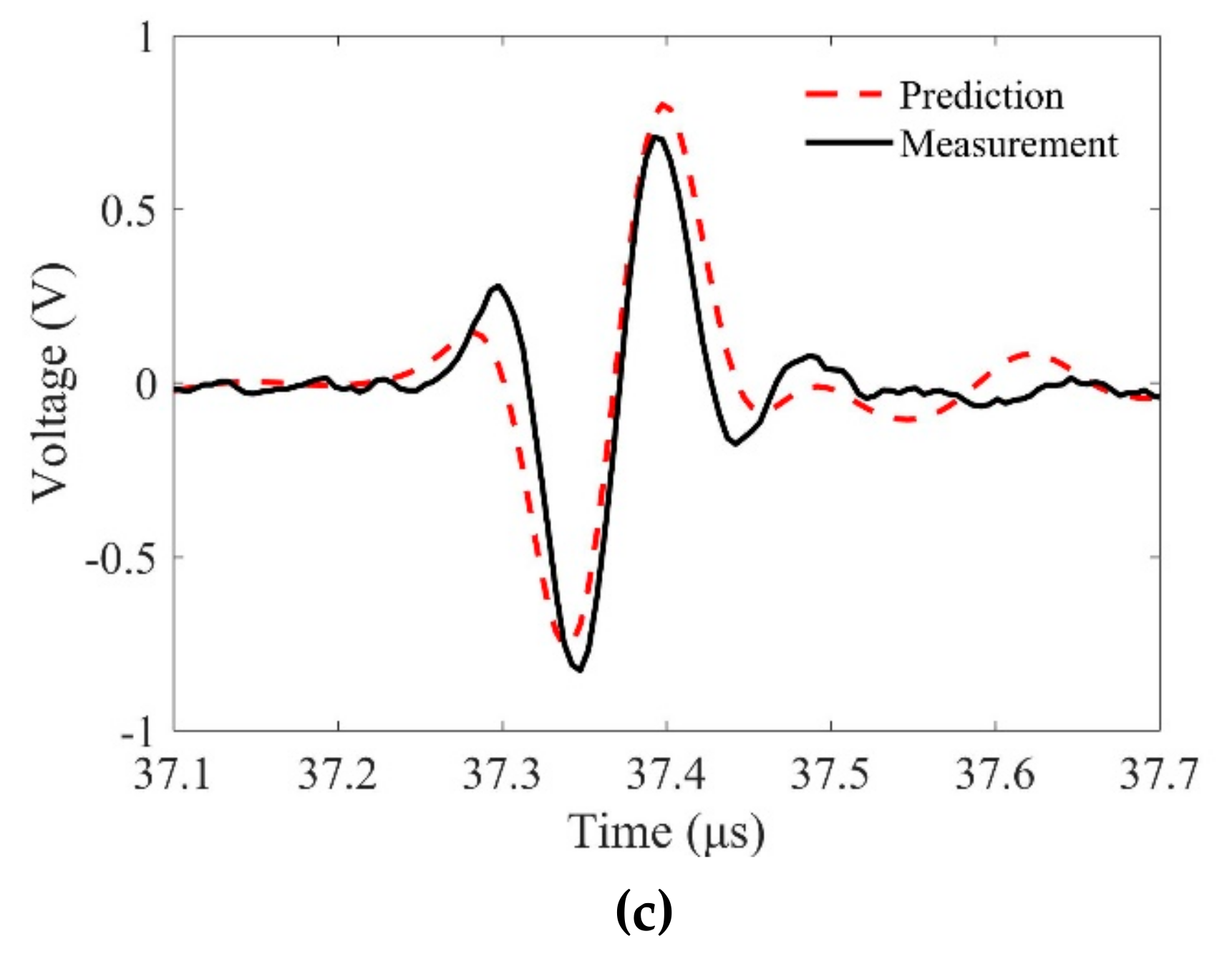

4.3. Results Obtained Using Shear Waves

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Jin, H.; Wu, E.; Han, Y.; Yang, K.; Chen, J. Frequency domain synthetic aperture focusing technique for variable-diameter cylindrical components. J. Acoust. Soc. Am. 2017, 142, 1554–1562. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Zhang, D.; Zhang, L.; Wang, B. Detection of defects in reinforced concrete structures using ultrasonic nondestructive evaluation with piezoceramic transducers and the time reversal method. Sensors 2018, 18, 4176. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Z.; Guo, Y.; Geng, L.; Wu, J.; Zhang, F.; Wang, W.; Liu, Y. Acoustic field of a linear phased array: A simulation study of ultrasonic circular tube material. Sensors 2019, 19, 2352. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Lu, D.; Lu, Y.; Liu, H.; Gao, Z.; Wu, B.; He, C. Velocity measurements of cylindrical surface waves with a large aperture line-focus acoustic transducer. Measurement 2016, 90, 103–109. [Google Scholar] [CrossRef]

- Casula, O.; Poidevin, C.; Cattiaux, G.; Dumas, P. Control of complex components with smart flexible phased arrays. Ultrasonics 2006, 44, 647–651. [Google Scholar] [CrossRef]

- Schmerr, L.W.; Song, S.J.; Sedov, A. Ultrasonic flaw sizing inverse problems. Inverse Probl. 2002, 18, 1775–1793. [Google Scholar] [CrossRef]

- Auld, B.A. General electromechanical reciprocity relations applied to the calculation of elastic wave scattering coefficients. Wave Motion 1979, 1, 3–10. [Google Scholar] [CrossRef]

- Thompson, R.B.; Gray, T.A. A model relating ultrasonic scattering measurements through liquid–solid interfaces to unbounded medium scattering amplitudes. J. Acoust. Soc. Am. 1983, 74, 140–146. [Google Scholar] [CrossRef]

- Schmerr, L.W. Fundamentals of Ultrasonic Nondestructive Evaluation; Springer: New York, NY, USA, 2016. [Google Scholar]

- Kim, H.J.; Song, S.J.; Schmerr, L.W. Modeling ultrasonic pulse-echo signals from a flat-bottom hole in immersion testing using a multi-Gaussian beam. J. Nondestruct. Eval. 2004, 23, 11–19. [Google Scholar] [CrossRef]

- Xiao, H.; Sun, Y.; Chen, D.; Xu, J. Prediction of flat-bottom hole signals received by a spherically focused transducer for an ultrasonic pulse echo immersion testing. Meas. Sci. Technol. 2016, 27, 115001. [Google Scholar] [CrossRef]

- Jeong, H.; Schmerr, L.W. Ultrasonic transducer fields modeled with a modular multi-Gaussian beam and application to a contact angle beam testing. Res. Nondestruct. Eval. 2008, 19, 87–103. [Google Scholar] [CrossRef]

- Zhao, X.; Gang, T.; Xu, C. Prediction of side-drilled hole signals captured by a dual crystal contact probe. J. Nondestruct. Eval. 2010, 29, 105–110. [Google Scholar] [CrossRef]

- Jeong, H.; Schmerr, L.W. Ultrasonic beam propagation in highly anisotropic materials simulated by multi-Gaussian beams. J. Mech. Sci. Technol. 2007, 21, 1184–1190. [Google Scholar] [CrossRef]

- Huang, R.; Schmerr, L.W.; Sedov, A. Improving the Born approximation for the scattering of ultrasound in elastic solids. Ultrasonics 2006, 44, e981–e984. [Google Scholar] [CrossRef] [PubMed]

- Zernov, V.; Fradkin, L.; Darmon, M. A refinement of the Kirchhoff approximation to the scattered elastic fields. Ultrasonics 2012, 52, 830–835. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Yu, P.; Gang, T. Measurement of the ultrasonic scattering matrices of near-surface defects using ultrasonic arrays. Nondestruct. Test. Eval. 2016, 31, 303–318. [Google Scholar] [CrossRef]

- Clough, M.; Fleming, M.; Dixon, S. Circumferential guided wave EMAT system for pipeline screening using shear horizontal ultrasound. NDT E Int. 2017, 86, 20–27. [Google Scholar] [CrossRef]

- Lopez-Sanchez, A.L.; Kim, H.J.; Schmerr, L.W.; Sedov, A. Measurement models and scattering models for predicting the ultrasonic pulse-echo response from side-drilled holes. J. Nondestruct. Eval. 2005, 24, 83–96. [Google Scholar] [CrossRef]

- Wen, J.J.; Breazeale, M.A. A diffraction beam field expressed as the superposition of Gaussian beams. J. Acoust. Soc. Am. 1988, 83, 1752–1756. [Google Scholar] [CrossRef]

- Kim, H.J.; Schmerr, L.W.; Sedov, A. Generation of the basis sets for multi-Gaussian ultrasonic beam models—An overview. J. Acoust. Soc. Am. 2006, 119, 1971–1978. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Hu, P.; Li, X.; Jeong, H. Calibration of focused circular transducers using a multi-Gaussian beam model. Appl. Acoust. 2018, 133, 182–185. [Google Scholar] [CrossRef]

- Huang, R.; Schmerr, L.W.; Sedov, A. Multi-Gaussian ultrasonic beam modeling for multiple curved interfaces—an ABCD matrix approach. Res. Nondestruct. Eval. 2005, 16, 143–174. [Google Scholar] [CrossRef]

- Lopez-Sanchez, A.L.; Schmerr, L.W. Simplified method for complete characterization of an ultrasonic NDE measurement system. Res. Nondestruct. Eval. 2007, 18, 23–43. [Google Scholar] [CrossRef]

- Ginsberg, J.H.; Rogers, P.H.; van Buren, A.L. Comments on radiation from a concave piston source. J. Acoust. Soc. Am. 1988, 84, 442–442. [Google Scholar] [CrossRef]

- Liu, Y.; Song, Y.; Li, X.; Chen, C.; Zhou, K. Evaluating the reinforcement content and elastic properties of Mg-based composites using dual-mode ultrasonic velocities. Ultrasonics 2017, 81, 167–173. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Liu, X.; Li, X.; Xu, G.; Zhang, S. Modeling Flaw Pulse-Echo Signals in Cylindrical Components Using an Ultrasonic Line-Focused Transducer with Consideration of Wave Mode Conversion. Sensors 2019, 19, 2744. https://doi.org/10.3390/s19122744

Wang W, Liu X, Li X, Xu G, Zhang S. Modeling Flaw Pulse-Echo Signals in Cylindrical Components Using an Ultrasonic Line-Focused Transducer with Consideration of Wave Mode Conversion. Sensors. 2019; 19(12):2744. https://doi.org/10.3390/s19122744

Chicago/Turabian StyleWang, Weixin, Xiling Liu, Xiongbing Li, Gang Xu, and Shuzeng Zhang. 2019. "Modeling Flaw Pulse-Echo Signals in Cylindrical Components Using an Ultrasonic Line-Focused Transducer with Consideration of Wave Mode Conversion" Sensors 19, no. 12: 2744. https://doi.org/10.3390/s19122744

APA StyleWang, W., Liu, X., Li, X., Xu, G., & Zhang, S. (2019). Modeling Flaw Pulse-Echo Signals in Cylindrical Components Using an Ultrasonic Line-Focused Transducer with Consideration of Wave Mode Conversion. Sensors, 19(12), 2744. https://doi.org/10.3390/s19122744